Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review

Abstract

1. Introduction

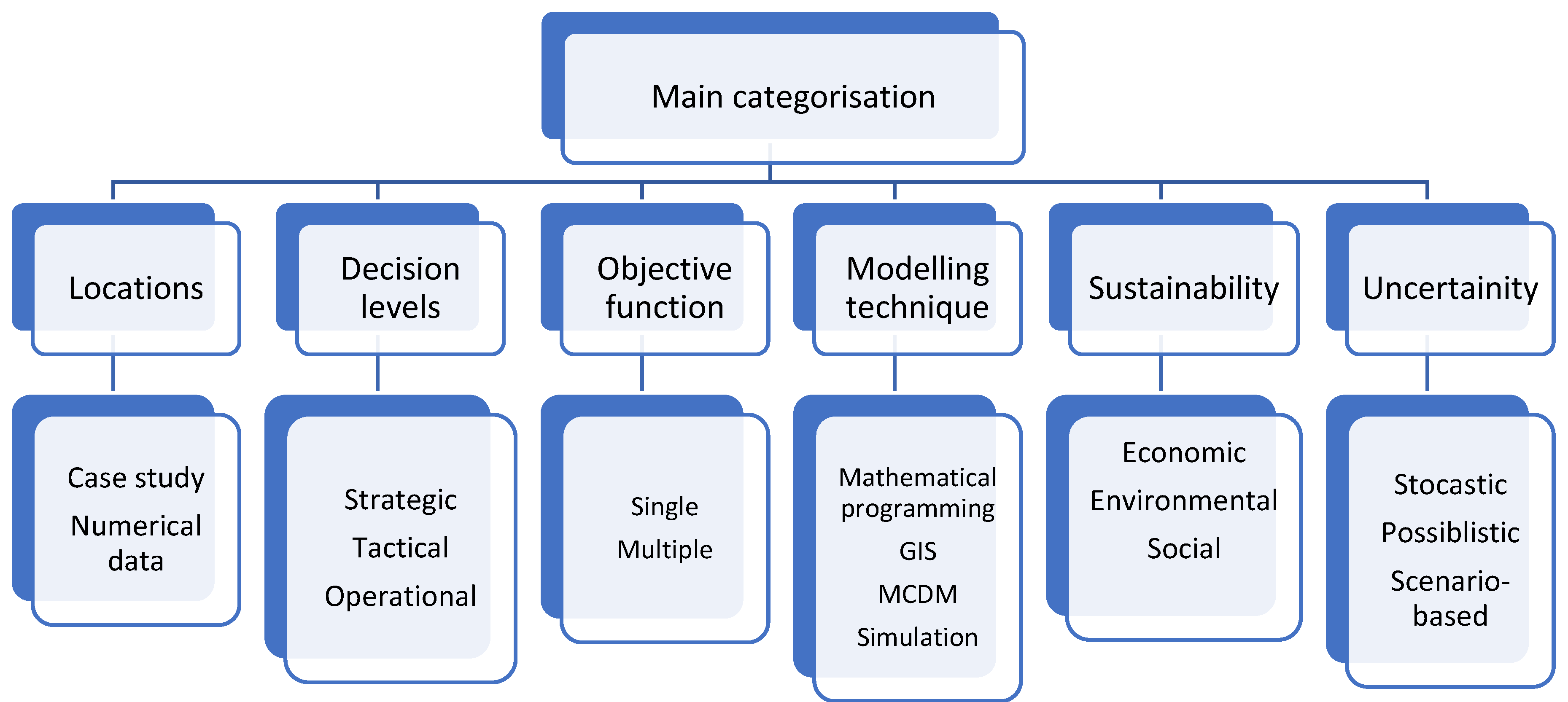

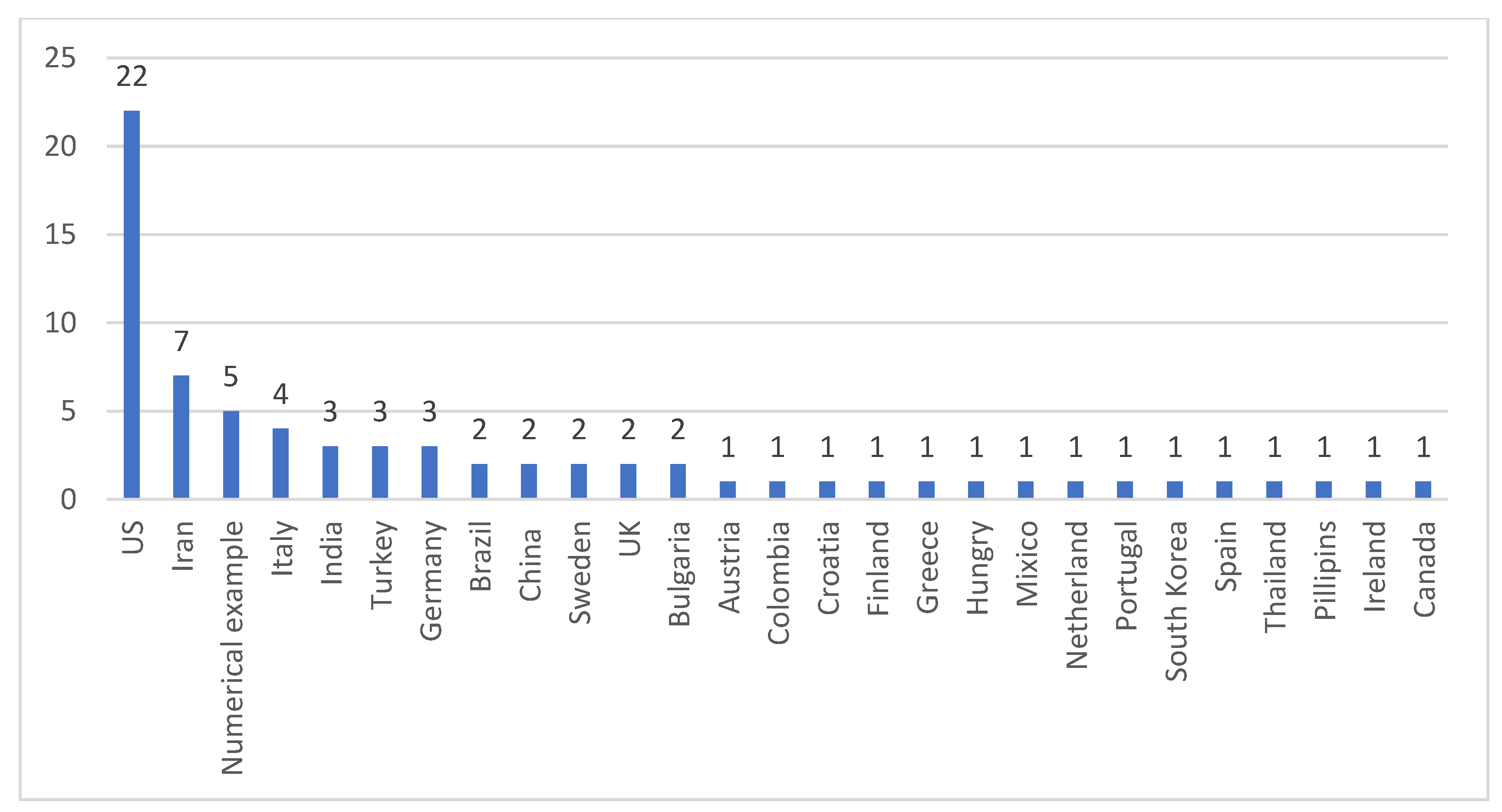

2. Methodology for Reviewing the Literature

3. Results

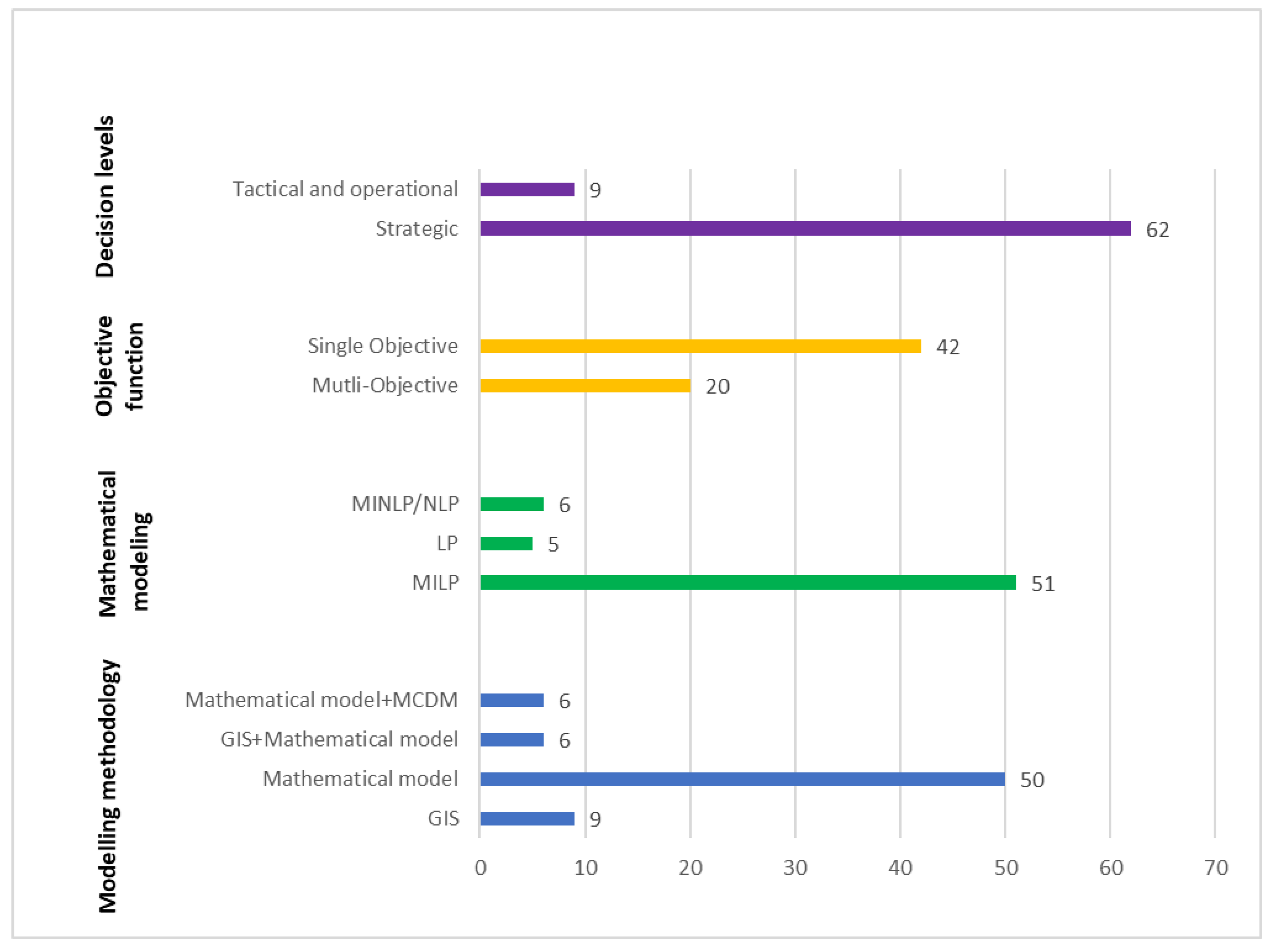

3.1. Decision Levels in Supply Chain Management

3.1.1. Strategic Decisions

3.1.2. Tactical Decisions

3.1.3. Operational Decisions

3.2. Objective Function

3.3. Modelling Methodology

3.3.1. Mathematical Models

Linear Programming (LP)

Mixed-Integer Linear Programming (MILP)

Nonlinear Programming (NLP)/Mixed-Integer Nonlinear Programming (MINLP)

