Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System

Abstract

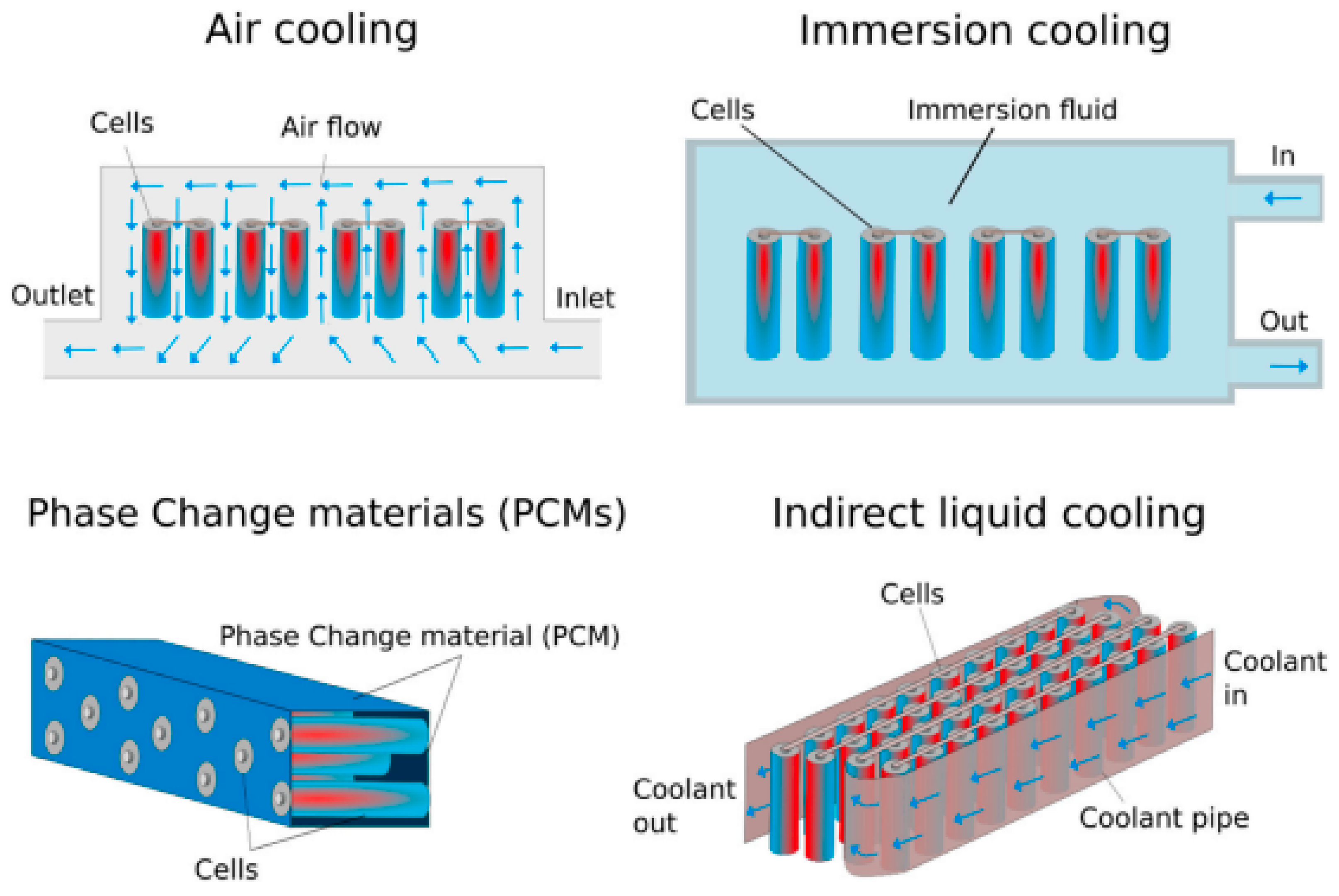

1. Introduction

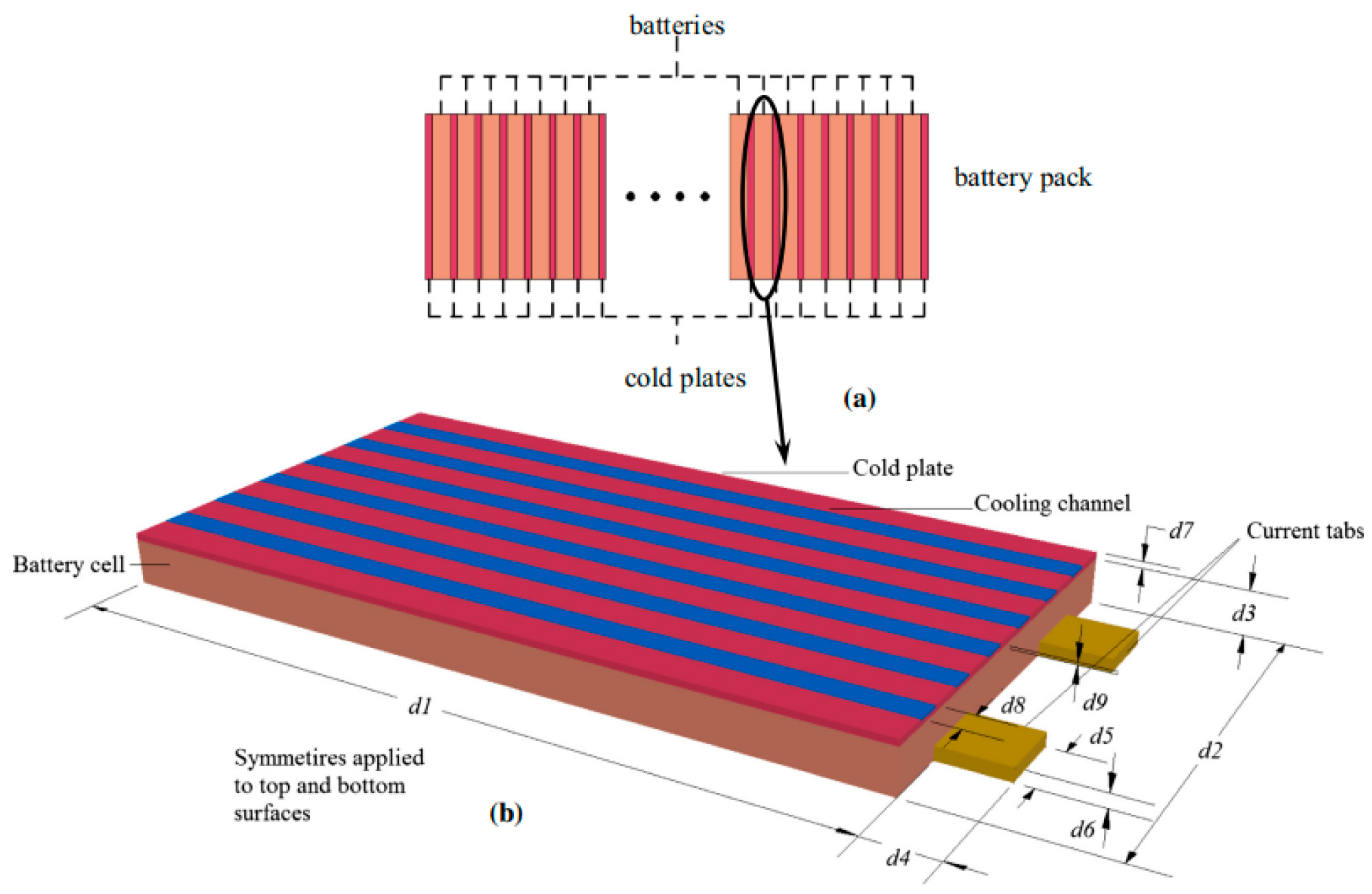

2. Parallel Cold Plate Liquid Cooling

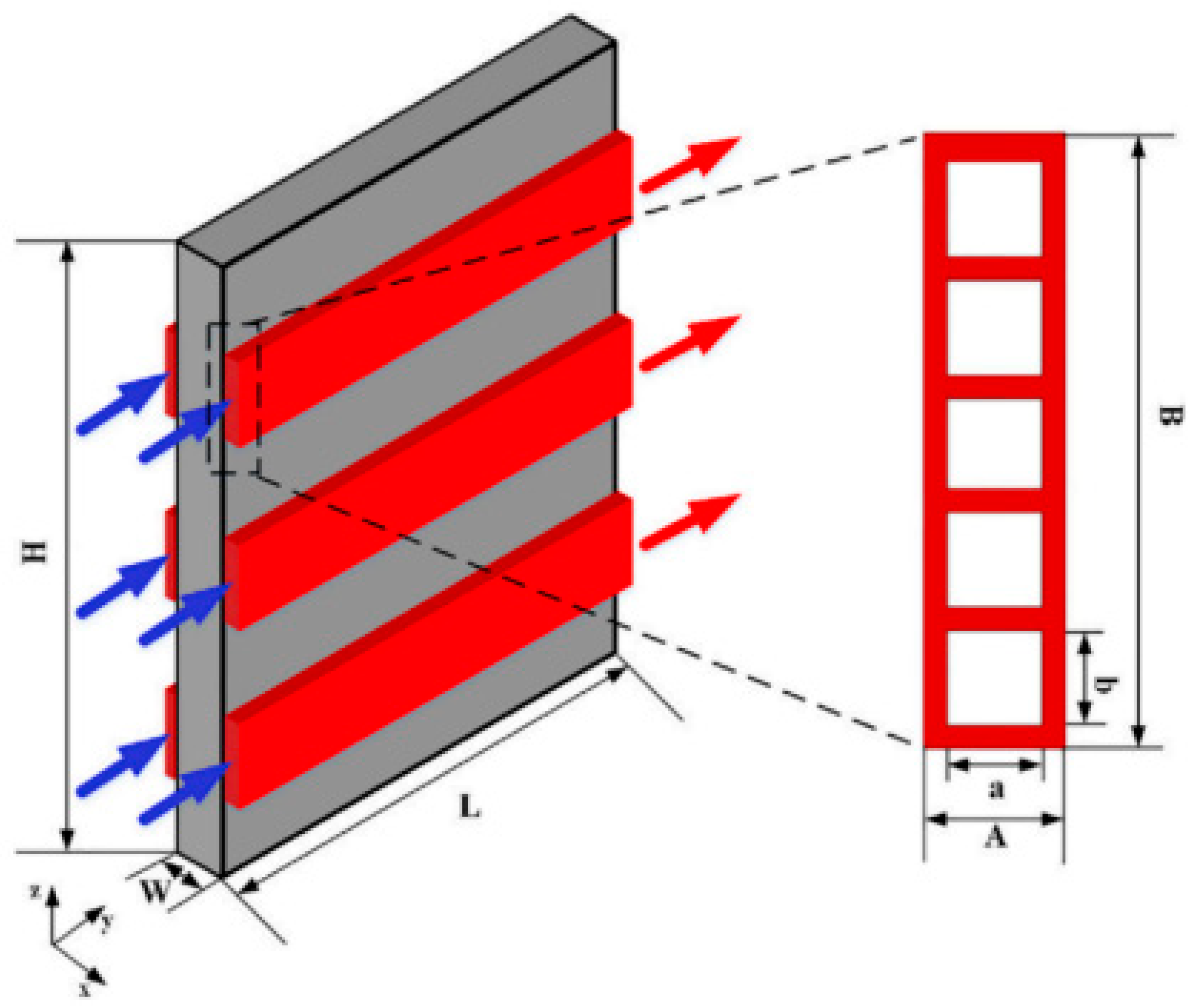

2.1. Mass Flow Rate

2.2. Number of Channels

2.3. Discharging Rate

2.4. Configuration

2.5. Variable Contact Resistance and Cooling Agent

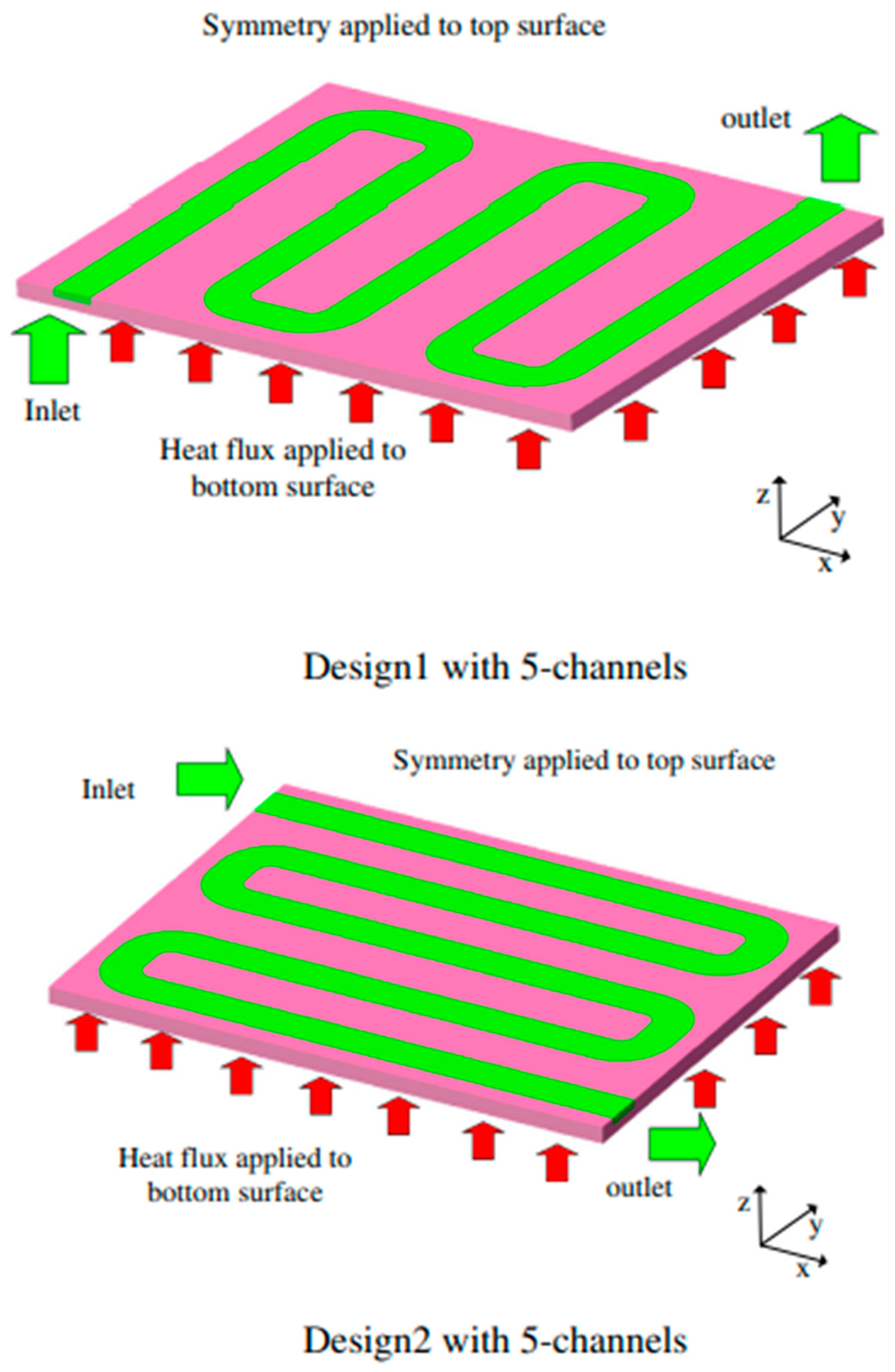

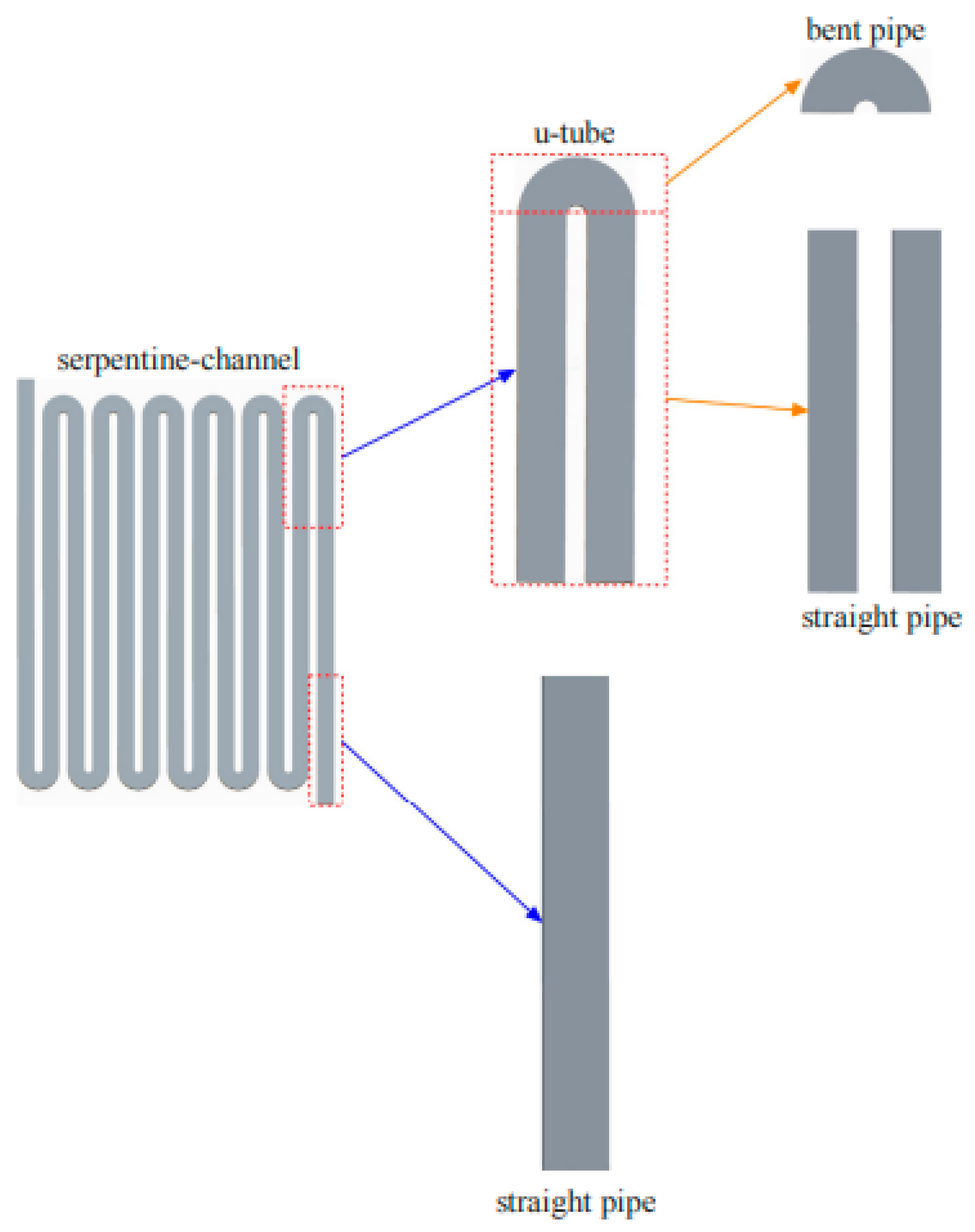

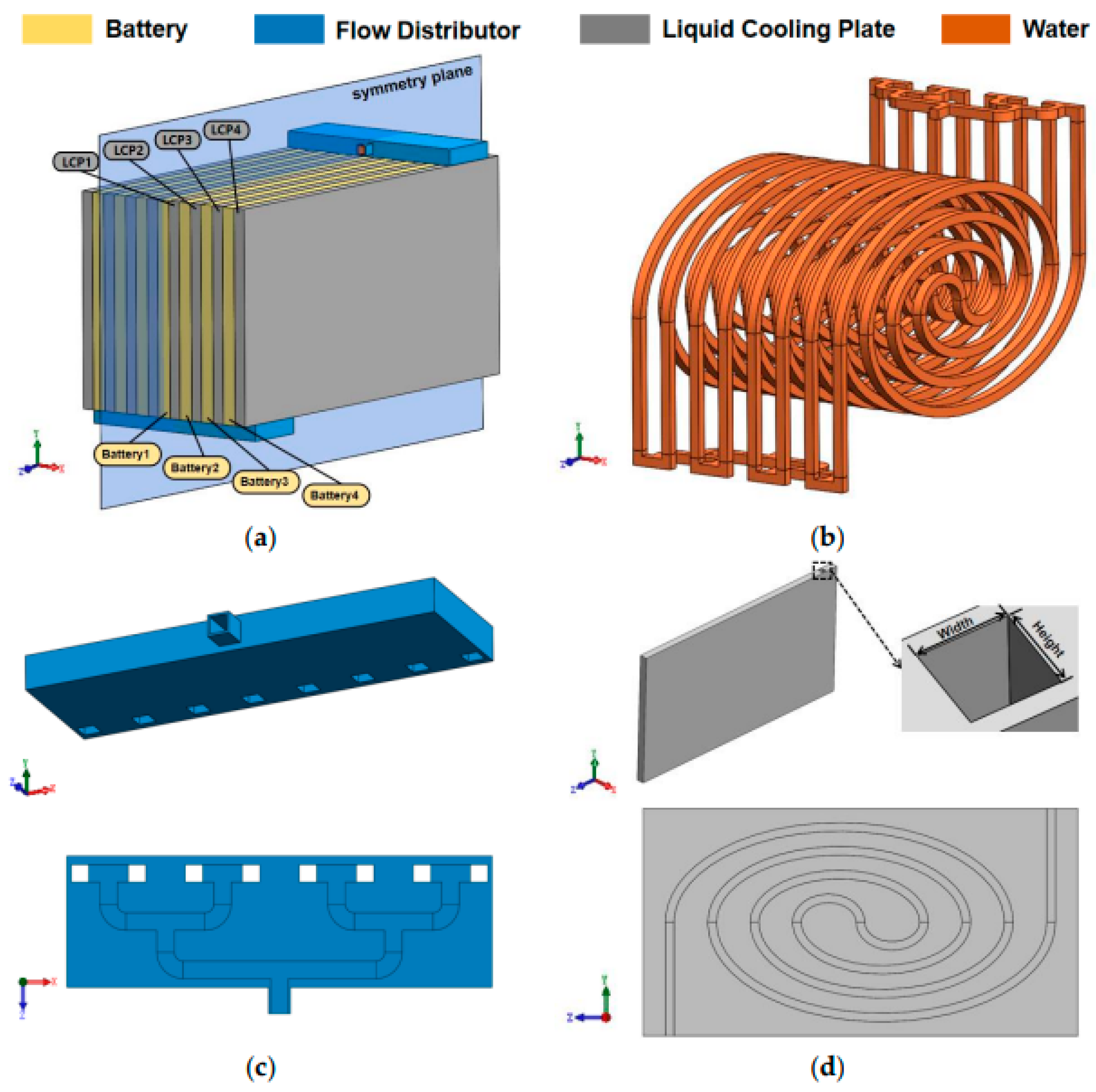

3. Serpentine Cold Plate Liquid Cooling

3.1. Discharging Rates

3.2. Different Coolants

3.3. For Peak Demands

3.4. Configurations

3.5. Thermal Resistance Model

3.6. Dichotomos Flow Distributor

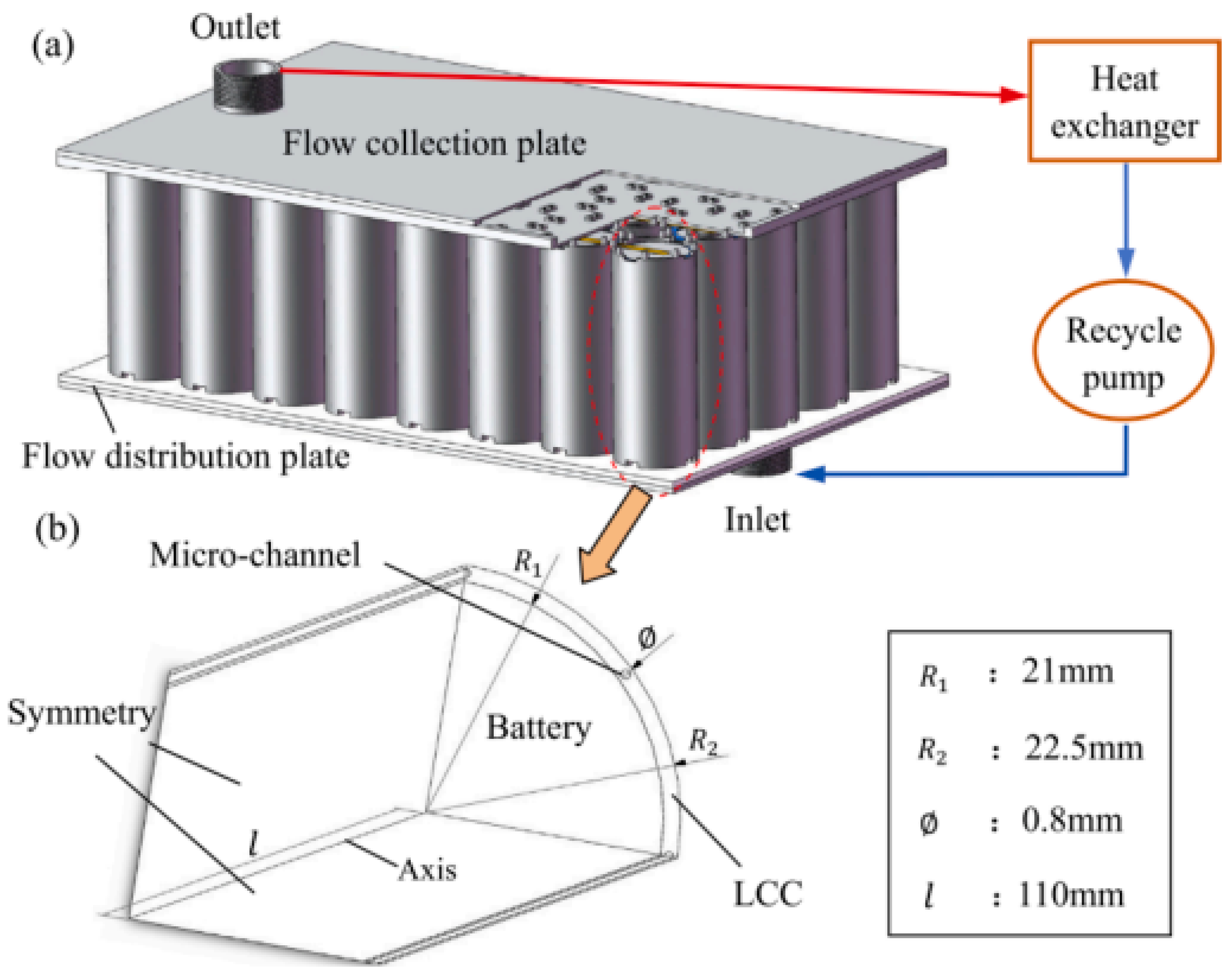

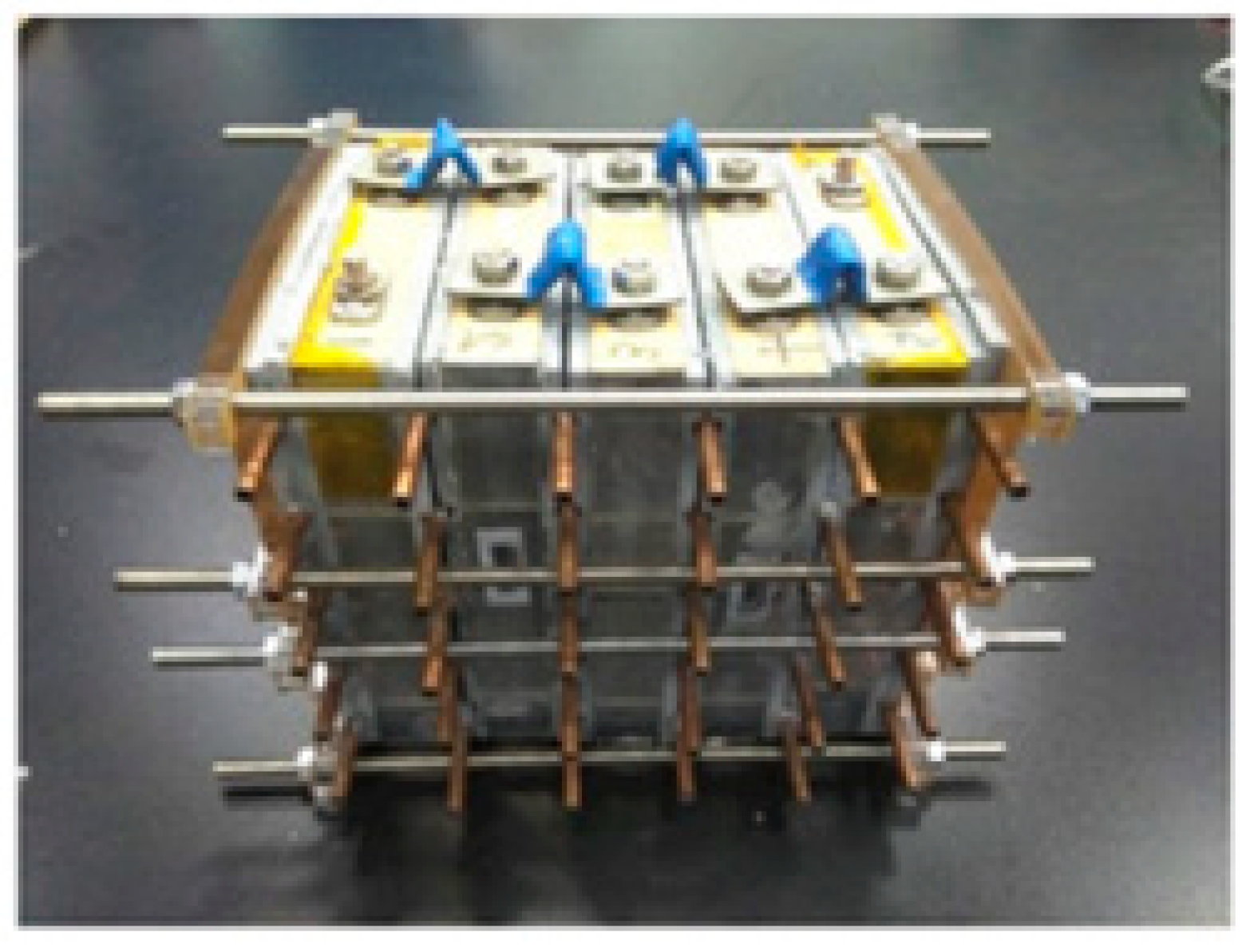

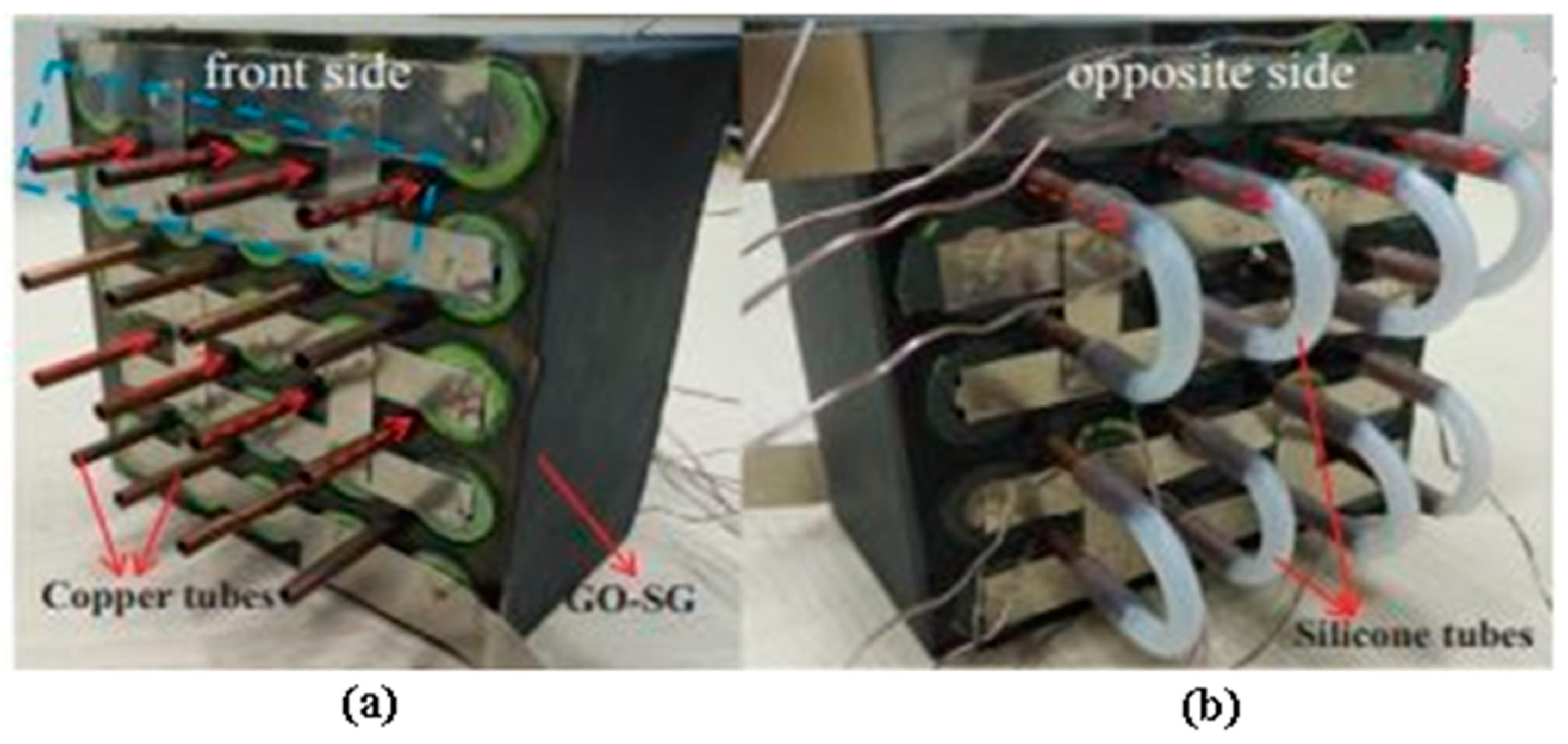

4. Discrete Tube Liquid Cooling

4.1. Natural and Forced Cooling

4.2. GO-SG: Graphene Oxide-Modified Silica Gel

4.3. Discharge Rate

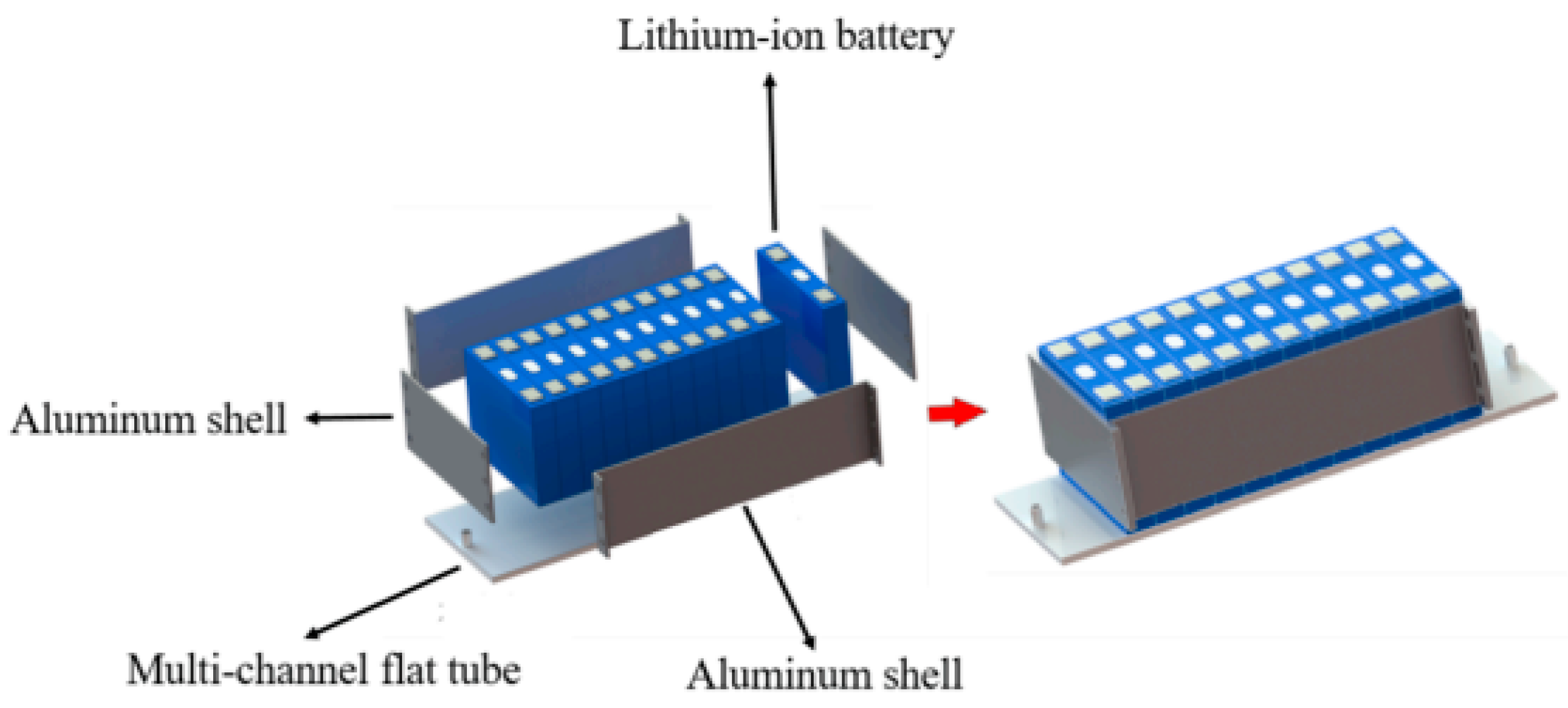

4.4. Multichannel Flat Tube

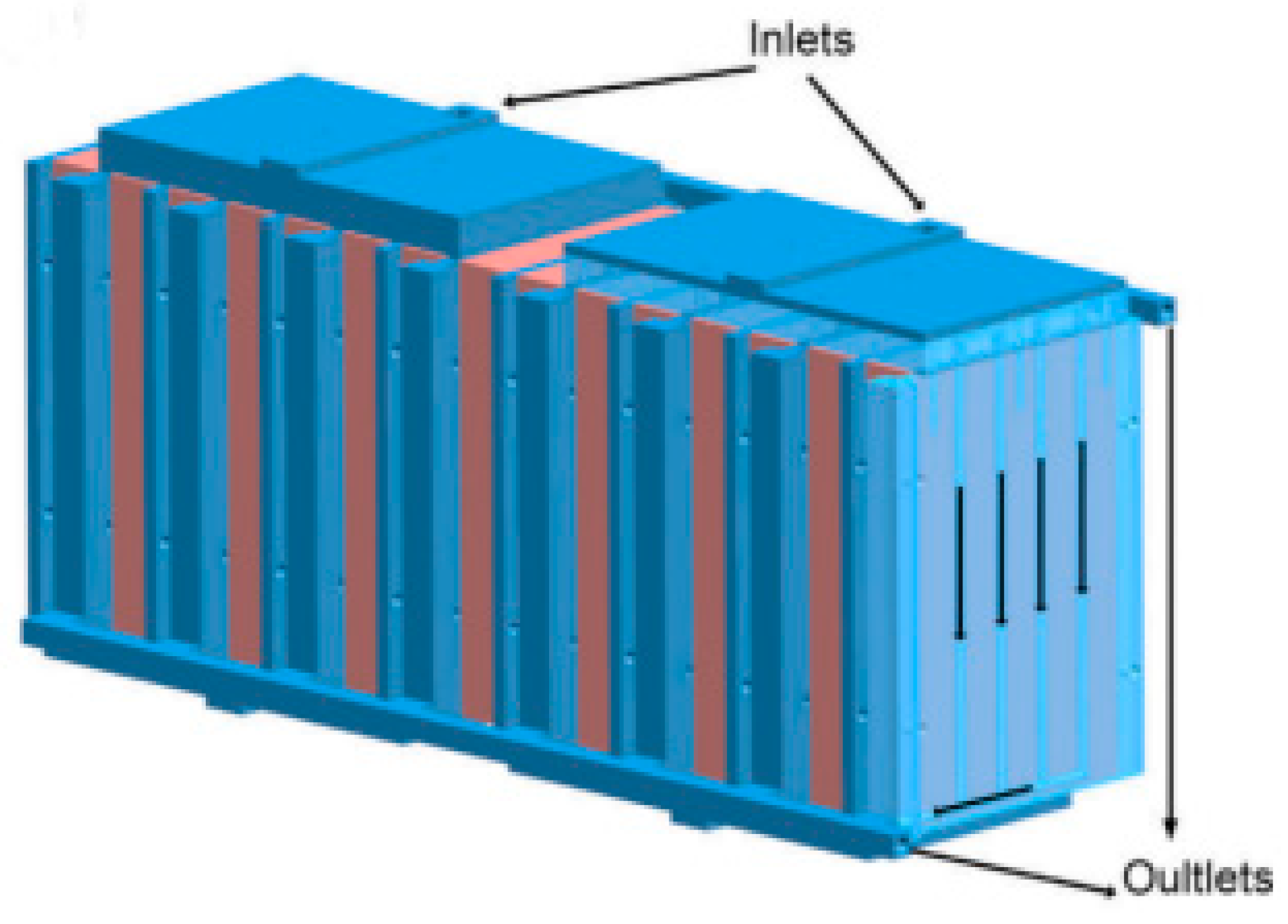

