Effects of CO2 Geosequestration on Opalinus Clay

Abstract

1. Introduction

2. CFD-FEM Model

3. Methods and Materials

3.1. Opalinus Clay Model and Properties

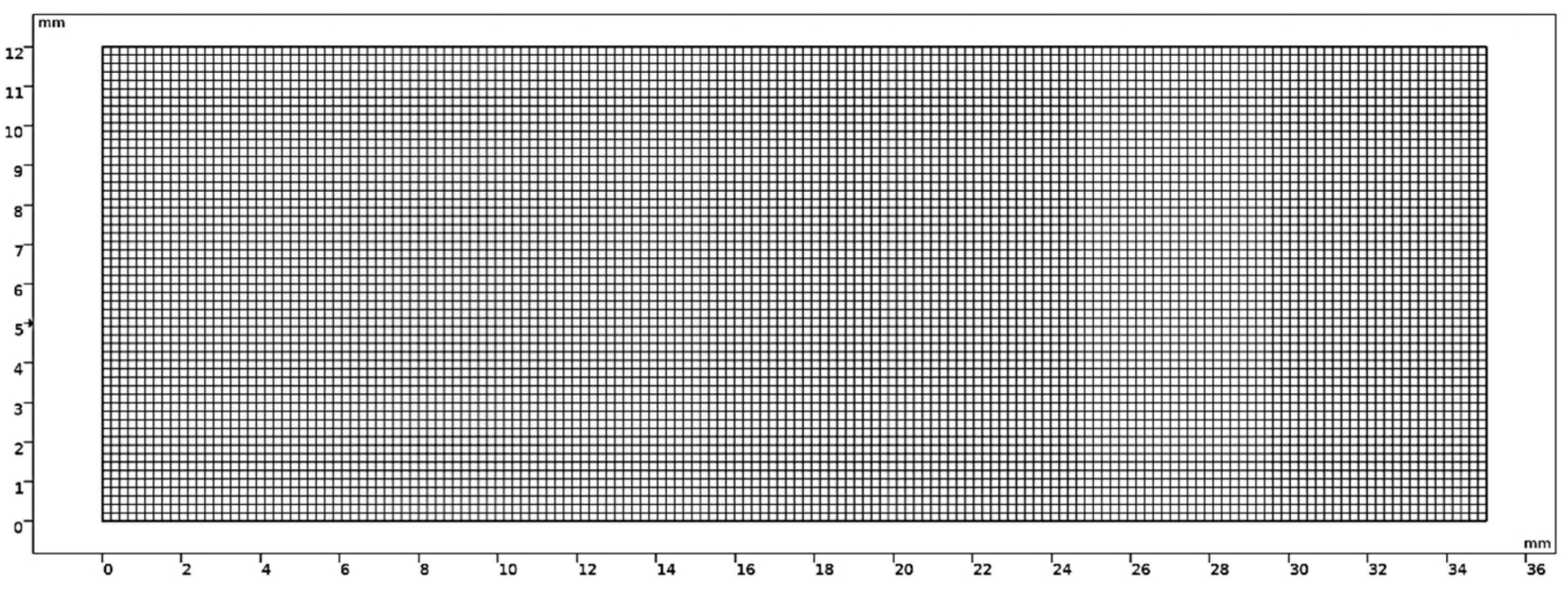

3.2. Meshing of the Flow Domain

3.3. Scope of Work

3.4. Numerical Model Setup

4. Results and Discussion

4.1. Validation of the Numerical Model

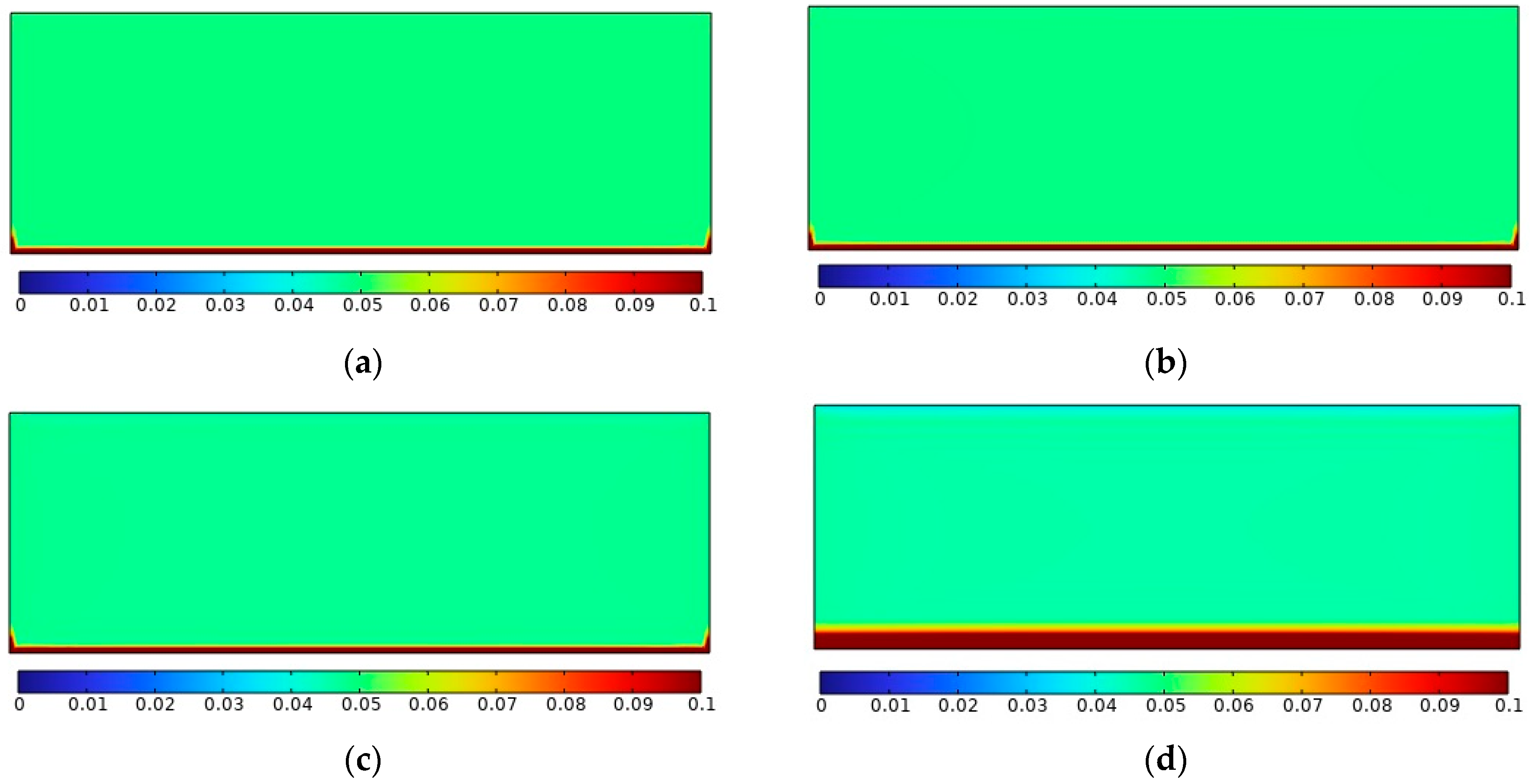

4.2. CO2 Saturation under No Pressure Gradient

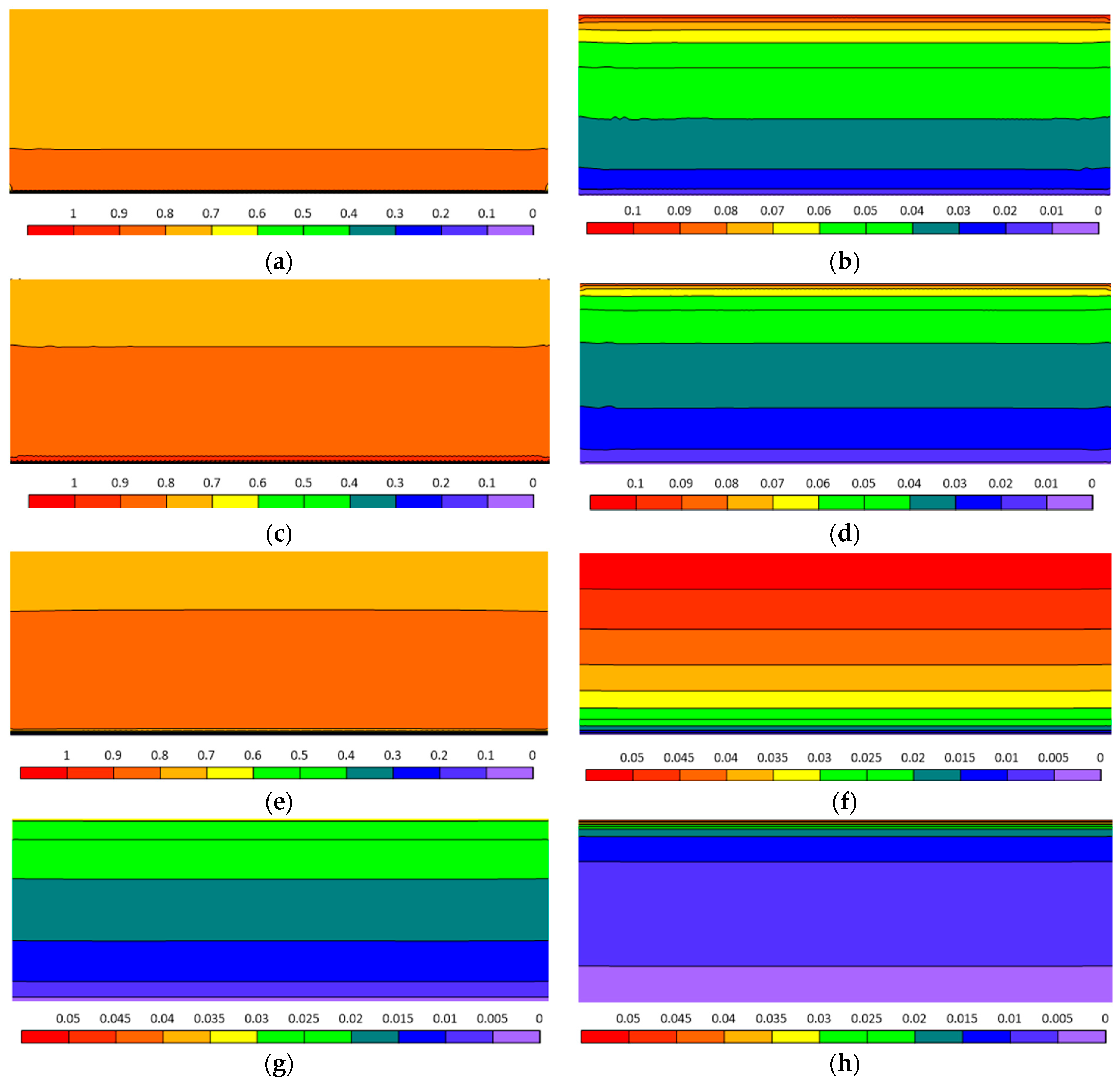

