Developments and Issues in Renewable Ecofuels and Feedstocks

Abstract

1. Introduction

2. Electrofuels

2.1. e-Hydrogen

2.2. e-Methanol

2.3. C8–C18 Liquid e-Fuels

2.4. e-Ammonia

2.5. e-LNG

2.6. Other e-Fuels

2.7. e-Fuels Issues

- -

- Economic and technical: e-Fuels are costly to produce, and the price of renewable electricity futures is difficult to predict; furthermore, their optimal production routes are not yet fully established from a technical point of view. At present, not enough CO2 from circular sources is commercially available, making the future evolution of CO2 feedstock prices uncertain. CO2 sequestration/capture efforts should be increased. Depreciation issues of existing assets, targeted on fossil fuels, will affect the economic positioning of e-Fuels: new infrastructure and the development of optimized engines and fuel cells will be needed;

- -

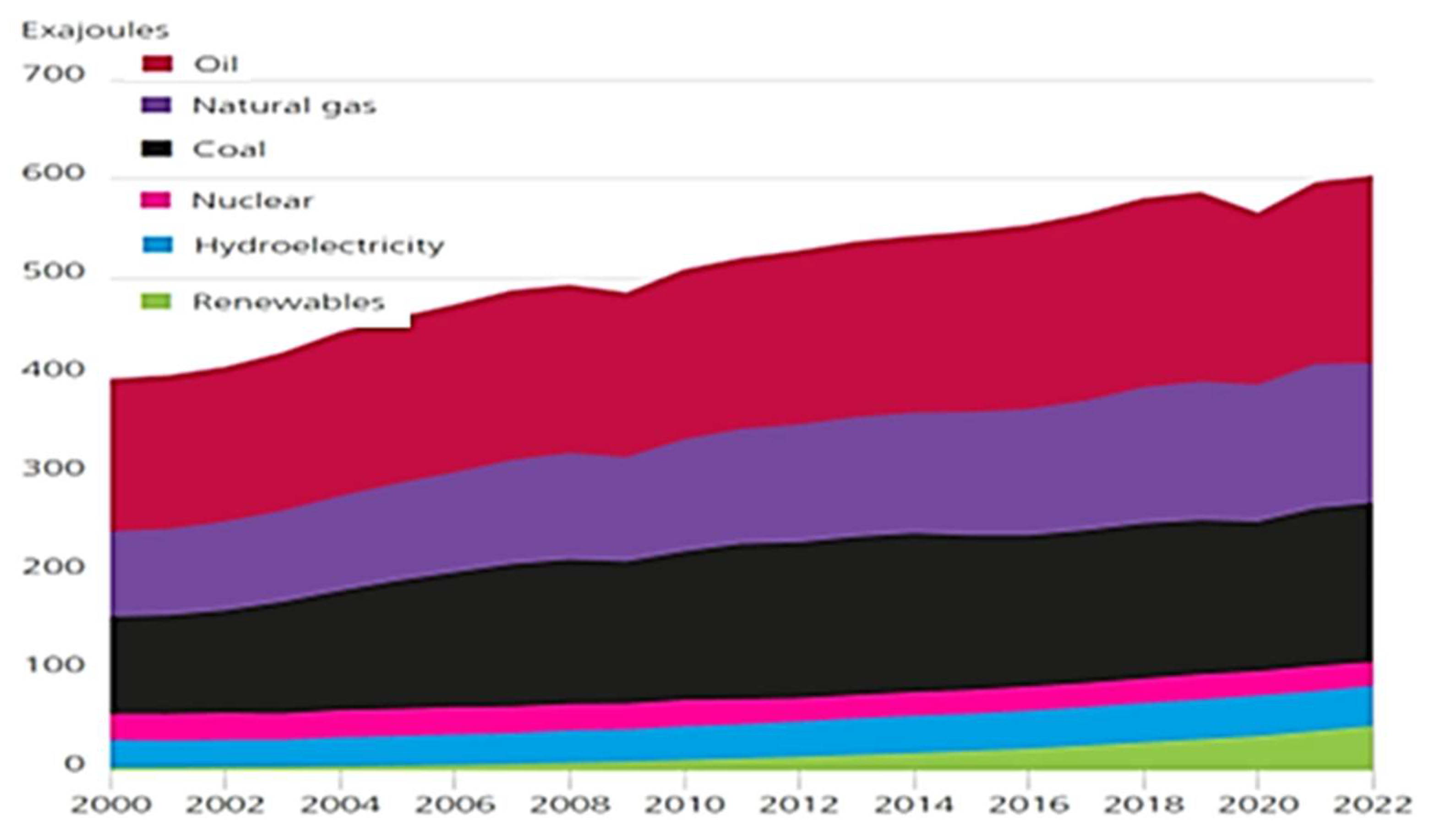

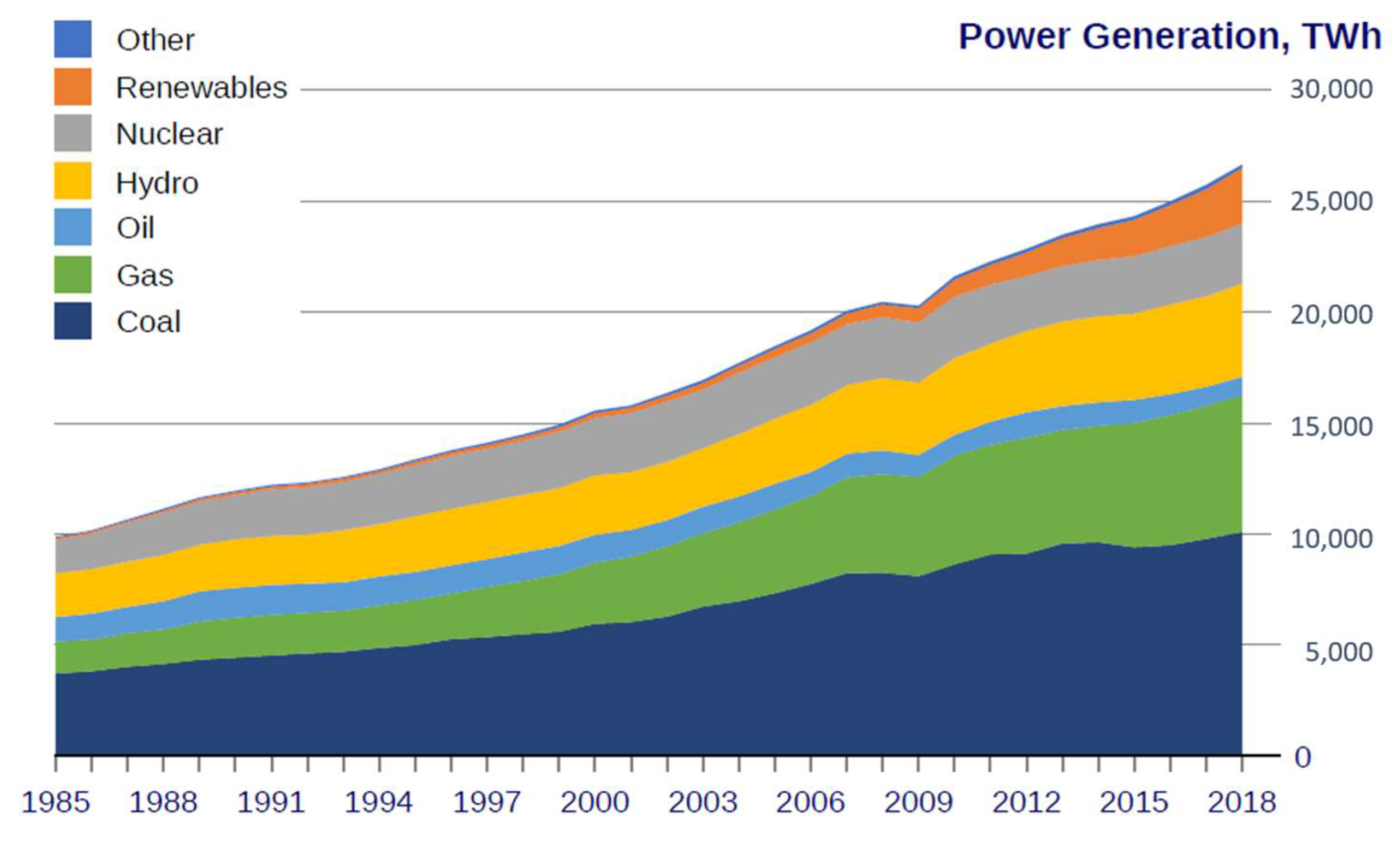

- Organizational: System perspectives and stakeholders’ cooperation, still largely lacking, are necessary. e-Fuel production is highly dependent on RES availability; however, the current grid energy mix is still largely dependent on fossil sources. Several EU countries at the moment are highly dependent on electricity imports for normal operation, and even conventional electric capacity (from mixed sources) surplus is scarce. Current policies on battery vehicles and hydrogen mobility are not designed nor suitable for long-distance transport applications;

- -

- Regulatory: Fossil fuels and CO2 emissions are still relatively inexpensive, preventing companies and consumers from choosing more sustainable alternatives. The high time-variability of fossil energy is an obstacle to the adoption of alternative sources. The constant evolution of tax regimes for vehicles and fuels makes the outlook in the sector uncertain: long-term financial and fiscal aspects must be established. e-Fuels are not yet universally certified, while the transport industry relies on global standards. There is not a sufficiently uniform policy at the global level for achieving sustainability in the transport sector.

3. Biofuels

3.1. Second-Generation Biofuels

3.1.1. Thermochemical Approach to 2-G Biofuels

3.1.2. Biochemical Approach

- Lignocellulosic biorefinery, based on natural dry raw materials, such as cellulose-containing biomasses, and wastes;

- Green biorefinery, based on natural wet biomasses, such as green grass, alfalfa, clover, or immature cereal;

- Two-platform concept biorefinery, based on sugar and syngas platforms;

- Conventional biorefinery, based on existing industries, such as sugar and starch;

- Marine biorefinery, based on marine biomass;

- Liquid-phase catalytic processing biorefinery, based on the production of functionalized hydrocarbons from intermediates derived from biomass;

- Forest-based biorefinery, based on integrated biomass and other feedstocks (including energy) processing for production of pulp, (paper) fibers, chemicals, and energy;

- Brown biorefinery, based on wet biomass from waste processing operations, such as municipal or industrial sewage.

3.2. Third-Generation Biofuels

3.3. Biofuel Types

3.3.1. Gaseous Biofuels: Biogas, Biomethane, Syngas, and Bio-Hydrogen

3.3.2. Liquid Biofuels

- -

- Those produced from food and feed crops (Article 26), for example, biodiesel from oil from rapeseed, sunflower, palm, and soy, or bioethanol from corn, wheat, sugar beet, barley, and rye;

- -

