Comprehensive Analysis of Factors Underpinning the Superior Performance of Ducted Horizontal-Axis Helical Wind Turbines

Abstract

1. Introduction

- The inclusion of a duct was anticipated to augment the airflow passing through the turbine.

- The turbine’s design aimed to function akin to a funnel, pulling air inward and potentially averting the generation of backward force.

- The design’s intention was to facilitate smoother airflow through the turbine, preventing the formation of a concentrated stream tube around it.

2. Materials and Methods

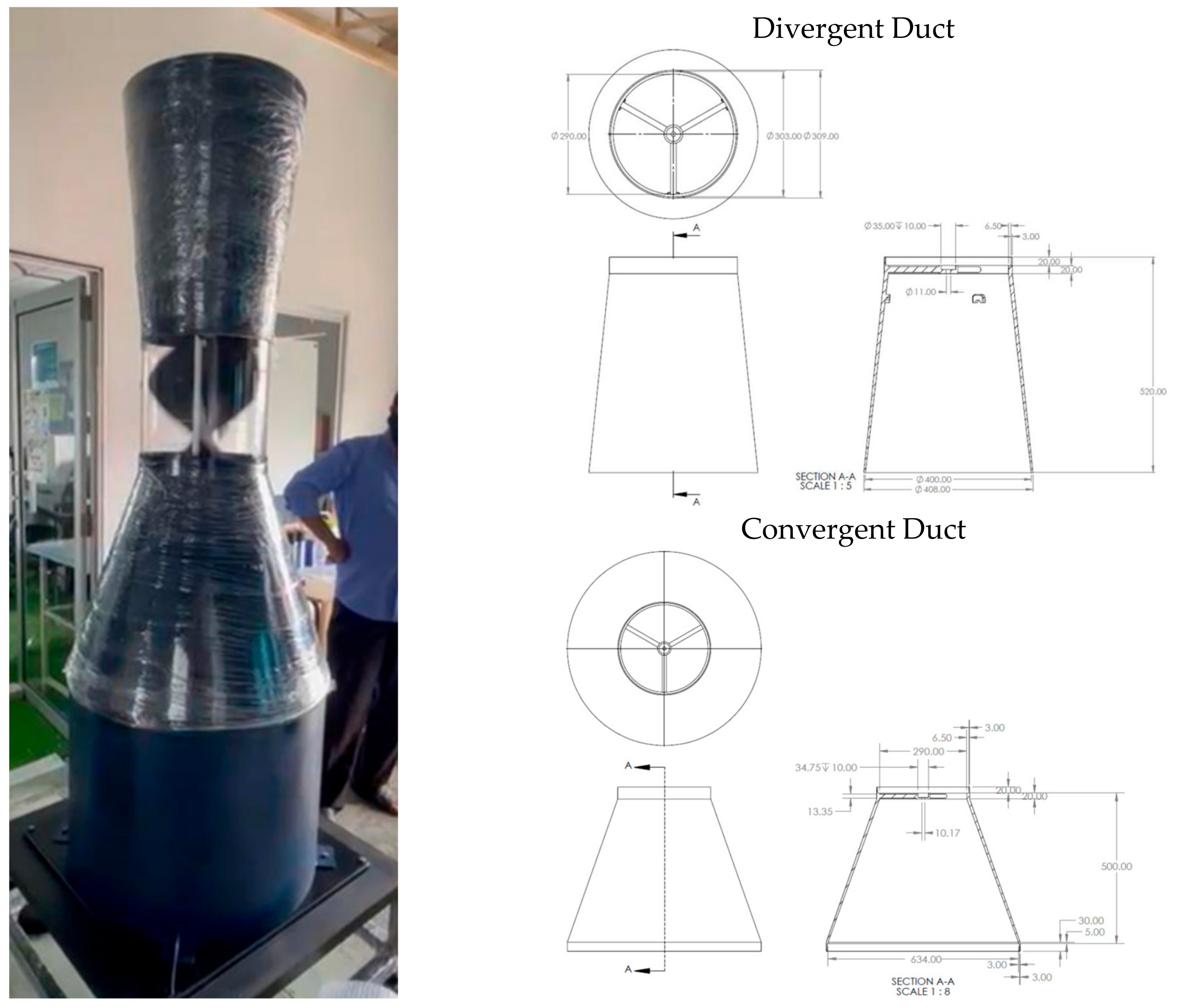

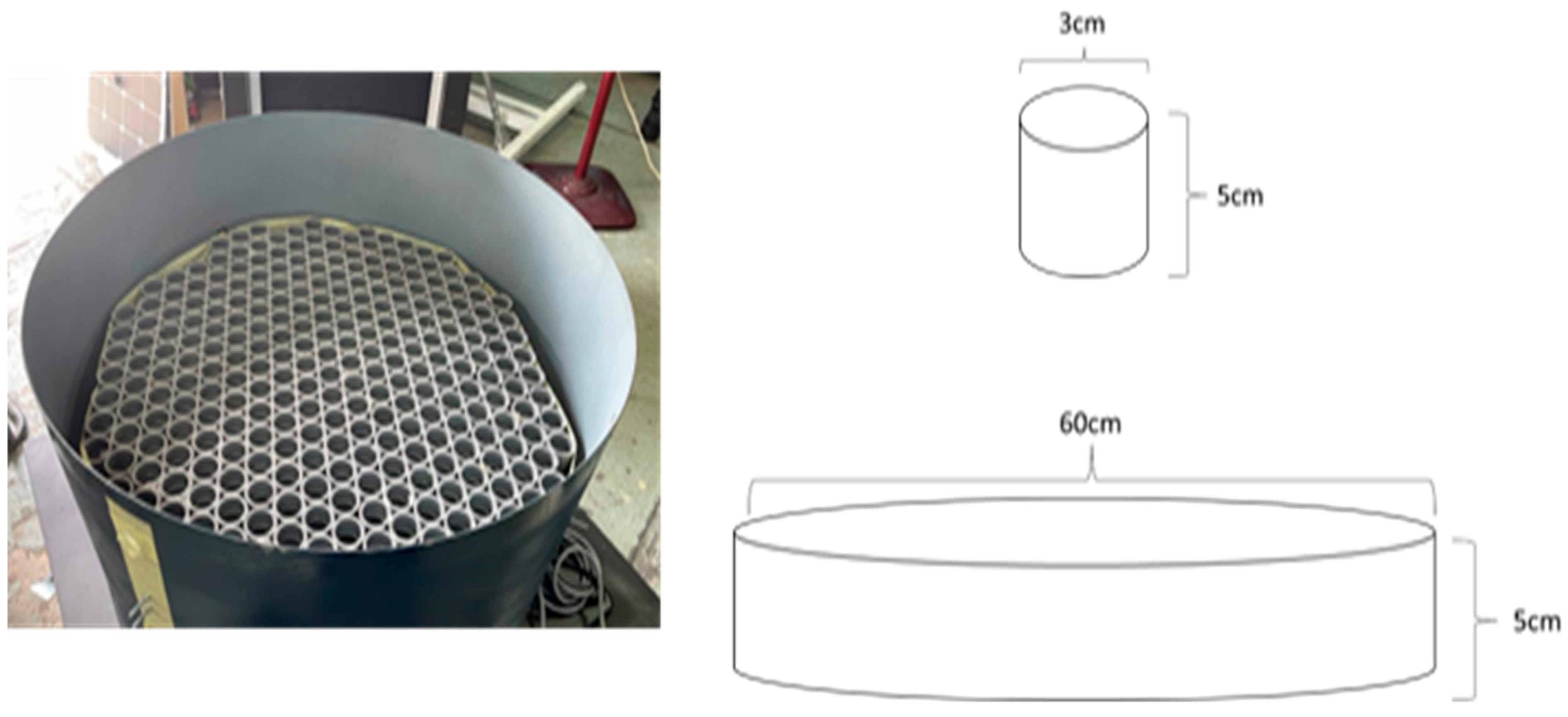

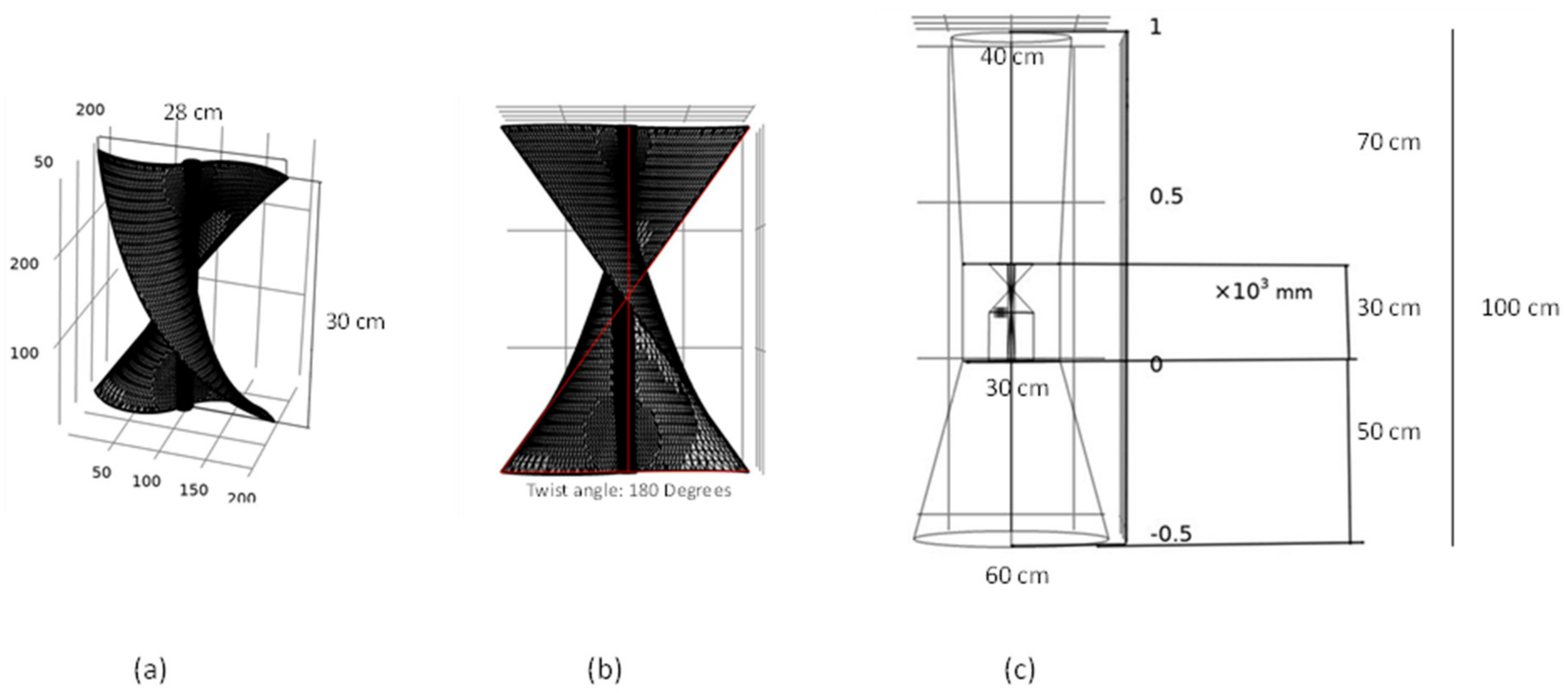