3.3.2. Geographic Information System (GIS)

3.3.3. Multi-Criteria Decision Making (MCDM)

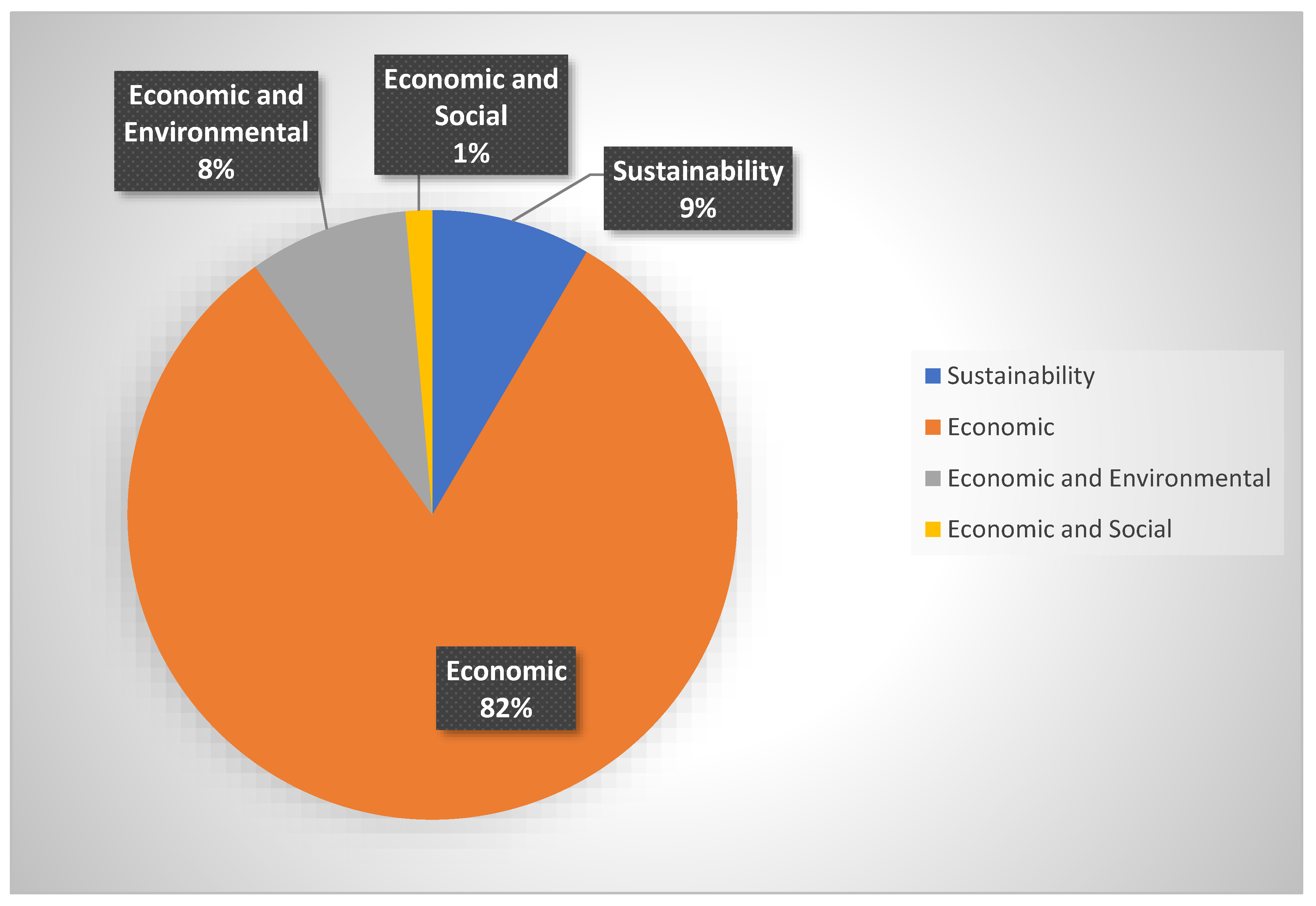

3.4. Sustainability

3.4.1. Economic Aspects

3.4.2. Environmental Aspects

3.4.3. Social Aspects

3.5. Uncertainty in AWCB Supply Chain

Techniques to Deal with Uncertainty

4. Main Findings and Future Opportunities

5. Conclusions

Funding

Conflicts of Interest

References

- Murphy, F.; Devlin, G.; Deverell, R.; McDonnell, K. Biofuel Production in Ireland—An Approach to 2020 Targets with a Focus on Algal Biomass. Energies 2013, 6, 6391–6412. [Google Scholar] [CrossRef]

- Scarlat, N.; Martinov, M.; Dallemand, J.-F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef]

- White, & Oldfield. Holistic Analysis of Agricultural Waste, Co-Products, and By-Products (AWCB) Chains and Logistics of AWCB Valorisation Systems. 2016. Available online: http://multisite.iris.cat/agrocycle/files/2017/12/D1.3_FHolisticAnalysisAWCB.pdf (accessed on 2 May 2022).

- Priefer, C.; Jörissen, J.; Frör, O. Pathways to Shape the Bioeconomy. Resources 2017, 6, 10. [Google Scholar] [CrossRef]

- Singh, A.; Smyth, B.M.; Murphy, J.D. A biofuel strategy for Ireland with an emphasis on production of biomethane and minimization of land-take. Renew. Sustain. Energy Rev. 2010, 14, 277–288. [Google Scholar] [CrossRef]

- Singh, A.; Karmakar, S.; Jacob, B.S.; Bhattacharya, P.; Kumar, S.P.J.; Banerjee, R. Enzymatic polishing of cereal grains for improved nutrient retainment. J. Food Sci. Technol. 2014, 52, 3147–3157. [Google Scholar] [CrossRef] [PubMed]

- Ghaderi, H.; Pishvaee, M.S.; Moini, A. Biomass supply chain network design: An optimization-oriented review and analysis. Ind. Crops Prod. 2016, 94, 972–1000. [Google Scholar] [CrossRef]

- Prasad, S.; Singh, A.; Korres, N.E.; Rathore, D.; Sevda, S.; Pant, D. Sustainable utilization of crop residues for energy generation: A life cycle assessment (LCA) perspective. Bioresour. Technol. 2020, 303, 122964. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tatsiopoulos, I.P. Locating a bioenergy facility using a hybrid optimization method. Int. J. Prod. Econ. 2010, 123, 196–209. [Google Scholar] [CrossRef]

- Ajanovic, A. Biofuels versus food production: Does biofuels production increase food prices? Energy 2011, 36, 2070–2076. [Google Scholar] [CrossRef]

- Ajanovic, A.; Haas, R. On the future prospects and limits of biofuels in Brazil, the US and EU. Appl. Energy 2014, 135, 730–737. [Google Scholar] [CrossRef]

- Ooba, M.; Fujii, M.; Hayashi, K. Geospatial distribution of ecosystem services and biomass energy potential in eastern Japan. J. Clean. Prod. 2016, 130, 35–44. [Google Scholar] [CrossRef]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Sengupta, S.; Gupta, A.; Kumar, S.S.; Vijay, V.; Kumar, V.; Vijay, V.K.; Pant, D. Valorization of agricultural waste for biogas based circular economy in India: A research outlook. Bioresour. Technol. 2020, 304, 123036. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Biomass supply chain environmental and socio-economic analysis: 40-Years comprehensive review of methods, decision issues, sustainability challenges, and the way forward. Biomass Bioenergy 2020, 142, 105777. [Google Scholar] [CrossRef]

- Sosa, A.; Acuna, M.; McDonnell, K.; Devlin, G. Controlling moisture content and truck configurations to model and optimise biomass supply chain logistics in Ireland. Appl. Energy 2015, 137, 338–351. [Google Scholar] [CrossRef]

- Ba, B.H.; Prins, C.; Prodhon, C. Models for optimization and performance evaluation of biomass supply chains: An Operations Research perspective. Renew. Energy 2016, 87, 977–989. [Google Scholar] [CrossRef]

- Balaman, Y.; Selim, H. A network design model for biomass to energy supply chains with anaerobic digestion systems. Appl. Energy 2014, 130, 289–304. [Google Scholar] [CrossRef]

- EkşioğLu, S.D.; Li, S.; Zhang, S.; Sokhansanj, S.; Petrolia, D. Analyzing Impact of Intermodal Facilities on Design and Management of Biofuel Supply Chain. Transp. Res. Rec. J. Transp. Res. Board 2010, 2191, 144–151. [Google Scholar] [CrossRef]

- Espinoza-Vázquez, Y.M.; Gómez-Castro, F.I.; Ponce-Ortega, J.M. Optimization of the supply chain for the production of biomass-based fuels and high-added value products in Mexico. Comput. Chem. Eng. 2021, 145, 107181. [Google Scholar] [CrossRef]

- Yue, D.; You, F.; Snyder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput. Chem. Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Ivanova, P.; Chalova, V.; Uzunova, G.; Koleva, L.; Manolov, I. Biochemical Characterization of Industrially Produced Rapeseed Meal as a Protein Source in Food Industry. Agric. Agric. Sci. Procedia 2016, 10, 55–62. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Farhadkhani, M. Sustainable supply chain planning for biomass-based power generation with environmental risk and supply uncertainty considerations: A real-life case study. Int. J. Prod. Res. 2020, 59, 3084–3108. [Google Scholar] [CrossRef]

- Cooper, N.; Panteli, A.; Shah, N. Linear estimators of biomass yield maps for improved biomass supply chain optimisation. Appl. Energy 2019, 253, 113526. [Google Scholar] [CrossRef]

