Multi-Scale Characterization of Porosity and Cracks in Silicon Carbide Cladding after Transient Reactor Test Facility Irradiation

Abstract

:1. Introduction

2. Methods

2.1. Experimental Data

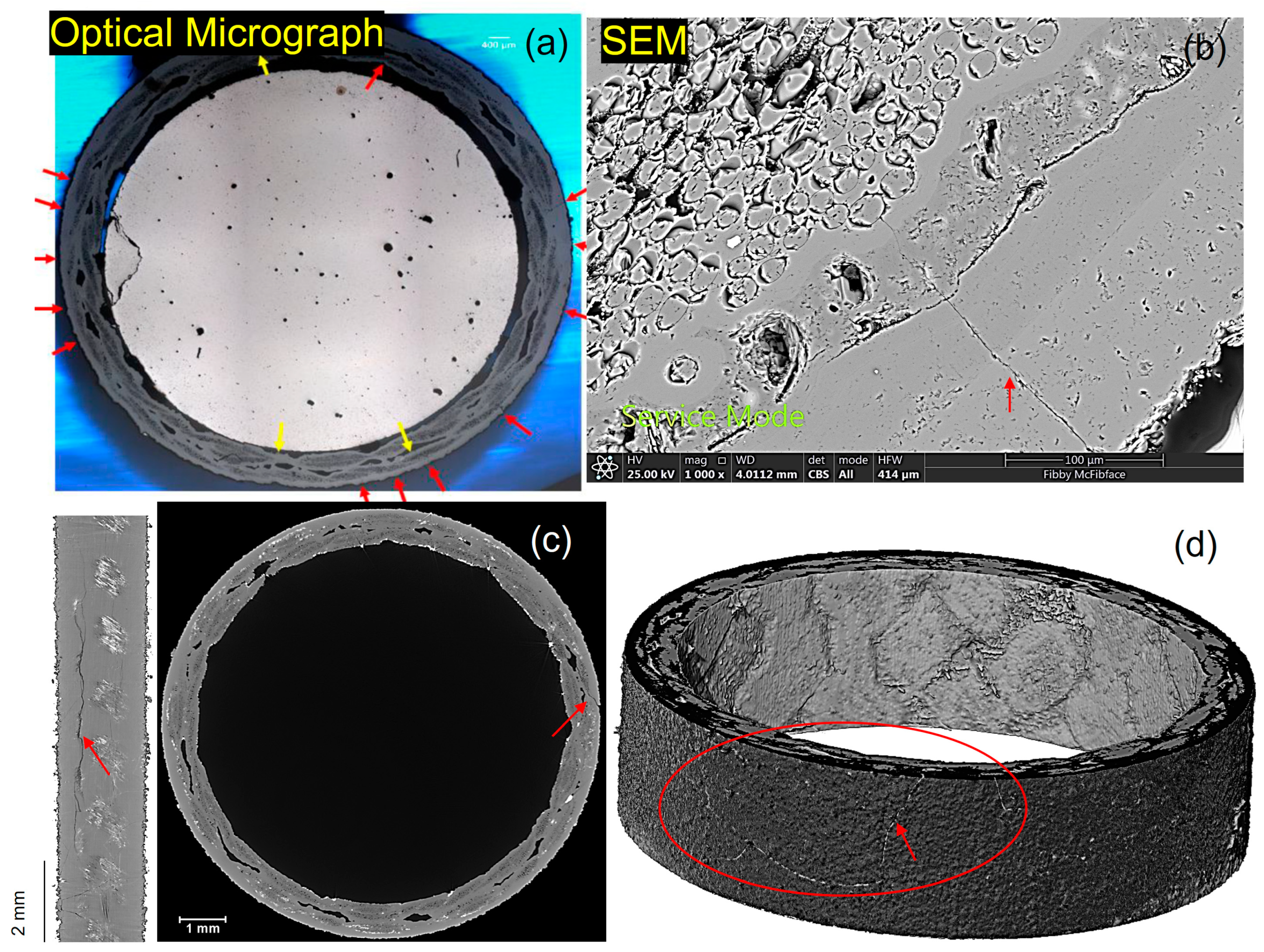

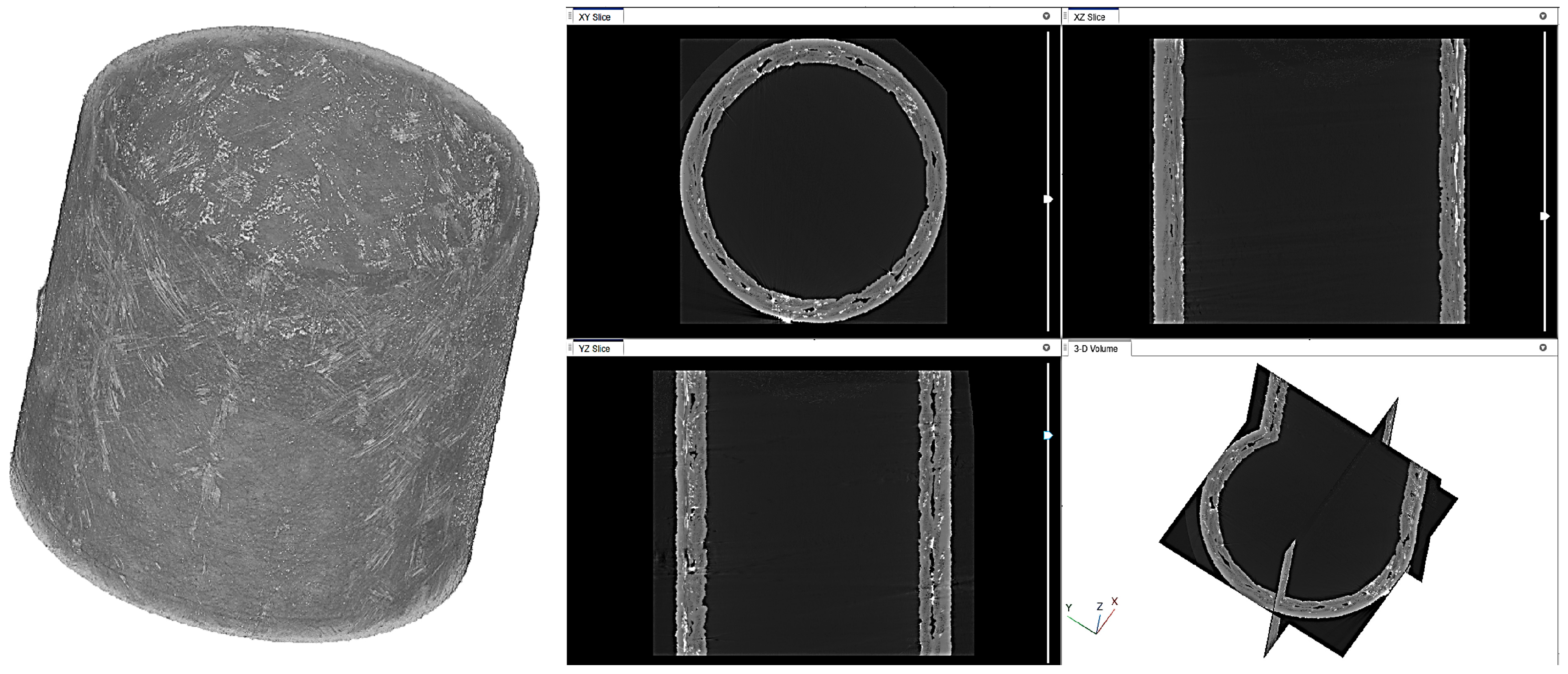

2.2. Engineering-Scale Characterization

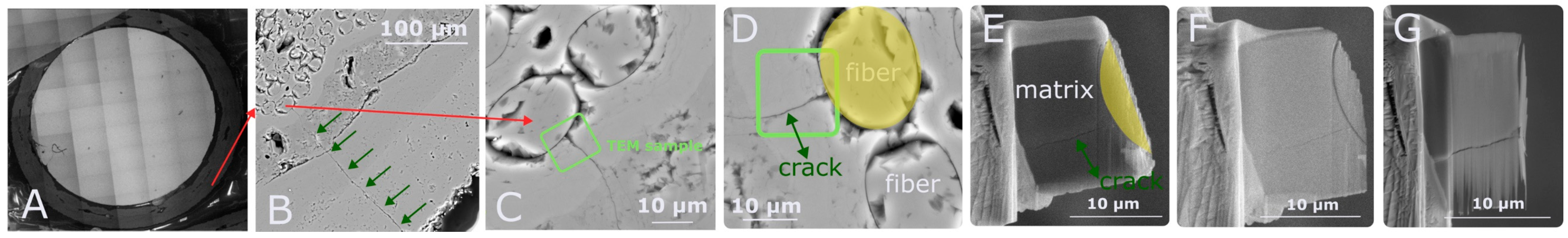

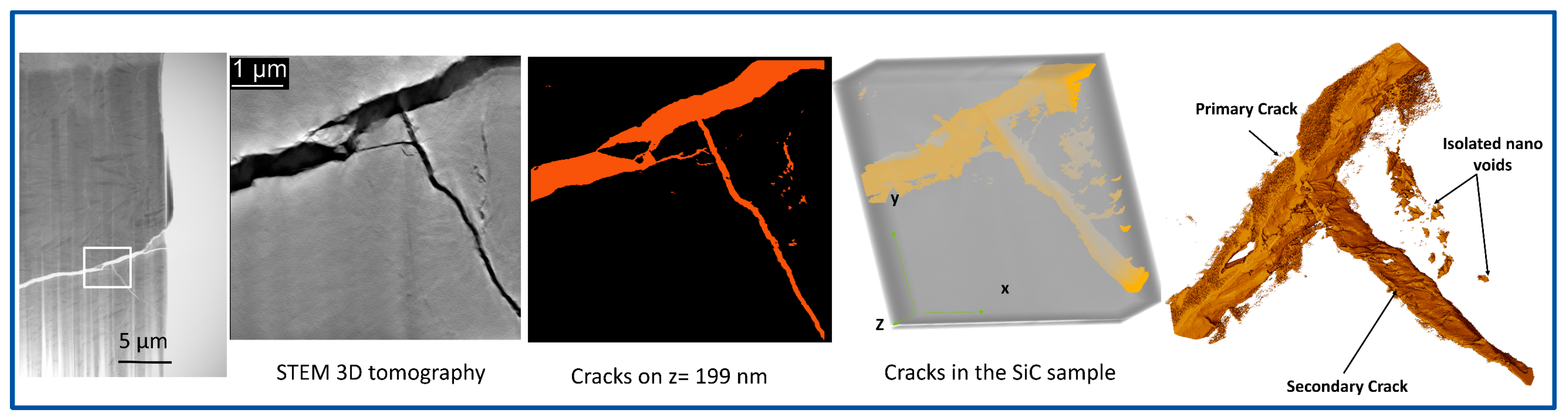

2.3. Microstructure Characterization

3. Results and Discussion

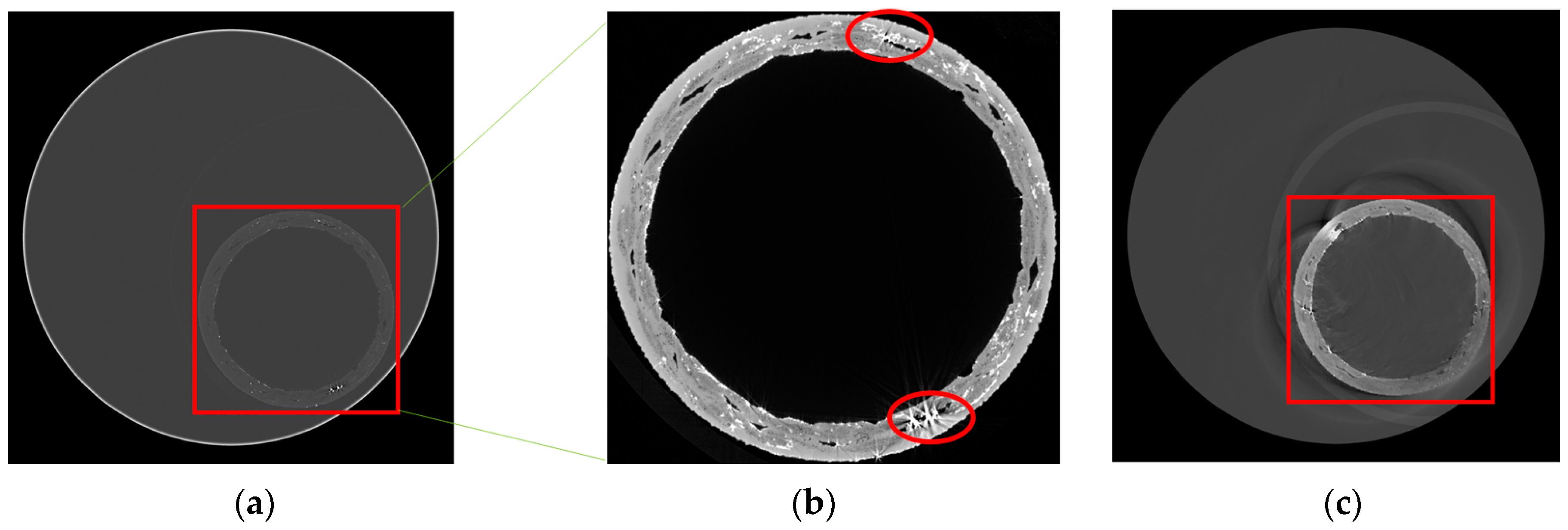

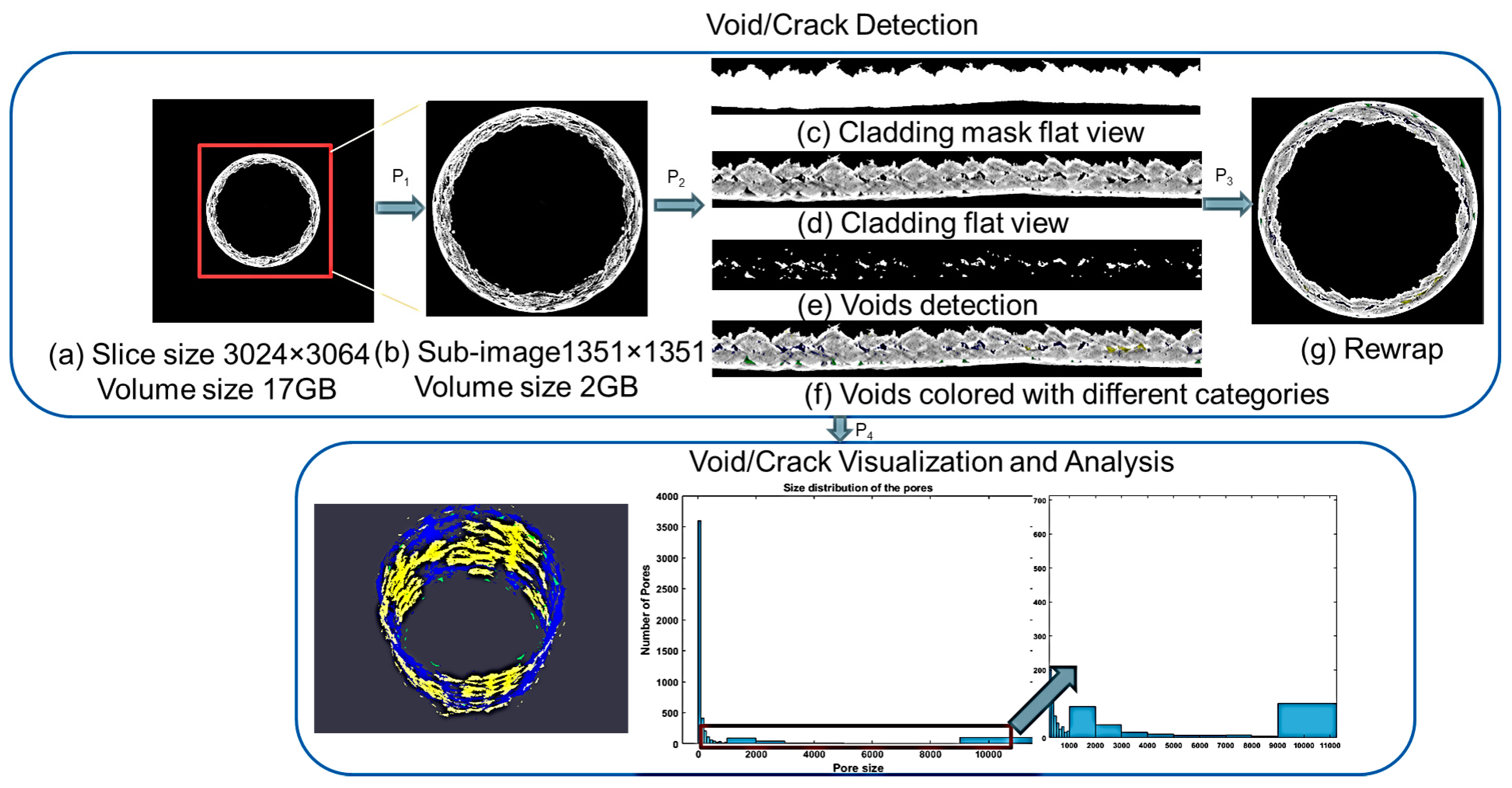

