Investigation of Heat Extraction in an Enhanced Geothermal System Embedded with Fracture Networks Using the Thermal–Hydraulic–Mechanical Coupling Model

Abstract

1. Introduction

2. Physical and Mathematical Models

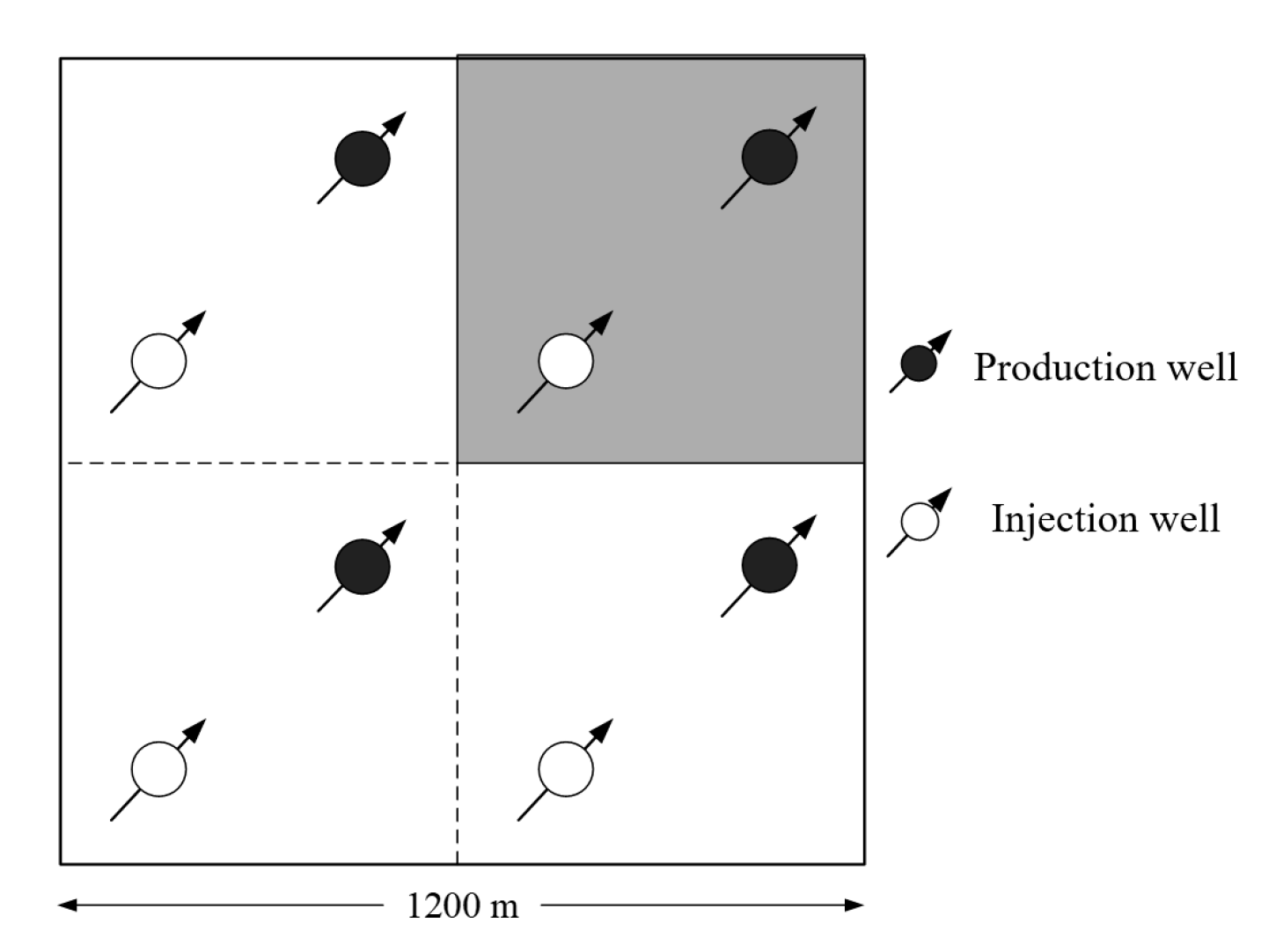

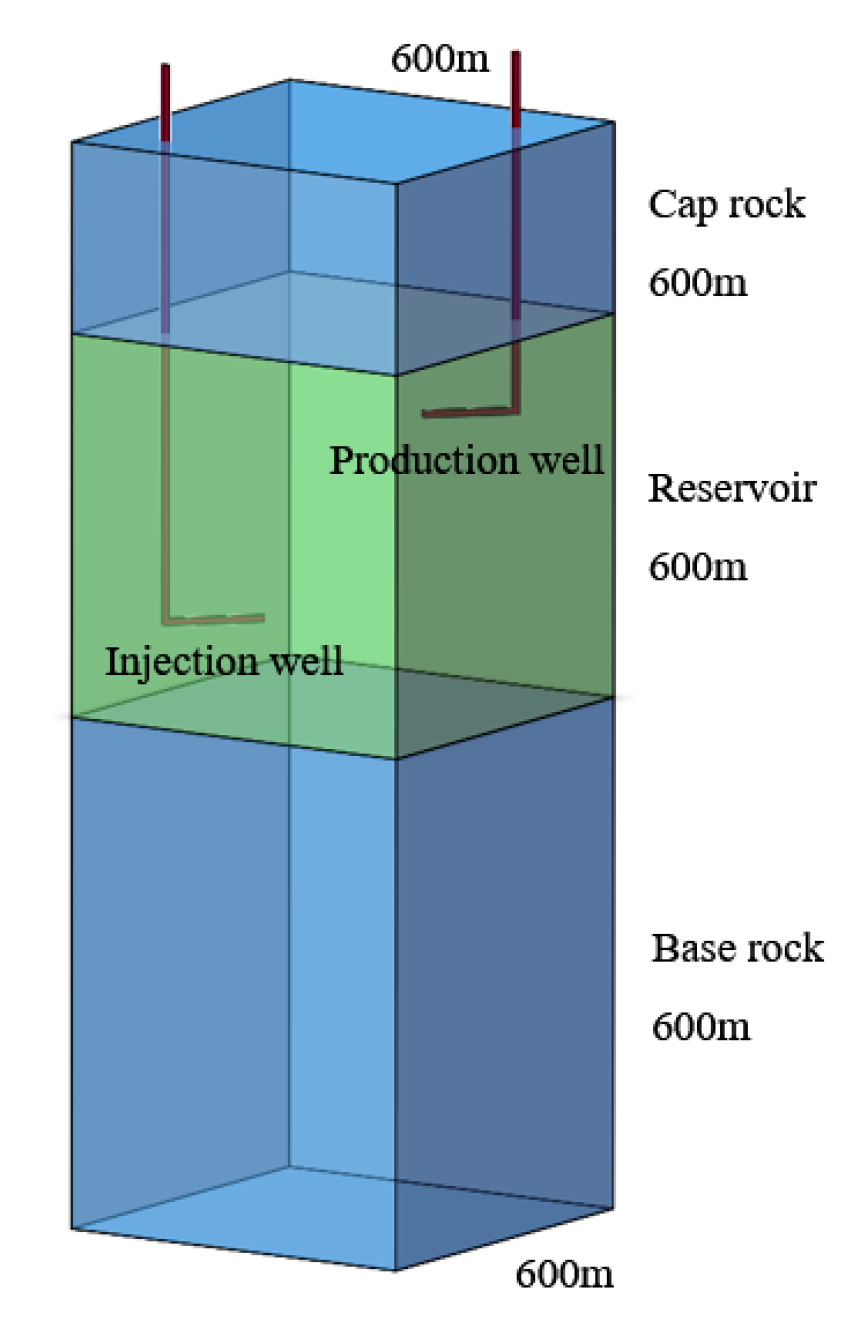

2.1. Physical Model and Boundary Conditions

