Geochemical Characteristics of Mature to High-Maturity Shale Resources, Occurrence State of Shale Oil, and Sweet Spot Evaluation in the Qingshankou Formation, Gulong Sag, Songliao Basin

Abstract

1. Introduction

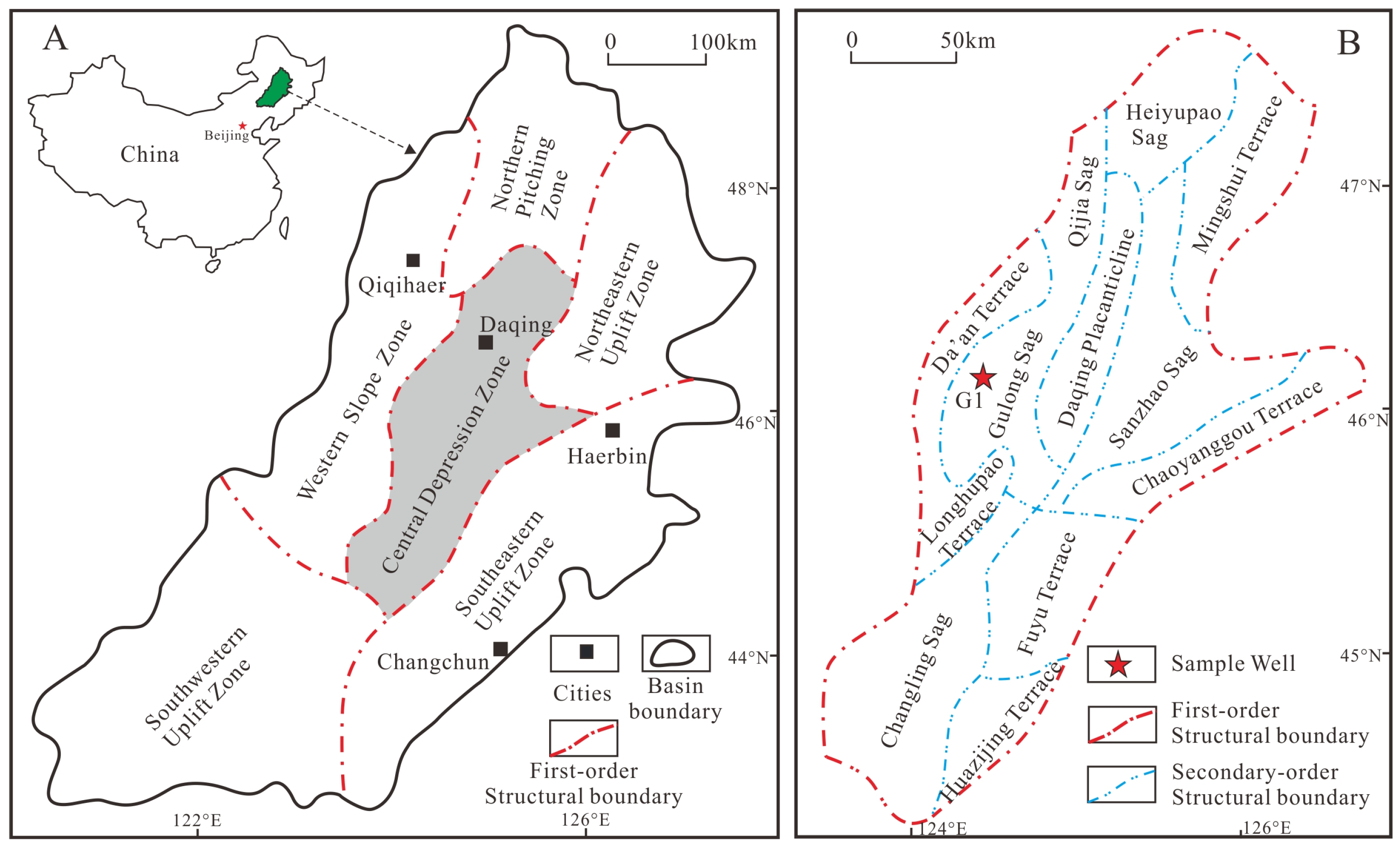

2. Geological Setting

3. Samples and Experiments

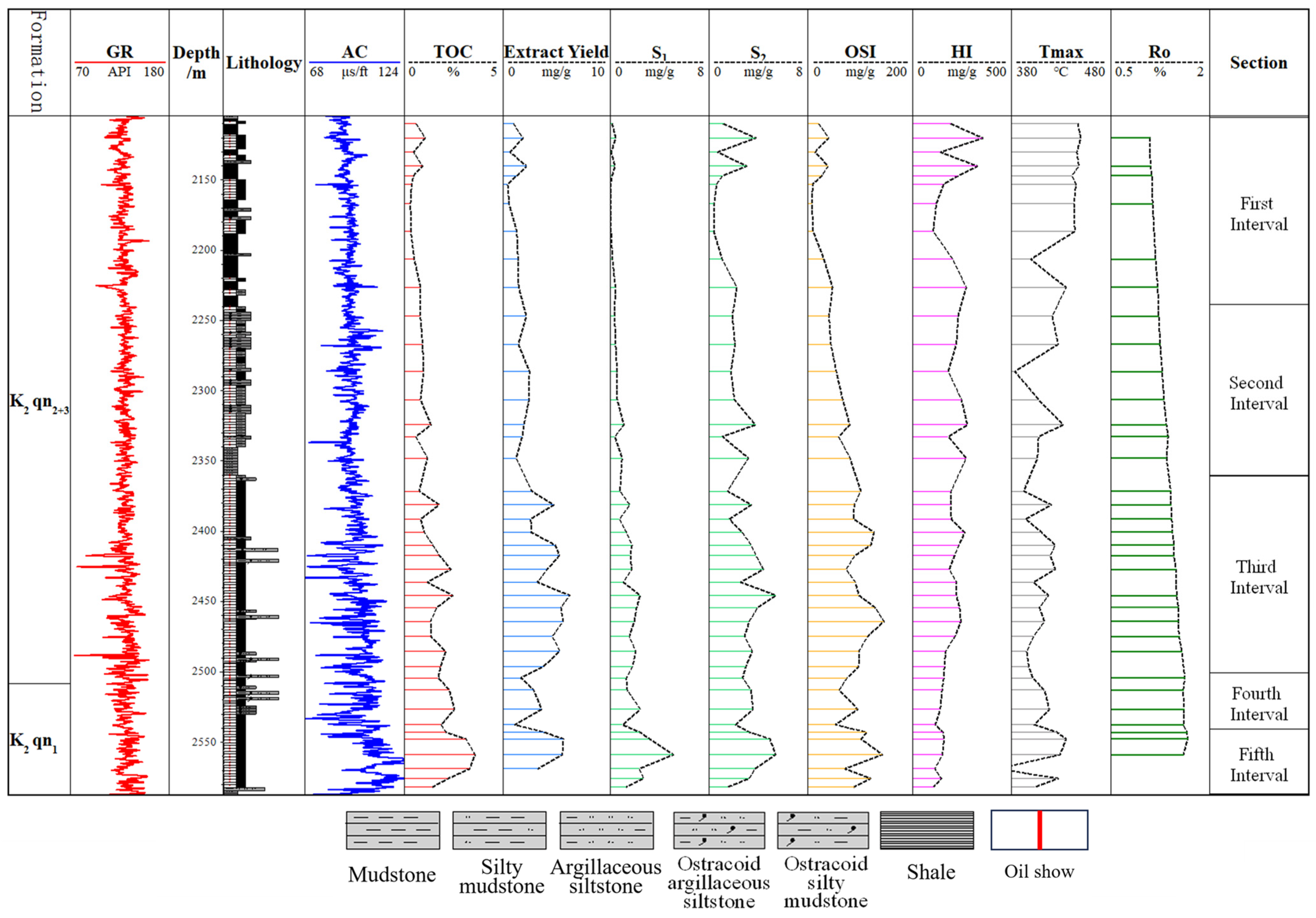

3.1. Sample Collection

3.2. Organic Geochemical Analysis

4. Results

4.1. Abundance of Organic Matter in Source Rocks

4.1.1. TOC

