Abstract

This study explores the hydrothermal carbonization (HTC) process applied to the exhausted chestnut produced by the tannin extraction industry, utilizing process water recirculation to enhance the efficiency and sustainability of the conversion process. Tannin extraction from wood typically involves hot water treatment, leaving behind residual wood biomass known as exhausted wood. These by-products maintain their renewable properties because they have only been exposed to hot water under a high pressure, which is unlikely to cause major alterations in their structural components. Hydrothermal treatment was carried out at temperatures of 220 °C and 270 °C for 1 h, with process water being recirculated four times. This investigation focused on analyzing the effects of recirculation on the yield and fuel properties of hydrochar, as well as characterizing the combustion behavior of the obtained hydrochar. The results indicated that recirculation of process water led to improvements in both the mass and energy yields of hydrochar. The mass yield of the hydrochar samples increased by 5–6%, and the ERE of the hydrochar samples increased by 5–8% compared to the HTC reference sample. However, alterations in the combustion characteristics were observed, including decreases in ignition temperature and combustion reactivity. The results indicate that, with PW recirculations, the combustion index decreased by about 14% and 18% for 220 °C and 270 °C, respectively. Overall, this research demonstrates the potential of utilizing HTC on chestnut tannin residue with process water recirculation to produce stable solid fuel and provides insights into the combustion behavior of the resulting hydrochar.

1. Introduction

Natural resources like coal have been utilized for over 3000 years, making them the preferred choice for many countries in addressing energy crises [1,2]. Due to rapid industrial development over the past centuries, the depletion of high-quality coal has become increasingly apparent, leaving behind vast reserves of low-rank coal, including lignite, long-flame coal, non-caking coal, weakly caking coal, and others, which have been extensively exploited [1,3].

In today’s rapidly evolving energy landscape, the quest for sustainable and efficient energy sources has become paramount [4]. With traditional energy reservoirs like oil and coal facing depletion and environmental repercussions, there is a pressing need for alternative solutions that can meet our energy needs while mitigating environmental impacts. Biomass-derived resources offer a promising avenue towards achieving these goals, leveraging organic materials like agricultural residues and industrial by-products to produce renewable energy [5].

Within the European Union alone, an estimated 50 million cubic meters of wood wastes are generated annually, underscoring the significance of wood residues as potential feedstocks for energy and material production [6]. Within wood processing sectors, notably those engaged in tannin extraction, numerous by-products emerge, including spent wood biomass, obtained from the hot water extraction of tannins [7].

In the tanning industry sector, chestnut tannin has the highest price, reaching approximately 15–16 €/kg [8]. Its annual production, primarily concentrated in Europe (Italy, Slovenia, France, Portugal, and Spain), is estimated at 30,000 tons. Specifically, spent wood biomass has been identified as a readily accessible material with favorable antioxidant qualities and effective adsorption capabilities for pollutants [9]. Furthermore, it could be employed in the energy sector as a fuel for biomass thermal power plants to generate electricity, or it can be processed into pellets through extrusion for use in stoves.

However, the actual uses of spent chestnut wood biomass involve an energy-intensive drying phase to reduce its inherently high moisture content prior to any further processing or application. For this reason, emerging technologies such as hydrothermal carbonization (HTC) offer a compelling alternative pathway by potentially bypassing the need for this energy-intensive drying step. Unlike conventional methods that require feedstocks to be thoroughly dried, HTC operates effectively with wet lignocellulosic biomass waste. The hydrothermal temperature has a strong influence on the process [10]: by subjecting the biomass to elevated temperatures (ranging from 180 to 300 °C) in a water-based environment under autogenous pressure, HTC facilitates the conversion of the wet biomass into a valuable carbonaceous product [11,12].

In the realm of tannin extraction residues, particularly spent chestnut wood biomass, HTC presents a promising path for its valorization. By subjecting exhausted chestnut residues to hydrothermal treatment, it is possible to produce hydrochar, a solid fuel with potential applications in energy generation. However, to optimize the efficiency and sustainability of the HTC process, innovative strategies such as process water recirculation must be explored [13].

Process water recirculation entails reusing the aqueous phase generated during the HTC process, which typically contains valuable organic compounds and by-products. By recirculating process water, it is possible to enhance the efficiency of hydrochar production while minimizing water consumption and environmental impacts. Furthermore, process water recirculation holds the potential to influence the physicochemical properties and combustion behavior of the resulting hydrochar, thereby offering insights into its suitability as a solid fuel [14].

Prior investigations conducted by [15,16,17,18] have yielded promising results, showcasing the potential benefits of process water recycling in terms of enhancing hydrochar yield, improving energy recovery, optimizing combustion performance, and mitigating environmental impacts. Upon review of the existing literature, it became evident that there is a lack of studies investigating process water recycling specifically within the HTC process applied to spent chestnut wood biomass.

This research aims to clarify the impact of process water recirculation on the yield, composition, and fuel properties of hydrochar derived from exhausted chestnut biomass by conducting a series of hydrothermal treatment experiments at varying temperatures (220 °C and 270 °C) and recirculating the process water four times. Additionally, the combustion behavior of the obtained hydrochar was comprehensively characterized to assess its potential as a sustainable solid fuel.

Overall, this study endeavors to contribute to the efficient utilization of exhausted chestnut resources for solid fuel production through HTC, thereby advancing the principles of sustainable development and circular economy in the agri-food industry. Through detailed characterization and exploration of innovative valorization strategies, this research aims to unlock the full potential of tannin extraction residues for sustainable resource management and energy generation.

2. Materials and Methods

2.1. Materials and Sample Preparation

The exhausted chestnut wood (ECW) from tannin extraction was collected from a tannin company site in Radicofani (SI), Italy. The initial moisture content of the ECW was 43 wt%. The material was dried at 105 °C for over 24 h, then the dried samples were finely ground and sieved to achieve a particle size smaller than 0.25 mm. Preparing biomass with drying prior to HTC aimed at easing storage and handling while preventing sample degradation. Also, it assisted in grinding the sample, achieving homogenization, and adjusting the biomass-to-water ratio. The standard NREL protocols [19] were utilized to conduct a fiber analysis on the ECW, revealing cellulose, hemicelluloses, lignin, and extractive contents of 13.7%, 13.4%, 56.1%, and 15.6%, respectively. Before the HTC tests, all the samples were carefully stored in plastic containers. The selection of solvent (either deionized water or recirculated process water) was decided immediately before each HTC run to attain the requested dry biomass-to-water ratio (B/W).