2.2. Governing Equations

2.3. Embedded Discrete Fracture Model

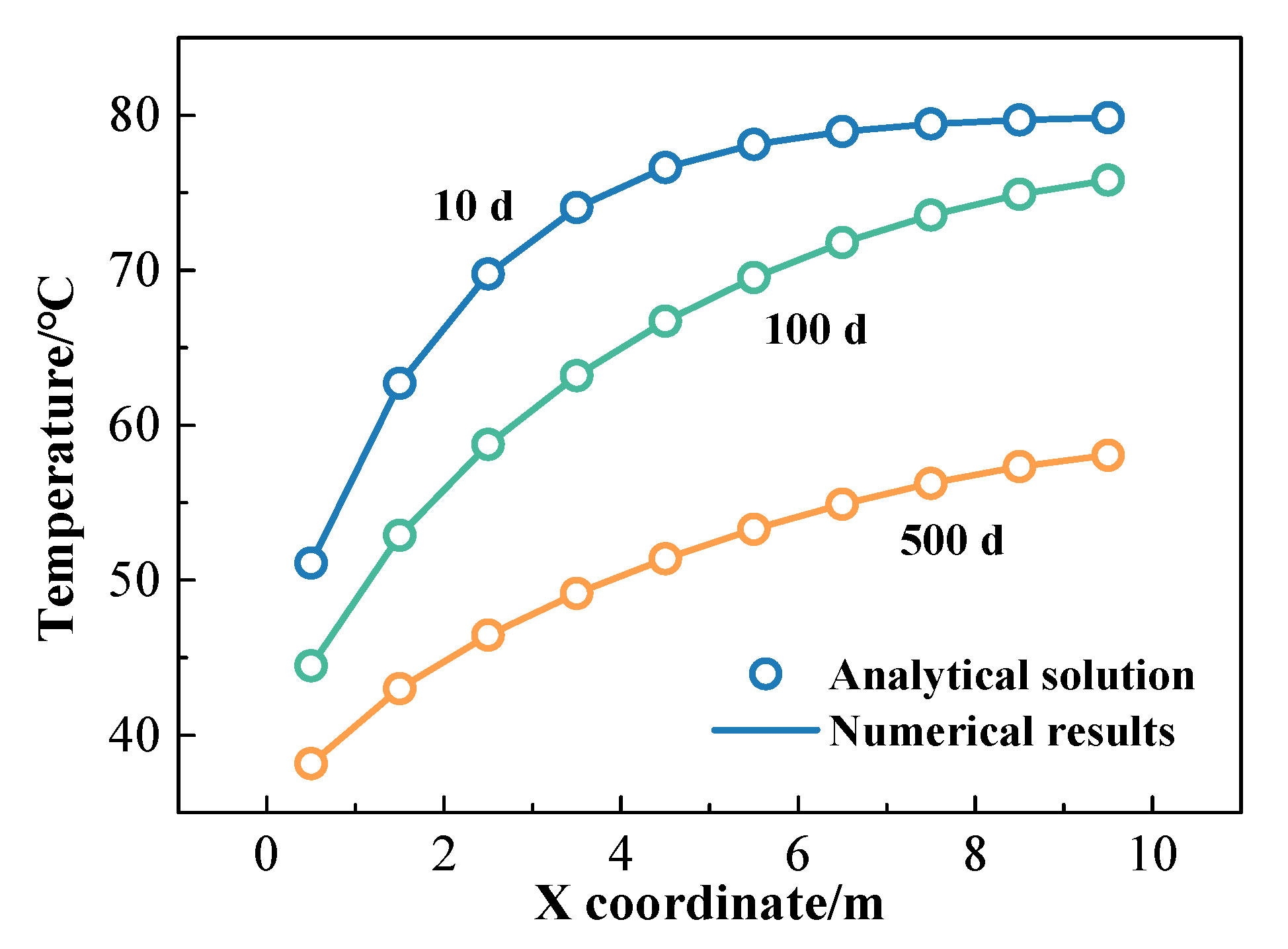

2.4. Method and Model Verification

3. Results and Discussion

