Research Progress of Battery Life Prediction Methods Based on Physical Model

Abstract

1. Introduction

2. Methods Based on Electrochemical Models

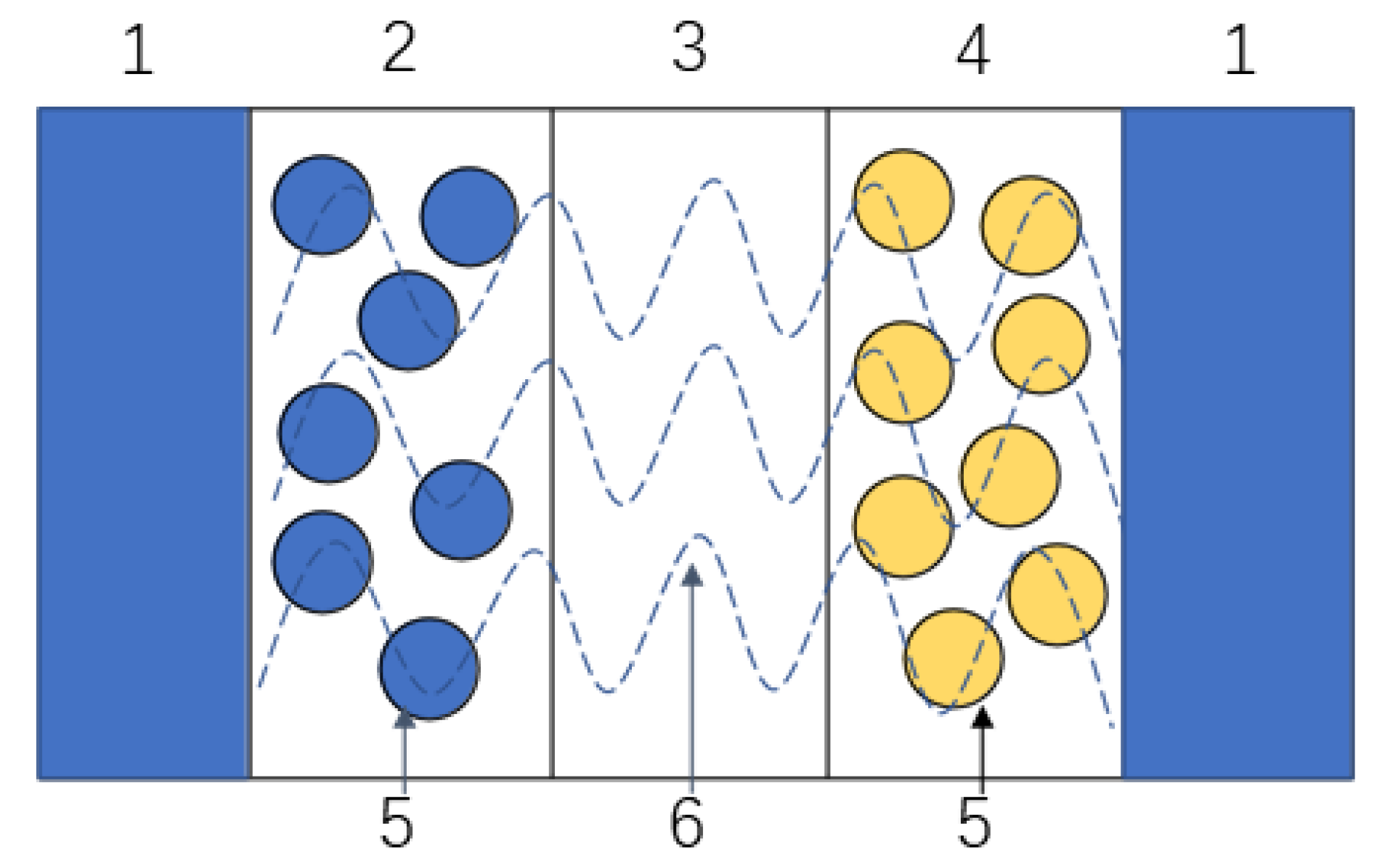

2.1. P2D Model

2.2. SP Model

2.3. Electrochemical Coupling Model

2.4. Comparison of Electrochemical Models

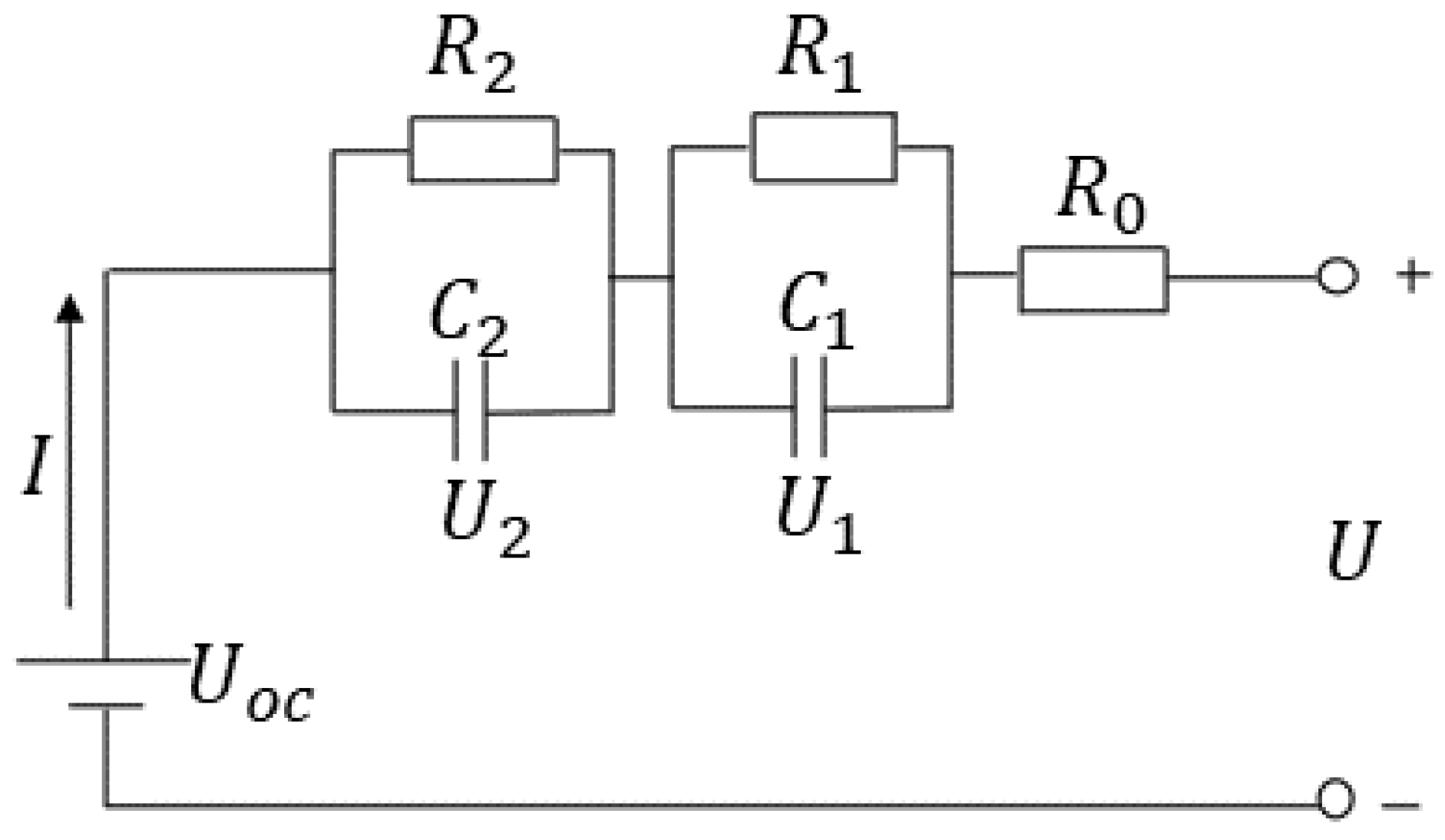

3. Method Based on Equivalent Circuit Model

3.1. Rint Model

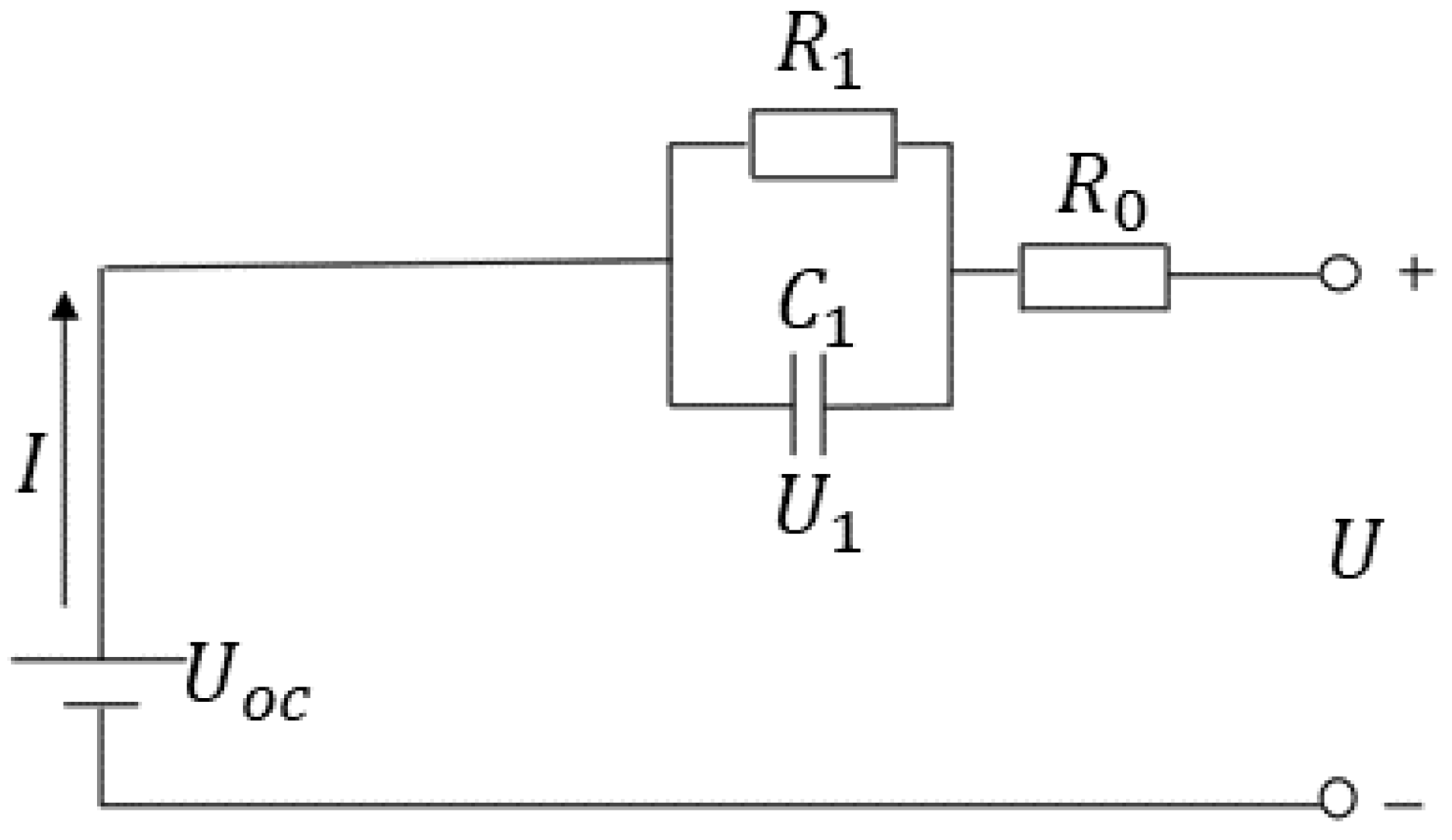

3.2. Thevenin Model

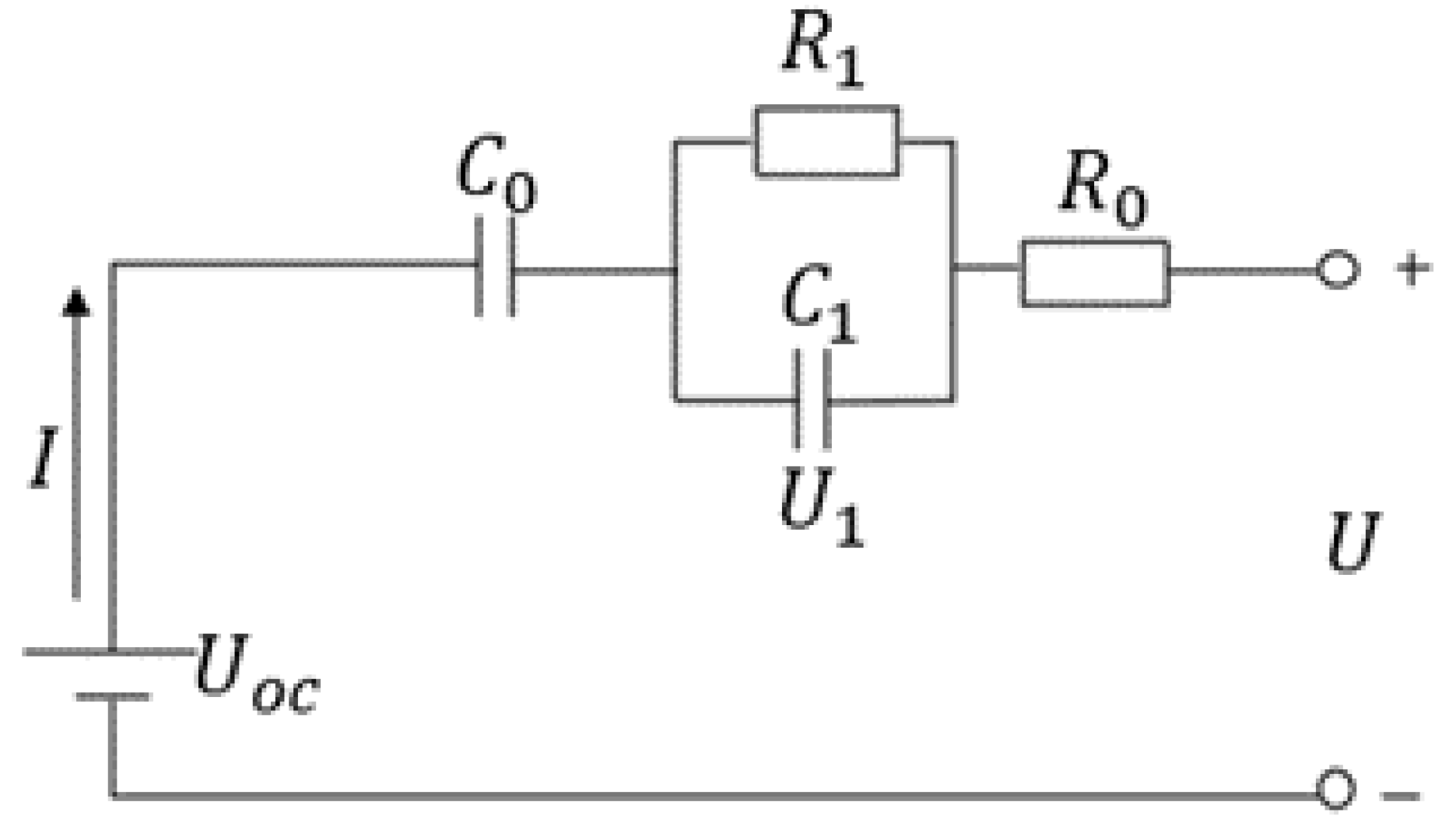

3.3. PNGV Model

3.4. RC Model

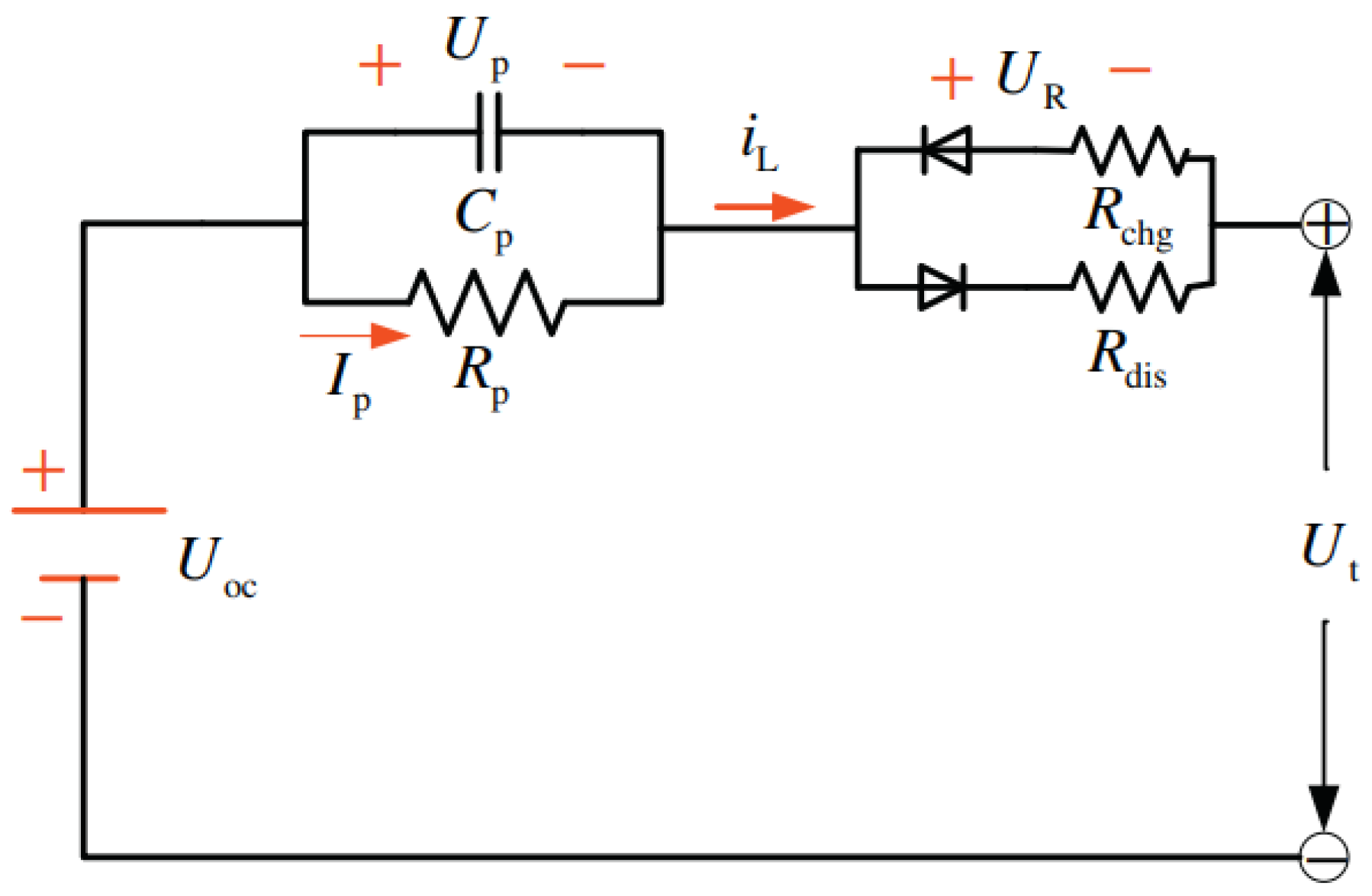

3.5. Comparison of Equivalent Circuit Models

4. An Empirical Model-Based Approach

4.1. Exponential Model

4.2. Polynomial Model

4.3. Exponential and Polynomial Mixed Model

4.4. Capacity Regeneration Model

4.5. Comparison of Empirical Models

4.5.1. KF Algorithm

4.5.2. PF Algorithm

5. Conclusions

- (1)

- To improve the efficiency of electrochemical model prediction, current research focuses on simplifying the model while considering as many factors as possible and determining the parameters by different methods. In addition, with the continuous development of modern technology, health factors are no longer limited to traditional parameters such as voltage and current. In the future, some