Infill Well Location Optimization Method Based on Recoverable Potential Evaluation of Remaining Oil

Abstract

1. Introduction

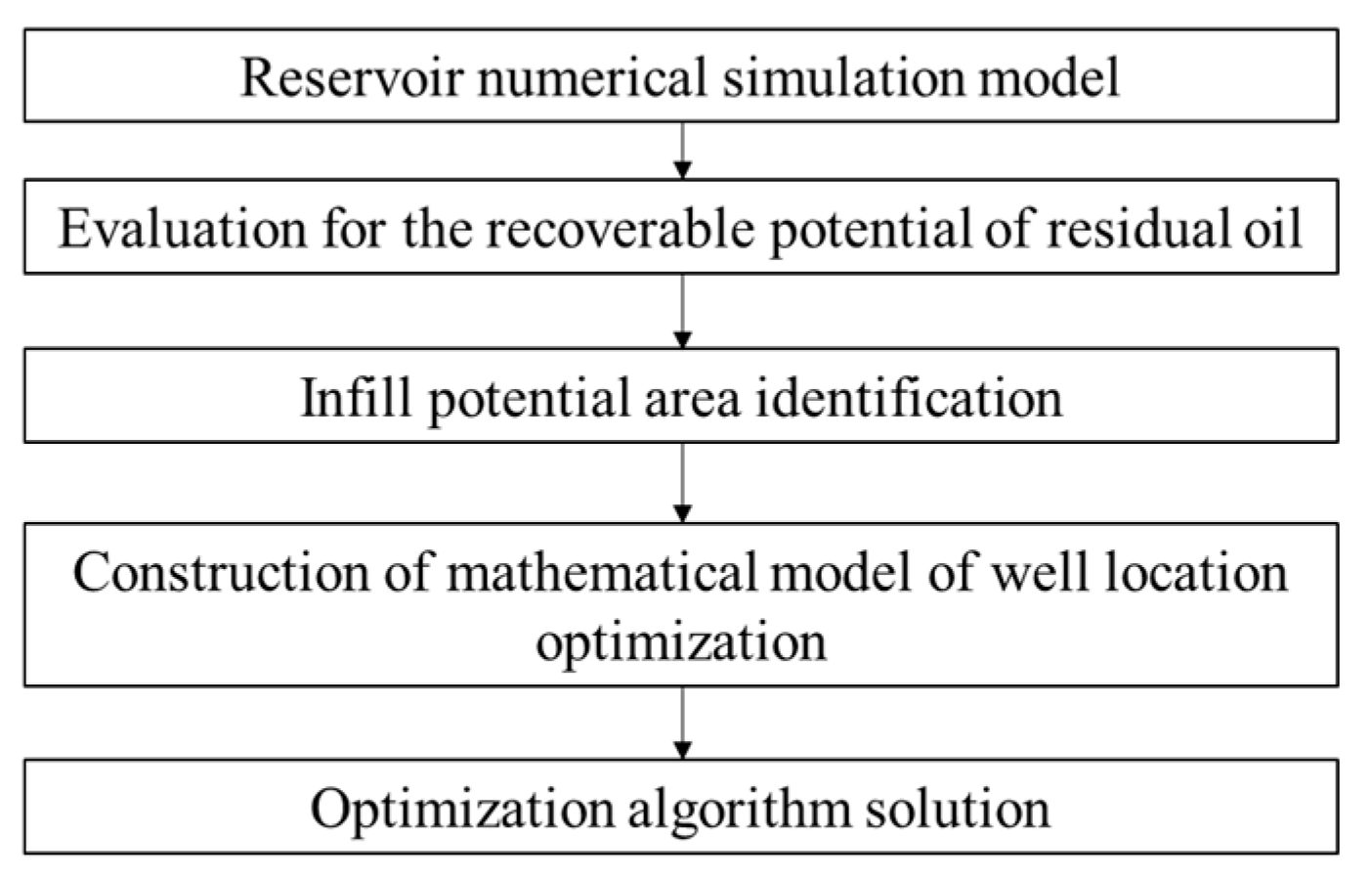

2. Establishment of Remaining Oil Recoverable Potential Evaluation Method

2.1. Evaluation Index Construction

2.2. Establishment of Evaluation Model

3. Construction of Infill Well Location Optimization Method

3.1. Construction of Mathematical Optimization Model

3.1.1. Optimization Variables

3.1.2. Objective Function

3.1.3. Constraint Conditions

- Feasible infill range constraints:

