Abstract

In view of the increasing demand for clean energy and the growing awareness of environmental sustainability, a bibliometric study examines the various facets of renewable natural gas (biomethane). Sustainable fuels are gaining importance as an alternative to fossil fuels because they are renewable and can reduce greenhouse gas emissions. In addition, an overview of the use of biomethane was compiled for Brazil. The country was chosen because it is the authors’ home country. These emerging energy sources have the potential to play a critical role in the transition to a cleaner, more sustainable and cost-effective energy landscape, thereby reducing environmental impact and strengthening the resilience of our energy future.

1. Introduction

In recent decades, there has been a significant increase in human population and, at the same time, new industrial layouts; thus, the use of conventional fossil fuels has developed greatly. Resource depletion and climate change due to human activities and the excessive burning of fossil fuels are the driving forces for research into alternative clean energy sources [1]. The depletion of fossil fuels, the increasing concerns about climate change and the need to reduce greenhouse gas emissions, in addition to the desire for energy independence and security, have led to the development of various biogas upgrading techniques that can provide a reliable and sustainable source of energy [2]. Increasing pollution and strict emission regulations have increased the demand for alternative green fuels as a sustainable energy source for engines and general industrial applications, which include manufacturing processes, power generation, material handling, transport and other activities that contribute to industrial production and operations [3].

Biogas (upgraded to biomethane) and natural gas (methane) are taking center stage among renewable fuels due to their environmental compatibility; these gaseous fuels have significant environmental advantages over conventional petroleum-based or fossil fuels [4]. A large number of scientific publications with a wide variety of topics has increased the need for review articles in the last decade [5]. In the last twenty years, there has been a large amount of literature on how to improve methane production performance, but few systematic reviews have been conducted [6]. However, there is a lack of practical research on new standards, engine performance and costs for low carbon intensity [7]. The overview of limitations and perspectives highlights a number of opportunities for research areas that can further contribute to increasing sustainability in biofuel production and thus achieving the SDGs (sustainable development goals), since there is little work assessing the actual impact of biofuels on sustainable development [8]. Renewable energy gases such as biomethane are expected to replace natural gas, provided they strictly comply with the quality standards for natural gas, which prescribe maximum levels for various trace chemicals [9].

Biogas is considered one of the most promising alternative renewable fuels, but the raw biogas must be upgraded before it can be used in vehicles or injected into the natural gas grid, and the resulting biomethane must be liquefied to be transported to distant locations [10]. However, in order to sustainably integrate these gases into the current energy mix, their quality must be controlled in terms of their major, minor and trace components in order to maintain the integrity of the infrastructure in which they are burned, transported or stored [11].

An article evaluated a series of coupled computational physics and fluid dynamics models developed with the aim of assessing the feasibility of producing photothermal synthetic fuel from mixtures of biogas (biomethane) and water vapor using plasmonic Ag/TiO2 substrate nanostructures (each 0.1 μm thick) within a boundary layer for heat, momentum and mass transport in a microreactor [12]. The biochemical methane potential (BMP), biodegradability index (BI), competitiveness index (IC), physicochemical properties and elemental composition of cassava vinasse (CV) derived from an ethanol distillery were investigated by experimental analysis and instrumentation [13].

Biomethane (BM) is a highly competitive bioenergy alternative to reduce dependence on fossil fuels worldwide [14]. Biogas is a cornerstone of a clean and sustainable energy portfolio, while hydrogen production from biogas is a key enabler for methane conversion and carbon dioxide valorization to mitigate greenhouse gas emissions stove [14].

The anaerobic digestion (AD) of different organic wastes is a promising technique to increase the production of clean energy (bioenergy) and manure (slurry), reducing stress on the environment [15,16].

Anaerobic digestion is one of the routes available to recover energy from waste through the production of biogas, while reducing organic load and pollutants in the environment [17]. It has attracted the scientific community for its simplicity and ease of handling, and has the potential to use any type of organic waste to produce a mixture of combustible gases, that is, biogas and digested leachate, which has other applications in agriculture, solid biofuels and purification [18].

A study investigates the effect of the specially designed adsorptive packed column system (APCS) on improving biogas quality up to biomethane purity [19]. The production of biogas from food waste with the AD process and co-digestion process achieved high purity of biogas [20].

A study points to the need for the complete cleaning of Renewable Natural Gas (RNG) before its injection into the Natural Gas (NG) network [21].

For the purpose of achieving a flexible and economical energy storage, a transcritical energy cycle study combining CO2 was added to biomethane plants to form a liquefied biomethane storage system [22].

The expected increase in the proportion of biomethane in NG networks could increase fluctuations in the composition of the NG–biomethane mixture in amplitude and frequency [23].

The degree of substitutability of current impure fuels and the net greenhouse gas emissions avoided by using this biomethane is assessed for three different end-use scenarios: electricity production, cooking and road transport [24].

The injection of biomethane into the existing gas infrastructure is a fundamental opportunity to be promoted, but one that leads to increasing complexity in the management of natural gas networks [25]. The same study evaluated the role of line-pack in determining the absorption capacity of the gas network and tested the smart management of pressure set points and injection flow to minimize the reduction in biomethane.

For data from 2021 onwards, the methodology for reporting the main activity of producing CHP plants has been updated to include biomethane that is injected into the natural gas network; in 2018, a new biomethane plant was installed, leading to increases in the blending of biogas with natural gas; and 2017 is the first year that biogas was mixed with natural gas [26].

Biomethane can be used as an environmentally friendly substitute for natural gas for various applications such as transportation, heating and electricity generation [27,28]. The composition of biogas and biomethane is well known in terms of main compounds, which include methane, carbon dioxide and hydrogen sulfide; also, the metal concentrations of natural gas and treated biomethane were compared [29].

Work was carried out in a pilot plant to clean and recover real biogas from anaerobic digestion using the chemical absorption method [30]. A 29-month stability study of reference gas mixtures of 10 μmol mol−1 ammonia in methane and synthetic biogas is also reported [31]. Research carried out the processing of a mixed stream of gases with a typical biogas composition using a gas separation membrane with the aim of producing a stream of purified biomethane [32].

An effective model was developed that takes into account both the molecular chemistry of the solvent with the partition coefficient of CO2 and methane in the mono-ethanolamine (MEA), and the process parameters to upgrade the biomethane for use as a renewable fuel, as well as sustainable waste management. In order to optimize the process, several sensitivity analyses were carried out with variations in the number of absorption and removal stages [33].