- “advanced biofuels” from wastes, residues, and co-products (Part A, Annex IX), for example, algae, biomass fraction of municipal waste, straw, palm oil mill effluent, non-food cellulosic, or ligno-cellulosic material, using advanced technologies;

- -

- Biofuels from wastes, residues, and co-products (Part B, Annex IX) such as used cooking oil and animal fats not fit for human food or animal feed that can be processed using mature technologies.

3.4. Biofuel Issues

- -

- Economic and technical: Biofuels still compete with other sectors for raw materials (e.g., the food sector, but also the cosmetic, pharmaceutical, bio-plastic, and heat production sectors). This affects the availability and market prices of these materials. Biofuels were supposed to increase energy independence, but in practice, they often distorted feedstock material markets: in the early 2000s, the EU-25’s biofuel consumption was 90% covered by domestic feedstock and just 10% by imports; two decades later, dependence on import has vastly increased due to rising biomass demand for biofuels. The EU-27’s biofuel consumption from used cooking oil feedstock increased from 0.09 Mtoe to 2.53 Mtoe (+2700%) between 2011 and 2020, with more than half of the used oil now imported from outside the EU at increasing prices. According to the IEA, “biodiesel, renewable diesel and biojet fuel producers are headed for a feedstock supply crunch during 2022–2027, if current trends do not change” [103];

- -

- Organizational: The EU has adopted various strategies for transport and biofuels over the years; however, the specific strategy for biofuels has never been updated or revised since 2006, while the complex operating framework of the biofuel industry has evolved significantly since. Additionally, there is no clear indication of the EU policy on biofuels after the 2030 horizon, which may discourage research, development, and investments in the sector;

- -

- Regulatory: Some transportation sectors have long-term decarbonization objectives, but no roadmap concerning their achievement. The constant evolution of tax regimes for vehicles and fuels makes the outlook in the sector uncertain: for example, sustainable aviation fuel (SAF) production is supported under long-term fiscal provisions in the United States, but no EU-level roadmap yet exists on production speed-up and support. Different feedstocks are even treated differently under various regulatory targets, increasing their implementation complexity; the same feedstock may be differently classified across EU member states. On the GHG emission calculation aspect, savings from biofuel use are determined according to official formulas that may not be fully reliable or consistent. For example, the EU approach does not factor in the risk of indirect land use change for crop-based biofuels, leading to a possible overestimation of GHG emission target achievement by over 60% [97]. Overestimations of emission reduction may also come from the use of default values for feedstock types, irrespective of origin: as an example, CO2 emission factors from used cooking oil transport and distribution originating from Germany or France were calculated with the same coefficients used for used cooking oil imported from China [98]. Better-defined procedures and goals are therefore needed.

4. Non-Biomass Waste-Derived Fuels

5. Discussion and Future Perspectives

Future Perspectives

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Worldometer. World Oil Reserves. Available online: https://www.worldometers.info/oil/ (accessed on 3 April 2024).