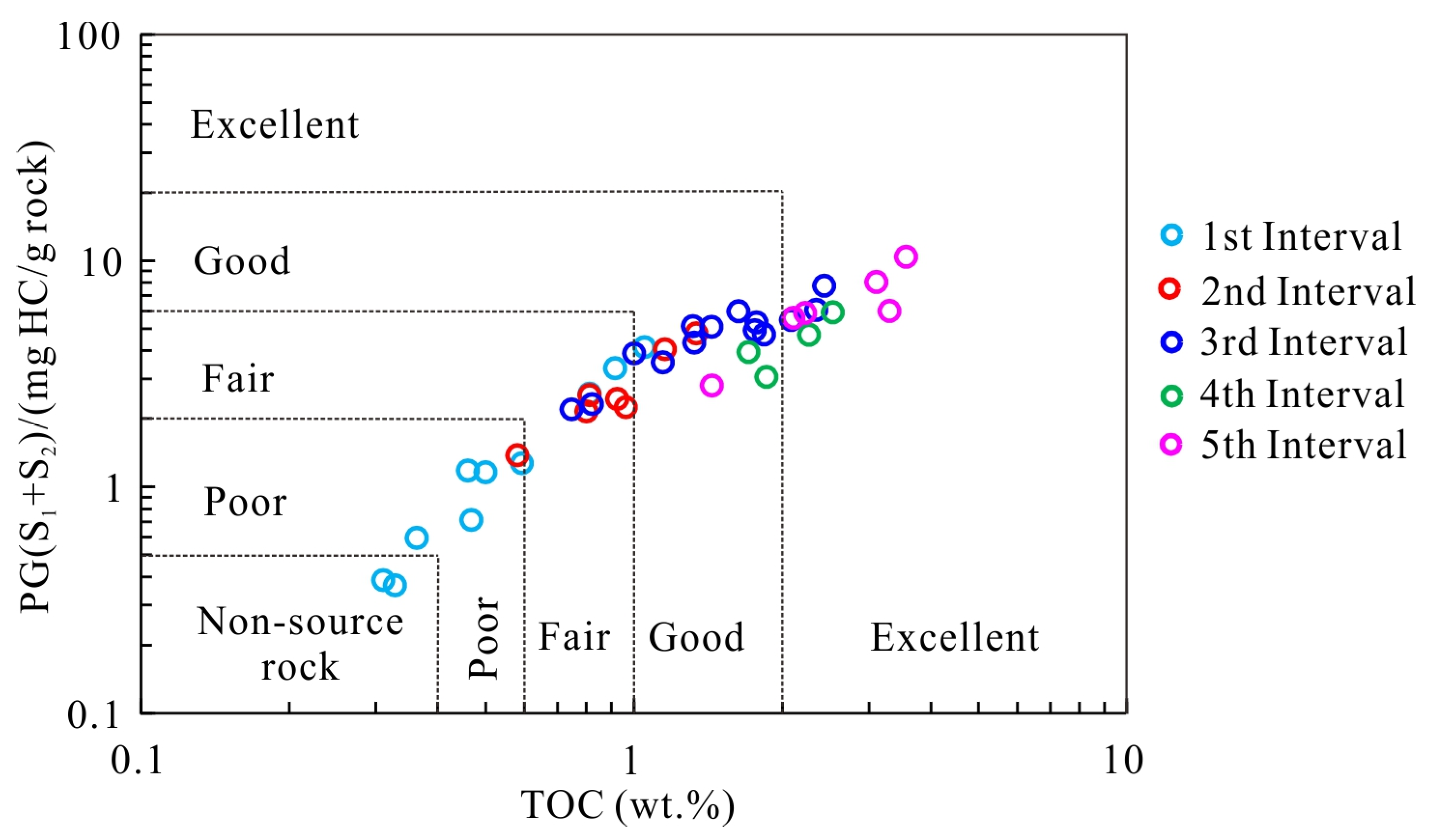

4.1.2. Potential of Generating Hydrocarbon (PG)

4.1.3. Chloroform Asphalt “A”

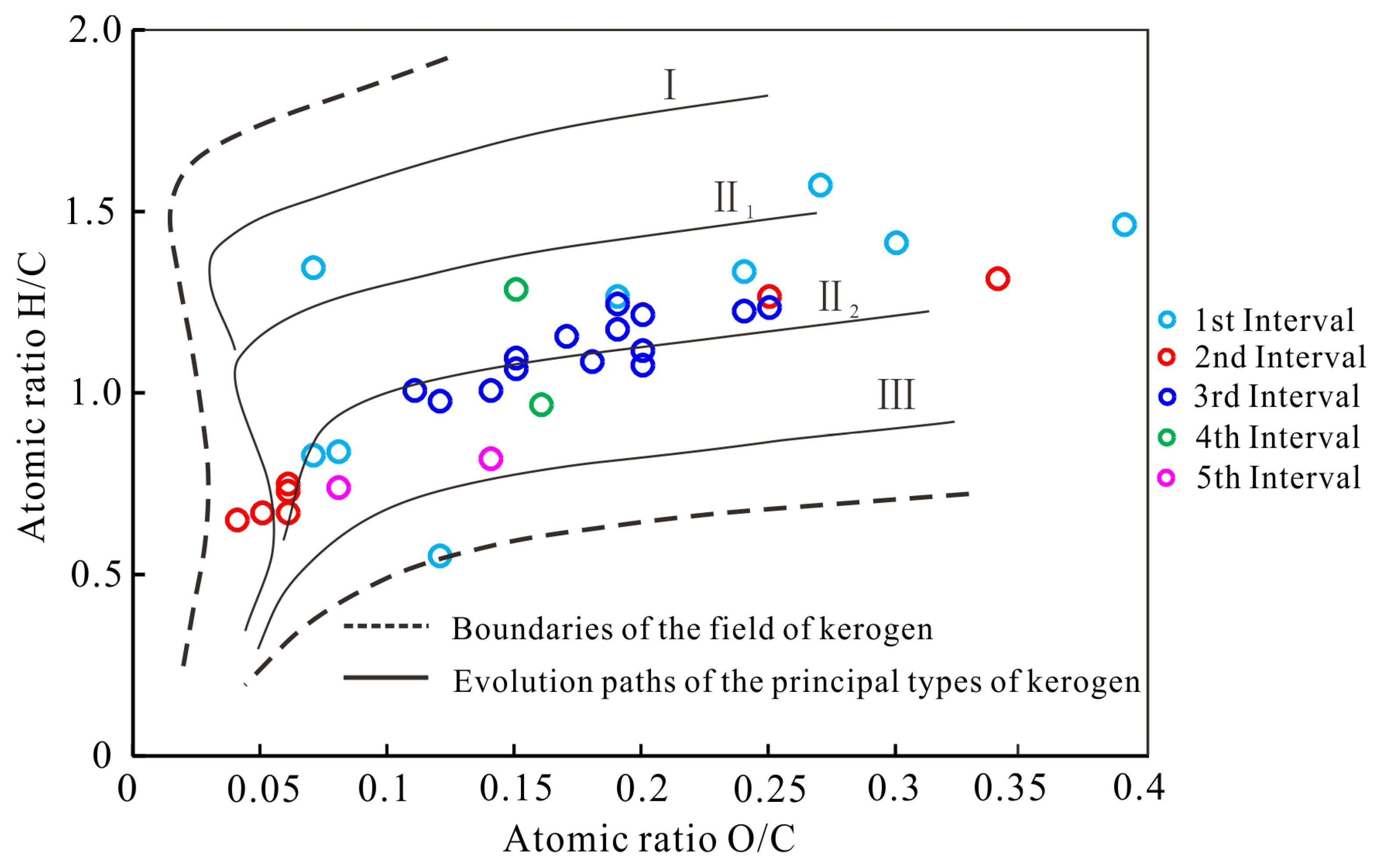

4.2. Types of Organic Matter in Source Rocks

4.2.1. Van Krevelen Diagram

4.2.2. Comparison of TOC and S2

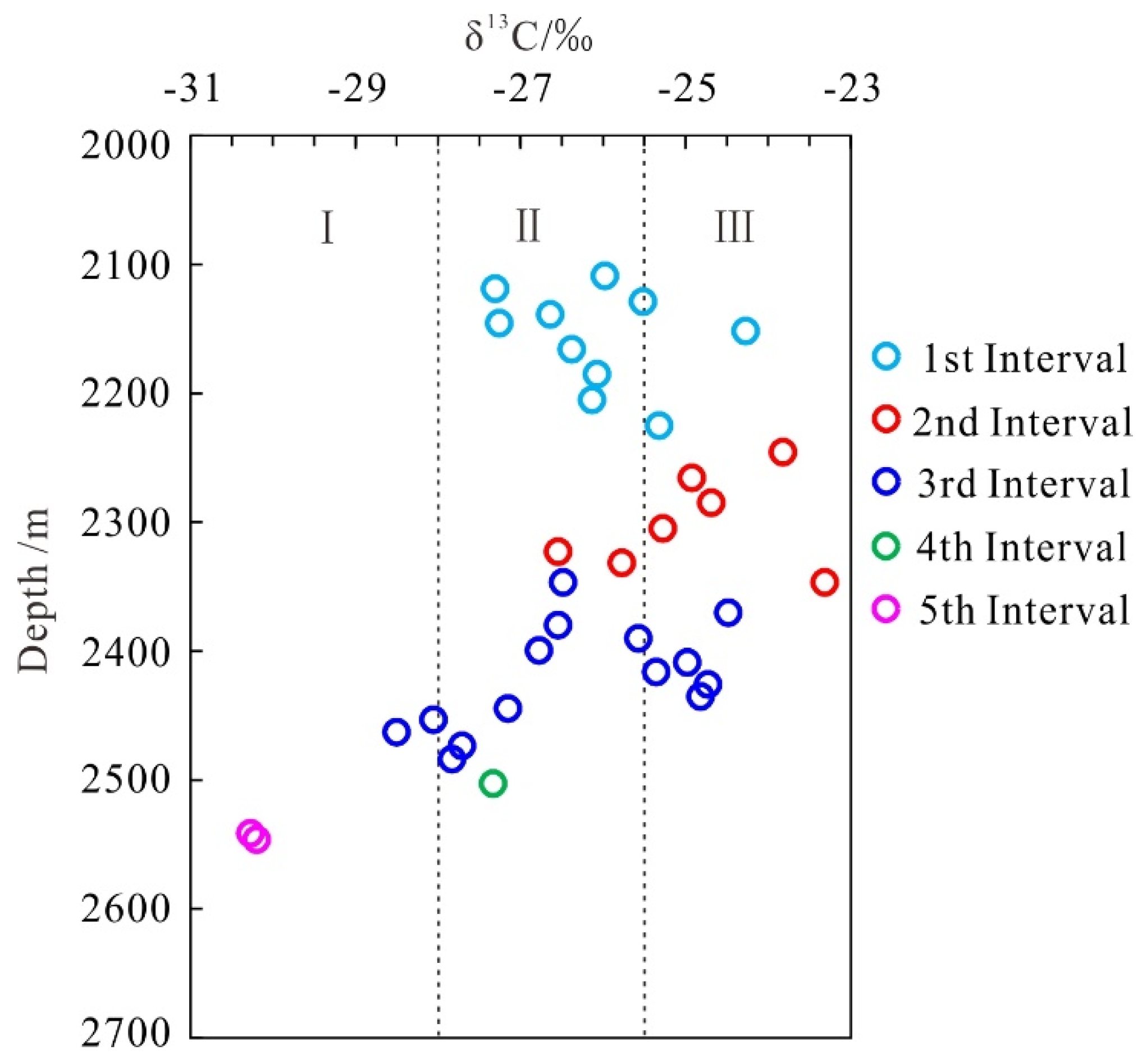

4.2.3. Kerogen Carbon Isotope

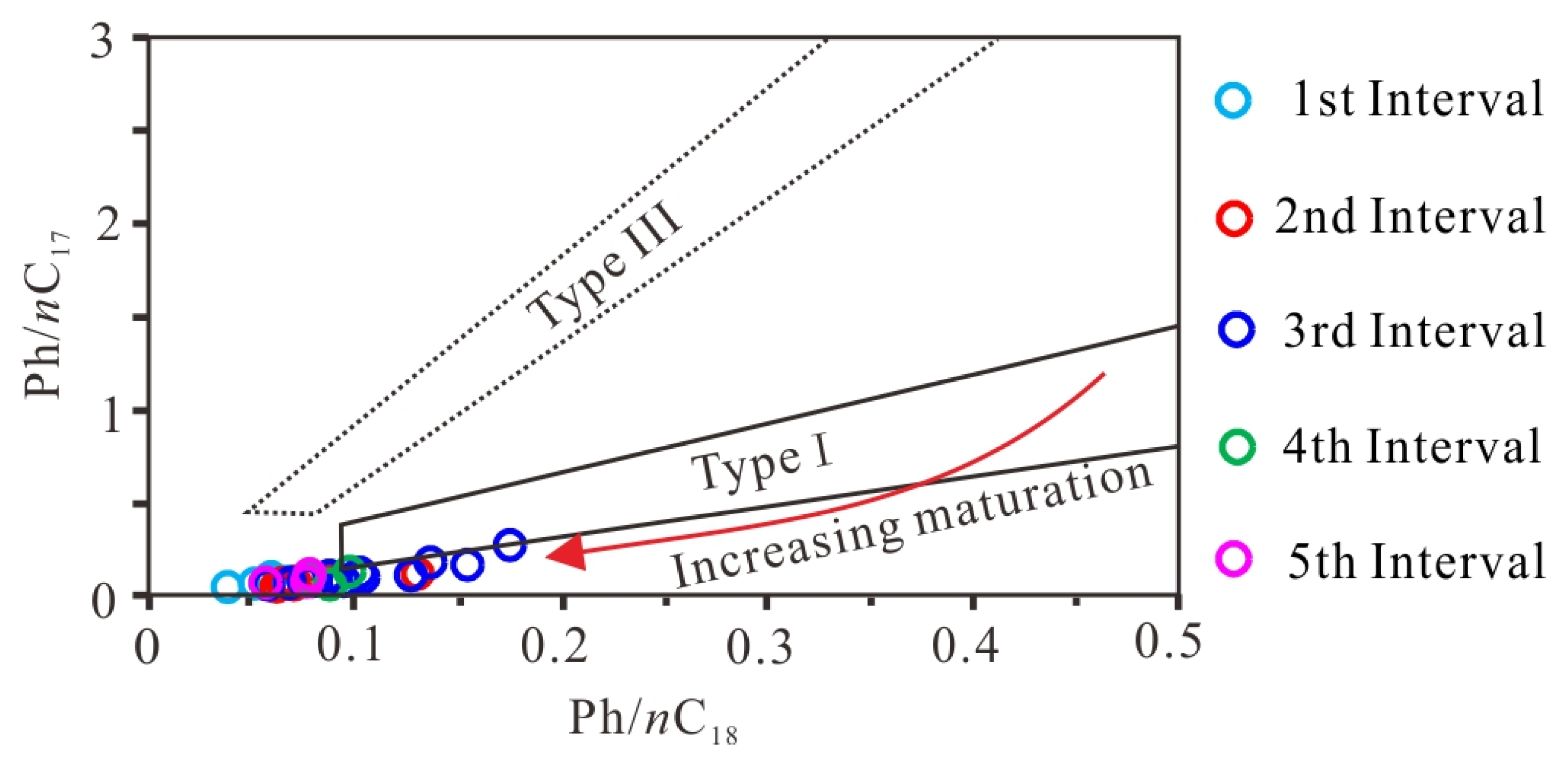

4.2.4. Intersection Diagram of Pr/nC17 and Ph/nC18

4.2.5. Determination of Organic Matter Types