A study investigated the performance of a multi-cylinder SI engine using 10%, 20% (ethanol, methanol, methyl acetate) and 100% compressed biomethane gas (CBG) as alternative fuels. The minimum average gas emission was found in CBG at RPM minimum and maximum, indicating that CBG offers the best emission result with engine performance compared to all alternative fuels [34].

A comparison of the operational performance of biomethane with natural gas and gasoline was carried out in a small pickup truck. Three different purity levels were used for biomethane, with the lowest having a methane concentration of 83%. The study compares the performance of a biomethane-powered vehicle by measuring its power, torque, emissions, fuel efficiency and cost to examine the benefits and problems of using biomethane [35].

The composition of biomethane was studied in an experimental pilot plant that treats organic waste through dry anaerobic digestion, using a solid ash matrix obtained from a wood-fired central heating plant. European limits were considered and respected for the injection of biomethane into the gas network [36].

The selective removal of CO2 during biogas upgrading and subsequent sequestration can transform the biomethane produced from a carbon-neutral energy source to a carbon-negative energy source. Such technology can be considered as bioenergy with carbon capture and storage (BECCS), that is, as a negative emission technology (NET) [37].

Biomethane is more suitable to become an engine fuel than other gaseous fuels due to its bioderived nature and burning characteristics [38].

The technical feasibility of a small-scale, environmentally sustainable system is lacking in the literature [39]. Circular economy concepts for electricity production could be adopted for the transition to green energy [36].

The scarcity of studies on the effects of heat transfer on the rupture curves and bed temperature profile of the biomethane upgrading process in the literature leads us to investigate these effects in more detail [40].

As mentioned, biomethane is a renewable and clean energy source which can be used to reduce greenhouse gas emissions and support sustainable development; it is used in the production of electricity, for heating purposes and as fuel for vehicles that have engines [20,41,42].

Several studies were carried out to reduce biogas from waste, aiming to make full use of residual biomass in a circular economy context [43]. The waste and biomass used in research for biomethane production were the following: slaughterhouse waste as substrates with high organic content [44]; different percentages of fats, oils and grease in anaerobic co-digestion with slaughterhouse wastewater [45]; waste from the agri-food sector, such as chestnut shells [46]; co-digested sheep manure and kitchen waste [47]; effluents from E. coli fermenters through anaerobic fermentation using wastewater treatment sludge [48]; straw corn coupled with disk refining to increase biomethane production [49]; and avocado oil and wastewater, which can potentially be digested anaerobically to produce biomethane [50] from pine sawdust [51], okra waste and pig manure [52]; however, landfills and ETEs are more viable sources of biomethane production in terms of cost efficiency [53].

In detail, by-products represent a cheap, renewable and abundant raw material, useful for several new products, including biochemicals, biomaterials and, above all, biogas, which are taking on an increasing role [54].

The potential for biomethane production through anaerobic digestion depends not only on the availability of resources in the territory considered, but also on their physicochemical characteristics [55].

Most biomethane production is obtained through the anaerobic digestion process, which is an important tool for sustainable energy production [44]. It can be used with different organic waste and is a promising technique to increase the production of clean energy (bioenergy), thus reducing stress on the environment [15,56,57].

Another technique that can also be used is the gasification of biomass, which generates a gas mixture (synthesis gas) that constitutes a rich source of carbon and energy for the production of second-generation renewable fuels, such as biomethane [58]. A new approach for the production of CH4 with high yield and biomass selectivity using a pressurized fixed two-stage bed reactor system incorporating hydropyrolysis and gas-phase hydrotreatment is also considered [51].

Still in the context of biomethane production, some research has evaluated a green route for biomethane and green hydrogen production by integrating pressure swing adsorption with steam methane reforming using low-grade biogas mixture as feedstock [14] and the performance of a custom optical feedback cavity enhancing absorption spectroscopy (OFCEAS) instrument for determining the composition of energetic gases [59]. A proposal for the simultaneous decarburization, desulfurization and dehydration of biogas with deep eutectic solvent (DES) based on quaternary ammonium salt was also developed [59].

2. Bibliometric Search Analysis

2.1. Bibliometric Database Training

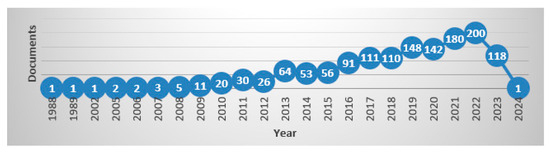

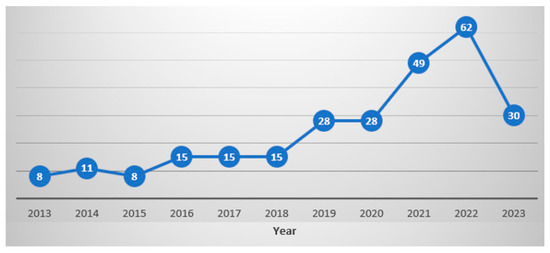

The analysis of blends of renewable natural gas and biomethane is a promising approach to improve the quality of fuels used in different sectors such as transport, industry and power generation. Considering that blends of these renewable gases with natural gas, which are currently widely used in industrial processes and generally in many other activities, may be present in different proportions, the opportunity arises to adapt their properties to the specific needs of each application. In this sense, continuous advances in production, storage and distribution technologies are essential to realize synergies between renewable gases. To start building a database, it was important to clearly define the scope of the topic. In this case, the research focused on finding studies dealing with technical, production and configuration data relevant to this field. In addition, the prospects in the consumer market for renewable natural gas or biomethane were investigated. The research began with a search for the most important keywords on the Scopus platform. A bibliometric analysis was carried out in the Scopus database, searching for the keywords “renewable natural gas” or “biomethane” in the titles and articles. Initially, 1376 references were found that contained the selected keywords. However, the search gave articles published since 1988 (Figure 1). Considering that the main objective is to show current scenarios, new filters were applied to improve and select articles according to the expected perspectives. We first included the words “mixture|” or “blend” in the search to select articles specifically dealing with these topics, as one of the objectives of this research is also the analysis of blends containing renewable natural gas/biomethane, and then the following filters were selected, to obtain a result with a high search relevance selection of the last 10 years of publication, as seen in Figure 2. Then, topics were selected from the subjective area of publication, type of documents, articles or literature reviews, disregarding books or conferences, and finally we restricted to articles published in English.

Figure 1.

