Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard

Abstract

1. Introduction

2. State of the Art

2.1. Literature Review

2.2. ISO 15118 V2G Messages

2.3. RISE V2G Open-Source Library

3. Charging Emulation System

3.1. Characterization

3.2. Architecture

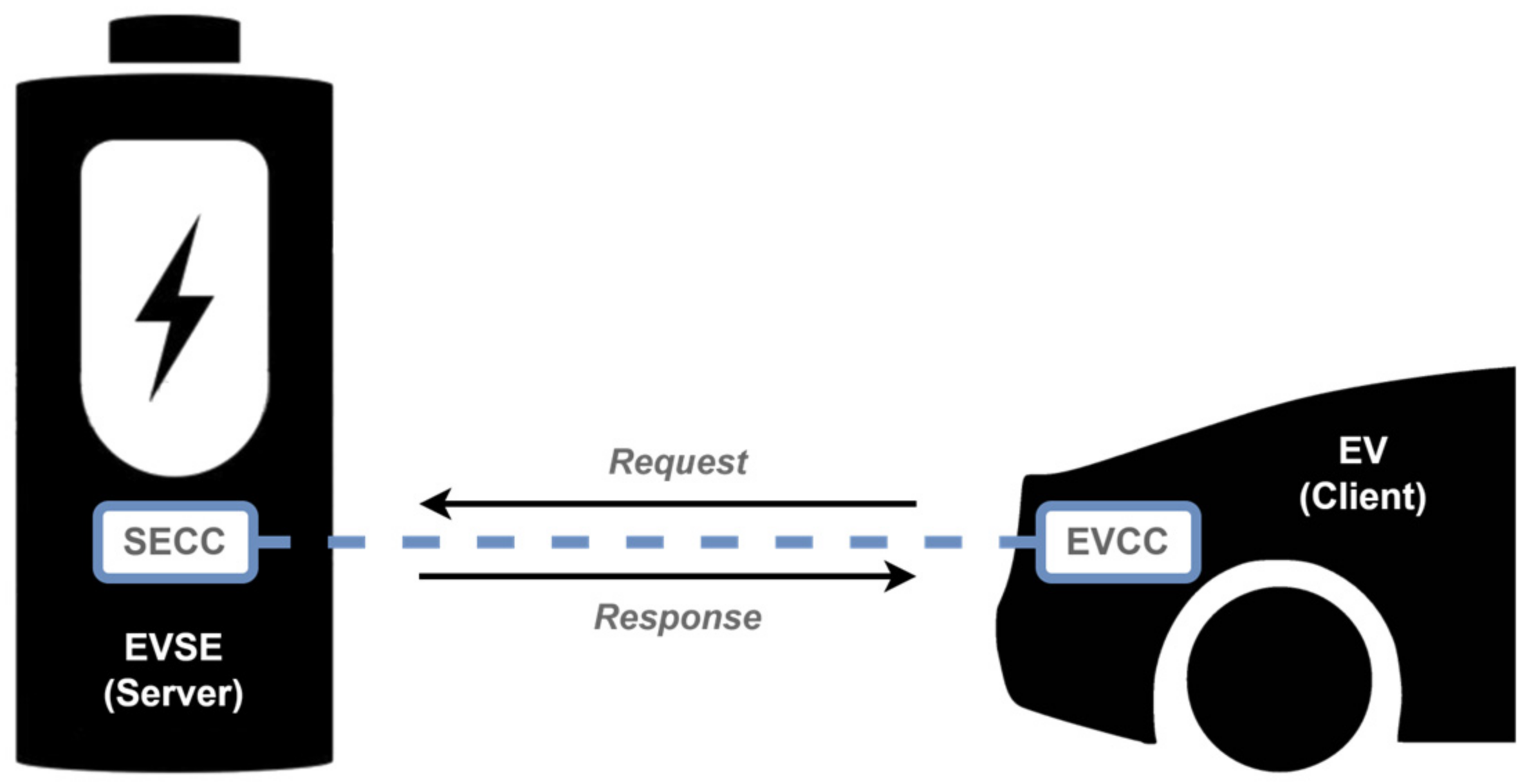

3.2.1. Communication Controllers

3.2.2. Parameter Files

3.2.3. Management Codes

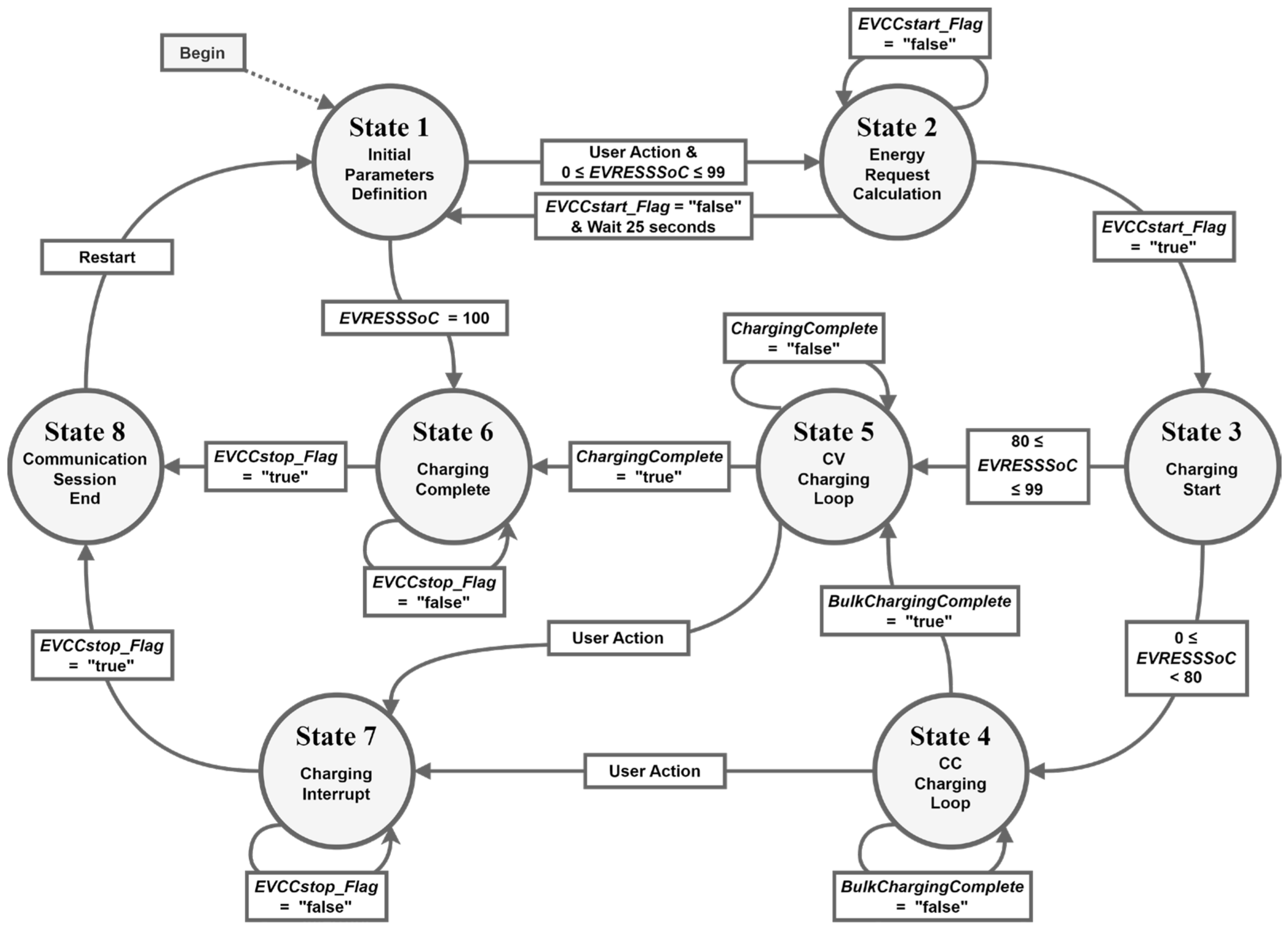

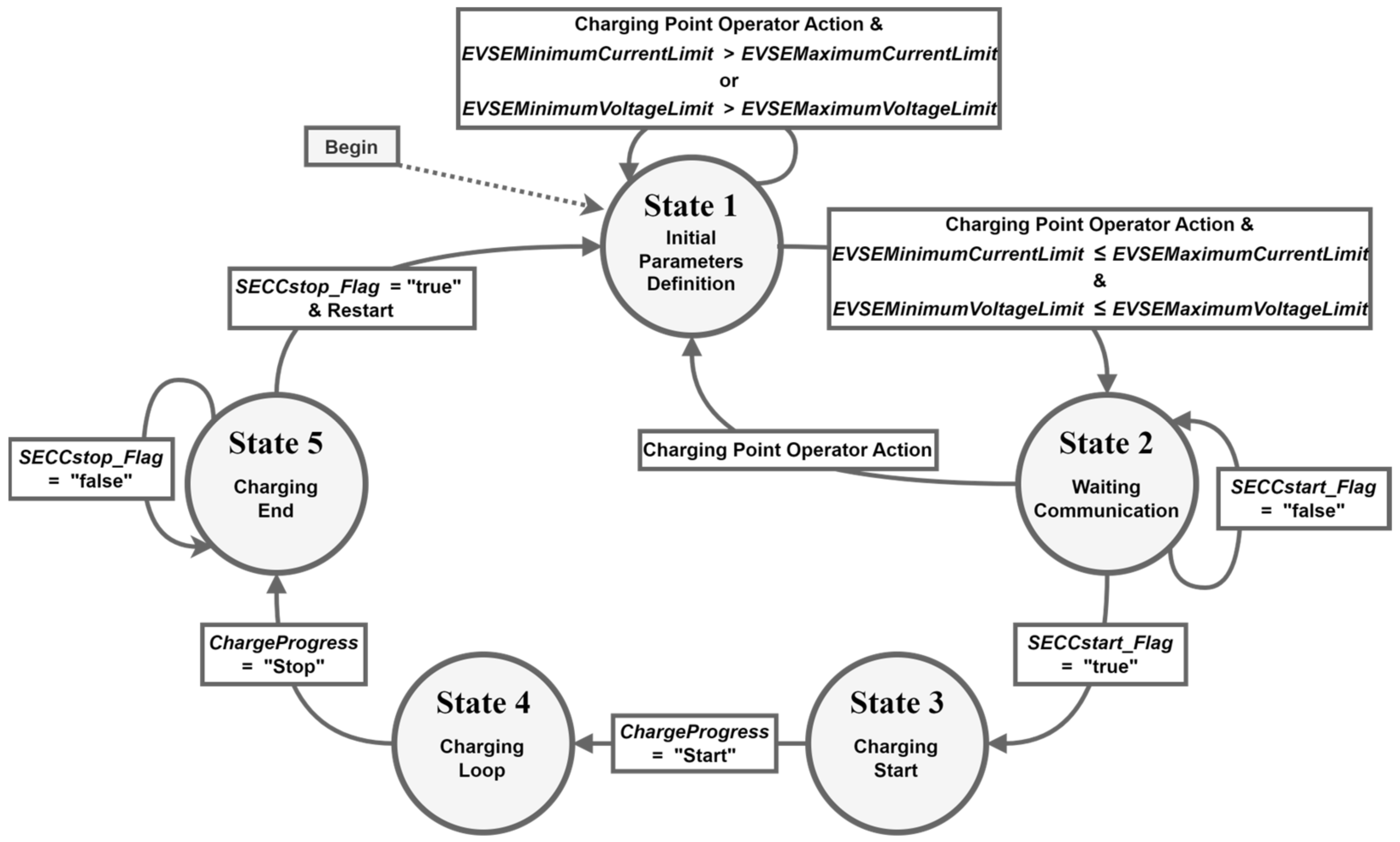

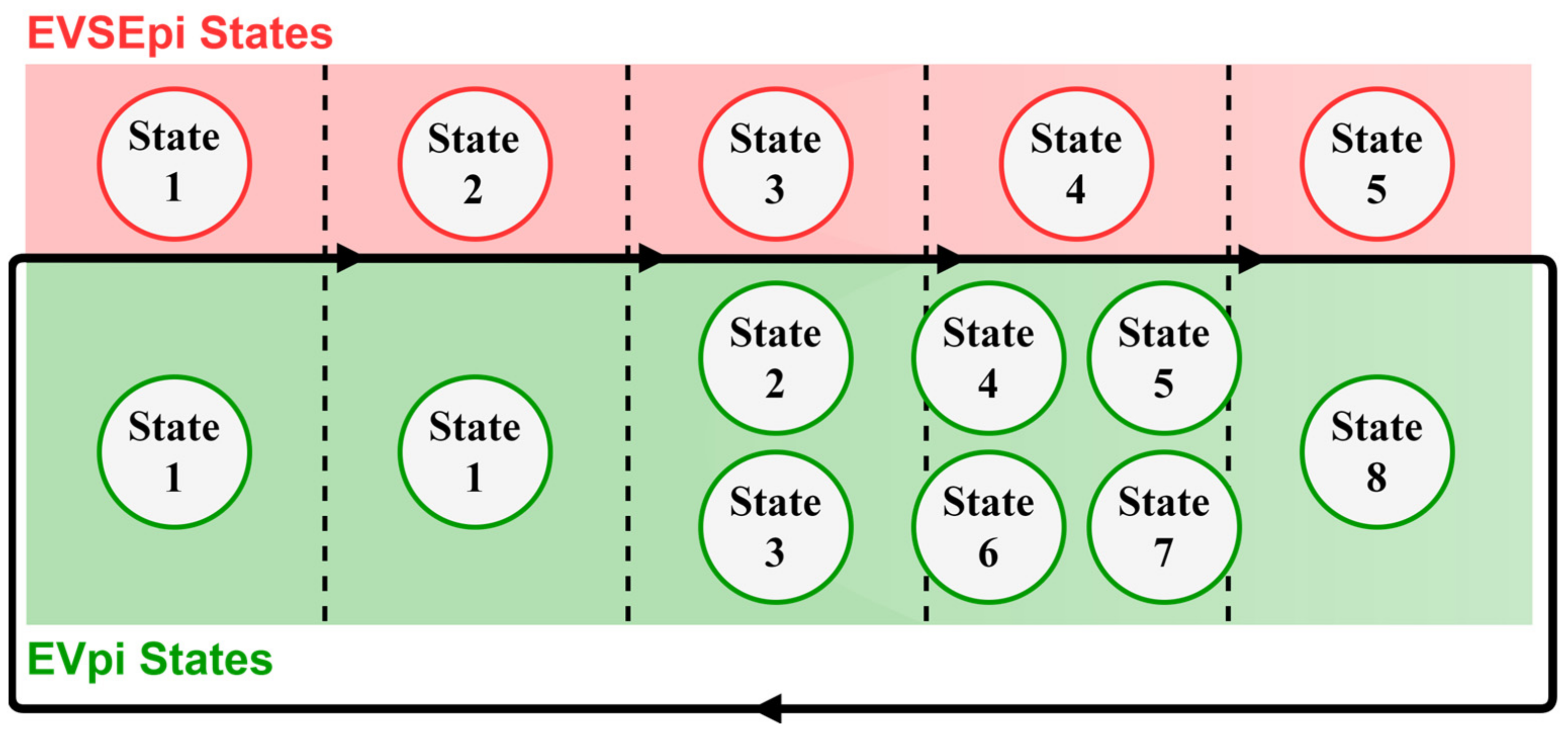

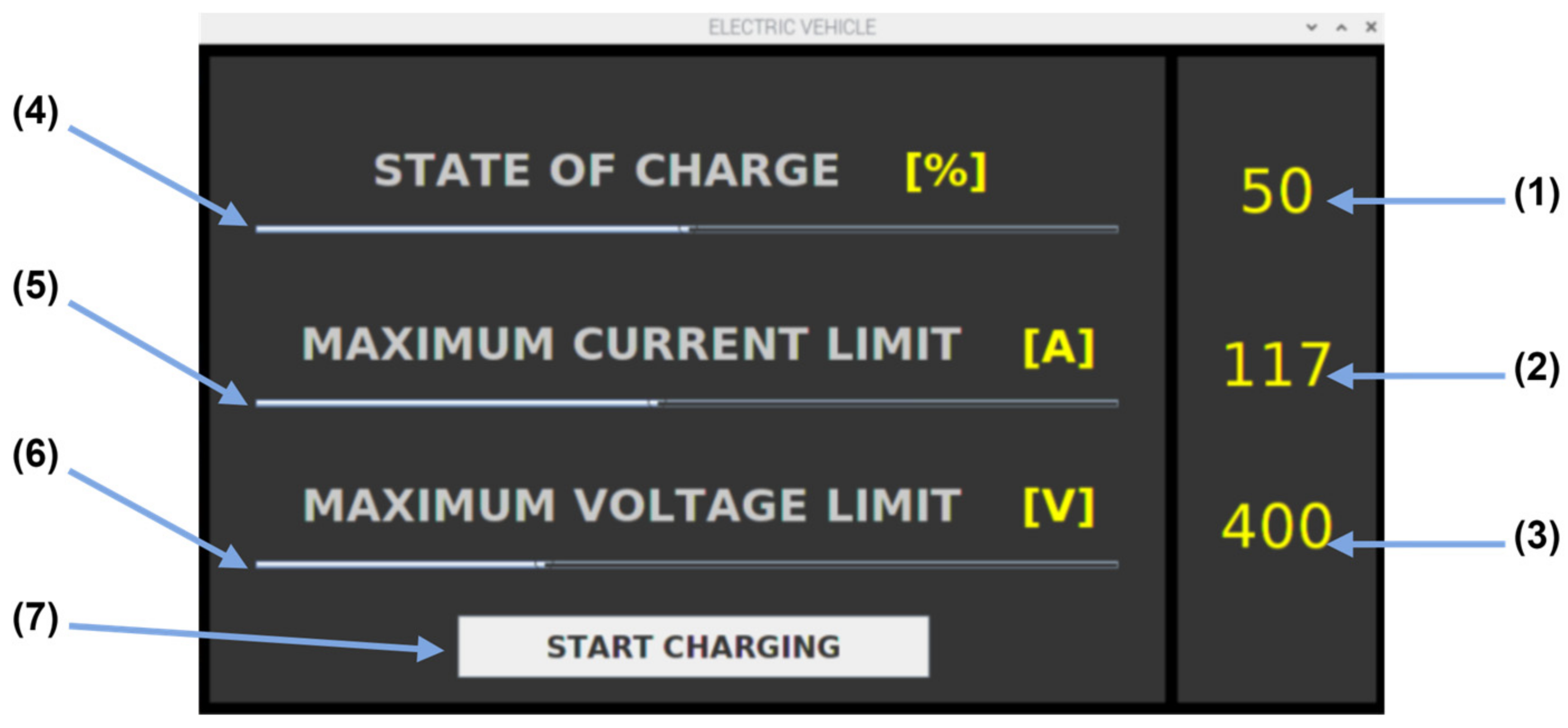