4.3. Maturity of Organic Matter

4.3.1. Vitrinite Reflectance (Ro)

4.3.2. Maximum Pyrolysis Peak Temperature (Tmax)

5. Discussion

5.1. Pyrolytic Light-Hydrocarbon Loss and Heavy Hydrocarbon Correction

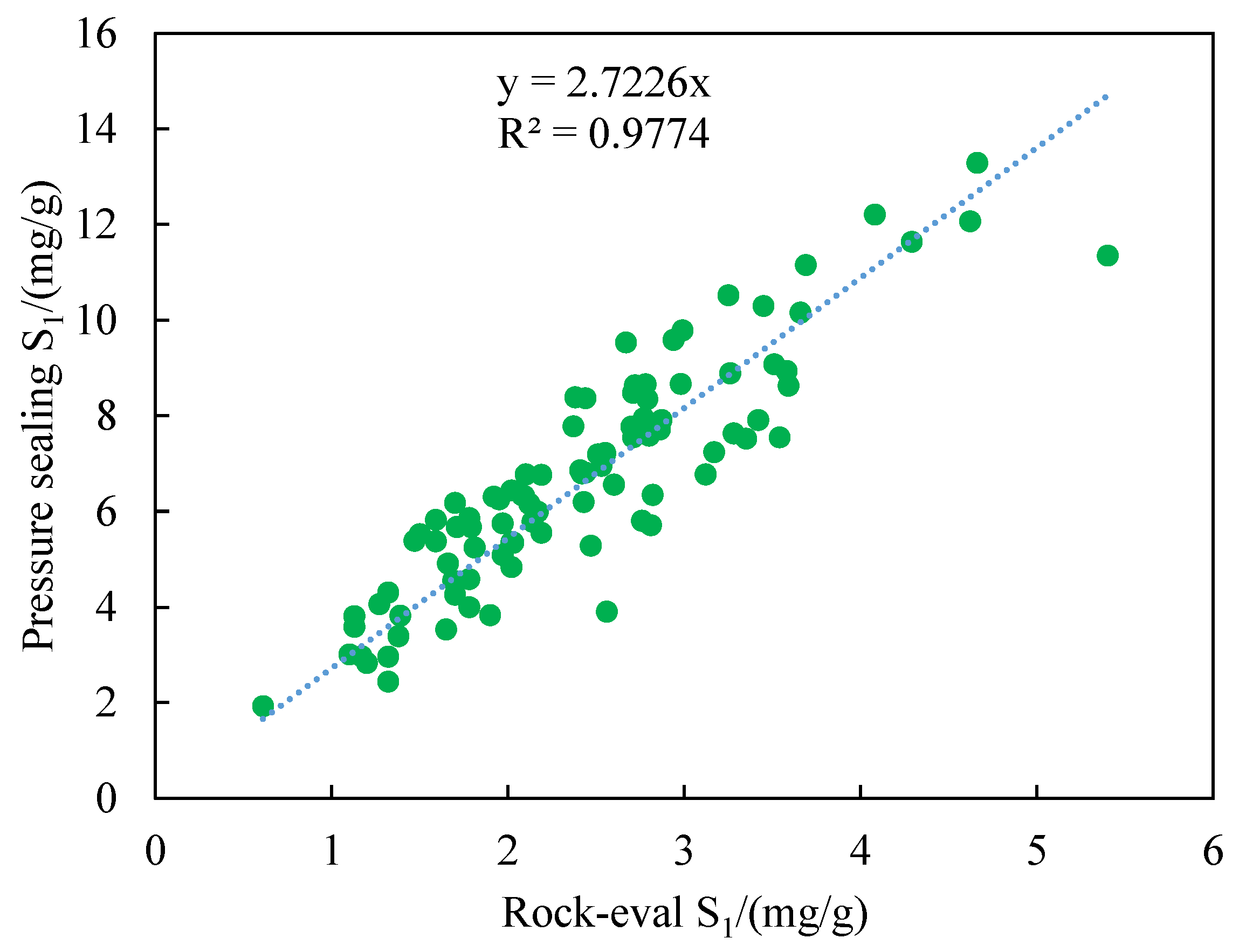

5.1.1. Recovery of Light-Hydrocarbon Loss during Pyrolysis S1

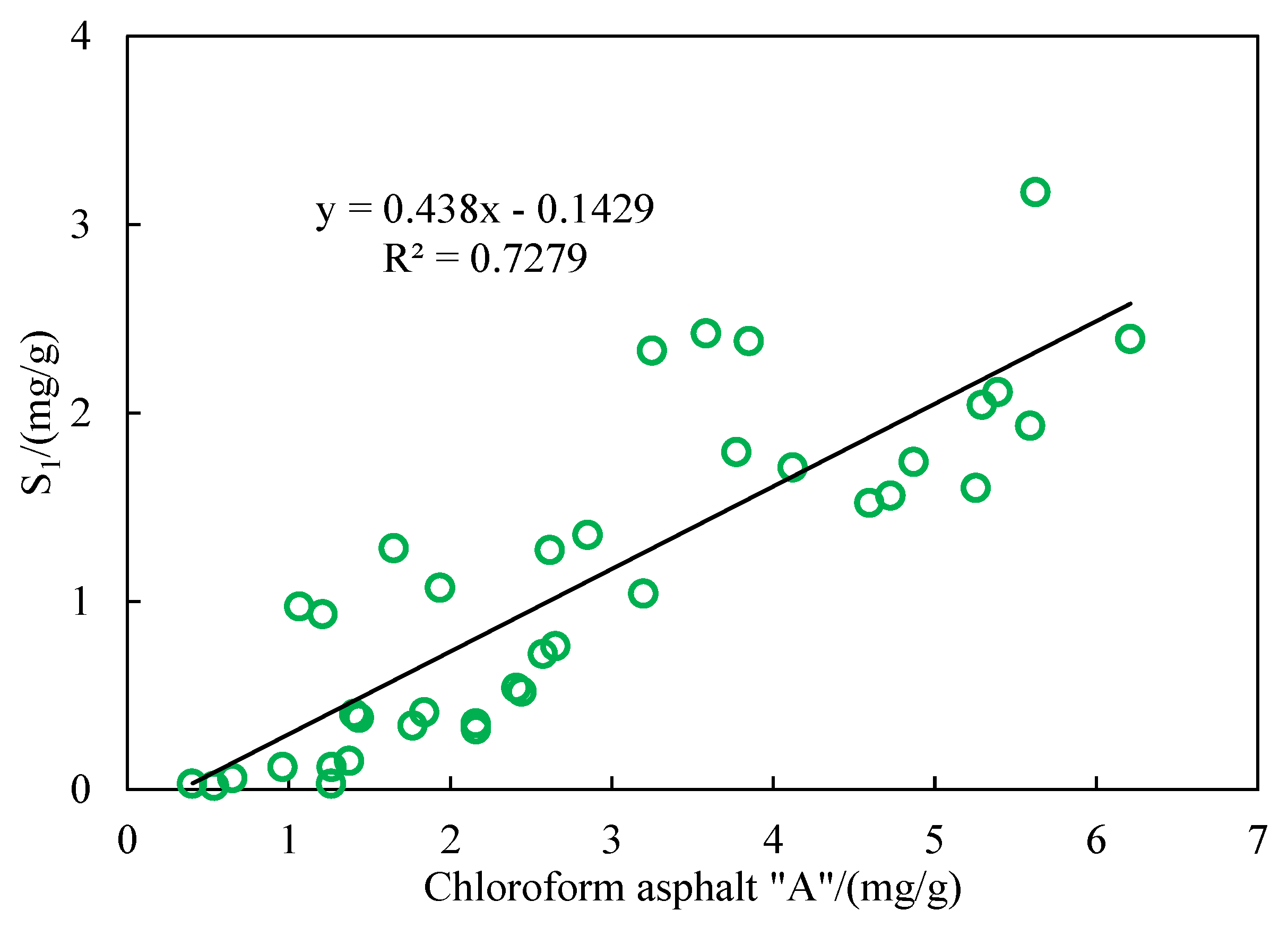

5.1.2. Pyrolysis S1 Heavy Hydrocarbon Correction

5.2. Shale Oil Occurrence and Mobility Evaluation

5.2.1. Adsorbed Oil