new factors can be extracted by ultrasonic and infrared technologies to meet the requirements of small number and comprehensive reflection, thus improving the accuracy and range of prediction.

- (2)

- The simulation accuracy of a single equivalent circuit is low, so series resistors or capacitors were used to improve the dynamic stability during the study, which reduced the influence of environmental factors and incorporated parameter identification into the algorithm to compensate for the poor prediction accuracy. However, as the number of series-connected components increased, the cumulative error also increased. How to reduce this error is one of the focuses of future research on equivalent circuit models.

- (3)

- The empirical model-based RUL prediction method constructed a degradation model by fitting the historical degradation data of lithium-ion batteries with an empirical model, and used a filtering method to update the model parameters to achieve the RUL prediction of batteries. The simple empirical model established the relationship between the battery characteristics through complex mathematical formulas, which had a low prediction accuracy and poor stability. Based on this, PF, KF, and their improved filtering methods were used to update the data, and influence factors were added to improve the accuracy and reduce the error. Future research will focus on finding more comprehensive mathematical methods to construct empirical models and update the model data by other intelligent optimization methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tian, J.; Gao, H.; Zhang, Y.; Wang, Y. Research of life prediction methods for power Li-ion battery in electric vehicles. J. Power Sources 2020, 44, 767–770. [Google Scholar]

- Song, K.; Hu, D.; Tong, Y.; Yue, X.G. Remaining life prediction of lithium-ion batteries based on health management: A review. J. Energy Storage 2023, 57, 106193. [Google Scholar] [CrossRef]

- Zhao, J.H.; Zhu, Y.; Zhang, B.; Liu, M.Y.; Wang, J.X.; Liu, C.H.; Hao, X.W. Review of State Estimation and Remaining Useful Life Prediction Methods for Lithium-Ion Batteries. Sustainability 2023, 15, 5014. [Google Scholar] [CrossRef]

- Shao, L.Y.; Zhang, Y.; Zheng, X.J.; He, X.; Zheng, Y.F.; Liu, Z.W. A Review of Remaining Useful Life Prediction for Energy Storage Components Based on Stochastic Filtering Methods. Energies 2023, 16, 1469. [Google Scholar] [CrossRef]

- Deng, Y.; Li, J.; Li, T.; Gao, X.; Yuan, C. Life cycle assessment of lithium sulfur battery for electric vehicles. J. Power Sources 2017, 343, 284–295. [Google Scholar] [CrossRef]