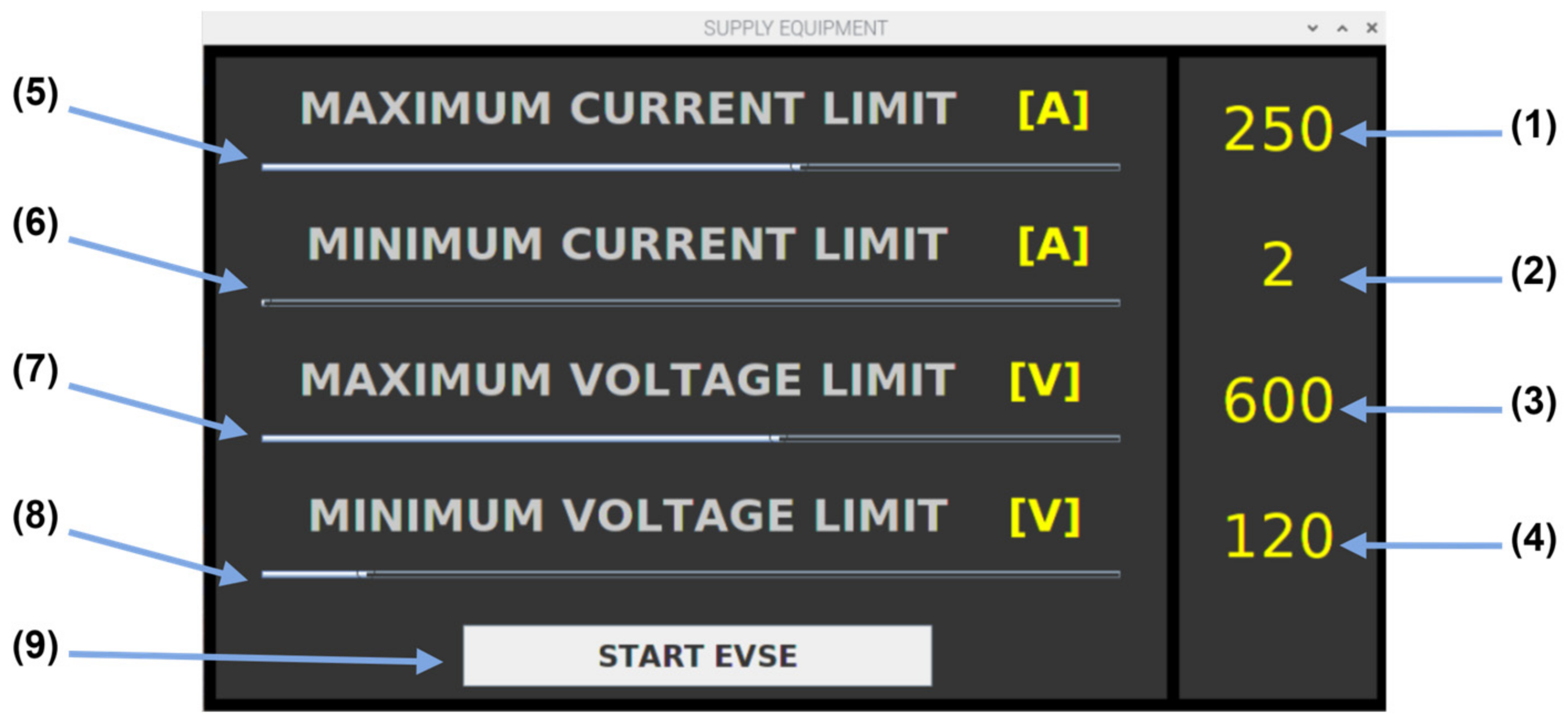

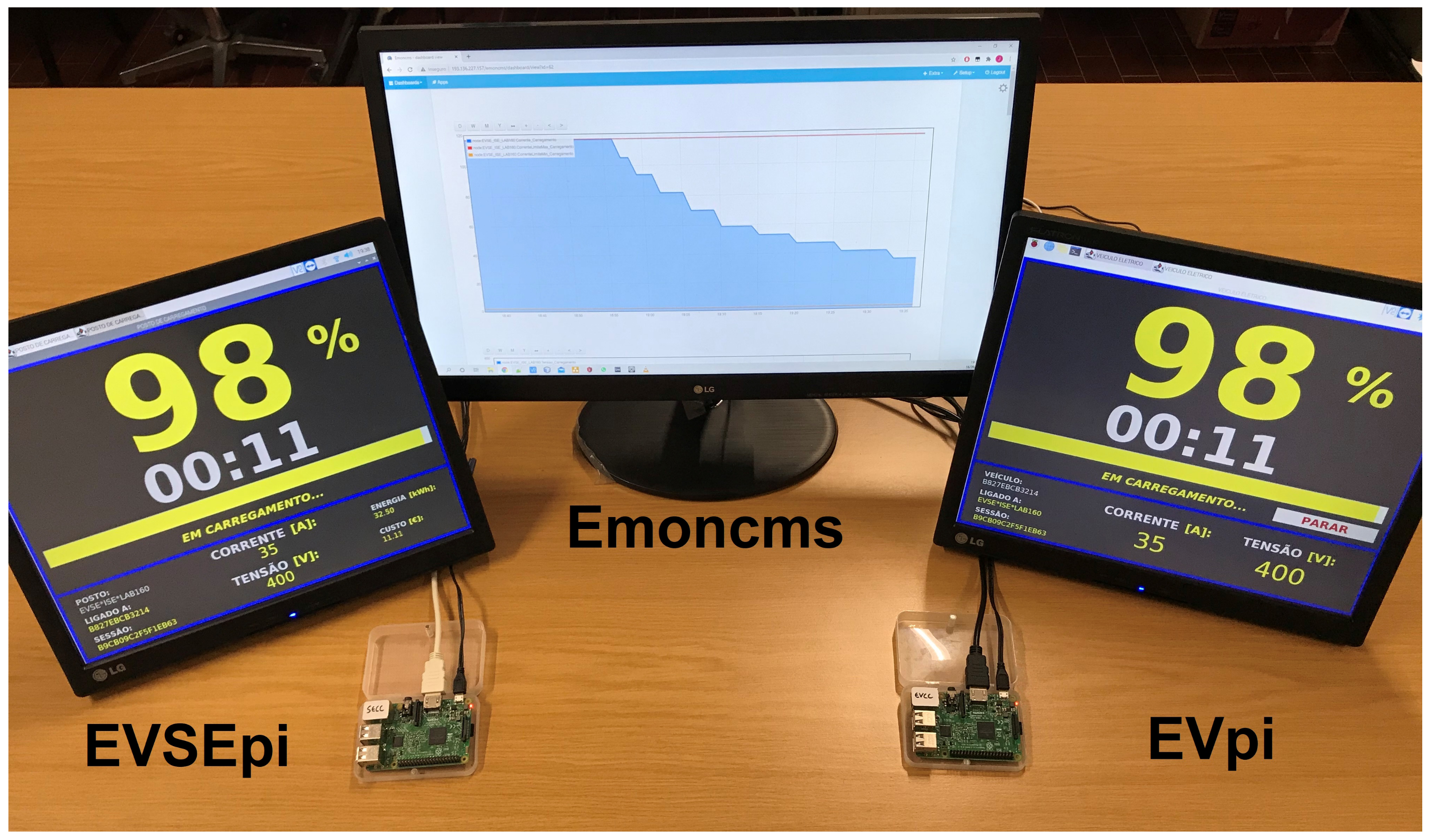

3.2.4. Human–Machine Interfaces

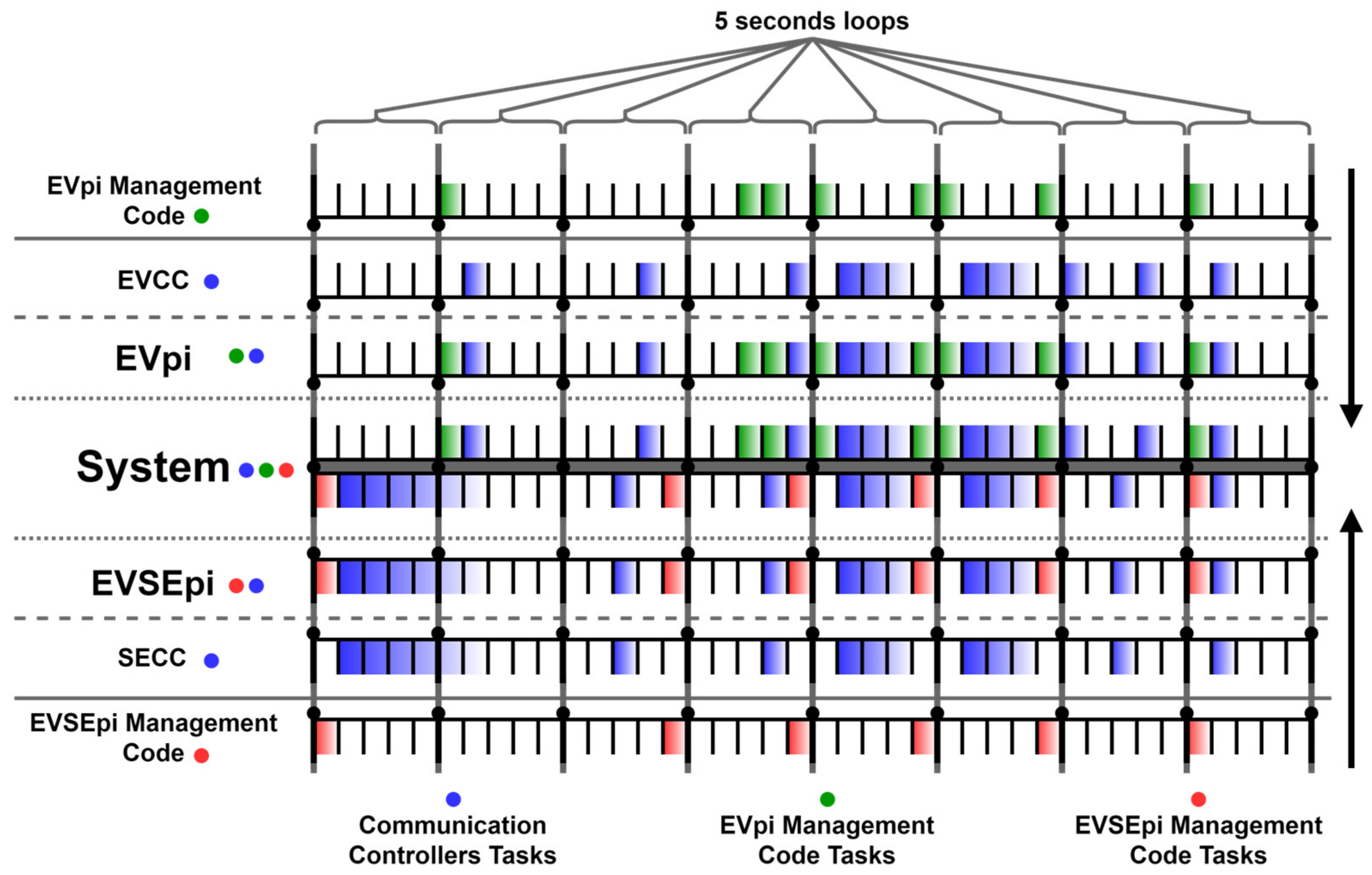

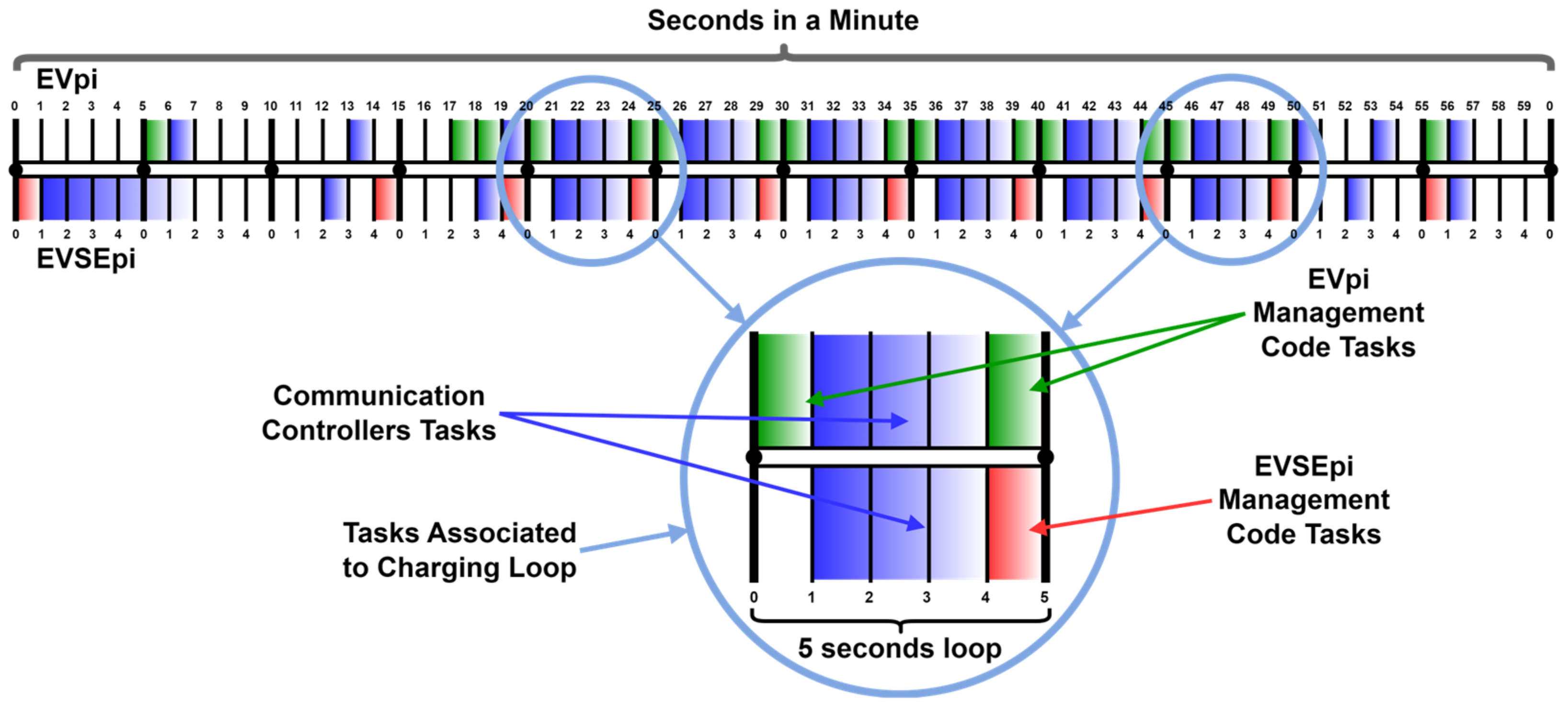

3.3. Task-Scheduling Algorithm

3.4. Parameter Exchange during the Charging Process

- The EVpi management code generates the updated values of vehicle parameters and sends them to the register list of the parameters file;

- The EVCC, when preparing to send the request message (CurrentDemandReq), sends the updated values to the register list of the vehicle parameters file;