- Aranguren, M.; Castillo-Villar, K.K.; Aboytes-Ojeda, M. A two-stage stochastic model for co-firing biomass supply chain networks. J. Clean. Prod. 2021, 319, 128582. [Google Scholar] [CrossRef]

- Ghani, N.M.A.M.A.; Vogiatzis, C.; Szmerekovsky, J. Biomass feedstock supply chain network design with biomass conversion incentives. Energy Policy 2018, 116, 39–49. [Google Scholar]

- Esmaeili, S.A.H.; Szmerekovsky, J.; Sobhani, A.; Dybing, A.; Peterson, T.O. Sustainable biomass supply chain network design with biomass switching incentives for first-generation bioethanol producers. Energy Policy 2020, 138, 111222. [Google Scholar] [CrossRef]

- Duc, D.N.; Meejaroen, P.; Nananukul, N. Multi-objective models for biomass supply chain planning with economic and carbon footprint consideration. Energy Rep. 2021, 7, 6833–6843. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, J.; Yi, W.; Cai, H.; Li, Y.; Su, Z. Agri-biomass supply chain optimization in north China: Model development and application. Energy 2021, 239, 122374. [Google Scholar] [CrossRef]

- Ge, Y.; Li, L.; Yun, L. Modeling and economic optimization of cellulosic biofuel supply chain considering multiple conversion pathways. Appl. Energy 2021, 281, 116059. [Google Scholar] [CrossRef]

- Aboytes-Ojeda, M.; Castillo-Villar, K.K.; Roni, M.S. A decomposition approach based on meta-heuristics and exact methods for solving a two-stage stochastic biofuel hub-and-spoke network problem. J. Clean. Prod. 2020, 247, 119176. [Google Scholar] [CrossRef]

- Zhu, X.; Yao, Q. Logistics system design for biomass-to-bioenergy industry with multiple types of feedstocks. Bioresour. Technol. 2011, 102, 10936–10945. [Google Scholar] [CrossRef]

- Abriyantoro, D.; Dong, J.; Hicks, C.; Singh, S.P. A stochastic optimisation model for biomass outsourcing in the cement manufacturing industry with production planning constraints. Energy 2019, 169, 515–526. [Google Scholar] [CrossRef]

- Cobuloglu, H.I.; Büyüktahtakın, I.E. A two-stage stochastic mixed-integer programming approach to the competition of biofuel and food production. Comput. Ind. Eng. 2017, 107, 251–263. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K. A multi-stage stochastic program for the sustainable design of biofuel supply chain networks under biomass supply uncertainty and disruption risk: A real-life case study. Transp. Res. Part E Logist. Transp. Rev. 2018, 118, 534–567. [Google Scholar] [CrossRef]

- Nilsson, D. SHAM—A simulation model for designing straw fuel delivery systems. Part 2: Model applications. Biomass Bioenergy 1999, 16, 39–50. [Google Scholar] [CrossRef]

- Nilsson, D. Dynamic Simulation of Straw Harvesting Systems: Influence of Climatic, Geographical and Biological Factors on Performance and Costs. J. Agric. Eng. Res. 2000, 76, 27–36. [Google Scholar] [CrossRef]

- Kim, J.; Realff, M.J.; Lee, J.H.; Whittaker, C.; Furtner, L. Design of biomass processing network for biofuel production using an MILP model. Biomass Bioenergy 2011, 35, 853–871. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Total footprints-based multi-criteria optimisation of regional biomass energy supply chains. Energy 2012, 44, 135–145. [Google Scholar] [CrossRef]

- Bairamzadeh, S.; Pishvaee, M.S.; Saidi-Mehrabad, M. Multiobjective Robust Possibilistic Programming Approach to Sustainable Bioethanol Supply Chain Design under Multiple Uncertainties. Ind. Eng. Chem. Res. 2016, 55, 237–256. [Google Scholar] [CrossRef]

- Yue, D.; You, F. Game-theoretic modeling and optimization of multi-echelon supply chain design and operation under Stackelberg game and market equilibrium. Comput. Chem. Eng. 2014, 71, 347–361. [Google Scholar] [CrossRef]

- Akgul, O.; Mac Dowell, N.; Papageorgiou, L.; Shah, N. A mixed integer nonlinear programming (MINLP) supply chain optimisation framework for carbon negative electricity generation using biomass to energy with CCS (BECCS) in the UK. Int. J. Greenh. Gas Control. 2014, 28, 189–202. [Google Scholar] [CrossRef]

- Bruglieri, M.; Liberti, L. Optimal running and planning of a biomass-based energy production process. Energy Policy 2008, 36, 2430–2438. [Google Scholar] [CrossRef][Green Version]

- Roni, M.S.; Eksioglu, S.D.; Cafferty, K.G.; Jacobson, J.J. A multi-objective, hub-and-spoke model to design and manage biofuel supply chains. Ann. Oper. Res. 2017, 249, 351–380. [Google Scholar] [CrossRef]

- Akgul, O.; Zamboni, A.; Bezzo, F.; Shah, N.; Papageorgiou, L.G. Optimization-Based Approaches for Bioethanol Supply Chains. Ind. Eng. Chem. Res. 2011, 50, 4927–4938. [Google Scholar] [CrossRef]

- Leão, R.R.d.C.C.; Hamacher, S.; Oliveira, F. Optimization of biodiesel supply chains based on small farmers: A case study in Brazil. Bioresour. Technol. 2011, 102, 8958–8963. [Google Scholar] [CrossRef]

- Bowling, I.M.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Facility Location and Supply Chain Optimization for a Biorefinery. Ind. Eng. Chem. Res. 2011, 50, 6276–6286. [Google Scholar] [CrossRef]

- Morrow, W.R.; Griffin, W.M.; Matthews, H.S. Modeling Switchgrass Derived Cellulosic Ethanol Distribution in the United States. Environ. Sci. Technol. 2006, 40, 2877–2886. [Google Scholar] [CrossRef] [PubMed]

- Ren, J.; Manzardo, A.; Toniolo, S.; Scipioni, A.; Tan, S.; Dong, L.; Gao, S. Design and modeling of sustainable bioethanol supply chain by minimizing the total ecological footprint in life cycle perspective. Bioresour. Technol. 2013, 146, 771–774. [Google Scholar] [CrossRef] [PubMed]

- You, F.; Wang, B. Life Cycle Optimization of Biomass-to-Liquid Supply Chains with Distributed–Centralized Processing Networks. Ind. Eng. Chem. Res. 2011, 50, 10102–10127. [Google Scholar] [CrossRef]

- Tatsiopoulos, I.; Tolis, A. Economic aspects of the cotton-stalk biomass logistics and comparison of supply chain methods. Biomass Bioenergy 2003, 24, 199–214. [Google Scholar] [CrossRef]

- Albashabsheh, N.T.; Stamm, J.L.H. Optimization of lignocellulosic biomass-to-biofuel supply chains with mobile pelleting. Transp. Res. Part E Logist. Transp. Rev. 2019, 122, 545–562. [Google Scholar] [CrossRef]