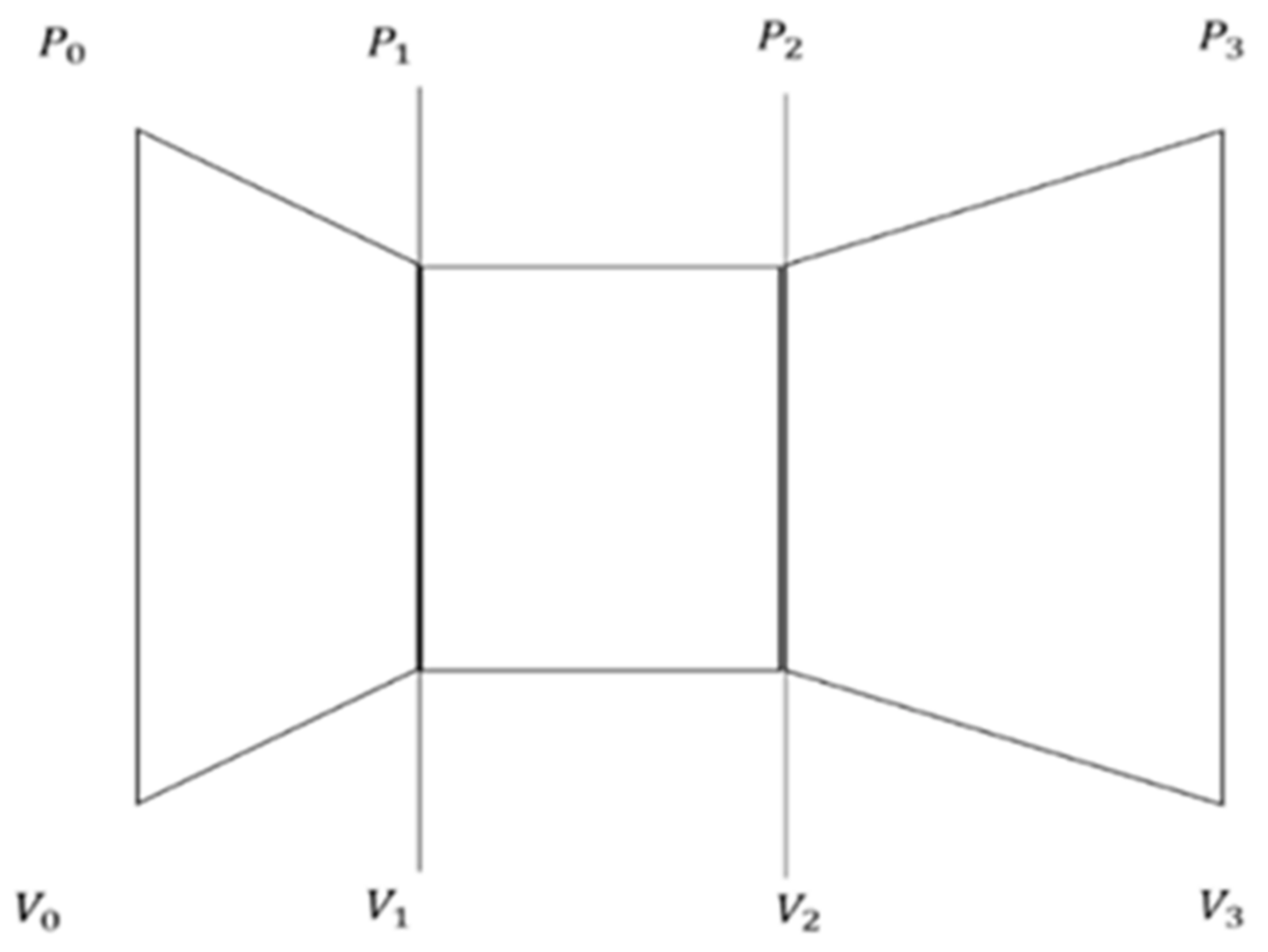

2.1. Geometry

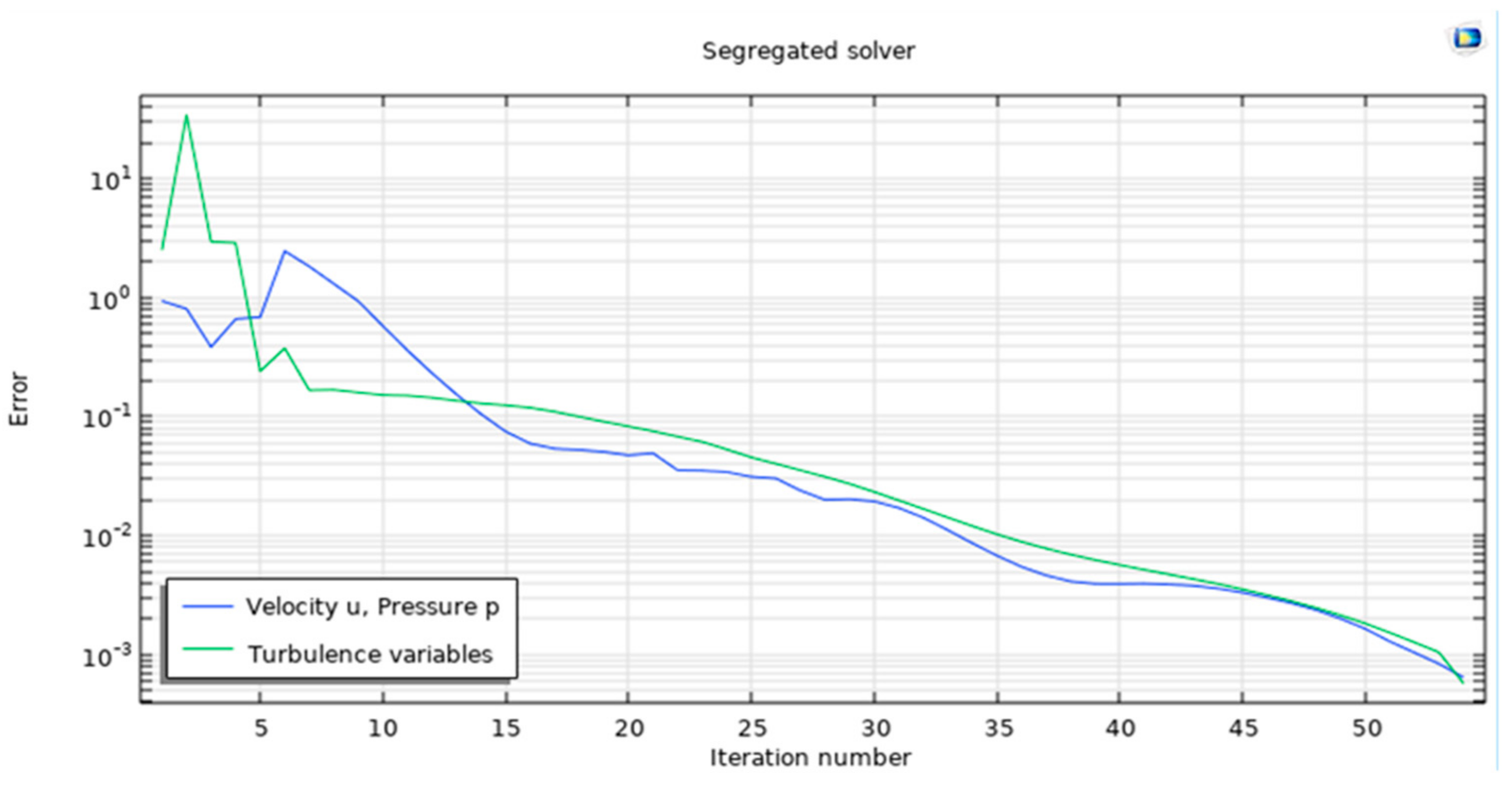

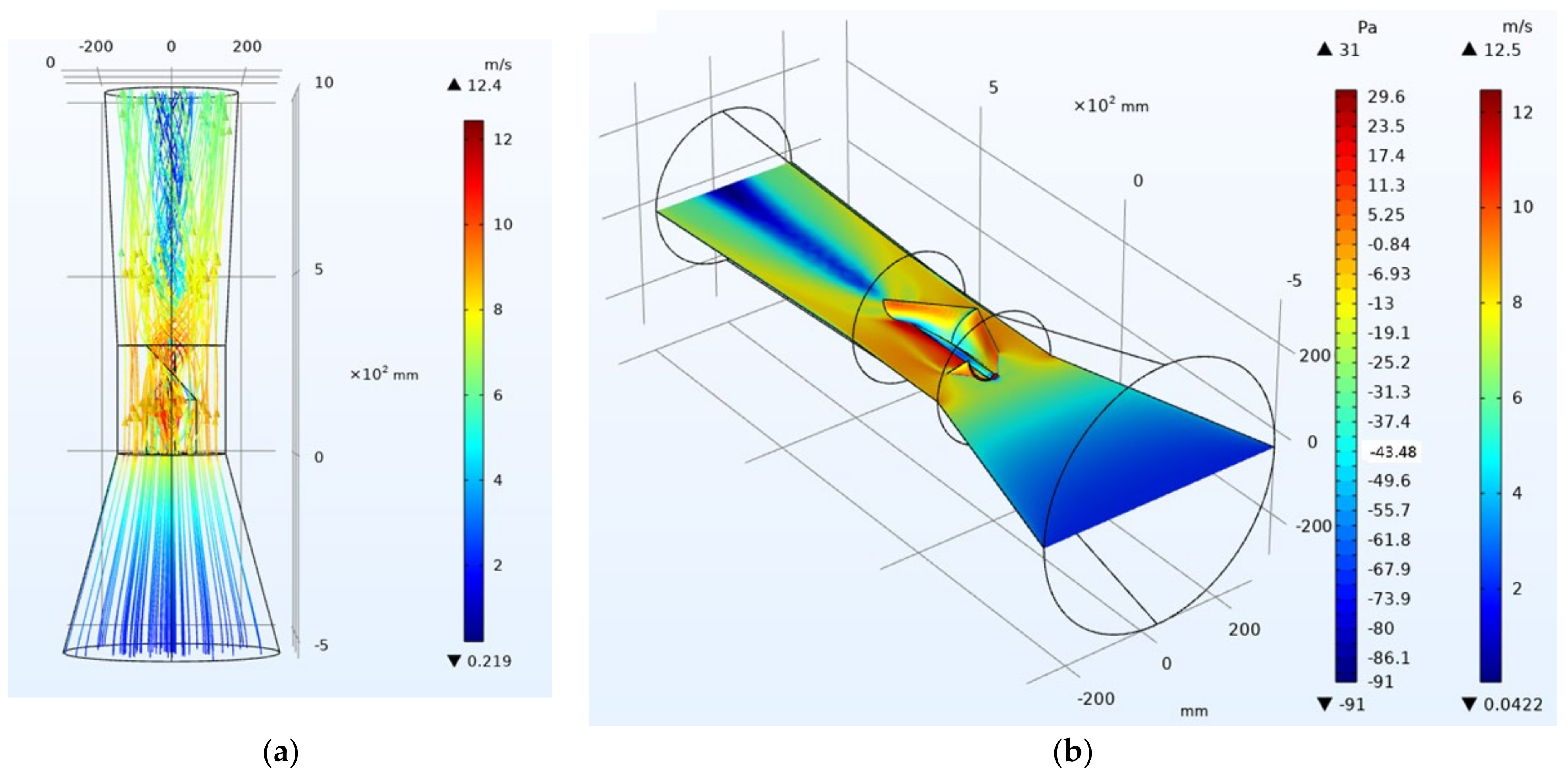

2.2. CFD Simulation for Stationary Turbine

- The domain of the turbine was selected to be solid.