Number of publications per year considering the first stage of researched articles, based on data from the Scopus platform, until July 2023 (source: the authors).

Figure 2.

Number of publications per year considering the last 10 years, based on data from the Scopus platform, until July 2023 (source: the authors).

These documents were ordered chronologically according to the most recent year of publication, taking into account the last 10 years, since articles with more than 30 years of publication appeared in this study and the current scenarios are very different, whereupon the articles with the highest number of citations but more recent publications were also taken into account. This information was essential for carrying out several bibliometric analyses. The information contained in these articles was extracted in CSV format (comma-separated values) from the Scopus database. To ensure the quality of this information, records with inconsistent data were removed from the current analysis.

The bibliometric searches were carried out using chains linking topics across the title field of articles published up to July 2023. After applying these filters, 269 articles were selected for a more detailed reading selection and the start of the research, initially considering the most recent and most cited for conducting this bibliometric analysis.

2.2. Results

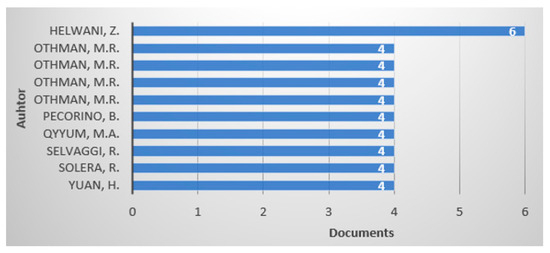

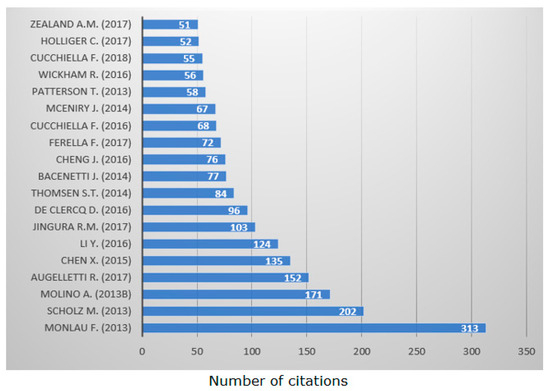

From here onwards, the entire discussion of bibliometric analysis is based on the 269 selected articles. The number of articles published by the authors were analysed, and the 10 authors with the highest number of publications were selected. These are shown in Figure 3. Then, an analysis was carried out containing the highest number of citations of the authors with the highest number of publications (Figure 4). This article argues that the relevance of a publication is associated with the timeliness of the publications and the significant numbers of citations it receives. Therefore, the year of publication and number of citations were used as an important weighted indicator of relevance.

Figure 3.

Number of documents published by author based on the selection of articles carried out in the Scopus database. Source: the authors.

Figure 4.

Number of citations per author based on the selection of articles carried out in the Scopus database. Source: the authors.

Highly cited publications can be considered as references to provide perspective on a topic or provide a solution to a problem.

According to this analysis, in the last 10 years, the topic with renewable fuels, especially blends between natural gas and biomethane, has gained considerable attention, as the large number of publications has increased, especially since 2019 (Figure 2).

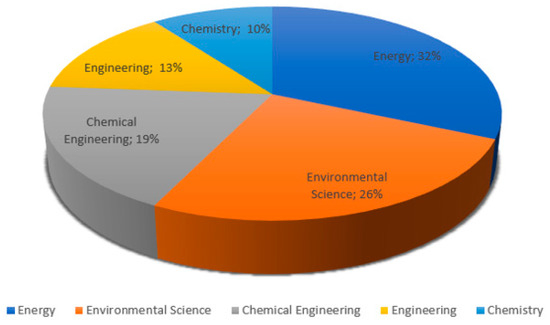

It is also important to highlight the thematic areas of Energy, Chemistry, Environmental Sciences, Engineering and Chemical Engineering, which are areas that are directly correlated to the development of techniques that allow the use of renewable gases or biomethane in industrial processes, or even areas that are linked to sustainable development, as shown in Figure 5.

Figure 5.

Distribution of scientific publications by thematic area, based on the selection of articles carried out in the Scopus database. Source: the authors.

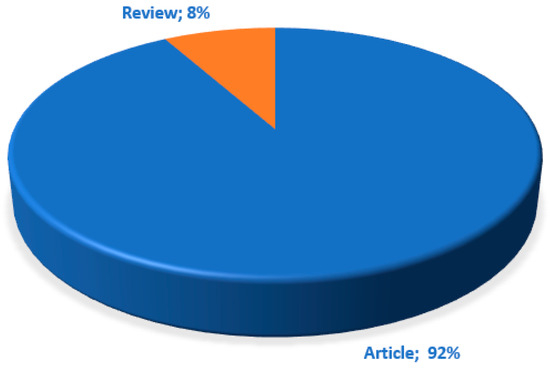

One of the selection topics was determined by the type of publication, with only works published in an article format and in a review format being selected, considering the last 10 years of research on the topic. The majority of works were published in article form, representing a total of 92% of the results presented by the Scopus platform, and only 8% were reviews, as shown in Figure 6.

Figure 6.

Distribution of scientific publications by thematic area, based on the selection of articles published in the Scopus database. Last 10 years. Source: the authors.

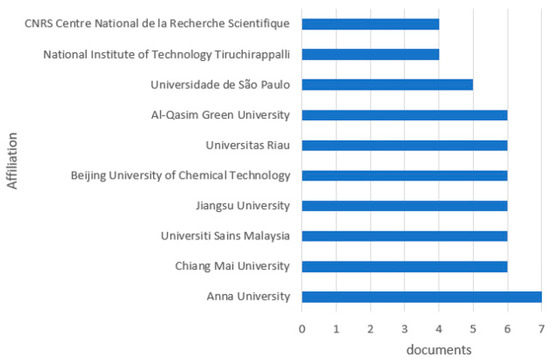

In terms of circulation, these articles can be found in more than 140 different journals. However, 19% of the published articles are found in 10 of these journals, with the journal of Anna University of India being the one that published the most articles in the 10-year period, with 7 articles. The journals Chiang Mai University, from Thailand, Universiti Sains Malaysia, from Malaysia, Jiangsu University and Beijing University of Chemical Technology, both from China, Universitas Riau, from Indonesia and Al-Qasim Green University, from Iraq, appear in succession with 6 publications each, as shown in Figure 7; the other journals contain between 5 and 4 publications.

Figure 7.