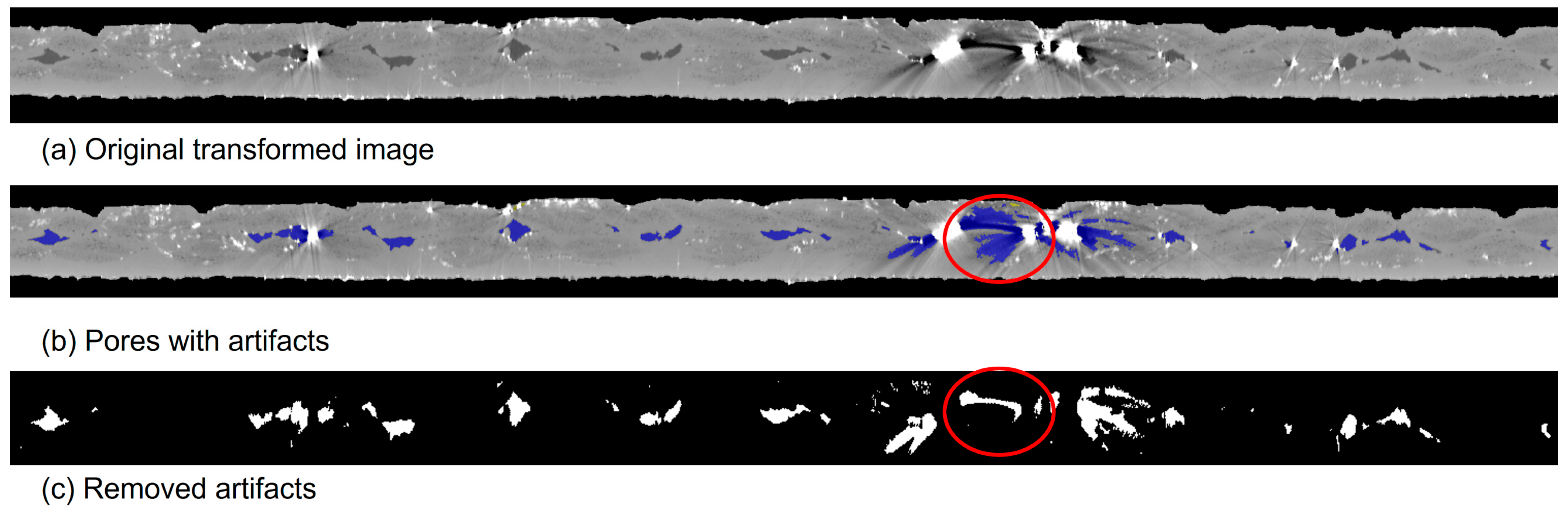

3.1. Defects Detection on XCT Data

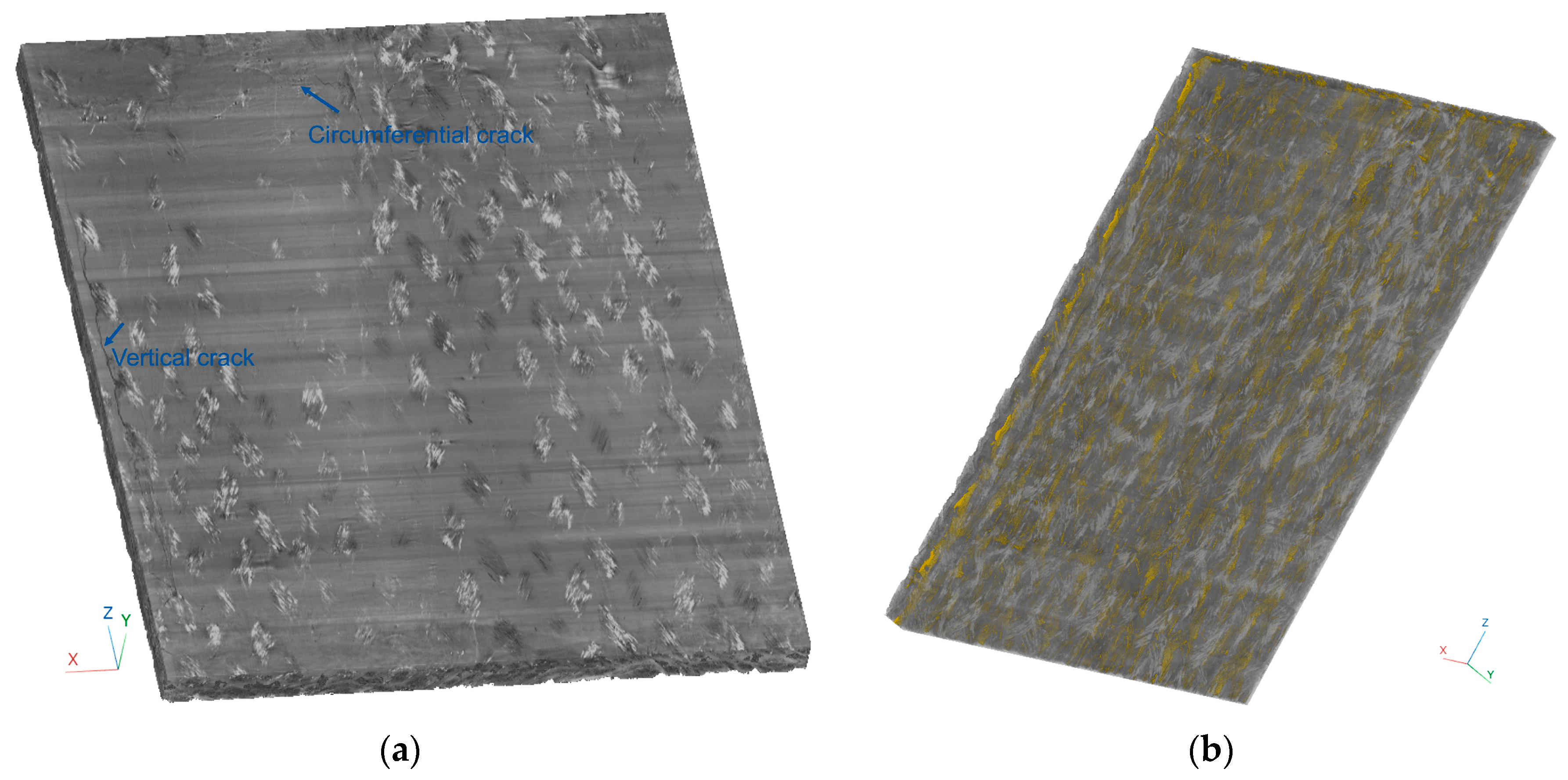

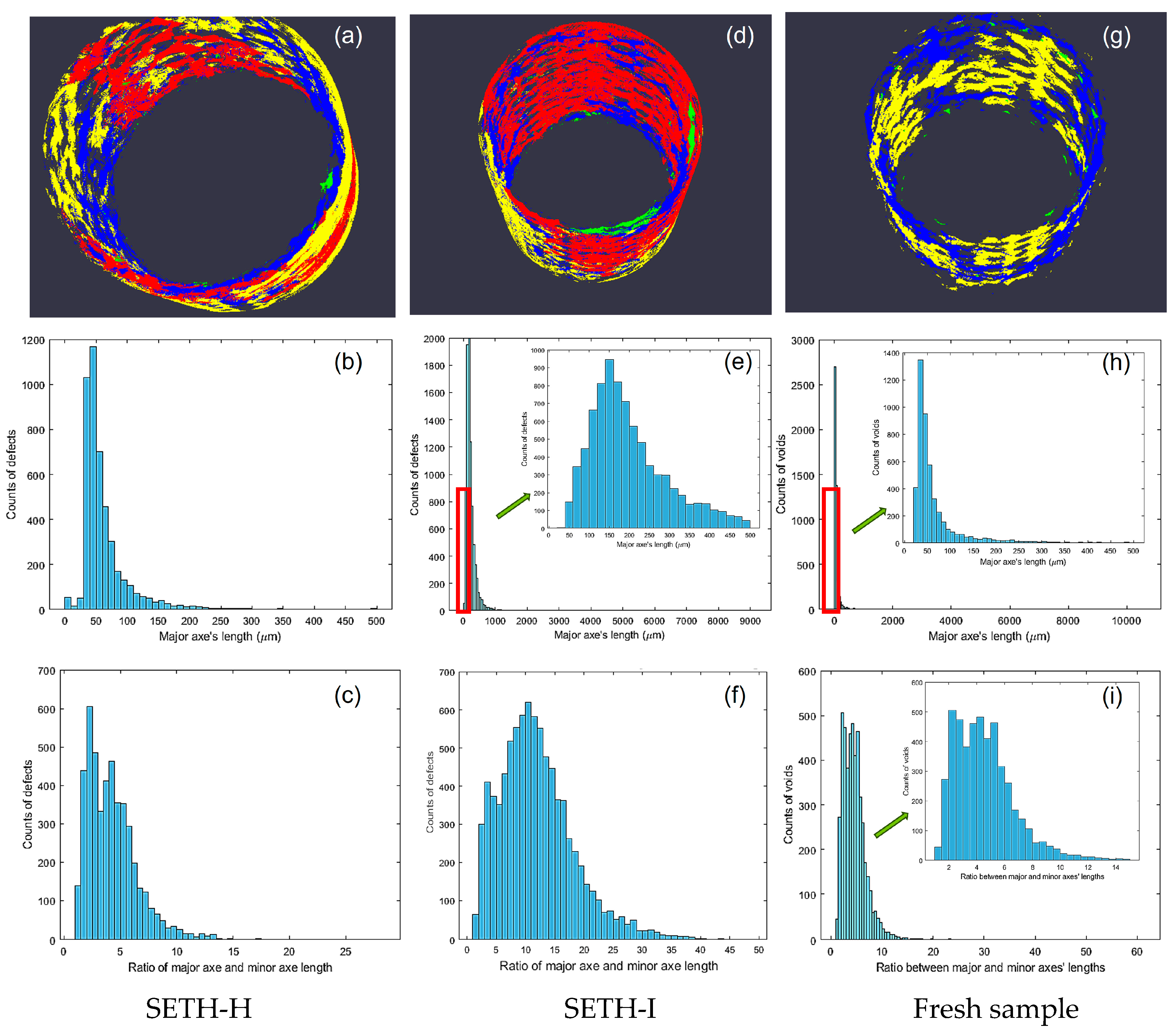

3.2. Visualization and Analysis Discussion of Defects and Voids on XCT Data

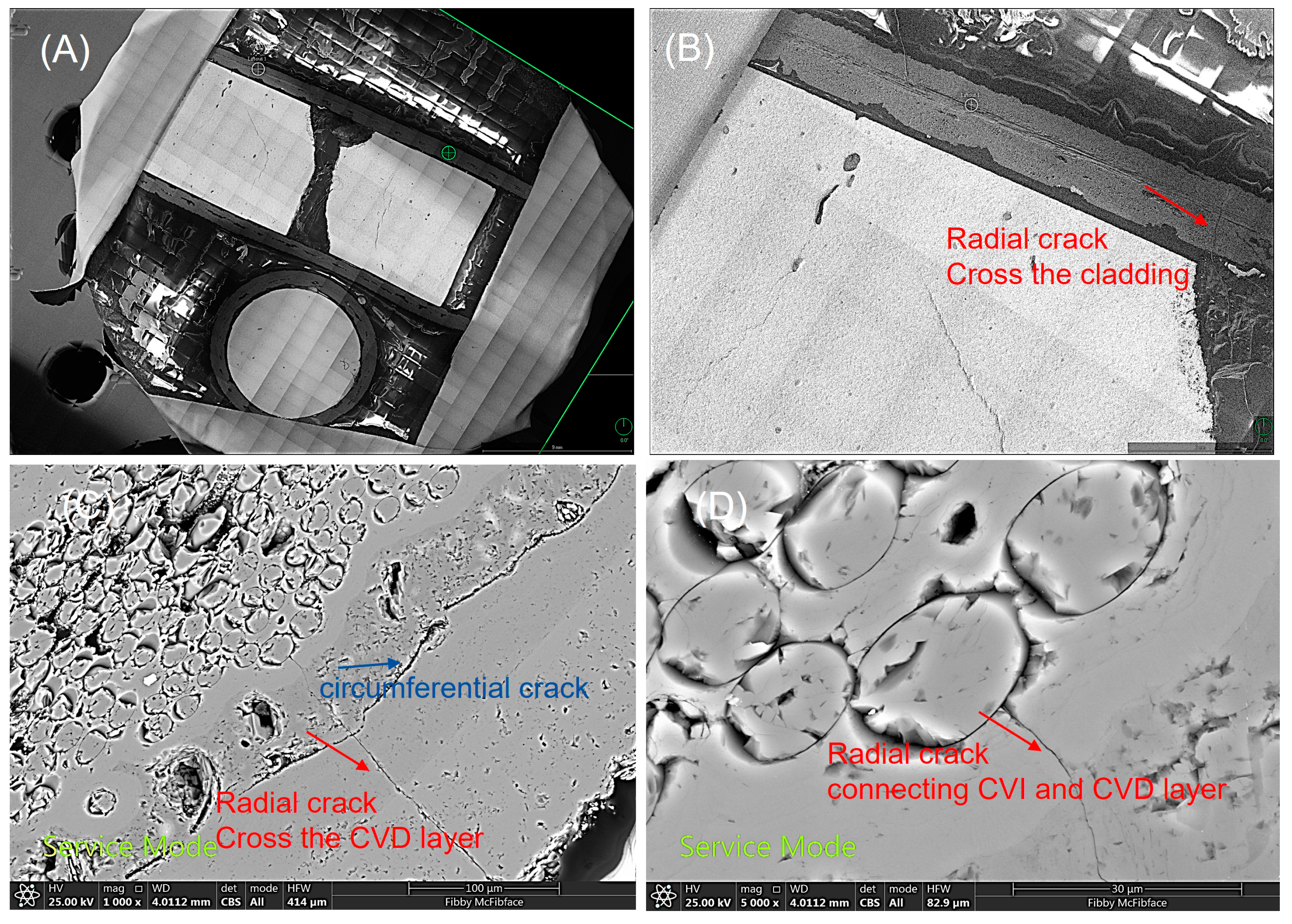

3.3. Analysis Discussion of PFIB and TEM Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United States Department of Energy. Development of Light Water Reactor Fuels with Enhanced Accident Tolerance; Report to Congress; United States Department of Energy: Washington, DC, USA, 2015. Available online: https://www.energy.gov/sites/prod/files/2015/06/f23/Report%20to%20Congress%20-%20Accident%20Tolerant%20Fuels.pdf (accessed on 14 November 2020).

- Zinkle, S.J.; Terrani, K.A.; Gehin, J.C.; Ott, L.J.; Snead, L.L. Accident tolerant fuels for LWRs: A perspective. J. Nucl. Mater. 2014, 448, 374–379. [Google Scholar] [CrossRef]

- Alrwashdeh, M.; Alameri, S.A. Chromium-Coated Zirconium Cladding Neutronics Impact for APR-1400 Reactor Core. Energies 2022, 15, 8008. [Google Scholar] [CrossRef]

- Yueh, K.; Terrani, K.A. Silicon carbide composite for light water reactor fuel assembly applications. J. Nucl. Mater. 2014, 448, 380–388. [Google Scholar] [CrossRef]

- Katoh, Y.; Snead, L.L.; Henager, C.H.; Hasegawa, A.; Kohyama, A.; Riccardi, B.; Hegeman, H. Current status and critical issues for development of SiC composites for fusion applications. J. Nucl. Mater. 2007, 367–370, 659–671. [Google Scholar] [CrossRef]

- Deck, C.P.; Jacobsen, G.M.; Sheeder, J.; Gutierrez, O.; Zhang, J.; Stone, J.; Khalifa, H.E.; Back, C.A. Characterization of SiC-SiC composites for accident tolerant fuel cladding. J. Nucl. Mater. 2015, 466, 667–681. [Google Scholar] [CrossRef]