2.2. HTC Experimental Procedure

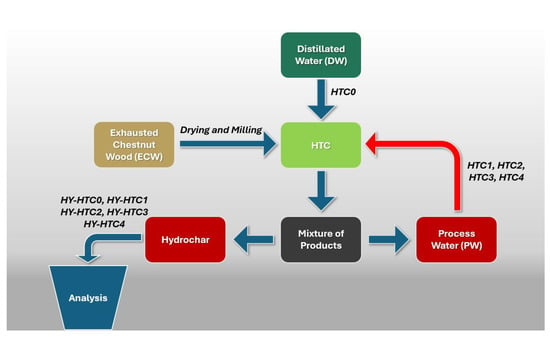

A stainless-steel Parr 4560 mini-batch reactor with a volume of 600 mL was used for the hydrothermal carbonization treatment. A schematic representation of the experimental procedure is displayed in Figure 1. At the start of the initial HTC test, 30 g of ECW was combined with 270 mL of deionized water (DW), and nitrogen was used to purge the air from the reactor. The reactor was then heated to the target temperatures of 220 °C and 270 °C and maintained for 1 h, with the stirring rate set at 200 rpm.

Figure 1.

Schematic representation of the HTC process.

The operating conditions were chosen based on the existing literature, according to which HTC tests on lignocellulosic biomass are carried out within time intervals ranging from 30 min to 12 h, with residence times of 1 to 2 h being the most common, and temperatures ranging between 175 °C and 300 °C [20]. After the residence time, an internal cooling coil connected to an external chiller allowed for an immediate decrease in temperature by the coolant. The separation of the solid and process water (PW) was achieved using a Büchner funnel, along with a vacuum pump and filter paper (Whatman filter paper, 8 µm). After washing the hydrochar with distilled water multiple times and drying it in an oven at 105 °C for 24 h to eliminate any remaining moisture, the PW was used in the next HTC experiment to analyze the effects of the recirculation.

The reduction in water volume post-HTC (due to sample filtration and drying or potential water consumption during the reaction) was compensated by the addition of DW until reaching 270 mL for the subsequent run. Four PW recycles were conducted at each reaction temperature. The corresponding hydrochar from each experimental test was labeled as HY-HTCn-T, where n refers to the number of recirculations (from 0 to 4) and T is the HTC reaction temperature (220 and 270 °C).

Each experimental test was conducted a minimum of three times to assess data variance and guarantee reproducibility (the results were deemed acceptable and valid if the error (Er) ≤ 2.5%).

2.3. Sample Characterization

The ultimate analysis of the raw feedstock and hydrochars was performed using a LECO Truspec C-H-N analyzer, in accordance with UNI EN 15104 [21]. Additionally, a proximate analysis was carried out using a thermogravimetric analyzer (TGA-701, LECO Corp., St. Joseph, MI, USA) following the standards EN 14774-2 [22], EN 15148 [23], and EN 14775 [24] for the moisture content, volatile matter (VM), and ash content, respectively. The fixed carbon (FC) and oxygen contents were calculated based on differences. The higher heating value (HHV) of the biomass materials was estimated from the ultimate analyses based on the experimental correlation [25] reported in Equation (1), where C, H, and O are expressed in wt %.

HHV [MJ/kg] = −1.3675 + 0.3137C + 0.7009H + 0.0318O

A Thermogravimetric Analyzer TGA/DSC 3+ STARe System (Mettler Toledo, Columbus, OH, USA) was used to study the combustion properties. The samples were placed in a 70 µL Al2O3 pan and heated from 25 °C to 800 °C at a heating rate of 20 °C/min. An oxidizing atmosphere (21%O2/79%N2) was used with a gas flow rate of 50 mL/min.

2.4. Calculations

The mass yield (MY) of the HTC process was computed as the ratio of the mass of hydrochar (Mf) to that of the initial feedstock (M0) on a dry basis using Equation (2):

Furthermore, the energy density (ED) and energy recovery efficiency (ERE) were determined according to Equations (3) and (4), respectively, where HHVh is the higher heating value of the hydrochar and HHVf of the feedstock.

Also, the fuel ratio (FR) was calculated by dividing the fixed carbon content of the sample (FC) by its volatile matter content (VM), as reported in Equation (5).

Additionally, carbon retention (CR) was defined as the ratio of the carbon fractions in the hydrochar (CHY) and feedstock (Cf), as described by Equation (6).

Based on the analysis of the weight loss curves (TG) and the corresponding first-order derivatives (differential thermogravimetric (DTG)), several combustion parameters were evaluated. These included the ignition temperature (Ti), at which a conversion of 1% of the initial mass occurred after the initial weight loss due to moisture release; the burnout temperature (Tb), which is the temperature at which the conversion rate reached 1%/min at the conclusion of the DTG curve; and the peak temperature (Tp), which corresponds to the temperature where the highest weight loss rate was observed. Moreover, the combustion performance of the samples was evaluated based on the combustion index (S) as follows:

where DTGmax is the maximum weight loss rate and DTGmean is the average conversion rate between Ti and Tb.

3. Results and Discussion

3.1. Effects on the Mass Yield of Hydrochars

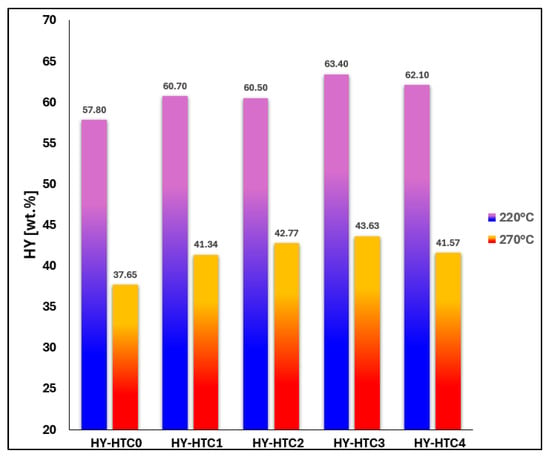

Figure 2 illustrates how recycling PW affected the mass yield of the hydrochars produced via the HTC tests conducted at varying temperatures (220 °C and 270 °C). Initially, it was noted that the mass yields of the hydrochars decreased with increasing temperatures from 220 °C to 270 °C. This was mainly due to the higher HTC temperature that promoted greater biomass degradation in terms of cellulose, hemicellulose, and lignin [15,26,27].

Figure 2.

Hydrochar yields with PW recirculations at 220 °C and 270 °C. Average values are shown (Er% ≤ 2.1%).