5. Immersion or Direct Cooling

5.1. Working Fluid

5.2. Parasitic Power

5.3. Heat Transfer Fluid

5.4. Configurations

5.5. Nanoparticles

5.6. Boiling Fluid

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, J.; Mao, X.Q.; Hu, T.; Zeng, A.; Xing, Y.K.; Corsetti, G. Implications of the 11th and 12th Five-Year Plans for Energy Conservation and CO2 and Air Pollutants Reduction: A Case Study from the City of Urumqi, China. J. Clean. Prod. 2016, 112, 1767–1777. [Google Scholar] [CrossRef]

- Tursun, H.; Li, Z.; Liu, R.; Li, Y.; Wang, X. Contribution Weight of Engineering Technology on Pollutant Emission Reduction Based on IPAT and LMDI Methods. Clean. Technol. Environ. Policy 2015, 17, 225–235. [Google Scholar] [CrossRef]

- O’Mahony, T. Decomposition of Ireland’s Carbon Emissions from 1990 to 2010: An Extended Kaya Identity. Energy Policy 2013, 59, 573–581. [Google Scholar] [CrossRef]

- Nam, K.M.; Waugh, C.J.; Paltsev, S.; Reilly, J.M.; Karplus, V.J. Carbon Co-Benefits of Tighter SO2 and NOx Regulations in China. Glob. Environ. Chang. 2013, 23, 1648–1661. [Google Scholar] [CrossRef]