- Laasasenaho, K.; Lensu, A.; Lauhanen, R.; Rintala, J. GIS-data related route optimization, hierarchical clustering, location optimization, and kernel density methods are useful for promoting distributed bioenergy plant planning in rural areas. Sustain. Energy Technol. Assessments 2019, 32, 47–57. [Google Scholar] [CrossRef]

- Razm, S.; Nickel, S.; Saidi-Mehrabad, M.; Sahebi, H. A global bioenergy supply network redesign through integrating transfer pricing under uncertain condition. J. Clean. Prod. 2019, 208, 1081–1095. [Google Scholar] [CrossRef]

- Ng, R.T.; Maravelias, C.T. Design of biofuel supply chains with variable regional depot and biorefinery locations. Renewable Energy 2017, 100, 90–102. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Jonkman, J.; Kanellopoulos, A.; Bloemhof, J.M. Designing an eco-efficient biomass-based supply chain using a mul-ti-actor optimisation model. J. Clean. Product. 2019, 210, 1065–1075. [Google Scholar] [CrossRef]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Huhnke, R.L.; Khanchi, A. Scenario optimization modeling approach for design and management of biomass-to-biorefinery supply chain system. Bioresour. Technol. 2013, 150, 163–171. [Google Scholar] [CrossRef] [PubMed]

- Tan, R.R.; Aviso, K.B.; Barilea, I.U.; Culaba, A.B.; Cruz, J.B., Jr. A fuzzy multi-regional input–output optimization model for biomass production and trade under resource and footprint constraints. Appl. Energy 2012, 90, 154–160. [Google Scholar] [CrossRef]

- Poudel, S.R.; Marufuzzaman, M.; Bian, L. Designing a reliable bio-fuel supply chain network considering link failure probabilities. Comput. Ind. Eng. 2016, 91, 85–99. [Google Scholar] [CrossRef]

- Hombach, L.E.; Cambero, C.; Sowlati, T.; Walther, G. Optimal design of supply chains for second generation biofuels incorporating European biofuel regulations. J. Clean. Prod. 2016, 133, 565–575. [Google Scholar] [CrossRef]

- Paulo, H.; Azcue, X.; Barbosa-Póvoa, A.P.; Relvas, S. Supply chain optimization of residual forestry biomass for bioenergy production: The case study of Portugal. Biomass Bioenergy 2015, 83, 245–256. [Google Scholar] [CrossRef]

- D’amore, F.; Bezzo, F. Strategic optimisation of biomass-based energy supply chains for sustainable mobility. Comput. Chem. Eng. 2016, 87, 68–81. [Google Scholar] [CrossRef]

- Woo, Y.B.; Cho, S.; Kim, J.; Kim, B.S. Optimization-based approach for strategic design and operation of a bio-mass-to-hydrogen supply chain. Int. J. Hydrogen Energy 2016, 41, 5405–5418. [Google Scholar] [CrossRef]

- Singh, A.; Olsen, S.I.; Pant, D. Importance of Life Cycle Assessment of Renewable Energy Sources. In Life Cycle Assessment of Renewable Energy Sources. Green Energy and Technology; Singh, A., Pant, D., Olsen, S., Eds.; Springer: London, UK, 2013; pp. 1–11. [Google Scholar]

- Delivand, M.K.; Cammerino, A.R.B.; Garofalo, P.; Monteleone, M. Optimal locations of bioenergy facilities, biomass spatial availability, logistics costs and GHG (greenhouse gas) emissions: A case study on electricity productions in South Italy. J. Clean. Prod. 2015, 99, 129–139. [Google Scholar] [CrossRef]

- Kühmaier, M.; Kanzian, C.; Stampfer, K. Identification of potential energy wood terminal locations using a spatial multicriteria decision analysis. Biomass Bioenergy 2014, 66, 337–347. [Google Scholar] [CrossRef]

- Balaman, Y.; Selim, H. Sustainable design of renewable energy supply chains integrated with district heating systems: A fuzzy optimization approach. J. Clean. Prod. 2016, 133, 863–885. [Google Scholar] [CrossRef]

- Parker, N.; Tittmann, P.; Hart, Q.; Nelson, R.; Skog, K.; Schmidt, A.; Gray, E.; Jenkins, B. Development of a biorefinery optimized biofuel supply curve for the Western United States. Biomass Bioenergy 2010, 34, 1597–1607. [Google Scholar] [CrossRef]

- Singh, J.; Panesar, B.; Sharma, S. Geographical distribution of agricultural residues and optimum sites of biomass based power plant in Bathinda, Punjab. Biomass Bioenergy 2011, 35, 4455–4460. [Google Scholar] [CrossRef]

- Perpiña, C.; Martínez-Llario, J.C.; Pérez-Navarro, Á. Multicriteria assessment in GIS environments for siting biomass plants. Land Use Policy 2013, 31, 326–335. [Google Scholar] [CrossRef]

- Sharma, B.; Birrell, S.; Miguez, F. Spatial modeling framework for bioethanol plant siting and biofuel production potential in the U.S. Appl. Energy 2017, 191, 75–86. [Google Scholar] [CrossRef]

- Lovrak, A.; Puksec, T.; Duic, N. A Geographical Information System (GIS) based approach for assessing the spatial distribution and seasonal variation of biogas production potential from agricultural residues and municipal biowaste. Appl. Energy 2020, 267, 115010. [Google Scholar] [CrossRef]

- Yılmaz, S.; Selim, H. A review on the methods for biomass to energy conversion systems design. Renew. Sustain. Energy Rev. 2013, 25, 420–430. [Google Scholar] [CrossRef]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Shastri, Y.; Hansen, A.; Rodríguez, L.; Ting, K. Development and application of BioFeed model for optimization of herbaceous biomass feedstock production. Biomass Bioenergy 2011, 35, 2961–2974. [Google Scholar] [CrossRef]

- Munasinghe, M.; Jayasinghe, P.; Deraniyagala, Y.; Matlaba, V.J.; dos Santos, J.F.; Maneschy, M.C.; Mota, J.A. Value–Supply Chain Analysis (VSCA) of crude palm oil production in Brazil, focusing on economic, environmental and social sustainability. Sustain. Prod. Consum. 2019, 17, 161–175. [Google Scholar] [CrossRef]

- Ahmadi, L.; Kannangara, M.; Bensebaa, F. Cost-effectiveness of small scale biomass supply chain and bioenergy production systems in carbon credit markets: A life cycle perspective. Sustain. Energy Technol. Assess. 2020, 37, 100627. [Google Scholar] [CrossRef]

- Cundiff, J.S.; Dias, N.; Sherali, H.D. A linear programming approach for designing a herbaceous biomass delivery system. Bioresour. Technol. 1997, 59, 47–55. [Google Scholar] [CrossRef]

- Recio, B.; Rubio, F.; Criado, J. A decision support system for farm planning using AgriSupport II. Decis. Support Syst. 2003, 36, 189–203. [Google Scholar] [CrossRef]

- Smith, R. Chemical Process: Design and Integration; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Winston, W.L.; Goldberg, J.B. Operations Research: Applications and Algorithms (Volume 3); Thomson Brooks/Cole: Belmont, OH, USA, 2004. [Google Scholar]