5.2.2. Free Oil

5.2.3. Shale Oil Mobility Evaluation

5.3. Shale Oil Desert Section

5.3.1. Shale Oil Desert Evaluation Parameters

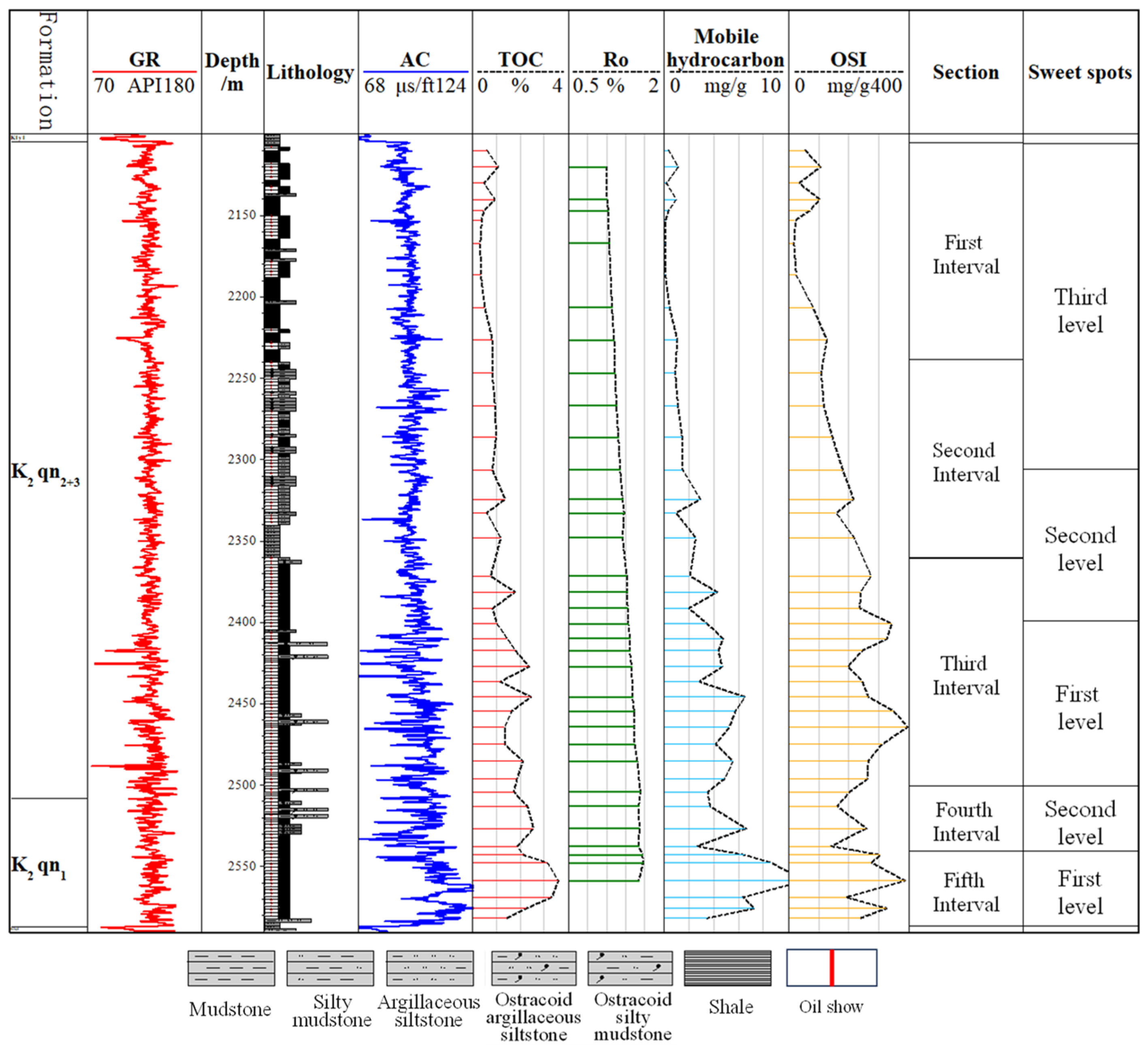

5.3.2. Evaluation of Shale Oil Geological Sweet Spots

6. Conclusions

- The Qingshankou Formation shale in the Gulong Sag, Songliao Basin, is an oil-source rock dominated by type I and type II1 kerogen with high organic matter abundance and has reached the stage of mature to high-maturity evolution.