4.3. CO2 Saturation under Positive Pressure Gradient

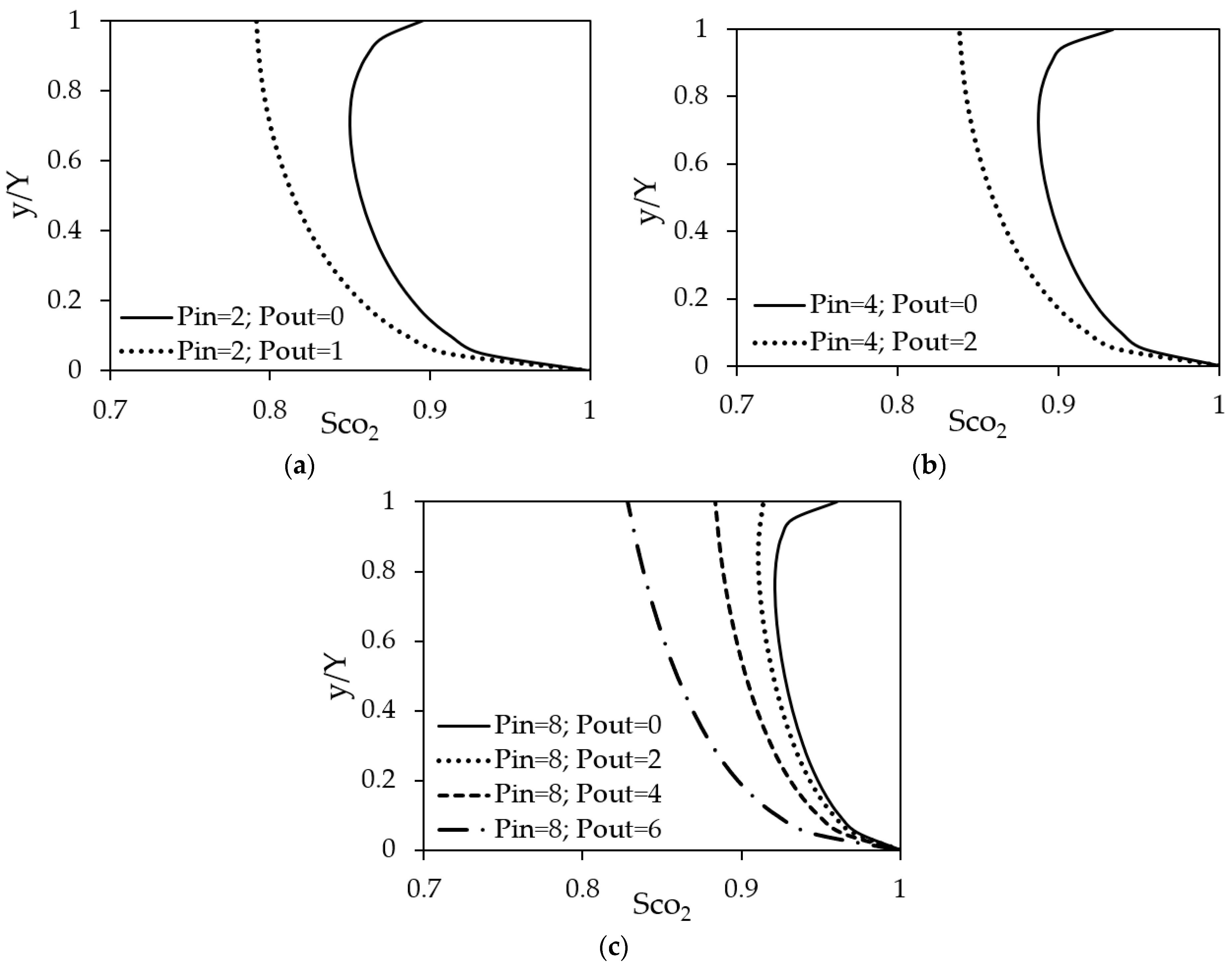

4.4. Effects of Outlet Pressure on CO2 Saturation

5. Conclusions

- Sub-critical CO2 injection in Opalinus Clay for geosequestration is possible under the right conditions.

- Sub-critical CO2 injection in Opalinus Clay under no pressure gradient leads to very low CO2 concentration (maximum 5%).

- An increase in pressure gradient leads to higher CO2 concentration in Opalinus Clay.

- An increase in outlet pressure results in lower CO2 concentration in the model.

- For optimal sub-critical CO2 geosequestration in Opalinus Clay, the injection pressure should be 8 MPa, and the outlet pressure should be minimum, ideally close to 0 MPa.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rigby, S.P.; Alsayah, A.; Seely, R. Impact of Exposure to Supercritical Carbon Dioxide on Reservoir Caprocks and Inter-Layers during Sequestration. Energies 2022, 15, 7538. [Google Scholar] [CrossRef]

- Allen, M.J.; Faulkner, D.R.; Worden, R.H.; Rice-Birchall, E.; Katirtsidis, N.; Utley, J.E.P. Geomechanical and petrographic assessment of a CO2 storage site: Application to the Acorn CO2 Storage Site, offshore United Kingdom. Int. J. Greenh. Gas Control 2020, 94, 102923. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Rasouli, V.; Rabiei, M. Significant aspects of carbon capture and storage—A review. Petroleum 2019, 5, 335–340. [Google Scholar] [CrossRef]