Furthermore, it was observed that the PW recirculation increased the MY to a maximum of 10% and 16% for both the hydrochars obtained with the third PW recirculation at 220 °C and 270 °C, respectively. This indicates that the recirculation of the process water had a positive impact on the hydrochar yield, also suggesting that organic compounds in the process water underwent hydrothermal treatment, generating additional solid substances, which subsequently boosted the mass yield of the hydrochars [26]. Moreover, the increase in the MY of the hydrochars related to PW recirculation could be due to the effect of the latter, which potentially obstructs the diffusion of degraded sugar monomers from the surface of the hydrochars into the solution, consequently augmenting the MY of the hydrochars [28].

Additionally, the organic acids in the PW played a key role. If recirculated, they might serve as a catalyst, accelerating dehydration reactions that notably enhance the carbonization process. This acceleration contributes to hydrochar production through condensation and back-polymerization reactions [29,30,31]. Additionally, acidic conditions could facilitate further biomass degradation into monosaccharides, yielding more water-soluble intermediates, such as the dehydration of glucose into 5-hydroxymethyl furfural (HMF). Numerous intermediates with notable reactivity could participate in condensation and polymerization reactions, forming organic compounds that transform into solid-phase aromatic clusters and aggregate into carbonaceous microspheres. A significant portion of these microspheres precipitates onto the hydrochar surface, leading to its increased mass [13,32,33].

Finally, in both cases, where HTC was conducted at 220 °C and 270 °C, the hydrochar’s mass yield reached its peak value with the third recirculation of PW (63.4% and 43.63%, respectively). However, there was a slight decrease in the MY with the last recirculation, possibly because the concentration of organic acids reached an equilibrium value [13,34,35].

3.2. Effects on Proximate and Elemental Composition of Hydrochars

3.2.1. Proximate Analysis

Table 1 shows the results of the proximate analysis for the ECW and for the obtained hydrochars. The process temperature reported a significant influence on the variations in volatile matter (VM) and fixed carbon (FC). Without PW recirculation, HTC0-220 exhibited a decrease in VM content from 79.48% of the raw ECW to 73.58%, along with an increase in FC content from 19.27% to 25.58%. On the other hand, for HTC0-270, VM and FC values of 50.97% and 48.57% were achieved, respectively. This indicates that at a temperature of 270 °C, there was a significant increase in the FC content alongside a substantial reduction in the VM content, highlighting that higher temperatures raise devolatilization and the formation of FC [36]. In terms of ash content, a more pronounced reduction was observed at 270 °C, dropping from 1.25% in the initial biomass to 0.46%, compared to the 0.84% obtained from the 220 °C process. The reduction in ash content observed is attributable to the leaching effects of the aqueous solvent [37,38].

Table 1.

Proximate composition of ECW and obtained hydrochars at 220 °C and 270 °C with PW recirculations. Average values are shown (Er% ≤ 1.6%).

Ding et al. [34] found that the ash content of rice husk at 220 °C showed an increasing trend, while Reza et al. [39] found that the ash content of miscanthus and corn stover at 200 °C showed a significant decrease.

The differences in the results could be attributed to variations in the ash composition and hydrothermal process parameters [40]. During HTC, inorganics are extracted into the process water, removing them from the hydrochar, while organics dissolve, reducing overall mass yield. If the organic loss exceeds the inorganic reduction, the ash content increases. Elements like K, Si, Cl, and Fe tend to remain on the solid matrix, becoming insoluble during HTC and increasing the ash content in the hydrochar [41,42].

Furthermore, PW recirculations at 220 °C resulted in rather constant VM and FC, with VM contents decreasing only slightly from 73.58% to 71.92% and FC increasing modestly from 25.58% to 27.48%. The impact of recirculation at 270 °C exhibited a similar trend of VM decreasing and FC increasing, albeit with minimal influence.

Regarding the ash contents, an opposite trend was noted. At 220 °C, the ash content decreased with the recirculation of PW. This might be attributed to the growing hindrance effect caused by ash precipitating on the hydrochar’s surface, which impedes the degradation of organic compounds in later cycles [43]. At 270 °C, the ash content exhibited an irregular fluctuation with PW recirculation, suggesting that the recirculation had no significant impact on the ash content.

It is noteworthy that in both cases, the ash contents of the hydrochars remained below that of the ECW (1.25%). Similar results were found in the literature [44,45,46]. After four recirculations, the ashes stabilized around 0.60%, showing a reduction of about 50% compared to those of the raw biomass, suggesting that inorganic constituents may accumulate in the PW [36].

3.2.2. Elemental Composition Analysis

Ultimate analysis is an important tool for studying the composition of biomass according to its basic elements, since it can help researchers to understand the quality of the final product. Table 2 shows the results of the ultimate analysis for the ECW and for the obtained hydrochars, with different PW recirculations (HTC0, HTC1, HTC2, HTC3, and HTC4) at different temperatures (220 and 270 ℃).

Table 2.

Ultimate composition of ECW and obtained hydrochars at 220 °C and 270 °C with different PW recirculations. Average values are shown (Er% ≤ 1.9%). Atomic ratio is reported as well.

In terms of carbon contents, there was a slight increase (2–5%) observed at a process temperature of 220 °C compared to the raw ECW. Similarly, the oxygen content also showed a negligible change, decreasing by approximately 1–2%. However, the higher HTC reaction temperature had larger influences on the carbon and oxygen contents. The HTC performed at 270 °C increased the carbon content in the hydrochar by 32–34% while decreasing the oxygen content by around 41%. This suggests that the HTC process at 220 °C is unable to significantly enhance the quality of the raw ECW, unlike the process conducted at 270 °C [47]. On the other hand, the H and N levels exhibited minimal alterations; a common occurrence during the hydrothermal carbonization process of lignocellulosic biomass [13,48].

In addition, the PW recirculation within the HTC process did not significantly increase carbon formation (ranging from 53.43% to 54.85% for 220 °C and 69.23% to a maximum of 70% for 270 °C), nor did it significantly reduce oxygen levels (varying from 40.59% to 39.34% for 220 °C and 25.06% to a minimum of 24.25% for 270 °C) within the final hydrochar.