- Barre, A.; Deguilhem, B.; Grolleau, S. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Deng, Y.L.; Li, J.Y.; Li, T.H.; Zhang, J.Y.; Yang, F.; Yuan, C. Life cycle assessment of high capacity molybdenum disulfide lithium ion battery for electric vehicles. Energy. 2017, 123, 77–88. [Google Scholar] [CrossRef]

- Hu, X.; Guo, Y.; Zhang, R. A Review of Lithium-ion Battery State of Health Estimation Methods. J. Power Supply 2021, 12, 113. [Google Scholar]

- Wu, L.; Fu, X.; Guan, Y. Review of the Remaining Useful Life Prognostics of Vehicle Lithium-Ion Batteries Using Data-Driven Methodologies. Appl. Sci. 2016, 6, 166. [Google Scholar] [CrossRef]

- Wang, X.X.; Liu, S.R.; Zhang, Y.J.; Lv, S.S.; Ni, H.J.; Deng, Y.L.; Yuan, Y.N. A Review of the Power Battery Thermal Management System with Different Cooling, Heating and Coupling System. Energies 2022, 15, 1963. [Google Scholar] [CrossRef]

- Hu, X.S.; Xu, L.; Lin, X.K. Battery Lifetime Prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H.; Moyeen, S.I.; Das, S.K.; Ali, M.F.; Islam, M.R.; et al. A Comprehensive Review of Available Battery Datasets, RUL Prediction Approaches, and Advanced Battery Management. IEEE Access 2021, 9, 86166–86193. [Google Scholar] [CrossRef]