- Doyle, P.J.; Ang, C.; Snead, L.; Katoh, Y.; Terrani, K.; Raiman, S.S. Hydrothermal corrosion of first-generation dual-purpose coatings on silicon carbide for accident-tolerant fuel cladding. J. Nucl. Mater. 2021, 544, 152695. [Google Scholar] [CrossRef]

- Koyanagi, T.; Katoh, Y.; Nozawa, T. Design and strategy or next-generation silicon carbide composites for nuclear energy. J. Nucl. Mater. 2020, 540, 152375. [Google Scholar] [CrossRef]

- Petrie, C.M.; Koyanagi, T.; McDuffee, J.L.; Deck, C.P.; Katoh, Y.; Terrani, K.A. Experimental design and analysis for irradiation of SiC/SiC composite tubes under a prototypic high heat flux. J. Nucl. Mater. 2017, 491, 94–104. [Google Scholar] [CrossRef]

- Stone, J.G.; Schleicher, R.; Deck, C.P.; Jacobsen, G.M.; Khalifa, H.E.; Back, C.A. Stress analysis and probabilistic assessment of multi-layer SiC-based accident tolerant nuclear fuel cladding. J. Nucl. Mater. 2015, 466, 682–697. [Google Scholar] [CrossRef]

- Li, W.; Shirvan, K. U3Si2-SiC fuel performance analysis in BISON during normal operation. Ann. Nucl. Energy 2019, 132, 34–45. [Google Scholar] [CrossRef]

