Abstract

Bifacial photovoltaic (BPV) panels represent one of the main solar technologies that will be used in the near future for renewable energy production, with a foreseen market share in 2030 of 70% among all the photovoltaic (PV) technologies. Compared to monofacial panels, bifaciality can ensure a gain in energy production per unit panel area together with a competitive cost. However, it is of paramount importance to identify whether there is also an environmental benefit when adopting bifacial technologies as opposed to traditional monofacial ones. To obtain a proper insight into the environmental impact, this paper reviews the Life Cycle Assessment (LCA) studies of bifacial solar panels, identifying the most crucial processes and materials that raise environmental burdens. The analysis also contributes to determining whether the major aspects that influence energy production in real operation scenarios and, most of all, that can ensure the gain associated with bifaciality, are considered and how these can further affect the overall environmental impacts. In this sense, it was found that the installation parameters like the mounting structure, or the choice of ground material to raise the albedo as well as the diffuse irradiation that hits the rear surface of thepanel, are commonly not considered during LCA analysis. However, none of the analyzed studies address the issue in a comprehensive way, hampering an effective comparison between both the different works and traditional monofacial PV panels. Recommendations for future LCAs are finally proposed.

1. Introduction

The ever-increasing global energy crisis and the escalation in the emission of greenhouse gases have led to a constant rise in the use of renewable sources for power production to satisfy the world’s energy demand. According to the International Energy Agency, in terms of total installed capacity, the major increase in contribution from the year 2000 up today is associated with photovoltaic systems, followed by wind and hydroelectric power production. The latest available data report that the worldwide solar power installed capacity in 2021 was approximately 885 GW, with a global energy production of 1003 TWh. With respect to 2020, energy generation from photovoltaic panels increased by 467 TWh, marking a yearly +25% and accounting for 4.5% of global energy production [1].

Despite the significant reduction in the environmental impacts of solar technologies in comparison to those of traditional fossil-fuelled thermoelectric plant [2], lots of efforts are still being focused on improving the eco-profile of PV cells, panels and plants. Enhancing conversion efficiency together with a reduction in energy and materials consumption, are still the major concerns of PV developers. In this sense, the research of new technologies that can boost electricity generation with lower environmental impacts is still to be realized.

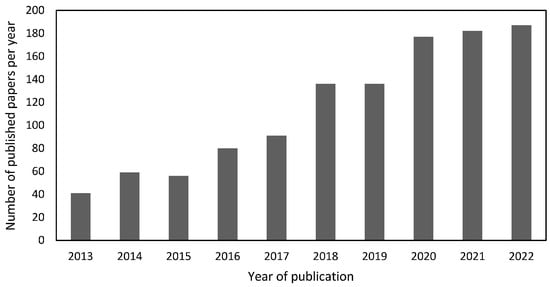

During the last decade, among the most investigated PV systems, bifacial solar technology has played a major role thanks to its readiness level and the rapid increase in the installation market share over the last few years. Indeed, as reported by the International Technology Roadmap for Photovoltaic, a constant rise is foreseen in the market share of PV systems for bifacial solar cells from 20% in the year 2020 up to 70% in 2030. The academic community has also been focusing its attention on bifacial solar cells, as can be seen from the research trend over the last decade reported in Figure 1. From 2013 up to 2022, the yearly number of published papers found in the Scopus database on bifacial solar systems increased from 41 to 187, marking the academic interest in the technology.

Figure 1.

Trend in published research papers on bifacial solar cells.

It is, however, of paramount importance to identify the environmental burdens associated with any energy production system and, therefore, also those for bifacial PV panels. Life cycle assessment (LCA) methodology is a powerful tool to determine the environmental impacts and energy consumption associated with each life cycle stage, including of the raw materials supply, production, use and final disposal, of any kind of goods and services. Through LCA it is possible to identify the most energy-intensive processes as well as the materials and life cycle steps that present the higher associated environmental impacts.

To assess the potential of this technology, the focus of this paper is considered to be dual. On one hand, it presents a review of the current literature on LCA studies applied to bifacial solar cells, with the purpose of finding less-impacting technologies and production processes, highlighting the aspects that still need further study in order to be improved. On the other hand, it evaluates whether the approach of using the same methodological considerations used for monofacial systems can also be adopted for bifacial systems, or if further analysis should be integrated into the computation of the environmental impacts.

The Section 1 of this work presents the analysis of the state of the art of the PV system, from the first generation of solar cells up today’s technologies, with a focus on bifacial systems. The Section 2 focuses on LCA methodology and its critical aspects, while the Section 3 is dedicated to the analysis of the current published literature on the LCA of bifacial solar panels. The Section 4 presents the results from the literature for comparison.

2. Bifacial Solar Cell Technologies

It is fairly well-known that sunlight is one of the most abundant and widespread sources of energy available on the Earth, with normal incident values at sea level of about 1000 W/m2 [3]. In comparison to other renewable energy sources, its higher natural abundance and reliability, as well as the technological readiness and easy and economical installation for domestic applications, have made solar cells the most used and widespread devices for energy production from non-conventional sources [4]. In a traditional photovoltaic system, aside from the solar panels, other different components, usually referred to as Balance of System (BOS), are needed to allow correct operation. Within the BOS are included all the cables and switches, the inverter, the mounting structure, the batteries as well as other possible components used to monitor the external conditions, such as solar meters, anemometers, solar trackers, etc.

From the early stage of development of solar cells up today, three main PV technologies can be listed:

- First generation: The solar cells are made of crystalline silicon which can be in the form of either mono- or multi-crystalline. These represent the two technologies that have achieved the highest market share among all, due to the consolidated production process and knowledge of the conversion mechanism.

- Second generation: this typically refers to thin-film solar cells, like amorphous silicon, cadmium telluride (CdTe), copper-indium-gallium-selenide (CIGS) or the more recent silicon hetero-junction solar panels.

- Third generation: All the panels do not use silicon as the main substrate but rather adopt organic or semi-organic materials. In this category perovskite solar cells, quantum dot cells and dye-sensitized solar cells can be listed.