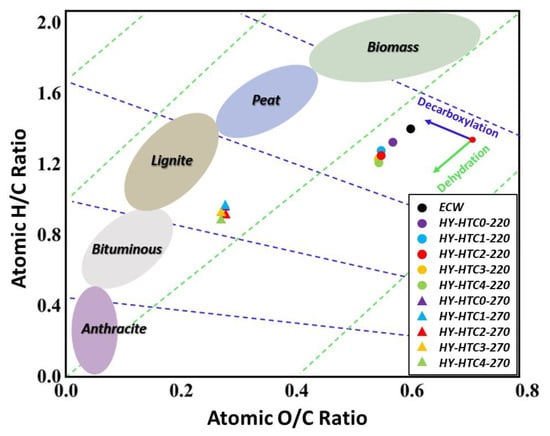

The atomic O/C and H/C ratios were also analyzed and displayed in a Van Krevelen diagram (Figure 3). This diagram offers valuable information about the qualities and types of different fuels and biomasses. A lower O/C–H/C atomic ratio indicates favorable characteristics such as reduced smoke, water vapor, and energy losses during combustion [49]. Additionally, the calorific value of biomass decreases with increasing O/C and H/C ratios. For HTC0, the H/C and O/C ratios decreased significantly at a temperature of 270 °C, mainly due to dehydration and decarboxylation. Throughout PW recirculation, there was no notable decrease in the H/C and O/C ratios, suggesting that the organic compounds in the PW were more favorable for the decarboxylation reaction. Wang et al. [29] similarly noted a significant decrease in the O/C ratio with increasing PW recovery, while the H/C ratio remained relatively stable.

Figure 3.

Van Krevelen diagram of the raw biomass and hydrochars with areas of known coal and biomass materials.

3.3. Effects on the Energy Recovery Efficiency

Table 3 shows the energy value results for the ECW and hydrochars. As the hydrothermal temperature rose from 220 to 270 °C, the HHVs of the hydrochars displayed an increasing trend. At a temperature of 220 °C, the change in HHV was minimal, showing a slight increase of around 1–2%, whereas it was much more pronounced at 270 °C (22–23%). This could be attributed to the fact that at elevated temperatures, a greater proportion of biomass (cellulose and lignin) engages in the reaction, whereas at lower temperatures, it is predominantly hemicellulose that undergoes degradation [50]. Usually, temperature plays a primary role in governing the reactions within HTC and enhances biomass conversion efficiency by supplying additional energy for breaking the intermolecular bonds in the material [51,52]. Moreover, for both the hydrothermal temperatures, the HHV of hydrochars remained almost constant with an increase in the number of PW recycling cycles. These results are in line with the findings of Uddin et al. [28], which confirmed that PW recirculation did not increase the HHV significantly.

Table 3.

Energy parameters of ECW and obtained hydrochars at 220 °C and 270 °C with PW recirculations. Average values of HHV are shown (Er% ≤ 1.2%).

At a temperature of 220 °C, the energy density of the hydrochars remained, with small fluctuations, rather similar to the starting biomass. By contrast, at a temperature of 270 °C, a higher energy density was obtained, with values around 1.22. The marginal increase in the energy density of hydrochars might result from the presence of organic acids in the process water (PW), which facilitate the dehydration of hydrolyzed by-products of hemicellulose and cellulose, leading to the formation of water-soluble intermediates [53]. These intermediates could undergo polymerization, thereby enhancing the abundance of solid microparticles. They could increase the carbon contents of the hydrochars, thus increasing the energy density [13,29].

As the hydrothermal temperature rose, the ERE, which depends on hydrochar yield, reduced. As the HTC temperature approached 270 °C, the decrease in hydrochar yield occurred because dehydration and decarboxylation reactions were more prominent at higher temperatures [54]. Comparing HY-HTC0-220 and HY-HTC0-270, it can be seen that the ERE exhibited a different trend to that of the energy density: the first one decreased with temperature, while the second increased with temperature. Thus, at lower temperatures, a higher hydrochar yield is obtained, but with a lower quality. Moreover, the higher energy density could be translated into the possibility of transporting, at the same volume, a greater amount of energy.

Table 3 shows the variations in ERE with PW recirculation at different temperatures (220 °C and 270 °C). At a temperature of 220 °C, it was noticeable that the ERE rose from 58.47% (in HTC0) to 61.81% (in HTC1), subsequently peaking at 64.91% (in HTC3), indicating an overall increase of approximately 8%. Then, it slowly decreased to 63.48% (in HTC4). Additionally, at the temperature of 270 °C, the ERE of hydrochars followed a similar trend: it increased from a value of 45.86% (in HTC0) to 50.56% (in HTC1), then reached a maximum value of 53.58% (in HTC3). Then, it slowly decreased to 50.70% (in HTC4).

The trends observed in both the carbon retention rate and ERE were similar, indicating that ERE was mainly influenced by the degree of carbon enrichment. Moreover, the development of a carbon framework structure on the hydrochar surface can increase both hydrochar yield and energy density [36].

Another useful parameter to establish the quality of a solid fuel is the fuel ratio; that is, the ratio between its fixed carbon and its volatile matter [55]. Usually, a low fuel ratio leads to increased flaming combustion, reduced char combustion, and faster burnout [56]. In this study, as can be seen from Table 3, a fuel ratio of 0.348 and 0.953 was obtained for HTC0 at 220 °C and 270 °C, respectively, indicating that the hydrochar obtained was less readily combustible than the starting biomass.

3.4. Combustion Behavior of Hydrochars

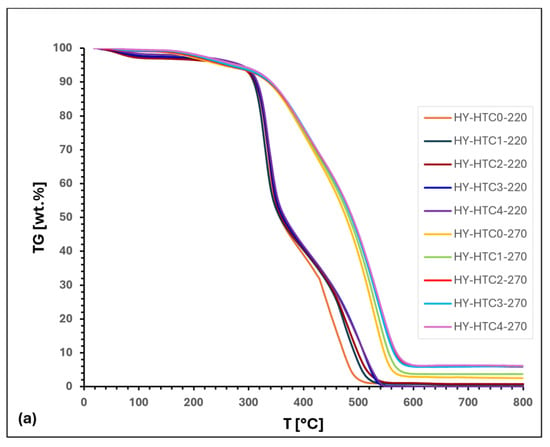

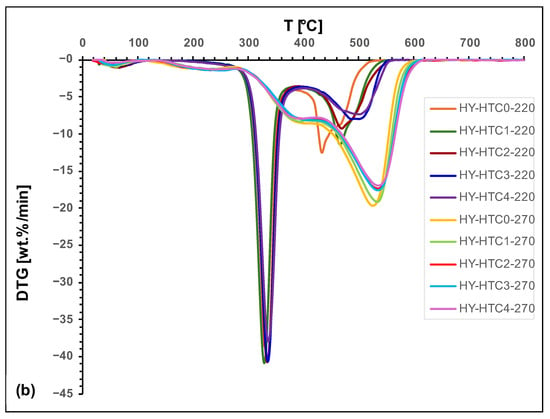

Figure 4 shows the TG and DTG curves of the obtained hydrochars at different HTC temperatures and PW recirculations. The initial and subsequent weight loss peaks observed on the DTG curve primarily correspond to the combustion of volatiles and fixed carbon, respectively [57].

