Table 2 is a summary of the biomass wastes/byproducts generated from each of the most important crop value chains. It is evident from

Table 2 that the potential biomass waste from some of the crop value chains is relatively higher than that obtainable from their counterparts, even when cultivated on a considerably lower total annual surface area and/or produced in smaller amounts. With a total cultivated annual surface area of 1,200,000 ha, the bean value chain ranks second highest but only generates 2,821,500 MT of biomass waste compared to the 3,293,570 MT generated from the sugarcane value chain, which ranks as one of the lowest in terms of total annual cultivated surface area. In view of this observation, the three most important crop value chains are the banana, maize, and sugarcane value chains. These are described in the subsequent sections.

3.2.1. Maize

According to UBOS [

5], the average maize production of maize in Uganda over five years (2015–2020) was approximately 3.212 million metric tons (MT). Results from the Ugandan

Annual Agricultural Survey (AAS) for 2018 indicate that the total production of maize in Uganda was estimated to be 4.56 million metric tons, from an estimated planted area of about 1.854 million hectares [

12]. The production trend showed an increase in maize production by about six times from 739,000 MT in the UNHS 1999/2000 compared with 4.56 million MT in the AAS 2020 survey.

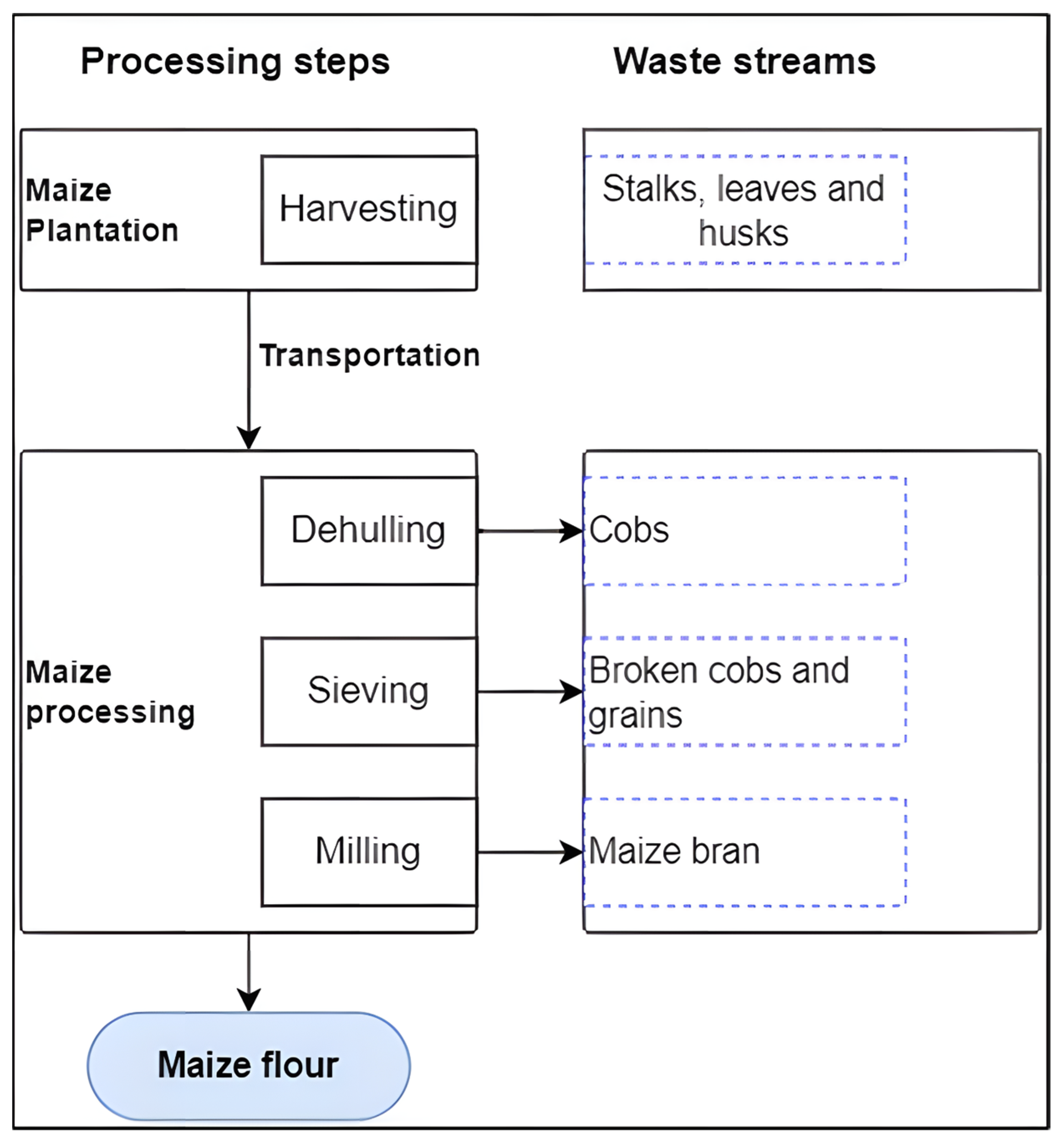

The main biomass wastes and the points of respective waste generation along the maize value chain are illustrated in

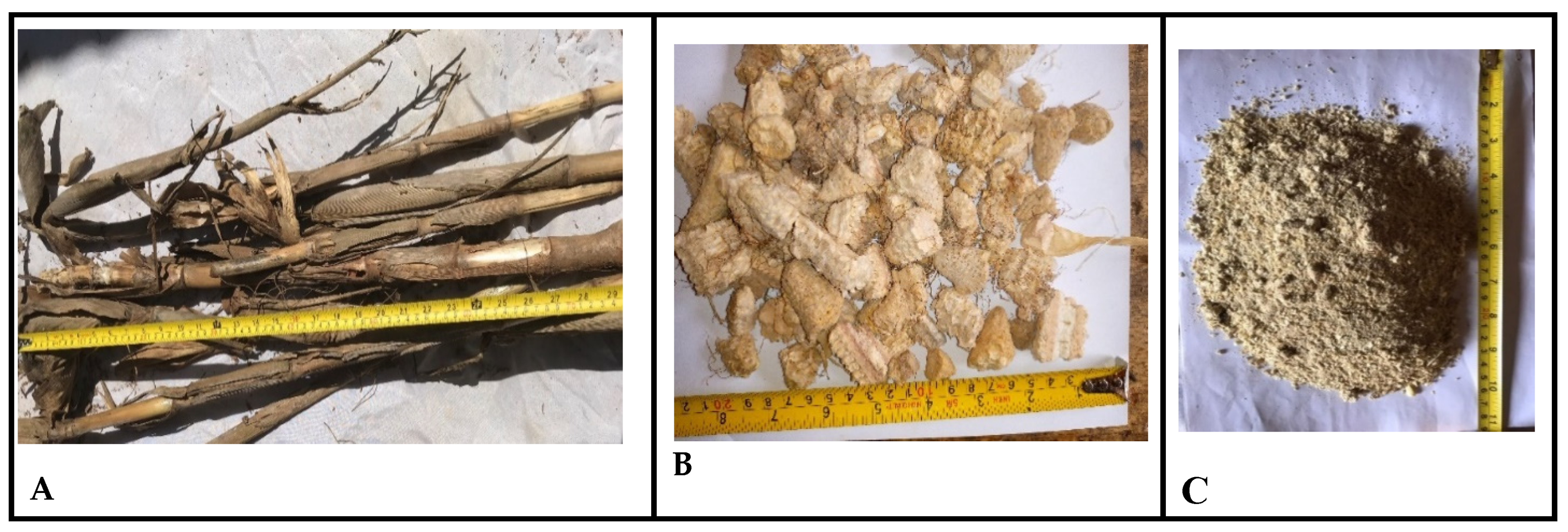

Figure 1. The wastes include maize cobs and stover, with the latter comprising stalks, leaves, and husks (

