The Influence of Solid Heat Carrier Load of Char on Pyrolysis Characteristics of Pulverized Coal in a Fluidized Bed Reactor

Abstract

1. Introduction

2. Experimental

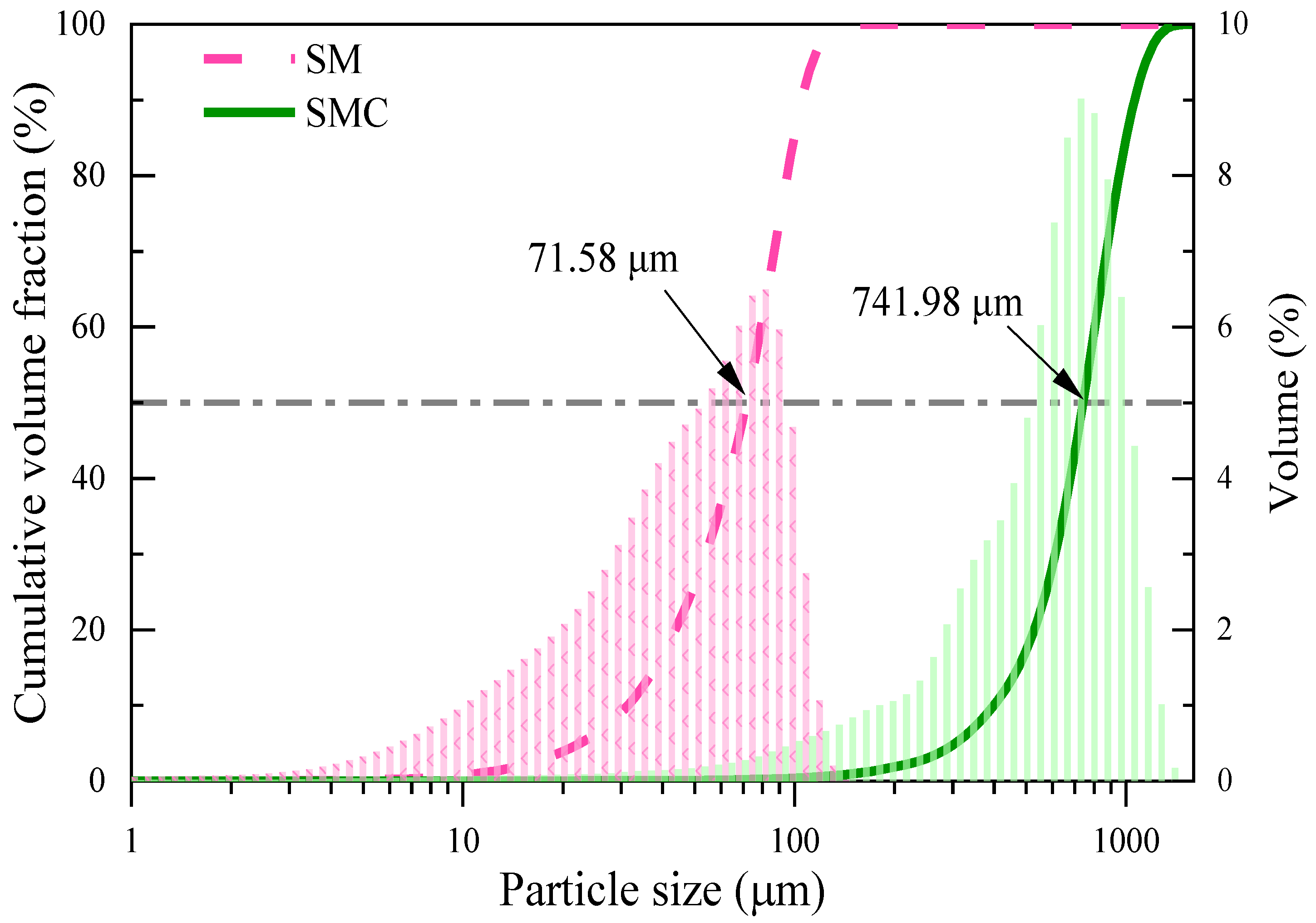

2.1. Samples

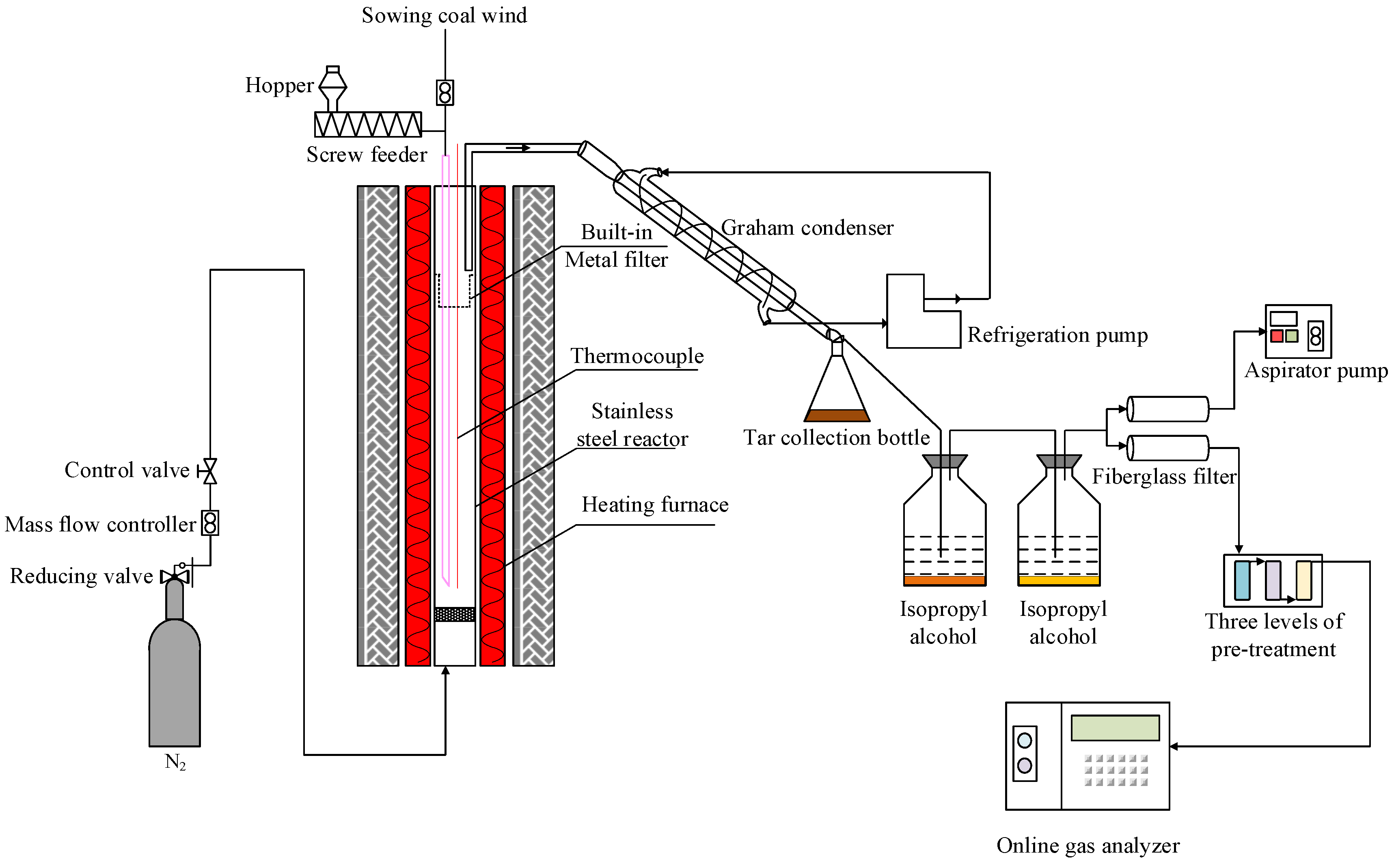

2.2. Experimental Apparatus and Procedure

