Clean hydrogen has the potential to meet up to 24% of the world’s energy demand. As the global community, including the European Union, commits to reducing reliance on fossil fuels, hydrogen is emerging as a versatile solution for converting renewable energy from sources like wind and solar into storable forms. Most renewable energy sources are intermittent, opening spatial and temporal gaps between the availability of the energy and its consumption by end users [

1]. To address these issues, it is necessary to develop suitable energy conversion or generating systems for the power grid. Hence, hydrogen can be used as a medium for energy conversion. Hydrogen can serve as a feedstock, fuel, energy carrier, and storage medium, offering numerous applications across industries, transportation, power generation, and construction [

1]. In the realm of zero-emission vehicle technologies, there are two prominent developments: battery-powered electric vehicles using lithium-ion batteries exclusively, and fuel cell vehicles employing compressed hydrogen tanks and proton exchange membrane (PEM) fuel cells to generate electricity from hydrogen gas [

2]. In the context of fuel cell assemblies, one crucial and energy-intensive component is the air compressor [

3]. Generally, a higher airflow enhances the fuel cell voltage and efficiency [

4], while lower mass flows can lead to operational challenges like the condensation of water and an insufficient oxygen supply [

5]. The large-scale commercialization of PEMFCs requires higher current densities and power. The degradation of cell performance could appear at high operating current densities due to the massive accumulation of liquid water, which leads to flooding and impedes the gas diffusion [

6]. In this case, water condensation is unfavorable, since it is more likely to worsen the tendency of flooding. However, if the generated water is very low and the membrane is going to dry, water condensation should be preferred. Proper water management is important to achieving a better fuel cell performance. High-velocity airflow is essential for removing water produced on the cathode side of the fuel cell, and it also increases the oxygen partial pressure, thereby boosting the fuel cell voltage [

7]. However, extended operation at high airflow rates can lead to insufficient membrane moisture and potential drying issues [

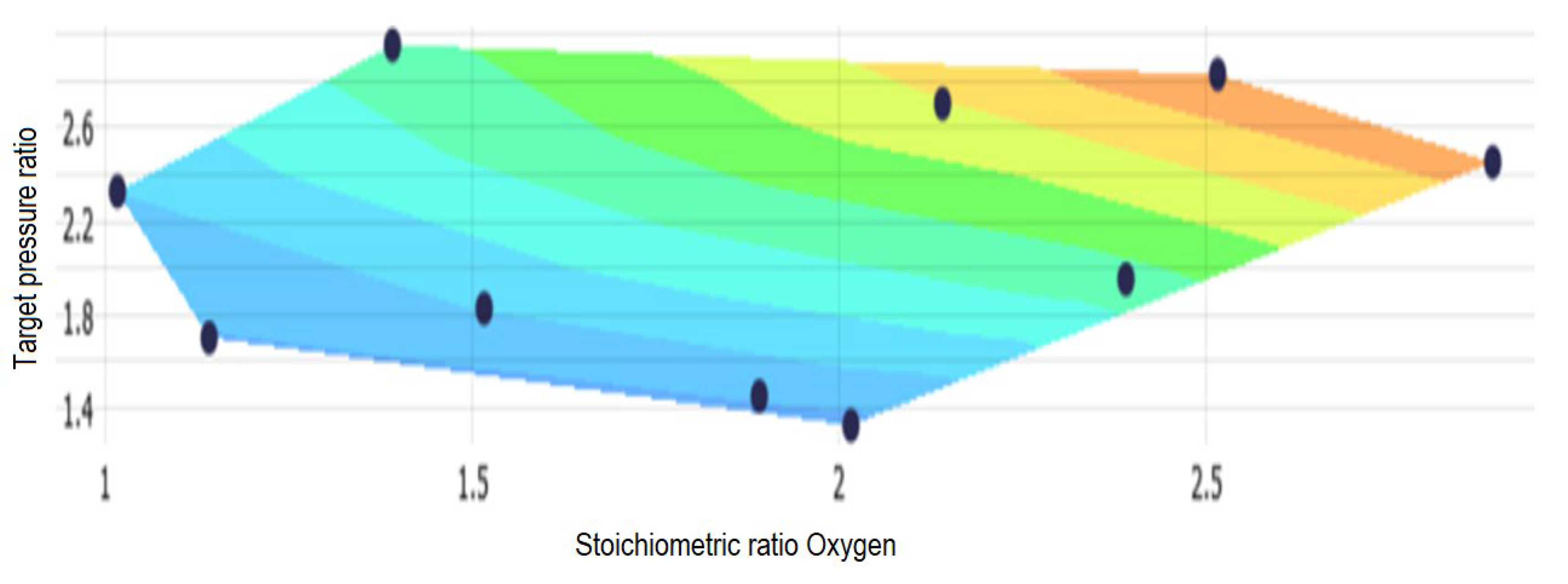

8]. The concept of the excess air ratio is vital, representing the ratio of actual airflow through the air compressor to the stoichiometric airflow required for complete oxygen consumption within the system [

9]. Typical values range from 1.5 to 3.0, depending on system parameters and design considerations [