Figure 4.

Thermogravimetric analysis for the different hydrochars with and without recirculation: (a) TG curves of the obtained hydrochars (b) DTG curves of the obtained hydrochars.

As the process temperature increased, the first peak of the DTG curve decreased. The reason for this could be the increased removal of volatiles and less-stable volatile substances as the HTC temperature rose [58]. Conversely, the growth of the second peak might be attributed to a series of reactions occurring during hydrothermal treatment [59,60,61], such as dehydration and decarboxylation. These reactions lead to the polymerization of unstable components in the volatile fractions into relatively stable carbon bonding structures, thereby boosting both FC contents and carbon contents [36].

Table 4 gives the characteristic parameters obtained from the combustion process of the hydrochars.

Table 4.

Combustion parameters of ECW and obtained hydrochars at 220 °C and 270 °C with PW recirculations.

The ignition temperature, Ti, refers to the temperature at which the rate of weight loss reaches 1%/min after the initial weight loss due to moisture removal [62,63]. A higher Ti value signifies lower reaction activity [64,65]. The final combustion temperature, Tb, is determined as the temperature where the DTG profile reaches 1%/min at its conclusion [62,66]. DTGmax represents the maximum value of the mass-loss rate during combustion, with Tp being the temperature corresponding to DTGmax. Additionally, DTGmean is the average conversion rate from Ti to Tb [67].

By increasing the HTC temperature, a slight increase in Ti was observed, while Tp and Tb exhibited a much more pronounced increase. For HY-HTC0, the temperature at the start of combustion varied by about 4 °C, while the peak and burnout temperatures varied by about 197 °C and 73 °C, respectively. With PW recirculations, the Ti and Tp temperatures at 220 °C showed a small variation, with a maximum of about 5 °C and 7 °C, respectively, while the burnout temperature showed a much more pronounced change (from 508.6 °C to 548.1 °C). Similarly, at a temperature of 270 °C, Ti and Tp showed a slight variation with increasing recirculation, while Tb showed a marked increase. This was also reflected in the increasing trend assumed by the fuel ratio. Therefore, the process temperature and PW recirculation increased the combustion range, whereas the temperature had a greater influence. As the HTC temperature increased, the DTGmax for the hydrochars exhibited a decreasing trend, while there was a slight increase in the corresponding peak temperature (Tp). This was related to the reduction in volatiles and the concurrent increase in fixed carbon contents [54].

Moreover, the combustion index (S) was computed to assess the combustion efficiency of the hydrochar. It serves as an integrated measure of ignition and burn-out characteristics during combustion, with a higher value indicating superior overall combustion reactivity [62,67]. Table 4 shows a significant decrease in S as the process temperature increases, suggesting that the hydrochar approached a less violent combustion reaction and higher flame stability [63]. This behavior is related to the lower VM content, as also reported by Wu et al. [36]. A high VM content improves flame combustion and reactivity, but an excessively high VM content can result in unstable fuel combustion and considerable heat loss [58]. At a temperature of 220 °C, with the recycling cycles, S exhibited a light decreasing trend, and the same behavior was found at a temperature of 270 °C.

4. Conclusions

This study explored the utilization of exhausted chestnut wood biomass, a by-product of the tannin extraction process, for hydrothermal carbonization to produce hydrochar. This research focused on optimizing the HTC process by investigating the effects of process water recirculation on hydrochar yield, composition, and fuel properties.

The results revealed that the HTC temperature significantly influenced the hydrochar yield, composition, and energy recovery efficiency. At higher temperatures (270 °C), the hydrochar yield decreased, but the energy density and HHV increased significantly compared to the lower temperature (220 °C). PW recirculation positively impacted the hydrochar yield, enhancing it by up to 16% at 270 °C, likely due to organic compounds catalyzing carbonization reactions. The proximate and ultimate parameters were only slightly affected by the PW recirculation, while temperature had a significant role. At 270 °C, the FC increased to 48.57% while the VM decreased to 50.97%, compared to 220 °C with 25.58% FC and 73.58% VM. The ash content dropped notably at 270 °C to 0.46% compared to 1.25% at 220 °C. Also, at 270 °C, significant increases in carbon (32–34%) and decreases in oxygen (around 41%) were observed, suggesting improved quality. A thermogravimetric analysis showed that the combustion index decreased significantly as the temperature rose, indicating improved combustion stability due to the decrease in the VM content. In fact, an excessively high VM content can result in unstable fuel combustion and substantial heat loss. Additionally, the PW recirculation enhanced the flame stability and combustion performance.

The findings of this paper demonstrate that process water recirculation does not compromise the properties of hydrochar under diverse experimental conditions. A more thorough examination of conversion products could be advantageous in providing additional clarity on the mechanisms of hydrochar formation during process water recirculation.

Author Contributions

Conceptualization, M.B. and M.R.; methodology, A.C. and M.B.; validation, A.C., M.B. and M.R.; formal analysis, M.R.; resources, M.R.; data curation, C.C. and F.P.; writing—original draft preparation, A.C., C.C. and F.P.; writing—review and editing, M.B., A.C. and M.R.; visualization, A.C.; supervision, M.R.; funding acquisition, M.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the project “Network 4 Energy Sustainable Transition—NEST” project (MIUR project code PE000021, Concession Degree No. 1561 of 11 October 2022) within the framework of the NextGenerationEU PNRR plan (CUP C93C22005230007).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Cheng, G.; Zhang, M.; Lu, Y.; Zhang, H.; Lau, E.V. New Insights for Improving Low-Rank Coal Flotation Performance via Emulsified Waste Fried Oil Collector. Fuel 2024, 357, 129925. [Google Scholar] [CrossRef]

- Karamaneas, A.; Koasidis, K.; Frilingou, N.; Xexakis, G.; Nikas, A.; Doukas, H. A Stakeholder-Informed Modelling Study of Greece’s Energy Transition amidst an Energy Crisis: The Role of Natural Gas and Climate Ambition. Renew. Sustain. Energy Transit. 2023, 3, 100049. [Google Scholar] [CrossRef]