Figure 2). The cob has a residue-to-product ratio of 0.27, whereas the stover has a ratio of 2.0, making it the most significant waste from maize [

13]. The maize stalks, husks, and cobs are employed on agricultural fields as mulch. They are also often used as a fuel source for households, whereas the raw stalks and husks are, at times, fed to animals [

14]. In areas where fuelwood scarcity is not a problem, the maize stalks and husks are merely burnt in open space to clear the field for the next planting season. Farmers and/or traders often shell their maize to separate it from its cob prior to milling producing cobs, chuff, and broken maize in the process of sorting and/or sieving. During the milling process, there are also byproducts generated including maize bran and flour dust. Maize bran is rich in fiber like other cereal brans; hence, it is widely used as animal and chicken feed [

14].

3.2.2. Banana

According to UBOS [

5], a total of 8,326,000 tons of bananas from 668,000 ha were produced in 2019. This annual production represents a 28% increase from the total production of 2018 (6,494,057 tons). Banana is grown mainly in Western, Central, and parts of Eastern Uganda. In the harvest periods from 2015 to 2019, banana production increased by 80%, increasing its influence in the global market by 2%. The successful implementation of several government initiatives has contributed to Uganda’s rising yields. In 2015, the Ministry of Agriculture, Animal Industry, and Fisheries launched a five-year project, ‘

Reducing vulnerability of banana-producing communities to climate change through banana value-added activities–Enhancing food security and employment generation’ [

15]. This helped in the development of a sustainable banana industry by providing disease-free, banana-planting materials, demonstrating the use of banana waste for biogas and compost for soil fertility, and introducing new agricultural practices to improve field and plantation nutrient retention. In 2018, a two-year project, ‘

Improving banana agronomy practices for small scale farmers in East Africa’, under the National Agricultural Research Organization (NARO) and other partners, was conducted [

16]. This taught extension workers and farmers more about better site selection when growing crops, as well as enhanced land preparation, appropriate spacing, mulching, improved varieties, water and soil conservation, and pest and disease control management, among others.