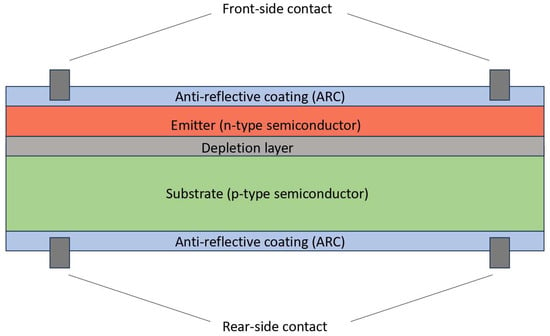

If on one hand second- and third-generation PV systems still struggle to achieve a significant market share, on the other hand, the recently developed bifacial PV is making its way to becoming the most used solar system in the near future. One of the major advantages that contributed to the fast and widespread development of this system is that it adopts the same technology used in monofacial silicon crystalline cells, with the main difference being replacing the opaque rear surface with a transparent one in order to allow light to hit the cell’s back surface. In this way, energy production can be enhanced thanks to the possibility of exploiting the reflected and diffuse light that hits the rear side of the panel. A schematic cross-section of a p-type bifacial solar cell is presented in Figure 2. To realize the photovoltaic panel, the solar cell is further encapsulated and placed between two sheets of solar glass.

Figure 2.

Schematic section of a bifacial solar cell.

In the following Table 1, the main characteristics of the available bifacial solar cell technologies are listed [5,6]:

Table 1.

Main technologies used in bifacial solar cells.

Among the technologies reported in the previous table, PERC seems to be the most promising for bifacial applications. Indeed, the enhanced efficiency and energy production, the longer lifetime, a more favourable temperature coefficient, together with the possibility of using the already-available industrial production lines, make PERC the best option from a cost-effective perspective.

The use of bifacial panels can boost energy production from 7.75% to 15% per unit surface in comparison to the same monofacial panel, depending on the albedo and installation conditions [7]. Although there is a higher price per Watt for bifacial solar panels in comparison to that for monofacials [8], the Levelized Cost of Energy (LCOE) for these systems can be in the range of 2% to 6% lower than their monofacial counterparts [9]. Nowadays, one of the proposed strategies to reduce panel cost is to lower the amount of silver used for the front contact and replace it with copper. The use of Cu-plating instead of Ag paste could also lower the thermal energy demand required for the production process [10]. Yet, problems related to the possible shunting of the p-n junction still need to be properly addressed.

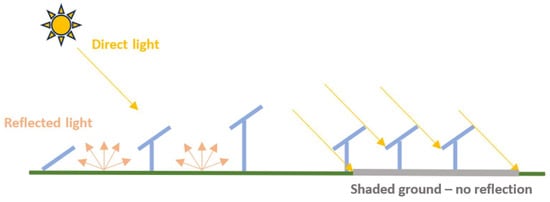

When dealing with bifacial solar cells, more installation variables in comparison to those for monofacial systems must be considered to maximize the incident irradiation on the rear surface of the panels. Figure 3 presents a schematic layout of an open field installation that shows the configuration parameters that can affect energy production. Module elevation, as well as inter-row distance, can significantly change both the amount of incident light that reaches the ground as well as reflected light that hits the back surface of the cell. If, on one hand, a higher installation, and an increased row distance raise energy production, on the other hand the corresponding rise in material and energy consumption to ensure an optimal field configuration could lower the overall energy and environmental benefits related to the energy production during the use phase. The choice of ground material also presents a direct impact on the environmental burdens of the plant. Indeed, the material adopted affects the albedo of the ground surface and therefore the amount of reflected light that can hit the panel’s back surface. Light reflectors as plane or adjustable mirrors, or even prisms placed between adjacent solar panels, were also proposed as possible options to enhance the amount of irradiation that hits the back surface [11].

Figure 3.

Schematic layout of shading problems in open field bifacial solar panel installation.

3. Critical Aspect of LCA Methodology Applied to Solar Cell Technology

When approaching and comparing different LCA studies of solar cell technologies, particular attention must be paid to the main variables that can majorly affect the results. Indeed, both LCA and solar cell parameters can induce relevant variations in the outcome of the analysis. Hereafter are presented the principal variables of the LCA method and the PV cell parameters that shall be considered [12,13].

3.1. LCA Variables

- Functional unit (F.U.): The functional unit is the parameter to which all the impacts refer. The International Energy Agency proposed three possible functional units when dealing with solar systems: 1 kWh of energy produced, 1 kWp of rated power and 1 m2 (or other geometrical aspect, e.g., 1 panel or 1 cm2, etc.) of active surface. It is therefore clear that changing the F.U. will lead to different results, since all the energy and material flows will be relative to a different parameter.

- System boundaries: The system boundary defines the extension of the analysis that it is meant to pursue. Although the manufacturing of the cell requires the highest share of energy and is responsible for most of the emissions, restricting the analysis only to this stage would arrive at partial and incomplete results. Different studies have computed the possible benefits of the recycling process of solar panels [14,15,16,17]; however, this stage is often not included in the computation due to the scarcity of data on commercially viable processes.

- Definition of the impact categories: The choice of the impact categories and their definition through the assessment methodology is freely performed by the authors of each study. The Photovoltaic Power System Program of the International Energy Agency [18] as well as the JRC report on life cycle impact assessment methodology [19] define a wide range of significant impact categories that should be considered when studying the eco-profile of solar technologies. In fact, the main issue when dealing with a restricted panel of impact indicators is that a distinct process or material used can have almost negligible effects on the chosen indicator but significantly impact another. Gazbour et al. [13] proposed a rank of impact categories in order of importance that should be considered when defining the eco-profile of a solar system, by normalizing the impacts in relation to other renewable and non-renewable energy sources. The analysis showed that material and energy depletion, land use, water consumption and eutrophication, and effects on human health should be the main aspects to be considered when approaching a LCA analysis of solar cells.

- Data quality: A relevant aspect that influences the accuracy of a LCA study is the quality of the data used, which can be directly derived from measurement or by the producers or either gathered from the literature, databases or LCA libraries. In [20], it is shown how using updated data can significantly improve the eco-profile of monofacial and bifacial solar panels. Indeed, the authors compared the data obtained by using only the Ecoinvent database with those obtained by updating process production and available technologies (in terms of cell efficiency, material consumption, auxiliary devices, etc). Analyzing the carbon footprint, the results showed a reduction in emissions from approximately 70 gCO2eq/kWh for traditional monofacial panels modelled through the Ecoinvent database, to approximately 16 gCO2eq/kWh and 13 gCO2eq/kWh, for, respectively, updated monofacial panels and bifacial solar panels mounted on a wooden structure [18,19,20,21]. Finally, although PV systems have reached their maturity level, production companies are still undertaking continuous ongoing research to improve the efficiency and reduce material consumption both in the production of the panels and all the auxiliary devices. However, inventory datasets are often not updated at the same rate as the technological progress, resulting in outdated values for material and energy consumption.

