Sand-Laden Wind Erosion Pair Experimental Analysis of Aerodynamic Performance of the Wind Turbine Blades

Abstract

1. Introduction

2. Materials and Methods

2.1. Blade Model

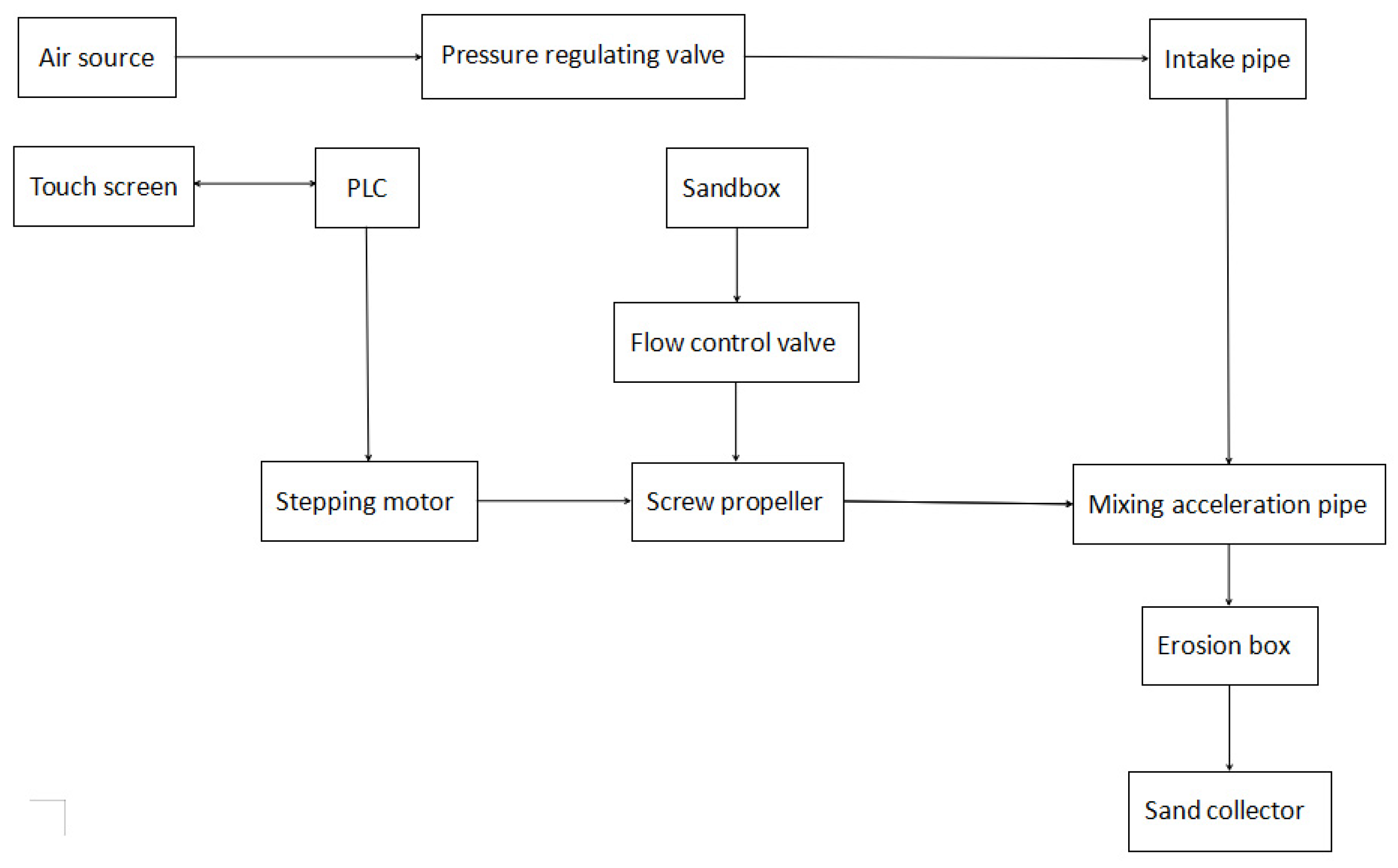

2.2. Blade-Erosion Wear Device

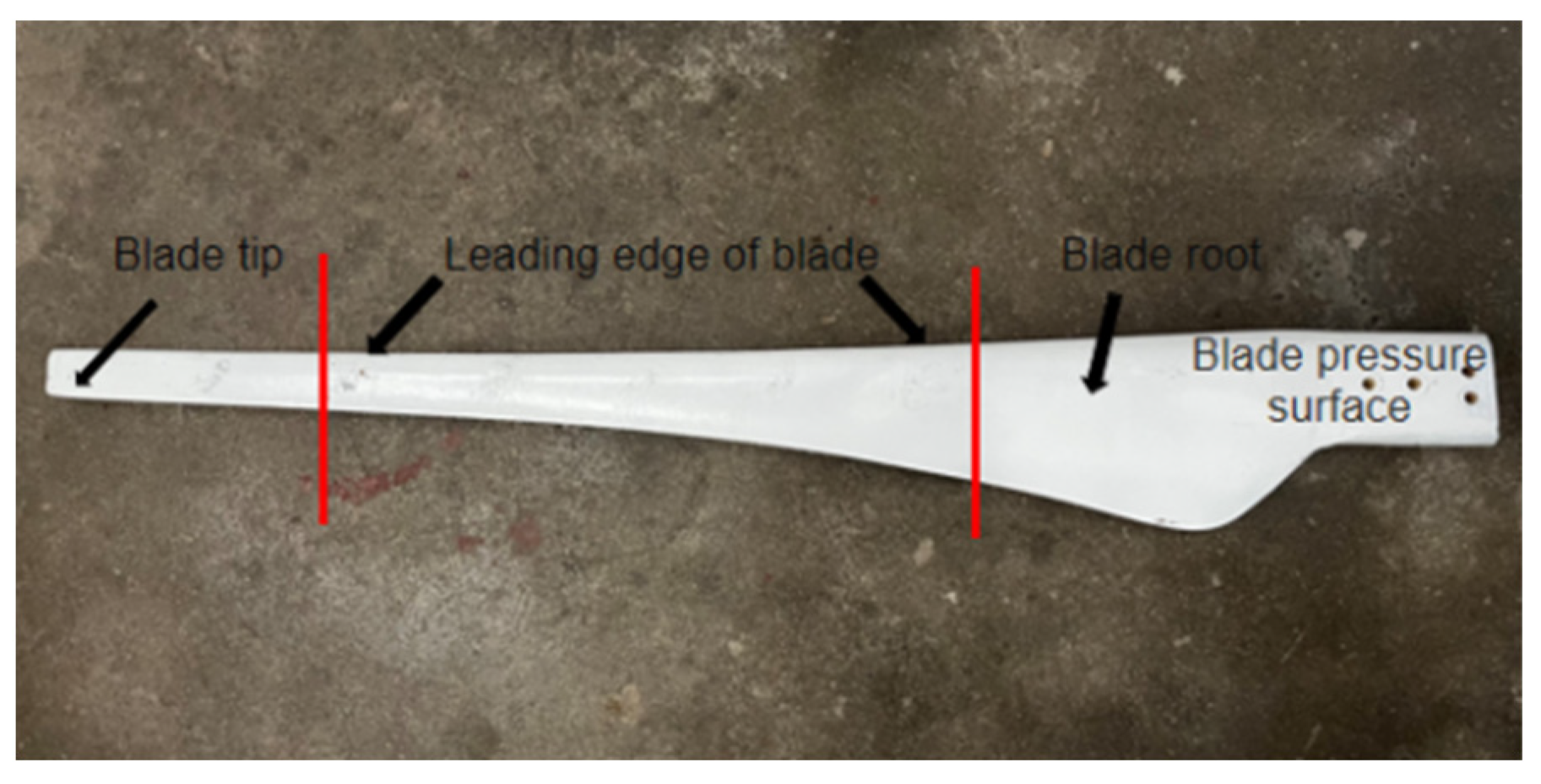

2.3. Sand Grain Size Selection and Blade Erosion Zoning

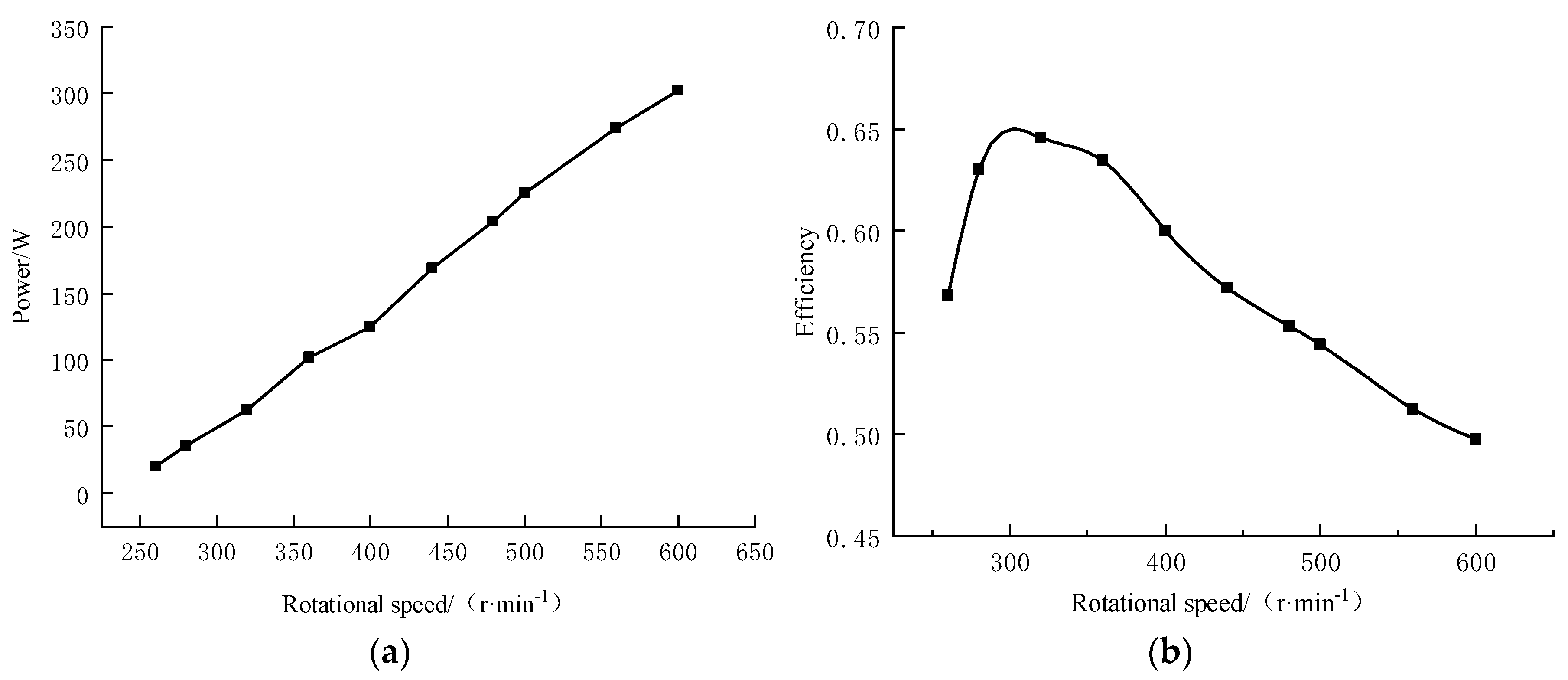

2.4. Generator Characteristic Test

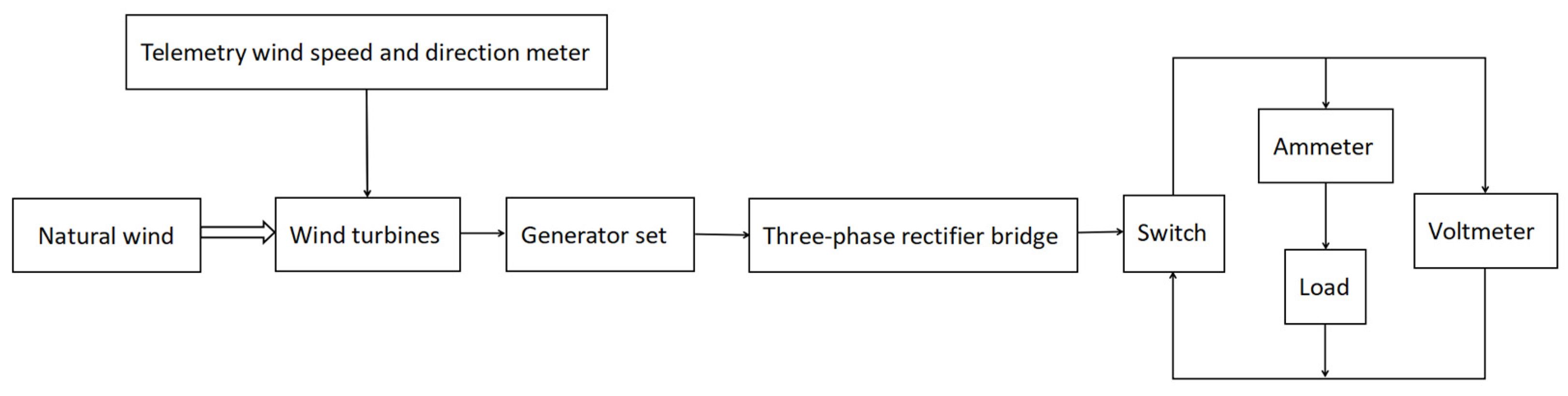

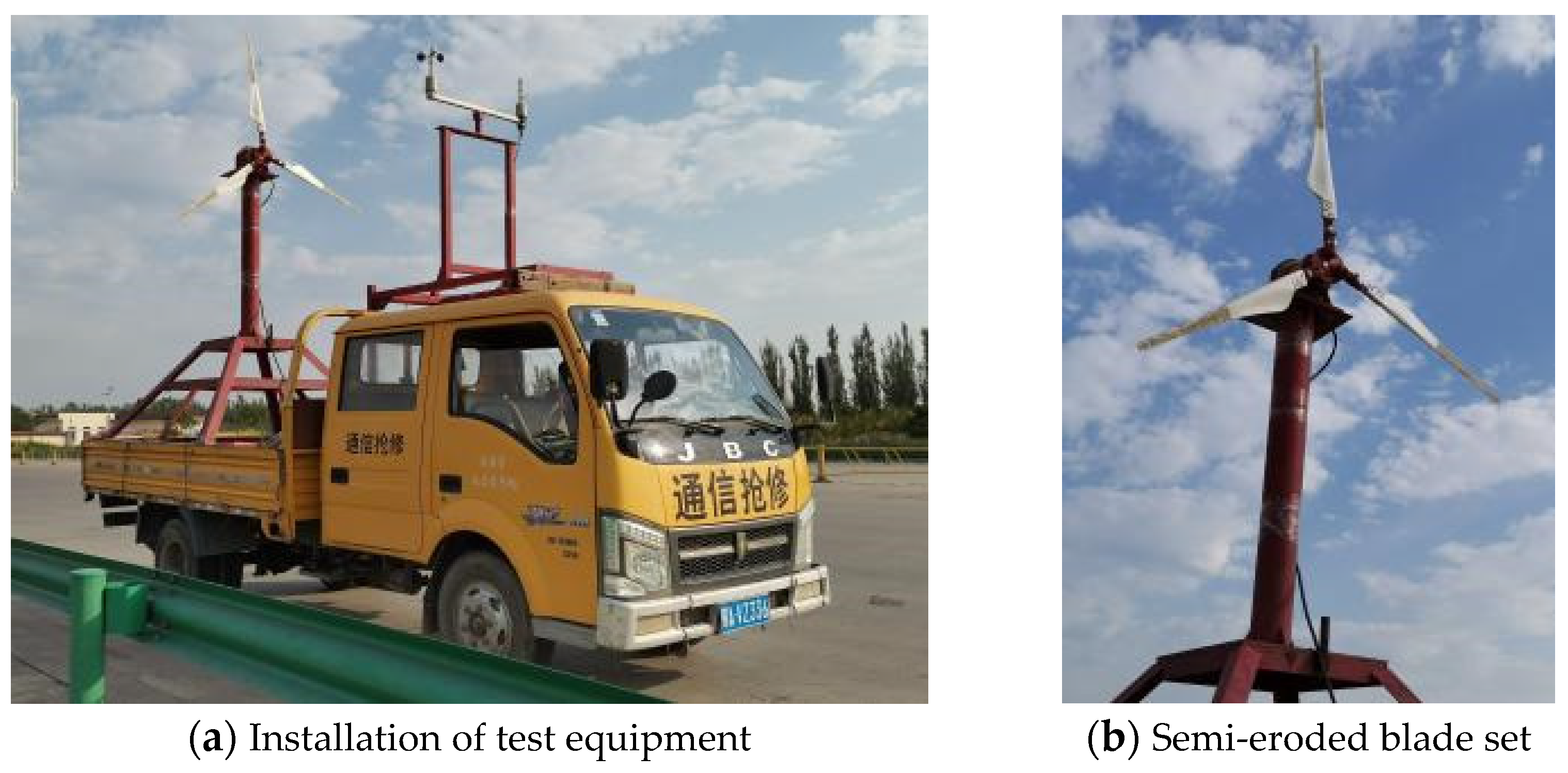

2.5. Wind Turbine Blade Power Characteristic Test

3. Results and Analysis

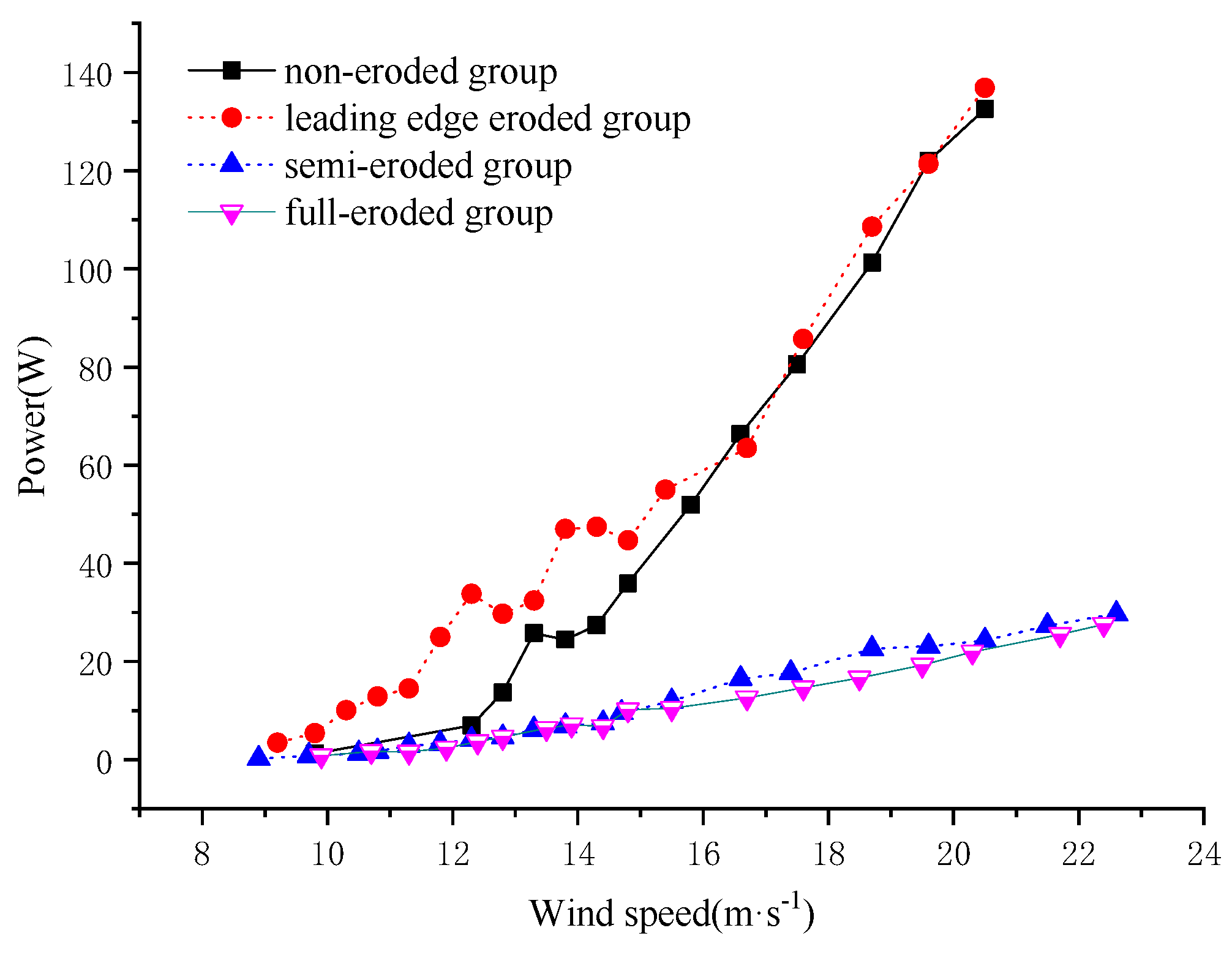

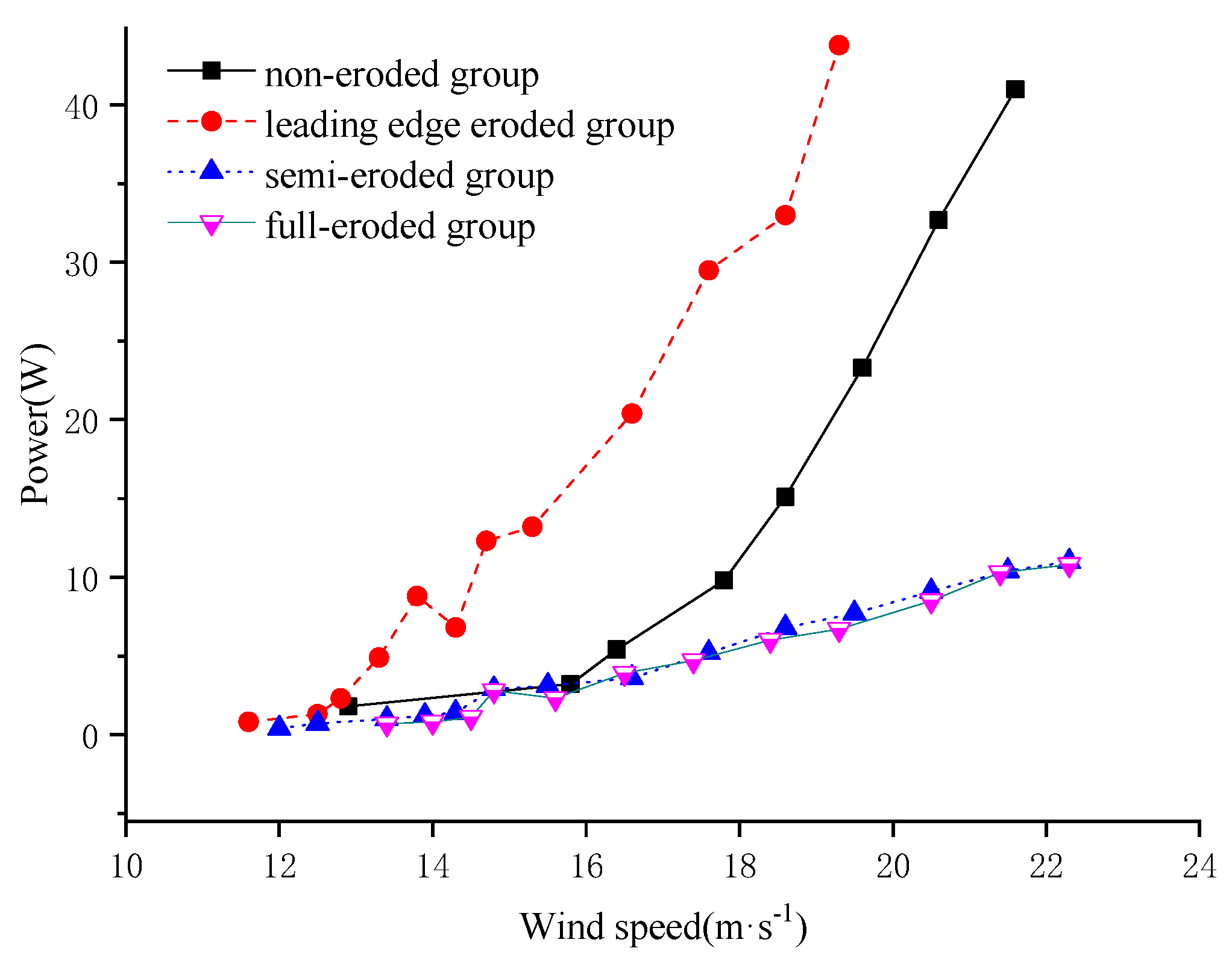

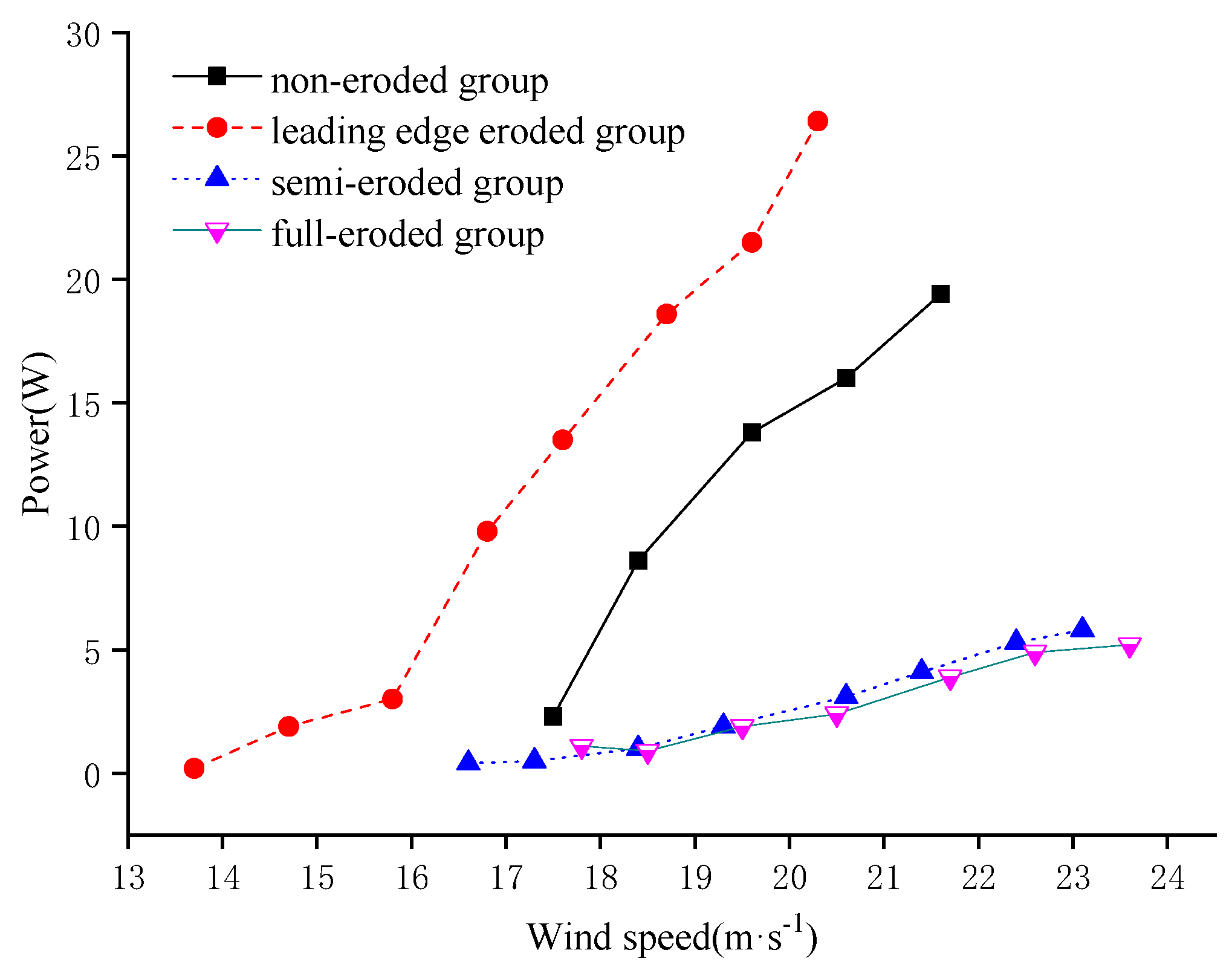