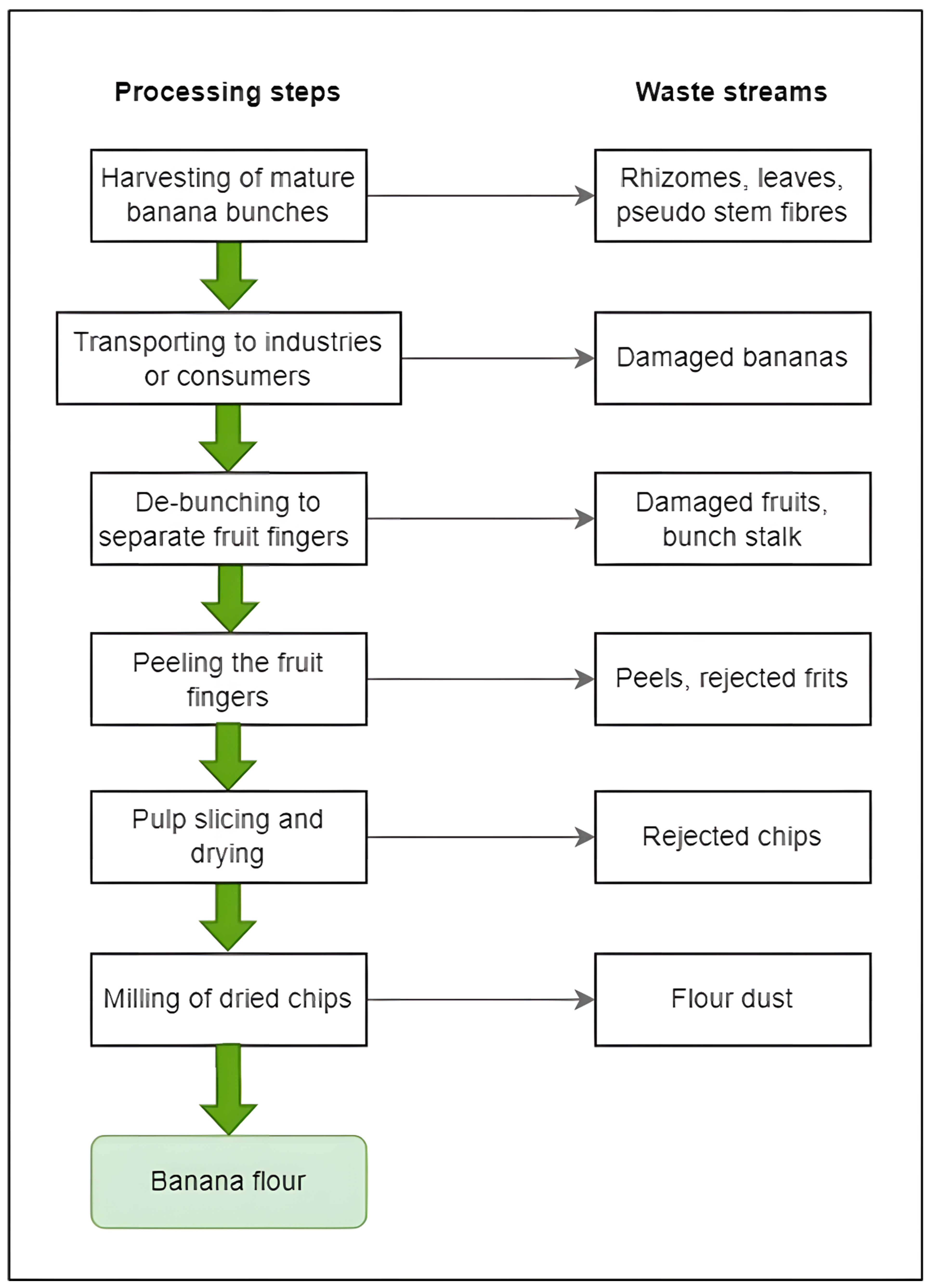

The banana value chain in Uganda typically generates nine types of wastes including (i) pseudo stems, (ii) pseudo stem fibers, (iii) leaves, (iv) rhizome, (v) fruit bunch stem/or stalk, (vi) banana peels, (vii) rejected fruits, (viii) rejected chips, and (ix) flour dust, as illustrated in

Figure 3.