- Minimum well-spacing constraint:

- Well length constraint:

- Orientation angle range constraint:

3.2. Solution of Mathematical Optimization Model

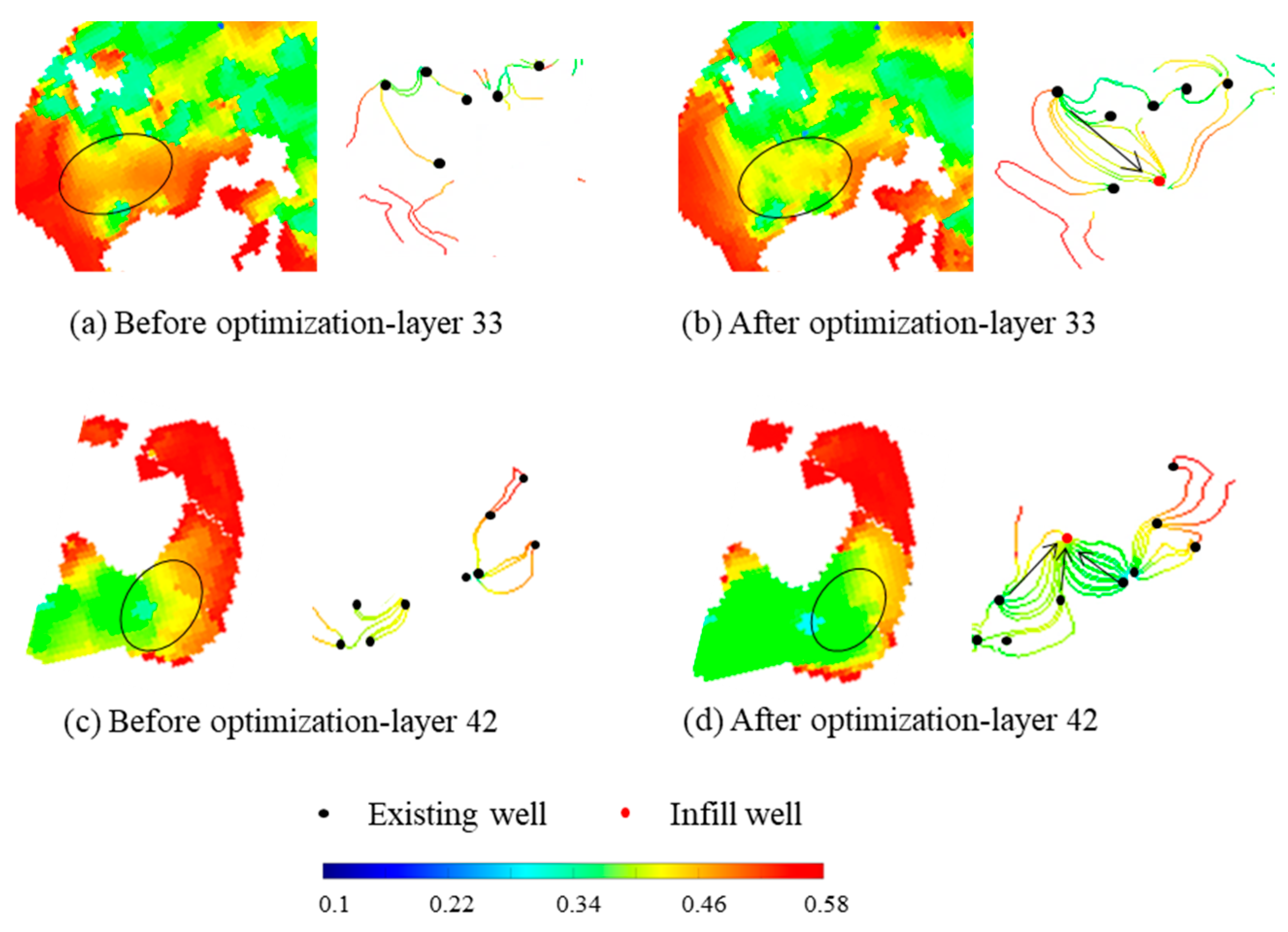

4. Field Application

4.1. Reservoir Model Description

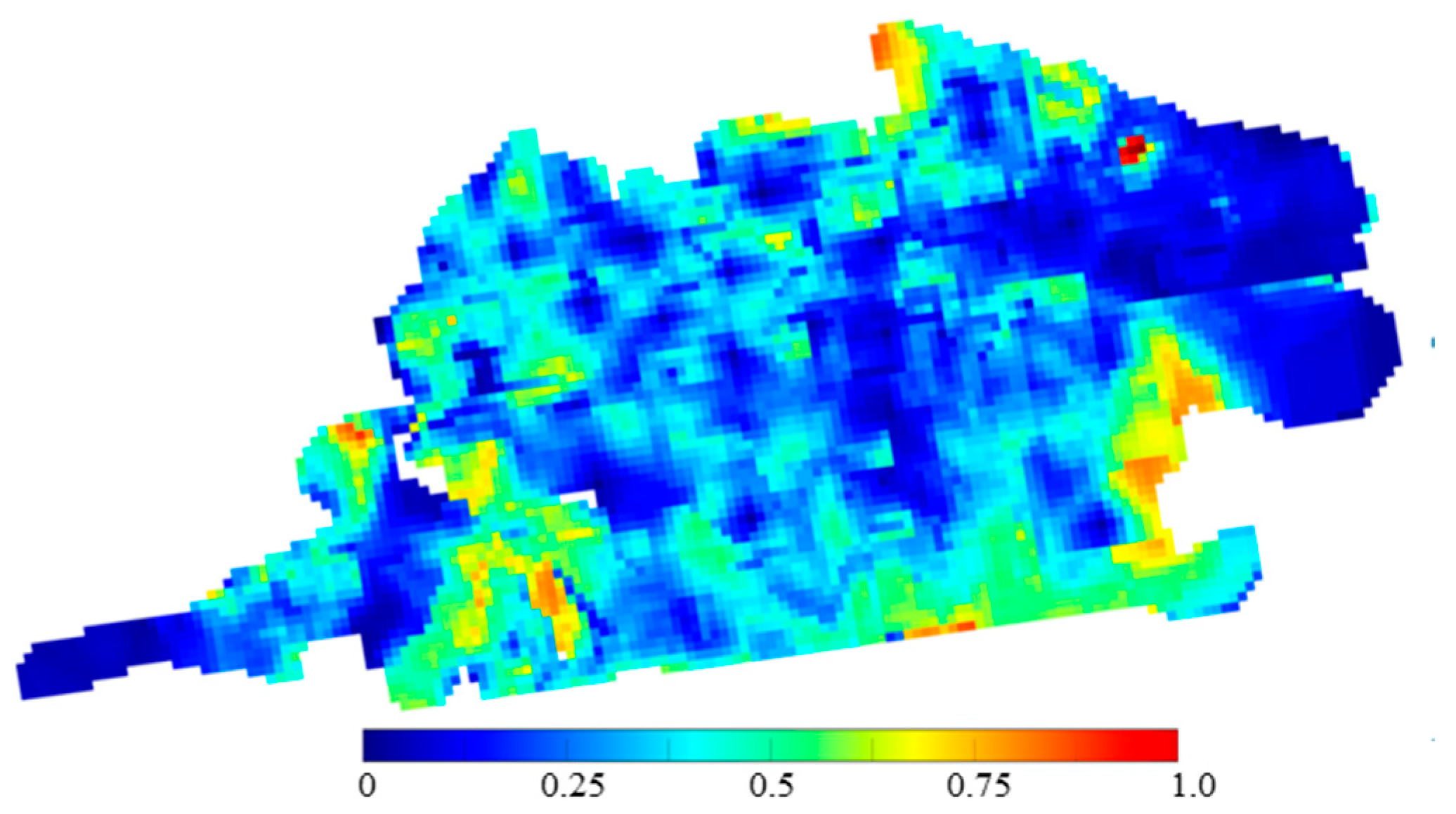

4.2. Determination of Encryption Potential Area

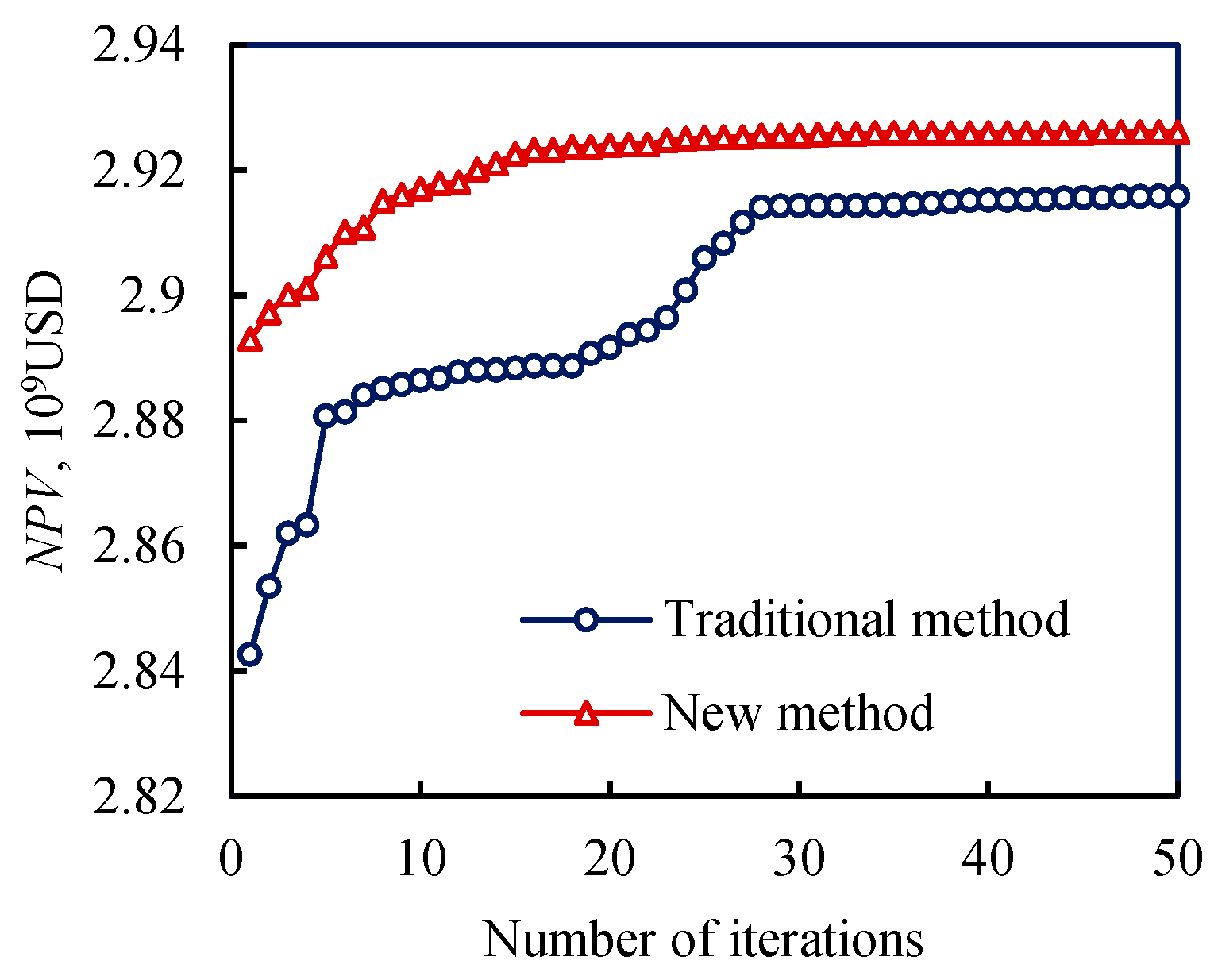

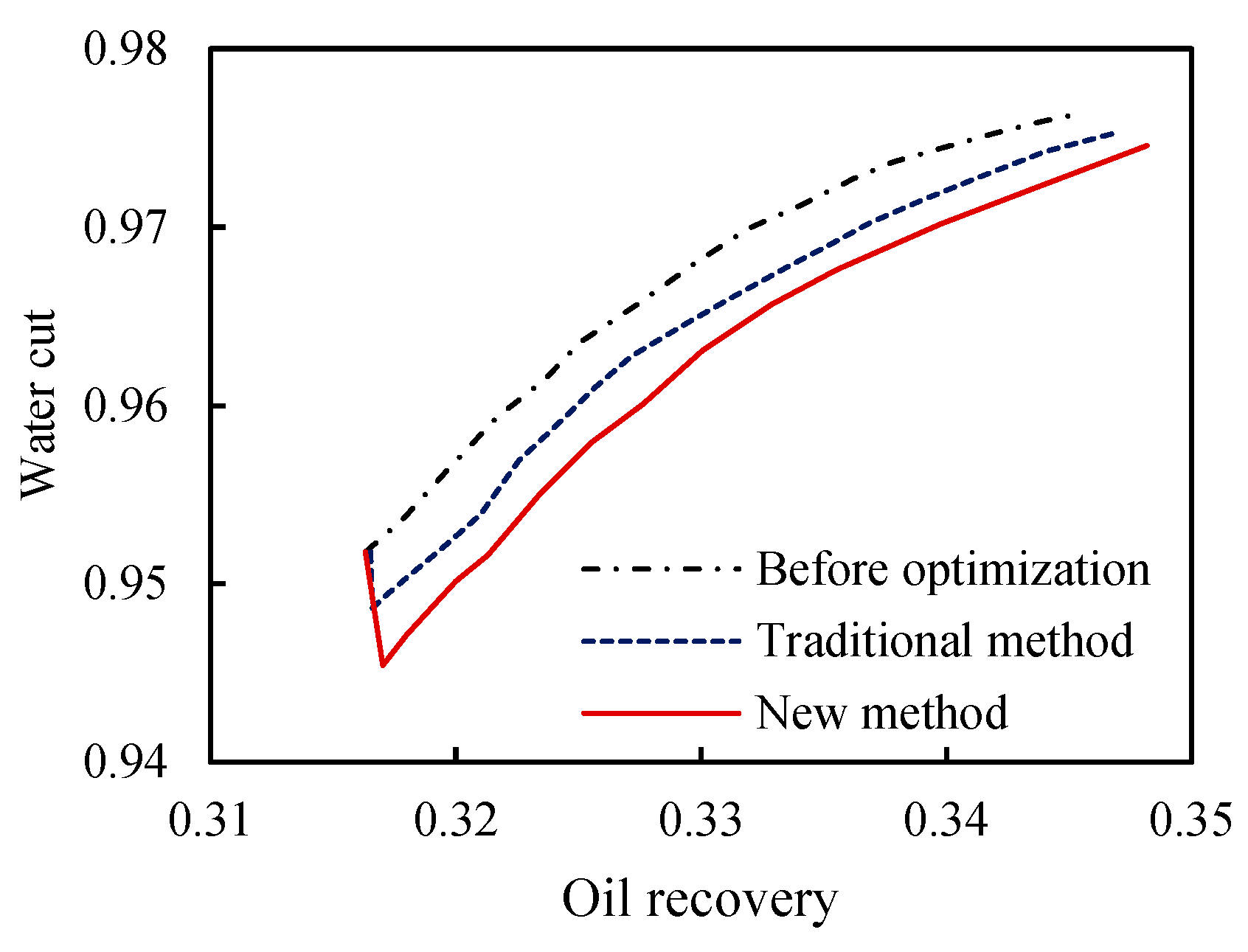