- The domain of the duct was selected to be non-solid.

- The fluid material selected was air of equilibrium discharge.

- Properties of the fluid were user-defined to 30° Celsius.

- The material at the walls of the duct was selected as polyvinyl chloride (PVC).

- At the wall, NO SLIP condition was applied.

- Inlet- and outlet-specified.

- Outlet pressure was set to adjust in accordance with the ambient pressure to account for the back pressure.

- Inlet velocity was for the range 1 m/s to 4 m/s.

2.3. Experimental Evaluation

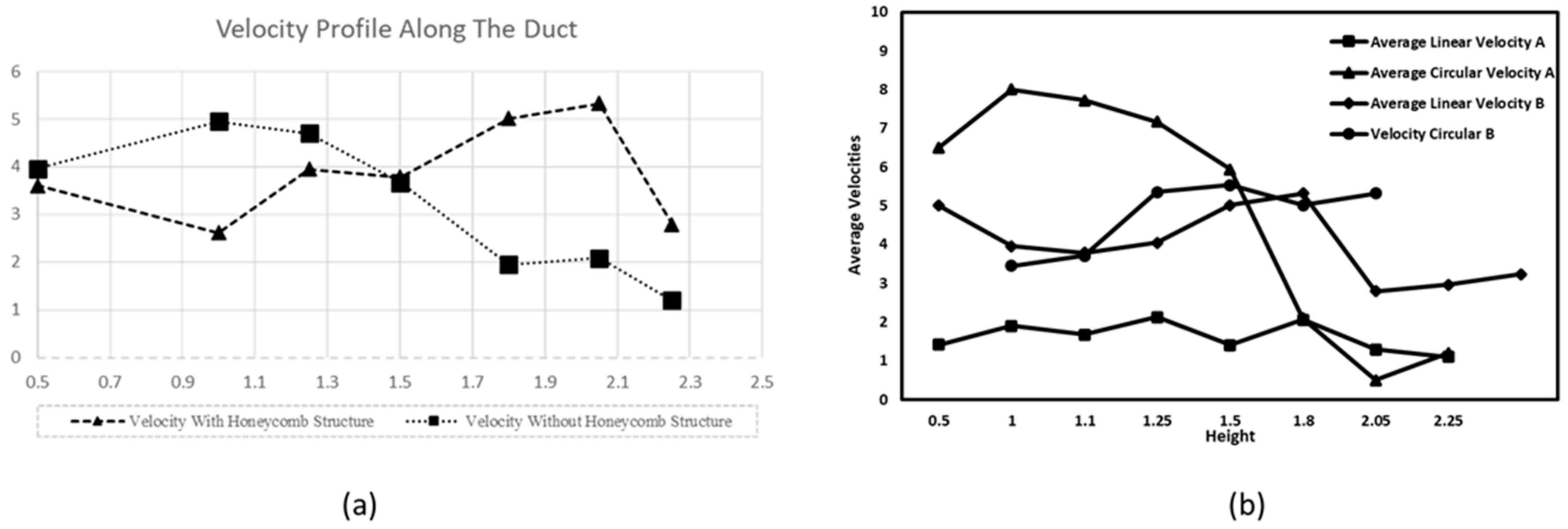

2.3.1. Measuring Velocity

2.3.2. Measuring Electrical Output

3. Results and Discussion

3.1. Air Velocity Profile

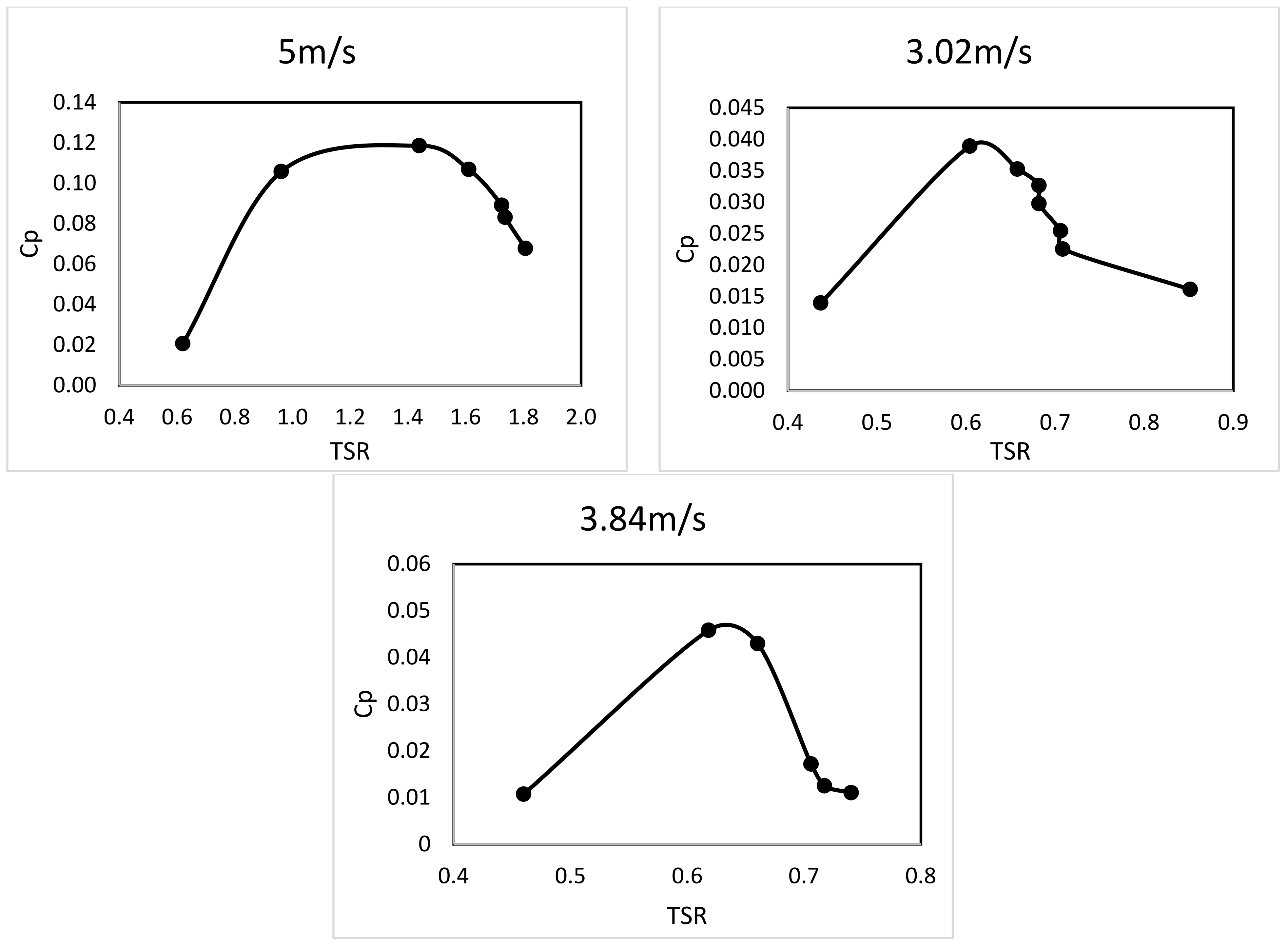

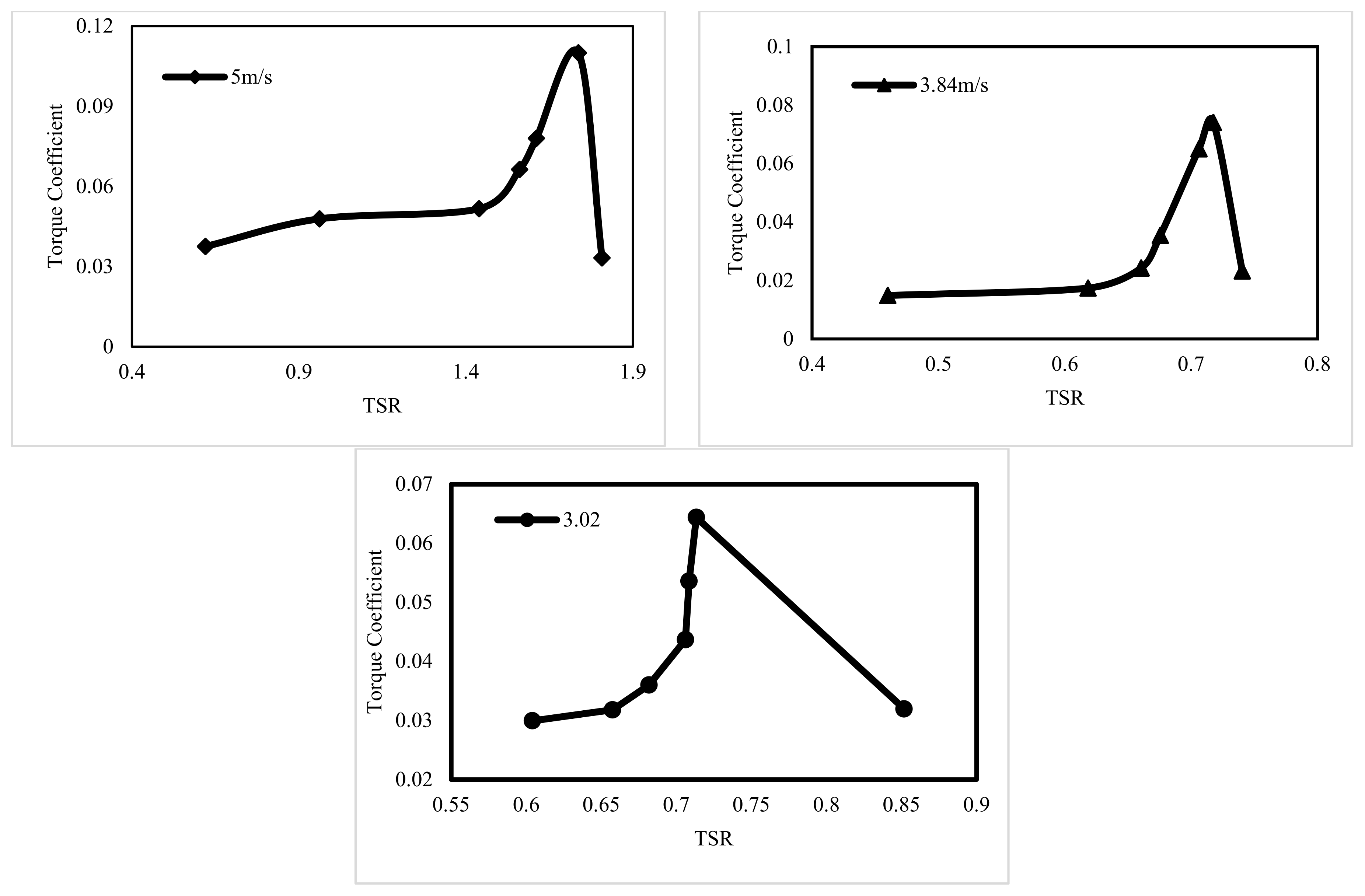

3.2. Wind Turbine Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Irvine, K.N.; Suwanarit, A.; Likitswat, F.; Srilertchaipanij, H.; Ingegno, M.; Kaewlai, P.; Boonkam, P.; Tontisirin, N.; Sahavacharin, A.; Wongwatcharapaiboon, J.; et al. Smart City Thailand: Visioning and Design to Enhance Sustainability, Resiliency, and Community Wellbeing. Urban Sci. 2022, 6, 7. [Google Scholar] [CrossRef]

- Abbas, J.; Wang, L.; Ben Belgacem, S.; Pawar, P.S.; Najam, H.; Abbas, J. Investment in Renewable Energy and Electricity Output: Role of Green Finance, Environmental Tax, and Geopolitical Risk: Empirical Evidence from China. Energy 2023, 269, 126683. [Google Scholar] [CrossRef]