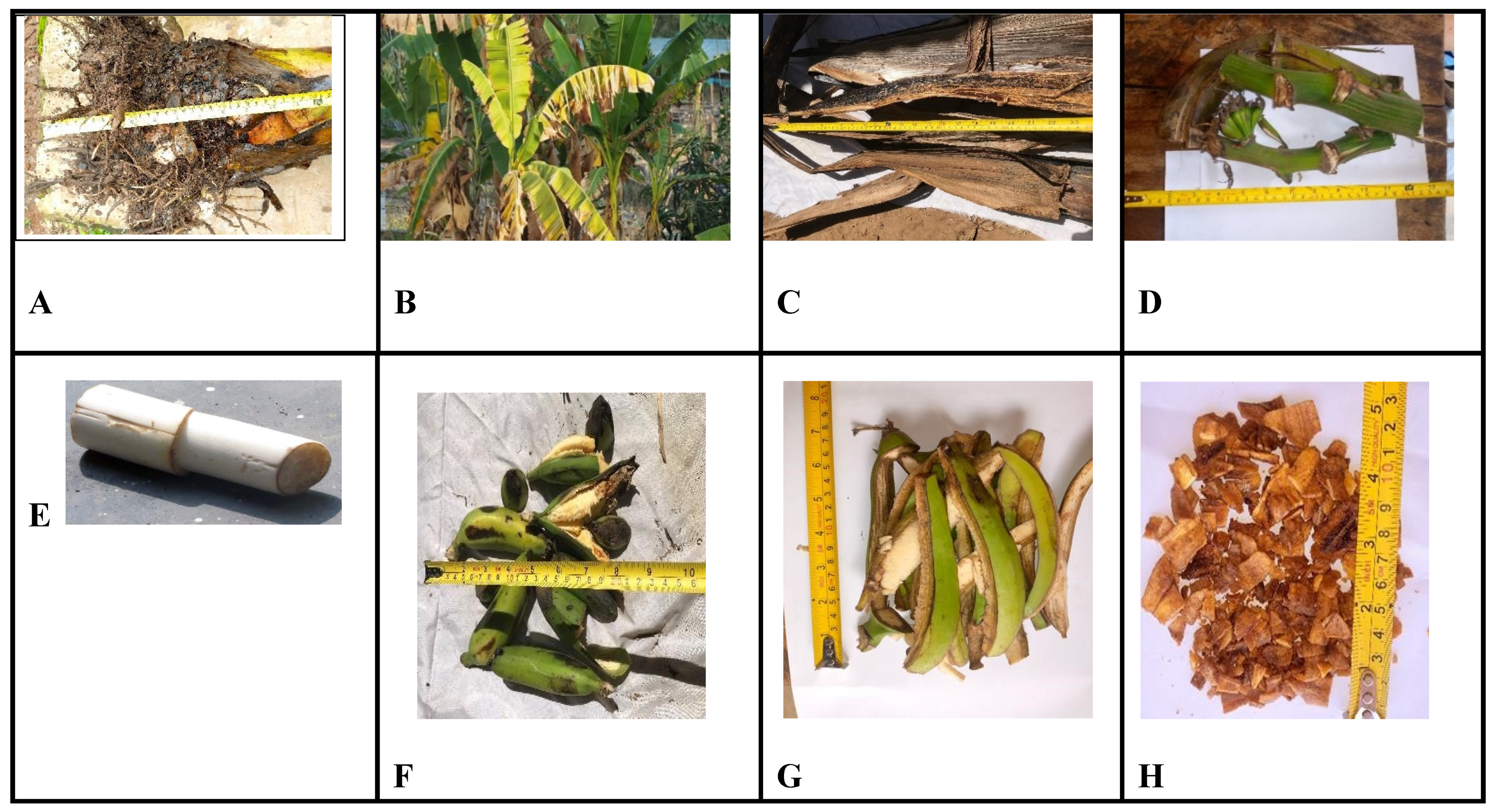

Figure 4 shows the pictures of each of these wastes. The pseudo stems, fibers, leaves, and rhizomes are generated and left in the field during harvesting time. In most cases, these biomass wastes remain in the field after the fruit bunches are cut off. The remaining wastes, including the fruit bunch stalk, banana peels, and rejected fruits, are generated during the processing of bananas. Essentially, for every ton of bananas harvested, about 4.18 MT of lignocellulosic biomass wastes are generated, including 3.0 MT of pseudo stem, 0.48 MT of leaves, 0.44 MT of banana peels, 0.16 MT of stalks, and 0.10 MT of rotten fruits [

17].

The rhizome is the root part that remains in the ground after cutting off the pseudo stem. The pseudo stem is the part of the banana plant that transports nutrients from the soil to the fruits. When dried, it turns to fibers. Typically, fibers have a density of 750–950 kg/m

3, length from 2000 to 5000 mm, and diameter from 0.080 to 0.250 mm [

18]. Banana leaves are the large, wide, elongated, and slightly rounded parts of the banana plant responsible for trapping sunlight. They are, on average, 2 and 0.5 m in length and width, respectively. Each banana plant can have between 8 and 12 leaves.