10]. Furthermore, the pressure within the fuel cell system is influenced by the air compressor pressure ratio to the pressure drop across the fuel cell [

11]. When using a throttle valve after the fuel cell assembly, it may lead to increased pressure resistance and cathode side pressure [

12]. Alternatively, employing an expander (turbine) in place of a throttle valve allows for the utilization of the energy from the pressurized air mass flow, enhancing system efficiency [

13]. The system of air supply is of utmost importance for ensuring the efficient and stable operation of the fuel cell system [

14]. Proper air supply system operation aids in moisture removal, impacting humidity levels, while the oxygen content in the air directly affects the fuel cell voltage and efficiency. The compressor air can be supplied at various flow rates and pressures to the chimney, and these operational parameters, along with the corresponding compressor power consumption of the compressor, significantly influence system efficiency [

15]. The maximum inlet air pressure in the fuel cell is constrained by the air compressor surging line [

16], while the lowest pressure is determined by the pressure drop of the fuel cell and the air compressor’s choke. Operating points below the choke line and above the surging line has to be avoided to prevent compressor damage due to overheating and a high pressure [

17]. The fuel cell power and efficiency are increased with a higher reactant pressure [

18]. PEM fuel cells’ typical operating pressure is between 3 and 4 bar, and above 4 bar, there are mass transfer limitations [

19]. One study has suggested that an operating pressure of 2 bar yields an optimal system efficiency, especially when using a screw compressor [

20]. Another study utilized the Nernst equation to determine 2 bar as the optimum air pressure and 2 as the optimum excess ratio [

21]. In another study [

22], an 80 kW fuel cell vehicle was analyzed, and it was concluded that due to the modeled humidity inside the stack, affected by the excess air ratio and back pressure, the system power decreases as the regulating back pressure valve opens. At high loads, the system power increases when the back pressure valve opens. In study [

23] it is shown that for 30 kW PEM fuel stack, the higher air pressures and lower air excess ratios increase the system efficiency at high loads. The maximum achieved system efficiency is 55.21% at the lowest continuous load point and 43.74% at the highest continuous load point. Furthermore, research into air mass flow and pressure optimization for PEM systems for fuel cell range extension found that various factors, such as the feed gas humidity, operating temperature, feed gas stoichiometry, air pressure, fuel cell size, and gas flow patterns, affect both steady-state and dynamic fuel cell responses [

24]. For air pressures exceeding 1.8 bar(a), the fuel cell stack’s power gain due to pressurization is offset by the increased power required for air compression [

25]. The optimization of super-high-speed electric air compressors for hydrogen fuel cell vehicles is a subject of investigation [

26]. The positive influence of the air flow rate and air distribution inside a hydrogen fuel cell with a proton exchange membrane PEM on the performance characteristics was verified in research [

27]. The authors conclude that for the long-term operation of the fuel cell at maximum power for a given voltage, it will be necessary to control the air flow depending on other parameters such as the air humidity and the temperature of the fuel cell. The influence of the operating parameters of the air pressure and excess air ratio on the dynamic response of stack voltage and on the net output power of a PEMFC system is analyzed. The optimal flow shows a tendency to be gradually larger as the current increases, and the optimal pressure to the output maximum net power was in a lower-value region [

28]. In developing a computational model for PEMFCs mathematically, the calculation of the specific model parameters (activation losses, the electronic and ionic resistance, the oxygen concentration, and the current density) that are usually unknown is very important. The optimal parameter identification process of the fuel-cell model has been investigated using different recent optimization algorithms [

29]. The durability and efficiency of PEM fuel cells depend on the temperature, and a typical operating temperature range is between 60 °C and 90 °C. A high temperature leads to membrane dehydration and a loss of conductivity, resulting in irreversible performance loss, and accelerates the degradation of the membrane of the PEM FC. In that case, severe ohmic polarization, a reduction in catalyst activity, and a rise in proton impedance due to the low temperature could appear [