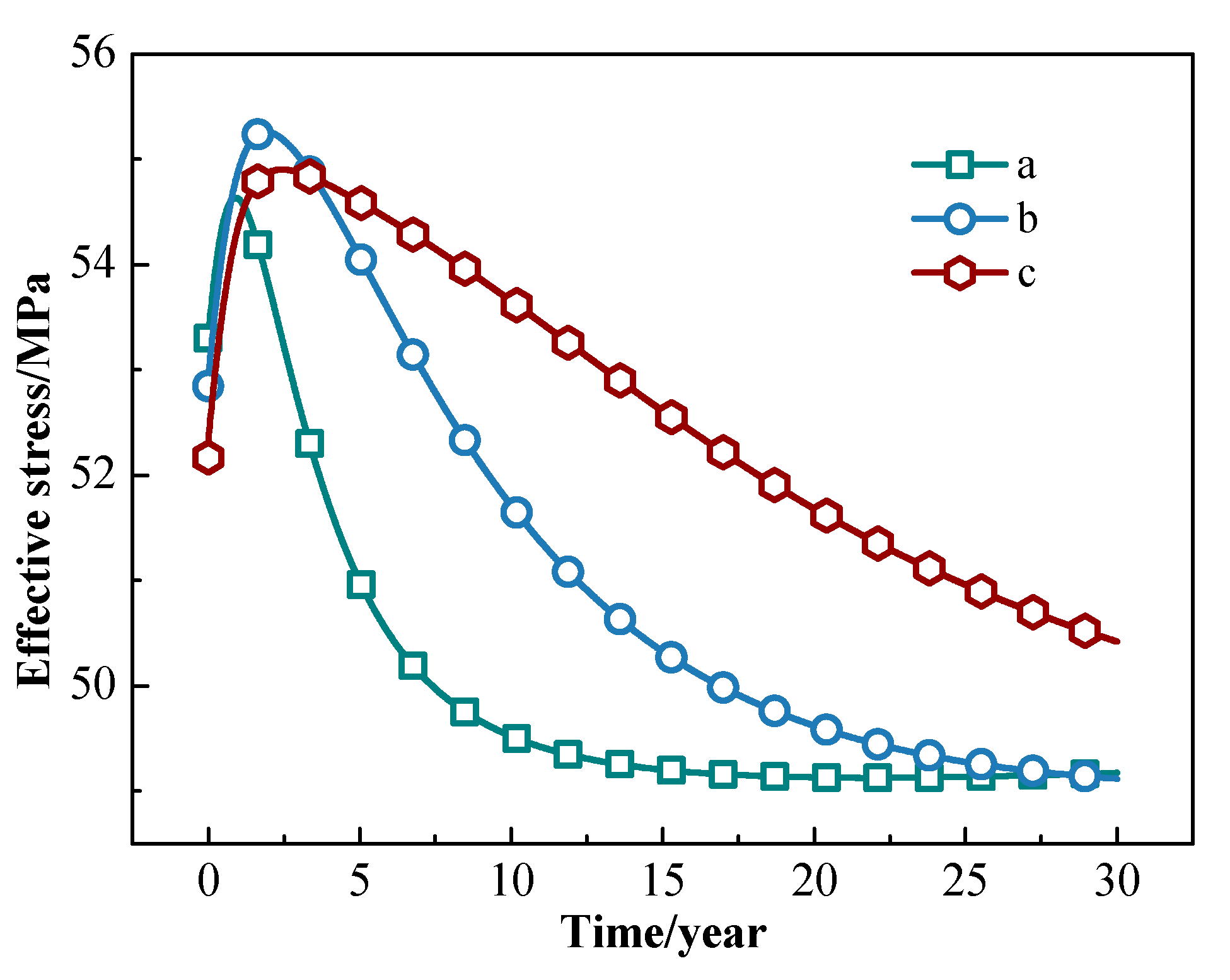

3.1. Thermal-Hydraulic-Mechanical Characteristics of EGS with Fracture Networks

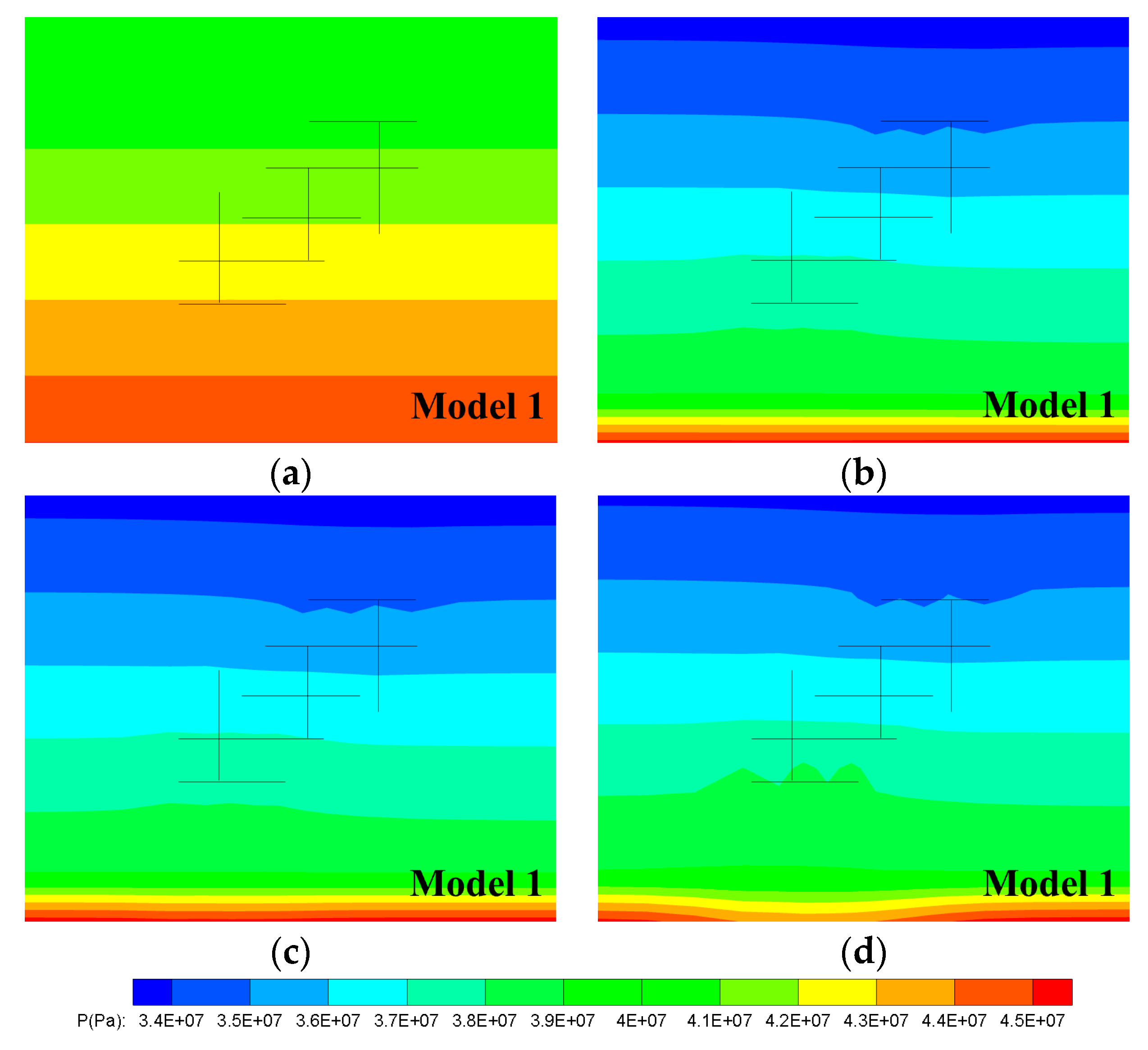