Number of publications by periodicals with more than 4 publications, based on the selection of articles carried out in the Scopus database. Period considered 2013–2023. Source: the authors.

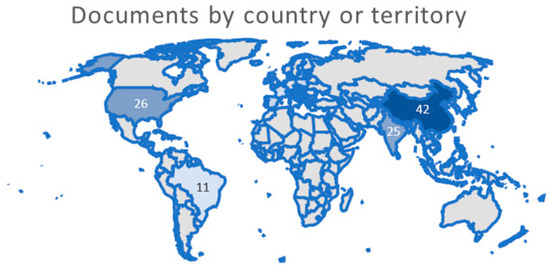

These results demonstrate that on all continents, there is broad interest in research on renewable natural gas/biomethane, and this research is being published in large university centers. The largest numbers of publications are concentrated in China, India, the United States and Brazil, as seen in Figure 8, which facilitates access to a reasonable number of researchers, and there is still a lot to be researched in this area, since mixtures containing this type of fuel can be applied in many commercial, industrial and domestic sectors.

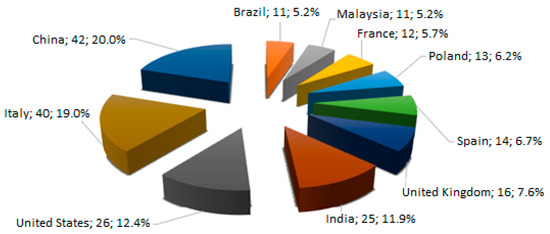

Figure 8.

Number of publications by countries based on the selection of articles carried out in the Scopus database. Period considered 2013–2023. Source: the authors.

The countries that feature the most publications on the topic are China first with 16%, followed by Italy with 15%, the United States with 10%, India with 9% and finally Brazil with 4%, as shown in Figure 9. These five countries represent 54% of the publications on the selected topic.

Figure 9.

Percentage of publications by countries based on the selection of articles carried out in the Scopus database. Period considered 2013–2023. Source: the authors.

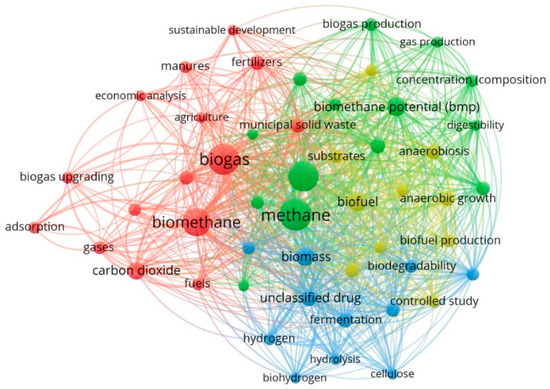

A network graph containing the main highlights of keywords was constructed to identify trends in the use of biomethane and to understand the relationship between the techniques developed for gas mixtures using fuels produced from renewable sources. To build this map, as seen in Figure 10, a dictionary of keywords extracted from articles in the Scopus database was applied, and the pre-treatment of these data was carried out so that there were no repetitions of keywords with the same meaning (for example: gas and gases, fuel and fuels) which were written in slightly different ways.

Figure 10.

Co-occurrence network of keywords (minimum of five occurrences), parents based on the selection of articles carried out in the Scopus database (www.scopus.com) and VOSviewer (version 1.6.18) as bibliometric mapping software. Period considered 2013–2023. Source: the authors.

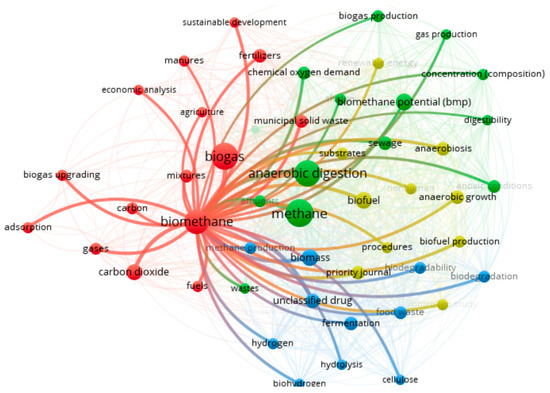

After the necessary executions of this pre-treatment, four main keyword network clusters were created: red, green, blue and yellow. As expected, biogas, biomethane, methane, biofuels, biofuel production, biogas production and carbon dioxide are the keywords that are most prominent, as shown in Figure 11. The four clusters substantially present the highlighted keywords of this study. The focus of the research is that biomethane is interconnected with the other clusters, interacting mainly with the production of biofuels, biomass, biogas production, biogas, sustainable development, fuels and carbon dioxide, among others.

Figure 11.

Details of the keyword co-occurrence network (minimum of five occurrences) showing the links between the keyword biomethane and the other clusters, information based on the selection of articles carried out in the Scopus database and VOSviewer as bibliometric mapping software. Period considered 2013–2023. Source: the authors.

3. Biomethane in Brazil

3.1. Overview

Brazil has historical concerns with renewable energy sources, mainly because it is the largest tropical country in the world, receiving intense solar radiation, which is the basis for biomass production [60].

Several technologies have been disseminated to digest organic waste, capture biogas and provide energy. Despite numerous efforts to finance biogas technology in Brazil, uptake remains slow. This may be due to the low recognition among key actors supporting technology with resources in a broader innovation system [61].

The Brazilian Association of Biogas and Biomethane (ABiogás) reports a biogas production potential of 41.4 billion m3 per year in the sugar-energy sector. However, less than 2% of this value is a success, reducing the fact that biogas is still chemically, economically and politically invisible [62].

Biogas production in Brazil provides three main categories of substrates, as described in Table 1 [63].

Table 1.

Three main categories of substrates for biogas production in Brazil [63].

In Brazil, biogas is used mainly in three ways: in the generation of thermal energy, in the production of electrical energy and in the production of biomethane [64].

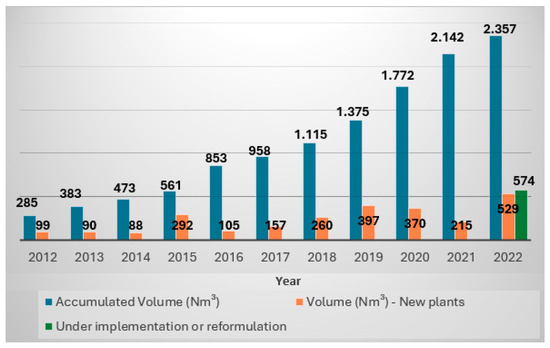

Although biogas technologies in Brazil have enormous potential and a long history, few studies have examined biogas in Brazil as a technological field [64], even though it contains a thriving agricultural sector and has high potential for using agricultural waste in the production of biogas and, consequently, high potential for energy generation, as indicated by data from the Biogas Panorama in Brazil Ciobiogas, as seen in Figure 12.