- EEA. Renewable Energy. European Environmental Agency. Available online: https://www.eea.europa.eu/en/topics/in-depth/renewable-energy (accessed on 3 April 2024).

- Energy Institute. 2023 Statistical Review of World Energy, 72nd ed.; Energy Institute: London, UK, 2023. [Google Scholar]

- EEA. Total Net Greenhouse Gas Emission Trends and Projections in Europe. European Environmental Agency. Available online: https://www.eea.europa.eu/en/analysis/indicators/total-greenhouse-gas-emission-trends (accessed on 24 June 2024).

- Raboni, M.; Viotti, P.; Capodaglio, A.G. A comprehensive analysis of the current and future role of biofuels for transport in the European Union (EU). Revista Amb. Agua 2015, 10, 10–21. [Google Scholar] [CrossRef]

- European Commission. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources; European Commission: Brussels, Belgium, 2018.

- European Commission. COM/2019/640 Final. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2019%3A640%3AFIN (accessed on 7 May 2024).

- Melin, H.E.; Rajaeifar, M.A.; Ku, A.Y.; Kendall, A.; Harper, G.; Heidrich, O. Global implications of the EU battery regulation. Science 2021, 373, 384–387. [Google Scholar] [CrossRef] [PubMed]

- Melin, H.E. The Lithium-Ion Battery End-of-Life Market 2018–2025; Circular Energy Storage: London, UK, 2018. [Google Scholar]

- Mrozik, W.; Rajaeifar, M.A.; Heidrich, O.; Christensen, P. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ. Sci. 2021, 14, 6099–6121. [Google Scholar] [CrossRef]

- Helgeson, B.; Peter, J. The role of electricity in decarbonizing European road transport—Development and assessment of an integrated multi-sectoral model. Appl. Energy 2020, 262, 114365. [Google Scholar] [CrossRef]

- Prussi, M.; Yugo, M.; de Prada, L.; Padella, M.; Edwards, R.; Lonza, L. JEC Well-to-Tank Report v5. 2020; p. 248. Available online: https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/jec-well-tank-report-v5 (accessed on 16 April 2024).

- Prussi, M.; Laveneziana, L.; Testa, L.; Chiaramonti, L. Comparing e-Fuels and Electrification for Decarbonization of Heavy-Duty Transports. Energies 2022, 15, 8075. [Google Scholar] [CrossRef]

- Majewski, W.A. Energy Alternatives. Available online: https://dieselnet.com/tech/energy_alternatives.php (accessed on 22 April 2024).

- IRENA. Hydrogen. Available online: https://www.irena.org/Energy-Transition/Technology/Hydrogen (accessed on 22 April 2024).

- Energy Transitions Commission. Mission Possible: Reaching Net-Zero Carbon Emissions from Harder-to-Abate Sectors. 2018. Available online: https://www.energy-transitions.org/publications/mission-possible (accessed on 5 May 2024).

- Hydrogen Insight. Impossible Dreams? The 11 Biggest Green Hydrogen Projects Announced around the World So Far. Available online: https://www.hydrogeninsight.com/production/impossible-dreams-the-11-biggest-green-hydrogen-projects-announced-around-the-world-so-far/2-1-1517618 (accessed on 25 June 2024).

- Wallington, T.J.; Anderson, J.E.; Siegel, D.J.; Tamor, M.A.; Mueller, S.A.; Winkler, S.L.; Nielsen, O.J. Sustainable Mobility, Future Fuels, and the Periodic Table. J. Chem. Educ. 2013, 90, 440–445. [Google Scholar] [CrossRef]

- Callegari, A.; Bolognesi, S.; Cecconet, D.; Capodaglio, A.G. Production technologies, current role, and future prospects of biofuels feedstocks: A state-of-the-art review. Crit. Rev. Environ. Sci. Technol. 2020, 50, 384–436. [Google Scholar] [CrossRef]

- Gebre, S.H.; Sendeku, M.G.; Bahri, M. Recent Trends in the Pyrolysis of Non-Degradable Waste Plastics. Chem. Open 2021, 10, 1202–1226. [Google Scholar] [CrossRef]

- Han, W.; Han, D.; Chen, H. Pyrolysis of Waste Tires: A Review. Polymers 2023, 15, 1604. [Google Scholar] [CrossRef]

- Callegari, A.; Hlavinek, P.; Capodaglio, A.G. Production of energy (biodiesel) and recovery of materials (biochar) from pyrolysis of urban waste sludge. Rev. Amb. Agua 2018, 13, e2128. [Google Scholar] [CrossRef]

- EURACTIV. Available online: https://www.euractiv.com/section/politics/news/e-fuels-for-new-combustion-cars-must-be-100-climate-neutral-eu-commission-draft/ (accessed on 25 September 2023).

- Jin, C.; Yao, M.; Liu, H.; Lee, C.F.F.; Ji, J. Progress in the production and application of n-butanol as a biofuel. Ren. Sust. Energ. Rev. 2011, 15, 4080–4106. [Google Scholar] [CrossRef]

- Candelaresi, D.; Spazzafumo, G. Chapter 1—Introduction: The Power-to-Fuel Concept, Power to Fuel; Spazzafumo, G., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 1–15. [Google Scholar]

- d’Amore, F.; Nava, A.; Colbertaldo, P.; Visconti, C.G.; Romano, M.C. Turning CO2 from fuel combustion into e-Fuel? Consider alternative pathways. Energy Convers. Manag. 2023, 289, 117170. [Google Scholar] [CrossRef]

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Liu, Q. A critical review of technologies, costs, and projects for production of carbon-neutral liquid e-fuels from hydrogen and captured CO2. Energy Adv. 2022, 1, 580. [Google Scholar] [CrossRef]

- Bolognesi, S.; Bañeras, L.; Perona-Vico, E.; Capodaglio, A.G.; Balaguer, M.D.; Puig, S. Carbon dioxide to bio-oil in a bioelectrochemical system-assisted microalgae biorefinery process. Sustain. Energy Fuels 2022, 6, 150–161. [Google Scholar] [CrossRef]

- Scarlat, N.; Prussi, M.; Padella, M. Quantification of the carbon intensity of electricity produced and used in Europe. Appl. Energy 2022, 305, 117901. [Google Scholar] [CrossRef]

- Vadivel, D.; Dondi, D.; Capodaglio, A.G. Present achievements and future directions of advanced CO2 reduction strategies. Curr. Opin. Chem. Eng. 2024, 45, 101029. [Google Scholar] [CrossRef]

- Dai, F.; Zhang, S.; Luo, Y.; Wang, K.; Liu, Y.; Ji, X. Recent Progress on Hydrogen-Rich Syngas Production from Coal Gasification. Processes 2023, 11, 1765. [Google Scholar] [CrossRef]

- Chen, W.H.; Biswas, P.P.; Ong, H.C.; Hoang, A.T.; Nguyen, T.B.; Dong, C.D. A critical and systematic review of sustainable hydrogen production from ethanol/bioethanol: Steam reforming, partial oxidation, and autothermal reforming. Fuel 2023, 33, 126526. [Google Scholar] [CrossRef]