3.1.1. Evolution of Pressure Field

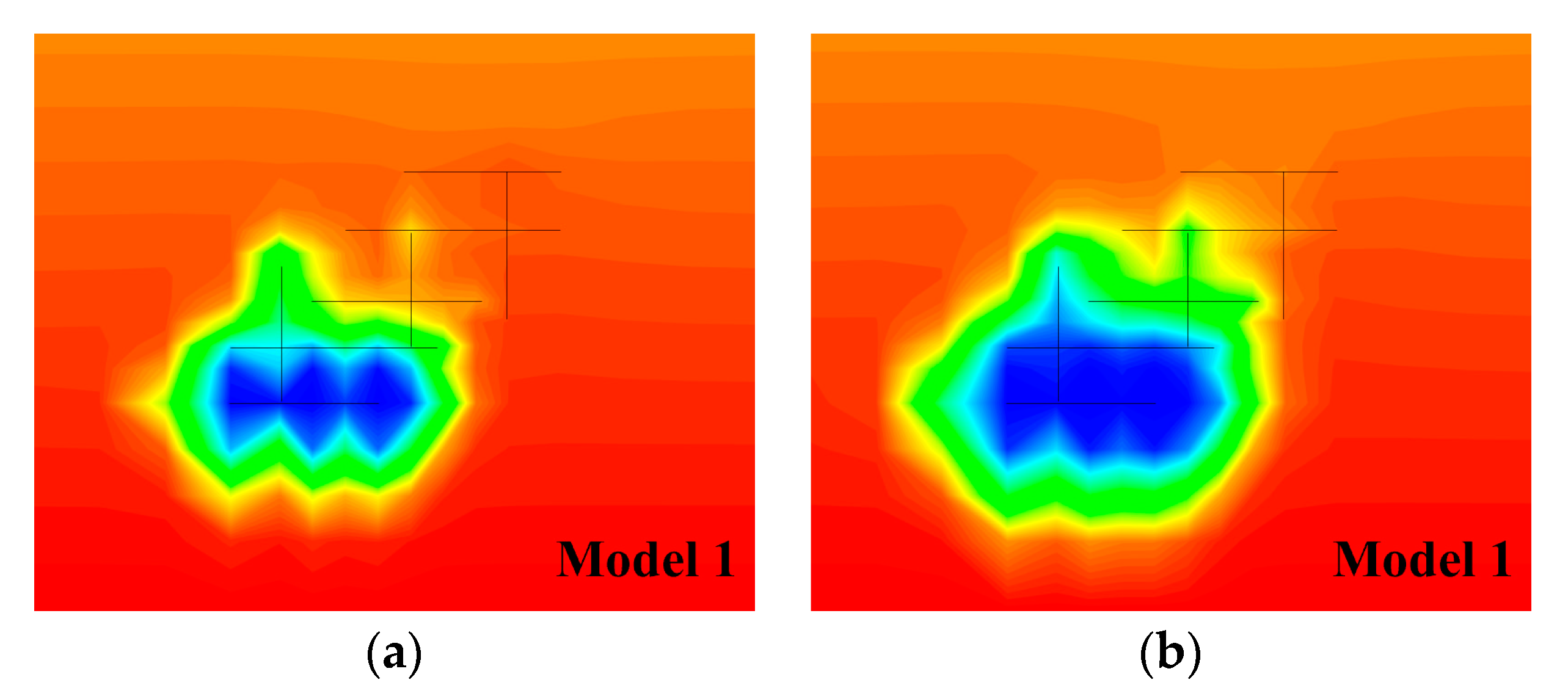

3.1.2. Evolution of Temperature Field

3.1.3. Evolution of Effective Stress Field

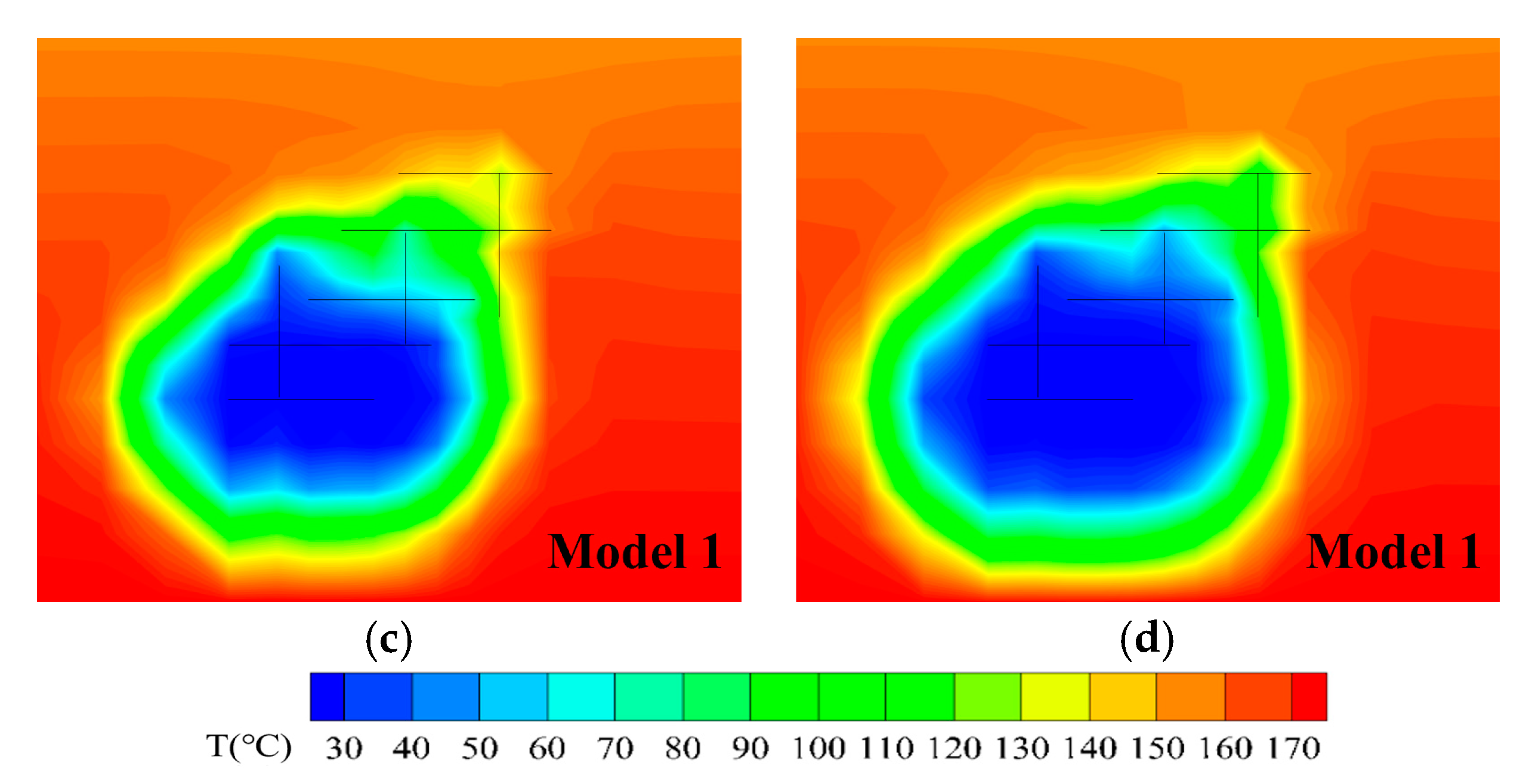