- Alajmi, R.G. Factors That Impact Greenhouse Gas Emissions in Saudi Arabia: Decomposition Analysis Using LMDI. Energy Policy 2021, 156, 112454. [Google Scholar] [CrossRef]

- Gu, S.; Fu, B.; Thriveni, T.; Fujita, T.; Ahn, J.W. Coupled LMDI and System Dynamics Model for Estimating Urban CO2 Emission Mitigation Potential in Shanghai, China. J. Clean. Prod. 2019, 240, 118034. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ang, L.; Ng, K.C. Energy-Water-Environment Nexus Underpinning Future Desalination Sustainability. Desalination 2017, 413, 52–64. [Google Scholar] [CrossRef]

- Hema, R.; Venkatarangan, M.J. Adoption of EV: Landscape of EV and Opportunities for India. Meas. Sens. 2022, 24, 100596. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Zhang, Y. Research on Carbon Emissions of Road Traffic in Chengdu City Based on a LEAP Model. Sustainability 2022, 14, 5625. [Google Scholar] [CrossRef]

- Gao, R.; Fan, Z.; Liu, S. A Gradient Channel-Based Novel Design of Liquid-Cooled Battery Thermal Management System for Thermal Uniformity Improvement. J. Energy Storage 2022, 48, 104014. [Google Scholar] [CrossRef]