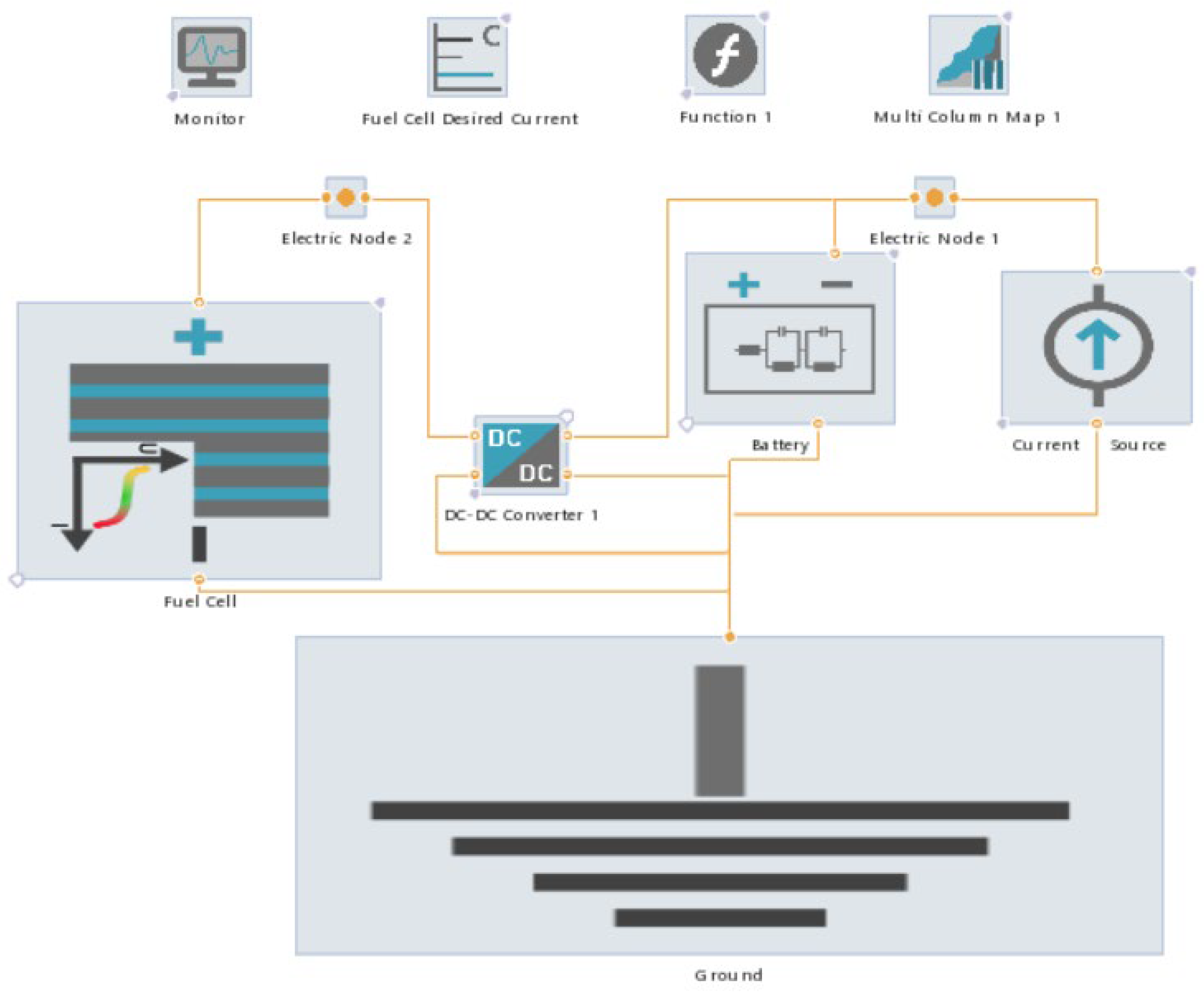

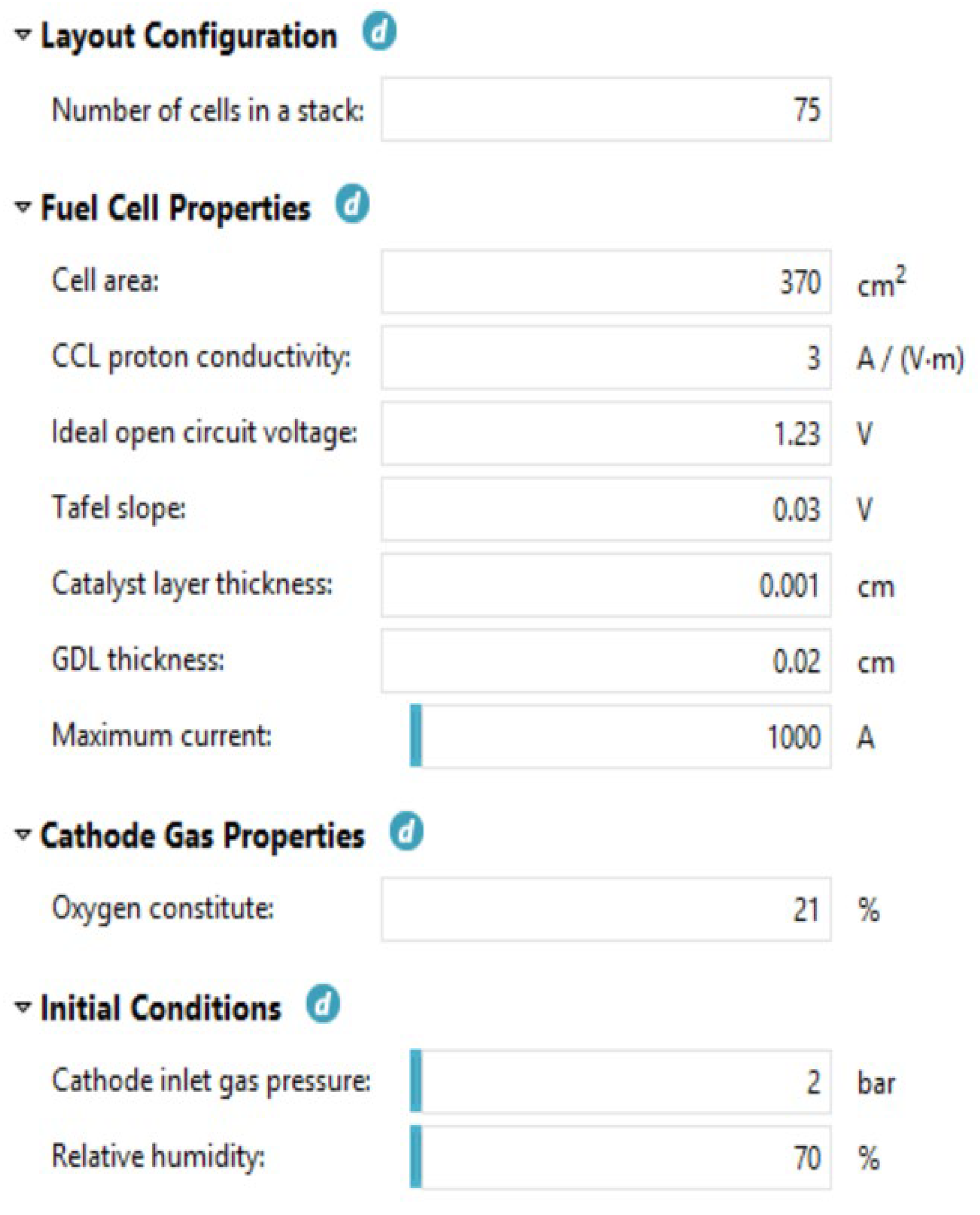

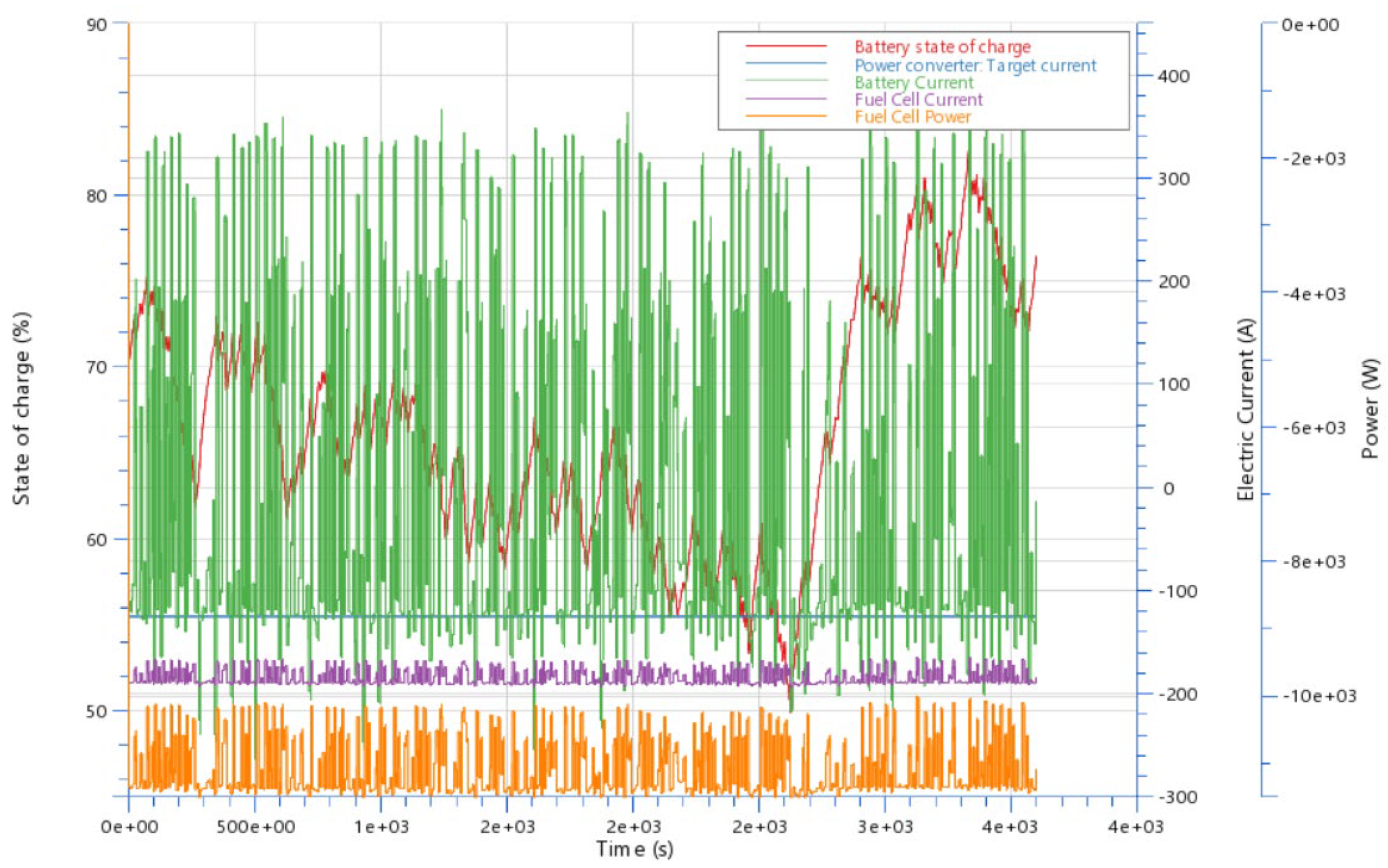

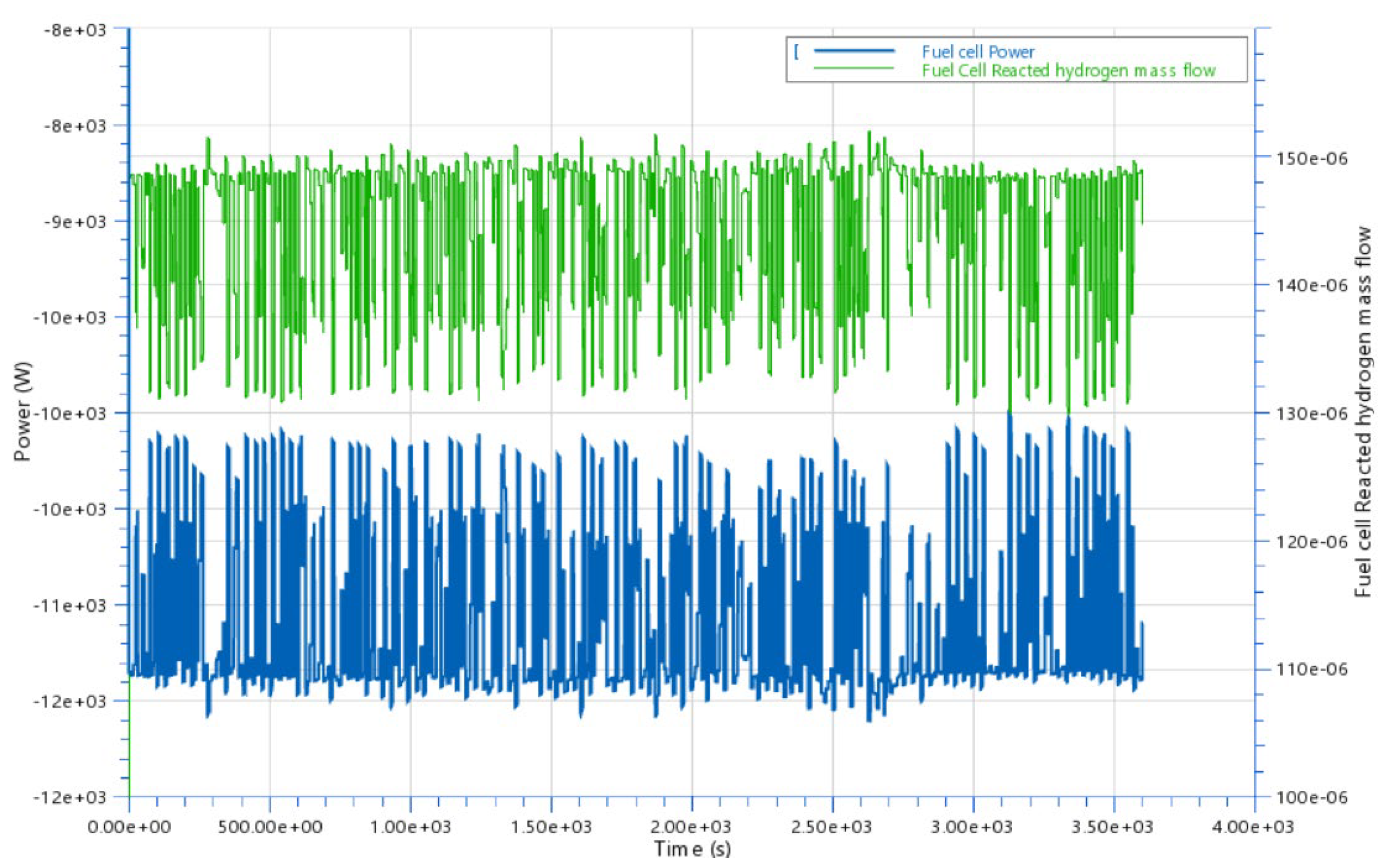

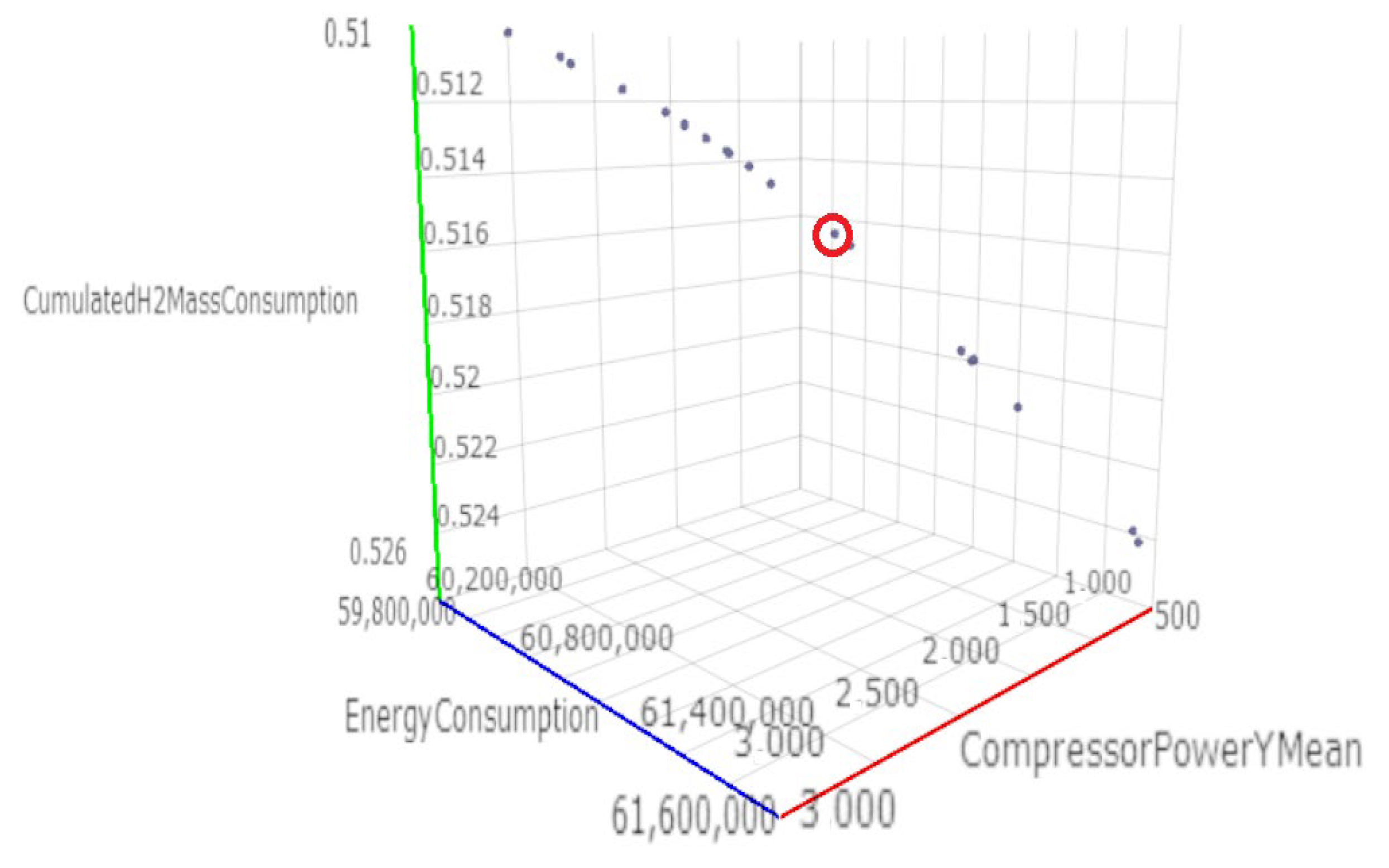

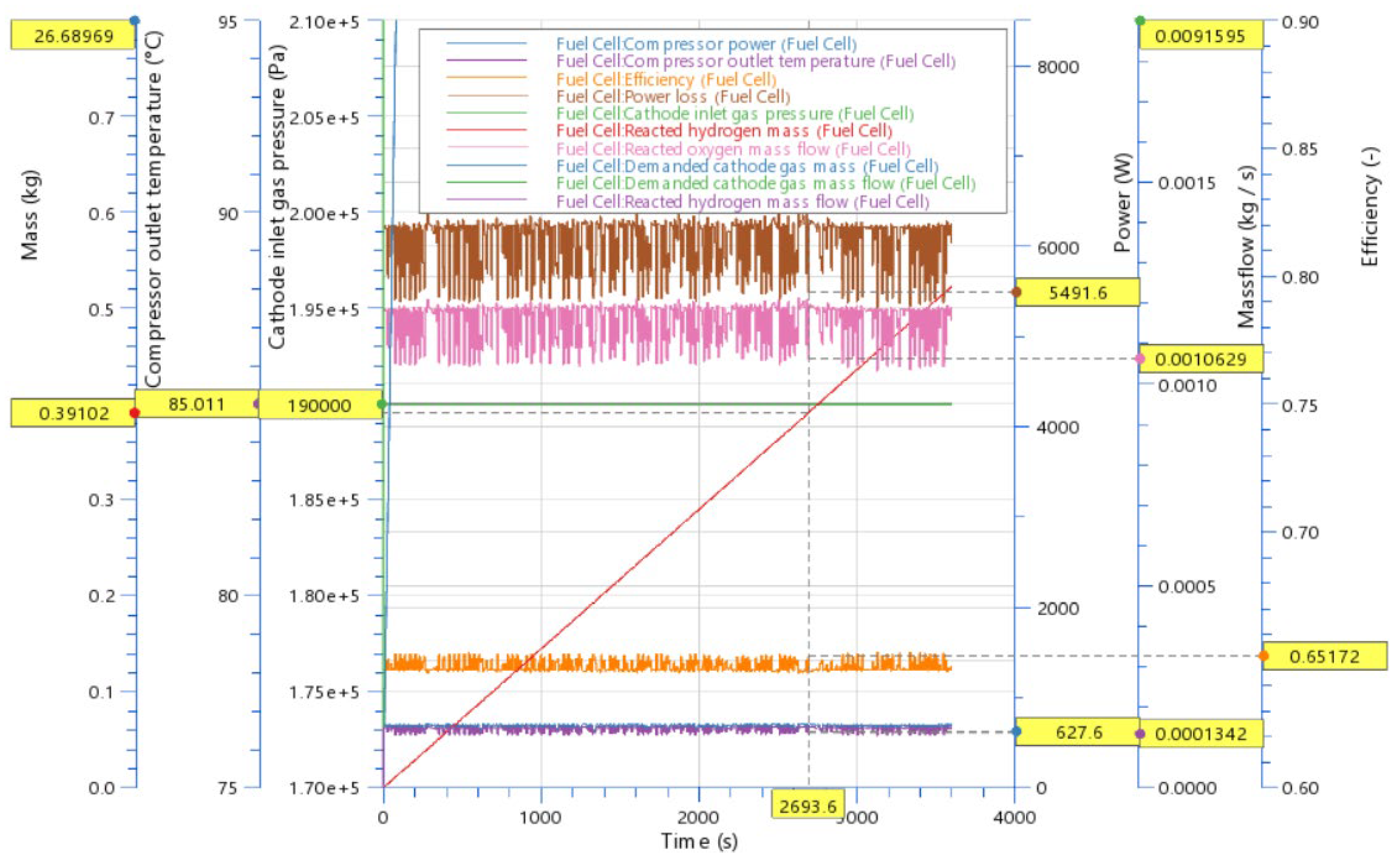