Figure 12.

Accumulated volume; biogas (Nm3) [63].

Agricultural, animal, industrial and food waste are excellent substrates used for the production of clean and sustainable energy in a circular economy context [64].

Of the volume of biogas produced in these units, the sanitation sector was responsible for 74% of the total volume produced, followed by the industrial (16%) and agricultural (10%) sectors.

Due to relatively low investment, operating costs and technical requirements, landfills are still a more widespread alternative for the final provision of municipal solid waste. The biogas produced in the landfill, a renewable energy source, can be an important alternative for generating electricity. Brazil has a significant number of landfills in operation, which receive most of the MSW collected. However, the country has only 17 landfill biogas power plants [65].

In terms of the volume of biogas for energy purposes, the increase in annual production was very representative, with an increase of 22% compared to the previous year, going from 2.3 billion cubic meters in 2021 to 2.8 billion Nm3 in 2022. The growth rate of biogas production in plants in operation from 2022 was higher than the average recorded in the previous three years (average growth of 17% per year) [65].

Research evaluated the performance of a custom Optical Feedback Cavity Enhancing Absorption Spectroscopy (OFCEAS) instrument for determining the composition of energetic gases [66].

A work was prepared with a proposal for the simultaneous decarburization, desulfurization and dehydration of biogas with a deep eutectic solvent (DES) based on quaternary ammonium salt [59].

Biomethane specifications in Brazil are regulated by the following resolutions [67,68]:

- ANP Resolution No. 886/2022—Establishes the specification and rules for approving the quality control of biomethane from landfills and sewage treatment plants intended for vehicular use and residential, industrial and commercial installations, to be sold in national territory.

- ANP Resolution No. 906/2022—Provides for the specifications of biomethane from agroforestry and commercial organic products and waste intended for vehicular use and residential and commercial installations to be sold throughout the national territory.

3.2. Economic Aspects

In mid-2023, the price of biomethane in Brazil was USD 0.774/m3 (m3 at 1 atm and 20 °C). At the same time, the price of natural gas for consumers using more than 2 million m3/month was USD 0.708/m3. The average lower heating values (LHV) of Brazilian biomethane and natural gas are 34.25 and 39.66 MJ/Nm3, respectively.

Biomethane is supplied by trucks with a capacity of 10,000 m3/day, which would replace 8636 m3/day of natural gas (8636 = 34.25/39.66 × 10,000). At a cost of USD 7740/day compared to USD 6114/day, this leads to a cost increase of USD 1626/day per 10,000 m3/day of biomethane.

This cost increase is not mitigated by carbon credits, because in Brazil these credits belong to the landfill that supplies the biogas for upgrading.

Biomethane is therefore currently more expensive for consumers than natural gas. However, this scenario could change over the years, as the price of natural gas, a fossil fuel with no unlimited reserves, is expected to rise. If carbon credits are allowed for end users, the carbon credits can also be used to reduce the cost of biomethane.

4. Conclusions

This article presents a bibliometric study on the various facets of renewable natural gas (biomethane). An overview of the use of biomethane in Brazil was also given, along with a brief analysis of the costs compared to natural gas, in figures from 2023.

The idea was to create a guide for authors interested in compiling the main publications in this area. The main points discussed in the bibliometric study were the following:

- Number of publications per year considering the first level of articles researched;

- The increase in the number of publications per year over the last 10 years;

- Number of documents published per author;

- Number of citations per author;

- Distribution of scientific publications by subject area;

- Number of publications by journal with more than four publications;

- Number of publications by country;

- Percentage of publications by country;

- Co-occurrence network of keywords (at least five occurrences);

- Details of the network of keywords (at least five occurrences) showing the links between the keyword biomethane and the other clusters.

Finally, an overview of the situation of biomethane in Brazil was given. The cost of the renewable fuel is not offset by carbon credits in Brazil, as these credits are linked to the landfill that supplies the biogas for upgrading. Biomethane is currently more expensive for consumers than natural gas. However, this situation could change in the coming years as the price of natural gas—a finite fossil fuel resource—is expected to rise. Should end users be allowed to utilize carbon credits, these credits could potentially help to reduce the costs associated with biomethane.

Author Contributions

Conceptualization, M.V.d.S.M., I.Á. and J.A.d.C.J.; Methodology, M.V.d.S.M. and I.Á.; Validation, M.V.d.S.M., I.Á. and J.A.d.C.J.; Investigation, M.V.d.S.M.; Writing—original draft preparation, M.V.d.S.M., I.Á. and J.A.d.C.J.; Writing—review and editing, M.V.d.S.M., I.Á. and J.A.d.C.J. Supervision, I.Á. and J.A.d.C.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors thank ANP for the scholarship received by M.V.S.M. through the PRH 34.1 institutional project.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Faisal, S.; Ebaid, R.; Li, L.; Zhao, F.; Wang, Q.; Huang, J.; Abomohra, A. Enhanced waste hot-pot oil (WHPO) anaerobic digestion for biomethane production: Mechanism and dynamics of fatty acids conversion. Chemosphere 2022, 307, 135955. [Google Scholar] [CrossRef] [PubMed]

- Nandala, S.P.; Tallam, A.; Choudhary, N.R.; Sundergopal, S.; Bhargava, S.K. Design and optimization of multilayer composite membrane for biomethane enrichment: Process simulations and economics. Sep. Purif. Technol. 2023, 319, 124073. [Google Scholar] [CrossRef]

- Abdul Hameed, N.; Kurien, C.; Kaipakam Jaychandra, R.; Mittal, M. Effect of biomethane substitution on combustion noise and performance of a dual fuel common rail direct injection diesel engine. Environ. Prog Sustain. Energy 2022, 41, e13915. [Google Scholar] [CrossRef]

- Memetova, A.; Tyagi, I.; Karri, R.R.; Kumar, V.; Tyagi, K.; Suhas; Memetov, N.; Zelenin, A.; Pasko, T.; Gerasimova, A.; et al. Porous carbon-based material as a sustainable alternative for the storage of natural gas (methane) and biogas (biomethane): A review. Chem. Eng. J. 2022, 446, 137373. [Google Scholar] [CrossRef]