4.3. Infill Well Location Optimization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, J.; Yang, E.; Zhao, Y.; Fu, H.; Dong, C.; Du, Q.; Zheng, X.; Wang, Z.; Yang, B.; Zhu, J. A New Method for Optimizing Water-Flooding Strategies in Multi-Layer Sandstone Reservoirs. Energies 2024, 17, 1828. [Google Scholar] [CrossRef]

- Ng, C.S.W.; Ghahfarokhi, A.J.; Wiranda, W. Fast Well Control Optimization with Two-Stage Proxy Modeling. Energies 2023, 16, 3269. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Q.; Zhang, X.; Wang, S.; Ma, Z.; Zhou, W.; Liu, C. A meta-optimized hybrid global and local algorithm for well placement optimization. Comput. Chem. Eng. 2018, 117, 209–220. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Q.; Zhang, X.; Wang, S.; Zhou, W.; Liu, C. Well placement optimization for offshore oilfield based on Theil index and differential evolution algorithm. J. Pet. Explor. Prod. Technol. 2017, 8, 1225–1233. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Q.; Zhang, X.; Wang, S.; Zhou, W.; Liu, F. Well Placement Optimization With Cat Swarm Optimization Algorithm Under Oilfield Development Constraints. J. Energy Resour. Technol. 2018, 141, 012902. [Google Scholar] [CrossRef]

