Abstract

This study emphasizes how crucial it is to consider battery service lifetime when determining the optimal battery size in PV–diesel hybrid systems. It investigates how battery size influences the evaluation of hybrid systems and their lifetime due to battery cycling. Unlike previous research that relies on assumed battery lifetimes, this study delves into the tangible impact of battery cycling, revealing the intricate relationship between battery size, cycling behavior, and service lifetime. Utilizing HOMER Pro version 3.14.2 software, a case study assessed three battery capacities (300 Ah, 800 Ah, and 1000 Ah) in a hybrid PV system catering to a 24 kWh daily demand. Across varying assumed lifetimes (5, 10, and 20 years), the study found that a 300 Ah battery was the most feasible under a 5-year assumed battery lifetime. However, for 10-year and 20-year battery lifetimes, the 800 Ah system emerged as the optimal choice, emphasizing the influence of assumed lifetime on determining the optimal battery size. Throughput battery lifetime analysis estimated service lifetimes of 4.9, 10.96, and 13.64 years for the 300 Ah, 800 Ah, and 1000 Ah batteries, respectively. Notably, smaller-rated batteries exhibited shorter estimated service lifetimes linked to usage patterns. Among the systems assuming a 20-year calendar lifetime, the optimal 800 Ah system, with a service lifetime of 10.96 years, yielded an energy cost of 0.312 USD/kWh, annual costs of USD 2736.5, and a total cost of USD 37,450. Considering service lifetime, the 800 Ah system emerged as optimal, contrasting the initially favored 300 Ah system under a 5-year assumed lifetime. This underscores the crucial significance of comprehending and integrating service lifetime considerations to optimize the economic feasibility of PV hybrid systems.

1. Introduction

1.1. Backgrond

Many remote rural areas rely on diesel generators to generate electricity, which often operate inefficiently, consume excessive fuel, and contribute to environmental pollution [1]. Therefore, renewable energy systems have emerged as a promising solution to electrify these remote areas. PV systems offer cleaner, more sustainable, and economically viable energy than diesel systems. However, the success of these systems in rural areas depends on the availability of potential resources. For example, solar PV systems require appropriate levels of solar radiation to ensure their feasibility and effectiveness [2]. The electrical power produced by PV systems is intermittent, as it depends on intermittent solar radiation. Thus, this intermittency necessitates the use of battery systems. In hybrid systems, batteries enhance reliability and enable clean electricity usage throughout the day, not only during peak solar radiation periods. PV and batteries entail high investment costs, necessitating optimal component sizing to reduce expenses while maintaining power system reliability [3]. However, solar cell and battery systems alone might not suffice for continuous twenty-four-hour electricity provision due to seasonal solar radiation fluctuations. For instance, lower solar radiation levels persist during winter for extended periods. Simply enlarging the PV and battery systems in such cases raises initial costs significantly, making hybrid energy systems, integrating multiple sources, a preferable solution to meet rural electricity demand [4]. Hybrid PV–diesel–battery systems, specifically, show promise in providing cost-effective solutions compared to standalone PV–battery systems [5]. Integrating the diesel generator into the hybrid system reduces the size of the battery system and PV panels while enhancing power supply reliability. Adding the diesel generator to PV battery system ensuring continuous and reliable electricity supply by meeting power demand and charging batteries when they have a low state of charge (SOC) [6]. The cost of hybrid systems encompasses a high initial cost and low operational cost for solar cells and batteries. In contrast, there is a low initial cost for a diesel generator but a high operational cost. This emphasizes the importance of seeking the optimal system size to ensure the economic feasibility of these systems. The cost of battery storage system in PV hybrid systems is a crucial aspect to consider, both in terms of initial investment and replacement costs over the lifetime of the hybrid PV diesel system, as the lifespan of batteries is typically shorter than the lifespan of PV panels. Therefore, it is necessary to calculate the number of replacements required throughout the hybrid system duration. Battery lifespan is an important factor to consider in the economic evaluation of PV battery storage systems or hybrid systems. The battery lifetime is often provided by the manufacturers in terms of battery expected lifetime (calendar lifetime), also provide number of cycles at the recommended depth of discharge (DOD). Many researchers assume battery lifetime without considering its cycling or the number of charge discharge cycles that determine the actual battery service lifetime. Therefore, this approach is considered unrealistic as it does not account for specific operating conditions [7]. This leads to inaccurate results in optimizing PV diesel systems and conducting economic evaluations.

1.2. Literature Survey

Numerous studies have centered on optimizing the components of PV hybrid systems, specifically sizing and evaluating the economic viability of hybrid PV diesel systems. However, in many of these studies [8,9,10,11,12,13,14,15,16,17,18,19,20], authors consistently assumed a battery lifetime ranging from 5 to 20 years. For instance, the authors in [8] proposed an improved search space reduction algorithm to optimize the sizing of a photovoltaic/wind/battery hybrid system, which includes electric vehicles. The battery technology used is lead acid, with an assumed lifetime of 10 years. Al Afif et al. conducted a feasibility and optimal sizing analysis of hybrid renewable energy systems in Al-Karak, Jordan [9]. The system integrates wind, biogas, PV, and batteries, utilizing lead–acid battery technology with an assumed lifetime of 20 years. Halabi et al. perform a performance analysis of a hybrid PV/diesel/battery system in Sabah, Malaysia [10]. The battery technology employed is lead–acid, with an assumed lifetime of 7 years. A study conducted on standalone solar PV/Wind hybrid energy systems in India assumed a battery lifetime of 5 years [11]. Wassie et al. conducted a reliability analysis of an off-grid PV mini-grid system in rural Ethiopia, assuming a battery lifetime of 10 years [12]. Additionally, optimization strategies for designing standalone hybrid renewable energy systems were explored, considering a battery lifetime of 25 years [13]. Moreover, another study detailing a techno-economic assessment of a stand-alone hybrid system in rural Bangladesh is presented in [14], utilizing lead–acid batteries with a 15-year lifespan for energy storage. An additional study [15] explores the design and operational optimization of hydrogen/battery hybrid energy storage systems, assuming a lead–acid battery lifespan of 12 years. These research papers encompass various methodologies, such as simulation modeling, optimization algorithms, and system sizing, enabling the evaluation of system performance, economic viability, and feasibility considerations. Table 1 summarizes the objectives of the studies and the consideration of battery lifetime as found in references [8,9,10,11,12,13,14,15,16,17,18,19,20].

Table 1.

Literature survey summary.

It is worth noting that the assumed battery lifetimes specified in these studies are not fixed but assumed with different values. Additionally, the cycling of the battery in PV hybrid systems is not considered, despite its significant impact on the service lifetime of the batteries, which is not explicitly addressed. Furthermore, the operational or cycling aspects of the battery, which can affect its lifespan, are not considered in these analyses. Therefore, this research emphasizes the critical importance of considering the battery service lifetime for a comprehensive and accurate economic evaluation of PV hybrid systems.