- Xue, Z.W.; Liu, J.L.; Zhang, Z.Y.; Kitila, H.; Lian, H.Y.; Sun, B.; Zhu, A.M. Mechanism study on gliding arc (GA) plasma reforming: Reaction and energy pathways for H2 production from methanol steam reforming. Chem. Eng. J. 2023, 462, 142319. [Google Scholar] [CrossRef]

- Patlolla, S.R.; Katsu, K.; Sharafian, A.; Wei, K.; Herrera, O.E.; Mérida, W. A review of methane pyrolysis technologies for hydrogen production. Renew. Sust. Energy Rev. 2023, 181, 113323. [Google Scholar] [CrossRef]

- Dahiya, S.; Chatterjee, S.; Sarkar, O.; Mohan, S.V. Renewable hydrogen production by dark-fermentation: Current status, challenges and perspectives. Bioresour. Technol. 2021, 321, 124354. [Google Scholar] [CrossRef] [PubMed]

- Putatunda, C.; Behl, M.; Solanki, P.; Sharma, S.; Bhatia, S.K.; Walia, A.; Bhatia, R.K. Current challenges and future technology in photofermentation-driven biohydrogen production by utilizing algae and bacteria. Int. J. Hydrogen Energy 2023, 48, 21088–21109. [Google Scholar] [CrossRef]

- Song, H.; Yang, G.; Xue, P.; Li, Y.; Zou, J.; Wang, S.; Yang, H.; Chen, H. Recent development of biomass gasification for H2 rich gas production. Appl. Energy Combust. Sci. 2022, 10, 100059. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, Q. Redox-Mediated Water Splitting for Decoupled H2 Production. ACS Mater. Lett. 2021, 3, 641–651. [Google Scholar] [CrossRef]

- Khan, M.A.; Al-Attas, T.; Roy, S.; Rahman, M.M.; Ghaffour, N.; Thangadurai, V.; Lartere, S.; Hu, J.; Ajayan, P.M.; Kibria, M.D. Seawater electrolysis for hydrogen production: A solution looking for a problem? Energy Environ. Sci. 2021, 14, 4831–4839. [Google Scholar] [CrossRef]

- Dong, X.; Pang, D.; Luo, G.; Zhu, X. Microbial Water Electrolysis Cells for Efficient Wastewater Treatment and H2 Production. ACS Sustain. Chem. Eng. 2024, 12, 10. [Google Scholar] [CrossRef]

- Aimikhe, V.J.; Oghenegare, E.E. Recent Advances in White Hydrogen Exploration and Production: A Mini Review. J. Energy Res. Rev. 2023, 13, 64–79. [Google Scholar] [CrossRef]

- Karimi, M.; Shirzad, M.; Silva, J.A.C.; Rodrigues, A.R. Carbon dioxide separation and capture by adsorption: A review. Environ. Chem. Lett. 2023, 21, 2041–2084. [Google Scholar] [CrossRef]

- Shen, M.; Tong, L.; Yin, S.; Liu, C.; Wang, L.; Feng, W.; Ding, Y. Cryogenic technology progress for CO2 capture under carbon neutrality goals: A review. Sep. Purif. Technol. 2022, 299, 121734. [Google Scholar] [CrossRef]

- Yadav, S.; Mondal, S.S. A review on the progress and prospects of oxy-fuel carbon capture and sequestration (CCS) technology. Fuel 2022, 308, 122057. [Google Scholar] [CrossRef]

- Jin, B.; Wei, K.; Ouyang, T.; Fan, Y.; Zhao, H.; Zhang, H.; Liang, Z. Chemical looping CO2 capture and in-situ conversion: Fundamentals, process configurations, bifunctional materials, and reaction mechanisms. Appl. Energy Comb. Sci. 2023, 16, 100218. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Lootah, M.A.; Sayed, E.T.; Wilberforce, T.; Alawadhi, H.; Yousef, B.A.; Olabi, A.G. Fuel cells for carbon capture applications. Sci. Tot. Environ. 2021, 769, 144243. [Google Scholar] [CrossRef] [PubMed]

- Castro-Muñoz, R.; Ahmad, M.Z.; Malankowska, M.; Coronas, J. A new relevant membrane application: CO2 direct air capture (DAC). Chem. Eng. J. 2022, 446, 137047. [Google Scholar] [CrossRef]

- van Kranenburg, K.; van Delft, Y.; Gavrilova, A.; de Kler, R.; Schipper, C.; Smokers, R.; Verbeek, M.; Verbeek, R. e-Fuels: Towards a More Sustainable Future for Truck Transport, Shipping and Aviation. Available online: https://www.voltachem.com/images/uploads/20-11482_whitepaper_Voltachem-10.pdf (accessed on 15 May 2024).

- Agyekum, E.B.; Nutakor, C.; Agwa, A.M.; Kamel, S. A Critical Review of Renewable Hydrogen Production Methods: Factors Affecting Their Scale-Up and Its Role in Future Energy Generation. Membranes 2022, 12, 173. [Google Scholar] [CrossRef] [PubMed]

- Zang, G.; Sun, P.; Elgowainy, A.; Wang, M. Technoeconomic and Life Cycle Analysis of Synthetic Methanol Production from Hydrogen and Industrial Byproduct CO2. Environ. Sci. Technol. 2021, 55, 5248–5257. [Google Scholar] [CrossRef] [PubMed]

- Schemme, S.; Breuer, J.L.; Köller, M.; Meschede, S.; Walman, F.; Samsun, R.C.; Peters, R.; Stolten, D. H2-based synthetic fuels: A technoeconomic comparison of alcohol, ether and hydrocarbon production. Int. J. Hydrogen Energy 2020, 45, 5395–5414. [Google Scholar] [CrossRef]

- Sheldon, D. Methanol production—A technical history. Johns. Matthey Technol. Rev. 2017, 61, 172–182. [Google Scholar] [CrossRef]

- Brynolf, S.; Taljegard, M.; Grahn, M.; Hansson, J. Electrofuels for the transport sector: A review of production costs. Renew. Sustain. Energy Rev. 2018, 81, 1887–1905. [Google Scholar] [CrossRef]

- Christensen, A. CO2-Based Synthetic Fuel: Assessment of Potential European Capacity and Environmental Performance, International Council on Clean Transportation. United States of America. 2017. Available online: https://policycommons.net/artifacts/3802653/co2-based-synthetic-fuel/4608481/ (accessed on 15 May 2024).

- Wärtsilä. Meet the World’s First 4-Stroke Ammonia Solution for Marine. Available online: https://www.wartsila.com/marine/wartsila-25-ammonia (accessed on 1 June 2024).