- Sharifipour, M.; Nakhaee, A.; Yousefzadeh, R.; Gohari, M. Well placement optimization using shuffled frog leaping algorithm. Comput. Geosci. 2021, 25, 1939–1956. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.; Xiao, C.; Zhang, S. Hierarchical Surrogate-Assisted Evolutionary Algorithm for Integrated Multi-Objective Optimization of Well Placement and Hydraulic Fracture Parameters in Unconventional Shale Gas Reservoir. Energies 2022, 16, 303. [Google Scholar] [CrossRef]

- Tavallali, M.; Karimi, I.; Teo, K.; Baxendale, D.; Ayatollahi, S. Optimal producer well placement and production planning in an oil reservoir. Comput. Chem. Eng. 2013, 55, 109–125. [Google Scholar] [CrossRef]

- Tavallali, M.S.; Karimi, I.A. Integrated oil-field management: From well placement and planning to production scheduling. Ind. Eng. Chem. Res. 2016, 55, 978–994. [Google Scholar] [CrossRef]

- Park, H.-Y.; Yang, C.; Al-Aruri, A.D.; Fjerstad, P.A. Improved decision making with new efficient workflows for well placement opti-mization. J. Pet. Sci. Eng. 2017, 152, 81–90. [Google Scholar] [CrossRef]

- Al Dossary, M.A.; Nasrabadi, H. Well Placement optimization using imperialist competition algorithm. J. Pet. Sci. Eng. 2016, 147, 237–248. [Google Scholar] [CrossRef]

- Yousefzadeh, R.; Sharifi, M.; Rafiei, Y. An efficient method for injection well location optimization using fast marching method. J. Pet. Sci. Eng. 2021, 204, 108620. [Google Scholar] [CrossRef]

- Wang, X.; Haynes, R.D.; He, Y.; Feng, Q. Well control optimization using derivative-free algorithms and a multiscale approach. Comput. Chem. Eng. 2018, 123, 12–33. [Google Scholar] [CrossRef]

- Wang, X.; Haynes, R.D.; Feng, Q. A multilevel coordinate search algorithm for well placement, control and joint optimization. Comput. Chem. Eng. 2016, 95, 75–96. [Google Scholar] [CrossRef]

- Akın, S.; Kok, M.V.; Uraz, I. Optimization of well placement geothermal reservoirs using artificial intelligence. Comput. Geosci. 2010, 36, 776–785. [Google Scholar] [CrossRef]

- Ding, S.; Jiang, H.; Li, J.; Liu, G.; Mi, L. Optimization of well location, type and trajectory by a modified particle swarm optimization algorithm for the PUNQ-S3 model. J. Ind. Intell. Inf. 2016, 4, 27–33. [Google Scholar] [CrossRef][Green Version]

- Hamida, Z.; Azizi, F.; Saad, G. An efficient geometry-based optimization approach for well placement in oil fields. J. Pet. Sci. Eng. 2017, 149, 383–392. [Google Scholar] [CrossRef]

- Badru, O.; Kabir, C. Well placement optimization in field development. In In Proceedings of the SPE Annual Technical Conference and Exhibition? Denver, CO, USA, 5–8 October 2003; SPE-84191-MS. SPE: Richardson, TX, USA, 2003. [Google Scholar] [CrossRef]

- Onwunalu, J.E.; Durlofsky, L.J. A new well-pattern-optimization procedure for large-scale field development. SPE J. 2011, 16, 594–607. [Google Scholar] [CrossRef]

- Nasrabadi, H.; Morales, A.; Zhu, D. Well placement optimization: A survey with special focus on application for gas/gas-condensate reservoirs. J. Nat. Gas Sci. Eng. 2012, 5, 6–16. [Google Scholar] [CrossRef]

- Cheng, Y.; McVay, D.A.; Lee, W.J. A practical approach for optimization of infill well placement in tight gas reservoirs. J. Nat. Gas Sci. Eng. 2009, 1, 165–176. [Google Scholar] [CrossRef]