1.3. Research Contributions

The major contributions of the paper can be summarized as follows: Firstly, the research investigates the impact of battery lifetime assumptions on the economic analysis and sizing methodology, providing valuable insights into their significance. Secondly, the paper explores the influence of battery size on battery cycling and service lifetime. Thirdly, the paper introduces a method for sizing PV hybrid systems based on battery service lifetime. It highlights the significance of incorporating battery service lifetime in system sizing and economic analysis. Lastly, the research includes the design requirements of a PV battery diesel system, encompassing system components, models, and practical considerations such as selecting the right PV modules and system DC voltage. These contributions collectively enhance our understanding of hybrid PV systems, battery service lifetime, and the implications of different battery lifetime assumptions on system sizing and economic analysis.

1.4. Paper Outline

The remainder of this paper is structured as follows: Section 2 details the research methodology, Section 3 focuses on system component models, Section 4 discusses economic factors and considerations of lifetime components. Section 5 addresses a case study description and the sizing of system components. In Section 6, simulation results are presented and discussed. Finally, Section 7 presents the conclusions and outlines future work.

2. Methodology

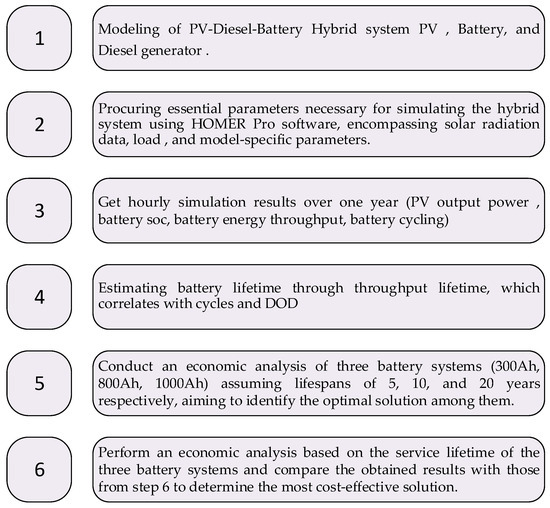

The methodology comprised several key steps, as illustrated in Figure 1, providing a comprehensive summary of its sequential steps and processes. First, a comprehensive model of the PV–diesel–battery hybrid system was developed, integrating PV panels, a battery unit, and a diesel generator. Second, essential parameters essential for simulating the hybrid system were gathered, including solar radiation data, load profiles, and model-specific parameters, facilitated through HOMER Pro version 3.14.2 software. Subsequently, hourly simulation results over a year were obtained, encompassing variables such as PV output power, battery SOC, battery energy throughput, and battery cycling information. Further steps involved estimating the battery lifetime using the concept of throughput lifetime, accounting for battery cycles and DOD. An economic analysis was then conducted considering three battery systems (300 Ah, 800 Ah, 1000 Ah) with assumed lifespans of 5, 10, and 20 years, respectively. The aim was to identify the most optimal solution among these systems based on the economic evaluation. Moreover, an additional economic analysis was performed, this time considering the service lifetime of the three battery systems. Results obtained from this analysis were compared with those from the previous step, aiming to determine the most cost-effective solution for the PV–diesel–battery hybrid system.

Figure 1.

Block diagram of methodology used.

3. Mathematical Modeling of System Components

In this section, mathematical modeling of the system component is presented as the purpose of system simulation, namely to check the cycling of the battery system and to estimate battery replacement cost considering the variation of PV output and the load. It is performed using mathematical models of PV array, and batteries. The input data are hourly data of solar radiation, ambient temperature and daily load curve. A brief description of such mathematical models is represented in the following subsections.

3.1. PV Output Power Estimation

PV output power estimation: DC Power generated from PV system is mainly dependent on different factors including PV peak power at standard test condition (STC), solar radiation and ambient temperature. This simple model is represented in Equation (1) [21].

where PPV-out is the output power of the PV array, PPV-peak is the power of the PV array at STC, G is solar radiation in W/m2, Gref is solar radiation at STC amounting to 1000 W/m2, and KT is the temperature coefficient of mono and poly-crystalline Si cells amounting to . Tref is the reference temperature at STC amounting to 25 °C, and TC represents the cell temperature.

The cell temperature can be calculated using (2) [22], a widely adopted empirical formula in numerous research papers. It assists in estimating the PV cell temperature by considering ambient temperature and solar radiation.

where Tamb is the ambient temperature.

3.2. Diesel Generator Output Power

The diesel generator plays a crucial role when the PV system and battery are unable to meet the load demand, typically occurring when the PV output power is lower than the load power and the DOD of the batteries reaches its maximum value. In such situations, the diesel generator starts operating to fulfill the load demand and simultaneously charge the battery system. This strategy ensures power supply continuity, particularly on days with low solar radiation. Charging the battery from the diesel generator allows it to operate closer to its rated power, thereby improving generator efficiency. Additionally, the generator remains active until it charges the battery up to a specified set point, reducing the number of startups and minimizing associated startup costs. This approach is commonly referred to as the cycling charging strategy, which is discussed in [23,24].

3.3. Battery System Models

Batteries are crucial for environmental sustainability in electric cars and renewable energy systems [25,26]. Lead–acid batteries, known for their reliability and cost-effectiveness, contrast with the growing popularity of lithium-ion batteries [27], offering higher energy density and durability and thus impacting PV system efficiency based on cost, performance, and unique needs. The battery system in a PV hybrid system serves the purpose of harnessing solar energy by storing the excess power generated from the PV system. This stored energy is then utilized during periods when sunlight is not available, such as at night. Additionally, the battery system plays a crucial role in stabilizing the overall system. It charges when the PV power generated is greater than the load power, ensuring that excess power is stored. Conversely, it discharges when the PV power is insufficient to meet the load power, providing the necessary energy to supplement the deficit. The charging and discharging modes of the battery system can be described by Equations (3)–(6).

where PPV represents the PV output power, PL signifies the load power, ηinv denotes the inverter efficiency, Eb signifies the battery energy, Echarge indicates the energy intended for charging the battery, E-discharge represents the energy required to discharge from the battery, ηch refers to the charging efficiency, ηdisch signifies the discharging efficiency, Eb denotes the energy of the battery at time t, and ∆t designates the simulation step duration of one hour.

The charging and discharging efficiencies are distinct measures that represent the effectiveness of energy conversion within a battery. Charging efficiency quantifies how efficiently the battery can accept and store energy during the charging process. Discharging efficiency, on the other hand, refers to the efficiency of converting stored energy within the battery into usable electrical energy during the discharge process [22]. The battery energy contents can be with range from Eb−min to Eb−max as in (7)–(9). The battery SOC indicates the level of energy stored within the battery in relation to its rated energy as shown in (10). The battery DOD signifies the proportion of a battery’s total capacity that has been utilized, calculated as shown in (11).

where Eb-min is the minimum energy recommended to be kept in the battery. Eb-max is the maximum energy that can be stored in a battery.

4. Economic Factors and Lifetime Components

In PV–diesel–battery systems, costs significantly influence component sizing. These costs fall into two categories: investment (initial setup of PV panels, diesel generator, and batteries) and operational (ongoing expenses such as fuel, maintenance). Moreover, the replacement of battery system. Balancing these costs ensures an efficiently performing, cost-effective system throughout its lifespan.