- Chiong, M.C.; Chong, T.C.; Ng, J.N.; Mashruk, S.; Chong, W.W.F.; Samiran, N.A.; Mong, G.R.; Valera-Medina, A. Advancements of combustion technologies in the ammonia-fuelled engines. Energy Convers. Manag. 2021, 244, 114460. [Google Scholar] [CrossRef]

- H2 Energy News. GAC and Toyota Introduce Ammonia-Burning Engine for Passenger Cars. Available online: https://energynews.biz/gac-and-toyota-introduce-ammonia-burning-engine-for-passenger-cars/ (accessed on 1 June 2024).

- Ojelade, O.A.; Zaman, S.F.; Ni, B.J. Green ammonia production technologies: A review of practical progress. J. Environ. Manag. 2023, 342, 118348. [Google Scholar] [CrossRef]

- Müller, K.; Fleige, M.; Rachow, F.; Schmeißer, D. Sabatier based CO2-methanation of Flue Gas Emitted by Conventional Power Plants. Energy Procedia 2013, 40, 240–248. [Google Scholar] [CrossRef]

- de Miranda, P.E.V. Application of Hydrogen by Use of Chemical Reactions of Hydrogen and Carbon Dioxide, Chapter 5.3.3. In Science and Engineering of Hydrogen-Based Energy Technologies; Academic Press: Cambridge, MA, USA, 2019; pp. 279–289. [Google Scholar]

- Barelli, L.; Bidini, G.; Ottaviano, P.A.; Perla, M. Liquefied Synthetic Natural Gas. Produced through Renewable Energy Surplus: Impact Analysis on Vehicular Transportation by 2040 in Italy. Gases 2021, 1, 80–91. [Google Scholar] [CrossRef]

- Styring, P.; Sanderson, P.W.; Gell, I.; Skorikova, G.; Sánchez-Martínez, C.; Garcia-Garcia, G.; Sluijter, S.N. Carbon footprint of Power-to-X derived dimethyl ether using the sorption enhanced DME synthesis process. Front. Sustain. 2022, 3, 1057190. [Google Scholar] [CrossRef]

- Rüde, T.; Dürr, D.; Preuster, P.; Wolf, M.; Wasserscheid, P. Benzyltoluene/perhydro benzyltoluene—Pushing the performance limits of pure hydrocarbon liquid organic hydrogen carrier (LOHC) systems. Sustain. Energy Fuels 2022, 6, 1541–1553. [Google Scholar] [CrossRef]

- Pizarro-Loaiza, C.A.; Antón, A.; Torrellas, M.; Torres-Lozada, P.; Palatsi, J.; Bonmatí, A. Environmental, social and health benefits of alternative renewable energy sources. Case study for household biogas digesters in rural areas. J. Clean Prod. 2021, 297, 126722. [Google Scholar] [CrossRef]

- Biofuel. First-Generation Biofuels, Biofuel Organization UK. 2018. Available online: http://biofuel.org.uk/first-generation-biofuel.html (accessed on 4 May 2024).

- Cecconet, D.; Capodaglio, A.G. Sewage Sludge Biorefinery for Circular Economy. Sustainability 2022, 14, 14841. [Google Scholar] [CrossRef]

- Sharma, P.; Bano, A.; Singh, S.-P.; Atkinson, J.D.; Lam, S.S.; Iqbal, H.M.N.; Tong, Y.W. Biotransformation of food waste into biogas and hydrogen fuel—A review. Int. J. Hydrogen Energy 2024, 52, 46–60. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Bolognesi, S. Ecofuel feedstocks and their prospects. Adv. Eco-Fuels A Sustain. Environ. 2018, 15–51. [Google Scholar] [CrossRef]

- Lee, R.A.; Lavoie, J.M. From first- to third-generation biofuels: Challenges of producing a commodity from a biomass of increasing complexity. Anim. Front. 2013, 3, 6–11. [Google Scholar] [CrossRef]

- Sansaniwal, S.K.; Pal, K.; Rosen, M.A.; Tyagi, S.K. Recent advances in the development of biomass gasification technology: A comprehensive review. Renew. Sustain. Energy Rev. 2017, 72, 363–384. [Google Scholar] [CrossRef]

- Capodaglio, A.G. Biorefinery of Sewage Sludge: Overview of Possible Value-Added Products and Applicable Process Technologies. Water 2023, 15, 1195. [Google Scholar] [CrossRef]

- Marinangeli, R.; Boldingh, E.; Cabanban, S.; Fei, Z.; Ellis, G.; Bain, R.; Hsu, D.; Elliott, D. Pyrolysis Oil to Gasoline-Final Report. Pacific Northwest National Laboratory Contract DE-AC05-76RL01830; US Department of Energy: Washington, DC, USA, 2009.

- IEA. Bioenergy Task 42 on Biorefineries. International Energy Agency. Available online: www.biorefinery.nl\IEABioenergy-Task42 (accessed on 4 April 2024).

- Cherubini, F.; Jungmeier, G.; Wellisch, M.; Willke, T.; Skiadas, I.; Van Ree, R.; de Jong, E. Toward a common classification approach for biorefinery systems. Biofuels Bioprod. Bioref. 2009, 3, 534–546. [Google Scholar] [CrossRef]

- Iram, A.; Cekmecelioglu, D.; Demirci, A. Ideal Feedstock and Fermentation Process Improvements for the Production of Lignocellulolytic Enzymes. Processes 2021, 9, 38. [Google Scholar] [CrossRef]

- Hess, J.R.; Ray, A.E.; Rials, T.G. Advancements in biomass feedstock preprocessing: Conversion ready feedstocks. Front. Energy Res. 2019, 7, 140. [Google Scholar] [CrossRef]

- Capodaglio, A.G. Pulse electric field technology for wastewater and biomass residues’ improved valorization. Processes 2021, 9, 736. [Google Scholar] [CrossRef]

- Milledge, J.J.; Heaven, S. Methods of energy extraction from microalgal biomass: A review. Rev. Environ. Sci. Biotechnol. 2014, 13, 301–320. [Google Scholar] [CrossRef]

- Capodaglio, A.G. Urban Wastewater Mining for Circular Resource Recovery: Approaches and Technology Analysis. Water 2023, 15, 3967. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Bolognesi, S.; Cecconet, D. Sustainable, decentralized sanitation and reuse with hybrid nature-based systems. Water 2021, 13, 1583. [Google Scholar] [CrossRef]

- Pedersen, T.C.; Gardner, R.D.; Gerlach, R.; Peyton, B.M. Assessment of Nannochloropsis gaditana growth and lipid accumulation with increased inorganic carbon delivery. J. Appl. Phycol. 2018, 30, 2155–2166. [Google Scholar] [CrossRef]

- Onay, M. Enhancing carbohydrate productivity from Nannochloropsis gaditana for bio-butanol production. Energy Rep. 2020, 6, 63–67. [Google Scholar] [CrossRef]

- Mavridis, S.; Voudrias, E.A. Using biogas from municipal solid waste for energy production: Comparison between anaerobic digestion and sanitary landfilling. Energy Convers. Manag. 2021, 247, 114613. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A. Energy and resources recovery from excess sewage sludge: A holistic analysis of opportunities and strategies. Resour. Conserv. Recycl. Adv. 2023, 19, 200184. [Google Scholar] [CrossRef]