- The average loss of light hydrocarbons in the Qingshankou Formation is 4.27 mg/g, accounting for 63.27% of the total amount of stranded free hydrocarbons, which is also the main component of mobile hydrocarbons. The mobile hydrocarbon content in intervals 2~5 is higher than the adsorbed hydrocarbon content, the shale oil has the best mobility, and the saturated hydrocarbon content of the extract is between 70% and 80%.

- The Qingshankou Formation can be divided into three resource types—rich, moderately rich, and low-efficiency—with TOC limits of 1% and 2%, OSI limits of 200 mg/g, and mobile hydrocarbon limits of 2 mg/g and 5 mg/g.

- The shale oil enrichment sweet spot of the G1 well is distributed in interval 5 and most of interval 3, while the moderately enriched shale oil is distributed in interval 4 and parts of interval 2 and 3, and the low-efficiency resources are mainly distributed in interval 1 and the upper part of interval 2. This study provides a geological basis for the selection of shale oil sweet spots of the Qingshankou Formation in the Gulong Sag.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Number | Lithology | Section | Depth/m | TOC/% | S1 /(mg/g) | S2 /(mg/g) | PG /(mg/g) | Tmax /°C | PI | HI | S1/TOC × 100 /(mg/g TOC) | Chloroform Bitumen “A”/% | Carbon Isotope of Kerogen/‰ | Ro/% | Standard Deviation | Test Points |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| G1-1 | Black mudstone | First Interval | 2110.01 | 0.60 | 0.12 | 1.16 | 1.28 | 447 | 0.09 | 194.08 | 20.08 | 0.096 | −25.962 | / | ||

| G1-2 | Black mudstone | First Interval | 2120.12 | 1.06 | 0.41 | 3.76 | 4.17 | 450 | 0.10 | 354.72 | 38.68 | 0.184 | −27.288 | 1.09 | 0.06 | 14 |

| G1-3 | Black mudstone | First Interval | 2130.12 | 0.47 | 0.06 | 0.66 | 0.72 | 446 | 0.08 | 139.74 | 12.70 | 0.065 | −25.498 | / | ||

| G1-4 | Black mudstone | First Interval | 2140.12 | 0.92 | 0.35 | 3.02 | 3.37 | 448 | 0.10 | 327.12 | 37.91 | 0.216 | −26.622 | 1.10 | 0.05 | 8 |

| G1-5 | Black mudstone | First Interval | 2146.96 | 0.46 | 0.12 | 1.07 | 1.19 | 441 | 0.10 | 230.31 | 25.83 | 0.127 | −27.238 | 1.12 | 0.05 | 9 |

| G1-6 | Black mudstone | First Interval | 2152.96 | 0.37 | 0.03 | 0.57 | 0.60 | 445 | 0.05 | 155.82 | 8.20 | 0.040 | −24.253 | / | ||

| G1-7 | Black mudstone | First Interval | 2166.96 | 0.31 | 0.02 | 0.37 | 0.39 | 443 | 0.05 | 118.25 | 6.39 | 0.054 | −26.362 | 1.14 | 0.04 | 7 |

| G1-8 | Black mudstone | First Interval | 2186.54 | 0.33 | 0.03 | 0.34 | 0.37 | 444 | 0.08 | 102.75 | 9.07 | 0.126 | −26.058 | / | ||

| G1-9 | Black mudstone | First Interval | 2206.48 | 0.50 | 0.15 | 1.02 | 1.17 | 399 | 0.13 | 202.22 | 29.74 | 0.138 | −26.117 | 1.18 | 0.04 | 21 |

| G1-10 | Black mudstone | First Interval | 2226.48 | 0.82 | 0.38 | 2.22 | 2.60 | 435 | 0.15 | 270.83 | 46.36 | 0.144 | −25.302 | 1.22 | 0.06 | 9 |

| G1-11 | Black mudstone | Second Interval | 2246.92 | 0.81 | 0.32 | 1.85 | 2.17 | 421 | 0.15 | 229.02 | 39.61 | 0.216 | −23.802 | 1.23 | 0.05 | 14 |

| G1-12 | Black mudstone | Second Interval | 2266.92 | 0.93 | 0.40 | 2.06 | 2.46 | 427 | 0.16 | 220.77 | 42.87 | 0.141 | −24.905 | 1.25 | 0.06 | 16 |

| G1-13 | Black mudstone | Second Interval | 2286.30 | 0.97 | 0.52 | 1.74 | 2.26 | 383 | 0.23 | 179.22 | 53.56 | 0.244 | −24.673 | 1.28 | 0.05 | 18 |

| G1-14 | Black mudstone | Second Interval | 2306.30 | 0.82 | 0.54 | 2.02 | 2.56 | 407 | 0.21 | 246.43 | 65.88 | 0.241 | −25.258 | 1.31 | 0.05 | 8 |

| G1-15 | Black lamellar shale | Second Interval | 2324.34 | 1.35 | 1.07 | 3.73 | 4.80 | 432 | 0.22 | 276.50 | 79.32 | 0.194 | −26.53 | 1.35 | 0.09 | 20 |

| G1-16 | Black lamellar shale | Second Interval | 2332.74 | 0.58 | 0.34 | 1.05 | 1.39 | 407 | 0.24 | 179.52 | 58.13 | 0.177 | −25.753 | 1.37 | 0.06 | 9 |

| G1-17 | Black mudstone | Second Interval | 2347.96 | 1.17 | 0.93 | 3.15 | 4.08 | 406 | 0.23 | 270.34 | 79.81 | 0.121 | −23.295 | 1.35 | 0.06 | 15 |

| G1-18 | Black lamellar shale | Third Interval | 2371.53 | 0.75 | 0.76 | 1.46 | 2.22 | 392 | 0.34 | 193.61 | 100.78 | 0.265 | −26.467 | 1.41 | 0.06 | 7 |

| G1-19 | Black lamellar shale | Third Interval | 2381.33 | 1.77 | 1.56 | 3.40 | 4.96 | 420 | 0.31 | 191.66 | 87.94 | 0.473 | −24.464 | 1.42 | 0.08 | 22 |

| G1-20 | Black lamellar shale | Third Interval | 2391.40 | 0.83 | 0.72 | 1.62 | 2.34 | 394 | 0.31 | 195.25 | 86.78 | 0.258 | −26.526 | 1.43 | 0.07 | 8 |

| G1-21 | Black lamellar shale | Third Interval | 2400.80 | 1.01 | 1.27 | 2.65 | 3.92 | 410 | 0.32 | 262.64 | 125.87 | 0.262 | −25.555 | 1.44 | 0.07 | 9 |

| G1-22 | Black lamellar shale | Third Interval | 2410.00 | 1.45 | 1.74 | 3.39 | 5.13 | 424 | 0.34 | 234.12 | 120.17 | 0.487 | −26.761 | 1.46 | 0.07 | 9 |

| G1-23 | Black lamellar shale | Third Interval | 2417.42 | 1.79 | 1.60 | 3.77 | 5.37 | 419 | 0.30 | 210.85 | 89.49 | 0.526 | −24.963 | 1.46 | 0.07 | 9 |

| G1-24 | Black lamellar shale | Third Interval | 2427.22 | 2.36 | 1.71 | 4.38 | 6.09 | 424 | 0.28 | 185.36 | 72.37 | 0.412 | −25.337 | 1.49 | 0.08 | 9 |

| G1-25 | Black lamellar shale | Third Interval | 2436.42 | 1.16 | 1.04 | 2.54 | 3.58 | 402 | 0.29 | 219.91 | 90.04 | 0.320 | −24.71 | / | ||

| G1-26 | Black lamellar shale | Third Interval | 2445.79 | 2.45 | 2.39 | 5.40 | 7.79 | 417 | 0.31 | 220.14 | 97.43 | 0.621 | −24.8 | 1.50 | 0.07 | 8 |

| G1-27 | Black lamellar shale | Third Interval | 2454.49 | 1.64 | 2.11 | 3.90 | 6.01 | 408 | 0.35 | 237.23 | 128.35 | 0.539 | −27.135 | 1.53 | 0.08 | 8 |