3.1. Output Power of the Turbine after the Blade Eroded in Different Areas

3.2. Wind Energy Coefficient of Performance under Different Blade Abrasion Characteristics

4. Discussion

5. Conclusions

- (1)

- The overall power of the wind turbine decreases with the increase in installation angle, which indicates that the change in installation angle will reduce the aerodynamic performance of the wind turbine.

- (2)

- No matter what installation angle, the power increase in the semi-eroded group and the full-eroded group is not big, and the power decreases obviously with the increase in wind speed, which is less than 100 W rated power, but the power of the semi-eroded group is slightly greater than that of the full-eroded group in the same wind speed range.

- (3)

- The leading edge eroded group has the same effect on the output power of wind turbines. When the installation angle is large, the output power is larger than that of the non-eroded group and reaches the rated power first in the same wind speed range, which improves the aerodynamic performance. When the installation angle is small, the output power of the leading edge eroded group is lower than that of the non-eroded group except in the wind speed range of 11.9 m/s to 13.6 m/s, and the other wind speed ranges are higher than that of the non-eroded group and reach the rated power first than that of the non-eroded group.

- (4)

- The erosion in the chordal direction, especially at the blade tip, significantly degrades the aerodynamic performance. However, the aerodynamic performance of the wind turbine after leading-edge erosion has been enhanced. This discovery initially suggests that leading-edge erosion may, to some extent, enhance the aerodynamic performance of the blade. Although this study preliminarily explores the positive impact of pit degradation on this phenomenon, the exact mechanism requires further investigation through more detailed simulation modeling and experimental research.

- (5)

- The wind energy coefficient of performance of wind turbines decreases with the increase in installation angle, and the wind energy coefficient of performance of semi-eroded group