The rhizomes and pseudo stems are normally decomposed in the garden or heaped and burnt to curb the risk of spreading banana bacterial wilt by banana waste obtained from infected banana plants. Pseudo stems and leaves are also used for mulching the plantations, as well as for composting purposes. Fresh pseudo stems and leaves are utilized as livestock feed. Their low protein and high fiber levels, low digestibility, and the presence of anti-nutrients like tannin and alkaloids are the main limitations to their usage as the only source of feed for animals. As a result, numerous research methods have been used to improve their feeding value, including crushing, microbial degradation, enzyme treatment, and combining with other agricultural wastes [

19]. Alternative uses of the pseudo stems, fibers, and leaves are being sought, for instance, in house construction, banana silk extraction, energy production, and manufacture of paper, ropes, table mats, and handbags, as well as in food preparation at a household level and in restaurants and hotels, among others [

20].

Banana fruit bunches are de-bunched upon arrival at the industry or home, separating the fruit fingers from the fruit bunch stalk. The stalks are usually openly dumped or left to dry and subsequently utilized as fuel for households. Rejected fruits/fingers are fruit residues deemed unusable during banana processing. They are usually partially rotten and contaminated with soil or diseased. The rejected fruits are used to feed domestic animals and are sometimes employed as a feedstock for biogas production. However, in situations where the rejected fruits do not have immediate application, the fruits are merely openly dumped.

Banana peels are the outer cover for the banana fingers that are removed to expose the pulp. For every ton of fingers processed, about 500 kg of peels is generated [

21]. These are, in most cases, used as animal feed. However, since they are produced in large quantities than can be consumed, some of them end up rotting and are subsequently dumped. Rejected chips are chopped into pulp pieces rejected along the processing chain usually due to contamination. Rejected chips are characterized by low moisture content (<15%) and ease of handling and transport as a result of their particle size < 20 mm.

3.2.3. Sugarcane

Uganda’s sugarcane production increased from 1.72 million tons in 1971 to 5.34 million tons in 2021, growing at an average annual rate of 3.76% [