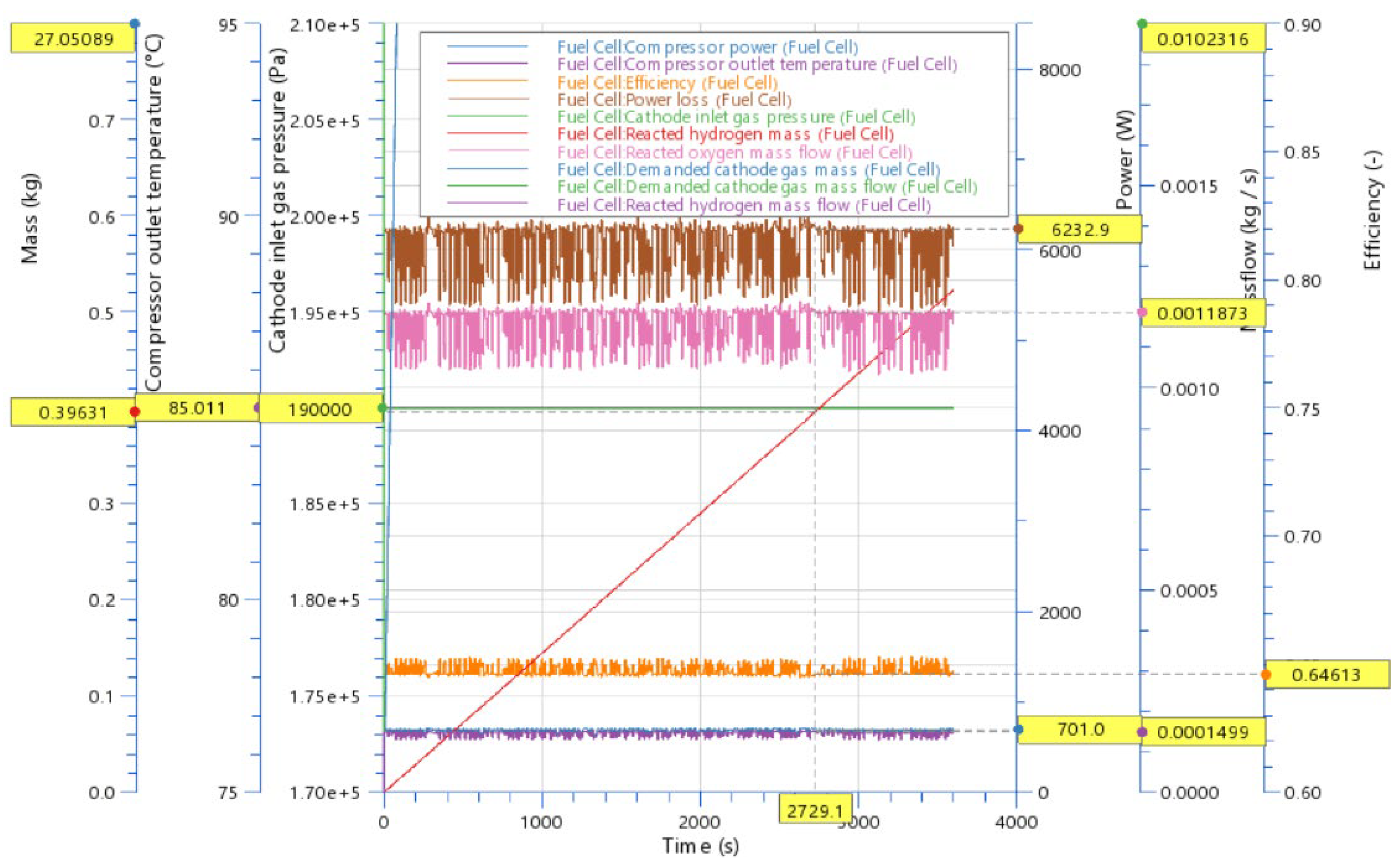

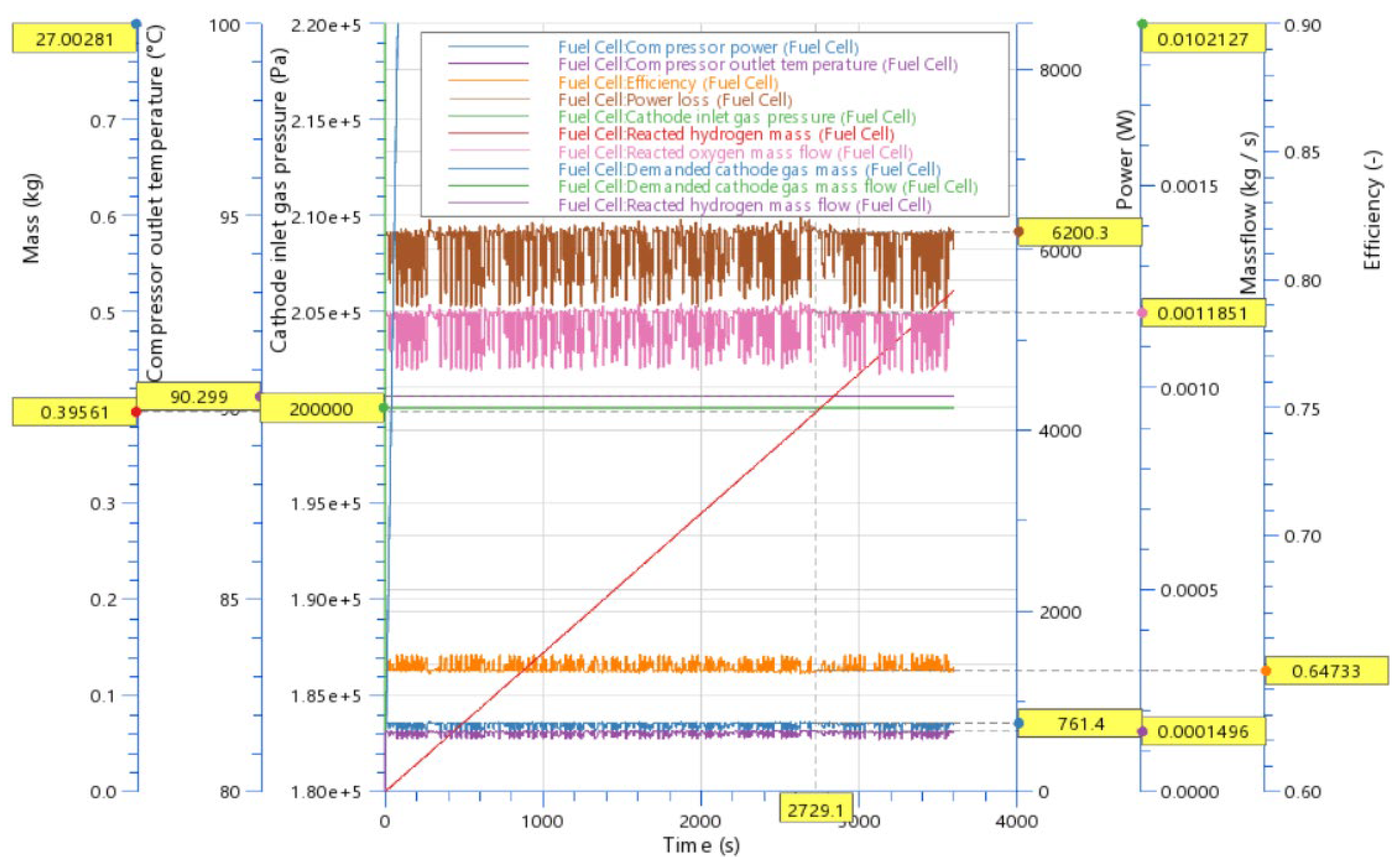

30]. This paper assesses the best PEM FC system efficiency at different load points. The optimization model for determining the working points of each parameter, aiming at the improvement of the efficiency of PEMFC system, is presented. The novelty in the work is a self-developed and verified model, as well as the research into the influence of the pressure and air flow on the system efficiency of an 11 kW power module with a PEM fuel cell designed for forklift applications. The study analyzes the relation between a higher oxygen partial pressure inside the stack (resulting in a higher efficiency) and the air compressor power consumption (leading to a lower efficiency) for two distinct load points during dynamical load operation. To achieve this, a power module with a fuel cell stack model was developed and validated using experimental data obtained during forklift operations under VDI60 load cycles in real-world conditions. Simulations encompass various parameters of the air mass flow and air pressure to assess their impact on system efficiency.