| G1-28 | Black lamellar shale | Third Interval | 2464.29 | 1.33 | 1.93 | 3.23 | 5.16 | 413 | 0.37 | 243.22 | 145.33 | 0.559 | −28.04 | 1.53 | 0.08 | 8 |

| G1-29 | Black lamellar shale | Third Interval | 2474.99 | 1.34 | 1.52 | 2.85 | 4.37 | 402 | 0.35 | 213.16 | 113.69 | 0.460 | −28.485 | 1.54 | 0.09 | 13 |

| G1-30 | Black lamellar shale | Third Interval | 2485.29 | 2.10 | 2.04 | 3.47 | 5.51 | 395 | 0.37 | 165.24 | 97.14 | 0.529 | −27.692 | 1.58 | 0.08 | 9 |

| G1-31 | Black lamellar shale | Third Interval | 2495.99 | 1.85 | 1.79 | 2.96 | 4.75 | 397 | 0.38 | 159.74 | 96.60 | 0.377 | −27.813 | / | ||

| G1-32 | Black lamellar shale | Fourth Interval | 2504.21 | 1.72 | 1.28 | 2.69 | 3.97 | 401 | 0.32 | 156.15 | 74.30 | 0.165 | −27.318 | 1.63 | 0.09 | 21 |

| G1-33 | Black lamellar shale | Fourth Interval | 2512.91 | 2.29 | 1.35 | 3.38 | 4.73 | 413 | 0.29 | 147.92 | 59.08 | 0.285 | / | 1.60 | 0.06 | 12 |

| G1-34 | Black lamellar shale | Fourth Interval | 2526.52 | 2.55 | 2.42 | 3.53 | 5.95 | 418 | 0.41 | 138.32 | 94.83 | 0.358 | / | 1.61 | 0.07 | 13 |

| G1-35 | Black lamellar shale | Fourth Interval | 2537.52 | 1.87 | 0.97 | 2.11 | 3.08 | 403 | 0.31 | 112.72 | 51.82 | 0.107 | / | 1.61 | 0.07 | 12 |

| G1-36 | Black lamellar shale | Fifth Interval | 2542.87 | 2.12 | 2.38 | 3.25 | 5.63 | 426 | 0.42 | 153.01 | 112.05 | 0.385 | −30.257 | 1.66 | 0.09 | 25 |

| G1-37 | Black lamellar shale | Fifth Interval | 2547.66 | 3.13 | 3.17 | 4.92 | 8.09 | 435 | 0.39 | 157.34 | 101.38 | 0.562 | −30.183 | 1.67 | 0.08 | 18 |

| G1-38 | Black lamellar shale | Fifth Interval | 2558.76 | 3.59 | 5.10 | 5.36 | 10.46 | 429 | 0.49 | 149.30 | 142.06 | 0.553 | / | 1.61 | 0.08 | 19 |

| G1-39 | Black lamellar shale | Fifth Interval | 2568.82 | 3.32 | 2.33 | 3.70 | 6.03 | 322 | 0.39 | 111.35 | 70.12 | 0.325 | / | / | ||

| G1-40 | Black lamellar shale | Fifth Interval | 2575.71 | 2.24 | 2.68 | 3.23 | 5.91 | 427 | 0.45 | 144.00 | 119.48 | / | / | / | ||

| G1-41 | Black lamellar shale | Fifth Interval | 2581.66 | 1.45 | 1.28 | 1.54 | 2.82 | 404 | 0.45 | 106.13 | 88.22 | / | / | / |

References

- Potter, P.E.; Maynard, J.B.; Pryor, W.A. Sedimentology of Shale: Study Guide and Reference Source; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1980. [Google Scholar]

- Morris, N.; Potra, A.; Samuelsen, J.R. Paleoenvironmental constraints on Paleozoic shale deposition in the midcontinent United States. AAPG Bull. 2024, 108, 1119–1147. [Google Scholar]

- Zheng, D.; Miska, S.; Ozbayoglu, E.; Zhang, J. Combined Experimental and Well Log Study of Anisotropic Strength of Shale. In SPE Annual Technical Conference and Exhibition? SPE: Kuala Lumpur, Malaysia, 2023; p. D031S046R003. [Google Scholar]

- Potter, P.E.; Maynard, J.B.; Depetris, P.J. Mud and Mudstones: Introduction and Overview; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Stow, D.A.V. Sedimentary Rocks in the Field: A Color Guide; Gulf Professional Publishing: Houston, TX, USA, 2005. [Google Scholar]

- Jiang, Z.; Liang, C.; Wu, J.; Zhang, J.; Zhang, W.; Wang, Y. Several issues in sedimentological studies on hydrocarbon-bearing fine-grained sedimentary rocks. Acta Pet. Sin. 2013, 34, 1031–1039, (In Chinese with English Abstract). [Google Scholar]

- Zou, C.; Zhu, R.; Chen, Z.; Ogg, J.; Wu, S.; Dong, D.; Qiu, Z.; Wang, Y.; Wang, L.; Lin, S.; et al. Organic-matter-rich shales of China. Earth-Sci. Rev. 2019, 189, 51–78. [Google Scholar] [CrossRef]

- Meng, M.; Ge, H.; Shen, Y.; Wang, L. Influence of rock fabric on salt ion diffusion behavior in upper cretaceous lacustrine shale from Songliao Basin. J. Pet. Sci. Eng. 2022, 208, 109355. [Google Scholar] [CrossRef]

- Folk, R.L. The distinction between grain size and mineral composition in sedimentary rock nomenclature. J. Geol. 1954, 62, 344–359. [Google Scholar] [CrossRef]

- Loucks, R.; Reed, R.; Ruppel, S.; Jarvie, D. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Slatt, R.; O’Brien, N. Pore types in the Barnett and Woodford gas shales: Contribution to understanding gas storage and migration pathways in fine-grained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 14–26. [Google Scholar] [CrossRef]

- Wirth, R. Focused Ion Beam (FIB) combined with SEM and TEM: Advanced analytical tools for studies of chemical composition, microstructure and crystal structure in geomaterials on a nanometre scale. Chem. Geol. 2009, 261, 217–229. [Google Scholar] [CrossRef]

- Klaver, J.; Desbois, G.; Urai, J.; Littke, R. BIB-SEM study of the pore space morphology in early mature Posidonia Shale from the Hils area, Germany. Int. J. Coal Geol. 2012, 103, 12–25. [Google Scholar] [CrossRef]

- Wei, M.; Zhang, L.; Xiong, Y.; Li, J.; Peng, P. Nanopore structure characterization for organic-rich shale using the non-local-density functional theory by a combination of N2 and CO2 adsorption. Microporous Mesoporous Mater. 2016, 227, 88–94. [Google Scholar] [CrossRef]

- Zhang, P.; Lu, S.; Li, J. Characterization of pore size distributions of shale oil reservoirs: A case study from Dongying sag, Bohai Bay basin, China. Mar. Pet. Geol. 2019, 100, 297–308. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Li, J.; Wang, M.; Lu, S.; Liu, L.; Li, M.; Zhang, Y.; Wang, X.; Zhao, X.; Zhang, J.; Zhao, Y. Quantitative evaluation model of shale oil adsorption: A case study of the 1st member of Cretaceous Qingshankou Formation in northern Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 1137–1150. [Google Scholar] [CrossRef]

- Jiang, F.; Hu, M.; Zhu, T.; Lv, J.; Huang, L.; Liu, C.; Jiang, Z.; Huang, R.; Zhang, C.; Wu, G.; et al. Major controlling factors and model of shale oil enrichment in Lower Permian Fengcheng Formation, Mahu Sag, Junggar Basin, NW China. Pet. Explor. Dev. 2023, 50, 812–825. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, X.; Bai, L.; Lu, R. Investigation of oil and water migrations in lacustrine oil shales using 20 MHz 2D NMR relaxometry techniques. Pet. Sci. 2022, 19, 1007–1018. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, J.; Zhang, J.; Zhao, B.; Zhao, Y.; Liu, X.; Xia, D. Resource potential and exploration direction of Gulong shale oil in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 20–34. [Google Scholar]

- Sun, L.; Liu, H.; He, W.; Li, G.; Zhang, S.; Zhu, R.; Jin, X.; Meng, S. An analysis of major scientific problems and research paths of Gulong shale oil in Daqing Oilfield, NE China. Pet. Explor. Dev. 2021, 48, 453–463. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, W.; Liu, H.; Zhu, R.; Bai, B.; Kang, Y.; Zhang, J.; Wu, S. Concept and application of “sweet spot” in shale oil. Acta Pet. Sin. 2023, 44, 1–13. [Google Scholar]

- Wang, M.; Xue, H.; Tian, S.; Ronald, W.T.; Wang, Z. Fractal characteristics of upper Cretaceous lacustrine shale from the Songliao Basin, NE China. Mar. Pet. Geol. 2015, 67, 144–153. [Google Scholar] [CrossRef]