4.1. PV Panel Cost and Lifetime

The cost of PV panels depends on technology, quality of materials used, and how they are made. Still, advancements in technology, better manufacturing processes, and scale have significantly reduced PV panel costs. The lifespan of these panels, their durability, and performance are often backed by warranties of up to 20 years. PV panel costs are commonly measured as USD per kilowatt peak (USD/kWp), simplifying comparisons based on their power output.

4.2. Diesel Generator Costs and Lifetime

The costs associated with a diesel generator include initial cost and running costs, which include installation costs and fuel costs. Initial costs include the initial investment required to purchase the generator equipment. The running costs include the fuel cost of a diesel generator and can be calculated by first determining the power delivered by the generator. The fuel consumption can be estimated using the fuel power curve specific to the generator model. The fuel power curve provides information on the fuel consumption rate at different power levels as in (12) [28]. The lifetime of a diesel generator can be estimated by counting the operating running hours overall the project lifespan.

where F0 Fuel curve intercept, F1 Fuel curve slope, and Pgen generator output power.

4.3. Battery System Cost and Lifetime

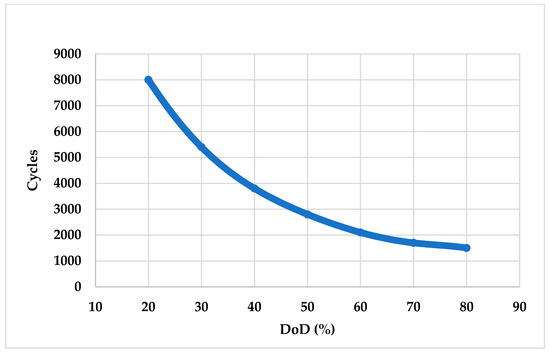

The battery system is a significant cost component in PV–diesel hybrid systems, requiring substantial investment and undergoing multiple replacement periods. In many cases, the battery lifetime is assumed to be fixed within a range of 5 to 20 years; however, in reality, this assumption is insufficient as the actual lifetime of the battery depends on its cycle life. Figure 2 illustrates the relationship between the DOD and the number of cycles for a solar lead–acid battery [29]. For example, if the battery’s DOD is set at 50%, it is projected to provide approximately 3000 cycles before reaching the end of its usable life. It is evident from the figure that as the DOD increases, the number of cycles decreases. This observation highlights the inverse correlation between DOD and the cycle life of the battery, indicating that higher levels of DOD lead to a reduced number of cycles before performance degradation occurs.

Figure 2.

Service life in cycles and DOD.

There are many approaches used to estimate the lifespan of a battery. Some of these approaches are classified as complex, requiring a lot of details and computations, while others can be simple. However, both methods lead to the conclusion that there is no contradiction in the result of this research, which emphasizes the significance of considering the battery service lifetime linked to battery cycling, as more cycling will lead to a shorter lifetime. Therefore, it is important to consider service lifetime rather than its assumed lifetime. To estimate the battery service lifetime more straightforwardly the concept of throughput lifetime is employed as in (13)– (15) [30]. The throughput concept accounts for battery cycling and it quantifies the total energy that the battery can deliver over its operational lifetime.

where Eth,rated is the rated energy throughput in kWh and Eth,ann is the annual energy delivered by the battery (kWh/year).

The rated energy throughput can be calculated by using (14), which is influenced by the DOD, the rated energy of the battery, and the number of cycles until failure.

The annual energy delivered from the battery can be calculated by (15).

where EB,charge and EB,discharge are the annual charging and discharging energy determined by (3) and (5) over one year.

4.4. Economic Factors

The effectiveness and economic viability of PV diesel hybrid systems depend on careful consideration and optimization of multiple economic factors, including the net present cost (NPC), annual cost (AC), and cost of energy (COE).

4.4.1. Net Present Cost

The NPC is a crucial economic factor used to assess the lifetime costs associated with the installation, operation, and maintenance of hybrid PV–battery–diesel systems. It takes into account both the initial investment costs and the operational expenses over the system’s lifetime. In the context of a PV–diesel–battery- system, when comparing different configurations or dispatch strategies, the system with the lowest NPC will be the most economical option. This means that the system with the lowest NPC will result in the most cost-effective solution among the alternatives.

The NPC of the project at time t = 0 involves summing the present values of all project-related costs, as defined by (16) [31]. The discounting factor (DF) serves to convert future costs into present costs and can be determined using (17). the salvage value (SV) represents the expected income from selling an asset at the end of its useful life or project duration, calculated by (18) [32]. Iti is important to note that DF varies with time (t). For instance, when determining the present value of SV, t equals T.

where I0 is the investment cost at the beginning (t = 0), It is the cost in time period t, T is the lifetime of the project in years, and i is the discount rate. The parameters Crep, Rrem, and Rcomp contained within Equation (18) are the component replacement cost, remaining life, and componenet lifetime, respectively.

4.4.2. Annual Cost

The annual cost (AC) can be computed using (19), which involves converting the present cost of the project into annual cost. This is achieved by multiplying the NPC by the capital recovery factor (CRF), calculated according to (20) [31].

4.4.3. Cost of Energy

The cost of energy (COE) is considered as a critical economic indicator for evaluating the cost of generated energy unit (USD/kWh). It can be determined by considering the aggregate costs linked to system installation, component sizing, running expenses, and maintenance, consolidated into an annual cost. This annual cost is then divided by the energy consumed by the load, as calculated in (21) [32,33].

where Eload is the annual electrical energy consumed by the load.

5. Case Study

This section presents a case study to follow the steps mentioned in the previous sections to design the PV–diesel hybrid system to provide electricity to a rural community for 24 h.

5.1. Daily Load Curve

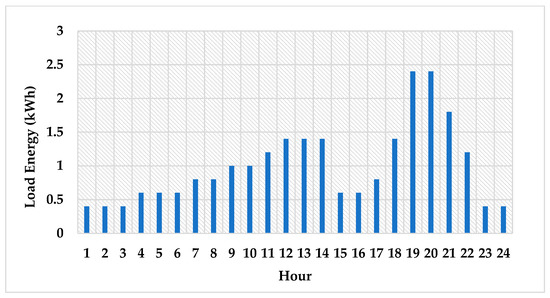

The system of hybrid system will be designed to supply the daily load of 24 kWh/day. With maximum power at 2.4 kW and minimum power 0.4 kW as illustrated in Figure 3.

Figure 3.

Typical daily load curve.

5.2. System Configuration

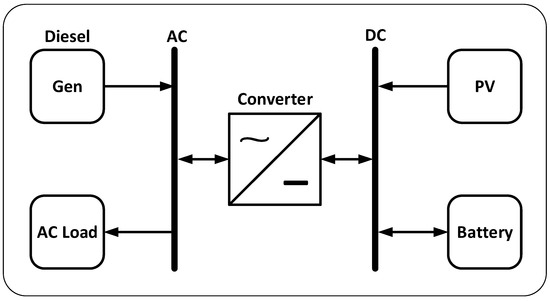

The PV hybrid battery diesel configuration involves two separate buses: the AC bus and the DC bus, as shown in Figure 4. The DC bus houses the PV panels and the battery system. Arrows in Figure 4 indicate unidirectional and bidirectional power flow from each hybrid system component. For instance, the power flow is unidirectional out from PV and diesel generator, while it is bidirectional for the battery and converter.