- Singh, J.; Panesar, B.; Sharma, S. Energy potential through agricultural biomass using geographical information system—A case study of Punjab. Biomass Bioenergy 2007, 32, 301–307. [Google Scholar] [CrossRef]

- Wang, B.; Gebreslassie, B.H.; You, F. Sustainable design and synthesis of hydrocarbon biorefinery via gasification pathway: Integrated life cycle assessment and technoeconomic analysis with multiobjective superstructure optimization. Comput. Chem. Eng. 2013, 52, 55–76. [Google Scholar] [CrossRef]

- Thompson, E.; Wang, Q.; Li, M. Anaerobic digester systems (ADS) for multiple dairy farms: A GIS analysis for optimal site selection. Energy Policy 2013, 61, 114–124. [Google Scholar] [CrossRef]

- Leduc, S.; Starfelt, F.; Dotzauer, E.; Kindermann, G.; McCallum, I.; Obersteiner, M.; Lundgren, J. Optimal location of lignocellulosic ethanol refineries with polygeneration in Sweden. Energy 2010, 35, 2709–2716. [Google Scholar] [CrossRef]

- Liu, W.; Phillips, V.D.; Singh, D. A spatial model for the economic evaluation of biomass production systems. Biomass Bioenergy 1992, 3, 345–356. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzalez, E. Mathematical algorithms to locate factories to transform biomass in bioenergy focused on logistic network construction. Renew. Energy 2010, 35, 2136–2142. [Google Scholar] [CrossRef]

- Viana, H.; Cohen, W.B.; Lopes, D.; Aranha, J. Assessment of forest biomass for use as energy. GIS-based analysis of geographical availability and locations of wood-fired power plants in Portugal. Appl. Energy 2010, 87, 2551–2560. [Google Scholar] [CrossRef]

- Voets, T.; Neven, A.; Thewys, T.; Kuppens, T. GIS-BASED location optimization of a biomass conversion plant on contaminated willow in the Campine region (Belgium). Biomass Bioenergy 2013, 55, 339–349. [Google Scholar] [CrossRef]

- Lourinho, G.; Brito, P. Assessment of biomass energy potential in a region of Portugal (Alto Alentejo). Energy 2015, 81, 189–201. [Google Scholar] [CrossRef]

- Okello, C.; Pindozzi, S.; Faugno, S.; Boccia, L. Bioenergy potential of agricultural and forest residues in Uganda. Biomass Bioenergy 2013, 56, 515–525. [Google Scholar] [CrossRef]

- Wang, J.-J.; Jing, Y.-Y.; Zhang, C.-F.; Zhao, J.-H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 2263–2278. [Google Scholar] [CrossRef]

- Buchholz, T.; Rametsteiner, E.; Volk, T.A.; Luzadis, V.A. Multi Criteria Analysis for bioenergy systems assessments. Energy Policy 2009, 37, 484–495. [Google Scholar] [CrossRef]

- Sacchelli, S. 9-Social, Economic, and Environmental Impacts of Biomass and Biofuel Supply Chains. In Biomass Supply Chains for Bioenergy and Biorefining; Holm-Nielsen, J.B., Ehimen, E.A., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 191–213. [Google Scholar] [CrossRef]

- Mas, M.D.; Giarola, S.; Zamboni, A.; Bezzo, F. Capacity planning and financial optimization of the bioethanol supply chain under price uncertainty. Comput. Aided Chem. Eng. 2010, 28, 97–102. [Google Scholar] [CrossRef]

- Gebreslassie, B.H.; Yao, Y.; You, F. Design under uncertainty of hydrocarbon biorefinery supply chains: Multiobjective stochastic programming models, decomposition algorithm, and a Comparison between CVaR and downside risk. AIChE J. 2012, 58, 2155–2179. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Incorporating social benefits in multi-objective optimization of forest-based bioenergy and biofuel supply chains. Appl. Energy 2016, 178, 721–735. [Google Scholar] [CrossRef]

- Malczewski, J.; Rinner, C. Multicriteria Decision Analysis in Geographic Information Science; Springer: Berlin, Germany, 2015; pp. 23–54. [Google Scholar] [CrossRef]

- Gnansounou, E.; Dauriat, A.; Villegas, J.; Panichelli, L. Life cycle assessment of biofuels: Energy and greenhouse gas balances. Bioresour. Technol. 2009, 100, 4919–4930. [Google Scholar] [CrossRef] [PubMed]

- Sabri, E.H.; Beamon, B.M. A multi-objective approach to simultaneous strategic and operational planning in supply chain design. Omega 2000, 28, 581–598. [Google Scholar] [CrossRef]

- Amigun, B.; Musango, J.K.; Stafford, W. Biofuels and sustainability in Africa. Renew. Sustain. Energy Rev. 2011, 15, 1360–1372. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. A comprehensive review of biomass resources and biofuels potential in Ghana. Renew. Sustain. Energy Rev. 2011, 15, 404–415. [Google Scholar] [CrossRef]

- Hong, B.H.; How, B.S.; Lam, H.L. Overview of sustainable biomass supply chain: From concept to modelling. Clean Technol. Environ. Policy 2016, 18, 2173–2194. [Google Scholar] [CrossRef]

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar] [CrossRef]

- Kim, Y.; Jeon, Y.J.; Yim, J.-H.; Jeong, K.-H.; Park, Y.-K.; Kim, T.; Lee, J.; Kwon, E.E. Livestock manure valorization to biochemicals and energy using CO2: A case study of goat excreta. J. CO2 Util. 2019, 30, 107–111. [Google Scholar] [CrossRef]

- Jury, C.; Benetto, E.; Koster, D.; Schmitt, B.; Welfring, J. Life Cycle Assessment of biogas production by monofer-mentation of energy crops and injection into the natural gas grid. Biomass Bioenergy 2010, 34, 54–66. [Google Scholar] [CrossRef]

- Panepinto, D.; Viggiano, F.; Genon, G. The potential of biomass supply for energetic utilization in a small Italian region: Basilicata. Clean Technol. Environ. Policy 2014, 16, 833–845. [Google Scholar] [CrossRef]

- Zahraee, S.; Assadi, M.K.; Saidur, R. Application of Artificial Intelligence Methods for Hybrid Energy System Optimization. Renew. Sustain. Energy Rev. 2016, 66, 617–630. [Google Scholar] [CrossRef]

- You, F.; Grossmann, I.E.; Wassick, J.M. Multisite Capacity, Production, and Distribution Planning with Reactor Modifications: MILP Model, Bilevel Decomposition Algorithm versus Lagrangean Decomposition Scheme. Ind. Eng. Chem. Res. 2011, 50, 4831–4849. [Google Scholar] [CrossRef]

- Panepinto, D.; Genon, G. Biomass thermal treatment: Energy recovery, environmental compatibility and determi-nation of external costs. Waste Biomass Valoriz. 2012, 3, 197–206. [Google Scholar] [CrossRef]

- Kangas, A.S.; Kangas, J. Probability, possibility and evidence: Approaches to consider risk and uncertainty in forestry decision analysis. For. Policy Econ. 2004, 6, 169–188. [Google Scholar] [CrossRef]