2.3. Sample Characterization

2.4. Data Processing

3. Results and Discussion

3.1. Pyrolysis Process of SMC

3.2. Products Distribution

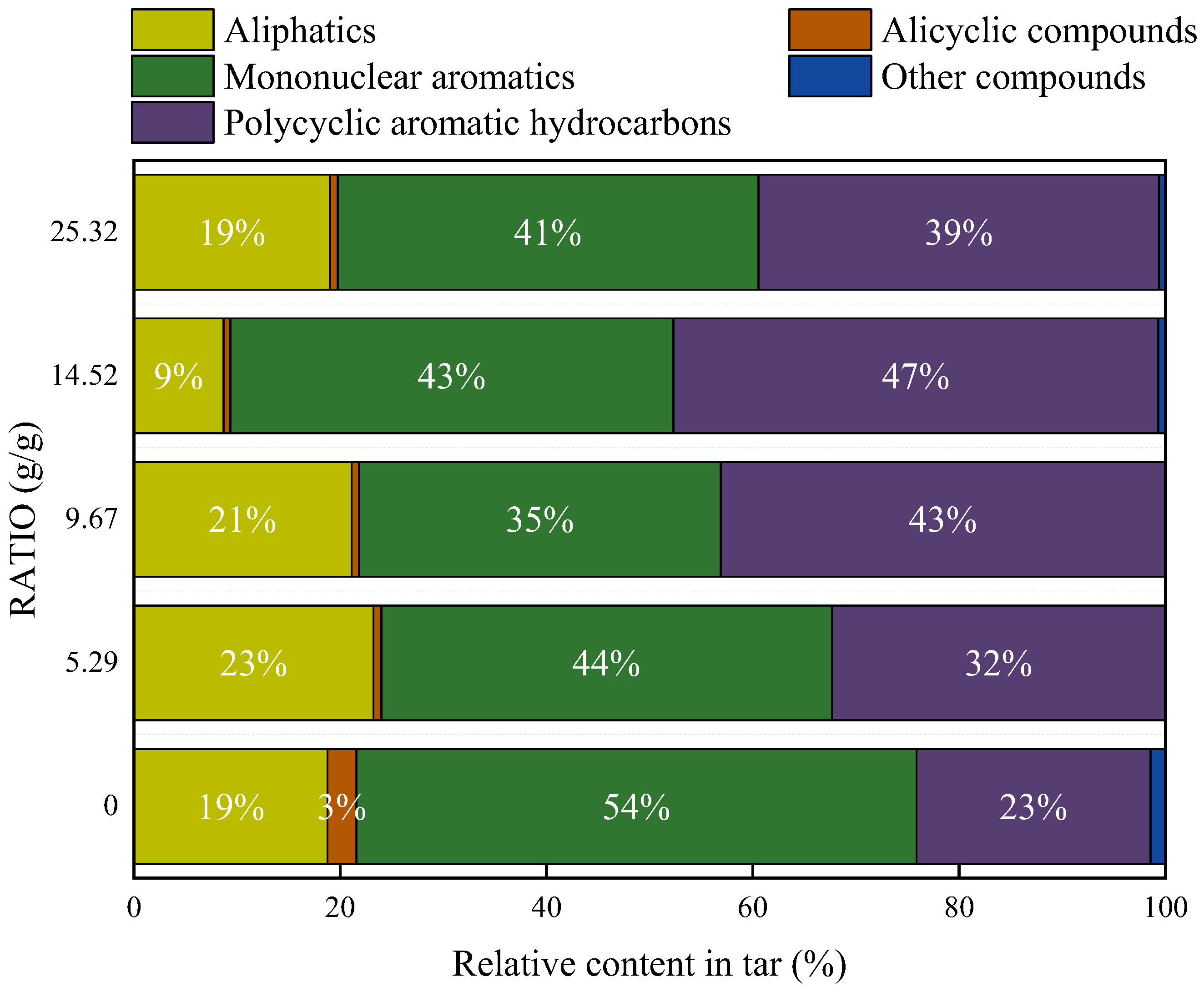

3.3. Composition of Tar

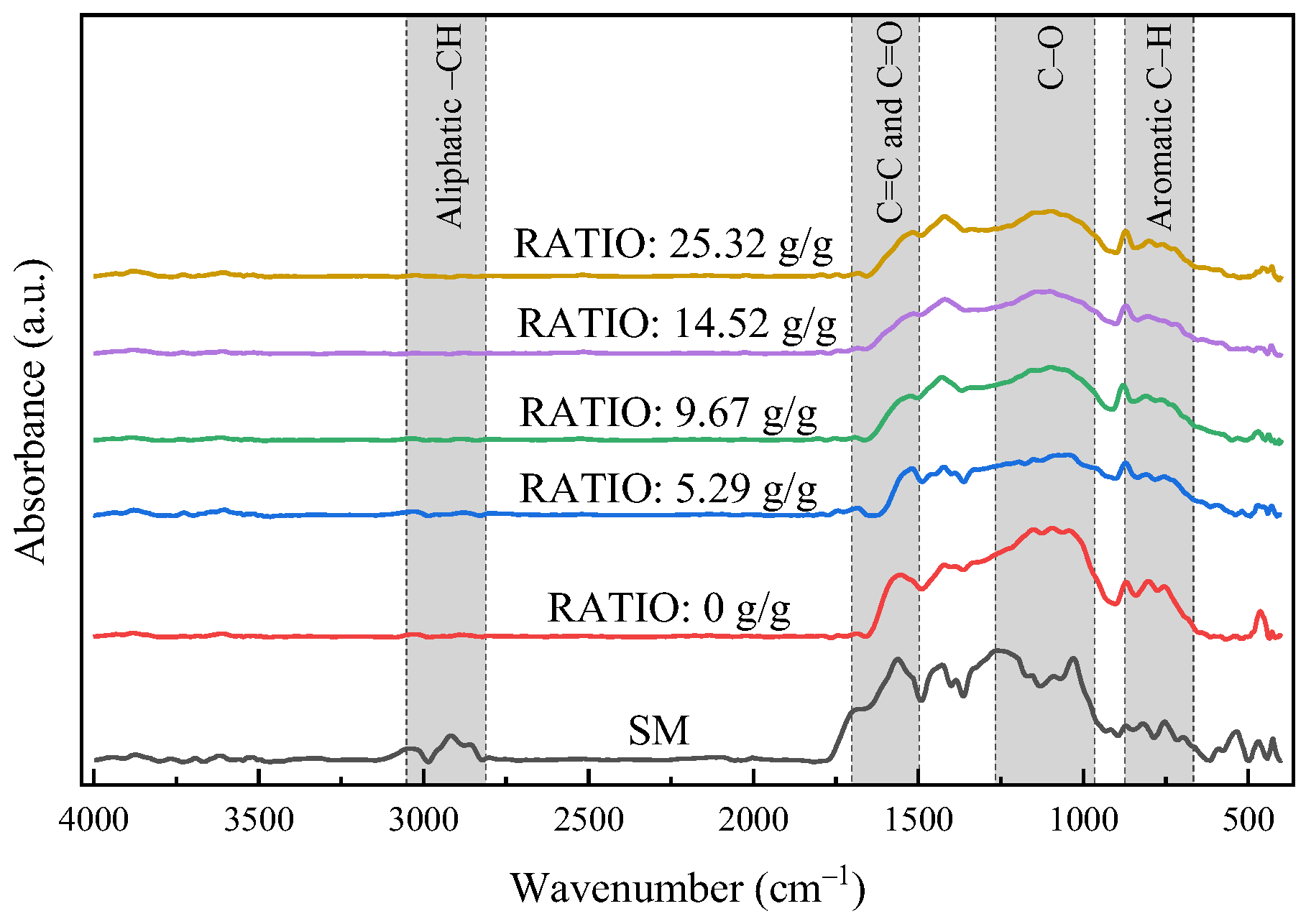

3.4. Characterization Analysis of Char

4. Conclusions

- (1)