- Cheng, G.; Li, Y.; Cao, Y.; Zhang, Z. A Novel Method for the Desulfurization of Medium–High Sulfur Coking Coal. Fuel 2023, 335, 126988. [Google Scholar] [CrossRef]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Mahmood Ali, B.; Algburi, S.; Alzoubi, H.M.; Khudhair Al-Jiboory, A.; Zuhair Sameen, A.; Salman, H.M.; Jaszczur, M. The Renewable Energy Role in the Global Energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Popp, J.; Kovács, S.; Oláh, J.; Divéki, Z.; Balázs, E. Bioeconomy: Biomass and Biomass-Based Energy Supply and Demand. New Biotechnol. 2021, 60, 76–84. [Google Scholar] [CrossRef]

- Moccia, F.; Gallucci, N.; Giovando, S.; Zuorro, A.; Lavecchia, R.; D’Errico, G.; Panzella, L.; Napolitano, A. A Tunable Deep Eutectic Solvent-Based Processing for Valorization of Chestnut Wood Fiber as a Source of Ellagic Acid and Lignin. J. Environ. Chem. Eng. 2022, 10, 107773. [Google Scholar] [CrossRef]

- Romani, A.; Simone, G.; Campo, M.; Moncini, L.; Bernini, R. Sweet Chestnut Standardized Fractions from Sustainable Circular Process and Green Tea Extract: In Vitro Inhibitory Activity against Phytopathogenic Fungi for Innovative Applications in Green Agriculture. PLoS ONE 2021, 16, e0247298. [Google Scholar] [CrossRef]

- Emporio Enologico Albanese, Tannino Di Castagno Etann C 1 Kg. 2024. Available online: https://www.Emporioenologico.com/it/catalogo/prodotti-enologici/tannini/tannino-di-castagno-etann-c-1-kg-513.html (accessed on 8 April 2024).

- Panzella, L.; Moccia, F.; Toscanesi, M.; Trifuoggi, M.; Giovando, S.; Napolitano, A. Exhausted Woods from Tannin Extraction as an Unexplored Waste Biomass: Evaluation of the Antioxidant and Pollutant Adsorption Properties and Activating Effects of Hydrolytic Treatments. Antioxidants 2019, 8, 84. [Google Scholar] [CrossRef]

- Cheng, G.; Niu, Z.; Zhang, C.; Zhang, X.; Li, X. Extraction of Humic Acid from Lignite by KOH-Hydrothermal Method. Appl. Sci. 2019, 9, 1356. [Google Scholar] [CrossRef]

- Cavali, M.; Libardi Junior, N.; De Sena, J.D.; Woiciechowski, A.L.; Soccol, C.R.; Belli Filho, P.; Bayard, R.; Benbelkacem, H.; De Castilhos Junior, A.B. A Review on Hydrothermal Carbonization of Potential Biomass Wastes, Characterization and Environmental Applications of Hydrochar, and Biorefinery Perspectives of the Process. Sci. Total Environ. 2023, 857, 159627. [Google Scholar] [CrossRef]

- Zhuang, X.; Liu, J.; Zhang, Q.; Wang, C.; Zhan, H.; Ma, L. A Review on the Utilization of Industrial Biowaste via Hydrothermal Carbonization. Renew. Sustain. Energy Rev. 2022, 154, 111877. [Google Scholar] [CrossRef]

- Picone, A.; Volpe, M.; Messineo, A. Process Water Recirculation during Hydrothermal Carbonization of Waste Biomass: Current Knowledge and Challenges. Energies 2021, 14, 2962. [Google Scholar] [CrossRef]

- Maniscalco, M.P.; Volpe, M.; Messineo, A. Hydrothermal Carbonization as a Valuable Tool for Energy and Environmental Applications: A Review. Energies 2020, 13, 4098. [Google Scholar] [CrossRef]

- Köchermann, J.; Görsch, K.; Wirth, B.; Mühlenberg, J.; Klemm, M. Hydrothermal Carbonization: Temperature Influence on Hydrochar and Aqueous Phase Composition during Process Water Recirculation. J. Environ. Chem. Eng. 2018, 6, 5481–5487. [Google Scholar] [CrossRef]

- Xu, Z.-X.; Song, H.; Li, P.-J.; He, Z.-X.; Wang, Q.; Wang, K.; Duan, P.-G. Hydrothermal Carbonization of Sewage Sludge: Effect of Aqueous Phase Recycling. Chem. Eng. J. 2020, 387, 123410. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, X.; Zheng, C.; Huang, T.; Lu, X.; Tian, Y. Co-Hydrothermal Carbonization of Water Hyacinth and Sewage Sludge: Effects of Aqueous Phase Recirculation on the Characteristics of Hydrochar. Energy Fuels 2020, 34, 14147–14158. [Google Scholar] [CrossRef]

- Lu, X.; Ma, X.; Qin, Z.; Chen, X.; Qi, X. Investigation of Aqueous Phase Recirculation on Co-Hydrothermal Carbonization of Sewage Sludge and Lignite: Hydrochar Properties and Heavy Metal Chemical Speciation. J. Environ. Chem. Eng. 2022, 10, 107111. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D.L.A.P. Determination of Structural Carbohydrates and Lignin in Biomass. Lab. Anal. Proced. 2008, 1617, 1–16. [Google Scholar]

- Antero, R.V.P.; Alves, A.C.F.; De Oliveira, S.B.; Ojala, S.A.; Brum, S.S. Challenges and Alternatives for the Adequacy of Hydrothermal Carbonization of Lignocellulosic Biomass in Cleaner Production Systems: A Review. J. Clean. Prod. 2020, 252, 119899. [Google Scholar] [CrossRef]

- UNI EN 15104:2011; Solid biofuels—Determination of total content of carbon, hydrogen and nitrogen—Instrumental methods. European Committee for Standardization: Brussels, Belgium, 2011.

- EN 14774-2:2009; Solid biofuels—Determination of moisture content—Oven dry method—Part 2: Total moisture—Simplified method. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 15148:2009; Solid biofuels—Method for the determination of the content of volatile matter. European Committee for Standardization: Brussels, Belgium, 2009.

- EN 14775:2009; Solid biofuels—Method for the determination of ash content. European Committee for Standardization: Brussels, Belgium, 2009.