- Ells, A.; Bulte, E.; van Kooten, G.C. Uncertainty and Forest Land Use Allocation in British Columbia: Vague Priorities and Imprecise Coefficients. For. Sci. 1997, 43, 509–520. [Google Scholar] [CrossRef]

- Petrovic, D. Simulation of supply chain behaviour and performance in an uncertain environment. Int. J. Prod. Econ. 2001, 71, 429–438. [Google Scholar] [CrossRef]

- Iakovou, E.; Karagiannidis, A.; Vlachos, D.; Toka, A.; Malamakis, A. Waste biomass-to-energy supply chain management: A critical synthesis. Waste Manag. 2010, 30, 1860–1870. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S. Supply chain and logistics issues of bio-energy production. J. Clean. Prod. 2011, 19, 32–42. [Google Scholar] [CrossRef]

- Sahinidis, N.V. Optimization under uncertainty: State-of-the-art and opportunities. Comput. Chem. Eng. 2004, 28, 971–983. [Google Scholar] [CrossRef]

- Awudu, I.; Zhang, J. Uncertainties and sustainability concepts in biofuel supply chain management: A review. Renew. Sustain. Energy Rev. 2012, 16, 1359–1368. [Google Scholar] [CrossRef]

- Shapiro, J.F. Challenges of strategic supply chain planning and modeling. Comput. Chem. Eng. 2004, 28, 855–861. [Google Scholar] [CrossRef]

- Birge, J.R.; Louveaux, F. Introduction to Stochastic Programming; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Shabani, N.; Sowlati, T. A hybrid multi-stage stochastic programming-robust optimization model for maximizing the supply chain of a forest-based biomass power plant considering uncertainties. J. Clean. Prod. 2016, 112, 3285–3293. [Google Scholar] [CrossRef]

- Guo, C.; Hu, H.; Wang, S.; Rodriguez, L.F.; Ting, K.C.; Lin, T. Multiperiod stochastic programming for biomass supply chain design under spatiotemporal variability of feedstock supply. Renew. Energy 2022, 186, 378–393. [Google Scholar] [CrossRef]

| Reference | Type of Biomass | Uncertainty | Decision Level | Objective | Technology | Seasonality | Sustainability | Modelling Technique | Case Study | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strategic | Tactical and Operational | Single | Multiple | Single | Multiple | Mathematical Model | LCA | GIS | ||||||

| Ivanov et al. (2022) [21] | Dairy waste scum | * | * | * | * | Bulgaria | ||||||||

| Fattahi et al. (2021) [22] | Biomass | * | * | * | * | * | * | * | Iran | |||||

| Cooper et al. (2019) [23] | Wheat straw, barley straw, and corn stover | * | * | * | * | * | Hungry | |||||||

| Aranguren et al. (2021) [24] | Corn, wheat, switchgrass, Miscanthus, Sorghum | * | * | * | * | * | US | |||||||

| Ghani et al. (2018) [25] | Corn stover | * | * | * | * | US | ||||||||

| Esmaeili et al. (2020) [26] | Corn and corn stover | * | * | * | US | |||||||||

| Duc et al. (2021) [27] | Rice husk | * | * | * | * | * | * | Thailand | ||||||

| Wu et al. (2021) [28] | Agri-biomass (straw) | * | * | * | * | China | ||||||||

| Ge et al. (2021) [29] | Agricultural residues (corn stover) and urban waste wood (discarded furniture) | * | * | * | * | * | * | US | ||||||

| Aboytes-Ojeda et al. (2020) [30] | Lignocellulosic | * | * | * | * | * | * | US | ||||||

| Espinoza-Vázquez et al. (2021) [19] | Agricultural residues (corn, sorghum, wheat, and barley) | * | * | * | Mexico | |||||||||

| Zhu and Yao (2011) [31] | Switchgrass, corn stalk, and wheat straw | US | ||||||||||||

| Abriyantoro et al. (2019) [32] | Biomass | * | * | * | ||||||||||

| Cobuloglu and Büyüktahtakın (2017) [33] | Switchgrass, corn | * | * | * | * | * | US | |||||||

| Castillo-Villar et al. (2017) [23] | Switchgrass | * | US | |||||||||||

| Fattahi and Govindan (2018) [34] | Agricultural residues (corn Stover, wheat straw, and rice straw) and forest biomass | * | * | * | * | * | * | Iran | ||||||

| Nilsson (1999) [35] | Straw | * | * | Sweden | ||||||||||

| Nilsson (2000) [36] | Straw | * | * | Sweden | ||||||||||

| Kim et al. (2011b) [37] | Thinnings, prunings, grasses, chips/shavings | * | * | * | US | |||||||||

| Čuček et al. (2012) [38] | Corn, corn stover, wood chips, MSW (municipal solid waste), manure, and timber | * | * | * | * | * | Numerical data | |||||||

| Bairamzadeh et al. (2016) [39] | Corn stover, wheat straw | * | * | * | * | * | * | * | * | * | Iran | |||

| Yue and You (2014) [40] | Corn stover | * | * | * | US | |||||||||

| Akgul et al. (2014) [41] | Woody biomass | * | * | * | * | UK | ||||||||

| Bruglieri and Liberti (2008) [42] | Agricultural products, biological waste | * | * | * | Italy | |||||||||

| Roni et al. (2017) [43] | Cellulosic biomass | * | * | * | * | US | ||||||||

| Akgul et al. (2011) [44] | Corn stover | * | * | * | Italy | |||||||||

| Leão et al. (2011) [45] | Vegetable oil | * | * | * | Brazil | |||||||||

| Bowling et al. (2011) [46] | Vegetable oil | * | * | Numerical | ||||||||||

| Morrow et al. (2006) [47] | Corn and switchgrass | * | * | * | * | US | ||||||||

| Ren et al. (2013) [48] | Multiple | * | * | * | China | |||||||||

| You and Wang (2011) [49] | Corn stover, energy crops, wood residues | * | * | * | * | * | * | US | ||||||

| Tatsiopoulos and Tolis (2003) [50] | Chopped cotton-plant stalks | * | * | LP | * | Greece | ||||||||

| Albashabsheh and Stamm (2019) [51] | Corn stover and switchgrass | * | * | * | * | * | US | |||||||

| Laasasenaho et al. (2019) [52] | Manures, biowastes, Sewage sludge | * | * | * | * | Finland | ||||||||

| Razm et al. (2019) [53] | Forest residues, woodwork factory residues, agricultural residues, switchgrass | * | * | * | * | * | Iran/Armenia | |||||||

| Ng and Maravelias (2017) [54] | Corn stover, switchgrass | * | * | * | * | US | ||||||||

| Sarker et al. (2019) [55] | Crops, grass, wood residue, and livestock waste | * | * | * | * | * | US | |||||||

| Jonkman et al. (2019) [56] | Sugar beet | * | * | * | * | Netherland | ||||||||

| Sharma et al. (2013) [57] | Switchgrass | * | * | * | * | * | * | US | ||||||

| Tan et al. (2012) [58] | Sugarcane and corn | * | * | * | * | * | Philippines | |||||||

| Poudel et al. (2016) [59] | Corn stover and forest residues | * | * | * | * | * | * | * | US | |||||