- Pandey, S.V.; Parikh, N.; Prochowicz, D.; Akin, S.; Satapathi, S.; Tavakoli, M.M.; Kalam, A.; Yadav, P. Predicting the state parameters of lithium ion batteries: The race between filter-based and data driven approaches. Sustain. Energy Fuels 2023, 7, 598–628. [Google Scholar] [CrossRef]

- Cai, Y.; Chen, W.; Su, Y.; Jiang, K.; Huang, H. Review of remaining useful life prediction for lithium ion batteries. J. Power Sources 2021, 45, 678–682. [Google Scholar]

- Wang, S.; Han, W.; Chen, L.; Su, X. Prediction of lithium ion batteries remaining useful life based on particle filtering method. J. Power Sources 2020, 44, 346–351. [Google Scholar]

- Jokar, A.; Rajabloo, B.; Désilets, M.; Lacroix, M. Review of simplified Pseudo-two-Dimensional models of lithium-ion batteries. J. Power Sources 2016, 327, 44–55. [Google Scholar] [CrossRef]

- Guo, M.; Kim, G.; White, R. A three-dimensional multi-physics model for a Li-ion battery. J. Power Sources 2013, 240, 80–94. [Google Scholar] [CrossRef]

- Zhou, J.; Xing, B.; Wang, C. A review of lithium ion batteries electrochemical models for electric vehicles. E3S Web Conf. 2020, 185, 04001. [Google Scholar] [CrossRef]

- Kuchly, J.; Goussian, A.; Merveillaut, M.; Baghdadi, I.; Franger, S.; Nelson-Gruel, D.; Chamaillard, Y. Li-ion battery SOC estimation method using a neural network trained with data generated by a P2D model. IFAC Pap. 2021, 54, 336–343. [Google Scholar] [CrossRef]

- Jiang, G.; Zhuang, L.; Hu, Q.; Liu, Z.; Huang, J. An investigation of heat transfer and capacity fade in a prismatic Li-ion battery based on an electrochemical-thermal coupling model. Appl. Therm. Eng. 2020, 171, 115080. [Google Scholar] [CrossRef]

- Li, J.; Xiao, H. Review on modeling of lithium-ion battery. Energy Storage Sci. Technol. 2022, 11, 697–703. [Google Scholar]

- Li, X.; Yu, Y.; Zhang, Z.; Dong, X. Study on external characteristics of lithium-ion power battery based on ADME model. Acta Phys. Sin. 2022, 71, 345–353. [Google Scholar]

- Deng, Z.; Yang, L.; Deng, H. Polynomial approximation pseudo-two-dimensional battery model for online application in embedded battery management system. Energy 2018, 142, 838–850. [Google Scholar] [CrossRef]

- Li, C.; Cui, N.; Wang, C. Reduced-order electrochemical model for lithium-ion battery with domain decomposition and polynomial approximation methods. Energy 2021, 221, 119662. [Google Scholar] [CrossRef]

- Kim, J.; Chun, H.; Kim, M. Effective and practical parameters of electrochemical Li-ion battery models for degradation diagnosis. J. Energy Storage 2021, 42, 103077. [Google Scholar] [CrossRef]

- Li, J.; Zou, L.; Tian, F. Parameter Identification of Lithium-Ion Batteries Model to Predict Discharge Behaviors Using Heuristic Algorithm. J. Electrochem. Soc. 2016, 163, A1646–A1652. [Google Scholar] [CrossRef]

- Laue, V.; Röder, F.; Krewer, U. Practical identifiability of electrochemical P2D models for lithium-ion batteries. J. Appl. Electrochem. 2021, 51, 1253–1265. [Google Scholar] [CrossRef]

- Xu, L.; Lin, X.; Xie, Y.; Hu, X. Enabling high-fidelity electrochemical P2D modeling of lithium-ion batteries via fast and non-destructive parameter identification. Energy Storage Mater. 2022, 45, 952–968. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, X.; Gao, Y.; Guo, B. Estimating state of Li-ion battery based on reduced-order electrochemical model. Battery 2021, 51, 110–113. [Google Scholar]

- Li, J.; Landers, R.; Park, J. A comprehensive single-particle-degradation model for battery state-of-health prediction. J. Power Sources 2020, 456, 227950. [Google Scholar] [CrossRef]

- Cen, Z.; Kubiak, P. Lithium-ion battery SOC/SOH adaptive estimation via simplified single particle model. Int. J. Energy Res. 2020, 44, 12444–12459. [Google Scholar] [CrossRef]

- Zhou, X.; Stein, J.; Ersal, T. Battery state of health monitoring by estimation of the number of cyclable Li-ions. Control Eng. Pract. 2017, 66, 51–63. [Google Scholar] [CrossRef]

- Bi, Y.; Yin, Y.; Choe, S. Online state of health and aging parameter estimation using a physics-based life model with a particle filter. J. Power Sources 2020, 476, 228655. [Google Scholar] [CrossRef]

- Sadabadi, K.; Jin, X.; Rizzoni, G. Prediction of remaining useful life for a composite electrode lithium ion battery cell using an electrochemical model to estimate the state of health. J. Power Sources 2021, 481, 228861. [Google Scholar] [CrossRef]

- Li, J.; Wang, D.; Deng, L. Aging modes analysis and physical parameter identification based on a simplified electrochemical model for lithium-ion batteries. J. Energy Storage 2020, 31, 101538. [Google Scholar] [CrossRef]

- Li, J.; Adewuyi, K.; Lotfi, N.; Landers, R.; Park, J. A single particle model with chemical/mechanical degradation physics for lithium ion battery State of Health (SOH) estimation. Appl. Energy 2018, 212, 1178–1190. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Prasad, G.; Rahn, C. Model based identification of aging parameters in lithium ion batteries. J. Power Sources 2013, 232, 79–85. [Google Scholar] [CrossRef]

- Han, X.; Ouyang, M.; Lu, L.; Li, J. Simplification of physics-based electrochemical model for lithium ion battery on electric vehicle. Part II: Pseudo-two-dimensional model simplification and state of charge estimation. J. Power Sources 2015, 278, 814–825. [Google Scholar] [CrossRef]