Figure 4.

Hybrid system configuration.

The PV panels supply energy to the DC bus, while the battery delivers energy during discharge and absorbs energy during charging. On the other hand, the AC bus comprises the AC load and the AC generator. The AC generator is utilized to provide power to the AC bus in two scenarios: either to meet the power demands of the AC load or to charge the battery when there is an excess of power available. This is why the power converter is bidirectional, enabling bidirectional power flow as required.

5.3. Solar Energy Potential

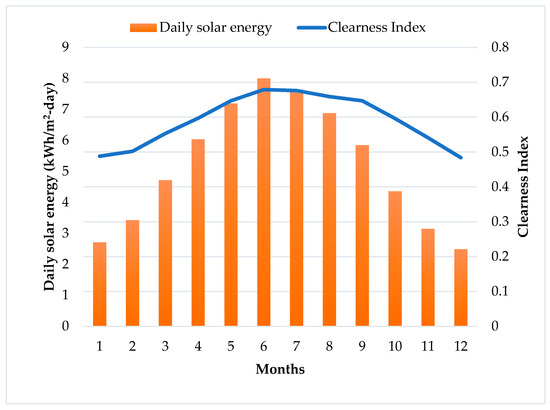

The solar radiation hourly data is for a location with latitude 32 deg and longitude 35 deg. The solar energy levels are depicted in Figure 5. The average daily solar energy ranges between 2.7 and 8 kWh/m2-day with annual average amounts of 5.4 kWh/m2-day. The clearness index is lower during the winter months (November to February) and higher in other months.

Figure 5.

The solar energy and clearness index.

5.4. PV Generator Sizing

The PV rated power is determined by calculating the daily energy requirement, incorporating the peak sunshine hours as specified in (22) [31]. The calculated rated power is intended to meet the demand for a 24 h period, with the battery serving as a source of power during the night and periods of low solar radiation. In months with higher solar radiation exceeding 5.4 kWh/m2-day, the PV system will generate a surplus of maximum power. Conversely, during periods of lower solar radiation, the system will generate less power, potentially leading to increased reliance on the battery system and diesel generator. Understanding these variations in power generation is crucial for the effective utilization of the battery system and diesel generator.

where Ed represents the daily energy demand, PSH denotes the peak sunshine hours, and ηinv refers to the inverter efficiency.

By substituting Ed =24 kWh/day, PSH = 5.4 h/day, ηinv = 95%,

To enhance safety measures and comply with industry norms, the PV system will incorporate PV modules with a peak power of 340 Wp each. A total of 14 modules will be utilized, resulting in a combined rated power of 4760 watts. The PV modules can be either poly or mono crystalline and are designed with 72 cells connected in series, resulting in a nominal voltage of 24 volts. In this specific configuration, the PV generator will be structured with 7 parallel strings, where each string comprises two PV modules connected in series. This connection is chosen to achieve a DC bus voltage of 48 V, ensuring that the DC current remains within an appropriate range for efficient operation.

5.5. Genset and Power Converter Sizing

The generator sizing and converter selection to meet the peak demand of the load, a generator with a capacity of 3 kVA is chosen. This generator rated power is sufficient to handle the peak load demand may experience.

The converter is selected to have a rated power of 4 kW. While the average load demand may be lower, there can be occasional power surges or spikes in demand that require a higher power capacity from the converter. By choosing a converter with a higher rated power, the system can accommodate these temporary load fluctuations without compromising its performance or stability.

5.6. Battery Sizing

The battery sizing for the PV–diesel–battery system is determined through simulation to find the optimal size that results in the lowest cost of energy. To maintain the proper DC voltage range, a DC voltage of 48 V is chosen, leading to the selection of 2 V batteries. Consequently, each string will require 24 batteries (48 V/2 V = 24 batteries).

The amper-hour (Ah) capacity of the batteries is also determined through simulation, considering three options: 300 Ah, 800 Ah, and 1000 Ah. As a result, the storage system will have capacities of 17.08 kWh, 46.08 kWh, and 57.36 kWh, respectively. These storage capacities will be discussed in detail in Section 5.

5.7. Simulation Parameters

In this study, the parameters for the hybrid PV–diesel system are as shown in Table 2.

Table 2.

Simulation parameters.

The battery cost and maintenance cost are essential factors to consider in system design and economic analysis. The initial cost of the battery is 200 USD/kWh, representing the investment required for energy storage procurement. Furthermore, the replacement cost of the battery is also 200 USD/kWh, accounting for potential replacements during the system’s lifetime. As for maintenance, the battery incurs an annual cost equivalent to 5% of its initial cost. Based on this information, the battery costs are tabulated in Table 3.

Table 3.

Cost of batteries with different Ah ratings (per battery).

6. Simulation Results

HOMER Pro version 3.14.2, developed by the National Renewable Energy Laboratory (NREL), serves engineers by facilitating the optimization and selection of viable solutions from technical, economic, and environmental perspectives [34]. Widely referenced in research papers [8,9,10,11,12,13,14,15,16,17,18,19,20], HOMER Pro version 3.14.2 is employed in this study to simulate a recommended hybrid system for a specific site. Additionally, Matlab is utilized for further simulations required in this research. The results of the hourly data for one year aim to justify the objectives of this research.

6.1. Impacts of Battery Sizing on Hybrid System

In this subsection, it is important to understand how the performance parameters of the PV diesel hybrid system are affected by considering different battery ratings. This is crucial for comprehending the economic analysis discussed in the next section, as it is closely connected to the operation of the hybrid system, including factors such as fuel consumption, excess electricity, and renewable fraction. As mentioned before, the PV rated capacity is calculated based on the average daily solar energy of 5.4 kWh/m2-day to meet the demand. In summer, the solar energy is high while in winter, it will be lower. Therefore, the role of the battery in the hybrid system is crucial. Since the system is designed to serve the load for 24 h, and solar energy is available only during the daytime, batteries are essential to store excess energy and cover the demand during the nights or periods with low solar radiation. This allows for full utilization of PV energy and reduces the dependency on the diesel generator, contributing to a more sustainable and efficient operation.

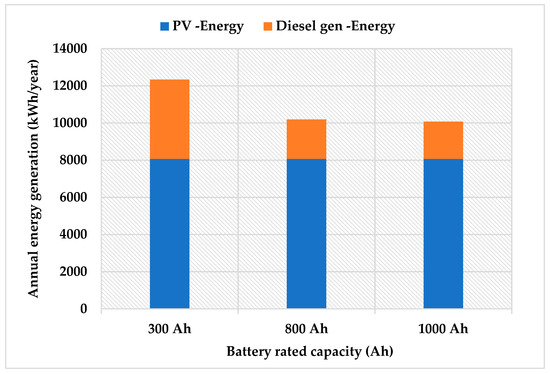

Table 4 illustrates that the annual generated PV energy remains constant at 8073 kWh for all three battery sizing scenarios as it is calculated based on the demand and average solar radiation. However, the energy from the diesel generator is significantly higher when using a smaller battery rated capacity. This is because the smaller battery cannot store all the excess PV energy and thus, the diesel generator is required to cover the remaining demand. Consequently, not only does this lead to increased fuel consumption by the diesel generator, but it also results in a larger amount of excess electricity that goes unused. For example, in the case of choosing a 300 Ah battery for this hybrid system, there is an excess of 2401 kWh of electricity per year, which is enough to cover the daily demand for 10 days.