3.2. Technological Variables

Many technological-related variables need to be addressed when approaching a LCA study of solar systems. Performance in terms of conversion efficiency, degradation and performance ratio, lifetime, intensity of solar irradiation to calculate energy production, the electrical mix of the production and installation country, and the upgrading of the manufacturing process can alter the final results of the LCA analysis.

- Efficiency: Photovoltaic technologies have witnessed yearly increases in conversion efficiency from their first application up to nowadays. The utilization of updated solar cells’ efficiency is of paramount importance when evaluating the eco-profile of any solar system. Indeed, efficiency is directly connected to the amount of energy that can be produced throughout the lifetime of the solar panel and, therefore, it affects the impacts per kWh across all the indicators.

- Manufacture: The country of manufacture of BPV panels influences the final results across all the available indicators. Indeed, the grid energy mix adopted can significantly alter the eco-profile of a solar panel [21]. A recent study conducted by Muller et al. [22] reports a percentage reduction in GWP index (in terms of kgCO2eq/kWp) of 27% and 40% when changing from a Chinese energy mix to, respectively, the German and European energy mixes for a glass backsheet solar panel. This condition is due to the fact that almost 63% of the GWP impacts of panel production are associated with the electricity consumption required for silicon transformation.

- Use phase: With respect to monofacial systems, in the case of BPV panels, more conditions must be fulfilled to ensure the best possible performance. In fact, not only must the maximization of the solar irradiation that directly hits the front side of the panel be ensured, the same condition should also be achieved for the diffuse irradiation that can be gathered from the rear side. Therefore, the use phase, in terms of energy produced during the entire lifetime of the panel, is strictly related to the installation site, in terms of both geographical location and system configuration. In fact, latitude and altitude decide the solar irradiation that directly hits the front side of the panel, as do the environmental conditions, like temperature, that significantly influence the voltage parameters [23]. At the same time, the choice of the mounting structure, system configuration and ground material have a direct effect on the energy gain associated with the rear surface and, therefore, of the global energy produced. The increase in installation height can boost the reflected irradiation gathered by the rear surface and reduce the self-shading effect of the panel, leading to a rise in energy production from the back side [24]. The analysis performed by Yusufoglu et al. [25] showed approximately 75% in rear-side gain when increasing panel elevation from 10 cm up to 1 m. The shading effect increases when the latitude decreases, imposing the need for higher mounting structures to ensure the same energy output [26]. Moreover, increasing the height favours the cooling effect of the rear side of the panels, raising efficiency and lifetime [26]. Common setups are considered between 0.5 and 1.5 m [24]. However, it must be considered that the more material and energy consumption associated with a bigger mounting structure could counterbalance the environmental gain associated with the rise in electricity generation [20]. In open field installations, row distance also has a direct impact on energy production. According to Shoukry et al. [27], a 5 × 11 installation configuration at a latitude of 27°, with a panel elevation of 1.5 m and a fixed distance between the rows of 2.5 m can induce an 18% reduction in energy gain for the elements placed at the centre of the field. In fact, comparing a standalone installation with a bifacial gain of 33.85%, for an open field configuration, the authors reported a decrease in bifacial gain from 31.41% (panels at the edge of the row) to 27.72% (panels at the centre). Finally, ground albedo represents one of the key factors that influence the amount of reflected irradiation that reaches the rear surface of the panel. The study reported in [26] shows that ground-mounted systems with an albedo of 0.25 result in a global average increase in power production of around 10%, both due to the shading effect and low reflectance of the ground. Increasing the albedo up to 0.5 can double the bifacial gain, while also considering that an installation height of 1 m can achieve a +30% energy gain with respect to the base scenario. Each natural or construction material presents a specific albedo that allows different bifacial gains to be achieved. Grass, cement and aluminium present values of albedo and bifacial gain of 0.2 and 8%, 0.3 and 13% and 0.5 and 21%, respectively [28]. However, significantly different are the environmental impacts associated with each of the possible ground materials, highlighting the importance of a proper evaluation when calculating the environmental burdens of the whole system.

A further aspect is related to the technical performance of BPV panels and, specifically, to the performance ratio, degradation rate and lifetime. The performance ratio depicts the amount of energy that is collected from the solar system, with respect to the theoretical amount that could be produced by the same plant. The degradation rate describes the annual loss of performance of a solar cell. Jeaun Kim et al. [29] recently conducted a review to establish the degradation rate of solar modules under different stress conditions during their lifetime, finding a strict connection with field work conditions and atmospheric parameters. Since most BPV panels adopt the same technology of silicon monofacial panels, it is helpful to understand what could be the performance and degradation rate of these panels, to determine the actual yearly energy production that a BPV can guarantee. On average, for European installations, the authors reported a degradation rate for multiple silicon solar cells in the range of 0.8–1.1%. Different considerations must be addressed when dealing with solar cells containing perovskite, due to its rapid degradation when exposed to external ambient parameters [30]. Accelerated degradation leads to a significant reduction in the lifetime of the cell. Rezaei Funami et al. [31] report a 50% performance loss after 10 days for reference perovskite technologies.

Therefore, particular attention should be paid in the decision-making process to the real operating parameters that are meant to be associated with the reference technology.

Since all emissions are directly scaled to the total energy produced, for a comprehensive evaluation, it is important to include all the considerations mentioned above when approaching a LCA study of bifacial PV plants. At present, despite the publication by the International Electrochemical Commission of a proposal for standardizing the irradiance test conditions for monofacial and bifacial solar panels, these are still not yet widely adopted [32].

4. Recent Literature Assessment

This section reports the results of the LCA studies on bifacial solar panels found in the literature. To collect all the articles, research was firstly conducted by employing the Scopus database using the following queries: “LCA bifacial solar cells”, “Life cycle assessment bifacial solar cells”, “LCA bifacial photovoltaic” and “LCA solar cells”. Of the 398 papers found, excluding duplicates and articles that were not in line with the focus of the research, 4 works were selected. Additionally, the research was extended through the consultation of numerous LCA review articles to find possible other works, but no other study related to the topics of interest was found.