- Lin, C.; Tang, A. Simplification and efficient simulation of electrochemical model for Li-ion battery in EVs. Energy Procedia 2016, 104, 68–73. [Google Scholar] [CrossRef]

- Kuang, K.; Sun, Y.; Ren, D.; Han, X.; Zheng, Y.; Geng, Z. Efficient Approach for Electrochemical-thermal Coupled Modeling of Large-format Lithium-ion Power Battery. J. Mech. Eng. 2021, 57, 10–22. [Google Scholar]

- Wang, D.; Zhang, Q.; Huang, H. An electrochemical–thermal model of lithium-ion battery and state of health estimation. J. Energy Storage 2021, 47, 103528. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, D.; Yang, B. Electrochemical model of lithium-ion battery for wide frequency range applications. Electrochim. Acta 2020, 343, 136094. [Google Scholar] [CrossRef]

- Li, J.; Wang, L.; Lyu, C.; Wang, H.; Liu, X. New method for parameter estimation of an electrochemical-thermal coupling model for LiCoO2 battery. J. Power Sources 2016, 307, 220–230. [Google Scholar] [CrossRef]

- He, Y.; Liu, X.; Zhang, C.; Chen, Z. Insulation detection algorithm for high-power battery system based on internal resistance model. J. Jilin Univ. 2013, 43, 1165–1170. [Google Scholar]

- Lei, Y.; Li, R.; Yu, J.; Liu, J.; Liu, F. Estimation of Lithium-ion Batteries’ SOC Based on Equivalent Circuit Model and CDKF. J. Chang. Aviat. Vocat. Tech. Coll. 2021, 21, 42–46. [Google Scholar]

- He, H.; Xiong, R.; Zhang, X.; Sun, F.; Fan, J. State-of-charge estimation of the lithium-ion battery using an adaptive extended Kalman filter based on an improved Thevenin model. IEEE Trans. Veh. Technol. 2011, 60, 1461–1469. [Google Scholar]

- Xiong, R.; He, H.; Zhao, K. Research on an online identification algorithm for a thevenin battery model by an experimental approach. Int. J. Green Energy 2015, 12, 272–278. [Google Scholar] [CrossRef]

- Fang, Y.; Cheng, X.; Yin, Y. SOC Estimation of Lithium-Ion Battery Packs Based on Thevenin Model. Appl. Mech. Mater. 2021, 7, 1271–1284. [Google Scholar] [CrossRef]

- Salazar, D.; Garcia, M. Estimation and Comparison of SOC in Batteries Used in Electromobility Using the Thevenin Model and Coulomb Ampere Counting. Energies 2022, 15, 7204. [Google Scholar] [CrossRef]

- Wang, W.; Yao, W.; Chen, W. Failure Warning at the End of Service-Life of Lead-Acid Batteries for Backup Applications. Appl. Sci. 2020, 10, 5760. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Z.; Lin, W. A new state-of-health estimation method for lithium-ion batteries through the intrinsic relationship between ohmic internal resistance and capacity. Measurement 2018, 116, 586–595. [Google Scholar] [CrossRef]

- Hossain, M.; Saha, S.; Arif, M. A Parameter Extraction Method for the Li-Ion Batteries with Wide-Range Temperature Compensation. IEEE Trans. Ind. Appl. 2020, 56, 5625–5636. [Google Scholar] [CrossRef]

- Nikohan, A.; Jaguemont, J.; de Hoog, J. Complete cell-level lithium-ion electrical ECM model for different chemistries (NMC, LFP, LTO) and temperatures (−5 degrees C to 45 degrees C)—Optimized modelling techniques. Int. J. Electr. Power Energy Syst. 2018, 98, 133–146. [Google Scholar]

- Ding, X.; Zhang, D.; Cheng, J.; Wang, B.; Luk, P. An improved Thevenin model of lithium-ion battery with high accuracy for electric vehicles. Appl. Energy 2019, 254, 113615. [Google Scholar] [CrossRef]

- Lyu, Z.; Gao, R. Li-ion battery state of health estimation through Gaussian process regression with Thevenin model. Int. J. Energy Res. 2020, 44, 10262–10281. [Google Scholar] [CrossRef]

- Sun, F. Model-based dynamic multi-parameter method for peak power estimation of lithium–ion batteries. Appl. Energy 2012, 96, 378–386. [Google Scholar] [CrossRef]

- Liu, D.; Fan, Y.; Wang, S.; Xia, L. Estimation of Li-ion battery SOC based on RFMRA and improved PNGV model. Battery 2021, 51, 470–473. [Google Scholar]

- Huang, Z.; Fang, Y.; Xu, J. Soc Estimation of Li-Ion Battery Based on Improved Ekf Algorithm. Int. J. Automot. Technol. 2021, 22, 335–340. [Google Scholar] [CrossRef]

- Li, P. An improved PNGV modeling and SOC estimation for lithium iron phosphate batteries. Environ. Mater. Sci. 2017, 94, 012012. [Google Scholar] [CrossRef]

- Lin, P.; Jin, P.; Zou, A. Real-time identification of partnership for a new generation of vehicles battery model parameters based on the model reference adaptive system. Int. J. Energy Res. 2021, 45, 9351–9368. [Google Scholar] [CrossRef]

- Liu, X.; Li, W.; Zhou, A. PNGV equivalent circuit model and SOC estimation algorithm for lithium battery pack adopted in AGV vehicle. IEEE Access 2018, 6, 23639–23647. [Google Scholar] [CrossRef]

- Gao, W.; Jiang, M.; Hou, Y. Research on PNGV model parameter identification of LiFePO4 Li-ion battery based on FMRLS. In Proceedings of the 2011 6th IEEE Conference on Industrial Electronics and Applications, Beijing, China, 21–23 June 2011; pp. 2294–2297. [Google Scholar]

- Yuyang, L. Research on Li-ion battery modeling and SOC estimation based on online parameter identification and improved 2RC-PNGV model. Energy Storage Sci. Technol. 2021, 10, 2312. [Google Scholar]