- Daldrup-Link, H.E. Writing a review article—Are you making these mistakes? Nanotheranostics 2018, 2, 197–200. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Maiyalagan, T.; Wang, X. Review on Recent Progress in Nitrogen-Doped Graphene: Synthesis, Characterization, and Its Potential Applications. ACS Catal. 2012, 2, 781–794. [Google Scholar] [CrossRef]

- dos Santos, V.A.; da Silva, P.P.; Serrano, L.M.V. The Maritime Sector and Its Problematic Decarbonization: A Systematic Review of the Contribution of Alternative Fuels. Energies 2022, 15, 3571. [Google Scholar] [CrossRef]

- Nazari, M.T.; Mazutti, J.; Basso, L.G.; Colla, L.M.; Brandli, L. Biofuels and their connections with the sustainable development goals: A bibliometric and systematic review. Environ. Dev. Sustain. 2021, 23, 11139–11156. [Google Scholar] [CrossRef]

- Lecharlier, A.; Carrier, H.; Bouyssiere, B.; Caumette, G.; Chiquet, P.; Le Hécho, I. Novel field-portable high-pressure adsorbent tube sampler prototype for the direct in situ preconcentration of trace compounds in gases at their working pressures: Application to biomethane. RSC Adv. 2022, 12, 10071–10087. [Google Scholar] [CrossRef]

- Khan, J.; Saif-Ul-Allah, M.W.; Qyyum, M.A.; Ahmed, F.; Yasin, M.; Hussain, A.; Gillani, Z.; Bazmi, A.A. Reduction in Specific Energy Consumption of Overall Biogas Upgrading and Biomethane Liquefaction Process: Energy and Exergy Analysis. Energy Convers. Manag. 2022, 271, 116269. [Google Scholar] [CrossRef]

- Lecharlier, A.; Carrier, H.; Le Hécho, I. Characterization of biogas and biomethane trace compounds: A critical review of advances in in situ sampling and preconcentration techniques. Anal. Chim. Acta 2022, 1229, 340174. [Google Scholar] [CrossRef] [PubMed]

- Sarafraz, M.; Christo, F.; Safaei, M.R. Potential of plasmonic microreactor for Photothermal hydrogen-enriched fuel production from biomethane. Int. J. Hydrogen Energy 2022, 47, 26355–26368. [Google Scholar] [CrossRef]

- Ibrahim, T.H.; Oyedele, J.O.; Betiku, E.; Solomon, B.O.; Dahunsi, S.O.; Gidado, R.S. Biomethane potential and physicochemical characterization of cassava vinasse from ethanol distillery. Curr. Res. Green Sustain. Chem. 2022, 5, 100338. [Google Scholar] [CrossRef]

- Abd, A.A.; Othman, M.R.; Majdi, H.S.; Helwani, Z. Green route for biomethane and hydrogen production via integration of biogas upgrading using pressure swing adsorption and steam-methane reforming process. Renew. Energy 2023, 210, 64–78. [Google Scholar] [CrossRef]

- Noor, R.S.; Ahmed, A.; Abbas, I.; Hussain, F.; Umair, M.; Noor, R.; Sun, Y. Enhanced biomethane production by 2-stage anaerobic co-digestion of animal manure with pretreated organic waste. Biomass Convers. Biorefin. 2021, 13, 2833–2847. [Google Scholar] [CrossRef]

- Agrawal, A.V.; Chaudhari, P.K.; Ghosh, P. Effect of mixing ratio on biomethane potential of anaerobic co-digestion of fruit and vegetable waste and food waste. Biomass Convers. Biorefin. 2023. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane recovery from olive mill residues through anaerobic digestion: A review of the state of the art technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Dhull, P.; Lohchab, R.K.; Kumar, S.; Kumari, M.; Shaloo; Bhankhar, A.K. Anaerobic Digestion: Advance Techniques for Enhanced Biomethane/Biogas Production as a Source of Renewable Energy. BioEnergy Res. 2023, 17, 1228–1249. [Google Scholar] [CrossRef]

- Piechota, G. Multi-step biogas quality improving by Adsorptive Packed Column System as application to biomethane upgrading. J. Environ. Chem. Eng. 2021, 9, 105944. [Google Scholar] [CrossRef]

- Devi, M.K.; Manikandan, S.; Kumar, P.S.; Yaashikaa, P.; Oviyapriya, M.; Rangasamy, G. A comprehensive review on current trends and development of biomethane production from food waste: Circular economy and techno economic analysis. Fuel 2023, 351, 128963. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, M.; Xu, D.; Wang, X.; Gutierrez, J.; Sosa, S.; Tsotsis, T. Pollutant Formation during Utilization of Renewable Natural Gas Containing Trace Ammonia Impurities. Ind. Eng. Chem. Res. 2020, 59, 19177–19184. [Google Scholar] [CrossRef]

- Pan, C.; Lu, F.; Zhu, H.; Pan, F.; Sun, J. Thermo-economic analysis of combined transcritical CO2 power cycle based on a novel liquefied-biomethane energy storage system. Appl. Therm. Eng. 2023, 222, 119922. [Google Scholar] [CrossRef]

- de Carvalho, F.S.; Reis, L.C.B.d.S.; Lacava, P.T.; de Araújo, F.H.M.; Carvalho, J.A.d.C., Jr. Substitution of Natural Gas by Biomethane: Operational Aspects in Industrial Equipment. Energies 2023, 16, 839. [Google Scholar] [CrossRef]

- Dey, A.; Thomson, R.C. India’s biomethane generation potential from wastes and the corresponding greenhouse gas emissions abatement possibilities under three end use scenarios: Electricity generation, cooking, and road transport applications. Sustain. Energy Fuels 2022, 7, 209–241. [Google Scholar] [CrossRef]

- Cavana, M.; Leone, P. Smart Gas Network with Linepack Managing to Increase Biomethane Injection at the Distribution Level. Energies 2022, 15, 8198. [Google Scholar] [CrossRef]

- IEA World Energy Balances Database. Database Documentation. July 2023. Available online: https://www.iea.org/data-and-statistics/data-product/world-energy-balances (accessed on 8 November 2023).