- The EVCC sends the CurrentDemandReq to the SECC, containing in its body the vehicle’s parameters;

- The SECC, upon receiving the CurrentDemandReq, sends the vehicle parameters to the register list of the supply equipment parameters file;

- The EVSEpi management code obtains the values of the parameters from the vehicle via the parameters file of the supply equipment. These parameters are used with the EVSE for the processing of the charging level, tariff calculation, and data monitoring via the CPO. It also allows applies scheduling algorithms (not used in this system);

- The EVSEpi management code, after receiving the vehicle’s parameters and processing them, makes this information available to its HMI;

- According to the available power, the EVSEpi management code generates the updated values of the parameters at the supply’s equipment and sends them to the register list of its parameter file;

- After receiving the request message (CurrentDemandReq) from the EVCC, the SECC creates the response message (CurrentDemandRes). It uses the updated values of the EVSE parameters through the list of registers in its parameter file;

- The SECC sends the response message (CurrentDemandRes) to the EVCC, containing in its body the EVSE parameters;

- The EVCC, upon receiving the CurrentDemandRes, sends the EVSE parameters to the register list of the parameters file on the EV side;

- The EVpi management code obtains the values of the EVSE parameters via the EV parameter file. These parameters are used via the vehicle for charge processing;

- The EVpi management code, after receiving the parameters from the EVSE and processing them, makes the resulting information available to its HMI.