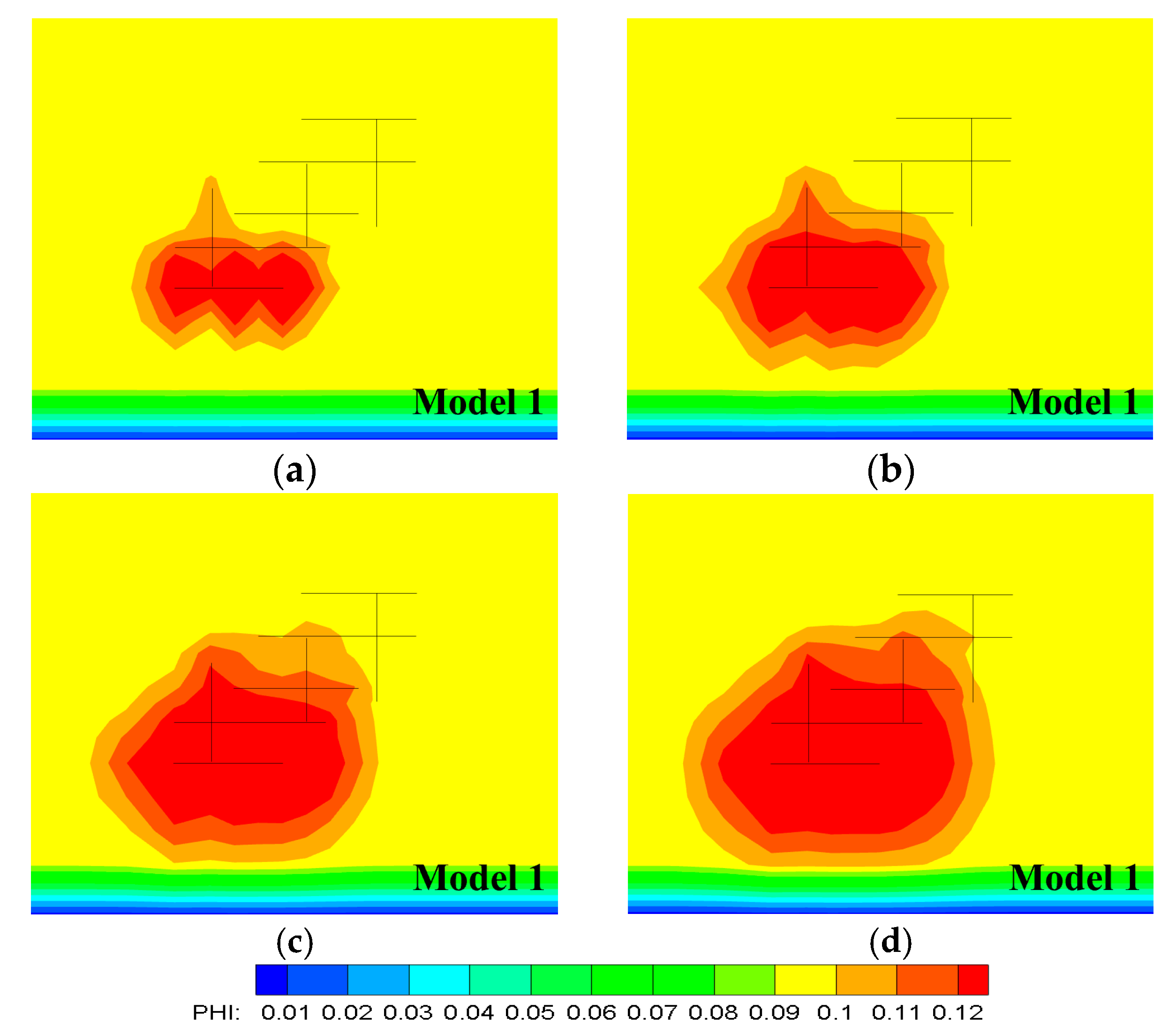

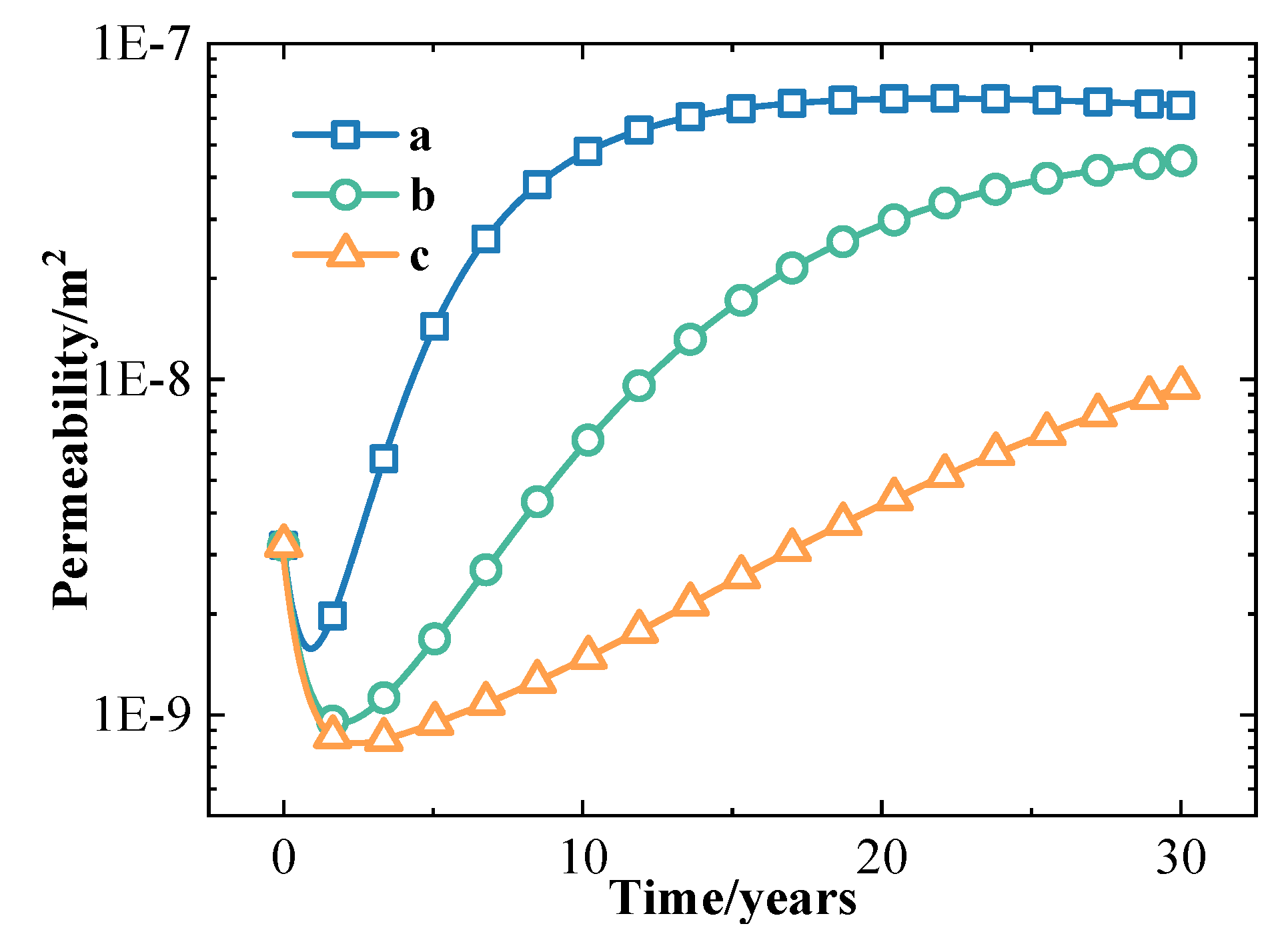

3.1.4. Evolution of Porosity and Permeability Properties