Table 4.

PV diesel hybrid system performance parameters.

It is essential to recognize that as the battery size increases, the renewable fraction also increases, indicating a higher proportion of energy coming from renewable sources (i.e., PV). Simultaneously, this increase in battery size contributes to reduced fuel consumption by the diesel generator and minimizes the amount of excess electricity, making the system more efficient and environmentally friendly.

Figure 6 presents the tabulated data from Table 4. It is crucial to observe that increasing the battery rated capacity results in a reduced reliance on the diesel generator.

Figure 6.

Hybrid system performance parameters.

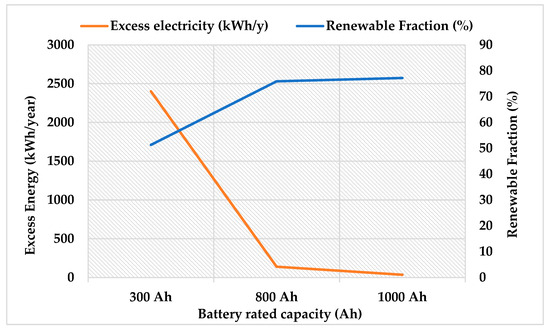

Figure 7 illustrates that increasing the battery rated capacity from 300 Ah to 800 Ah leads to a substantial increase in the renewable fraction, raising it from 51.3% to 75.9%. However, when the battery capacity is further increased from 800 Ah to 1000 Ah, the impact on the renewable fraction becomes less significant, as indicated by the relatively flatter slope of the lines. It is evident that beyond 800 Ah, adding more batteries does not significantly affect the operating parameters of the system.

Figure 7.

Renewable fraction and excess energy.

6.2. Battery Cycling Evaluation

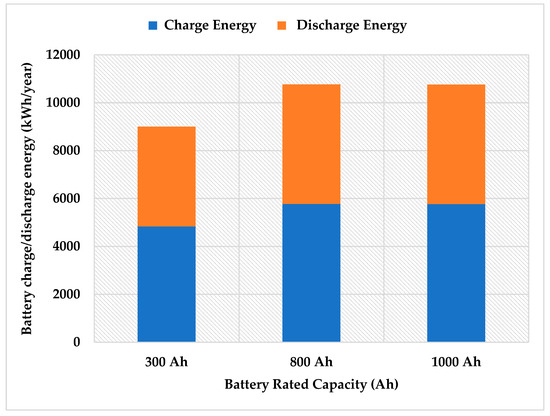

The charge and discharge energy in the battery storage varies depending on the load and solar energy availability, both of which are subject to fluctuations. These variations directly impact the battery cycling, as it determines how much energy is processed relative to the battery’s capacity. Choosing a small capacity battery may lead to frequent cycles, potentially reducing the overall cycle life of the battery. Conversely, opting for a larger capacity battery would result in less frequent cycling, ultimately extending the cycle life.

In this research, the battery throughput lifetime is calculated based on (14) by considering assumptions from [24] where DOD = 0.8 and cycles of 1600. The annual throughput is determined based on the energy input and output from the battery. It can be calculated by summing the hourly energy values for the entire year, and the average can be obtained using (15). The battery service lifetime can be determined using (13).

The results in Table 5 demonstrate that as the battery capacity increases, the cycle life also increases. It is worth noting that in Figure 8, the sum of charge and discharge power for a battery storage with a capacity of 300 Ah amounts to 8906 kWh/year, while for a capacity of 800 Ah, it amounts to 10762 kWh/year. However, it is essential to emphasize that the significant difference lies in the throughput lifetime, which amounts to 20496 kWh for 300 Ah and 55296 kWh for 800 Ah, respectively. This considerable difference directly affects the cycle life, making the 300 Ah battery have a shorter cycle life compared to the 800 Ah battery, as illustrated in Table 5.

Table 5.

Battery cycling parameters.

Figure 8.

Annual battery charge/discharge energy.

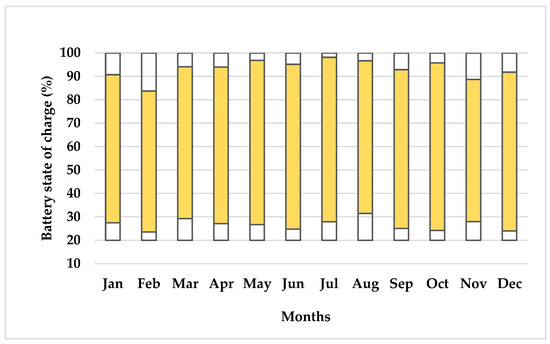

In order to show how battery size affects its cycling, I looked at the average highs and lows of daily battery SOC. Figure 9, Figure 10 and Figure 11 illustrate the possible SOC variation range from 20% to 100%. The colored region represents the simulated SOC variation based on the simulation results. Figure 8 focuses on a 300 Ah battery, revealing that it undergoes frequent and major charge–discharge cycles, hitting about 90% charge and dropping to around 25% often.

Figure 9.

Variation range of battery SOC (300 Ah).

Figure 10.

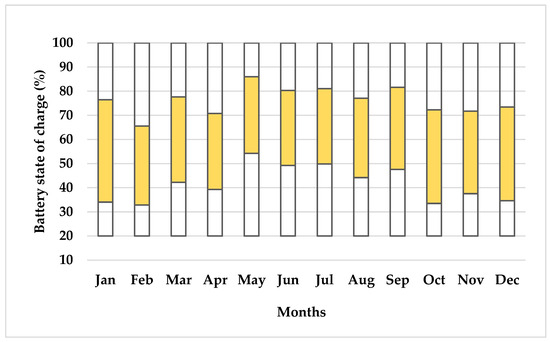

Variation range of battery SOC (800 Ah).

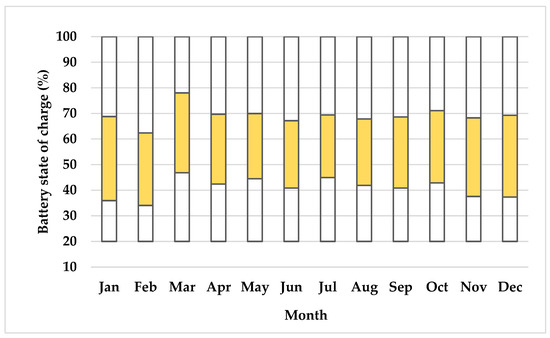

Figure 11.

Variation range of battery SOC (1000 Ah).