- Wei, X.; Mom, Y.; Feng, Z. Lithium-ion Battery Modeling and State of Charge Estimation. Integr. Ferroelectr. 2019, 200, 59–72. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, X.; Hou, G. State of health estimation for lithium ion batteries based on charging curves. J. Power Sources 2014, 249, 457–462. [Google Scholar] [CrossRef]

- Yang, J.; Xia, B.; Huang, W. Online state-of-health estimation for lithium-ion batteries using constant-voltage charging current analysis. Appl. Energy 2018, 212, 1589–1600. [Google Scholar] [CrossRef]

- Bi, J.; Zhang, T.; Yu, H. State-of-health estimation of lithium-ion battery packs in electric vehicles based on genetic resampling particle filter. Appl. Energy 2016, 182, 558–568. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, L.; Lv, T.; Si, X. SOC estimation for Li-ion battery based on improved model. Battery 2021, 51, 445–449. [Google Scholar]

- Gao, X.; Han, S. Collaborative estimation of SOC and SOH of Li-ion battery based on fractional order model. J. Power Sources 2021, 45, 1140–1143. [Google Scholar]

- Cheng, Z.; Wang, L.; Liu, J. Estimation of State of Charge of Lithium-Ion Battery Based on Photovoltaic Generation Energy Storage System. Teh. Vjesn. Tech. Gaz. 2016, 23, 695–700. [Google Scholar]

- Guha, A.; Patra, A. Online Estimation of the Electrochemical Impedance Spectrum and Remaining Useful Life of Lithium-Ion Batteries. IEEE Trans. Instrum. Meas. 2018, 67, 1836–1849. [Google Scholar] [CrossRef]

- Nejad, S.; Gladwin, D.; Stone, D. Sensitivity of lumped parameter battery models to constituent parallel-RC element parameterisation error. In Proceedings of the IECON 2014—40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 5660–5665. [Google Scholar]

- Ji, Y.; Qiu, S.; Li, G. Simulation of second-order RC equivalent circuit model of lithium battery based on variable resistance and capacitance. J. Cent. South Univ. 2020, 27, 2606–2613. [Google Scholar] [CrossRef]

- Deng, L.; Shen, W.; Wang, H. A rest-time-based prognostic model for remaining useful life prediction of lithium-ion battery. Neural Comput. Appl. 2021, 33, 2035–2046. [Google Scholar] [CrossRef]

- Huang, Z.; Yang, F. Quality classification of lithium battery in microgrid networks based on smooth localized complex exponential model. Complexity 2021, 2021, 6618708. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Y.; Li, B.; Luo, D. Battery states online estimation based on exponential decay particle swarm optimization and proportional-integral observer with a hybrid battery model. Energy 2020, 191, 116509. [Google Scholar] [CrossRef]

- Su, X.; Wang, S.; Pecht, M.; Zhao, L.; Ye, Z. Interacting multiple model particle filter for prognostics of lithium-ion batteries. Microelectron. Reliab. 2017, 70, 59–69. [Google Scholar] [CrossRef]

- Meyer, C.; Bockholt, H.; Haselrieder, W.; Kwade, A. Characterization of the calendering process for compaction of electrodes for lithium-ion batteries. J. Mater. Process. Technol. 2017, 249, 172–178. [Google Scholar] [CrossRef]

- Su, X.; Wang, S.; Pecht, M. Prognostics of lithium-ion batteries based on different dimensional state equations in the particle filtering method. Trans. Inst. Meas. Control 2017, 39, 1537–1546. [Google Scholar] [CrossRef]

- Abdollahi, A.; Han, X.; Raghunathan, N. Optimal charging for general equivalent electrical battery model, and battery life management. J. Energy Storage 2017, 9, 47–58. [Google Scholar] [CrossRef]

- Qin, W.; Lv, H.; Liu, C. Remaining useful life prediction for lithium-ion batteries using particle filter and artificial neural network. Ind. Manag. Data Syst. 2020, 120, 312–328. [Google Scholar] [CrossRef]

- Zhang, L.; Mu, Z.; Sun, C. Remaining useful life prediction for lithium-ion batteries based on exponential model and particle filter. IEEE Access 2018, 6, 17729–17740. [Google Scholar] [CrossRef]

- Ma, P.; Wang, S.; Zhao, L.; Pecht, M.; Su, X.; Ye, Z. An improved exponential model for predicting the remaining useful life of lithium-ion batteries. IEEE Conf. Progn. Health Manag. 2015, 62, 7762–7773. [Google Scholar]

- Yang, F.; Wang, D.; Xing, Y.; Tsui, K. Prognostics of Li (NiMnCo) O2-based lithium-ion batteries using a novel battery degradation model. Microelectron. Reliab. 2017, 70, 70–78. [Google Scholar] [CrossRef]

- Tseng, K.; Liang, J.; Chang, W.; Huang, S. Regression models using fully discharged voltage and internal resistance for state of health estimation of lithium-ion batteries. Energies 2015, 8, 2889–2907. [Google Scholar] [CrossRef]

- Feng, H.; Shi, G. SOH and RUL prediction of Li-ion batteries based on improved Gaussian process regression. J. Power Electron. 2021, 21, 1845–1854. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, G.; Zhao, J. Online Equivalent Degradation Indicator Calculation for Remaining Charging-Discharging Cycle Determination of Lithium-Ion Batteries. IEEE Trans. Veh. Technol. 2021, 70, 6613–6625. [Google Scholar] [CrossRef]

- Methekar, R. Computationally inexpensive dual filter approach for estimation and control of SOC for the lithium-ion battery. J. Renew. Sustain. Energy 2018, 10, 034104. [Google Scholar] [CrossRef]

- Sun, Y.; Hao, X.; Pecht, M. Remaining useful life prediction for lithium-ion batteries based on an integrated health indicator. Microelectron. Reliab. 2018, 88–90, 1189–1194. [Google Scholar] [CrossRef]

- Azis, N.; Joelianto, E.; Widyotriatmo, A. State of charge (SoC) and state of health (SoH) estimation of lithium-ion battery using dual extended kalman filter based on polynomial battery model. In Proceedings of the 2019 6th International Conference on Instrumentation, Control, and Automation (ICA), Bandung, Indonesia, 31 July–2 August 2019; pp. 88–93. [Google Scholar]