and full-eroded group decreases obviously and has little change. Under large installation angles, the wind energy coefficient of performance of the leading edge eroded group and the non-eroded group showed an overall upward trend with the increase in wind speed but showed a downward trend in the wind speed ranges of 13.8 m/s to 14.3 m/s, 14.7 m/s to 15.3 m/s, and 17.6 m/s to 18.6 m/s. In the same wind speed range, the average wind energy coefficient of performance of the leading edge eroded group was higher than that of the non-eroded group. When the installation angle is small, the wind energy coefficient of performance of the leading edge eroded group is lower than that of the non-eroded group in the wind speed ranges of 11.1 m/s to 12.2 m/s, 13.2 m/s to 14.1 m/s, 15.8 m/s to 16.6 m/s, 17.4 m/s to 17.9 m/s, and 19.4 m/s to 19.8 m/s, but higher than that of the non-eroded group in other wind speed ranges.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Miliket, T.A.; Ageze, M.B.; Tigabu, M.T. Aerodynamic performance enhancement and computational methods for H-Darrieus vertical axis wind turbines: Review. Int. J. Green Energy 2022, 19, 1428–1465. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, Y.; Duan, C.; Wang, L.; Jia, A. Insight into the effects of leading edge delamination on the aerodynamic performance of an airfoil and wind turbine. J. Renew. Sustain. Energy 2022, 14, 023305. [Google Scholar] [CrossRef]