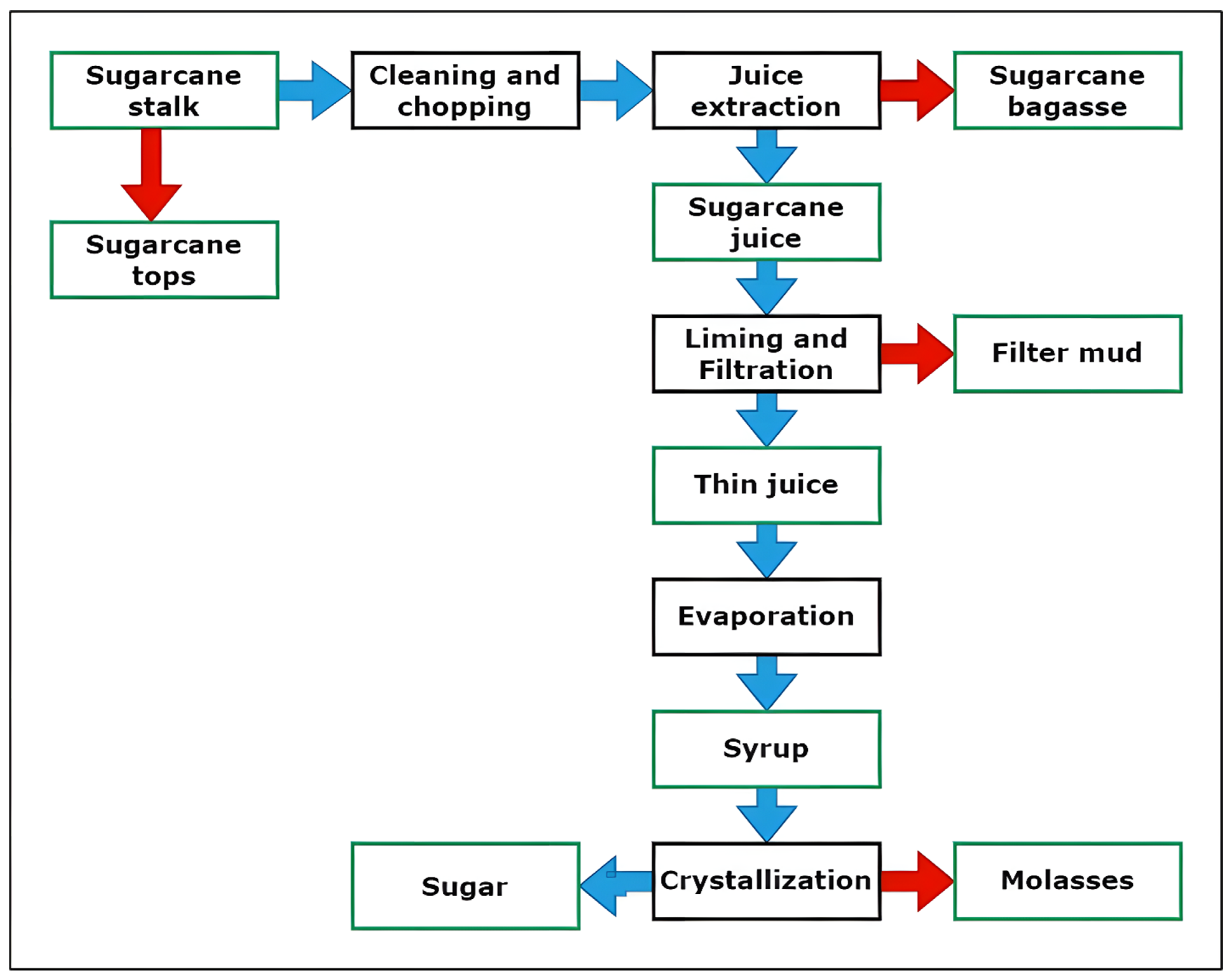

6] and becoming the largest producer of granular brown sugar in the East African community. This was attributed to the crop’s many end applications, rising pricing, and expanding global and regional consumption/demand. The sugarcane value chain generates four major biomass wastes/byproducts, including sugarcane tops, bagasse, fly ash, filter mud, and molasses, which are generated at different stages of the value chain (

Figure 5).