The main characteristics of bifacial solar cells discussed in the present review are reported in the following Table 2.

Table 2.

Main technological parameters of bifacial panels.

Of the four papers that analyze the LCA of bifacial solar panels, three of them investigated silicon technology while the last one compared silicon technology with single and tandem perovskite solar cells. For each topic, works are presented in chronological order of publication.

Gazbour et al. [33] compared Cumulative Energy Demand (CED), Energy Payback Time (EPBT) and Global Warming Potential (GWP) of classic monofacial mono-crystalline PV panels with mono and bifacial solar panels made using a more recent production technique proposed by her team at CEA-INES. For the first case, only the Ecoinvent 3.1 database was used as the data source, and the process was modelled by using process blocks present in SimaPro 8.1. The updated processes were modelled by collecting primary data and considering a diamond wire-sawing process instead of the less efficient slurry wire sawing, a frameless structure with a glass backsheet instead of aluminium and the use of monolike silicon, a newer structure that can guarantee performance which is almost as good as mono-crystalline silicon but with lower manufacturing costs. The Ecoinvent 3.1 database was used for the inventory regarding feedstock, mounting process and the inverter. The functional unit adopted was 1 kWh of electrical energy produced from a 570 kWp open ground system. The expected lifetime was 30 years, the average irradiation 1496 kWh/m2, while the performance ratio and the annual degradation were, respectively, 85% and 0.8%. A 15% increase in energy production was found when upgrading from monofacial panels (1272 kWh/kWp) to bifacial ones (1462 kWh/kWp). The results of the study showed a CED, EPBT and GWP for bifacial panels of 17.5 GJ/kWp, 1.05 years and 31.19 gCO2eq/kWh, respectively. Regarding the GWP, approximately 18 gCO2eq/kWh relates to a panel’s production, while the remaining part is associated with the BOS components. The upgrade in process production (from the standard to the newer techniques proposed by CEA-INES) and the use of bifacial panels instead of monofacials, led to a 21.47 GJ/kWp reduction in the CED index, which decreased from 39 GJ/kWp to 17.53 GJ/kWp. Energy consumption for the manufacture of ingots and wafers decreased from 6.08 GJ/kWp for monofacial panels to 4.39 GJ/kWp in the case of bifacials. Moreover, the adoption of the double-glass frameless solution in bifacial panels instead of the aluminium backsheet used in monofacials, allowed a reduction in energy demand from 5.94 GJ/kWp to 2.35 GJ/kWp. Finally, the authors reported a 58.4% reduction in carbon footprint (from 75.05 gCO2eq/kWh to 31.19 gCO2eq/kWh) when upgrading to monolike silicon bifacial panels.

Despite the use of primary data and the breakdown of the result for each singular component that support hotspot analysis, some gaps in the assessment are present. Specifically, data used in the assessment referred to the laboratory scale and not to industrial manufacturing processes, and the End of Life (EoL) stage is not included in the study. Only two indicators (GWP and CED) are analyzed, thereby restricting the scope of the study.

The work conducted by Jia et al. [34] evaluated the environmental profile of two monofacial and four bifacial solar panels, through the investigation of the impacts on six environmental indexes and one economic indicator. For all the different solar cells, the authors considered the PERC technology with a cell efficiency of 22.5%, and the traditional backsheet present in monofacial cells was replaced by a transparent backsheet. Aside from the technology adopted, modules differ by the number of cells, gross module area and weight. Regarding system boundaries, a comprehensive framework was proposed, including raw material supply, manufacturing, transportation, installation, use, maintenance and end of life. BOS was excluded.

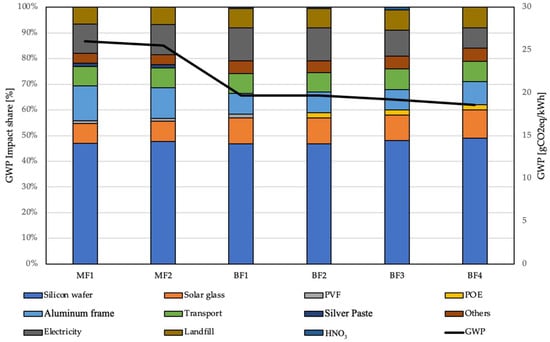

The determination of the life cycle inventory (LCI) was investigated through the collection of data directly from different China PV manufacturers, using questionnaires. By gathering information from the product warranties, lifetime was considered to be equal to 25 years for monofacial panels and 30 years for bifacials. The inventory analysis shows the following variation in material consumption, when upgrading from 1 kWp monofacial PERC to 1 kWp bifacial PERC panels: a +25% increase for solar glass, a reduction in the range of 33–43% for aluminium, a −67% decrease for the metallization paste, and a decrease of between 54% and 74% for tap water. Figure 4 presents, for each technology, the total GWP in terms of gCO2eq/kWh and the relative contribution of each material and process production.

Figure 4.

Global GWP and impact share for each material and process production.

The analysis of GWP showed a decrease of 23% in the emission of GHG when upgrading from monofacial to bifacial panels, thanks to the higher amount of energy produced per unit area. However, only part of this contribution is due to the adoption of bifacial systems, while the major share is related to the longer lifetime considered for bifacial systems in comparison to that for monofacials. Indeed, the authors reported a 10% rear-side gain in electricity production, together with a decrease in the emission when adopting a larger wafer size. In the same work, three further analyses were conducted to evaluate the differences in the energy gain from the back surface of the panels according to different ground conditions, the effect of a possible recycling process instead of landfill disposal and a comparison between a transparent backsheet and dual glass encapsulation. Regarding ground material, the authors included the impact analysis of the different terrains, finding that the three best materials to improve energy production and the eco-profile of the system were desert, thermoplastic polyolefin (TPO) and white gravel, allowing the generation of 25%, 25% and 20% more energy than the base scenario, respectively. In terms of GWP, desert and TPO allow an impact reduction of approximately 50% with respect to the worst scenario (light asphalt), while white gravel achieved almost a 30% decrease. The better effect of desert is mainly due to its natural origin, which avoids any further impact due to material production, while TPO combines a long lifetime together with narrow thickness and a modest material consumption. The recycling step especially allowed a reduction in the impacts on the Abiotic Depletion Potential, Freshwater Eutrophication Potential and Human Toxicity Potential with cancer effects, mostly thanks to the recovery of silver, aluminium, copper and silicon. The analysis conducted by the authors represents, at present, the most complete study on the environmental impacts of BPV panels found in the literature. In fact, the inclusion of the EoL phase, the broader panel of impact indicators, and the use of primary data gathered directly from the manufacturer factory and sensitivity analysis to evaluate the effect of different ground materials, allow a more complete picture of the environmental burdens associated with the entire lifetime of the plant. However, the choice of considering different lifetimes for the BPV and monofacial PV hinders the effective comparison of the two different technologies. Although the authors refer to the adoption of different lifetimes (30 years for BPV and 25 years for monofacial PV) in accordance with the product warranties, it is common to assume, for modern technologies like the ones presented in the study, an expected lifetime of 30 years, as also suggested in the guidelines for the LCA of mono and bifacial PV solar systems proposed by the IEA.