- Hawez, H.K.; Asim, T. Impact of Regional Pressure Dissipation on Carbon Capture and Storage Projects: A Comprehensive Review. Energies 2024, 17, 1889. [Google Scholar] [CrossRef]

- Kim, S.; Hosseini, S.A. Study on the ratio of pore-pressure/stress changes during fluid injection and its implications for CO2 geologic storage. J. Pet. Sci. Eng. 2017, 149, 138–150. [Google Scholar] [CrossRef]

- Rahman, M.J.; Fawad, M.; Mondol, N.H. 3D Field-Scale Geomechanical Modeling of Potential CO2 Storage Site Smeaheia, Offshore Norway. Energies 2022, 15, 1407. [Google Scholar] [CrossRef]

- Favero, V.; Laloui, L. Impact of CO2 injection on the hydro-mechanical behaviour of a clay-rich caprock. Int. J. Greenh. Gas Control 2018, 71, 133–141. [Google Scholar] [CrossRef]

- Song, Y.; Jun, S.; Na, Y.; Kim, K.; Jang, Y.; Wang, J. Geomechanical challenges during geological CO2 storage: A review. Chem. Eng. J. 2023, 456, 140968. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, Q.; Zhang, T.; Zhao, C.; Iltaf, K.H.; Liu, S.; Fukatsu, Y. Petrophysical properties of representative geological rocks encountered in carbon storage and utilization. Energy Rep. 2023, 9, 3661–3682. [Google Scholar] [CrossRef]

- Hawez, H.; Sanaee, R.; Faisal, N.H. Multiphase Flow Modelling in Fractured Reservoirs using a Novel Computational Fluid Dynamics Approach. In Proceedings of the 55th US Rock Mechanics/Geomechanics Symposium, Virtual, 18–25 June 2021. [Google Scholar]

- Ladubec, C.; Gracie, R.; Craig, J. An extended finite element method model for carbon sequestration. Int. J. Numer. Methods Eng. 2015, 102, 316–331. [Google Scholar] [CrossRef]

- Lesueur, M.; Rattez, H.; Zwarts, S.; Hajibeygi, H. Upscaling rocks mechanical properties to study Underground Hydrogen Storage feasibility. Symp. Energy Geotech. 2023, 2023, 2–3. [Google Scholar] [CrossRef]

- Ismail, I.; Gaganis, V. Carbon Capture, Utilization, and Storage in Saline Aquifers: Subsurface Policies, Development Plans, Well Control Strategies and Optimization Approaches—A Review. Clean Technol. 2023, 5, 609–637. [Google Scholar] [CrossRef]

- Mazzoldi, A.; Hill, T.; Colls, J.J. Assessing the risk for CO2 transportation within CCS projects, CFD modelling. Int. J. Greenh. Gas Control 2011, 5, 816–825. [Google Scholar] [CrossRef]

- Liu, X.; Asim, T.; Zhu, G.; Mishra, R. Theoretical and experimental investigations on the combustion characteristics of three components mixed municipal solid waste. Fuel 2020, 267, 117183. [Google Scholar] [CrossRef]

- Vafaie, A.; Cama, J.; Soler, J.M.; Kivi, I.R.; Vilarrasa, V. Chemo-hydro-mechanical effects of CO2 injection on reservoir and seal rocks: A review on laboratory experiments. Renew. Sustain. Energy Rev. 2023, 178, 113270. [Google Scholar] [CrossRef]

- Singh, D.; Charlton, M.; Asim, T.; Mishra, R.; Townsend, A.; Blunt, L. Quantification of additive manufacturing induced variations in the global and local performance characteristics of a complex multi-stage control valve trim. J. Pet. Sci. Eng. 2020, 190, 107053. [Google Scholar] [CrossRef]

- Cappa, F.; Guglielmi, Y.; Nussbaum, C.; De Barros, L.; Birkholzer, J. Fluid migration in low-permeability faults driven by decoupling of fault slip and opening. Nat. Geosci. 2022, 15, 747–751. [Google Scholar] [CrossRef]