Moving to Figure 10 of 800 Ah battery shows a more moderate cycling pattern. Here, the SOC swings from roughly 80% to 40%, suggesting a more balanced and less intense usage compared to the smaller 300 Ah battery.

Similarly, Figure 11 shows the results for battery of 1000 Ah, it demonstrates an even more stable cycling pattern. The average maximum SOC reaches approximately less 70%, while the average minimum SOC is around 40%. This indicates that the 1000 Ah battery undergoes less cycling compared to both the 300 Ah and 800 Ah batteries.

6.3. Economic Analysis Considering Assumed Battery Lifetime

In order to determine the optimal size for the battery system, it is crucial to conduct an economic analysis that takes into account various cost factors. The goal is to find the battery size that results in the most cost-effective and efficient performance over the system’s lifetime. Indeed, many research papers in the field of hybrid PV–diesel systems have traditionally assumed a fixed battery lifetime without thoroughly investigating its impact on sizing the optimal battery capacity. These assumed battery lifetimes typically range from 5 to 20 years, and their use as a constant parameter can lead to limitations and inaccuracies in the system design and economic analysis.

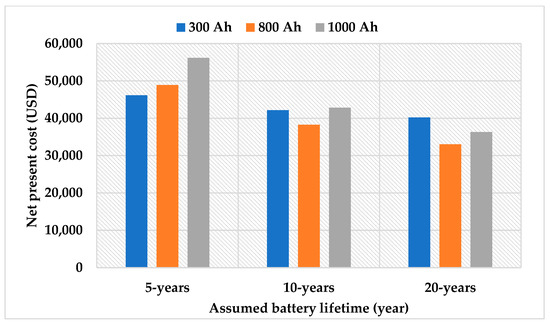

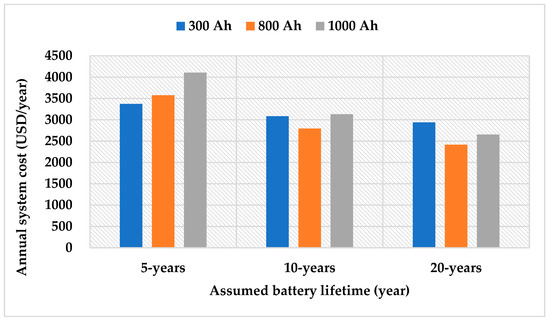

The economic analysis conducted in this research reveals a significant dependency between the optimal battery capacity and the assumed battery lifetime. As demonstrated in Table 6 and Figure 12, the selection of a specific assumed battery lifetime directly impacts the optimal rated capacity that results in the lowest cost for the hybrid PV–diesel system. For instance, when assuming a battery lifetime of 5 years, the economic analysis shows that the optimal rated capacity for the battery is 300 Ah. On the other hand, when assuming longer battery lifetimes of 10 and 20 years, the economic analysis indicates that the optimal rated capacity shifts to 800 Ah.

Table 6.

NPC of hybrid PV system with different battery capacity and lifetime.

Figure 12.

NPC of hybrid PV system with different battery capacity and lifetime.

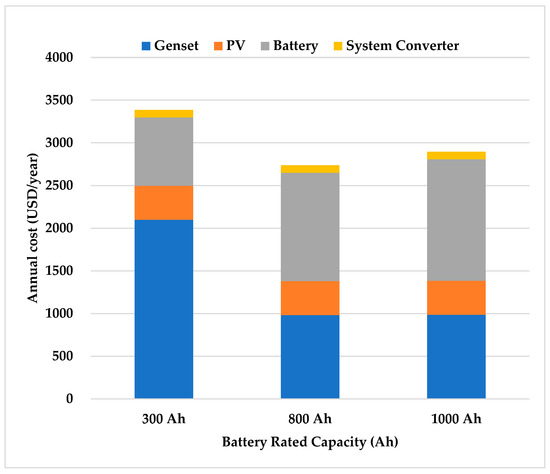

The annual cost of the PV diesel hybrid system as illustrated in Table 7 and Figure 13 also confirms the same conclusion as extracted from NPC. The lowest annual cost is observed in the scenario where the assumed battery lifetime is 5 years, and the battery capacity is 300 Ah. However, the results differ in cases where higher lifetimes of 10 or 20 years are assumed, as the optimal rated size of the battery system is then 800 Ah. This highlights the significant impact of assumed battery lifetime on the optimal sizing of the battery system and its associated costs in the economic analysis.

Table 7.

Annual cost of hybrid PV system with different battery capacity and lifetime.

Figure 13.

Annual costs of hybrid PV system with different battery capacity and lifetime.

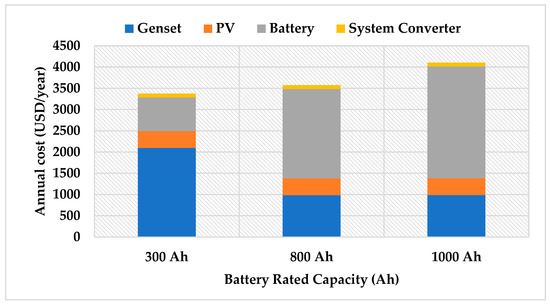

In the case of a 5-year assumed battery lifetime, the most economical rated capacity is 300 Ah. Figure 14 illustrates the breakdown of annual cost in system components. The PV and converter costs remain the same for both scenarios. However, the 300 Ah battery requires lower investment cost compared to the 800 Ah battery. While the genset cost for the 300 Ah scenario is higher than the 800 Ah scenario, the overall battery investment cost is still less for the 300 Ah option, making it the more economical choice.

Figure 14.

Annual costs for the hybrid system components (assuming 5-year battery lifetime).

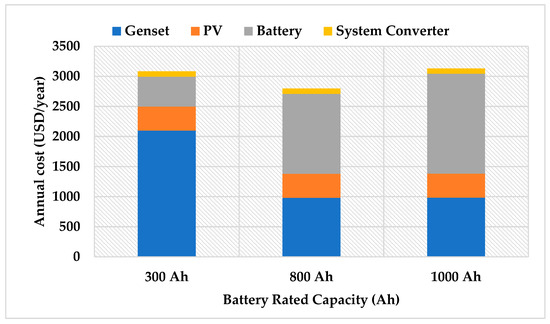

For the case of an assumed lifetime of 10 years, the rated battery that minimizes the annual cost is 800 Ah as shown in Figure 15. In the case of 300 Ah, the diesel fuel cost is higher when compared to the 800 Ah scenario. However, the diesel fuel cost for 800 Ah and 1000 Ah is very close. The main factor that makes the 800 Ah option more economical is its lower investment cost, as shown in Figure 15. Although the diesel fuel cost is similar between 800 Ah and 1000 Ah, the higher investment cost associated with the 1000 Ah battery makes it less cost-effective in the long run, and thus the 800 Ah battery remains the optimal choice in this scenario.

Figure 15.

Annual costs for the hybrid system components (assuming 10-year battery lifetime).