- As the RATIO increased, there was a rise in the yields of gas and tar but a decrease in the yield of char. Notably, at the RATIO of 14.52 g/g, the tar yield reached its peak within the range of 8.33–14.68%, accounting for 148.80–262.22% of the Gray–King analysis value.

- (2)

- A higher RATIO intensified the polymerization of monobenzene ring aromatic hydrocarbons, leading to a swift rise in both concentration and quantity of polycyclic aromatic hydrocarbons and thereby enhancing the aromaticity of the tar. Specifically, at the RATIO of 14.52 g/g, the tar mainly consisted of aromatic compounds, characterized with two or more aromatic rings and enriched in low-grade phenolic components, such as naphthalene and its derivatives (30.1%) and methyl phenol (21.32%). Moreover, the presence of solid heat carrier of char improved tar quality due to more light components in the tar.

- (3)

- Solid heat carrier promotes the release of volatile matter by intensifying the primary pyrolysis reaction, while suppressing it by enhancing the secondary cracking of tar. The removal ratio of volatile matter reaches a maximum of 83.34% at the RATIO of 9.67 g/g. The addition of solid heat carrier fractures the macromolecular benzene ring structure and the aromatic groups of char macromolecules, enhancing the thermal evolution process of char.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, S.; Zeng, X.; Han, Z.; Cheng, J.; Wu, R.; Chen, Z.; Masek, O.; Fang, X.; Xu, G. Quick pyrolysis of a massive coal sample via rapid infrared heating. Appl. Energy 2019, 242, 732–740. [Google Scholar] [CrossRef]

- Du, Z.; Li, W. The Catalytic Effect from Alkaline Elements on the Tar-Rich Coal Pyrolysis. Catalysts 2022, 12, 376. [Google Scholar] [CrossRef]

- Han, J.; Wang, X.; Yue, J.; Gao, S.; Xu, G. Catalytic upgrading of coal pyrolysis tar over char-based catalysts. Fuel Process. Technol. 2014, 122, 98–106. [Google Scholar] [CrossRef]

- Jin, X.; Li, X.; Kong, J.; Xie, W.; Wang, M.; Wang, J.; Bao, W.; Chang, L. Insights into coke formation during thermal reaction of six different distillates from the same coal tar. Fuel Process. Technol. 2021, 211, 106592. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, S.; Li, X.; Xu, J.; Wu, Z.; Yang, B. Process intensification on suspension pyrolysis of ultra-fine low-rank pulverized coal via conveyor bed on pilot scale: Distribution and characteristics of products. Fuel 2021, 286, 119341. [Google Scholar] [CrossRef]

- Liang, P.; Wang, Z.; Bi, J. Process characteristics investigation of simulated circulating fluidized bed combustion combined with coal pyrolysis. Fuel Process. Technol. 2007, 88, 23–28. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, Y.; Liu, L.; Zhang, L.; Zhang, Z.; Qiu, P. Evaluation of chemical structure, pyrolysis reactivity and gaseous products of Shenmu coal of different particle sizes. J. Anal. Appl. Pyrolysis 2018, 130, 294–304. [Google Scholar] [CrossRef]

- Zhu, W.; Song, W.; Lin, W. Effect of the Coal Particle Size on Pyrolysis and Char Reactivity for Two Types of Coal and Demineralized Coal. Energy Fuels 2008, 22, 2482–2487. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, Q.; Shi, L.; Yan, Y.; Liu, Z. Behaviors of coking and radicals during reaction of volatiles generated from fixed-bed pyrolysis of a lignite and a subbituminous coal. Fuel Process. Technol. 2017, 161, 304–310. [Google Scholar] [CrossRef]