- Sheng, C.; Azevedo, J.L.T. Estimating the Higher Heating Value of Biomass Fuels from Basic Analysis Data. Biomass Bioenergy 2005, 28, 499–507. [Google Scholar] [CrossRef]

- Ding, Y.; Li, D.; Lv, M.; Yuan, L.; Zhang, J.; Qin, S.; Wang, B.; Cui, X.; Guo, C.; Zhao, P. Influence of Process Water Recirculation on Hydrothermal Carbonization of Rice Husk at Different Temperatures. J. Environ. Chem. Eng. 2023, 11, 109364. [Google Scholar] [CrossRef]

- Yan, W.; Acharjee, T.C.; Coronella, C.J.; Vásquez, V.R. Thermal Pretreatment of Lignocellulosic Biomass. Environ. Prog. Sustain. Energy 2009, 28, 435–440. [Google Scholar] [CrossRef]

- Uddin, M.H.; Reza, M.T.; Lynam, J.G.; Coronella, C.J. Effects of Water Recycling in Hydrothermal Carbonization of Loblolly Pine. Environ. Prog. Sustain. Energy 2014, 33, 1309–1315. [Google Scholar] [CrossRef]

- Wang, R.; Jin, Q.; Ye, X.; Lei, H.; Jia, J.; Zhao, Z. Effect of Process Wastewater Recycling on the Chemical Evolution and Formation Mechanism of Hydrochar from Herbaceous Biomass during Hydrothermal Carbonization. J. Clean. Prod. 2020, 277, 123281. [Google Scholar] [CrossRef]

- Arauzo, P.J.; Olszewski, M.P.; Wang, X.; Pfersich, J.; Sebastian, V.; Manyà, J.; Hedin, N.; Kruse, A. Assessment of the Effects of Process Water Recirculation on the Surface Chemistry and Morphology of Hydrochar. Renew. Energy 2020, 155, 1173–1180. [Google Scholar] [CrossRef]

- Wang, F.; Wang, J.; Gu, C.; Han, Y.; Zan, S.; Wu, S. Effects of Process Water Recirculation on Solid and Liquid Products from Hydrothermal Carbonization of Laminaria. Bioresour. Technol. 2019, 292, 121996. [Google Scholar] [CrossRef]

- Reza, M.T.; Rottler, E.; Herklotz, L.; Wirth, B. Hydrothermal Carbonization (HTC) of Wheat Straw: Influence of Feedwater pH Prepared by Acetic Acid and Potassium Hydroxide. Bioresour. Technol. 2015, 182, 336–344. [Google Scholar] [CrossRef]

- Lynam, J.G.; Coronella, C.J.; Yan, W.; Reza, M.T.; Vasquez, V.R. Acetic Acid and Lithium Chloride Effects on Hydrothermal Carbonization of Lignocellulosic Biomass. Bioresour. Technol. 2011, 102, 6192–6199. [Google Scholar] [CrossRef]

- Ding, Y.; Guo, C.; Qin, S.; Wang, B.; Zhao, P.; Cui, X. Effects of Process Water Recirculation on Yields and Quality of Hydrochar from Hydrothermal Carbonization Process of Rice Husk. J. Anal. Appl. Pyrolysis 2022, 166, 105618. [Google Scholar] [CrossRef]

- Leng, L.; Xu, S.; Liu, R.; Yu, T.; Zhuo, X.; Leng, S.; Xiong, Q.; Huang, H. Nitrogen Containing Functional Groups of Biochar: An Overview. Bioresour. Technol. 2020, 298, 122286. [Google Scholar] [CrossRef]

- Wu, S.; Wang, Q.; Wu, D.; Cui, D.; Wu, C.; Bai, J.; Xu, F.; Liu, B.; Shan, Z.; Zhang, J. Influence of Temperature and Process Water Circulation on Hydrothermal Carbonization of Food Waste for Sustainable Fuel Production. J. Energy Inst. 2024, 112, 101459. [Google Scholar] [CrossRef]

- Picone, A.; Volpe, M.; Codignole Lùz, F.; Malik, W.; Volpe, R.; Messineo, A. Co-Hydrothermal Carbonization with Process Water Recirculation as a Valuable Strategy to Enhance Hydrochar Recovery with High Energy Efficiency. Waste Manag. 2024, 175, 101–109. [Google Scholar] [CrossRef]

- Volpe, M.; Picone, A.; Luz, F.C.; Mosonik, M.C.; Volpe, R.; Messineo, A. Potential Pitfalls on the Scalability of Laboratory-Based Research for Hydrothermal Carbonization. Fuel 2022, 315, 123189. [Google Scholar] [CrossRef]

- Reza, M.T.; Lynam, J.G.; Uddin, M.H.; Coronella, C.J. Hydrothermal Carbonization: Fate of Inorganics. Biomass Bioenergy 2013, 49, 86–94. [Google Scholar] [CrossRef]

- Kabadayi Catalkopru, A.; Kantarli, I.C.; Yanik, J. Effects of Spent Liquor Recirculation in Hydrothermal Carbonization. Bioresour. Technol. 2017, 226, 89–93. [Google Scholar] [CrossRef]

- Zhou, Y.; Remón, J.; Pang, X.; Jiang, Z.; Liu, H.; Ding, W. Hydrothermal Conversion of Biomass to Fuels, Chemicals and Materials: A Review Holistically Connecting Product Properties and Marketable Applications. Sci. Total Environ. 2023, 886, 163920. [Google Scholar] [CrossRef]

- Pavkov, I.; Radojčin, M.; Stamenković, Z.; Bikić, S.; Tomić, M.; Bukurov, M.; Despotović, B. Hydrothermal Carbonization of Agricultural Biomass: Characterization of Hydrochar for Energy Production. Solid Fuel Chem. 2022, 56, 225–235. [Google Scholar] [CrossRef]

- Islam, M.T.; Chambers, C.; Toufiq Reza, M. Effects of Process Liquid Recirculation on Material Properties of Hydrochar and Corresponding Adsorption of Cationic Dye. J. Anal. Appl. Pyrolysis 2022, 161, 105418. [Google Scholar] [CrossRef]

- Volpe, M.; Fiori, L.; Volpe, R.; Messineo, A. Upgrading of Olive Tree Trimmings Residue as Biofuel by Hydrothermal Carbonization and Torrefaction: A Comparative Study. Chem. Eng. Trans. 2016, 50, 13–18. [Google Scholar] [CrossRef]

- Benavente, V.; Calabuig, E.; Fullana, A. Upgrading of Moist Agro-Industrial Wastes by Hydrothermal Carbonization. J. Anal. Appl. Pyrolysis 2015, 113, 89–98. [Google Scholar] [CrossRef]