In [35], the authors calculated the energy and greenhouse gas payback time of mono-crystalline bifacial panels according to different mounting configurations, realized in a demonstration structure that was purpose-built in Chengdu (CN). The specific cell technology is not further described. The proposed locations were on an inclined roof and a “solar house” which included a vertical installation on the south façade, vertical installation on the east façade and a flat roof. Within the system boundaries, the authors also considered the BOS and the structure realized for the demonstrator. The work reports the GHG emission for the sole panel production, equal to 443.6 kgCO2eq, and the GHG payback time for the whole solar house and the inclined roof equalled 2.3 and 1.7 years, respectively. The energy payback time was 5 years for the inclined roof and 6.6 years for the flat installation.

The methodological approach, in terms of impact indicators considered, functional unit and specific panel technical parameters, does not allow the performance of either a comparison with other case studies or delineation of a complete eco-profile of the system and its components. In fact, since the results are reported in aggregated form in terms of kgCO2eq, it was not possible to distinguish the contribution of the impacts of the single system components. Moreover, the impacts related to the BOS and the building frame are not specifically reported but are directly included in the final computation of the payback time, hampering the possible evaluation of their incidence throughout the whole system.

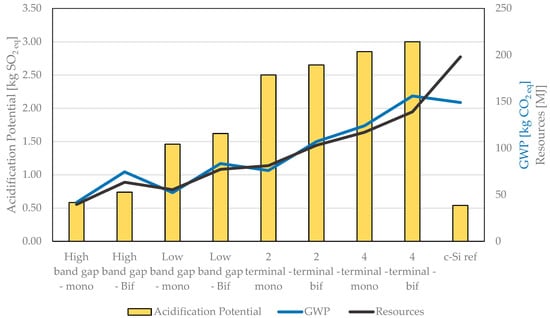

Ahangharnejhad et al. [36] studied the energy and environmental behaviour of different single- and multi-junction monofacial and bifacial perovskite solar cells according to different albedo conditions. The proposed technologies were high and low bandgap single-junction bifacial cells and two or four terminals with multi-junction configurations. The results were then compared to those for traditional single-junction crystalline silicon panels. The functional unit was 1 m2 of active area, a cradle-to-end-of-use was defined as system boundary with an expected lifetime of 25 years. The results show worse performance when using bifacial hetero-junction solar cells in comparison to standard c-Si and perovskite single-junction technologies. In terms of energy gain, among the four technologies considered, bifaciality allowed an increase in energy production of between 4% and 18% in comparison to that of their monofacial counterpart. As reported in Figure 5, when upgrading from a monofacial to a bifacial structure, the environmental impacts increase in the range of 20–60%, for each square metre of surface area produced. This condition is mainly due to a higher amount of solar glass, anti-reflective coating and the contacting layers. The authors also found an increase in energy yield of up to 61% for different configurations of bifacial silicon tandem perovskite solar cells with snow ground conditions, when changing the installation site from Toledo (Ohio) to Golden (Colorado). The reference values of the annual average global horizontal irradiance were, respectively, 5.5 kWh/m2 and 4 kWh/m2. The GWP of perovskite bifacial PV is reported to be in the range of 11–15 gCO2eq/kWh.

Figure 5.

Acidification potential, GWP and resources consumption for the different technologies.

The work was further completed using sensitivity analysis to evaluate the energy yield in relation to four different ground covers: snow, grass, sandstone and concrete. The results show that snow, followed by grass and concrete, is the best option to increase energy generation, while for sandstone the production is only slightly higher than for monofacial panels. However, although for the rest of the study, different impact indicators were considered, for this analysis, only the energy yield was found to hamper the evaluation of how the choice of ground material can alter the final eco-profile. Moreover, the analysis takes into account only the optimal performance in terms of the irradiation that hits the front and rear surfaces of the panel and does not consider any possible shading due to the installation configuration. Regarding the comparison work, bifacial perovskite PV presents a lower GWP index in terms of gCO2eq/kWh in comparison to that of traditional crystalline silicon PV. However, some deficiencies in the methodology should be pointed out. Firstly, it is not properly specified which reference crystalline technology was chosen as the reference benchmark, it being only specified that information was gathered from the Ecoinvent database. Secondly, for the perovskite technologies, it considered an optimistic expected lifetime of 25 years. At present, it is fairly widely assumed that perovskite technology ensures a very limited lifetime and is subject to fast degradation, with even a 50% performance loss during the first 10 days of operation [31]. Hence, impacts were calculated in accordance with a production process that cannot achieve the cell lifetime considered for the identification of the environmental burdens and energy production. Finally, in the study it also assumed a scale-up of the process from-lab-to-fab, introducing a further element of uncertainty in the determination of BPV performance [37,38].

5. Discussion

Among all the papers analyzed, in terms of environmental impacts, the highest share of energy consumption and emission of pollutants was found to be associated with the production stage of the silicon wafer and the module frame. When dealing with panel production, or in general with energy-intensive processes, the location of the industrial plant plays a significant role in the number and amount of pollutants generated [22]. Indeed, each country presents a specific national energy mix, according to the share of the different energy sources and the conversion technologies adopted, which can alter the environmental profile as well as the energy and greenhouse gas payback time. Moreover, the production process involves an extensive use of different chemical compounds [38] that need to be addressed in terms of environmental impacts and embodied energy. The following Table 3 and Table 4 list the main methodological aspects of the LCA analysis together with the key parameters of the technologies involved, as well as the results obtained in terms of GWP impact. As can be seen, there are several methodological and technical parameters that differ among the studies reported. Functional unit, irradiation, performance ratio, lifetime and degradation rate often differ from one work to another, hampering direct and effective comparison among them. To mitigate this condition, the IEA, in the methodological guidelines reported in [38], proposed a set of standardized parameters to be used during the LCA of mono and bifacial solar panels. The guidelines suggest the values that should be used for technical parameters (lifetime, degradation, performance rate, etc.) in relation to the installation configuration (rooftop, ground mounted, etc.) and the maturity of the technology considered. However, most of these parameters are found to be different in the studies reported in the present review.