- Hekmat, S.; Bamdezh, M.A.; Molaeimanesh, G.R. Hybrid Thermal Management for Achieving Extremely Uniform Temperature Distribution in a Lithium Battery Module with Phase Change Material and Liquid Cooling Channels. J. Energy Storage 2022, 50, 104272. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, F.; Fang, X.; Gao, X.; Zhang, Z. A Hybrid Thermal Management System for Lithium Ion Batteries Combining Phase Change Materials with Forced-Air Cooling. Appl. Energy 2015, 148, 403–409. [Google Scholar] [CrossRef]

- Qin, P.; Liao, M.; Zhang, D.; Liu, Y.; Sun, J.; Wang, Q. Experimental and Numerical Study on a Novel Hybrid Battery Thermal Management System Integrated Forced-Air Convection and Phase Change Material. Energy Convers. Manag. 2019, 195, 1371–1381. [Google Scholar] [CrossRef]

- Greco, A.; Jiang, X.; Cao, D. An Investigation of Lithium-Ion Battery Thermal Management Using Paraffin/Porous-Graphite-Matrix Composite. J. Power Sources 2015, 278, 50–68. [Google Scholar] [CrossRef]

- Rao, Z.; Qian, Z.; Kuang, Y.; Li, Y. Thermal Performance of Liquid Cooling Based Thermal Management System for Cylindrical Lithium-Ion Battery Module with Variable Contact Surface. Appl. Therm. Eng. 2017, 123, 1514–1522. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Qu, Z.G. Lithium–Ion Battery Thermal Management Using Heat Pipe and Phase Change Material during Discharge–Charge Cycle: A Comprehensive Numerical Study. Appl. Energy 2019, 242, 378–392. [Google Scholar] [CrossRef]

- Pesaran, A.A.; Keyser, M.; Kim, G.; Santhanagopalan, S.; Smith, K. Tools for Designing Thermal Management of Batteries in Electric Drive Vehicles Battery Temperature in XEVs. Adv. Automot. Batter. Conf. 2013, 13, 104–116. [Google Scholar] [CrossRef]

- Singirikonda, S.; Obulesu, Y.P. Adaptive Secondary Loop Liquid Cooling with Refrigerant Cabin Active Thermal Management System for Electric Vehicle. J. Energy Storage 2022, 50, 104624. [Google Scholar] [CrossRef]

- Tete, P.R.; Gupta, M.M.; Joshi, S.S. Developments in Battery Thermal Management Systems for Electric Vehicles: A Technical Review. J. Energy Storage 2021, 35, 102255. [Google Scholar] [CrossRef]

- Tang, X.; Guo, Q.; Li, M.; Wei, C.; Pan, Z.; Wang, Y. Performance Analysis on Liquid-Cooled Battery Thermal Management for Electric Vehicles Based on Machine Learning. J. Power Sources 2021, 494, 229727. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, Z.; Li, J.; Cheng, J. A Lightweight Liquid Cooling Thermal Management Structure for Prismatic Batteries. J. Energy Storage 2021, 42, 103078. [Google Scholar] [CrossRef]

- Wang, H.; Tao, T.; Xu, J.; Mei, X.; Liu, X.; Gou, P. Cooling Capacity of a Novel Modular Liquid-Cooled Battery Thermal Management System for Cylindrical Lithium Ion Batteries. Appl. Therm. Eng. 2020, 178, 115591. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Cui, W.; Guo, M. Experimental Investigation on the Thermal Performance of Vapor Chamber in a Compound Liquid Cooling System. Int. J. Heat Mass Transf. 2021, 170, 121026. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z.; Liu, X.; Zhao, J. Investigation of Power Battery Thermal Management by Using Mini-Channel Cold Plate. Energy Convers. Manag. 2015, 89, 387–395. [Google Scholar] [CrossRef]