- Hao, S.; Zhang, L.; Jia, Y. Synergistic effect of blast furnace slag on the pyrolysis process of oil-rich coal, tar product distribution and kinetic analysis. Energy Sources Part A-Recovery Util. Environ. Eff. 2021, 1–14. [Google Scholar] [CrossRef]

- Duan, W.; Yu, Q.; Xie, H.; Qin, Q. Pyrolysis of coal by solid heat carrier-experimental study and kinetic modeling. Energy 2017, 135, 317–326. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, X.; Shi, L.; He, W.; Wu, J.; Liu, Q.; Liu, J. Reaction of volatiles—A crucial step in pyrolysis of coals. Fuel 2015, 154, 361–369. [Google Scholar] [CrossRef]

- Fushimi, C.; Okuyama, S.; Kobayashi, M.; Koyama, M.; Tanimura, H.; Fukushima, H.; Thangavel, S.; Matsuoka, K. Pyrolysis of low-rank coal with heat-carrying particles in a downer reactor. Fuel Process. Technol. 2017, 167, 136–145. [Google Scholar] [CrossRef]

- Liang, P.; Wang, Z.; Dong, Y.; Bi, J. Experimental investigation of solid heat carrier pyrolysis of Huainan coal. J. Fuel Chem. Technol. 2005, 33, 257–262. [Google Scholar]

- Xue, F.; Li, D.; Guo, Y.; Liu, X.; Zhang, X.; Zhou, Q.; Ma, B. Technical Progress and the Prospect of Low-Rank Coal Pyrolysis in China. Energy Technol. 2017, 5, 1897–1907. [Google Scholar] [CrossRef]

- Qu, X.; Liang, P.; Wang, Z.; Zhang, R.; Sun, D.; Gong, X.; Gan, Z.; Bi, J. Pilot Development of a Polygeneration Process of Circulating Fluidized Bed Combustion combined with Coal Pyrolysis. Chem. Eng. Technol. 2011, 34, 61–68. [Google Scholar] [CrossRef]

- Cui, Y. Research status and prospects on pyrolysis technologies of the pulverized coal. Energy Chem. Ind. 2018, 39, 33–38. [Google Scholar]

- Silvestre, W.P.; Pauletti, G.F.; Godinho, M.; Baldasso, C. Fodder radish seed cake pyrolysis for bio-oil production in a rotary kiln reactor. Chem. Eng. Process. Process Intensif. 2018, 124, 235–244. [Google Scholar] [CrossRef]

- Daugaard, T.J.; Dalluge, D.L.; Brown, R.C.; Wright, M.M. Effect of thermophysical properties of heat carriers on performance of a laboratory-scale auger pyrolyzer. Fuel Process. Technol. 2018, 176, 182–189. [Google Scholar] [CrossRef]

- Qu, X.; Zhang, R.; Sun, D.; Bi, J. Experiment study on pyrolysis of Huolinhe lignite with solid heat carrier. J. Fuel Chem. Technol. 2011, 35, 85–89. [Google Scholar]

- Zhang, Y.; Liang, P.; Zhu, J.; Yu, J.; Qin, X. Secondary Catalytic Reaction of Circulating Ash on the Primary Volatiles of Coal Pyrolysis. J. Energy Eng. 2017, 143, 04017021. [Google Scholar] [CrossRef]

- Li, T.; Du, T.; Shen, Y.; Yan, L.; Kong, J.; Wang, M.; Wang, J.; Chang, L.; Bao, W. Effect of char powder on gaseous tar reaction during low-rank coal pyrolysis. J. Fuel Chem. Technol. 2021, 49, 626–633. [Google Scholar] [CrossRef]

- Li, X.H.; Li, B.F.; Fu, D.Q.; Feng, J.; Li, W.Y. The interaction between the char solid heat carrier and the volatiles during low-rank coal pyrolysis. J. Anal. Appl. Pyrolysis 2018, 136, 160–168. [Google Scholar] [CrossRef]