Table 3.

Comparison of LCA methodological aspects adopted in the different works.

Table 4.

Technological key parameters of the proposed PV systems.

From Table 3, not all the studies use the same methodological parameters to perform the LCA analysis. Two papers out of four adopt the kWh of energy produced as the functional unit, one uses both kWh and panel unit area (1 m2), and one refers to the whole system configuration.

Different approaches can also be found with respect to the selection of impact categories. Indeed, the only indicator that is used in all the works is the GWP or the greenhouse gas emissions. Only two papers report results for more than three impact categories, analyzing the effects on human health, resource depletion and environmental deterioration.

Regarding system boundaries, two works also include the end of life, while the other two consider only manufacturing and use phase. The extension of the system boundaries in terms of the components included in the LCA also differs among the studies. Indeed, while two papers investigate only the solar panel, the other two also include the contribution by the inverter and the mounting structure. As can be seen from Table 4, when also considering these latter components, the GWP of the system changes significantly in comparison to the average impact of only the panel itself. In [33], the inclusion of the inverter and the mounting structure led to a roughly 72% increase in the GWP, increasing from approximately 18 gCO2eq/kWh for the sole panel to 31 gCO2eq/kWh when considering the whole system. According to the authors, 85% of this further contribution (11 gCO2eq/kWh) is specifically due to the mounting structure, even though the geometry and material used are not specified. Hence, in general terms, the environmental analysis should be extended to include all the parameters and boundary conditions, like installation height, row distance, etc., that significantly affect energy production and the environmental impacts when scaled to a functional unit such as the kWh.

The study in [22] also includes within the system boundaries the building frame realized to install the solar system as well as the BOS and the auxiliary components. However, due to the peculiar functional unit adopted and the lack of specific data of the singular elements of the system, it was not possible to derive any information about the GWP index of each component (PV panel, inverter, building frame, etc.).

With respect to data quality, in [33,34], the authors used primary data gathered from producers, while in [36], manufacturing data were directly taken from the laboratory, but for the scale-up of the process, different assumptions were made to derive the associated impacts. The major concern about this last paper is that the authors consider for the base scenario an expected lifetime of the perovskite solar cell of 25 years, which is significantly higher than actual values. Moreover, it is considered that the same cell structure and material adopted could be optimal for the scale-up of the technology from-lab-to-fab, even if at present this option is very far from being realized. Hence, an objective comparison is hindered by the subjective assumption that the same technologies and manufacturing steps can lead to performance, in terms of total energy production and lifetime, that is even one or two orders of magnitude higher than the actual level. In [35], only the Ecoinvent database was used.

The variation in results, when using updated inventory data instead of secondary data, can clearly be seen in [34] where CED decreases from 39 GJ/kWp ( Ecoinvent database) to 24 GJ/kWp when primary data of the upgraded production process are used. The main reductions in terms of energy consumption are associated with the manufacturing of ingots and wafers, with the crystallization process requiring 16.7 GJ/kWp and 6.08 GJ/kWp, respectively.

Regarding performance evaluation, from Table 4, the major discrepancy among the analysis, except for the intrinsic technological parameters, is related to the irradiation conditions, which are different in each of the four works reported, introducing a further variable for the determination of the produced energy and the calculation of the impact associated with the functional unit. In this sense, neither the methodological guidelines for the LCA of PV systems, nor the standard for test conditions reported in [39] set unique values or procedures to conduct testing and performance evaluations. This latter standard provides three different irradiation methods to evaluate bifacial PV performance: an independent measurement of both sides, simultaneous illumination with 1000 W/m2 of the front side and two or more back surface irradiance values, and an outdoor assessment. Among the papers analyzed in the present review, only [34] adopts test conditions like the ones proposed in the standards, even if for the rear side only one irradiance value was considered.

6. Conclusions and Final Remarks

The study focused on the environmental performance of bifacial solar cell technologies, trying to highlight the main processes and materials responsible for the paramount environmental burdens, as well as the major aspects that must be addressed to ensure optimal energy production. The analyzed works report the better environmental performance of BPV panels in contrast to that of monofacial PV. Aside from the energy gain associated with bifaciality, which is strictly related to the ground albedo and the geometry of the installation, the reduced use of aluminium during manufacture (up to a −43%), due to the substitution of the backsheet with a glass layer, helps to decrease the impacts across different categories [34]. A significant reduction in water consumption (54–74%) and metallization paste (67%) is also reported. Among all the different technologies, the production of the silicon wafer still represents the paramount source of pollution and resource consumption both for bifacial and monofacial PV panels. Perovskite bifacial PV reported the best results in terms of gCO2eq/kWh, but the gaps in the methodological approach and the early stage of technological development hamper a definitive comparison.

For the use phase, BPV panels present more technical aspects that shall be accounted for in comparison to monofacials. In fact, the installation configuration, in terms of height, row distance and ground materials directly affects the energy production, which is the paramount factor that drives the adoption of BPV panels instead of traditional PV. However, these aspects are not considered when approaching the LCA study to identify the associated environmental burdens. This gap should be properly addressed in a more comprehensive way in comparison to what is generally the case for the BOS components, since these are the actual parameters that allow bifacial systems to exploit the back-side gain and, therefore, to perform the way in which they were projected to. As a matter of fact, the use of different ground materials, or mounting structures that require materials with high embodied energy, can counterbalance the positive gain associated with bifacial systems.

For the end of life, due to the lack of reliable data on recycling and end-of-life scenarios, most of the works tend to either exclude this step or account for it only through landfill disposal. Only one study compared the effect of recycling and landfill disposal in terms of percentage of impact reduction across seven impact indicators. However, there is still great uncertainty concerning real applications due to the limited number of operative plants and relative operational data.