4. Resulting System and Demand Response Evaluation

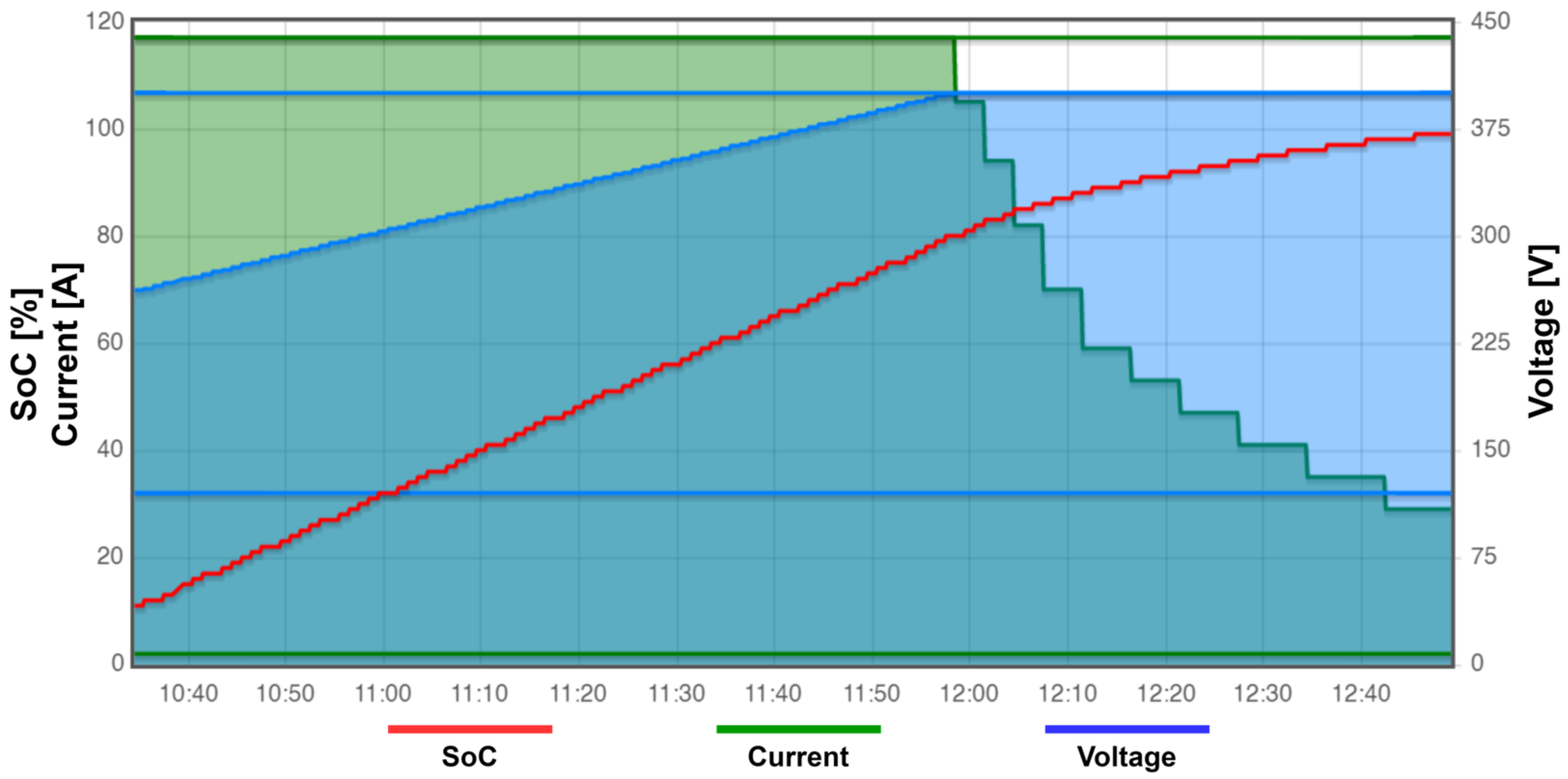

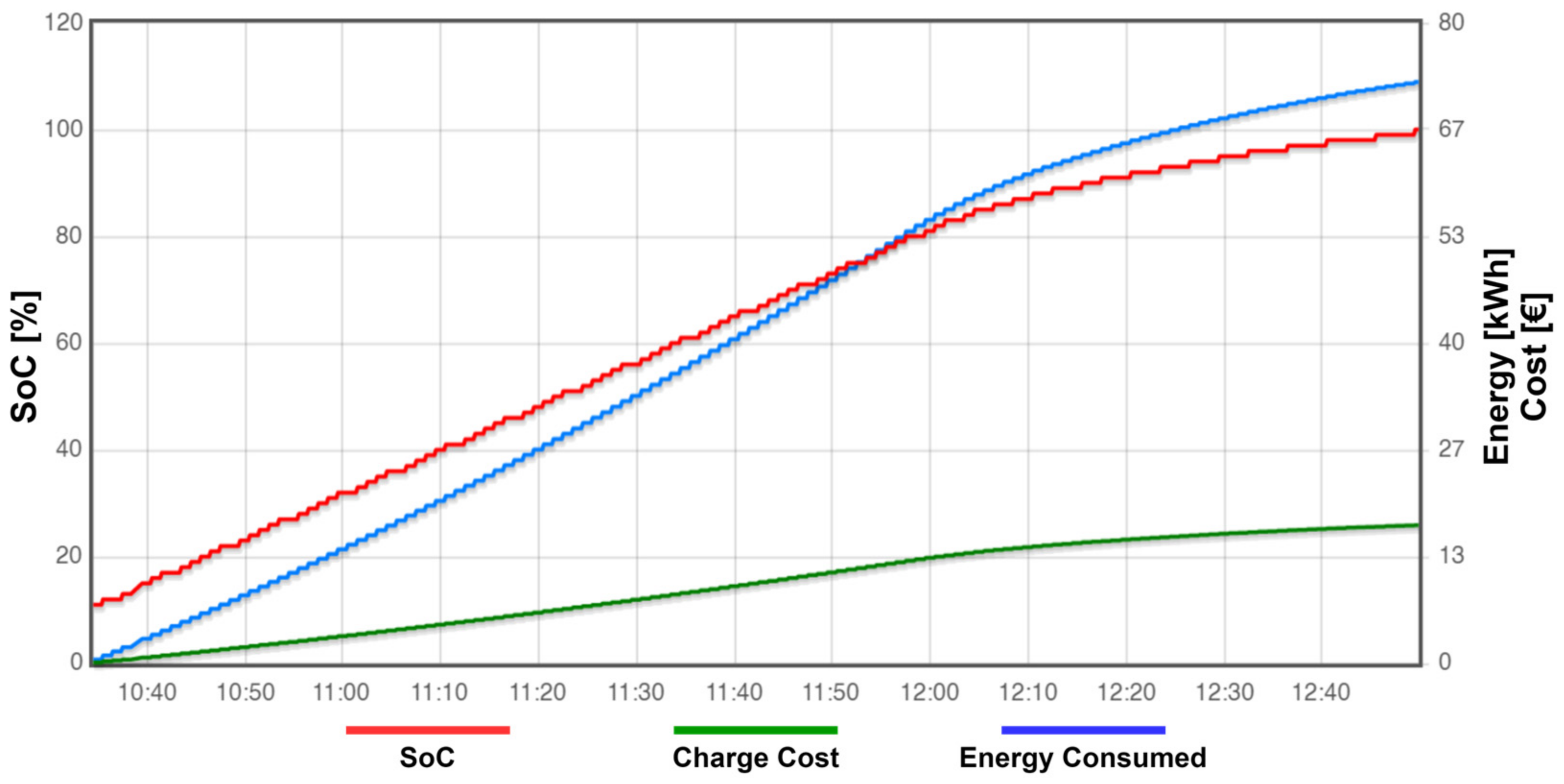

4.1. Results of an Emulated Charging Process

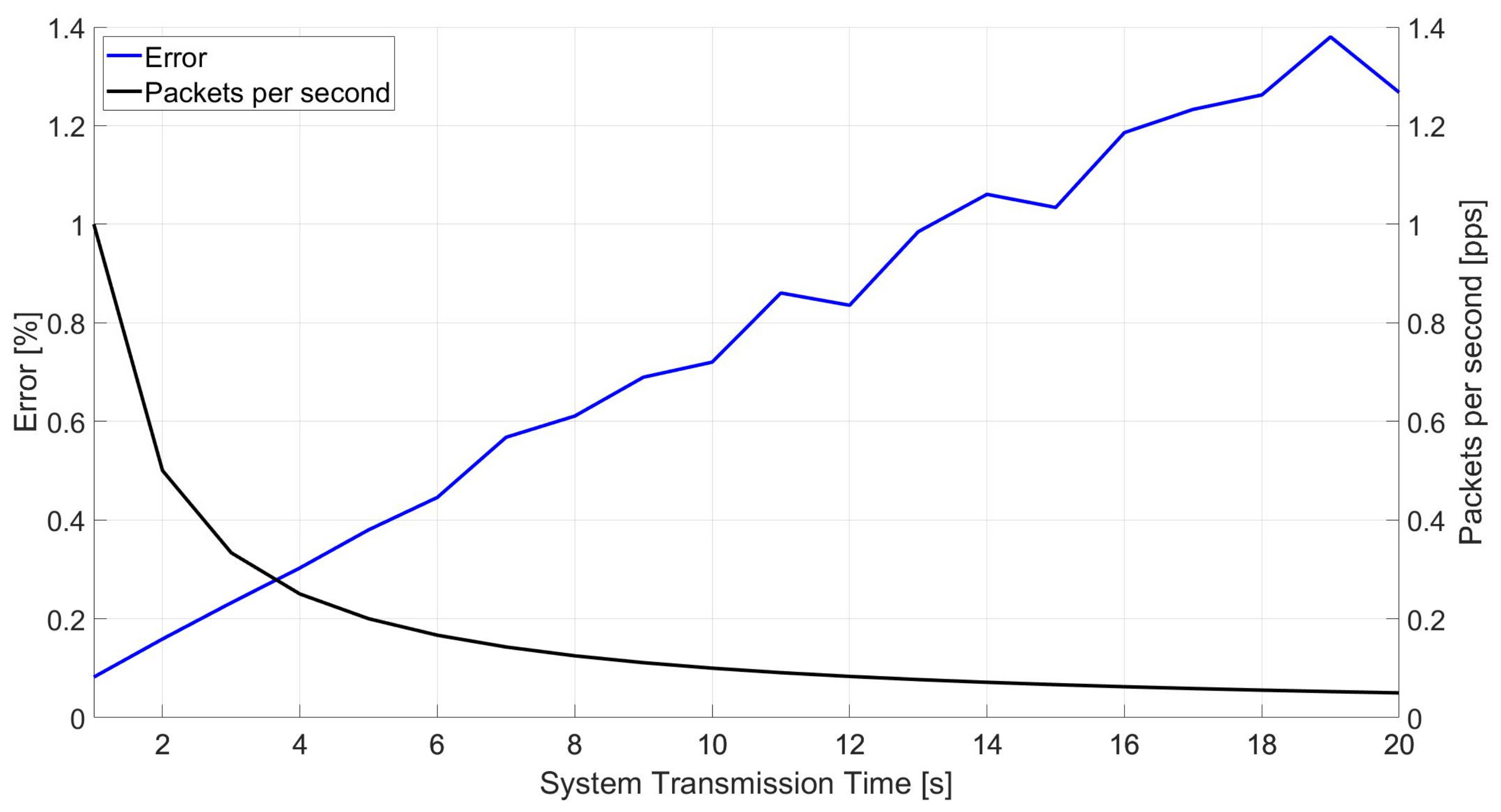

4.2. Evaluation of the Responsiveness of the System for Demand Response Purposes

5. Discussion, Conclusions, and Future Developments

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| AC | Alternate current |

| CC | Constant current |

| CPO | Charge point operator |

| CV | Constant voltage |

| DC | Direct current |

| EV | Electric vehicle |

| EVCC | Electric vehicle communication controller |

| EVSE | Electric vehicle supply equipment |

| HMI | Human–machine interface |

| IoT | Internet of Things |

| RES | Renewable energy sources |

| SECC | Supply equipment communication controller |

| SoC | State of charge |

| V2G | Vehicle-to-grid |

References

- Szumska, E.M. Electric Vehicle Charging Infrastructure along Highways in the EU. Energies 2023, 16, 895. [Google Scholar] [CrossRef]

- International Energy Agency. Global EV Outlook 2019. Available online: https://www.iea.org/reports/global-ev-outlook-2019 (accessed on 25 April 2024).

- International Energy Agency. Global EV Outlook 2024. Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 25 April 2024).

- Lopes, J.A.P.; Soares, F.J.; Almeida, P.M.R. Integration of Electric Vehicles in the Electric Power System. Proc. IEEE 2011, 99, 168–183. [Google Scholar] [CrossRef]

- de Hoog, J.; Thomas, D.A.; Muenzel, V.; Jayasuriya, D.C.; Alpcan, T.; Brazil, M.; Mareels, I. Electric vehicle charging and grid constraints: Comparing distributed and centralized approaches. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar] [CrossRef][Green Version]

- Momoh, K.; Zulkifli, S.A.; Korba, P.; Sevilla, F.R.S.; Afandi, A.N.; Velazquez-Ibañez, A. State-of-the-Art Grid Stability Improvement Techniques for Electric Vehicle Fast-Charging Stations for Future Outlooks. Energies 2023, 16, 3956. [Google Scholar] [CrossRef]

- International Electrotechnical Commission (IEC). IEC 61851-1: Electric vehicle conductive charging system—Part 1: General requirements. 2017. Available online: https://webstore.iec.ch/publication/33644 (accessed on 9 February 2024).

- ISO 15118; Road Vehicles—Vehicle to Grid Communication Interface (Parts 1–20). International Organization for Standardization (ISO): Geneva, Switzerland, 2022.