- Lyu, Q.; Yu, K.; Zhu, Z.; Meng, G. Pilot plant research on fast pyrolysis of coal in circulating fluidized bed with hot char carrier. J. China Coal Soc. 2012, 37, 1591–1595. [Google Scholar]

- Guo, M.; Bi, J. Experimental study on Fugu coal pyrolysis with solid heat carrier. Coal Convers. 2016, 39, 26–30, 61. [Google Scholar]

- Pan, D.F.; Qu, X.; Bi, J.C. Effect of gasified semi-coke on coal pyrolysis in the poly-generation of CFB gasification combined with coal pyrolysis. J. Anal. Appl. Pyrolysis 2017, 127, 461–467. [Google Scholar] [CrossRef]

- Li, X.H.; Ma, J.S.; Li, L.L.; Li, B.F.; Feng, J.; Turmel, W.; Li, W.Y. Semi-coke as solid heat carrier for low-temperature coal tar upgrading. Fuel Process. Technol. 2016, 143, 79–85. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Pei, X.; Wang, Y.; Zhou, Q. Research progress and key technology of improving coal tar yield and quality by coal pyrolysis. Coal Sci. Technol. 2019, 47, 227–233. [Google Scholar]

- Quan, S.; Shi, L.; Zhou, B.; Liu, Z.; Liu, Q. Study of temperature variation of walnut shell and solid heat carrier and their effect on primary pyrolysis and volatiles reaction. Fuel 2021, 292, 120290. [Google Scholar] [CrossRef]

- ASTM D2887-01a; Standard Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography. ASTM International: West Conshohocken, PA, USA, 2010.

- SH/T 0558-95; Method for Determination of Boiling Range Distribution of Petroleum Fractions (Gas Chromatography). China Petrochemical Corporation: Beijing, China, 1994.

- Jiang, Y.; Zong, P.; Ming, X.; Wei, H.; Zhang, X.; Bao, Y.; Tian, B.; Tian, Y.; Qiao, Y. High-temperature fast pyrolysis of coal: An applied basic research using thermal gravimetric analyzer and the downer reactor. Energy 2021, 223, 119977. [Google Scholar] [CrossRef]

- Jin, L.; Bai, X.; Li, Y.; Dong, C.; Hu, H.; Li, X. In-situ catalytic upgrading of coal pyrolysis tar on carbon-based catalyst in a fixed-bed reactor. Fuel Process. Technol. 2016, 147, 41–46. [Google Scholar] [CrossRef]

- Liu, F.; Wang, L.; Yang, W.; Li, Z.; Zhu, Y. Study on deep-processing technology of medium and low temperature coal tar and analysis of its market prospect. Mod. Chem. Ind. 2012, 32, 7–11. [Google Scholar]

- Li, X.; Jin, X.; Wang, M.; Yu, Y.; Kong, J.; Xie, W.; Wang, J.; Chang, L.; Bao, W. Effect of volatiles’ reaction on coking of tar during pyrolysis of Naomaohu coal in a downer-bed reactor. Fuel Process. Technol. 2021, 212, 106623. [Google Scholar] [CrossRef]

- Xing, X.; Zhao, H.; Zhou, L.; Wang, Y.; Chen, H.; Gao, Y.; Wang, Y.; Zhu, Y. Pyrolysis kinetics, thermodynamics of PTA sludge and product characterization of cyclic in-situ catalytic pyrolysis by using recycled char as a catalyst. Energy 2022, 251, 123821. [Google Scholar] [CrossRef]

- Zhang, W.; He, Y.; Wang, Y.; Li, G.; Chen, J.; Zhu, Y. Comprehensive investigation on the gasification reactivity of pyrolysis residue derived from Ca-rich petrochemical sludge: Roles of microstructure characteristics and calcium evolution. Energy Convers. Manag. 2022, 253, 115150. [Google Scholar] [CrossRef]