3.2. Parametric Study of the Thermal Recovery Capacity

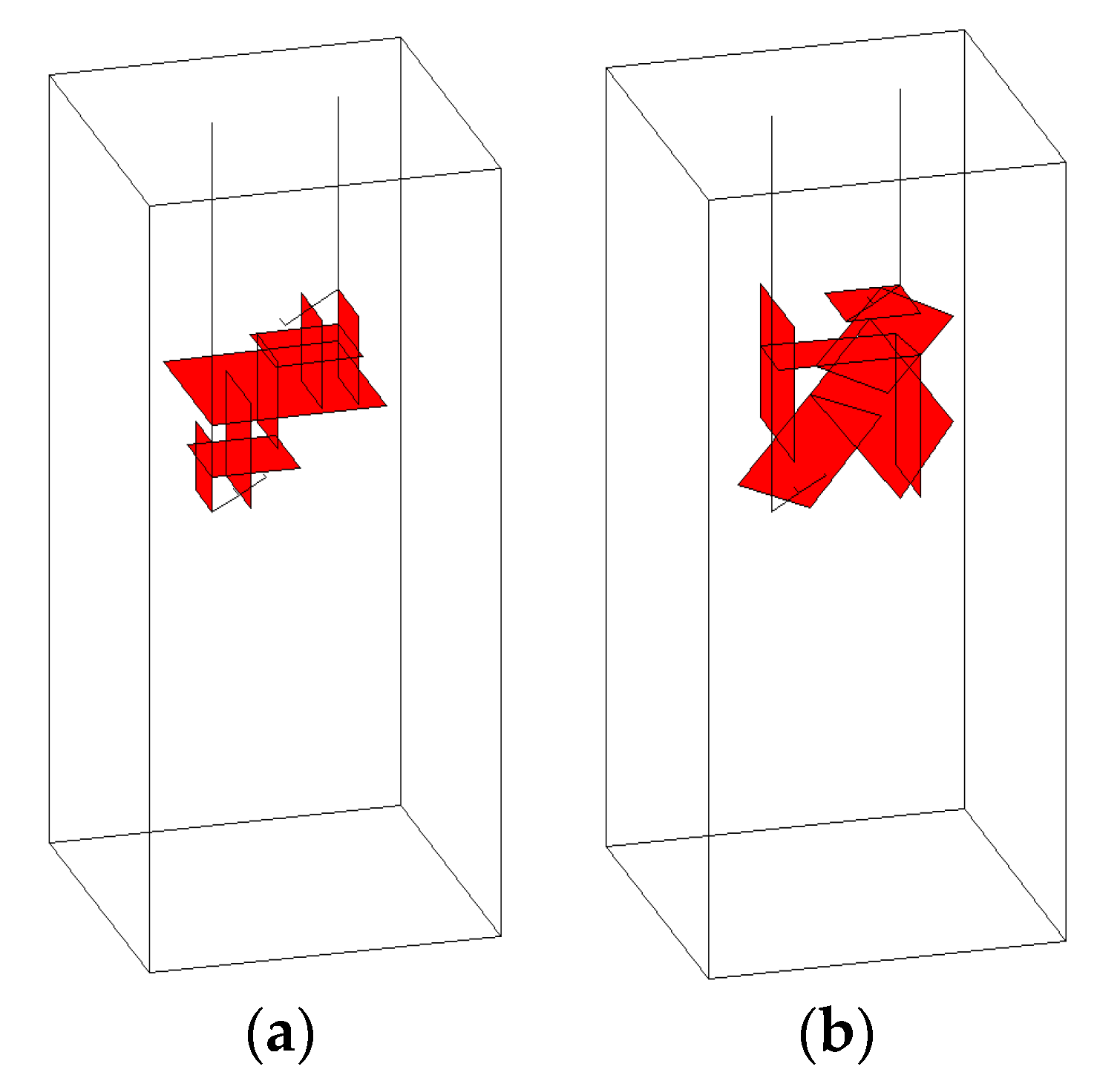

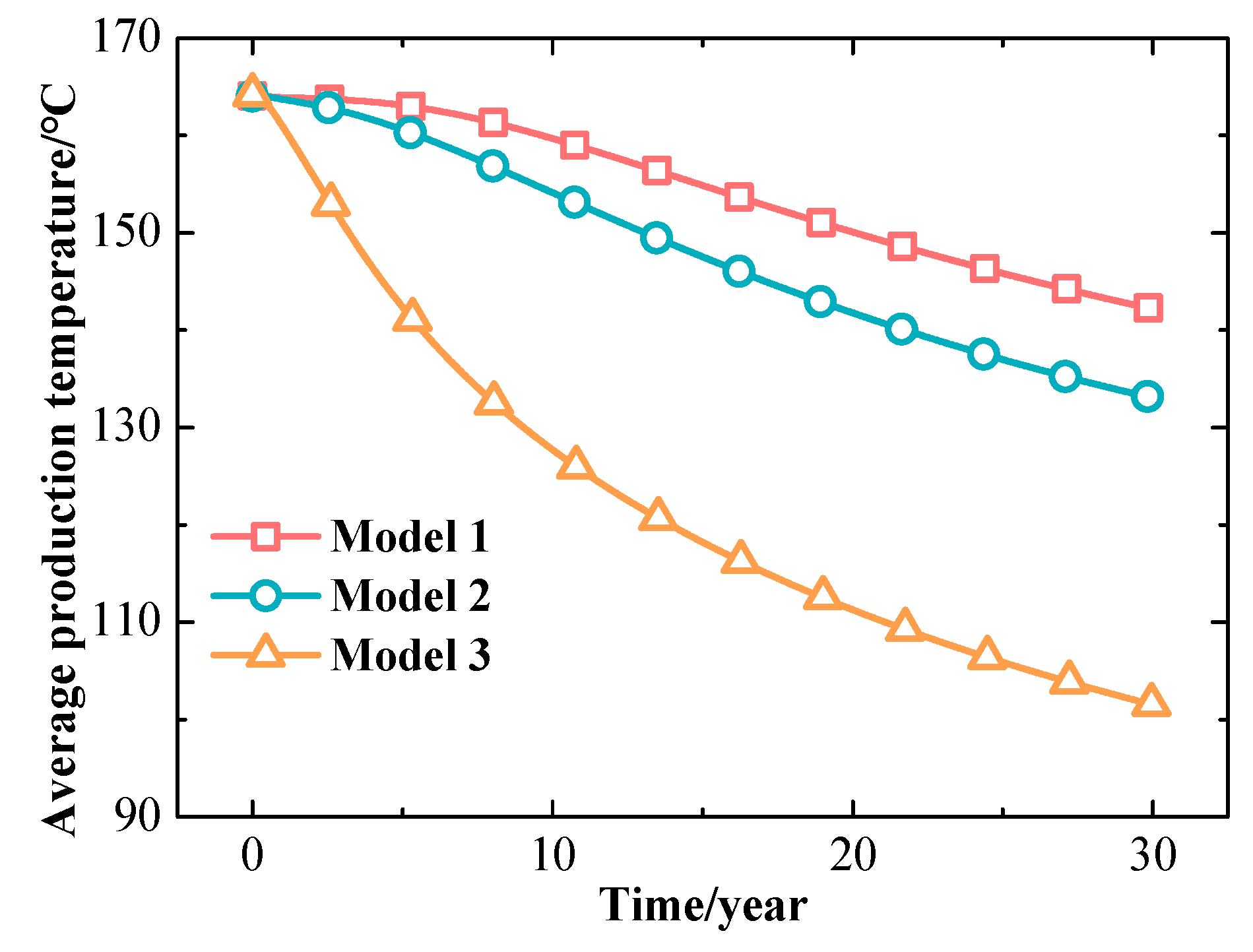

3.2.1. Effect of the Fracture Morphology