Beyond the environmental performance of the technology, the assessment presented in this paper shows the methodological gaps associated with the LCA of BPV panels. It was found that the use phase presents most of the criticality, since it is basically considered to contain the same elements and architecture as for monofacial panels, but with increased electricity production due to bifaciality. However, even if the energy gain is ensured only if more components are added to the systems, these are not properly accounted for in the environmental computation.

The LCA studies and the considerations reported here paint a picture of the favourable aspects and the limits of bifacial PV systems. It is evident that bifacial systems can favour electricity production through the gain associated with the back side, although such contribution is strictly related to the installation parameters. Despite all the studies reported in the present review showing better environmental performances of BPV panels over those of monofacial panels, the lack of uniformity and consistency in the methodological approach hinders a definitive comparison.

The present work sets a possible starting point to allow a more extensive and comprehensive LCA analysis of the optimization of bifacial gain and minimization of environmental burdens associated with the whole PV system. Moreover, future works will be useful to determine whether BPV panels ensure effectively better environmental performances in comparison to that of monofacial panels, since the studies published up today highlight gaps that hamper a definitive answer.

Author Contributions

Conceptualization, M.P.M., M.F. and S.L.; writing—original draft preparation, M.P.M.; writing—review and editing, M.F., M.P.M., S.L., G.M. and M.C.; funding acquisition, M.F. All authors have read and agreed to the published version of the manuscript.

Funding

The authors gratefully acknowledge the funding of the project “Best-4U—Tecnologia per celle solari bifacciali ad alta Efficienza a 4 terminali per ‘utility scale’” (project number ARS01_00519) by the Italian Ministry of Research.

Data Availability Statement

Not Applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Available online: https://www.iea.org/Reports/Solar-Pv (accessed on 24 October 2023).

- Bouman, E.A. A Life Cycle Perspective on the Benefits of Renewable Electricity Generation; European Topic Centre on Climate Change Mitigation and Energy: Brussels, Belgium, 2020. [Google Scholar]

- Dupont, E.; Koppelaar, R.; Jeanmart, H. Global Available Solar Energy under Physical and Energy Return on Investment Constraints. Appl. Energy 2020, 257, 113968. [Google Scholar] [CrossRef]

- Rabaia, M.K.H.; Abdelkareem, M.A.; Sayed, E.T.; Elsaid, K.; Chae, K.-J.; Wilberforce, T.; Olabi, A.G. Environmental Impacts of Solar Energy Systems: A Review. Sci. Total Environ. 2021, 754, 141989. [Google Scholar] [CrossRef] [PubMed]

- Sahu, P.K.; Roy, J.N.; Chakraborty, C. Performance Assessment of a Bifacial PV System Using a New Energy Estimation Model. Sol. Energy 2023, 262, 111818. [Google Scholar] [CrossRef]

- Liang, T.S.; Pravettoni, M.; Deline, C.; Stein, J.S.; Kopecek, R.; Singh, J.P.; Luo, W.; Wang, Y.; Aberle, A.G.; Khoo, Y.S. A Review of Crystalline Silicon Bifacial Photovoltaic Performance Characterisation and Simulation. Energy Environ. Sci. 2019, 12, 116–148. [Google Scholar] [CrossRef]

- Al-Masri, H.M.K.; Dawaghreh, O.M.; Magableh, S.K. Realistic Performance Evaluation and Optimal Energy Management of a Large-Scale Bifacial Photovoltaic System. Energy Convers. Manag. 2023, 286, 117057. [Google Scholar] [CrossRef]

- David, L.; Addison, T. A Guide to Bifacial Solar Panels. 2023. Available online: https://www.marketwatch.com/guides/home-improvement/bifacial-solar-panels/ (accessed on 14 September 2023).

- Patel, M.T.; Khan, M.R.; Sun, X.; Alam, M.A. A Worldwide Cost-Based Design and Optimization of Tilted Bifacial Solar Farms. Appl. Energy 2019, 247, 467–479. [Google Scholar] [CrossRef]

- Guerrero-Lemus, R.; Vega, R.; Kim, T.; Kimm, A.; Shephard, L.E. Bifacial Solar Photovoltaics—A Technology Review. Renew. Sustain. Energy Rev. 2016, 60, 1533–1549. [Google Scholar] [CrossRef]

- Lim, Y.S.; Lo, C.K.; Kee, S.Y.; Ewe, H.T.; Faidz, A.R. Design and Evaluation of Passive Concentrator and Reflector Systems for Bifacial Solar Panel on a Highly Cloudy Region—A Case Study in Malaysia. Renew. Energy 2014, 63, 415–425. [Google Scholar] [CrossRef]

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252. [Google Scholar] [CrossRef]

- Gazbour, N.; Razongles, G.; Monnier, E.; Joanny, M.; Charbuillet, C.; Burgun, F.; Schaeffer, C. A Path to Reduce Variability of the Environmental Footprint Results of Photovoltaic Systems. J. Clean. Prod. 2018, 197, 1607–1618. [Google Scholar] [CrossRef]

- Rossi, F.; Zuffi, C.; Parisi, M.L.; Fiaschi, D.; Manfrida, G. Comparative Scenario-Based LCA of Renewable Energy Technologies Focused on the End-of-Life Evaluation. J. Clean. Prod. 2023, 405, 136931. [Google Scholar] [CrossRef]

- Lim, M.S.W.; He, D.; Tiong, J.S.M.; Hanson, S.; Yang, T.C.-K.; Tiong, T.J.; Pan, G.-T.; Chong, S. Experimental, Economic and Life Cycle Assessments of Recycling End-of-Life Monocrystalline Silicon Photovoltaic Modules. J. Clean. Prod. 2022, 340, 130796. [Google Scholar] [CrossRef]

- Li, J.; Shao, J.; Yao, X.; Li, J. Life Cycle Analysis of the Economic Costs and Environmental Benefits of Photovoltaic Module Waste Recycling in China. Resour. Conserv. Recycl. 2023, 196, 107027. [Google Scholar] [CrossRef]

- Huang, B.; Zhao, J.; Chai, J.; Xue, B.; Zhao, F.; Wang, X. Environmental Influence Assessment of China’s Multi-Crystalline Silicon (Multi-Si) Photovoltaic Modules Considering Recycling Process. Sol. Energy 2017, 143, 132–141. [Google Scholar] [CrossRef]