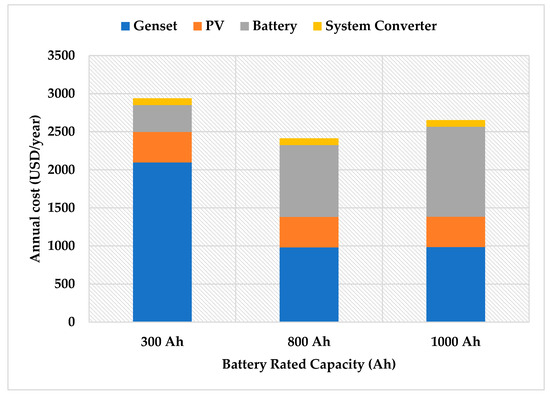

Figure 16 illustrates the results for the assumed battery lifetime of 20 years, and it shows that the optimal battery capacity that minimizes the annual cost is 800 Ah. Similar to the case of 10 years, the 800 Ah battery remains the most cost-effective option. Despite the longer assumed lifetime of 20 years, the 800 Ah battery still proves to be the most economical choice due to its lower investment cost and competitive diesel fuel cost. Indeed, it is essential to highlight that the assumed battery lifetime has a significant impact on the determination of the optimal battery sizing in hybrid PV–diesel systems. As demonstrated in this study, different assumed battery lifetimes, such as 5, 10, or 20 years, can lead to varying optimal battery capacities. Therefore, it is crucial for researchers, engineers, and system designers to carefully consider the chosen battery lifetime assumption during the design phase to achieve the most cost-effective and efficient system configuration.

Figure 16.

Annual costs for the hybrid system components (assuming 20-year battery lifetime).

6.4. Economic Analysis Considering Battery Service Lifetime

By assuming fixed battery lifetime, researchers may overlook important factors that can significantly influence the sizing and performance of the battery system. The actual battery operation, including charge and discharge cycles, DOD, and load variations, can all affect the actual lifetime of the battery, which may differ from the assumed value. Ignoring these factors can lead to suboptimal sizing decisions and potentially higher costs in the long run. To address these limitations and enhance the accuracy of hybrid PV–diesel system design and economic analysis, this section is to show the importance of conducting the economic analysis considering the battery cycle lifetime.

From Table 5, the service lifetime for battery capacities of 300 Ah, 800 Ah, and 1000 Ah are calculated to be 4.9 years, 10.96 years, and 13.64 years, respectively. The economic analysis conducted based on these service lifetimes clearly demonstrates that the optimal battery size is 800 Ah, which exhibits the most feasible economic alternative if assuming these batteries with same technology and type the calendar lifetime assumed with 20 years. Therefore, the service lifetime is less than the calendar lifetime in all cases; thus, the service lifetime should be considered in economic analysis. The results of the economic analysis in Table 8 reveal that the COE is the lowest when considering the 800 Ah battery, with a value of 0.312 USD/kWh. Additionally, the annual cost for the 800 Ah battery stands at 2736 USD/year, and NPC amounts to USD 37450.

Table 8.

Economic factors of hybrid system based on battery service lifetime.

Figure 17 presents the cost breakdown of hybrid system components. It is important to highlight that the costs of PV and converter components remain constant throughout the comparison. However, when comparing different battery capacities, the 800 Ah battery emerges as the most economical choice due to specific factors. In the case of comparing the 800 Ah battery to the 300 Ah battery, the 800 Ah battery exhibits lower annual cost. This is primarily because the diesel fuel cost is less for the 800 Ah battery, leading to overall cost savings. Moreover, the battery investment cost for the 800 Ah option is also lower compared to the 1000 Ah battery, making it a more feasible choice. These economic metrics indicate that selecting the 800 Ah battery ensures that the hybrid PV/diesel system operates with the most feasibel battery capacity. This finding highlights the importance of accurately estimating and incorporating the service lifetime into the design and sizing process of hybrid PV/diesel battery systems. it is evident that the service lifetime of the batteries plays a crucial role in determining the optimal rated of battery system in the hybrid PV–diesel system.

Figure 17.

Annual costs for the hybrid system components (considering battery service lifetime).

7. Conclusions and Future Work

In this study, the impact of assumed battery lifespan on determining optimal rated capacity for battery storage in hybrid PV standalone systems was explored. Findings across assumed lifespans of 5, 10, and 20 years showcased distinct variations in optimal battery capacity. Specifically, a 300 Ah battery appeared cost-effective within a 5-year assumed lifespan, while the 800 Ah battery emerged as the superior choice for 10- and 20-year lifespans. These decisions significantly influenced the economic analysis, accounting for both battery system investments and operational costs within the hybrid PV/diesel system. Thus, it is evident that the assumed battery lifespan significantly impacts the economic evaluation of PV/hybrid systems. Moreover, employing a throughput approach estimated service lifetimes for battery capacities of 300 Ah, 800 Ah, and 1000 Ah, at approximately 4.9 years, 10.96 years, and 13.64 years, respectively. This highlights the relationship between battery rated capacity and cycling effects on battery service lifespans. Notably, the 300 Ah battery exhibited a shorter service life, indicating limitations in relying solely on assumed lifespans. Factoring in the actual service lifetime in the economic analysis identified the 800 Ah battery as optimal. This is contrary to the suggestion that a 300 Ah optimal size with assumed 5-year battery lifespan might propose, highlighting the importance of considering the service lifetime in storage analysis within PV diesel hybrid systems. In future research, exploring alternative methods to estimate battery service lifetime based on diverse battery cycling algorithms could prove beneficial, allowing for a comparative assessment of various approaches.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Emad, D.; El-Hameed, M.A.; El-Fergany, A.A. Optimal techno-economic design of hybrid PV/wind system comprising battery energy storage: Case study for a remote area. Energy Convers. Manag. 2021, 249, 114847. [Google Scholar] [CrossRef]

- Odou, O.D.T.; Bhandari, R.; Adamou, R. Hybrid off-grid renewable power system for sustainable rural electrification in Benin. Renew. Energy 2020, 145, 1266–1279. [Google Scholar] [CrossRef]

- Falama, R.Z.; Saidi, A.S.; Soulouknga, M.H.; Salah, C.B. A techno-economic comparative study of renewable energy systems based different storage devices. Energy 2023, 266, 126411. [Google Scholar] [CrossRef]

- León Gómez, J.C.; De León Aldaco, S.E.; Aguayo Alquicira, J. A Review of Hybrid Renewable Energy Systems: Architectures, Battery Systems, and Optimization Techniques. Eng 2023, 4, 1446–1467. [Google Scholar] [CrossRef]

- Ennemiri, N.; Berrada, A.; Emrani, A.; Abdelmajid, J.; El Mrabet, R. Optimization of an off-grid PV/biogas/battery hybrid energy system for electrification: A case study in a commercial platform in Morocco. Energy Convers. Manag. X 2024, 21, 100508. [Google Scholar] [CrossRef]

- Kelly, E.; Medjo Nouadje, B.A.; Tonsie Djiela, R.H.; Kapen, P.T.; Tchuen, G.; Tchinda, R. Off grid PV/Diesel/Wind/Batteries energy system options for the electrification of isolated regions of Chad. Heliyon 2023, 9, e13906. [Google Scholar] [CrossRef] [PubMed]