- Cecconet, D.; Mainardis, M.; Callegari, A.; Capodaglio, A.G. Psychrophilic treatment of municipal wastewater with a combined UASB/ASD system, and perspectives for improving urban WWTP sustainability. Chemosphere 2022, 297, 134228. [Google Scholar] [CrossRef] [PubMed]

- Das, P.K.; Das, B.P.; Dash, P.; Das, B.K.; Gurunathan, B. Valorization of Agro-Waste Biomass into Biofuel: A Step Towards Effective Agro-Waste Management. In Value Added Products From Food Waste; Cherian, E., Gurunathan, B., Eds.; Springer: Cham, Switzerland, 2024. [Google Scholar]

- Capodaglio, A.G.; Callegari, A.; Lopez, M.V. European framework for the diffusion of biogas uses: Emerging technologies, acceptance, incentive strategies, and institutional-regulatory support. Sustainability 2016, 8, 298. [Google Scholar] [CrossRef]

- EC. Bioenergy Report Outlines Progress Being Made across the EU. Directorate-General for Energy, European Commission. Available online: https://energy.ec.europa.eu/news/bioenergy-report-outlines-progress-being-made-across-eu-2023-10-27_en#:~:text=Indigenous%20biogas%20production%20in%20the,9.4%25%2C%201.4%20mtoe (accessed on 16 April 2024).

- Pavičić, J.; Novak Mavar, K.; Brkić, V.; Simon, K. Biogas and Biomethane Production and Usage: Technology Development, Advantages and Challenges in Europe. Energies 2022, 15, 2940. [Google Scholar] [CrossRef]

- Hakawati, R.; Smyth, B.M.; McCullough, G.; De Rosa, F.; Rooney, D. What is the most energy efficient route for biogas utilization: Heat, electricity or transport? Appl. Energy 2017, 206, 1076–1087. [Google Scholar] [CrossRef]

- EN 16723-1:2016(MAIN); Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 1: Specifications for Biomethane for Injection in the Natural Gas Network. Available online: https://standards.iteh.ai/catalog/standards/sist/4e0bcbd1-2320-40d3-8a0f-834d083c06f0/sist-en-16723-1-2017 (accessed on 10 July 2024).

- EN 16723-2:2017(MAIN); Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 2: Automotive Fuels Specification. Available online: https://standards.iteh.ai/catalog/standards/cen/bb646037-ec22-4cd4-aad4-902ea1b8e0d5/en-16723-2-2017 (accessed on 10 July 2024).

- IEA. Outlook for Biogas and Biomethane: Prospects for Organic Growth. World Energy Outlook Special Report. International Energy Agency. 2020. Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth (accessed on 26 April 2024).

- Ghazi, F.M.G.; Abbaspour, M.; Rahimpour, M.R. Chapter 11—Biofuel production from syngas. In Advances in Synthesis Gas: Methods, Technologies and Applications; Rahimpour, M.R., Makarem, M.A., Meshksar, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 3, pp. 271–286. [Google Scholar]

- Argun, H.; Kargi, F. Bio-hydrogen production by different operational modes of dark and photo-fermentation: An overview. Int. J. Hydrogen Energy 2011, 36, 7443–7459. [Google Scholar] [CrossRef]

- JRC. Clean Energy Technology Observatory: Advanced Biofuels in the European Union—2022 Status Report on Technology Development, Trends, Value Chains and Markets, 2022; Publications Office of the European Union: Luxembourg, 2022. [Google Scholar]

- ECA. The EU’s Support for Sustainable Biofuels in Transport. An Unclear Route Ahead. Special Report 29; European Court of Auditors: Luxembourg, 2023.

- Hongloi, N.; Prapainainar, P.; Prapainainar, C. Review of green diesel production from fatty acid deoxygenation over Ni-based catalysts. Mol. Catal. 2022, 523, 111696. [Google Scholar] [CrossRef]

- Bharathiraja, B.; Jayamuthunagai, J.; Sudharsanaa, T.; Bharghavi, A.; Praveenkumar, R.; Chakravarthy, M.; Yuvaraj, D. Biobutanol—An impending biofuel for future: A review on upstream and downstream processing tecniques. Renew. Sustain. Energy Rev. 2017, 68, 788–807. [Google Scholar] [CrossRef]

- Cheng, H.H.; Whang, L.M.; Chan, K.C.; Chung, M.C.; Wu, S.H.; Liu, C.P.; Tien, S.Y.; Chen, S.Y.; Chang, J.S.; Lee, W.J. Biological butanol production from microalgae-based biodiesel residues by Clostridium acetobutylicum. Bioresour. Technol. 2014, 184, 379–385. [Google Scholar] [CrossRef]

- Wang, Y.; Ho, S.-H.; Yen, H.-W.; Nagarajan, D.; Ren, N.-Q.; Li, S.; Hu, Z.; Lee, D.-J.; Kondo, A.; Chang, J.-S. Current advances on fermentative biobutanol production using third-generation feedstock. Biotechnol. Adv. 2017, 35, 1049–1059. [Google Scholar] [CrossRef] [PubMed]

- Damyanov, A.; Hofmann, P.; Geringer, B.; Schwaiger, N.; Pichler, T.; Siebenhofer, M. Biogenous ethers: Production and operation in a diesel engine. Automot. Engine Technol. 2018, 3, 69–82. [Google Scholar] [CrossRef]

- IEA. Renewables 2022. International Energy Agency. Available online: https://www.iea.org/reports/renewables-2022 (accessed on 22 April 2024).

- Wang, Q.; Zhang, C.; Li, R. Plastic pollution induced by the COVID-19: Environmental challenges and outlook. Environ. Sci. Pollut. Res. Int. 2023, 30, 40405–40426. [Google Scholar] [CrossRef] [PubMed]

- Awang, M.S.N.; Mohd Zulkifli, N.W.; Abbas, M.M.; Amzar Zulkifli, S.; Kalam, M.A.; Ahmad, M.H.; Mohd Yusoff, M.N.A.; Yusoff, M.N.A.M.; Mazlan, M.; Daud, W.M.A.W. Effect of Addition of Palm Oil Biodiesel in Waste Plastic Oil on Diesel Engine Performance, Emission, and Lubricity. ACS Omega 2021, 6, 21655–21675. [Google Scholar] [CrossRef] [PubMed]

- Rogachuk, B.E.; Okolie, J.A. Waste tires based biorefinery for biofuels and value-added materials production. Chem. Eng. J. Adv. 2023, 14, 100476. [Google Scholar] [CrossRef]