- Raihan, A.; Rashid, M.; Voumik, L.C.; Akter, S.; Esquivias, M.A. The Dynamic Impacts of Economic Growth, Financial Globalization, Fossil Fuel, Renewable Energy, and Urbanization on Load Capacity Factor in Mexico. Sustainability 2023, 15, 13462. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Git, H.M.; Lee, S.L. Experimental Investigation on Solar—Flue Gas Chimney. J. Power Energy Eng. 2009, 3, 25–31. [Google Scholar]

- Wong, K.H.; Chong, W.T.; Yap, H.T.; Fazlizan, A.; Omar, W.Z.W.; Poh, S.C.; Hsiao, F.B. The Design and Flow Simulation of a Power-Augmented Shroud for Urban Wind Turbine System. Energy Procedia 2014, 61, 1275–1278. [Google Scholar] [CrossRef]

- Chilugodu, N.; Yoon, Y.J.; Chua, K.S.; Datta, D.; Baek, J.D.; Park, T.; Park, W.T. Simulation of Train Induced Forced Wind Draft for Generating Electrical Power from Vertical Axis Wind Turbine (VAWT). Int. J. Precis. Eng. Manuf. 2012, 13, 1177–1181. [Google Scholar] [CrossRef]

- Hossain, M.T.; Hasan, A.; Paul, R.; Akter, N. Producing Electrical Energy by Using Wastage Wind Energy from Exhaust Fans of Industries. Int. J. Sci. Eng. Res. 2013, 4, 1184–1187. [Google Scholar]

- Mann, H.S.; Singh, P.K. Effect of Number of Blades in Ducted Turbine System on Kinetic Energy Extraction from Chimney Flue Gases—Benchmarking with Wind Energy System. J. Mech. Sci. Technol. 2018, 32, 5443–5455. [Google Scholar] [CrossRef]

- Mann, H.S.; Singh, P.K. Kinetic Energy Recovery from the Chimney Flue Gases Using Ducted Turbine System. Chin. J. Mech. Eng. 2017, 30, 472–482. [Google Scholar] [CrossRef]

- Mann, H.S.; Singh, P.K. Conceptual Development of an Energy Recovery from the Chimney Flue Gases Using Ducted Turbine System. J. Nat. Gas Sci. Eng. 2016, 33, 448–457. [Google Scholar] [CrossRef]