- Sun, S.; Wang, T.; Yang, H.; Chu, F. Damage identification of wind turbine blades using an adaptive method for compressive beamforming based on the generalized minimax-concave penalty function. Renew. Energy 2022, 181, 59–70. [Google Scholar] [CrossRef]

- Kelly, J.; Vogel, C.; Willden, R. Impact and mitigation of blade surface roughness effects on wind turbine performance. Wind Energy 2021, 25, 660–677. [Google Scholar] [CrossRef]

- Lorenzo, C.; Alessio, C.; Aldo, B.; Edmondo, M.; Sergio, C.M. Machine learning-enabled prediction of wind turbine energy yield losses due to general blade leading edge erosion. Energy Convers. Manag. 2021, 245, 114567. [Google Scholar]

- Mishnaevsky, L.; Fæster, S.; Mikkelsen, L.P.; Kusano, Y.; Bech, J.I. Micromechanisms of leading edge erosion of wind turbine blades: X-ray tomography analysis and computational studies. Wind Energy 2020, 23, 547–562. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.; Jia, X. CFD Investigation of a Mobula Birostris-Based Bionic Vortex Generator on Mitigating the Influence of Surface Roughness Sensitivity of a Wind Turbine Airfoil. IEEE Access 2020, 8, 223889–223896. [Google Scholar] [CrossRef]

- Nikolov, I.A.; Madsen, C.B. Quantifying Wind Turbine Blade Surface Roughness using Sandpaper Grit Sizes: An Initial Exploration. In Proceedings of the VISIGRAPP, Virtual, 8–10 February 2021. [Google Scholar]

- Su, J.Y.; James, B. Simulations for Effect of Surface Roughness on Wind Turbine Aerodynamic Performance. J. Phys. Conf. Ser. 2020, 1452, 012055. [Google Scholar] [CrossRef]

- Mike, G.; Oliver, S.; Jurgita, Z.; Ismail, B.; Robert, W. The effect of temperature on the erosion of polyurethane coatings for wind turbine leading edge protection. Wear 2021, 476, 203720. [Google Scholar]

- Nikesh, K.; Puneet, M.; Suhail, A.; Leon, M. Engineered anti-erosion coating for wind turbine blade protection: Computational analysis. Mater. Today Commun. 2022, 31, 103362. [Google Scholar]

- Michael, S.; Vlaho, P.; Frederik, B.; Lars, N.; Martin, K.; Pao, L.Y. Wind Tunnel Testing of an Optimal Feedback/feedfoward Control Law for Wind Turbines. IFAC Pap. 2020, 53, 12638–12643. [Google Scholar]

- Zhao, X.; Zhou, P.; Liang, X.; Gao, S. The aerodynamic coupling design and wind tunnel test of contra-rotating wind turbines. Renew. Energy 2020, 146, 1–8. [Google Scholar] [CrossRef]

- Robert, F.; Frank, K.; Markus, F.; Stefan, W.; Ralf, S. Along-Wind Aerodynamic Damping of Wind Turbine Towers: Determination by Wind Tunnel Tests and Impact on Tower Lifetime. Energies 2022, 15, 1984. [Google Scholar] [CrossRef]

- Guo, W.; He, S.; Yan, L.; Fang, F.; Kotaro, T. Wind tunnel tests of the rime icing characteristics of a straight-bladed vertical axis wind turbine. Renew. Energy 2021, 179, 116–132. [Google Scholar] [CrossRef]

- Li, X.; Guo, W.; Li, Y.; Xu, Z.; Feng, F. Wind tunnel test of an anti-icing approach by heat pipe for wind turbine bladesunder the rime ice condition. Therm. Sci. 2021, 25 Pt B, 4485–4493. [Google Scholar] [CrossRef]

- Li, S.; Liang, J.; Guo, P.; Wang, X.; Li, P. A novel test method for the aerodynamic performance ofwind turbine airfoil using wind generated by a moving vehicle. Wind Struct. 2021, 32, 551. [Google Scholar]

- Li, S.; Li, Q.; Liang, J.; Guo, P. Investigation of the Transiting Test Method for the Aerodynamic Performance of Vertical Axis Wind Turbine Using Wind Generated by a Moving Vehicle. Exp. Tech. 2021, 46, 351–363. [Google Scholar] [CrossRef]

- GB/T 10760.2-2017; Generator of Small Wind Turbines—Part 2: Testing Methods. China National Standards: Beijing, China, 2017.

- GB/T 18451.2-2003; Wind Turbine Generator Systems-Wind Turbine Power Performance Testing. China National Standards: Beijing, China, 2003.