- Hu, Y.; Attia, M.; Tsabet, E.; Mohaddespour, A.; Munir, M.T.; Farag, S. Valorization of waste tire by pyrolysis and hydrothermal liquefaction: A mini-review. J. Mater. Cycles Waste Manag. 2021, 23, 1737–1750. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. Pyrolysis of plastic waste for liquid fuel production as prospective energy resource. IOP Conf. Ser. Mater. Sci. Eng. 2018, 334, 012001. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A.; Faussone, G.-C.; Karonis, D. Alternative Diesel from Waste Plastics. Energies 2017, 10, 1750. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Tariq, R.; Gul, K.; Ahmad, W. Pyrolysis Study of Polypropylene and Polyethylene Into Premium Oil Products. Int. J. Green Energy 2015, 12, 663–671. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Lopez, G.; Artetxe, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Waste tyre valorization by catalytic pyrolysis—A review. Renew. Sustain. Energy Rev. 2020, 129, 109932. [Google Scholar] [CrossRef]

- Martínez, J.D.; Veses, A.; Callén, M.S.; López, J.M.; García, T.; Murillo, R. On Fractioning the Tire Pyrolysis Oil in a Pilot-Scale Distillation Plant under Industrially Relevant Conditions. Energy Fuels 2023, 37, 2886–2896. [Google Scholar] [CrossRef] [PubMed]

- Pilusa, T.J.; Shukla, M.; Muzenda, E. Pyrolitic Tyre Derived Fuel: A Review. In Proceedings of the International Conference on Chemical, Mining and Metallurgical Engineering (CMME’2013), Johannesburg, South Africa, 27–28 November 2013. [Google Scholar]

- Czajczyńska, D.; Krzyżyńska, R.; Jouhara, H.; Spencer, N. Use of pyrolytic gas from waste tire as a fuel: A review. Energy 2017, 134, 1121–1131. [Google Scholar] [CrossRef]

- Oboirien, B.O.; North, B.C. A review of waste tyre gasification. J. Environ. Chem. Eng. 2017, 5, 5169–5178. [Google Scholar] [CrossRef]

- Lerner, A.S.; Bratsev, A.N.; Popov, V.E.; Kuznetsov, V.A.; Ufimtsev, A.A.; Shengel, S.V.; Subbotin, D.I. Production of hydrogen-containing gas using the process of steam-plasma gasification of used tires. Glass Phys. Chem. 2012, 38, 511–516. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Bezergianni, S. Hydrothermal liquefaction of various biomass and waste feedstocks for biocrude production: A state of the art review. Renew. Sustain. Energy Rev. 2017, 68, 113–125. [Google Scholar] [CrossRef]

- Lu, W.; Guo, Y.; Zhang, B. Co-deoxy-liquefaction of willow leaves and waste tires for high-caloric fuel production. J. Anal. Appl. Pyrolysis 2018, 135, 327–339. [Google Scholar] [CrossRef]

- Koyunoglu, C.; Eksioglu, O.; Yıldırım, O.; Karaca, H. Co-liquefaction of Yatağan lignite and waste tire under catalytic conditions. Part 1. Effect of fresh tetraline and recycled tetraline on the conversion. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 1068–1075. [Google Scholar] [CrossRef]

- Enciso, S.R.A.; Fellmann, T.; Dominguez, I.P.; Santini, F. Abolishing biofuel policies: Possible impacts on agricultural price levels, price variability and global food security. Food Policy 2016, 61, 9–26. [Google Scholar] [CrossRef]

- Ingrao, C.; Matarazzo, A.; Gorjian, S.; Adamczyk, J.; Failla, S.; Primerano, P.; Huisingh, D. Wheat-straw derived bioethanol production: A review of Life Cycle Assessments. Sci. Tot. Environ. 2021, 781, 146751. [Google Scholar] [CrossRef]

- Singh, A.; Singhania, R.R.; Soam, S.; Chen, C.W.; Haldar, D.; Varjani, S.; Chang, J.S.; Dong, C.D.; Patel, A.K. Production of bioethanol from food waste: Status and perspectives. Bioresour. Technol. 2022, 360, 127651. [Google Scholar] [CrossRef]

- Raj, T.; Chandrasekhar, K.; Kumar, A.N.; Banu, J.R.; Yoon, J.-J.; Bhatia, S.K.; Yang, Y.H.; Varjani, S.; Kim, S.H. Recent advances in commercial biorefineries for lignocellulosic ethanol production: Current status, challenges and future perspectives. Bioresour. Technol. 2022, 344, 126292. [Google Scholar] [CrossRef] [PubMed]

- Preethi, G.M.; Kumar, G.; Karthikeyan, O.P.; Varjani, S.; Banu, J.R. Lignocellulosic biomass as an optimistic feedstock for the production of biofuels as valuable energy source: Techno-economic analysis, Environmental Impact Analysis, Breakthrough and Perspectives. Environ. Technol. Innov. 2021, 24, 102080. [Google Scholar] [CrossRef]

- Ganesan, R.; Manigandan, S.; Samuel, M.S.; Shanmuganathan, R.; Brindhadevi, K.; Chi, N.T.L.; Duc, P.A.; Pugazhendhi, A. A review on prospective production of biofuel from microalgae. Biotechnol. Rep. 2020, 27, e00509. [Google Scholar] [CrossRef] [PubMed]

- Lehtveer, M.; Brynolf, S.; Grahn, M. What Future for Electrofuels in Transport? Analysis of CostCompetitiveness in Global Climate Mitigation. Environ. Sci. Technol. 2019, 53, 1690–1697. [Google Scholar] [CrossRef] [PubMed]

- European Commission. ETS2: Buildings, Road Transport and Additional Sectors. Available online: https://climate.ec.europa.eu/eu-action/eu-emissions-trading-system-eu-ets/ets2-buildings-road-transport-and-additional-sectors_en (accessed on 30 May 2024).

- Martins, H.; Henriques, C.O.; Figueira, J.R.; Silva, C.S.; Costa, A.S. Assessing policy interventions to stimulate the transition of electric vehicle technology in the European Union. Socio-Econ. Plann Sci. 2023, 87, 101505. [Google Scholar] [CrossRef]

- Xu, L.; Yilmaz, H.U.; Wang, Z.; Poganietz, W.R.; Jochem, P. Greenhouse gas emissions of electric vehicles in Europe considering different charging strategies. Transp. Res. Part. D Transp. Environ. 2020, 87, 102534. [Google Scholar] [CrossRef]

- European Council. How Is EU Electricity Produced and Sold? Available online: https://www.consilium.europa.eu/en/infographics/how-is-eu-electricity-produced-and-sold/#:~:text=In%202022%2C%20the%20EU%20produced,followed%20by%20coal%20(15.8%25) (accessed on 30 May 2024).