- Solomon, P.R.; Carangelo, R.M. FT-i.r. analysis of coal: 2. Aliphatic and aromatic hydrogen concentration. Fuel 1988, 67, 949–959. [Google Scholar] [CrossRef]

- He, X.; Liu, X.; Nie, B.; Song, D. FTIR and Raman spectroscopy characterization of functional groups in various rank coals. Fuel 2017, 206, 555–563. [Google Scholar] [CrossRef]

| Sample | Ultimate Analysis (%, ad) | Proximate Analysis (%, ad) | Gray–King Analysis (%, ad) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | H | O a | N | S | M | V | FC | A | Tar Yield (YG-K, tar) | |

| SM | 70.30 | 4.47 | 13.00 | 0.81 | 0.40 | 4.45 | 29.43 | 59.55 | 6.57 | 5.60 |

| SMC | 70.64 | 0.88 | 4.15 | 0.60 | 0.31 | 7.35 | 7.48 | 76.24 | 8.93 | Not detected |

| No. | RATIO (g/g) | SBET (m2/g) | VTOT (cm3/g) | Proximate Analysis (%, ad) | |||

|---|---|---|---|---|---|---|---|

| M | V | FC | A | ||||

| 1 | 0 | 3.648 | 0.02606 | 0.00 | 11.29 | 77.46 | 11.26 |

| 2 | 5.29 | 7.204 | 0.02655 | 0.00 | 9.94 | 78.00 | 12.07 |

| 3 | 9.67 | 7.138 | 0.02675 | 0.00 | 9.97 | 76.67 | 13.36 |

| 4 | 14.52 | 3.207 | 0.02236 | 0.00 | 10.94 | 76.03 | 13.03 |

| 5 | 25.32 | 3.253 | 0.02181 | 0.00 | 9.82 | 77.48 | 12.70 |

| Sample | RATIO (g/g) | |||||||

|---|---|---|---|---|---|---|---|---|

| SM | - | 88.78 | 231.41 | 2.40 | 1635.93 | 1.00 | 600.26 | 1.00 |

| Char | 0 | 11.84 | 18.63 | 1.45 | 688.00 | 0.42 | 905.33 | 1.51 |

| 5.29 | 26.74 | 35.71 | 1.23 | 389.44 | 0.24 | 785.09 | 1.31 | |

| 9.67 | 8.52 | 11.01 | 1.19 | 447.26 | 0.27 | 810.38 | 1.35 | |

| 14.52 | 1.04 | 2.08 | 1.84 | 434.16 | 0.26 | 701.09 | 1.17 | |

| 25.32 | 2.42 | 0.84 | 0.32 | 413.93 | 0.25 | 631.08 | 1.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Qi, X.; Chen, R.; Zhu, Z.; Wang, X. The Influence of Solid Heat Carrier Load of Char on Pyrolysis Characteristics of Pulverized Coal in a Fluidized Bed Reactor. Energies 2024, 17, 2282. https://doi.org/10.3390/en17102282

Li X, Qi X, Chen R, Zhu Z, Wang X. The Influence of Solid Heat Carrier Load of Char on Pyrolysis Characteristics of Pulverized Coal in a Fluidized Bed Reactor. Energies. 2024; 17(10):2282. https://doi.org/10.3390/en17102282

Chicago/Turabian StyleLi, Xinli, Xiaobin Qi, Rui Chen, Zhiping Zhu, and Xiaofang Wang. 2024. "The Influence of Solid Heat Carrier Load of Char on Pyrolysis Characteristics of Pulverized Coal in a Fluidized Bed Reactor" Energies 17, no. 10: 2282. https://doi.org/10.3390/en17102282

APA StyleLi, X., Qi, X., Chen, R., Zhu, Z., & Wang, X. (2024). The Influence of Solid Heat Carrier Load of Char on Pyrolysis Characteristics of Pulverized Coal in a Fluidized Bed Reactor. Energies, 17(10), 2282. https://doi.org/10.3390/en17102282