- Okolie, J.A.; Tabat, M.E.; Gunes, B.; Epelle, E.I.; Mukherjee, A.; Nanda, S.; Dalai, A.K. A techno-economic assessment of biomethane and bioethanol production from crude glycerol through integrated hydrothermal gasification, syngas fermentation and biomethanation. Energy Convers. Manag. X 2021, 12, 100131. [Google Scholar] [CrossRef]

- D‘Adamo, I.; Falcone, P.M.; Gastaldi, M.; Morone, P. RES-T trajectories and an integrated SWOT-AHP analysis for biomethane. Policy implications to support a green revolution in European transport. Energy Policy 2020, 138, 111220. [Google Scholar] [CrossRef]

- Cachia, M.; Bouyssiere, B.; Carrier, H.; Garraud, H.; Caumette, G.; Le Hécho, I. Characterization and Comparison of Trace Metal Compositions in Natural Gas, Biogas, and Biomethane. Energy Fuels 2018, 32, 6397–6400. [Google Scholar] [CrossRef]

- Bas, M.S.; Aragón, A.J.; Torres, J.C.; Osorio, F. Purification and upgrading biogas from anaerobic digestion using chemical asborption of CO2 with amines in order to produce biomethane as biofuel for vehicles: A pilot-scale study. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 10201–10213. [Google Scholar] [CrossRef]

- Culleton, L.P.; di Meane, E.A.; Ward, M.K.M.; Ferracci, V.; Persijn, S.; Holmqvist, A.; Arrhenius, K.; Murugan, A.; Brewer, P.J. Characterization of Fourier Transform Infrared, Cavity Ring-Down Spectroscopy, and Optical Feedback Cavity-Enhanced Absorption Spectroscopy Instruments for the Analysis of Ammonia in Biogas and Biomethane. Anal. Chem. 2022, 94, 15207–15214. [Google Scholar] [CrossRef]

- Zito, P.F.; Brunetti, A.; Barbieri, G. Renewable biomethane production from biogas upgrading via membrane separation: Experimental analysis and multistep configuration design. Renew. Energy 2022, 200, 777–787. [Google Scholar] [CrossRef]

- Luis, P. Use of monoethanolamine (MEA) for CO2 capture in a global scenario: Consequences and alternatives. Desalination 2015, 380, 93–99. [Google Scholar] [CrossRef]

- Meena, P.K.; Pal, A.; Gautam, S. Investigation of combustion and emission characteristics of an SI engine operated with compressed biomethane gas, and alcohols. Environ. Sci. Pollut. Res. 2022, 31, 10262–10272. [Google Scholar] [CrossRef] [PubMed]

- Aggarangsi, P.; Moran, J.; Koonaphapdeelert, S.; Tippayawong, N. Performance comparison of biomethane, natural gas and gasoline in powering a pickup truck. Biofuels 2022, 13, 957–964. [Google Scholar] [CrossRef]

- Papurello, D.; Silvestri, S.; Biasioli, F.; Lombardi, L. Wood ash biomethane upgrading system: A case study. Renew. Energy 2021, 182, 702–712. [Google Scholar] [CrossRef]

- Golmakani, A.; Nabavi, S.A.; Manovic, V. Production of negative-emission biomethane by twin double-bed pressure swing adsorption with tail gas sequestration. Chem. Eng. J. 2021, 408, 127312. [Google Scholar] [CrossRef]

- Corsino, S.F.; Torregrossa, M.; Viviani, G. Biomethane Production from Anaerobic Co-Digestion of Selected Organic Fraction of Municipal Solid Waste (OFMSW) with Sewage Sludge: Effect of the Inoculum to Substrate Ratio (ISR) and Mixture Composition on Process Performances. Int. J. Environ. Res. Public Health 2021, 18, 13048. [Google Scholar] [CrossRef]

- Jee, J.-G.; Lee, S.-J.; Lee, C.-H. Comparison of the adsorption dynamics of air on zeolite 5A and carbon molecular sieve beds. Korean J. Chem. Eng. 2004, 21, 1183–1192. [Google Scholar] [CrossRef]

- Abd, A.A.; Othman, M.R.; Helwani, Z.; Shabbani, H.J.K. Role of heat dissipation on carbon dioxide capture performance in biomethane upgrading system using pressure swing adsorption. Sep. Purif. Technol. 2022, 280, 119959. [Google Scholar] [CrossRef]

- Prasertsan, P.; Leamdum, C.; Chantong, S.; Mamimin, C.; Kongjan, P.; O-Thong, S. Enhanced biogas production by co-digestion of crude glycerol and ethanol with palm oil mill effluent and microbial community analysis. Biomass Bioenergy 2021, 148, 106037. [Google Scholar] [CrossRef]

- Abd, A.A.; Othman, M.R.; Helwani, Z. Production of ultrapure biomethane from stratified bed in non-adiabatic and non-isothermal plate pressure swing adsorption. Chem. Eng. Res. Des. 2023, 190, 335–352. [Google Scholar] [CrossRef]

- Scapini, T.; Bonatto, C.; Dalastra, C.; Bazoti, S.F.; Camargo, A.F.; Júnior, S.L.A.; Venturin, B.; Steinmetz, R.L.R.; Kunz, A.; Fongaro, G.; et al. Bioethanol and biomethane production from watermelon waste: A circular economy strategy. Biomass Bioenergy 2023, 170, 106719. [Google Scholar] [CrossRef]

- Philipp, M.; Ackermann, H.; Barbana, N.; Pluschke, J.; Geißen, S.U. Possibilities for Anaerobic Digestion of Slaughter Waste and Flotates for Biomethane Production. Water 2023, 15, 1818. [Google Scholar] [CrossRef]

- Agabo-Garcia, C.; Solera, R.; Perez, M. First approaches to valorizate fat, oil and grease (FOG) as anaerobic co-substrate with slaughterhouse wastewater: Biomethane potential, settling capacity and microbial dynamics. Chemosphere 2020, 259, 127474. [Google Scholar] [CrossRef] [PubMed]

- Bianco, F.; Şenol, H.; Papirio, S. Enhanced lignocellulosic component removal and biomethane potential from chestnut shell by a combined hydrothermal–alkaline pretreatment. Sci. Total Environ. 2020, 762, 144178. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.K.; Srichandan, H.; Ojha, S.K.; Pattnaik, R.; Verma, S.K.; Pal, S.; Singh, J.; Mishra, S. Evaluation of biomethane potential of codigested sheep manure and kitchen refuse. Biomass Convers. Biorefin. 2021, 13, 11879–11889. [Google Scholar] [CrossRef]