- Awotunde, A.A.; Naranjo, C. Well placement optimization constrained to minimum well spacing. In In Proceedings of the SPE SPE Latin America and Caribbean Petroleum Engineering Conference, Maracaibo, Venezuela, 21–23 May 2014; SPE-169272-MS. SPE: Richardson, TX, USA, 2014. [Google Scholar] [CrossRef]

- Bellout, M.C.; Ciaurri, D.E.; Durlofsky, L.J.; Foss, B.; Kleppe, J. Joint optimization of oil well placement and controls. Comput. Geosci. 2012, 16, 1061–1079. [Google Scholar] [CrossRef]

- Rodrigues, H.; Prata, B.; Bonates, T. Integrated optimization model for location and sizing of offshore platforms and location of oil wells. J. Pet. Sci. Eng. 2016, 145, 734–741. [Google Scholar] [CrossRef]

- Udy, J.; Hansen, B.; Maddux, S.; Petersen, D.; Heilner, S.; Stevens, K.; Lignell, D.; Hedengren, J.D. Review of field development optimization of waterflooding, EOR, and well placement focusing on history matching and optimization algorithms. Processes 2017, 5, 34. [Google Scholar] [CrossRef]

- Islam, J.; Vasant, P.M.; Negash, B.M.; Laruccia, M.B.; Myint, M.; Watada, J. A holistic review on artificial intelligence techniques for well placement optimization problem. Adv. Eng. Softw. 2020, 141, 102767. [Google Scholar] [CrossRef]

- Malozyomov, B.V.; Martyushev, N.V.; Kukartsev, V.V.; Tynchenko, V.S.; Bukhtoyarov, V.V.; Wu, X.; Tyncheko, Y.A.; Kukartsev, V.A. Overview of Methods for Enhanced Oil Recovery from Conventional and Unconventional Reservoirs. Energies 2023, 16, 4907. [Google Scholar] [CrossRef]

- Da Cruz, P.S.; Horne, R.N.; Deutsch, C.V. The quality map: A tool for reservoir uncertainty quantification and decision making. SPE Reserv. Eval. Eng. 2004, 7, 6–14. [Google Scholar] [CrossRef]

- Ding, S.; Lu, R.; Xi, Y.; Yue, J.; Liu, G.; Reynolds, A.C.; Yu, H. Optimizing vertical and deviated wells based on advanced initialization using new productivity potential map. J. Pet. Sci. Eng. 2020, 198, 108263. [Google Scholar] [CrossRef]

- Liu, N.; Jalali, Y. Closing the loop between reservoir modeling and well placement and positioning. In In Proceedings of the SPE SPE Intelligent Energy International Conference and Exhibition, Amsterdam, The Netherlands, 11–13 April 2006; SPE-98198-MS. SPE: Richardson, TX, USA, 2006. [Google Scholar] [CrossRef]

- Ding, S.; Jiang, H.; Li, J.; Tang, G. Optimization of well placement by combination of a modified particle swarm optimization algorithm and quality map method. Comput. Geosci. 2014, 18, 747–762. [Google Scholar] [CrossRef]

- Molina, A.R.; Rincon, A.A. Exploitation plan design based on opportunity index analysis in numerical simulation models. In In Proceedings of the SPE SPE Latin America and Caribbean Petroleum Engineering Conference, Cartagena de Indias, Colombia , 31 May–30 June 2009; SPE-122915-MS. SPE: Richardson, TX, USA. [Google Scholar] [CrossRef]

- Karim, M.G.A.; Raub, M.R.B.A. Optimizing development strategy and maximizing field economic recovery through simulation opportunity index. In In Proceedings of the SPE SPE Reservoir Characterisation and Simulation Conference and Exhibition? Abu Dhabi, UAE, 9–11 October 2011 ; SPE-148103-MS. SPE: Richardson, TX, USA. [Google Scholar] [CrossRef]

- Varela-Pineda, A.; Hutheli, A.H.; Mutairi, S.M. Development of mature fields using reservoir opportunity index: A case study from a Saudi field. In In Proceedings of the SPE SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 21–24 April 2014; SPE-172231-MS. SPE: Richardson, TX, USA. [Google Scholar] [CrossRef]