- Puttichaem, W.; Putivisutisak, S.; Boonyongmaneerat, Y.; Vadhanasindhud, P. Early Development of a Shaftless Horizontal Axis Wind Turbine for Generating Electricity from Air Discharged from Ventilation Systems. Int. J. Energy Res. 2020, 46, 212–222. [Google Scholar] [CrossRef]

- Puttichaem, W.; Boonyongmaneerat, Y.; Vadhanasindhu, P.; Putivisutisak, S. Performance of the Prototype Shaftless Small Scale Horizontal Wind Turbine for Electricity Generating from Industrial Exhaust Air System. IOP Conf. Ser. Earth Environ. Sci. 2020, 463, 012140. [Google Scholar] [CrossRef]

- Yeboah, D.; Ackor, N.; Abrowah, E. Evaluation of Wind Energy Recovery from an Underground Mine Exhaust Ventilation System. J. Eng. 2023, 2023, 8822475. [Google Scholar] [CrossRef]

- Chikere, A.O.; Al-Kayiem, H.H.; Karim, Z.A.A. Review on the Enhancement Techniques and Introduction of an Alternate Enhancement Technique of Solar Chimney Power Plant. J. Appl. Sci. 2011, 11, 1877–1884. [Google Scholar] [CrossRef]

- Venkatesh, G. Power Production Technique Using Exhaust Gas from Present Automobiles via Convergent-Divergent Nozzle. In Proceedings of the 2006 IEEE Conference on Electric and Hybrid Vehicles ICEHV, Pune, India, 18–20 December 2006. [Google Scholar] [CrossRef]

- Kolte, A.; Festa, G.; Ciampi, F.; Meissner, D.; Rossi, M. Exploring Corporate Venture Capital Investments in Clean Energy—A Focus on the Asia-Pacific Region. Appl. Energy 2023, 334, 120677. [Google Scholar] [CrossRef]