- Sabarikirishwaran, P.; Shen, M.-Y.; Ramaraj, R.; Unpaprom, Y.; Wu, H.-C.; Chu, C.-Y. Feasibility and optimizing assessments on biogas and biomethane productions from E. coli fermenter effluent. Biomass Bioenergy 2023, 173, 106783. [Google Scholar] [CrossRef]

- Ma, S.; Wang, H.; Li, L.; Gu, X.; Zhu, W. Enhanced biomethane production from corn straw by a novel anaerobic digestion strategy with mechanochemical pretreatment. Renew. Sustain. Energy Rev. 2021, 146, 111099. [Google Scholar] [CrossRef]

- Rashama, C.; Ijoma, G.N.; Matambo, T.S. Elucidating Biodegradation Kinetics and Biomethane Potential Trends in Substrates Containing High Levels of Phytochemicals: The Case of Avocado Oil Processing By-products. Waste Biomass Valorization 2022, 13, 2071–2081. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, J.; Meng, X.; Ragauskas, A.J. Coupling hydropyrolysis and vapor-phase catalytic hydrotreatment to produce biomethane from pine sawdust. Bioresour. Technol. 2023, 386, 129472. [Google Scholar] [CrossRef]

- Ugwu, S.N.; Enweremadu, C.C. Optimization of iron-enhanced anaerobic digestion of agro-wastes for biomethane production and phosphate release. Environ. Technol. 2022, 44, 721–738. [Google Scholar] [CrossRef] [PubMed]

- Dyer, A.; Miller, A.C.; Chandra, B.; Maza, J.G.; Tran, C.; Bates, J.; Olivier, V.; Tuininga, A.R. The Feasibility of Renewable Natural Gas in New Jersey. Sustainability 2021, 13, 1618. [Google Scholar] [CrossRef]

- Selvaggi, R.; Valenti, F.; Pecorino, B.; Porto, S.M.C. Assessment of Tomato Peels Suitable for Producing Biomethane within the Context of Circular Economy: A GIS-Based Model Analysis. Sustainability 2021, 13, 5559. [Google Scholar] [CrossRef]

- Bayard, R.; Liu, X.; Benbelkacem, H.; Buffiere, P.; Gourdon, R. Can Biomethane Potential (BMP) Be Predicted from Other Variables Such as Biochemical Composition in Lignocellulosic Biomass and Related Organic Residues? BioEnergy Res. 2016, 9, 610–623. [Google Scholar] [CrossRef]

- Liczbinski, P.L.; Borowski, S.; Cieciura-Włoch, W. Anaerobic co-digestion of kitchen waste with hyperthermophilically pretreated grass for biohydrogen and biomethane production. Bioresour. Technol. 2022, 364, 128053. [Google Scholar] [CrossRef] [PubMed]

- Antonini, C.; Treyer, K.; Streb, A.; van der Spek, M.; Bauer, C.; Mazzotti, M. Hydrogen production from natural gas and biomethane with carbon capture and storage—A techno-environmental analysis. Sustain. Energy Fuels 2020, 4, 2967–2986. [Google Scholar] [CrossRef]

- Asimakopoulos, K.; Grimalt-Alemany, A.; Lundholm-Høffner, C.; Gavala, H.N.; Skiadas, I.V. Carbon Sequestration through Syngas Biomethanation Coupled with H2 Supply for a Clean Production of Natural Gas Grade Biomethane. Waste Biomass Valorization 2021, 12, 6005–6019. [Google Scholar] [CrossRef]

- Xu, P.; Shang, Z.; Li, G.; Zhang, W.; Chen, Z. Biomethane purification with quaternary ammonium salts-based deep eutectic solvents: Experiment and computational thermodynamics. Sep. Purif. Technol. 2023, 318, 123980. [Google Scholar] [CrossRef]

- Pasqual, J.; Bollmann, H.; Scott, C.; Andersen, S.; Lange, M. Rural and urban transitions with biogas and biomethane in Brazil: A water-energy-food nexus analysis. Renew. Energy Power Qual. J. 2016, 1, 84–89. [Google Scholar] [CrossRef]

- Borges, C.P.; Silberg, T.R.; Uriona-Maldonado, M.; Vaz, C.R. Scaling actors’ perspectives about innovation system functions: Diffusion of biogas in Brazil. Technol. Forecast. Soc. Chang. 2023, 190, 122359. [Google Scholar] [CrossRef]

- Junior, A.D.N.F.; Etchebehere, C.; Perecin, D.; Teixeira, S.; Woods, J. Advancing anaerobic digestion of sugarcane vinasse: Current development, struggles and future trends on production and end-uses of biogas in Brazil. Renew. Sustain. Energy Rev. 2022, 157, 112045. [Google Scholar] [CrossRef]

- Freddo, A.; Vieira, A.C.; Martinez, D.G.; Alves, F. Panorama do Biogás no Brasil 2022. Foz do Iguaçu. January 2023. Available online: https://d335luupugsy2.cloudfront.net/cms%2Ffiles%2F54738%2F1694006188CIBiogs_Panorama_do_Biogs_no_Brasil_2022.pdf (accessed on 8 November 2023).

- De Oliveira, L.G.S.; Negro, S.O. Contextual structures and interaction dynamics in the Brazilian Biogas Innovation System. Renew. Sustain. Energy Rev. 2019, 107, 462–481. [Google Scholar] [CrossRef]

- Lima, R.M.; Santos, A.H.; Pereira, C.R.; Flauzino, B.K.; Pereira, A.C.O.; Nogueira, F.J.; Valverde, J.A.R. Spatially distributed potential of landfill biogas production and electric power generation in Brazil. Waste Manag. 2018, 74, 323–334. [Google Scholar] [CrossRef] [PubMed]

- Arrhenius, K.; Francini, L.; Fischer, A.; Büker, O.; Arques, L.G. Comparison of optical feedback cavity enhanced absorption spectroscopy and gas chromatography for the measurement of the main components and impurities in biogas, landfill gas, biomethane and carbon dioxide streams. Meas. Sci. Technol. 2023, 34, 095011. [Google Scholar] [CrossRef]

- ANP. Biometano; Agência Nacional do Petróleo, Gás Natural e Biocombustíveis: Rio de Janeiro, Brazil, 2020. [Google Scholar]

- ANP. Resolução 886 2022 da ANP; Agência Nacional do Petróleo, Gás Natural e Biocombustíveis: Rio de Janeiro, Brazil, 2022. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).