- Ataei, A.; Soni, S.; Chuah, B.; Huey, H.Y. Reservoir opportunity index—Advance in well and subsurface design for cost effective field development. In In Proceedings of the SPE SPE Asia Pacific Oil and Gas Conference and Exhibition, Adelaide, Australia, 14–16 October 2014; SPE-171460-MS. SPE: Richardson, TX, USA. [Google Scholar] [CrossRef]

- Geng, Z.; Jiang, H.; Chen, M.; Sun, M.; Zeng, Y. A new method for quantitative characterization on remaining oil potential in high water cut oil reservoirs. Pet. Geol. Recovery Effic. 2007, 6, 100–102. [Google Scholar]

- Ding, S.; Jiang, H.; Zhou, D.; Zhao, Y.; Kuang, X.; Wang, Q.; Wang, P. A new method for quantitatively evaluating the remaining oil potential of reservoir at medium-high water-cut stage and its application. Complex Hydrocarb. Reserv. 2016, 9, 41–45. [Google Scholar]

- Yu, S.; Lu, H. An integrated model of water resources optimization allocation based on projection pursuit model—Grey wolf optimization method in a transboundary river basin. J. Hydrol. 2018, 559, 156–165. [Google Scholar] [CrossRef]

- Sawyerr, B.; Adewumi, A.; Ali, M. Real-coded genetic algorithm with uniform random local search. Appl. Math. Comput. 2013, 228, 589–597. [Google Scholar] [CrossRef]

- Yu, X.; Li, X.; Wu, S. Dynamic evaluation of water resources sustainability in the Pearl River Delta based on the combined weight-cloud model. J. Water Resour. Water Eng. 2023, 34, 75–83. [Google Scholar]

- Isebor, O.J.; Durlofsky, L.J.; Ciaurri, D.E. A derivative-free methodology with local and global search for the constrained joint optimization of well locations and controls. Comput. Geosci. 2013, 18, 463–482. [Google Scholar] [CrossRef]

- Humphries, T.D.; Haynes, R.D.; James, L.A. Simultaneous and sequential approaches to joint optimization of well placement and control. Comput. Geosci. 2013, 18, 433–448. [Google Scholar] [CrossRef]

- Audet, C.; Dzahini, K.J.; Kokkolaras, M.; Le Digabel, S. Stochastic mesh adaptive direct search for blackbox optimization using prob-abilistic estimates. Comput. Optim. Appl. 2021, 79, 1–34. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Oil price Co, USD/m3 | 400 |

| Water production cost Cw, USD/m3 | 20 |

| Water injection cost CI, USD/m3 | 40 |

| Cost of drilling well Cd, USD/m | 100,000 |

| Annual discount rate b | 0.1 |

| Infill Well Name | Heel | Well Length/m | Azimuth Angle/° | Inclined Angle/° |

|---|---|---|---|---|

| IN1 | (7, 88, 1) | 195 | 244 | 36 |

| IN2 | (28, 74, 1) | 220 | 108 | 46 |

| IN3 | (32, 73, 1) | 153 | 0 | 0 |

| IN4 | (19, 31, 1) | 154 | 0 | 0 |

| IN5 | (20, 41, 1) | 197 | −60 | 37 |

| IN6 | (27, 35, 1) | 192 | −116 | 36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Feng, Q.; Zhou, W.; Li, S.; Zhang, X. Infill Well Location Optimization Method Based on Recoverable Potential Evaluation of Remaining Oil. Energies 2024, 17, 3492. https://doi.org/10.3390/en17143492

Liu C, Feng Q, Zhou W, Li S, Zhang X. Infill Well Location Optimization Method Based on Recoverable Potential Evaluation of Remaining Oil. Energies. 2024; 17(14):3492. https://doi.org/10.3390/en17143492

Chicago/Turabian StyleLiu, Chen, Qihong Feng, Wensheng Zhou, Shanshan Li, and Xianmin Zhang. 2024. "Infill Well Location Optimization Method Based on Recoverable Potential Evaluation of Remaining Oil" Energies 17, no. 14: 3492. https://doi.org/10.3390/en17143492

APA StyleLiu, C., Feng, Q., Zhou, W., Li, S., & Zhang, X. (2024). Infill Well Location Optimization Method Based on Recoverable Potential Evaluation of Remaining Oil. Energies, 17(14), 3492. https://doi.org/10.3390/en17143492