- Zhang, P.; Misch, D.; Hu, F.; Kostoglou, N.; Sachsenhofer, R.F.; Liu, Z.; Meng, Q.; Bechtel, A. Porosity evolution in organic matter-rich shales (Qingshankou Fm.; Songliao Basin, NE China): Implications for shale oil retention. Mar. Pet. Geol. 2021, 130, 105–139. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Tian, S.; Guo, Y.; Wang, L.; Qamar, Y.; Yang, J. Impact of thermal maturity on the diagenesis and porosity of lacustrine oil-prone shales: Insights from natural shale samples with thermal maturation in the oil generation window. Int. J. Coal Geol. 2022, 261, 104–179. [Google Scholar] [CrossRef]

- He, W.; Wang, M.; Wang, X.; Meng, Q.; Wu, Y.; Lin, T.; Li, J.; Zhang, J. Pore Structure Characteristics and Affecting Factors of Shale in the First Member of the Qingshankou Formation in the Gulong Sag, Songliao Basin. ACS Omega 2022, 7, 35755–35773. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, M.; Li, J.; Shao, H.; Deng, Z.; Wu, Y. Thermal maturity: The controlling factor of wettability, pore structure, and oil content in the lacustrine Qingshankou shale, Songliao Basin. J. Pet. Sci. Eng. 2022, 215, 110–618. [Google Scholar] [CrossRef]

- Sun, L.; He, W.; Feng, Z.; Zeng, H.; Jiang, H.; Pan, Z. Shale Oil and Gas Generation Process and Pore Fracture System Evolution Mechanisms of the Continental Gulong Shale, Songliao Basin, China. Energy Fuels 2022, 36, 6893–6905. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, H.; Bai, Y.; Chen, G.; Luo, J.; Zhang, Y. Pore Characteristics, Oil Contents and Factors Influencing Laminated Shale in the First Member of the Qingshankou Formation in the Gulong Sag, Northern Songliao Basin. Minerals 2023, 13, 1220. [Google Scholar] [CrossRef]

- Li, C.; Pang, X.; Huo, Z.; Wang, E.; Xue, N. A revised method for reconstructing the hydrocarbon generation and expulsion history and evaluating the hydrocarbon resource potential: Example from the first member of the Qingshankou Formation in the Northern Songliao Basin, Northeast China. Mar. Pet. Geol. 2020, 121, 104577. [Google Scholar] [CrossRef]

- Bai, L.; Liu, B.; Fu, X.; Hu, Q.; Huo, Q.; Wang, L.; Wang, Q.; Fu, L.; Ostadhassan, M. A new method for evaluating the oil mobility based on the relationship between pore structure and state of oil. Geosci. Front. 2023, 14, 101684. [Google Scholar] [CrossRef]

- Wang, M.; Li, M.; Li, J.; Xu, L.; Shao, H.; Yu, C.; Li, T. Comparative analysis of test methods for shale oil content. Acta Pet. Sin. 2022, 43, 1758–1769. [Google Scholar]

- Cui, B.; Chen, C.; Lin, X.; Zhao, Y.; Cheng, X.; Zhang, Y.; Lu, G. Characteristics and distribution of sweet spots in Gulong shale oil reserviors of Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 45–55. [Google Scholar]

- Li, Z.; Liu, Y.; He, J.; Sun, Z.; Leng, J.; Li, C.; Jia, M.; Xu, E.; Liu, P.; Li, M.; et al. Limits of critical parameters for sweet-spot interval evaluation of lacustrine shale oil. Oil Gas Geol. 2023, 44, 1453–1467. [Google Scholar]

- Wang, P.J.; Mattern, F.; Didenko, N.A.; Zhu, D.F.; Singer, B.; Sun, X.M. Tectonics and cycle system of the Cretaceous Songliao Basin: An inverted active continental margin basin. Earth Sci. Rev 2016, 159, 82–102. [Google Scholar] [CrossRef]

- Yuan, X.; Zhou, H.; Zhang, Z.; Wang, Z.; Cheng, D.; Guo, H.; Zhang, Y.; Dong, W. Depositional features and growth pattern of large shallow-water deltas in depression basin. Lithol. Reserv. 2021, 33, 1–11. [Google Scholar]

- Rafieepour, S.; Zheng, D.; Miska, S.; Ozbayoglu, E.; Takach, N.; Yu, M.; Zhang, J. Combined experimental and Well log evaluation of anisotropic mechanical properties of shales: An application to wellbore stability in Bakken Formation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020. [Google Scholar] [CrossRef]

- Zheng, D.; Ozbayoglu, E.; Miska, S.; Zhang, J. Experimental study of Anisotropic strength properties of Shale. In Proceedings of the ARMA 23241 at the 57th US Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 23–26 June 2023. [Google Scholar]

- Zhang, H.; Wang, X.; Jia, C.; Li, J.; Meng, Q.; Jiang, L.; Wang, Y.; Bai, X.; Zheng, Q. Whole petroleum system and hydrocarbon accumulation model in shallow and medium strata in northern Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 784–797. [Google Scholar] [CrossRef]

- Li, S.C.; Zhang, J.; Gong, F.; Zhu, H.; Bai, Y. The characteristics of mudstones of Upper Cretaceous Qingshankou Formation and favorable area optimization of shale oil in the north of Songliao Basin. Geol. Bull. China 2017, 36, 654–663. [Google Scholar]

- Lafargue, E.; Marquis, F.; Pillot, D. Rock-Eval 6 applications in hydrocarbon exploration, production, and soil contamination studies. Oil Gas Sci. Technol. 1998, 53, 421–437. [Google Scholar] [CrossRef]

- Behar, F.; Beaumont, V.; Penteado, H.L.; De, B. Rock-Eval 6 technology: Performances and developments. Oil Gas Sci. Technol. 2001, 56, 111–134. [Google Scholar] [CrossRef]

- Carvajal-Ortiz, H.; Gentzis, T. Critical considerations when assessing hydrocarbon plays using Rock-Eval pyrolysis and organic petrology data: Data quality revisited. Int. J. Coal Geol 2015, 152, 113–122. [Google Scholar] [CrossRef]

- National Energy Administration. Method of Determining Microscopically the Reflectance of Vitrinite in Sedimentary (SY/T 5124—2012); Petroleum Industry Press: Beijing, China, 2012. [Google Scholar]

- Schimmelmann, A.; Lewan, M.M.; Wintsch, R.P. D/H isotope ratios of kerogen, bitumen, oil, and water in hydrous pyrolysis of source rocks containing kerogen types I, II, IIS, and III. Geochim. Cosmochim. Acta 1999, 63, 3751–3766. [Google Scholar] [CrossRef]

- SY/T 5735—1995; Geochemical Evaluation Method of Continental Source Rocks. Standards Press of China: Beijing, China, 1995; China National Petroleum Corporation.

- Huo, Q.; Zeng, H.; Zhang, X.; Fu, L.; Wang, Y.; Chang, L.; Qiao, Y. Organic matter characteristics and shale oil formation of Gulong shale in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 86–96. [Google Scholar]

- Tissot, B.P.; Welte, D.H. Petroleum Formation and Occurrence: A New Approach to Oil and Gas Exploration; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1978. [Google Scholar]

- Langford, F.F.; Blanc-Valleron, M.M. Interpreting Rock-Eval pyrolysis data using graphs of pyrolizable hydrocarbons vs. Total Organic Carbon. AAPG Bull. 1990, 74, 799–804. [Google Scholar]

- Farouk, S.; Saada, S.A.; Fagelnour, M.S.; Arafat, M. Petrophysical and Gas Chromatographic Analysis Integration for Hydrocarbon Identifications in Cretaceous Reservoirs, Azhar Field, Beni Suef Basin, Egypt. Egypt. J. Pet. 2024, 33, 7. [Google Scholar] [CrossRef]

- Cornford, C.; Gardner, P.; Burgess, C. Geochemical truths in large data sets I: Geochemical screening data. Org. Geochem. 1998, 29, 519–530. [Google Scholar] [CrossRef]

- Stahl, W.J. Carbon and nitrogen isotopes in hydrocarbon research and exploration. Chem. Geol. 1977, 20, 121–130. [Google Scholar] [CrossRef]

- Huang, D.; Li, J.; Zhang, D. Kerogen types and study on effectiveness limitation and interrelation of their identification parameters. Acta Sedimentol. Sin. 1984, 2, 18–34. [Google Scholar]

- Huang, F.; Xin, M. Geochemical Evaluation Method of Nonmarine Source Rocks; China National Petroleum Corporation: Beijing, China, 1995. [Google Scholar]

- Xiong, Y.; Zhang, H.; Geng, A. Variation of carbon isotopic composition of kerogen during thermal evolution. Pet. Geol. Exp. 2004, 26, 484–487. [Google Scholar]