- He, Y.; Shirvan, K.; Wu, Y.; Su, G.H. Fuel performance optimization of U3Si2-SiC design during normal, power ramp and RIA conditions. Nucl. Eng. Des. 2019, 353, 110276. [Google Scholar] [CrossRef]

- Cordes, N.; Kane, J.; Craft, A. 3D X-ray Microscopy of Nuclear Energy Materials. Microsc. Microanal. 2020, 26, 872. [Google Scholar] [CrossRef]

- Chen, Y.T.; Lo, T.N.; Chu, Y.S.; Yi, J.; Liu, C.J.; Wang, J.Y.; Wang, C.L.; Chiu, C.W.; Hua, T.E.; Hwu, Y.; et al. Full-field hard X-ray microscopy below 30 nm: A challenging nanofabrication achievement. Nanotechnology 2008, 19, 395302. [Google Scholar] [CrossRef]

- Helmreich, G.W.; Richardson, D.; Venkatakrishnan, S.; Ziabari, A. Method for measurement of TRISO kernel and layer volumes by X-ray computed tomography. J. Nucl. Mater. 2020, 539, 152255. [Google Scholar] [CrossRef]

- Croom, B.P.; Xu, P.; Lahoda, E.J.; Deck, C.P.; Li, X. Quantifying the three-dimensional damage and stress redistribution mechanisms of braided SiC/SiC composites by in situ volumetric digital image correlation. Scr. Mater. 2017, 130, 238–241. [Google Scholar] [CrossRef]

- Singh, G.; Koyanagi, T.; Petrie, C.; Deck, C.; Terrani, K.; Arregui-Mena, J.D.; Katoh, Y. Elastic moduli reduction in SiC-SiC tubular specimen after high heat flux neutron irradiation measured by resonant ultrasound spectroscopy. J. Nucl. Mater. 2019, 523, 391–401. [Google Scholar] [CrossRef]

- Yuan, G.; Forna-Kreutzer, J.P.; Xu, P.; Gonderman, S.; Deck, C.; Olson, L.; Lahoda, E.; Ritchie, R.O.; Liu, D. In situ high-temperature 3D imaging of the damage evolution in a SiC nuclear fuel cladding material. Mater. Des. 2023, 227, 111784. [Google Scholar] [CrossRef]

- Schulthess, J.; Kamerman, D.; Winston, A.; Pomo, A.; Trowbridge, T.; Pu, X.; Woolstenhulme, N.; Imholte, D.; Jensen, C.; Wachs, D. Post-transient examination of performance of uranium silicide fuel and silicon-carbide composite cladding under reactivity-initiated accident conditions. J. Nucl. Mater. 2022, 560, 153520. [Google Scholar] [CrossRef]

- Kamerman, D.; Woolstenhulme, N.; Imholte, D.; Fleming, A.; Jensen, C.; Folsom, C.; Woolum, C.; Tritthart, K.; Schulthess, J.; Wachs, D. Transient testing of uranium silicide fuel in zircaloy and silicon carbide cladding. Ann. Nucl. Energy 2021, 160, 108410. [Google Scholar] [CrossRef]

- Snead, L.L.; Katoh, Y.; Connery, S. Swelling of SiC at intermediate and high irradiation temperatures. J. Nucl. Mater. 2007, 367–370, 677–684. [Google Scholar] [CrossRef]

- Olesinski, R.W.; Abbaschian, G.J. The C-Si (Carbon-Silicon) System. Bull. Alloy Phase Syst. 1984, 5, 486. [Google Scholar] [CrossRef]

- Kane, J.J.; Marshall, D.W.; Cordes, N.L.; Chuirazzi, W.C.; Kombaiah, B.; van Rooyen, I.; Stempien, J.D. 3D analysis of TRISO fuel compacts via X-ray computed tomography. J. Nucl. Mater. 2022, 565, 153745. [Google Scholar] [CrossRef]

- Gonzalez, R.C.; Woods, R.E. Thresholding. In Digital Image Processing; Pearson Education: London, UK, 2002; pp. 595–611. [Google Scholar]

- Zhao, S.; Robeltson, D.D.; Wang, G.; Whiting, B.; Bae, K.T. X-ray CT metal artifact reduction using wavelets: An application for imaging total hip prostheses. IEEE Trans. Med. Imaging 2000, 19, 1238–1247. [Google Scholar] [CrossRef] [PubMed]

- Hur, J.; Kim, D.; Shin, Y.G.; Lee, H. Metal artifact reduction method based on a constrained beam-hardening estimator for polychromatic X-ray CT. Phys. Med. Biol. 2021, 66, 065025. [Google Scholar] [CrossRef]

- Evans, A.G.; Zok, F.W. The physics and mechanics of fibre-reinforced brittle matrix composites. J. Mater. Sci. 1994, 29, 3857–3896. [Google Scholar] [CrossRef]

- Saucedo-Mora, L.; Lowe, T.; Zhao, S.; Lee, P.D.; Mummery, P.M.; Marrow, T.J. In situ observation of mechanical damage within a SiC-SiC ceramic matrix composite. J. Nucl. Mater. 2016, 481, 13–23. [Google Scholar] [CrossRef]

- Ritchie, R. Re: How to Define a Crack? 2020. Available online: https://www.researchgate.net/post/How_to_define_a_crack/5fb0372b481ded5a4637961c/citation/download (accessed on 14 November 2020).