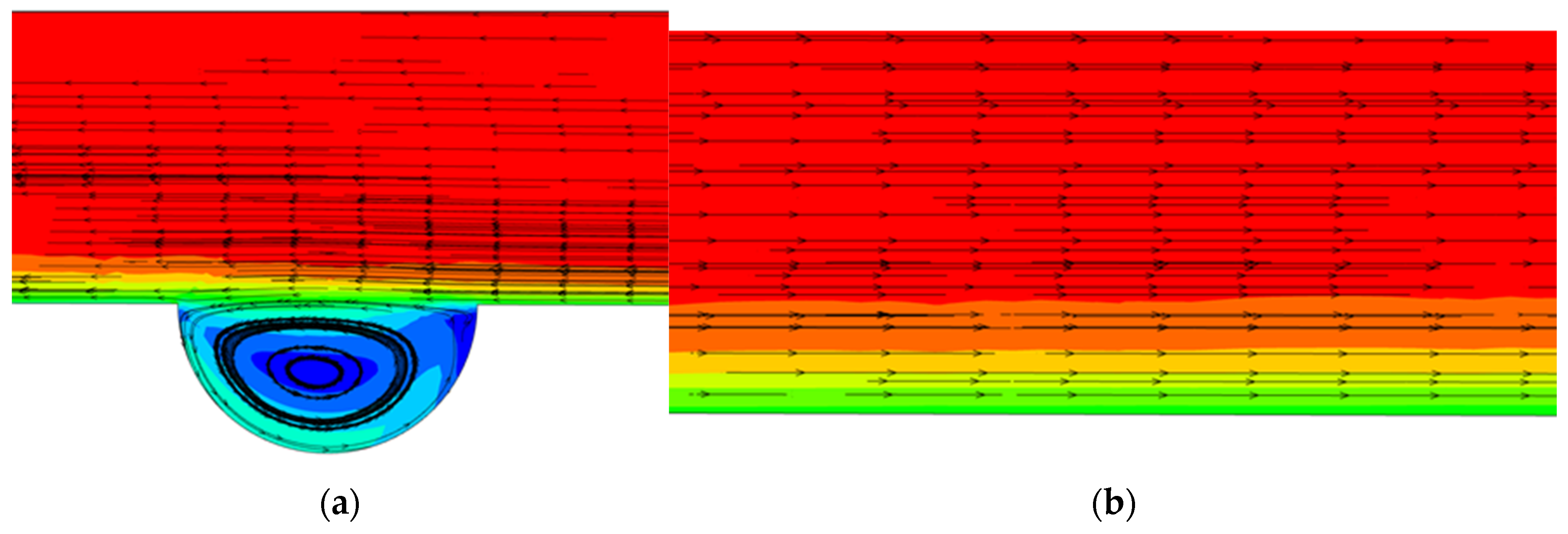

- Zhou, M.; Wang, G.; Liu, M.; Chen, Y. Drag Reduction Effect of Convex Non-smooth Surface on the Boat -type Tractor. J. Agric. Mech. Res. 2018, 40, 236–240+246. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Z. Study on Drag and Noise Reduction of Pantograph Rods based on Bionic Non-smooth Structures. Noise Vib. Control 2018, 38, 269–272. [Google Scholar]

- Yang, Y.; Lu, H.; Guo, S.; Pang, W.; Wang, Y.; Zhong, K. Effects of dimples with different depths in a highly loaded compressor cascade. J. Dalian Marit. Univ. 2018, 44, 83–91. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, H.; Shi, Y.; Zuo, H. Study on Drag Reduction Characteristics of Airfoil for Wind Turbine With Microgrooves on Surface. J. Eng. Thermophys. 2018, 39, 1258–1266. [Google Scholar]

- Wang, Y.; Lu, W.; Guo, S.; Wang, L.; Xin, J. Influence of Dimples on Aerodynamic Performance of Wind Turbine Airfoil. Chin. J. Turbomach. 2021, 63, 8–15. [Google Scholar] [CrossRef]

- Sun, Z. Numerical Simulation on Drag Reduction of Rotors with Non-smooth Surface. Shandong Text. Sci. Technol. 2009, 31, 117–121. [Google Scholar]

- Shahid, A.; Abdullah, K.; Imran, S.; Amin, K.T.; Yasir, A.; Umer, S.M.; Badar, R.; Won, J.D. Computational Fluid Dynamics and Experimental Analysis of a Wind Turbine Blade’s Frontal Section with and without Arrays of Dimpled Structures. Energies 2022, 15, 7108. [Google Scholar] [CrossRef]

| Particle Size Range (mm) | Proportion (%) | Classification |

|---|---|---|

| <0.075 | 3.5 | Extra fine sand |

| 0.075–0.154 | 45 | |

| 0.155–0.250 | 51 | Fine Sand |

| 0.251–0.300 | 0.25 | Coarse sand |

| 0.301–0.360 | 0.15 | |

| 0.361–0.500 | 0.05 | |

| 0.501–0.600 | 0.03 | |

| 0.601–0.900 | 0.02 | |

| >0.900 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, D.; Chen, S.; Li, D.; Zhen, Q.; Zhang, B. Sand-Laden Wind Erosion Pair Experimental Analysis of Aerodynamic Performance of the Wind Turbine Blades. Energies 2024, 17, 2279. https://doi.org/10.3390/en17102279

Wan D, Chen S, Li D, Zhen Q, Zhang B. Sand-Laden Wind Erosion Pair Experimental Analysis of Aerodynamic Performance of the Wind Turbine Blades. Energies. 2024; 17(10):2279. https://doi.org/10.3390/en17102279

Chicago/Turabian StyleWan, Daqian, Songli Chen, Danlan Li, Qi Zhen, and Bo Zhang. 2024. "Sand-Laden Wind Erosion Pair Experimental Analysis of Aerodynamic Performance of the Wind Turbine Blades" Energies 17, no. 10: 2279. https://doi.org/10.3390/en17102279

APA StyleWan, D., Chen, S., Li, D., Zhen, Q., & Zhang, B. (2024). Sand-Laden Wind Erosion Pair Experimental Analysis of Aerodynamic Performance of the Wind Turbine Blades. Energies, 17(10), 2279. https://doi.org/10.3390/en17102279