- SwitchEV. RISE-V2G. Available online: https://github.com/SwitchEV/RISE-V2G (accessed on 14 April 2024).

- Alotaibi, I.; Abido, M.A.; Khalid, M.; Savkin, A.V. A Comprehensive Review of Recent Advances in Smart Grids: A Sustainable Future with Renewable Energy Resources. Energies 2020, 13, 6269. [Google Scholar] [CrossRef]

- Sadeghian, O.; Oshnoei, A.; Mohammadi-ivatloo, B.; Vahidinasab, V.; Anvari-Moghaddam, A. A comprehensive review on electric vehicles smart charging: Solutions, strategies, technologies, and challenges. J. Energy Storage 2022, 54, 105241. [Google Scholar] [CrossRef]

- Ohanu, C.P.; Rufai, S.A.; Oluchi, U.C. A comprehensive review of recent developments in smart grid through renewable energy resources integration. Heliyon 2024, 10, e25705. [Google Scholar] [CrossRef] [PubMed]

- Mültin, M. ISO 15118 as the Enabler of Vehicle-to-Grid Application. In Proceedings of the 2018 International Conference of Electrical and Electronic Technologies for Automotive, Milan, Italy, 9–11 July 2018. [Google Scholar] [CrossRef]

- Madhusudhanan, S.; Sivraj, P. Development of Communication Simulator for Electric Vehicle Charging following ISO 15118. In Proceedings of the 2022 IEEE North Karnataka Subsection Flagship International Conference, Vijaypur, India, 20–21 November 2022. [Google Scholar] [CrossRef]

- Sayed, N.E. A Prototypical Implementation of an ISO-15118-Based Wireless Vehicle to Grid Communication for Authentication over Decoupled Technologies. In Proceedings of the 2019 AEIT International Conference of Electrical and Electronic Technologies for Automotive, Turin, Italy, 2–4 July 2019. [Google Scholar] [CrossRef]

- Oulcaid, M.; El Fadil, H.; Njili, S.; Zytoune, O.; Bajit, A. Experimental Implementation of a Wireless Communication System for Electric Vehicle WPT Charger. In Proceedings of the 10th International Conference on Innovation, Modern Applied Science & Environmental Studies, Istanbul, Turkey, 12–14 May 2022. [Google Scholar] [CrossRef]

- Wellisch, D.; Lenz, J.; Faschingbauer, A.; Pöschl, R.; Kunze, S. Vehicle-to-Grid AC Charging Station: An Approach for Smart Charging Development. IFAC-PapersOnLine 2015, 48, 55–60. [Google Scholar] [CrossRef]

- OCPP 2.0.1; Open Charge Point Protocol (OCPP). Open Charge Alliance (OCA): Arnhem, The Netherlands, 2020.