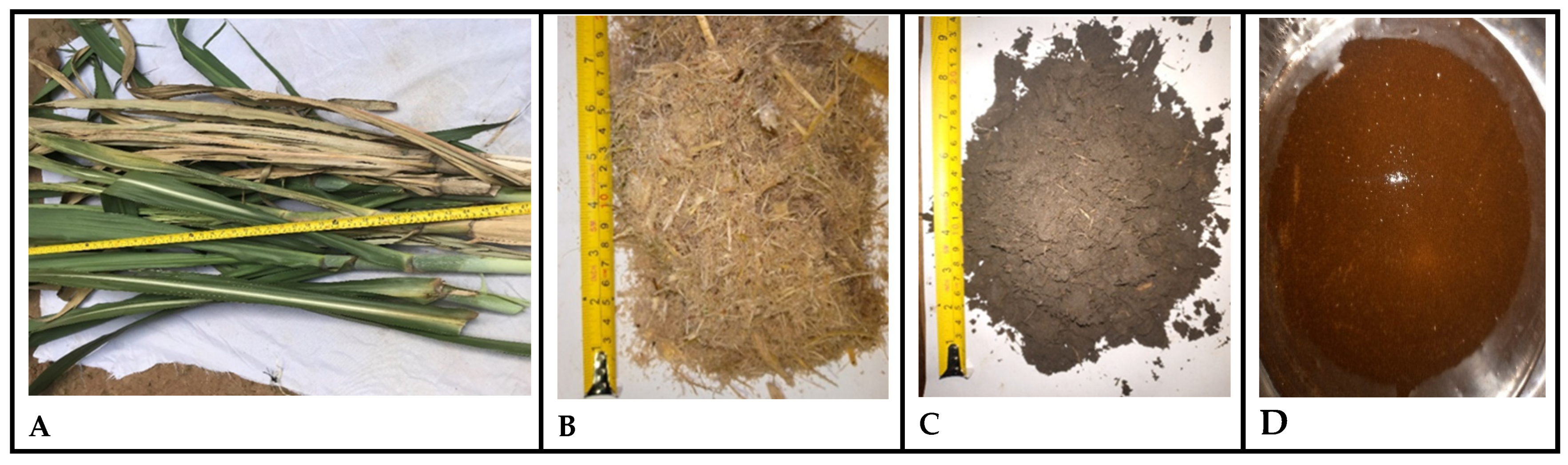

Figure 6 illustrates the various wastes generated along the sugarcane value chain.

The sugarcane’s top is a major waste material of the sugarcane industry, which is normally left in the field without immediate application after harvest. It consists of the green leaves, the leaf sheath bundle, and a variable amount of immature cane. The yield of sugarcane tops varies considerably with variety, age at harvest, growing conditions, and management practices [

22]. Sugarcane tops account for about 32% of the weight of the cane [

13]. Sugarcane leaves are used as animal feed [

23]. The leaves are chopped into smaller pieces and then mixed with molasses to feed goats. Farmers utilize them as mulch, while, in some rural areas, it is used as a fuel source for cooking food at a household level. However, some farmers burn the sugarcane tops openly. Open burning is known to cause air pollution and affects human health [

24,

25]. Open burning in agricultural production fields increases soil temperature, decreases soil water content and bulk density, and, consequently, leads to soil compaction, higher surface water runoff, and soil erosion [

26].

Sugarcane bagasse is a fibrous material generated from the milling process of sugarcane with the aim of extracting sugar. For every ton of sugarcane processed, 0.25 tons of bagasse is generated [

13]. Bagasse is burnt in boilers to produce high-pressure steam which is used to turn the factory mill turbines in the cogeneration of electricity [

27]. The resulting ash is used as a fertilizer and/or binder in brick production [

28]. However, the effectiveness of sugarcane bagasse ash in enhancing sugarcane yields is still doubted, and, as such, the application of ash in sugarcane plantations has instead been treated as merely a disposal option for the residue. Several sugarcane factories including Kakira Sugar Limited, Kinyara Sugar Limited, Sugar Cooperation of Uganda Limited (SCOUL), Mayuge Sugar Industries Limited, and Sugar and Allied Industries Limited (SAIL) Kaliro in Uganda use bagasse to produce heat and electricity in sugar mills (cogeneration); however, only three are licensed to supply to the national grid with a total installed capacity of 96.2 MW [

29]. Bagasse can also be used for a variety of other purposes such as in paper making, as cattle feed, and in the manufacturing of disposable food containers [

26]. The surplus bagasse is then applied to the fields and/or openly burnt.

Press mud, or a filter cake, is generated from the filtration and clarification processes of sugarcane juice. For each ton of ground sugarcane, 0.01 to 0.07 tons of press mud is generated [

26]. Though the press mud exhibits huge potential in various applications, its application in the country is mainly limited to the fertilization of agricultural fields.

Molasses is a byproduct of sugarcane extraction. During the processing of sugarcane, 35–45 kg of molasses is generated as a byproduct from 1 ton of cane biomass [

30]. It is a viscous liquid with numerous potential applications at both domestic and industrial levels, including cattle feed, edible syrup, fertilizer, boiler fuel, road surfacing, and alcohol production, among others. Molasses, in Uganda, is utilized in the production of bioethanol with biogas and manure as byproducts of the process [

27]. It is also utilized in briquette production as a binder.