| Hombach et al. (2016) [60] | Forest residues, agricultural residues/straw, sawmill waste, and miscanthus | * | * | * | * | Germany | ||||||||

| Paulo et al. (2015) [61] | Biomass | * | * | * | * | Portugal | ||||||||

| D’amore and Bezzo (2016) [62] | Corn, stover | * | * | * | * | Italy | ||||||||

| Woo et al. (2016) [63] | Agricultural residues (rice straw, rice husk, and barley straw), industrial residues, forestry residues, and energy crops | * | * | * | * | * | South Korea | |||||||

| Singh et al. (2008) [64] | Agricultural biomass | * | * | * | * | * | India | |||||||

| Delivand et al. (2015) [65] | Wheat and crop residue | * | * | * | Italy | |||||||||

| Kühmaier et al. (2014) [66] | Wood residue | * | * | * | * | Austria | ||||||||

| Balaman (2016) [67] | Wood and manure | * | * | * | * | * | Turkey | |||||||

| Parker et al. (2010) [68] | Agricultural, forest, urban, and energy crop biomass | * | * | * | * | * | US | |||||||

| Singh et al. (2011) [69] | Agricultural residues | * | India | |||||||||||

| Perpiña et al. (2013) [70] | Residual agricultural and forestry biomass | * | * | Spain | ||||||||||

| Sharma et al. (2017) [71] | Switchgrass, miscanthus, and corn stover | * | * | US | ||||||||||

| Lovrak et al. (2020) [72] | Manure and agriculture residue | * | * | * | Croatia | |||||||||

| Yılmaz Balam an et al. (2018) [73] | Manure/wood | * | * | * | * | * | * | UK | ||||||

| Durmaz & Bilgen, (2020) [74] | Poultry manure | * | * | * | * | Turkey | ||||||||

| Shastri et al. (2011) [75] | AWCB | * | * | * | * | * | Colombia | |||||||

| Balaman, (2016) [67] | Cattle and chicken manure, waste wood | * | * | * | * | * | Turkey | |||||||

| Murphy et al. (2016) [1] | Wood chip and wood pellets, willow, and miscanthus | * | * | * | * | * | * | Ireland | ||||||

| Munasinghe et al. (2019) [76] | Palm tree | * | * | * | Brazil | |||||||||

| Ahmadi et al. (2020) [77] | Residues | * | * | Canada | ||||||||||

| Uncertain Parameter | Reference |

|---|---|

| Availability of biomass | Cundiff et al. (1997) [78], Kim et al. (2011b) [37], Nilsson (2000) [36], Fattahi and Govindan (2018) [34], Abriyantoro et al. (2019) [32] |

| Demand | Kim et al. (2011b) [37], Abriyantoro et al. (2019) [32], Razm et al. (2019) [53] |

| Cost parameters | Cobuloglu and Büyüktahtakın (2017) [33], Fattahi and Govindan (2018), Abriyantoro et al. (2019) [32], Razm et al. (2019) [53] |

| Critical technical factors | Razm et al. (2019) [53] |

| Technology evolution | Razm et al. (2019) [53] |

| Selling price | Kim et al. (2011b) [37], Abriyantoro et al. (2019) [32] |

| Number of harvesting workdays | Sharma et al. (2013) [57], Nilsson (2000) [36], Razm et al. (2019) [53] |

| The consumed transportation fuel | Razm et al. (2019) [53] |

| The used fuel | Razm et al. (2019) [53] |

| The used electricity | Razm et al. (2019) [53] |

| The quantities of seed, fertiliser, pesticides, and herbicides | Razm et al. (2019) [53] |

| The used human labour | Nilsson (2000) [35], Razm et al. (2019) [53] |

| Velocity of the vehicle | Razm et al. (2019) [53] |

| Yield of crop | Nilsson (1999) [35], Cobuloglu and Büyüktahtakın (2017) [33], Razm et al. (2019) [53] |

| Rainfall value | Nilsson (1999) [35] |

| Moisture and ash contents | Nilsson (1999) [35], Castillo-Villar et al. (2017) [23], Abriyantoro et al. (2019) [32], Aboytes-Ojeda et al. (2020) [30] |

| Capacity of facilities | Fattahi and Govindan (2018) [34] |

| Uncertainty Method | Uncertainty Parameter | Level of Decision | Case Study | Reference |

|---|---|---|---|---|

| Scenario-based/MILP | Biomass availability, biofuel demand, price | Strategic | US | Kim et al. (2011b) [37] |

| Scenario-based/LP | Production levels of biomass | Strategic | US | Cundiff et al. (1997) [78] |

| Scenario-based/LP | Number of harvesting workdays | Strategic Tactical Operational | US | Sharma et al. (2013) [57] |

| Simulation | Average straw harvest, average combining to baling time, field area, fraction of the land area with harvestable straw, transport work between the stores and heating plant, number of days | Strategic | Sweden | Nilsson (2000) [36] |

| Simulation | Weather, stack size, type of crop, moisture content, straw yield, wind speed | Strategic | Sweden | Nilsson (1999) [35] |

| Two-stage stochastic model and L-shaped algorithm | Biomass price, yield of biomass | Strategic Operational | US | Cobuloglu and Büyüktahtakın (2017) [33] |

| Two-stage stochastic model | Moisture and ash contents | Strategic | US | Castillo-Villar et al. (2017) [23] |

| Multi-stage stochastic model/fuzzy | Facilities’ capacity, disruption risk, biomass supply, cost | Strategic tactical | Iran | Fattahi and Govindan (2018) [34] |

| Stochastic model | Delays in biomass delivery, biomass moisture content, cement demand | Strategic Tactical Operational | Abriyantoro et al. (2019) [32] | |

| Two-stage stochastic model | Moisture content, ash content | Strategic | US | Aboytes-Ojeda et al. (2020) [30] |

| The interval linear programming | Costs, prices, the consumed transportation fuel, demand, the used fuel, the used electricity, the quantity of seed, fertiliser, pesticide, and herbicide, the used human labour, the velocity of the vehicle, yield of grain | Strategic | Razm et al. (2019) [53] | |

| Stochastic and fuzzy | Demand | Strategic Tactical | Thailand | Duc et al. (2021) [27] |

| Two-stage stochastic model | Weather, moisture, and ash | US | Aranguren et al.(2021) [24] | |

| Two-stage stochastic model | Biomass supply | Strategic | Iran | Fattahi et al. (2021) [22] |

| Two-stage stochastic model | Collectible corn stover removal and farmer participation rates | Strategic Tactical | US | Guo et al. (2022) [121] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roudneshin, M.; Sosa, A. Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review. Energies 2024, 17, 2542. https://doi.org/10.3390/en17112542

Roudneshin M, Sosa A. Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review. Energies. 2024; 17(11):2542. https://doi.org/10.3390/en17112542

Chicago/Turabian StyleRoudneshin, Maryam, and Amanda Sosa. 2024. "Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review" Energies 17, no. 11: 2542. https://doi.org/10.3390/en17112542

APA StyleRoudneshin, M., & Sosa, A. (2024). Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review. Energies, 17(11), 2542. https://doi.org/10.3390/en17112542