- Zishan, S.; Molla, A.H.; Rashid, H.; Wong, K.H.; Fazlizan, A. Comprehensive Analysis of Kinetic Energy Recovery Systems for Efficient Energy Harnessing from Unnaturally Generated Wind Sources. Sustainability 2023, 15, 15345. [Google Scholar] [CrossRef]

- Suheel, S.Z.; Fazlizan, A. Workability of a New Kinetic Energy Recovery System Proven Mathematically. AIP Conf. Proc. 2021, 2339, 020159. [Google Scholar] [CrossRef]

- Kishore, R.A.; Coudron, T.; Priya, S. Small-Scale Wind Energy Portable Turbine (SWEPT). J. Wind Eng. Ind. Aerodyn. 2013, 116, 21–31. [Google Scholar] [CrossRef]

- Anant Kishore, R.; Priya, S. Design and Experimental Verification of a High Efficiency Small Wind Energy Portable Turbine (SWEPT). J. Wind Eng. Ind. Aerodyn. 2013, 118, 12–19. [Google Scholar] [CrossRef]

- Duquette, M.M.; Visser, K.D. Numerical Implications of Solidity and Blade Number on Rotor Performance of Horizontal-Axis Wind Turbines. J. Sol. Energy Eng. Trans. ASME 2003, 125, 425–432. [Google Scholar] [CrossRef]

| Researcher | System Source | Novelty | Velocity | Velocity Augmented | Turbine Type |

|---|---|---|---|---|---|

| Al-Kayiem et al. [4] | Industrial flue gas | Used industrial flue gas to increase the efficiency of the SCPP | 4.1 m/s | 4.6 m/s | Savonius wind rotor |

| Chong et al. [5] | Steam from cooling towers | Used guide vanes and side diffusers for an HAWT | 8 m/s | 30.4% | 5-bladed HAWT |

| Nikhita Chilugodu et al. [6] | Wind is generated from the kinematic movement of trains. | The use of VAWT in the vicinity of the MRT train system in Singapore | 6–8 m/s | 6% (with the increase in altitude) | VAWT |

| Md. Abir et al. [7] | Air from industrial exhaust systems | Suggested methods to conserve velocity until the wind turbine | 14.5–16 m/s | - | - |

| Mann and Singh [8,9,10] | Industrial flue gas | Suggested augmenting the velocity using the most appropriate diffuser and harnessing the kinetic energy in industrial flue gas | 20 m/s | 57.2 m/s | VAWT (NACA airfoils) |

| Wachira Puttichaem et al. [11,12] | Air conditioning systems’ exhaust | Suggested the use of a novel design of SSHWT equipped with a novel BDC generator | 1–5 m/s | - | SSHWT |

| Douglas Yeboah et al. [13] | Underground mine exhaust | Suggested the use of exhaust wind from underground mines | 7.67 m/s | - | - |

| Sections | Technical Specifications |

|---|---|

| Material | Cylindrical, convergent, and divergent ducts to be fabricated by custom 3D printing, using thermoplastic polyester polylactide (PLA) material. Note: alternative solution for cylindrical duct to use steel sheet. |

| Cylindrical Duct | Cylindrical duct: height 1000 mm; diameter 600 mm. |

| Convergent Duct | Convergent Duct: height 500 mm in flow diameter; 600 mm out flow diameter—300 mm. |

| Divergent Duct | Divergent duct: height 500 mm; in flow diameter = 300 mm; out flow diameter = 400 mm. |

| Test Cylinder | Test cylinder (provided by client): diameter 300 mm. |

| Support Base | Support base: including axial fan diameter 600 mm. |

| Energy Recovery System | Velocity (m/s) | System Size (cm) | Maximum Power | Power Harnessed (W) | Power Percentage (%) | |||

|---|---|---|---|---|---|---|---|---|

| Original | Incoming | Diameter | Original | Augmented | Augmented | Recovered | ||

| DHAHWT | 2.04 | 5 | 30 cm | 0.311 | 4.59 | 0.559 | 179.16% | 12.16% |

| SHWT [11] | 5.1 | 5.1 | 50 cm | 15.95 | 15.95 | 7.4 | N/A | 51.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suheel, S.Z.; Fazlizan, A.; Razali, H.; Wong, K.H.; Molla, A.H.; Rathore, R.S.; Lipu, M.S.H.; Sarker, M.R. Comprehensive Analysis of Factors Underpinning the Superior Performance of Ducted Horizontal-Axis Helical Wind Turbines. Energies 2024, 17, 3029. https://doi.org/10.3390/en17123029

Suheel SZ, Fazlizan A, Razali H, Wong KH, Molla AH, Rathore RS, Lipu MSH, Sarker MR. Comprehensive Analysis of Factors Underpinning the Superior Performance of Ducted Horizontal-Axis Helical Wind Turbines. Energies. 2024; 17(12):3029. https://doi.org/10.3390/en17123029

Chicago/Turabian StyleSuheel, Shaikh Zishan, Ahmad Fazlizan, Halim Razali, Kok Hoe Wong, Altaf Hossain Molla, Rajkumar Singh Rathore, M. S. Hossain Lipu, and Mahidur R. Sarker. 2024. "Comprehensive Analysis of Factors Underpinning the Superior Performance of Ducted Horizontal-Axis Helical Wind Turbines" Energies 17, no. 12: 3029. https://doi.org/10.3390/en17123029

APA StyleSuheel, S. Z., Fazlizan, A., Razali, H., Wong, K. H., Molla, A. H., Rathore, R. S., Lipu, M. S. H., & Sarker, M. R. (2024). Comprehensive Analysis of Factors Underpinning the Superior Performance of Ducted Horizontal-Axis Helical Wind Turbines. Energies, 17(12), 3029. https://doi.org/10.3390/en17123029