- Crisci, E.; Ferrari, A.; Giger, S.B.; Laloui, L. Hydro-mechanical behaviour of shallow Opalinus Clay shale. Eng. Geol. 2019, 251, 214–227. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, G.; Asim, T.; Zhang, Y.; Mishra, R. The innovative design of air caps for improving the thermal efficiency of CFB boilers. Energy 2021, 221, 119844. [Google Scholar] [CrossRef]

- COMSOL. Subsurface Flow Module User Guide, Version 6.0; COMSOL: Burlington, MA, USA, 2022. [Google Scholar]

- Chin, L.Y.; Raghavan, R.; Thomas, L.K. Fully Coupled Geomechanics and Fluid-Flow Analysis of Wells With Stress-Dependent Permeability. SPE J. 2000, 5, 32–45. [Google Scholar] [CrossRef]

- Winhausen, L.; Khaledi, K.; Jalali, M.; Bretthauer, M.; Amann, F. The Anisotropic Behavior of a Clay Shale: Strength, Hydro-Mechanical Couplings and Failure Processes. J. Geophys. Res. Solid Earth 2023, 128, e2023JB027382. [Google Scholar] [CrossRef]

- Sanaee, R.; Oluyemi, G.F.; Hossain, M.; Oyeneyin, M.B. Stress effects on flow partitioning in fractured reservoirs: Equivalent porous media versus poro-elasticity coupled modeling. In Proceedings of the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, CA, USA, 23–26 June 2013; American Rock Mechanics Association: San Francisco, CA, USA, 2013; Volume 3, pp. 2329–2337. [Google Scholar]

- Bai, M.; Elsworth, D. Modeling of subsidence and stress-dependent hydraulic conductivity for intact and fractured porous media. Rock Mech. Rock Eng. 1994, 27, 209–234. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Properties of Porous Media Affecting Fluid Flow. J. Irrig. Drain. Div. 1966, 92, 61–88. [Google Scholar] [CrossRef]

- Minardi, A.; Stavropoulou, E.; Kim, T.; Ferrari, A.; Laloui, L. Experimental assessment of the hydro-mechanical behaviour of a shale caprock during CO2 injection. Int. J. Greenh. Gas Control 2021, 106, 103225. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Initial Porosity | 0.1 [-] |

| Initial Permeability | 2.4 × 10−20 [m2] |

| Young Modulus | 6 [GPa] |

| Poisson ratio | 0.25 [-] |

| Initial Pore Pressure | 1 [atm] |

| Entry capillary pressure | 5 [Pa] |

| Pore size distribution index | 0.67 [-] |

| Biot-Willis coefficient | 0.76 [-] |

| Pin | Pout | Pressure Gradient |

|---|---|---|

| (MPa) | (MPa) | |

| 1 | 1 | No |

| 0 | Yes | |

| 2 | 2 | No |

| 1 | Yes | |

| 0 | Yes | |

| 4 | 4 | No |

| 2 | Yes | |

| 0 | Yes | |

| 8 | 8 | No |

| 6 | Yes | |

| 4 | Yes | |

| 2 | Yes | |

| 0 | Yes |

| Pin | Pout | dexperimental | dnumerical | Difference |

|---|---|---|---|---|

| (MPa) | (MPa) | (mm) | (mm) | (%) |

| 2 | 2 | 0.004 | 0.0042 | +5.0 |

| 4 | 2 | 0.007 | 0.0068 | +2.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asim, T.; Hawez, H.K. Effects of CO2 Geosequestration on Opalinus Clay. Energies 2024, 17, 2431. https://doi.org/10.3390/en17102431

Asim T, Hawez HK. Effects of CO2 Geosequestration on Opalinus Clay. Energies. 2024; 17(10):2431. https://doi.org/10.3390/en17102431

Chicago/Turabian StyleAsim, Taimoor, and Haval Kukha Hawez. 2024. "Effects of CO2 Geosequestration on Opalinus Clay" Energies 17, no. 10: 2431. https://doi.org/10.3390/en17102431

APA StyleAsim, T., & Hawez, H. K. (2024). Effects of CO2 Geosequestration on Opalinus Clay. Energies, 17(10), 2431. https://doi.org/10.3390/en17102431