- Wang, S.; Han, W.; Chen, L. Experimental verification of lithium-ion battery prognostics based on an interacting multiple model particle filter. Trans. Inst. Meas. Control. 2020, 1576. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.; Tsui, K. An ensemble model for predicting the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Wang, Q.; He, Y.; Shen, J.; Hu, X.; Ma, Z. State of charge-dependent polynomial equivalent circuit modeling for electrochemical impedance spectroscopy of lithium-ion batteries. IEEE Trans. Power Electron. 2017, 33, 8449–8460. [Google Scholar] [CrossRef]

- Guo, W.; He, M. An optimal relevance vector machine with a modified degradation model for remaining useful lifetime prediction of lithium-ion batteries. Appl. Soft Comput. 2022, 124, 108967. [Google Scholar] [CrossRef]

- Guha, A.; Patra, A. State of Health Estimation of Lithium-Ion Batteries Using Capacity Fade and Internal Resistance Growth Models. IEEE Trans. Transp. Electrif. 2018, 4, 135–146. [Google Scholar] [CrossRef]

- Pan, C.; Chen, Y.; Wang, L. Lithium-ion Battery Remaining Useful Life Prediction Based on Exponential Smoothing and Particle Filter. Int. J. Electrochem. Sci. 2019, 14, 9537–9551. [Google Scholar] [CrossRef]

- Li, J.; Lin, C.; Chen, K. Cycle Life Prediction of Aged Lithium-Ion Batteries from the Fading Trajectory of a Four-Parameter Model. J. Electrochem. Soc. 2018, 165, A3634–A3641. [Google Scholar] [CrossRef]

- Pang, X.; Huang, R.; Wen, J.; Shi, Y.; Jia, J.; Zeng, J. A lithium-ion battery RUL prediction method considering the capacity regeneration phenomenon. Energies 2019, 12, 2247. [Google Scholar] [CrossRef]

- Ma, Q.; Zheng, Y.; Yang, W.; Zhang, Y.; Zhang, H. Remaining useful life prediction of lithium battery based on capacity regeneration point detection. Energy 2021, 234, 121233. [Google Scholar] [CrossRef]

- Li, Q.; Li, R.; Ji, K. Kalman filter and its application. In Proceedings of the 2015 8th International Conference on Intelligent Networks and Intelligent Systems (ICINIS), Tianjin, China, 1–3 November 2015; pp. 74–77. [Google Scholar]

- Kunsch, H. Particle filters. Bernoulli 2013, 19, 1391–1403. [Google Scholar] [CrossRef]

| Model | Advantages | Disadvantages | Prediction Accuracy | Complexity |

|---|---|---|---|---|

| P2D model | It can describe the internal dynamic behavior of the battery, and has the advantages of accurate model and high calculation accuracy. | There are many parameters in the model and the calculation is complicated and the efficiency is low. | High ★★★★☆ | High ★★★★☆ |

| SP model | The modeling complexity is low and the calculation accuracy is high. | The physical properties of electrolyte are ignored and the problem of order reduction is not considered. | Higher ★★★★★ | Lower ★★☆☆☆ |

| Electrochemical fusion model | Strong robustness and high prediction accuracy. | The model is complicated due to the large amount of calculation and many optimization parameters. | High ★★★★☆ | High ★★★★☆ |

| Model | Advantages | Disadvantages | Prediction Accuracy | Complexity |

|---|---|---|---|---|

| Rint model | The model is simple and the parameter calculation is simple. | Unable to describe dynamic processes, poor accuracy when using high current, ignoring battery characteristics. | Lower ★★☆☆☆ | Lower ★★☆☆☆ |

| Thevenin model | In practical engineering applications, the polarization effect and battery characteristics are considered. | The stability of the model is poor, and factors such as battery aging and temperature change have great influence on the accuracy of the model. | Medium ★★★☆☆ | Medium ★★★☆☆ |

| PNGV model | Considering the influence of temperature, the model is robust and accurate. | The cumulative error of series capacitance will reduce the model accuracy and cannot reflect the polarization phenomenon well. | High ★★★★☆ | Medium ★★★☆☆ |

| RC model | The calculation is moderate and the model has high precision, which is closer to the real battery characteristics. | The calculation of structure and parameters is complicated. | High ★★★★☆ | High ★★★★☆ |

| Classification | Advantages | Disadvantages |

|---|---|---|

| Exponential model | For the nonlinear stage of capacity degradation, the fitting degree is high. | The linear stage of capacity degradation is poorly treated. |

| Polynomial model | The fitting degree is high for the linear stage of capacity degradation. | The nonlinear stage of capacity degradation is poorly treated. |

| A hybrid exponential and polynomial model | High accuracy and strong robustness. | Complex structure and many parameters. |

| Capacity degradation model | Besides the charge and discharge state of the battery, the rest state of the battery is also considered. | Insensitive to capacity degradation and regeneration. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Ye, P.; Liu, S.; Zhu, Y.; Deng, Y.; Yuan, Y.; Ni, H. Research Progress of Battery Life Prediction Methods Based on Physical Model. Energies 2023, 16, 3858. https://doi.org/10.3390/en16093858

Wang X, Ye P, Liu S, Zhu Y, Deng Y, Yuan Y, Ni H. Research Progress of Battery Life Prediction Methods Based on Physical Model. Energies. 2023; 16(9):3858. https://doi.org/10.3390/en16093858

Chicago/Turabian StyleWang, Xingxing, Peilin Ye, Shengren Liu, Yu Zhu, Yelin Deng, Yinnan Yuan, and Hongjun Ni. 2023. "Research Progress of Battery Life Prediction Methods Based on Physical Model" Energies 16, no. 9: 3858. https://doi.org/10.3390/en16093858

APA StyleWang, X., Ye, P., Liu, S., Zhu, Y., Deng, Y., Yuan, Y., & Ni, H. (2023). Research Progress of Battery Life Prediction Methods Based on Physical Model. Energies, 16(9), 3858. https://doi.org/10.3390/en16093858