- Li, W.; Zhuang, X.; Xu, X. Numerical Study of a Novel Battery Thermal Management System for a Prismatic Li-Ion Battery Module. Energy Procedia 2019, 158, 4441–4446. [Google Scholar] [CrossRef]

- Xie, J.; Xie, Y.; Yuan, C. Numerical Study of Heat Transfer Enhancement Using Vortex Generator for Thermal Management of Lithium Ion Battery. Int. J. Heat Mass Transf. 2019, 129, 1184–1193. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Li, Y. Thermal Performance of Mini-Channel Liquid Cooled Cylinder Based Battery Thermal Management for Cylindrical Lithium-Ion Power Battery. Energy Convers. Manag. 2015, 103, 157–165. [Google Scholar] [CrossRef]

- Qian, Z.; Li, Y.; Rao, Z. Thermal Performance of Lithium-Ion Battery Thermal Management System by Using Mini-Channel Cooling. Energy Convers. Manag. 2016, 126, 622–631. [Google Scholar] [CrossRef]

- Huang, Y.; Mei, P.; Lu, Y.; Huang, R.; Yu, X.; Chen, Z.; Roskilly, A.P. A Novel Approach for Lithium-Ion Battery Thermal Management with Streamline Shape Mini Channel Cooling Plates. Appl. Therm. Eng. 2019, 157, 33. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Han, D.; Qiu, A.; Zhu, H.; Deng, Y.; Chen, J.; Zhao, X.; Zuo, W.; Wang, H.; Chen, J.; et al. Orthogonal Experimental Design of Liquid-Cooling Structure on the Cooling Effect of a Liquid-Cooled Battery Thermal Management System. Appl. Therm. Eng. 2018, 132, 508–520. [Google Scholar] [CrossRef]

- Zhao, J.; Rao, Z.; Liu, C.; Li, Y. Experiment Study of Oscillating Heat Pipe and Phase Change Materials Coupled for Thermal Energy Storage and Thermal Management. Int. J. Heat Mass Transf. 2016, 99, 252–260. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A.; Mathew, M.; Fowler, M. Thermal and Electrical Performance Evaluations of Series Connected Li-Ion Batteries in a Pack with Liquid Cooling. Appl. Therm. Eng. 2018, 129, 472–481. [Google Scholar] [CrossRef]

- Yang, X.H.; Tan, S.C.; Liu, J. Thermal Management of Li-Ion Battery with Liquid Metal. Energy Convers. Manag. 2016, 117, 577–585. [Google Scholar] [CrossRef]

- Park, S.; Jang, D.S.; Lee, D.C.; Hong, S.H.; Kim, Y. Simulation on Cooling Performance Characteristics of a Refrigerant-Cooled Active Thermal Management System for Lithium Ion Batteries. Int. J. Heat Mass Transf. 2019, 135, 131–141. [Google Scholar] [CrossRef]

- Xu, X.; Li, W.; Xu, B.; Qin, J. Numerical Study on a Water Cooling System for Prismatic LiFePO4 Batteries at Abused Operating Conditions. Appl. Energy 2019, 250, 404–412. [Google Scholar] [CrossRef]

- Chung, Y.; Kim, M.S. Thermal Analysis and Pack Level Design of Battery Thermal Management System with Liquid Cooling for Electric Vehicles. Energy Convers. Manag. 2019, 196, 105–116. [Google Scholar] [CrossRef]

- Tang, A.; Li, J.; Lou, L.; Shan, C.; Yuan, X. Optimization Design and Numerical Study on Water Cooling Structure for Power Lithium Battery Pack. Appl. Therm. Eng. 2019, 159, 113760. [Google Scholar] [CrossRef]

- Jin, L.W.; Lee, P.S.; Kong, X.X.; Fan, Y.; Chou, S.K. Ultra-Thin Minichannel LCP for EV Battery Thermal Management. Appl. Energy 2014, 113, 1786–1794. [Google Scholar] [CrossRef]

- An, Z.; Jia, L.; Li, X.; Ding, Y. Experimental Investigation on Lithium-Ion Battery Thermal Management Based on Flow Boiling in Mini-Channel. Appl. Therm. Eng. 2017, 117, 534–543. [Google Scholar] [CrossRef]

- Mondal, B.; Lopez, C.F.; Mukherjee, P.P. Exploring the Efficacy of Nanofluids for Lithium-Ion Battery Thermal Management. Int. J. Heat Mass Transf. 2017, 112, 779–794. [Google Scholar] [CrossRef]

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal Design and Simulation of Mini-Channel Cold Plate for Water Cooled Large Sized Prismatic Lithium-Ion Battery. Appl. Therm. Eng. 2017, 122, 80–90. [Google Scholar] [CrossRef]

- Panchal, S.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal Modeling and Validation of Temperature Distributions in a Prismatic Lithium-Ion Battery at Different Discharge Rates and Varying Boundary Conditions. Appl. Therm. Eng. 2016, 96, 190–199. [Google Scholar] [CrossRef]

- Jrckb, P.; Ponangi, B.R. Design and Analysis of Cold Plate for Electric Vehicle Battery Pack. In Proceedings of the 25th National and 3rd International ISHMT-ASTFE Heat and Mass Transfer Conference (IHMTC-2019), Roorkee, India, 28–31 December 2019; Volume 1260, pp. 751–756. [Google Scholar] [CrossRef]

- Cao, W.; Zhao, C.; Wang, Y.; Dong, T.; Jiang, F. Thermal Modeling of Full-Size-Scale Cylindrical Battery Pack Cooled by Channeled Liquid Flow. Int. J. Heat Mass Transf. 2019, 138, 1178–1187. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Z.; Wu, W.T. Three-Dimensional Thermal Modeling of Li-Ion Battery Cell and 50 V Li-Ion Battery Pack Cooled by Mini-Channel Cold Plate. Appl. Therm. Eng. 2019, 147, 829–840. [Google Scholar] [CrossRef]

- Sheng, L.; Su, L.; Zhang, H.; Li, K.; Fang, Y.; Ye, W.; Fang, Y. Numerical Investigation on a Lithium Ion Battery Thermal Management Utilizing a Serpentine-Channel Liquid Cooling Plate Exchanger. Int. J. Heat Mass Transf. 2019, 141, 658–668. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, G.; Ran, Y.; Liu, P. Thermal Performance of Lithium Ion Battery Pack by Using Cold Plate. Appl. Therm. Eng. 2019, 160, 114088. [Google Scholar] [CrossRef]

- Deng, T.; Zhang, G.; Ran, Y. Study on Thermal Management of Rectangular Li-Ion Battery with Serpentine-Channel Cold Plate. Int. J. Heat Mass Transf. 2018, 125, 143–152. [Google Scholar] [CrossRef]

- Zhao, C.; Sousa, A.C.M.; Jiang, F. Minimization of Thermal Non-Uniformity in Lithium-Ion Battery Pack Cooled by Channeled Liquid Flow. Int. J. Heat Mass Transf. 2019, 129, 660–670. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Xu, S.; Deng, Y.; Zhu, H.; Zuo, W.; Wang, H.; Chen, J.; Peng, Q.; Zhang, Z. Investigation on Thermal Performance and Pressure Loss of the Fluid Cold-Plate Used in Thermal Management System of the Battery Pack. Appl. Therm. Eng. 2018, 145, 552–568. [Google Scholar] [CrossRef]

- Li, P.; Zhao, J.; Zhou, S.; Duan, J.; Li, X.; Zhang, H.; Yuan, J. Design and Optimization of a Liquid Cooling Thermal Management System with Flow Distributors and Spiral Channel Cooling Plates for Lithium-Ion Batteries. Energies 2023, 16, 2196. [Google Scholar] [CrossRef]

- An, Z.; Shah, K.; Jia, L.; Ma, Y. A Parametric Study for Optimization of Minichannel Based Battery Thermal Management System. Appl. Therm. Eng. 2019, 154, 593–601. [Google Scholar] [CrossRef]