- Krebs, L.; Frischknecht, R.; Stolz, P.; Sinha, P. Environmental Life Cycle Assessment of Residential PV and Battery Storage Systems. In IEA PVPS Task 12, International Energy Agency (IEA) PVPS Task 12; Report T12–17; nstitute of Natural Resource Sciences (IUNR):: Reno, NV, USA, 2020; ISBN 978-3-906042-97-8. [Google Scholar]

- Fazio, S.; Castellani, V.; Sala, S.; Schau, E.M.; Secchi, M.; Zampori, L. Supporting information to the characterisation factors of recommended EF Life Cycle Impact Assessment methods; EUR 28888 EN; European Commission: Ispra, Italy, 2018; ISBN 978-92-79-76742-5. [Google Scholar] [CrossRef]

- Besseau, R.; Tannous, S.; Douziech, M.; Jolivet, R.; Prieur-Vernat, A.; Clavreul, J.; Payeur, M.; Sauze, M.; Blanc, I.; Pérez-López, P. An Open-source Parameterized Life Cycle Model to Assess the Environmental Performance of Silicon-based Photovoltaic Systems. Prog. Photovolt. Res. Appl. 2023, 31, 908–920. [Google Scholar] [CrossRef]

- Antonanzas, J.; Quinn, J.C. Net Environmental Impact of the PV Industry from 2000–2025. J. Clean. Prod. 2021, 311, 127791. [Google Scholar] [CrossRef]

- Müller, A.; Friedrich, L.; Reichel, C.; Herceg, S.; Mittag, M.; Neuhaus, D.H. A Comparative Life Cycle Assessment of Silicon PV Modules: Impact of Module Design, Manufacturing Location and Inventory. Sol. Energy Mater. Sol. Cells 2021, 230, 111277. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Bali, T. An Experimental Analysis of Illumination Intensity and Temperature Dependency of Photovoltaic Cell Parameters. Appl. Energy 2013, 111, 374–382. [Google Scholar] [CrossRef]

- Gu, W.; Ma, T.; Ahmed, S.; Zhang, Y.; Peng, J. A Comprehensive Review and Outlook of Bifacial Photovoltaic (BPV) Technology. Energy Convers. Manag. 2020, 223, 113283. [Google Scholar] [CrossRef]

- Yusufoglu, U.A.; Pletzer, T.M.; Koduvelikulathu, L.J.; Comparotto, C.; Kopecek, R.; Kurz, H. Analysis of the Annual Performance of Bifacial Modules and Optimization Methods. IEEE J. Photovolt. 2015, 5, 320–328. [Google Scholar] [CrossRef]

- Sun, X.; Khan, M.R.; Deline, C.; Alam, M.A. Optimization and Performance of Bifacial Solar Modules: A Global Perspective. Appl. Energy 2018, 212, 1601–1610. [Google Scholar] [CrossRef]

- Shoukry, I.; Libal, J.; Kopecek, R.; Wefringhaus, E.; Werner, J. Modelling of Bifacial Gain for Stand-Alone and in-Field Installed Bifacial PV Modules. Energy Procedia 2016, 92, 600–608. [Google Scholar] [CrossRef]

- Ganesan, K.; Winston, D.P.; Sugumar, S.; Jegan, S. Performance Analysis of N-Type PERT Bifacial Solar PV Module under Diverse Albedo Conditions. Sol. Energy 2023, 252, 81–90. [Google Scholar] [CrossRef]

- Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.-C.; Yi, J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies 2021, 14, 4278. [Google Scholar] [CrossRef]

- Li, L.; Guo, Z.; Fan, R.; Zhou, H. Anti-Corrosion Strategy to Improve the Stability of Perovskite Solar Cells. Nanoscale 2023, 15, 8473–8490. [Google Scholar] [CrossRef] [PubMed]

- Mansour Rezaei Fumani, N.; Arabpour Roghabadi, F.; Alidaei, M.; Sadrameli, S.M.; Ahmadi, V.; Najafi, F. Prolonged Lifetime of Perovskite Solar Cells Using a Moisture-Blocked and Temperature-Controlled Encapsulation System Comprising a Phase Change Material as a Cooling Agent. ACS Omega 2020, 5, 7106–7114. [Google Scholar] [CrossRef]

- Liang, T.S.; Poh, D.; Pravettoni, M. Challenges in the Pre-Normative Characterization of Bifacial Photovoltaic Modules. Energy Procedia 2018, 150, 66–73. [Google Scholar] [CrossRef]

- Gazbour, N.; Razongles, G.; Schaeffer, C.; Charbuillet, C. Photovoltaic Power Goes Green. In Proceedings of the 2016 Electronics Goes Green 2016+, Berlin, Germany, 6–9 September 2016. [Google Scholar]

- Jia, X.; Zhou, C.; Tang, Y.; Wang, W. Life Cycle Assessment on PERC Solar Modules. Sol. Energy Mater. Sol. Cells 2021, 227, 111112. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, W.; He, B.; Xie, L.; Chen, M.; Li, J.; Zhao, O.; Wu, X. A Comprehensive Life Cycle Assessment Study of Innovative Bifacial Photovoltaic Applied on Building. Energy 2022, 245, 123212. [Google Scholar] [CrossRef]

- Hosseinian Ahangharnejhad, R.; Becker, W.; Jones, J.; Anctil, A.; Song, Z.; Phillips, A.; Heben, M.; Celik, I. Environmental Impact per Energy Yield for Bifacial Perovskite Solar Cells Outperforms Crystalline Silicon Solar Cells. Cell Rep. Phys. Sci. 2020, 1, 100216. [Google Scholar] [CrossRef]

- Mai, T.; Wiser, R.; Sandor, D.; Brinkman, G.; Heath, G.; Denholm, P.; Hostick, D.J.; Darghouth, N.; Schlosser, A.; Strzepek, K. Exploration of High-Penetration Renewable Electricity Futures. Vol. 1 of Renewable Electricity Futures Study; NREL/TP-6A20-52409-1; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Frischknecht, R.; Stolz, P.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity, 4th ed.; IEA PVPS Task 12; International Energy Agency Photovoltaic Power Systems Programme: Paris, France, 2020; Volume 12. [Google Scholar]

- Photovoltaic devices-Part 1–2: Measurement of current-voltage characteristics of bifacial photovoltaic (PV) devices. IEC TS 60904-1-2:2019; International Electrotechnical Commission: Geneva, Switzerland, 2019.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).