- Lehmann, G.; Legland, D. Efficient N-Dimensional Surface Estimation Using Crofton Formula and Run-Length Encoding. Insight J. 2012. Available online: https://insight-journal.org/browse/publication/852 (accessed on 14 November 2020). [CrossRef]

- Shoemake, K. Graphics Gems IV; Paul, S.H., Ed.; Morgan Kaufmann: Burlington, MA, USA, 1994; pp. 222–229. [Google Scholar]

| Sample | Fuel | Clad | Pellet Clad Gap (µm) | Rodlet Energy Deposited (J/g) | Pulse Width (ms) | Peak Fuel T (C) | Peak Clad T (C) | Objective |

|---|---|---|---|---|---|---|---|---|

| SETH-H | NE-U3Si2 | SiC | 80 | 528 | 95 | 2050 | 1133–1156 | PCI/fuel melting |

| SETH-I | NE-U3Si2 | SiC | 50 | 330 | 100 | 1440 | 831–840 | PCMI |

| Fresh | NE-U3Si2 | SiC | Fresh sample |

| Sample | Source to the Rotation Axis (RA) (mm) | Detector to the RA (mm) | Pixel Size (μm) | Number of Projections | Cone Angle | # of Slices |

|---|---|---|---|---|---|---|

| 1 | −26.0461 | 245.4407 | 7.1762 | 4501 | 14.9334 | 1932 |

| 2 | −26.0461 | 245.4392 | 7.1763 | 4501 | 14.9040 | 1932 |

| 3 | −21.0601 | 234.2374 | 6.1704 | 2401 | 15.8031 | 1932 |

| Samples | Measurements from X-ray CT Data | Pre-TREAT Measurements from CMMs [19] | Post-TREAT Manual Measurements | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average OD (mm) | Standard Deviation of OD | Minimum OD (mm) | Maximum OD (mm) | Average OD (mm) | Standard Deviation of OD | Minimum OD (mm) | Maximum OD (mm) | Average OD (mm) | Standard Deviation of OD | Minimum OD (mm) | Maximum OD (mm) | |

| SETH-H | 9.59 | 0.04 | 9.54 | 9.75 | 9.67 | 0.01 | 9.66 | 9.67 | 9.71 | 0.01 | 9.68 | 9.73 |

| SETH-I | 9.64 | 0.01 | 9.59 | 9.78 | 9.67 | 0.01 | 9.67 | 9.69 | 9.71 | 0.02 | 9.70 | 9.75 |

| Fresh | 9.47 | 0.02 | 9.41 | 9.49 | ||||||||

| Sample | Cladding Size (mm3) | # of Voids | Porosity | Void Portion in c1 | Void Portion in c2 | Void Portion in c3 | Void Portion in c4 | # of Voids of Type c4 |

| SETH-H | 55.39 | 97,446 | 5.73% | 26% | 40% | 1% | 33% | 8 |

| SETH-I | 92.98 | 84,333 | 6.96% | 23% | 11% | 2% | 63% | 2 |

| Fresh | 85.23 | 4828 | 3.01% | 99% | 1% | 0% | 0 | 0 |

| Sample | Voids’ Size < 10,000 µm3 | Voids’ Size < 0.001 mm3 | Voids’ Size ≤ 1 mm3 | Voids Size > 1 mm3 | Void Portion of Long Crack | Void Portion of Short Crack | Void Portion of Small Crack | Non-Crack Voids |

| SETH-H | 0.65% | 5.69% | 72.49% | 21.17% | 0 | 91.21% | 0 | 8.79% |

| SETH-I | 0.07% | 10.03% | 53.22% | 39.75% | 39.75% | 49.85% | 0.003% | 10.40% |

| Fresh | 0.41% | 1.69% | 94.89% | 0.00% | 0 | 83.68% | 1.06% | 15.26% |

| Sample | # of c4 Type Voids | Volume Size (mm3) | Principle Axis Length (mm) | ||

|---|---|---|---|---|---|

| SETH-H | 1 | 0.04 | 1.41 | 0.81 | 0.43 |

| 2 | 0.12 | 3.19 | 1.28 | 0.54 | |

| 3 | 0.28 | 5.50 | 2.71 | 0.37 | |

| 4 | 0.04 | 1.76 | 0.60 | 0.48 | |

| 5 | 0.32 | 5.11 | 3.21 | 0.56 | |

| 6 | 0.01 | 0.69 | 0.55 | 0.43 | |

| 7 | 0.16 | 3.25 | 2.79 | 0.26 | |

| 8 | 0.08 | 2.88 | 0.86 | 0.40 | |

| SETH-I | 1 | 3.23 | 17.38 | 6.97 | 0.72 |

| 2 | 0.87 | 13.51 | 3.66 | 0.63 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Yao, T.; Xu, P.; Schulthess, J.L.; Matos, M.D., II; Gonderman, S.; Gazza, J.; Kane, J.J.; Cordes, N.L. Multi-Scale Characterization of Porosity and Cracks in Silicon Carbide Cladding after Transient Reactor Test Facility Irradiation. Energies 2024, 17, 197. https://doi.org/10.3390/en17010197

Xu F, Yao T, Xu P, Schulthess JL, Matos MD II, Gonderman S, Gazza J, Kane JJ, Cordes NL. Multi-Scale Characterization of Porosity and Cracks in Silicon Carbide Cladding after Transient Reactor Test Facility Irradiation. Energies. 2024; 17(1):197. https://doi.org/10.3390/en17010197

Chicago/Turabian StyleXu, Fei, Tiankai Yao, Peng Xu, Jason L. Schulthess, Mario D. Matos, II, Sean Gonderman, Jack Gazza, Joshua J. Kane, and Nikolaus L. Cordes. 2024. "Multi-Scale Characterization of Porosity and Cracks in Silicon Carbide Cladding after Transient Reactor Test Facility Irradiation" Energies 17, no. 1: 197. https://doi.org/10.3390/en17010197

APA StyleXu, F., Yao, T., Xu, P., Schulthess, J. L., Matos, M. D., II, Gonderman, S., Gazza, J., Kane, J. J., & Cordes, N. L. (2024). Multi-Scale Characterization of Porosity and Cracks in Silicon Carbide Cladding after Transient Reactor Test Facility Irradiation. Energies, 17(1), 197. https://doi.org/10.3390/en17010197