- Farouk, S.; Khairy, A.; Shehata, A.M.; Uguna, C.N.; El Sheennawy, T.; Salama, A.; Meredith, W. Geochemical evaluation and hydrocarbon generation potential of the upper Cretaceous–Pliocene succession, offshore Nile Delta, Egypt. J. Afr. Earth Sci. 2023, 205, 105004. [Google Scholar] [CrossRef]

- Shanmugam, G. Significance of coniferous rain forests and related organic matter in generating commercial quantities of oil, Gippsland Basin, Australia. AAPG Bull. 1985, 69, 1241–1254. [Google Scholar] [CrossRef]

- Tissot, B.P.; Durand, B.; Espitalie, J.; Combaz, A. Influence of the nature and diagenesis of organic matter in formation of petroleum. AAPG Bull. 1974, 58, 499–506. [Google Scholar]

- Yang, S.Y.; Horsfield, B. Critical review of the uncertainty of Tmax in revealing the thermal maturity of organic matter in sedimentary rocks. Int. J. Coal Geol. 2020, 225, 103500. [Google Scholar] [CrossRef]

- Katz, B.J.; Lin, F. Consideration of the limitations of thermal maturity with respect to vitrinite reflectance, Tmax, and other proxies. AAPG Bull. 2021, 105, 695–720. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, B.; Wang, X.; Feng, Z.; He, K.; Wang, H.; Fu, X.; Liu, Y.; Yang, C. Gulong shale oil enrichment mechanism and orderly distribution of conventional–unconventional oils in Qingshankou Formation, Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 1045–1059. [Google Scholar] [CrossRef]

- Bordenave, M.L. Applied Petroleum Geochemistry; Techniq: Paris, France, 1993; pp. 1–524. [Google Scholar]

- Chen, J.; Pang, X.; Pang, H. Hydrocarbon evaporative loss evaluation of lacustrine shale oil based on massbalance method: Permian Lucaogou Formation in Jimusaer Depression, Junggar Basin. Mar. Pet. Geol. 2018, 91, 422–431. [Google Scholar] [CrossRef]

- Chen, Z.; Li, M.; Jiang, C. Shale oil resource potential and its mobility assessment: A case study of Upper Devonian Duvernay shale in Western Canada Sedimentary Basin. Oil Gas Geol. 2019, 40, 459–468. [Google Scholar]

- Zhu, R.; Zhang, L.; Li, J.; Liu, Q.; Li, Z.; Wang, R.; Zhang, L. Quantitative evaluation of residual liquid hydrocarbons in shale. Acta Pet. Sin. 2015, 36, 13–18. [Google Scholar]

- Jiang, C.; Chen, Z.; Mort, A.; Milovic, M.; Robinson, R.; Stewart, R.; Lavoie, D. Hydrocarbon evaporative loss from shale core samples as revealed by Rock-Evaland thermal desorption-gas chromatography analysis: Its geochemical and geological implications. Mar. Pet. Geol. 2016, 70, 294–303. [Google Scholar] [CrossRef]

- Qian, M.; Li, M.; Jiang, Q.; Li, Z.; Tao, G.; Bao, Y. Evaluation of evaporative loss of hydrocarbon in shale samples and its geological implications. Pet. Geol. Exp. 2022, 44, 497–514. [Google Scholar]

- Gao, B.; He, W.; Feng, Z.; Shao, H.; Zhang, A.; Pan, H.; Chen, G. Lithology, physical property, oil-bearing property and their controlling factors of Gulong shale in Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 68–79. [Google Scholar]

- Xue, H.; Tian, S.; Wang, W.; Zhang, W.; Du, T.; Mu, G. Correction of oil content—One key parameter in shale oil resource assessment. Oil Gas Geol. 2016, 37, 15–22. [Google Scholar]

- Clementz, D.M. Effect of oil and bitumen saturation on source-rock pyrolysis. Am. Assoc. Pet. Geol. Bull. 1979, 63, 12. [Google Scholar]

- Li, M.; Chen, Z.; Qian, M.; Jiang, Q.; Li, Z.; Tao, G.; Wu, S. What are in pyrolysis S1 peak and what are missed? Petroleum compositional characteristics revealed from programed pyrolysis and implications for shale oil mobility and resource potential. Int. J. Coal Geol. 2020, 217, 103321. [Google Scholar] [CrossRef]

- Zhang, L.; Bao, Y.; Li, J.; Li, Z.; Zhu, R.; Zhang, L.; Wang, Y. Hydrocarbon and crude oil adsorption abilities of minerals and kerogens in lacustrine shales. Pet. Geol. Exp. 2015, 37, 776–780. [Google Scholar]

- Delvaux, D.; Martin, H.; Leplat, P.; Paulet, J. Comparative Rock-Eval pyrolysis as an improved tool for sedimentary organic matter analysis. Org. Geochem. 1990, 16, 1221–1229. [Google Scholar] [CrossRef]

- Han, Y.; Mahlstedt, N.; Horsfield, B. The Barnett Shale: Compositional fractionation associated with intraformational petroleum migration, retention, and expulsion. AAPG Bull. 2015, 99, 2173–2202. [Google Scholar] [CrossRef]

- Zink, K.G.; Scheeder, G.; Stueck, H.L. Total shale oil inventory from an extended Rock-Eval approach on non-extracted and extracted source rocks from Germany. Int. J. Coal Geol. 2016, 163, 186–194. [Google Scholar] [CrossRef]

- Romero-Sarmiento, M.F. A quick analytical approach to estimate both free versus sorbed hydrocarbon contents in liquid rich source rocks. AAPG Bull. 2019, 103, 2031–2043. [Google Scholar] [CrossRef]

- Li, M.; Chen, Z.; Ma, X. Shale oil resource potential and oil mobility characteristics of the Eocene-Oligocene Shahejie Formation, Jiyang Super-Depression, Bohai Bay Basin of China. Int. J. Coal Geol. 2019, 204, 130–143. [Google Scholar] [CrossRef]

- Jarvie, D.M. Shale resource systems for oil and gas: Part 2—Shale-oil resource systems. In Shale Reservoirs—Giant Resources for the 21st Century; Breyer, J.A., Ed.; AAPG Memoir 97: Tulsa, OK, USA, 2012; Volume 97, pp. 89–119. [Google Scholar]

- Michael, G.E.; Packwood, J.; Holba, A. Determination of in-situ hydrocarbon volumes in liquid rich shale plays. In Proceedings of the Unconventional Resources Technology Conference, Denver, CO, USA, 12–14 August 2013. [Google Scholar]

- Jiang, Q.; Li, M.; Qian, M. Quantitative characterization of shale oil in different occurrence state and its application. Pet. Geol. Exp. 2016, 38, 842–849. [Google Scholar]

- Gorynski, K.E.; Tobey, M.H.; Enriquez, D.A. Quantification and characterization of hydrocarbon-filled porosity in oil-rich shales using integrated thermal extraction, pyrolysis, and solvent extraction. AAPG Bull. 2019, 103, 723–744. [Google Scholar] [CrossRef]

- Sun, L.; Cui, B.; Zhu, R. Shale oil enrichment evaluation and production law in Gulong Sag, Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 441–454. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, B.; Feng, Z.; Luo, J.; Shao, H.; Bai, Y.; Wang, J.; Zhang, Y.; Wang, Y.; Yan, M. Geochemical Characteristics of Mature to High-Maturity Shale Resources, Occurrence State of Shale Oil, and Sweet Spot Evaluation in the Qingshankou Formation, Gulong Sag, Songliao Basin. Energies 2024, 17, 2877. https://doi.org/10.3390/en17122877

Gao B, Feng Z, Luo J, Shao H, Bai Y, Wang J, Zhang Y, Wang Y, Yan M. Geochemical Characteristics of Mature to High-Maturity Shale Resources, Occurrence State of Shale Oil, and Sweet Spot Evaluation in the Qingshankou Formation, Gulong Sag, Songliao Basin. Energies. 2024; 17(12):2877. https://doi.org/10.3390/en17122877

Chicago/Turabian StyleGao, Bo, Zihui Feng, Jinglan Luo, Hongmei Shao, Yubin Bai, Jiping Wang, Yuxuan Zhang, Yongchao Wang, and Min Yan. 2024. "Geochemical Characteristics of Mature to High-Maturity Shale Resources, Occurrence State of Shale Oil, and Sweet Spot Evaluation in the Qingshankou Formation, Gulong Sag, Songliao Basin" Energies 17, no. 12: 2877. https://doi.org/10.3390/en17122877

APA StyleGao, B., Feng, Z., Luo, J., Shao, H., Bai, Y., Wang, J., Zhang, Y., Wang, Y., & Yan, M. (2024). Geochemical Characteristics of Mature to High-Maturity Shale Resources, Occurrence State of Shale Oil, and Sweet Spot Evaluation in the Qingshankou Formation, Gulong Sag, Songliao Basin. Energies, 17(12), 2877. https://doi.org/10.3390/en17122877