- Oumaima, B.; Hassan, E.F.; El Jeilani, S.; Halima, H.; Abdelaziz, K. Integration of Communication Between EV and EVSE Based on ISO 15118 with an OBD-II System. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Stahleder, D. Hardware-in-the-Loop Co-Simulation Environment for Testing Grid Integration of Electric Mobility with Precise Charging Models. Master’s Thesis, Technische Universität Wien, Vienna, Austria, 2018. [Google Scholar] [CrossRef]

- Pallander, R. Implementation of HomePlug Green Phy standard (ISO15118) into Electric Vehicle Supply Equipment (Dissertation). Luleå University of Technology 2021. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:ltu:diva-83881 (accessed on 9 February 2024).

- Jakó, Z.; Knapp, Á.; El Sayed, N. Wireless Authentication Solution and TTCN-3 based Test Framework for ISO-15118 Wireless V2G Communication. Infocommunications J. 2019, 11, 39–47. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 15118-1:2019. Available online: https://www.iso.org/standard/69113.html (accessed on 25 April 2024).

- Ju, S.-H.; Lee, I.-H.; Song, S.-H.; Seo, H.-S. Communication Interoperability between EV Charging Infrastructure and Grid. Int. J. Eng. Technol. 2018, 7, 215–221. [Google Scholar]

- International Organization for Standardization (ISO). ISO 15118-2:2014. Available online: https://www.iso.org/standard/55366.html (accessed on 25 April 2024).

- Thomson, S.J.; Thomas, P.A.R.; Rajan, E. Design and Prototype Modelling of a CC/CV Electric Vehicle Battery Charging Circuit. In Proceedings of the 2018 International Conference on Circuits and Systems in Digital Enterprise Technology, Kottayam, India, 21–22 December 2018. [Google Scholar] [CrossRef]

- Shen, W.; Vo, T.T.; Kapoor, A. Charging algorithms of lithium-ion batteries: An overview. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications, Singapore, 18–20 July 2012. [Google Scholar] [CrossRef]

- Emoncms.org. Emoncms. Available online: https://emoncms.org/ (accessed on 14 April 2024).

- Government of Canada. High-Resolution Solar Radiation Datasets. Available online: https://natural-resources.canada.ca/energy/renewable-electricity/solar-photovoltaic/18409 (accessed on 14 April 2024).

- Francisco, A.M.B.; Monteiro, J.; Cardoso, P.J.S. A Digital Twin of Charging Stations for Fleets of Electric Vehicles. IEEE Access 2023, 11, 125664–125683. [Google Scholar] [CrossRef]

- Santos, J.; Pacheco, A.; Monteiro, J. Implementation Process of a Local Energy Community in Portugal—The Case of Culatra Island. In INCREaSE 2023—Advances in Sustainability Science and Technology; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Pacheco, A.; Monteiro, J.; Santos, J.; Sequeira, C.; Nunes, J. Energy transition process and community engagement on geographic islands: The case of Culatra Island (Ria Formosa, Portugal). Renew. Energy 2022, 184, 700–711. [Google Scholar] [CrossRef]

| Ref. | ISO 15118 | Demand Response | RES Integration | Emulation | Simulation |

|---|---|---|---|---|---|

| [14] | ✔ | ✔ | ✔ | ||

| [15] | ✔ | ✔ | ✔ | ||

| [16] | ✔ | ✔ | ✔ | ||

| [17] | ✔ | ✔ | ✔ | ✔ | |

| [19] | ✔ | ✔ | ✔ | ||

| [20] | ✔ | ✔ | |||

| [21] | ✔ | ✔ | |||

| [22] | ✔ | ✔ | ✔ | ||

| This work | ✔ | ✔ | ✔ | ✔ | ✔ |

| V2G Message Types | Associated Action |

|---|---|

| SessionSetup [AC & DC] | Establish the V2G communication session |

| ServiceDiscovery [AC & DC] | EVSE makes available all its services to an EV (e.g., charging services and payment options) |

| ServiceDetail [AC & DC] | An EV gets more information about an additional EVSE service |

| PaymentServiceSelection [AC & DC] | An EV chooses which services to use, as provided via EVSE previously |

| PaymentDetails [AC & DC] | Exchange details when certificates are chosen as a payment option (e.g., e-mobility account identifier) |

| Authorization [AC & DC] | EVSE allows, or not, the EV to have access to its energy, depending on the validation of the payment option |

| ChargeParameterDiscovery [AC & DC] | An EV and EVSE negotiate charging parameters (e.g., current, voltage, and power limits) |

| PowerDelivery [AC & DC] | EVSE supplies power to its outlet terminals so the EV can charge its battery |

| CertificateUpdate [AC & DC] | An EV requests a new certificate when it is about to expire |

| CertificateInstallation [AC & DC] | An EV requests a new certificate when it does not have a valid one; SECC may have to request this certificate from a secondary actor |

| SessionStop [AC & DC] | Finish the V2G communication session |

| MeteringReceipt [AC & DC] | EVSE digitally signs the charging energy metering information |

| ChargingStatus [AC] | Responsible for the charging loop in AC power transfer mode; EV verifies and validates the power consumed via EVSE |

| CableCheck [DC] | Checks whether the connector is locked and whether the EV is ready for charge |

| PreCharge [DC] | Adjust EVSE voltage to EV battery voltage |

| CurrentDemand [DC] | Responsible for charging loop in DC power transfer mode; control parameters are exchanged |

| WeldingDetection [DC] | Safety-checks the electrical contacts after the power transfer derived from charging |

| Total Capacity | Maximum Current | Maximum Voltage | Minimum Voltage | Nominal Voltage |

|---|---|---|---|---|

| 235 Ah | 117 A | 400 V | 240 V | 350 V |

| EVSE Maximum Current Limit | 250 A | EV State of Charge | 10% |

| EVSE Minimum Current Limit | 2 A | EV Maximum Current Limit | 117 A |

| EVSE Maximum Voltage Limit | 600 V | EV Maximum Voltage Limit | 400 V |

| EVSE Minimum Voltage Limit | 120 V | Tariff Period | Peak |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, J.B.; Francisco, A.M.B.; Cabrita, C.; Monteiro, J.; Pacheco, A.; Cardoso, P.J.S. Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard. Energies 2024, 17, 3045. https://doi.org/10.3390/en17123045

Santos JB, Francisco AMB, Cabrita C, Monteiro J, Pacheco A, Cardoso PJS. Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard. Energies. 2024; 17(12):3045. https://doi.org/10.3390/en17123045

Chicago/Turabian StyleSantos, Jóni B., André M. B. Francisco, Cristiano Cabrita, Jânio Monteiro, André Pacheco, and Pedro J. S. Cardoso. 2024. "Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard" Energies 17, no. 12: 3045. https://doi.org/10.3390/en17123045

APA StyleSantos, J. B., Francisco, A. M. B., Cabrita, C., Monteiro, J., Pacheco, A., & Cardoso, P. J. S. (2024). Development and Implementation of a Smart Charging System for Electric Vehicles Based on the ISO 15118 Standard. Energies, 17(12), 3045. https://doi.org/10.3390/en17123045