- Sakipour, R.; Abdi, H. Optimizing Battery Energy Storage System Data in the Presence of Wind Power Plants: A Comparative Study on Evolutionary Algorithms. Sustainability 2020, 12, 10257. [Google Scholar] [CrossRef]

- Mahesh, A.; Sushnigdha, G. Optimal sizing of photovoltaic/wind/battery hybrid renewable energy system including electric vehicles using improved search space reduction algorithm. J. Energy Storage 2022, 56, 105866. [Google Scholar] [CrossRef]

- Al Afif, R.; Ayed, Y.; Maaitah, O.N. Feasibility and optimal sizing analysis of hybrid renewable energy systems: A case study of Al-Karak, Jordan. Renew. Energy 2023, 204, 229–249. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance analysis of hybrid PV/diesel/battery system using HOMER: A case study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Khan, F.A.; Pal, N.; Saeed, S.H.; Yadav, A. Techno-economic and feasibility assessment of standalone solar Photovoltaic/Wind hybrid energy system for various storage techniques and different rural locations in India. Energy Convers. Manag. 2022, 270, 116217. [Google Scholar] [CrossRef]

- Wassie, Y.T.; Ahlgren, E.O. Performance and reliability analysis of an off-grid PV mini-grid system in rural tropical Africa: A case study in southern Ethiopia. Dev. Eng. 2023, 8, 100106. [Google Scholar] [CrossRef]

- El-Sattar, H.A.; Kamel, S.; Hassan, M.H.; Jurado, F. An effective optimization strategy for design of standalone hybrid renewable energy systems. Energy 2022, 260, 124901. [Google Scholar] [CrossRef]

- Wali, S.B.; Hannan, M.A.; Ker, P.J.; Rahman, M.S.A.; Tiong, S.K.; Begum, R.A.; Mahlia, T.I. Techno-economic assessment of a hybrid renewable energy storage system for rural community towards achieving sustainable development goals. Energy Strategy Rev. 2023, 50, 101217. [Google Scholar] [CrossRef]

- Le, T.S.; Nguyen, T.N.; Bui, D.K.; Ngo, T.D. Optimal sizing of renewable energy storage: A techno-economic analysis of hydrogen, battery and hybrid systems considering degradation and seasonal storage. Appl. Energy 2023, 336, 120817. [Google Scholar] [CrossRef]

- Kerboua, A.; Hacene, F.B.; Goosen, M.F.A.; Ribeiro, L.F. Development of technical economic analysis for optimal sizing of a hybrid power system: A case study of an industrial site in Tlemcen Algeria. Results Eng. 2022, 16, 100675. [Google Scholar] [CrossRef]

- Muskan; Kaur Channi, H. Optimal designing of PV-diesel generator-based system using HOMER software. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Nutakor, C. Feasibility study and economic analysis of stand-alone hybrid energy system for southern Ghana. Sustain. Energy Technol. Assess. 2020, 39, 100695. [Google Scholar] [CrossRef]

- Salameh, T.; Ghenai, C.; Merabet, A.; Alkasrawi, M. Techno-economical optimization of an integrated stand-alone hybrid solar PV tracking and diesel generator power system in Khorfakkan, United Arab Emirates. Energy 2020, 190, 116475. [Google Scholar] [CrossRef]

- Khan, F.A.; Pal, N.; Saeed, S.H.; Yadav, A. Modelling and techno-economic analysis of standalone SPV/Wind hybrid renewable energy system with lead-acid battery technology for rural applications. J. Energy Storage 2022, 55, 105742. [Google Scholar] [CrossRef]

- Omar, M.A.; Mahmoud, M.M. Improvement Approach for Matching PV-array and Inverter of Grid Connected PV Systems Verified by a Case Study. Int. J. Renew. Energy Dev. 2021, 4, 687–697. [Google Scholar] [CrossRef]

- Omar, M.A.; Mahmoud, M.M. Design and Simulation of a PV System Operating in Grid-Connected and Stand-Alone Modes for Areas of Daily Grid Blackouts. Int. J. Photoenergy 2019, 17, 1–9. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Siddique, A.B. Technical and economic evaluation of nuclear powered hybrid renewable energy system for fast charging station. Energy Convers. Manag. X 2023, 17, 100342. [Google Scholar] [CrossRef]

- Ajlan, A.; Tan, C.W.; Abdilahi, A.M. Assessment of environmental and economic perspectives for renewable-based hybrid power system in Yemen. Renew. Sustain. Energy Rev. 2017, 75, 559–570. [Google Scholar] [CrossRef]

- Ullah, I.; Safdar, M.; Zheng, J.; Severino, A.; Jamal, A. Employing Bibliometric Analysis to Identify the Current State of the Art and Future Prospects of Electric Vehicles. Energies 2023, 5, 2344. [Google Scholar] [CrossRef]

- Ullah, I.; Zheng, J.; Jamal, A.; Zahid, M.; Almoshageh, M.; Safdar, M. Electric vehicles charging infrastructure planning: A review. Int. J. Green Energy 2023, 21, 1–19. [Google Scholar] [CrossRef]

- Jamal, H.; Khan, F.; Lim, H.; Kim, J.H. Restraining Lithium Dendrite Formation in All-Solid-State Li Metal Batteries Via Surface Modification of Ceramic Filler. Sustain. Mater. Technol. 2022, 35, e00548. [Google Scholar] [CrossRef]

- Jahangir, M.H.; Mousavi, S.A.; Vaziri Rad, M.A. A techno-economic comparison of a photovoltaic/thermal organic Rankine cycle with several renewable hybrid systems for a residential area in Rayen, Iran. Energy Convers. Manag. 2019, 195, 244–261. [Google Scholar] [CrossRef]

- Liu, C.; Wang, X.; Wu, X.; Guo, J. Economic scheduling model of microgrid considering the lifetime of batteries. IET Gener. Transm. Distrib. 2017, 11, 759–767. [Google Scholar] [CrossRef]

- Baruah, A.; Basu, M. Modelling of an off-grid roof-top residential photovoltaic nano grid system for an urban locality in India. Energy Sustain. Dev. 2023, 74, 471–498. [Google Scholar] [CrossRef]

- Omar, M.A.; Mahmoud, M.M. Grid connected PV- home systems in Palestine: A review on technical performance, effects and economic feasibility. Renew. Sustain. Energy Rev. 2018, 82, 2490–2497. [Google Scholar] [CrossRef]

- Omar, M.A. Economic evaluation of residential grid connected PV Systems based on Net-Metering and Feed-in-Tariff schemes in Palestine. Int. J. Renew. Energy Res. 2018, 8, 2106–2115. [Google Scholar] [CrossRef]

- Zhao, H.; Zhong, M.; Li, L.; Safdar, M.; Zhang, Z. A Comprehensive Evaluation Method for Planning and Design of Self-Sufficient Wind Power Energy Systems at Ports. Sustainability 2023, 15, 16189. [Google Scholar] [CrossRef]

- Babu, M.K.; Ray, P. Sensitivity analysis, optimal design, cost and energy efficiency study of a hybrid forecast model using HOMER pro. J. Eng. Res. 2023, 11, 100033. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).