- Desai, A.; Kanika; Patel, C.R. The impact of electric vehicle charging infrastructure on the energy demand of a city. Energy Rep. 2023, 9, 814–823. [Google Scholar] [CrossRef]

- Rahman, S.; Khan, I.A.; Khan, A.A.; Mallik, A.; Nadeem, M.F. Comprehensive review & impact analysis of integrating projected electric vehicle charging load to the existing low voltage distribution system. Renew. Sustain. Energy Rev. 2022, 153, 111756. [Google Scholar]

- Shi, K.; Guan, B.; Zhuang, Z.; Chen, J.; Chen, Y.; Ma, Z.; Zhu, C.; Hu, X.; Zhao, S.; Dang, H.; et al. Perspectives and Outlook of E-fuels: Production, Cost Effectiveness, and Applications. Energy Fuels 2024, 38, 7665–7692. [Google Scholar] [CrossRef]

- Sumathi, Y.; Dong, C.D.; Singhania, R.R.; Chen, C.W.; Gurunathan, B.; Patel, A.N. Advancements in Nano-Enhanced microalgae bioprocessing. Bioresour. Technol. 2024, 401, 130749. [Google Scholar] [CrossRef]

- Zhou, X.; Li, T.; Chen, R.; Wei, Y.; Wang, X.; Wang, N.; Li, S.; Kuang, M.; Yang, W. Ammonia marine engine design for enhanced efficiency and reduced greenhouse gas emissions. Nat. Commun. 2024, 15, 2110. [Google Scholar] [CrossRef] [PubMed]

| Process Technology | Description | Pros | Cons | Ref. |

|---|---|---|---|---|

| H2 Production (* indicates from fossil feedstock) | ||||

| Coal gasification * | Steam and O2 reacted with coal | Simple emissions control, low cost | Produces exhaust pollutants, use of fossil source | [31] |

| Steam reforming * | Endothermic catalytic reaction of steam and CH4 | Mature technology | Use of fossil sources, cost linked to NG price | [32] |

| Plasma reforming * | Similar to steam reforming but with use of plasma heat from electric discharge | No catalyst required, smaller reactors | High electricity requirement, less consolidated technology | [33] |

| Partial oxidation * | Exothermic non-catalytic reaction with steam and O2 | Fast reaction times, compact reactors, low cost | Use of fossil sources | [32] |

| Autothermal reforming | Combination of steam reforming and partial oxidation | Faster reaction and cheaper than steam reforming. Compact design | Use of fossil sources, still limited diffusion. Requires pure O2 or air separation unit- | [32] |

| Methane pyrolysis | Catalyzed, high-temperature CH4 cracking without oxygen | No CO2 generation, produces solid char residue, low cost | Produces tar residue which could plug the reactor. Less consolidated technology | [34] |

| Dark fermentation | Wet biomass fermented anaerobically in dark conditions | CO2 neutral, simple waste recycling technology | High cost, relatively low specific yield | [35] |

| Photofermentation | Wet biomass fermented anaerobically under light | CO2 neutral, simple waste recycling technology | High cost, relatively low specific yield | [36] |

| Biomass gasification | Dry biomass in abiotic conditions under controlled O2 and heat | CO2 neutral, simple waste recycling technology | Needs feedstock pretreatment, varying H2 yield due to feedstock, production of tar | [37] |

| Thermochemical water splitting | High temperature (800–900 °C) sequential H2O splitting | Suitable for large-scale production using sunlight or waste heat | Requires H2 distribution infrastructure due to large volumes, high cost, current viability uncertain, single-step conversion possible at T > 2500 °C | [38] |

| Photoelectrochemical water splitting | H2O splitting by irradiation-driven semiconductors in an electrolyte solution | Low-temperature and cost-effective electrode materials using unlimited solar energy | Overall high reactor costs and low solar conversion efficiency (˂3%) | [38] |

| Water electrolysis (various methods) | H2O direct splitting with electric energy input | Mature technology that can be integrated with renewable power sources | Use of corrosive electrolyte and costly proton exchange membranes (in some methods), slow startup, high costs linked to electric energy prices | [39] |

| Wastewater electrolysis | Water splitting in an organic-rich solution by Microbial Electrochemical Processes | Exploits the chemical energy of organics in solution, reducing required energy input by about 75% | Requires expensive proto-exchange membranes, experimental technology | [40] |

| Geological H2 extraction | Extraction of free H2 naturally present in geological media | Extraction with existing oil and gas drilling technology, most economical method | Geological occurrence not well understood | [41] |

| CO2 capture | ||||

| Sorption | Applicable to combustion flue gases, or syngas prior to combustion; CO2 and H2 (from syngas), N2 (from flue gases) captured by solvents, membranes, and adsorbers | Mature technology (depending on industrial sector) | Low capture efficiency with combustion gases | [42] |

| Criogenic | CO2 captured by direct phase change (gas to liquid/solid) with N2, SOx, and NOx | High CO2 capture | High CAPEX | [43] |

| Oxyfuel combustion | Sorption with pressure/temperature swings. Applicable to oxygen combustion flue gases, O2 supplied by air separation unit, CO2 and steam are recovered with solvents and membranes | High CO2 capture | High CAPEX | [44] |

| Chemical looping | Sorption with pressure/temperature swings, applicable to flue gases, O2 extracted internally from solid state carrier by redox reactions | Cost-effective alternative to oxycombustion | Less mature technology | [45] |

| Fuel cells | CO2 is recovered by selective ionic transport together with H2O and H2 | High capture efficiency, relatively cheap | Less mature technology | [46] |

| Direct Air Capture | Applicable to air without combustion, CO2 captured by membrane separation and/or sorption | Applicable anywhere without the need for point-source emissions | High CAPEX | [47] |

| Component Gas | Content (v/v) |

|---|---|

| Methane | 40–75% |

| Carbon dioxide | 15–60% |

| Hydrogen | Traces |

| Nitrogen | 0–5% |

| Moisture | 1–5% |

| Hydrogen sulfide | 0–5000 [ppm] |

| Ammonia | 0–500 [ppm] |

| Type of Feedstock | Crop | Oil Content % |

|---|---|---|

| Edible | Soybean | 15–20 |

| Rapeseed | 38–46 | |

| Sunflower | 25–35 | |

| Peanut oil | 45–55 | |

| Coconut | 63–65 | |

| Palm | 30–60 | |

| Nonedible | Jatropha seed | 35–40 |

| Pongamia Pinnata | 27–39 | |

| Neem oil | 20–30 | |

| Castor | 53 | |

| Other sources | Rubber seed | 40–50 |

| Sea mango | 54 | |

| Cotton seed | 18–25 | |

| Microalgae | 30–70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Capodaglio, A.G. Developments and Issues in Renewable Ecofuels and Feedstocks. Energies 2024, 17, 3560. https://doi.org/10.3390/en17143560

Capodaglio AG. Developments and Issues in Renewable Ecofuels and Feedstocks. Energies. 2024; 17(14):3560. https://doi.org/10.3390/en17143560

Chicago/Turabian StyleCapodaglio, Andrea G. 2024. "Developments and Issues in Renewable Ecofuels and Feedstocks" Energies 17, no. 14: 3560. https://doi.org/10.3390/en17143560

APA StyleCapodaglio, A. G. (2024). Developments and Issues in Renewable Ecofuels and Feedstocks. Energies, 17(14), 3560. https://doi.org/10.3390/en17143560