- Li, X.; Zhou, D.; Zhang, G.; Wang, C.; Lin, R.; Zhong, Z. Experimental Investigation of the Thermal Performance of Silicon Cold Plate for Battery Thermal Management System. Appl. Therm. Eng. 2019, 155, 331–340. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, D.; Yang, X.; Liu, X.; Li, X.; Zhang, G. Experimental Investigation on a Novel Liquid-Cooling Strategy by Coupling with Graphene-Modified Silica Gel for the Thermal Management of Cylindrical Battery. Appl. Therm. Eng. 2019, 159, 113885. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, F.; Zhang, Q.; Wang, Q.; Song, Z. Thermal Management of Cylindrical Lithium-Ion Battery Based on a Liquid Cooling Method with Half-Helical Duct. Appl. Therm. Eng. 2019, 162, 114257. [Google Scholar] [CrossRef]

- Li, K.; Yan, J.; Chen, H.; Wang, Q. Water Cooling Based Strategy for Lithium Ion Battery Pack Dynamic Cycling for Thermal Management System. Appl. Therm. Eng. 2018, 132, 575–585. [Google Scholar] [CrossRef]

- Lan, C.; Xu, J.; Qiao, Y.; Ma, Y. Thermal Management for High Power Lithium-Ion Battery by Minichannel Aluminum Tubes. Appl. Therm. Eng. 2016, 101, 284–292. [Google Scholar] [CrossRef]

- Basu, S.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Sohn, D.K.; Yeo, T. Coupled Electrochemical Thermal Modelling of a Novel Li-Ion Battery Pack Thermal Management System. Appl. Energy 2016, 181, 1–13. [Google Scholar] [CrossRef]

- Ren, R.; Zhao, Y.; Diao, Y.; Liang, L. Experimental Study on the Bottom Liquid Cooling Thermal Management System for Lithium-Ion Battery Based on Multichannel Flat Tube. Appl. Therm. Eng. 2023, 219, 119636. [Google Scholar] [CrossRef]

- Deng, Y.; Feng, C.E.J.; Zhu, H.; Chen, J.; Wen, M.; Yin, H. Effects of Different Coolants and Cooling Strategies on the Cooling Performance of the Power Lithium Ion Battery System: A Review. Appl. Therm. Eng. 2018, 142, 10–29. [Google Scholar] [CrossRef]

- Offer, G.; Patel, Y.; Hales, A.; Bravo Diaz, L.; Marzook, M. Cool Metric for Lithium-Ion Batteries Could Spur Progress. Nature 2020, 582, 485–487. [Google Scholar] [CrossRef] [PubMed]

- Nelson, P.; Dees, D.; Amine, K.; Henriksen, G. Modeling Thermal Management of Lithium-Ion PNGV Batteries. J. Power Sources 2002, 110, 349–356. [Google Scholar] [CrossRef]

- Karimi, G.; Dehghan, A.R. Thermal Analysis of High-Power Lithium-Ion Battery Packs Using Flow Network Approach. Int. J. Energy Res. 2014, 38, 1793–1811. [Google Scholar] [CrossRef]

- Karimi, G.; Li, X. Thermal Management of Lithium-Ion Batteries for Electric Vehicles. Int. J. Energy Res. 2013, 37, 13–24. [Google Scholar] [CrossRef]

- Kim, G.H.; Pesaran, A. Battery Thermal Management Design Modeling. World Electr. Veh. J. 2007, 1, 126–133. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Electrochemical Modeling and Performance Evaluation of a New Ammonia-Based Battery Thermal Management System for Electric and Hybrid Electric Vehicles. Electrochim. Acta 2017, 247, 171–182. [Google Scholar] [CrossRef]

- Pendergast, D.R.; Demauro, E.P.; Fletcher, M.; Stimson, E.; Mollendorf, J.C. A Rechargeable Lithium-Ion Battery Module for Underwater Use. J. Power Sources 2011, 196, 793–800. [Google Scholar] [CrossRef]

- Xia, G.; Cao, L.; Bi, G. A Review on Battery Thermal Management in Electric Vehicle Application. J. Power Sources 2017, 367, 90–105. [Google Scholar] [CrossRef]

- Park, S.; Jung, D. Battery Cell Arrangement and Heat Transfer Fluid Effects on the Parasitic Power Consumption and the Cell Temperature Distribution in a Hybrid Electric Vehicle. J. Power Sources 2013, 227, 191–198. [Google Scholar] [CrossRef]

- Saw, L.H.; Tay, A.A.O.; Zhang, L.W. Thermal Management of Lithium-Ion Battery Pack with Liquid Cooling. Annu. IEEE Semicond. Therm. Meas. Manag. Symp. 2015, 2015, 298–302. [Google Scholar] [CrossRef]

- Smith, J.; Hinterberger, M.; Hable, P.; Koehler, J. Simulative Method for Determining the Optimal Operating Conditions for a Cooling Plate for Lithium-Ion Battery Cell Modules. J. Power Sources 2014, 267, 784–792. [Google Scholar] [CrossRef]

- Ahmad, A. Pesaran Battery Thermal Management in EVs and HEVs: Issues and Solutions. Battery Man 2001, 43, 34–49. [Google Scholar]

- Chen, S.C.; Wan, C.C.; Wang, Y.Y. Thermal Analysis of Lithium-Ion Batteries. J. Power Sources 2005, 140, 111–124. [Google Scholar] [CrossRef]

- Jilte, R.D.; Kumar, R.; Ahmadi, M.H. Cooling Performance of Nanofluid Submerged vs. Nanofluid Circulated Battery Thermal Management Systems. J. Clean. Prod. 2019, 240, 118131. [Google Scholar] [CrossRef]

- Beheshti, A.; Shanbedi, M.; Heris, S.Z. Heat Transfer and Rheological Properties of Transformer Oil-Oxidized MWCNT Nanofluid. J. Therm. Anal. Calorim. 2014, 118, 1451–1460. [Google Scholar] [CrossRef]

- Sidney, S.; Dhasan, M.L.; Selvam, C.; Harish, S. Experimental Investigation of Freezing and Melting Characteristics of Graphene-Based Phase Change Nanocomposite for Cold Thermal Energy Storage Applications. Appl. Sci. 2019, 9, 1099. [Google Scholar] [CrossRef]

- Selvam, C.; Lal, D.M.; Harish, S. Thermal Conductivity Enhancement of Ethylene Glycol and Water with Graphene Nanoplatelets. Thermochim. Acta 2016, 642, 32–38. [Google Scholar] [CrossRef]

- Huo, Y.; Rao, Z. The Numerical Investigation of Nanofluid Based Cylinder Battery Thermal Management Using Lattice Boltzmann Method. Int. J. Heat Mass Transf. 2015, 91, 374–384. [Google Scholar] [CrossRef]

- Al-Zareer, M.; Dincer, I.; Rosen, M.A. Novel Thermal Management System Using Boiling Cooling for High-Powered Lithium-Ion Battery Packs for Hybrid Electric Vehicles. J. Power Sources 2017, 363, 291–303. [Google Scholar] [CrossRef]

- Hirano, H.; Tajima, T.; Hasegawa, T.; Sekiguchi, T.; Uchino, M. Boiling Liquid Battery Cooling for Electric Vehicle. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Van Gils, R.W.; Danilov, D.; Notten, P.H.L.; Speetjens, M.F.M.; Nijmeijer, H. Battery Thermal Management by Boiling Heat-Transfer. Energy Convers. Manag. 2014, 79, 9–17. [Google Scholar] [CrossRef]

- Wang, Y.F.; Wu, J.T. Thermal Performance Predictions for an HFE-7000 Direct Flow Boiling Cooled Battery Thermal Management System for Electric Vehicles. Energy Convers. Manag. 2020, 207, 112569. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anisha; Kumar, A. Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System. Energies 2023, 16, 3857. https://doi.org/10.3390/en16093857

Anisha, Kumar A. Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System. Energies. 2023; 16(9):3857. https://doi.org/10.3390/en16093857

Chicago/Turabian StyleAnisha, and Anil Kumar. 2023. "Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System" Energies 16, no. 9: 3857. https://doi.org/10.3390/en16093857

APA StyleAnisha, & Kumar, A. (2023). Identification and Mitigation of Shortcomings in Direct and Indirect Liquid Cooling-Based Battery Thermal Management System. Energies, 16(9), 3857. https://doi.org/10.3390/en16093857