- Arauzo, P.; Olszewski, M.; Kruse, A. Hydrothermal Carbonization Brewer’s Spent Grains with the Focus on Improving the Degradation of the Feedstock. Energies 2018, 11, 3226. [Google Scholar] [CrossRef]

- Kambo, H.S.; Minaret, J.; Dutta, A. Process Water from the Hydrothermal Carbonization of Biomass: A Waste or a Valuable Product? Waste Biomass Valor 2018, 9, 1181–1189. [Google Scholar] [CrossRef]

- Volpe, M.; Messineo, A.; Mäkelä, M.; Barr, M.R.; Volpe, R.; Corrado, C.; Fiori, L. Reactivity of Cellulose during Hydrothermal Carbonization of Lignocellulosic Biomass. Fuel Process. Technol. 2020, 206, 106456. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Kent Hoekman, S.; Balasubramanian, R. Production of Solid Biochar Fuel from Waste Biomass by Hydrothermal Carbonization. Fuel 2013, 103, 943–949. [Google Scholar] [CrossRef]

- Heidari, M.; Dutta, A.; Acharya, B.; Mahmud, S. A Review of the Current Knowledge and Challenges of Hydrothermal Carbonization for Biomass Conversion. J. Energy Inst. 2019, 92, 1779–1799. [Google Scholar] [CrossRef]

- Akhtar, J.; Saidina Amin, N. A Review on Operating Parameters for Optimum Liquid Oil Yield in Biomass Pyrolysis. Renew. Sustain. Energy Rev. 2012, 16, 5101–5109. [Google Scholar] [CrossRef]

- Nakason, K.; Panyapinyopol, B.; Kanokkantapong, V.; Viriya-empikul, N.; Kraithong, W.; Pavasant, P. Characteristics of Hydrochar and Liquid Fraction from Hydrothermal Carbonization of Cassava Rhizome. J. Energy Inst. 2018, 91, 184–193. [Google Scholar] [CrossRef]

- Wang, T.; Zhai, Y.; Zhu, Y.; Li, C.; Zeng, G. A Review of the Hydrothermal Carbonization of Biomass Waste for Hydrochar Formation: Process Conditions, Fundamentals, and Physicochemical Properties. Renew. Sustain. Energy Rev. 2018, 90, 223–247. [Google Scholar] [CrossRef]

- Akarsu, K.; Duman, G.; Yilmazer, A.; Keskin, T.; Azbar, N.; Yanik, J. Sustainable Valorization of Food Wastes into Solid Fuel by Hydrothermal Carbonization. Bioresour. Technol. 2019, 292, 121959. [Google Scholar] [CrossRef]

- Nhuchhen, D.; Afzal, M. HHV Predicting Correlations for Torrefied Biomass Using Proximate and Ultimate Analyses. Bioengineering 2017, 4, 7. [Google Scholar] [CrossRef]

- Adeleke, A.A.; Odusote, J.K.; Ikubanni, P.P.; Lasode, O.A.; Malathi, M.; Paswan, D. The Ignitability, Fuel Ratio and Ash Fusion Temperatures of Torrefied Woody Biomass. Heliyon 2020, 6, e03582. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, S.; Yuan, X.; Xi, Y.; Huang, Z.; Tan, M.; Li, C. The Effects of Temperature and Color Value on Hydrochars’ Properties in Hydrothermal Carbonization. Bioresour. Technol. 2018, 249, 574–581. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Zhou, X.; Zheng, R.; Zhou, Z.; Zhang, Y.; Zhu, G.; Yu, C.; Hantoko, D.; Yan, M. Hydrothermal Carbonization of Food Waste after Oil Extraction Pre-Treatment: Study on Hydrochar Fuel Characteristics, Combustion Behavior, and Removal Behavior of Sodium and Potassium. Sci. Total Environ. 2021, 754, 142192. [Google Scholar] [CrossRef] [PubMed]

- Periyavaram, S.R.; Uppala, L.; Sivaprakash, S.; Reddy, P.H.P. Thermal Behaviour of Hydrochar Derived from Hydrothermal Carbonization of Food Waste Using Leachate as Moisture Source: Kinetic and Thermodynamic Analysis. Bioresour. Technol. 2023, 373, 128734. [Google Scholar] [CrossRef] [PubMed]

- Xie, X.; Peng, C.; Song, X.; Peng, N.; Gai, C. Pyrolysis Kinetics of the Hydrothermal Carbons Derived from Microwave-Assisted Hydrothermal Carbonization of Food Waste Digestate. Energy 2022, 245, 123269. [Google Scholar] [CrossRef]

- Fu, M.-M.; Mo, C.-H.; Li, H.; Zhang, Y.-N.; Huang, W.-X.; Wong, M.H. Comparison of Physicochemical Properties of Biochars and Hydrochars Produced from Food Wastes. J. Clean. Prod. 2019, 236, 117637. [Google Scholar] [CrossRef]

- Islam, M.T.; Reza, M.T. Evaluation of Fuel and Combustion Properties of Hydrochar Derived from Co-Hydrothermal Carbonization of Biomass and Plastic. Biomass Bioenergy 2023, 172, 106750. [Google Scholar] [CrossRef]

- Barbanera, M.; Cotana, F.; Di Matteo, U. Co-Combustion Performance and Kinetic Study of Solid Digestate with Gasification Biochar. Renew. Energy 2018, 121, 597–605. [Google Scholar] [CrossRef]

- Cong, K.; Zhang, Y.; Gan, Y.; Li, Q. Experimental Study of the Ignition Temperatures of Low-Rank Coals Using TGA under Oxygen-Deficient Conditions. J. Therm. Anal. Calorim. 2018, 133, 1597–1607. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, Z.; Zhang, H.; Yang, H.; Zhang, D. An Experimental Investigation on the Effect of Convection on the Ignition Behaviour of Single Coal Particles under Various O2 Concentrations. Fuel 2014, 116, 77–83. [Google Scholar] [CrossRef]

- Buratti, C.; Barbanera, M.; Bartocci, P.; Fantozzi, F. Thermogravimetric Analysis of the Behavior of Sub-Bituminous Coal and Cellulosic Ethanol Residue during Co-Combustion. Bioresour. Technol. 2015, 186, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Meng, J.; Moore, A.M.; Chang, J.; Gou, J.; Park, S. Thermogravimetric Investigation on the Degradation Properties and Combustion Performance of Bio-Oils. Bioresour. Technol. 2014, 152, 267–274. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).