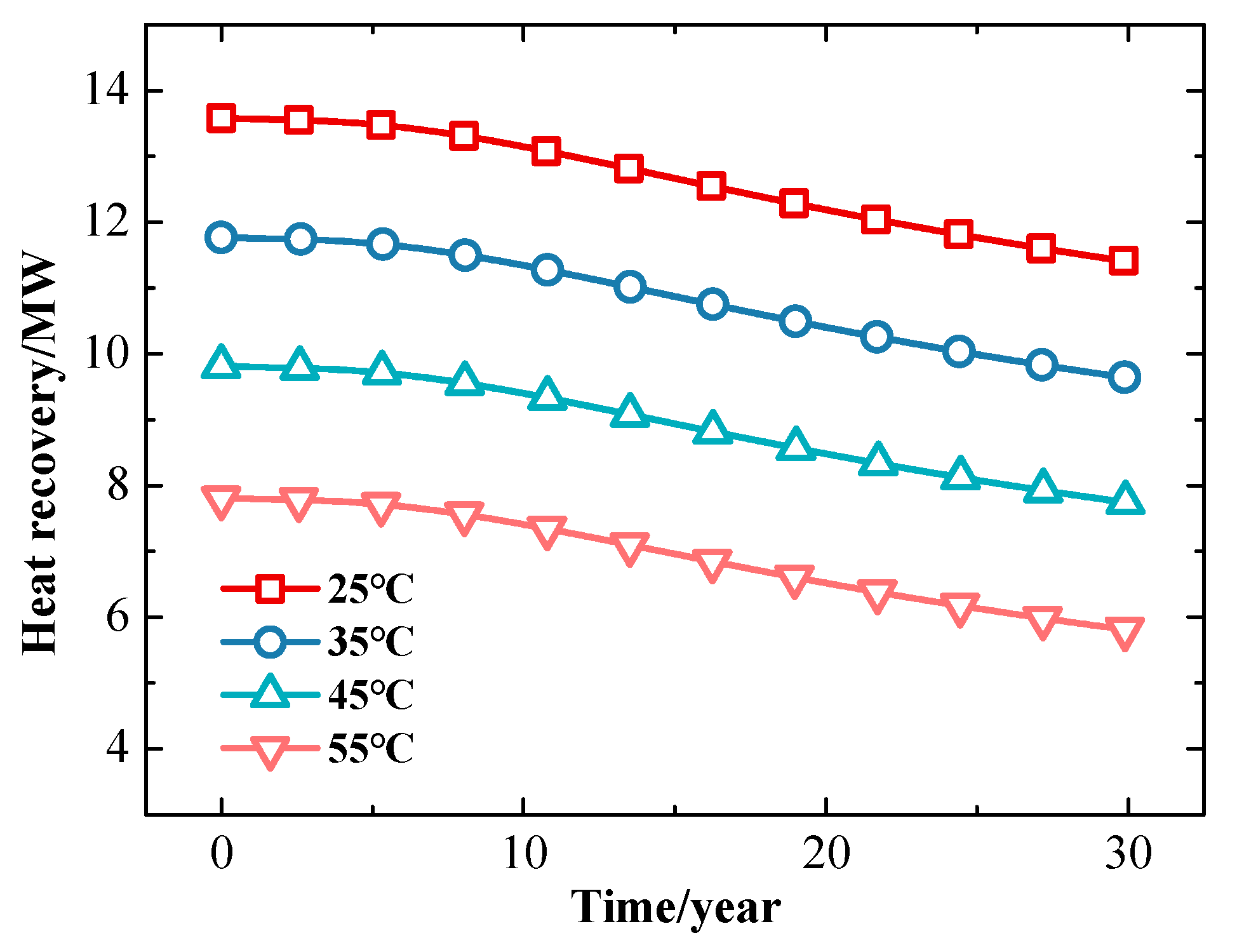

3.2.2. Effect of the Injection Temperature

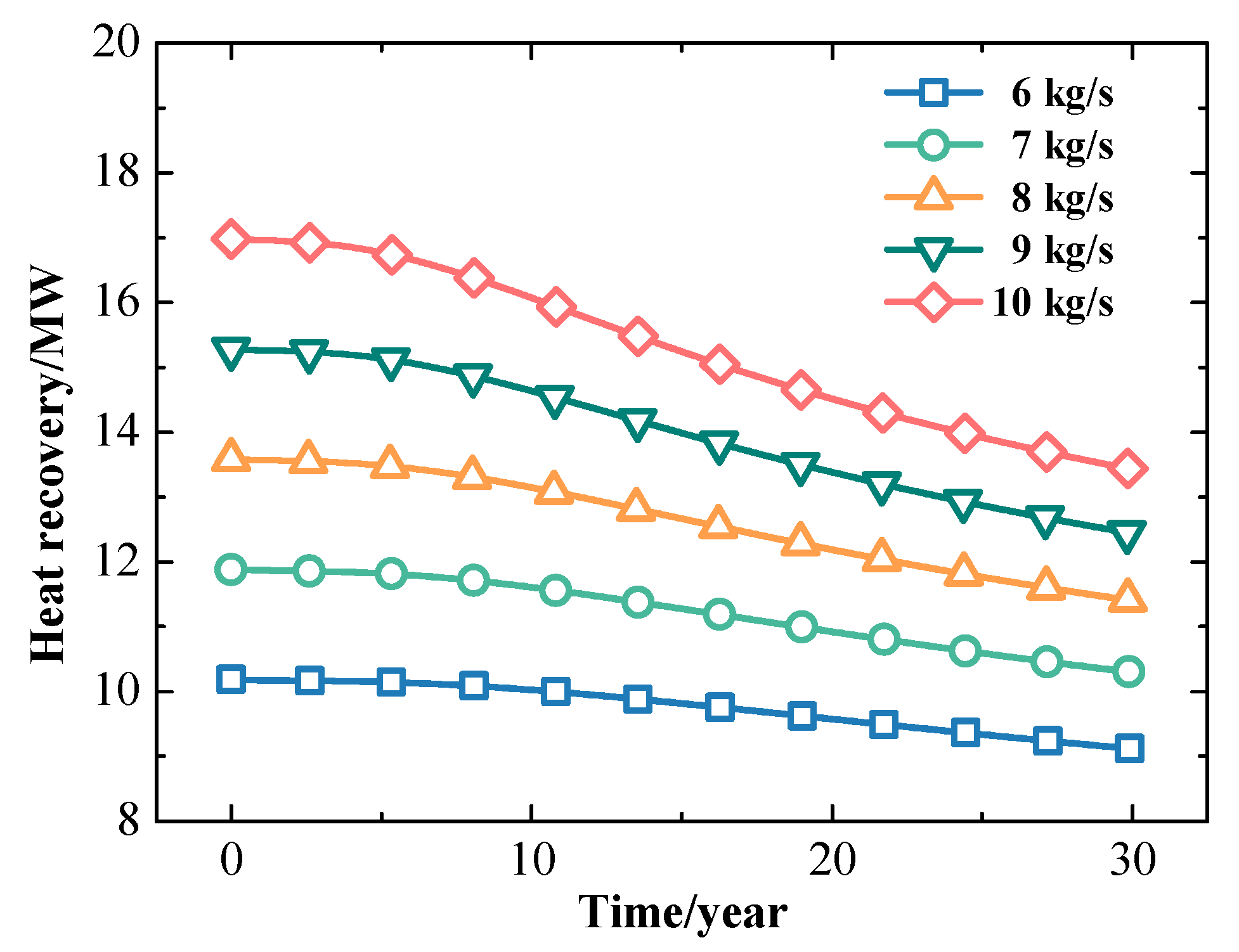

3.2.3. The Effect of the Injection Flow Rates

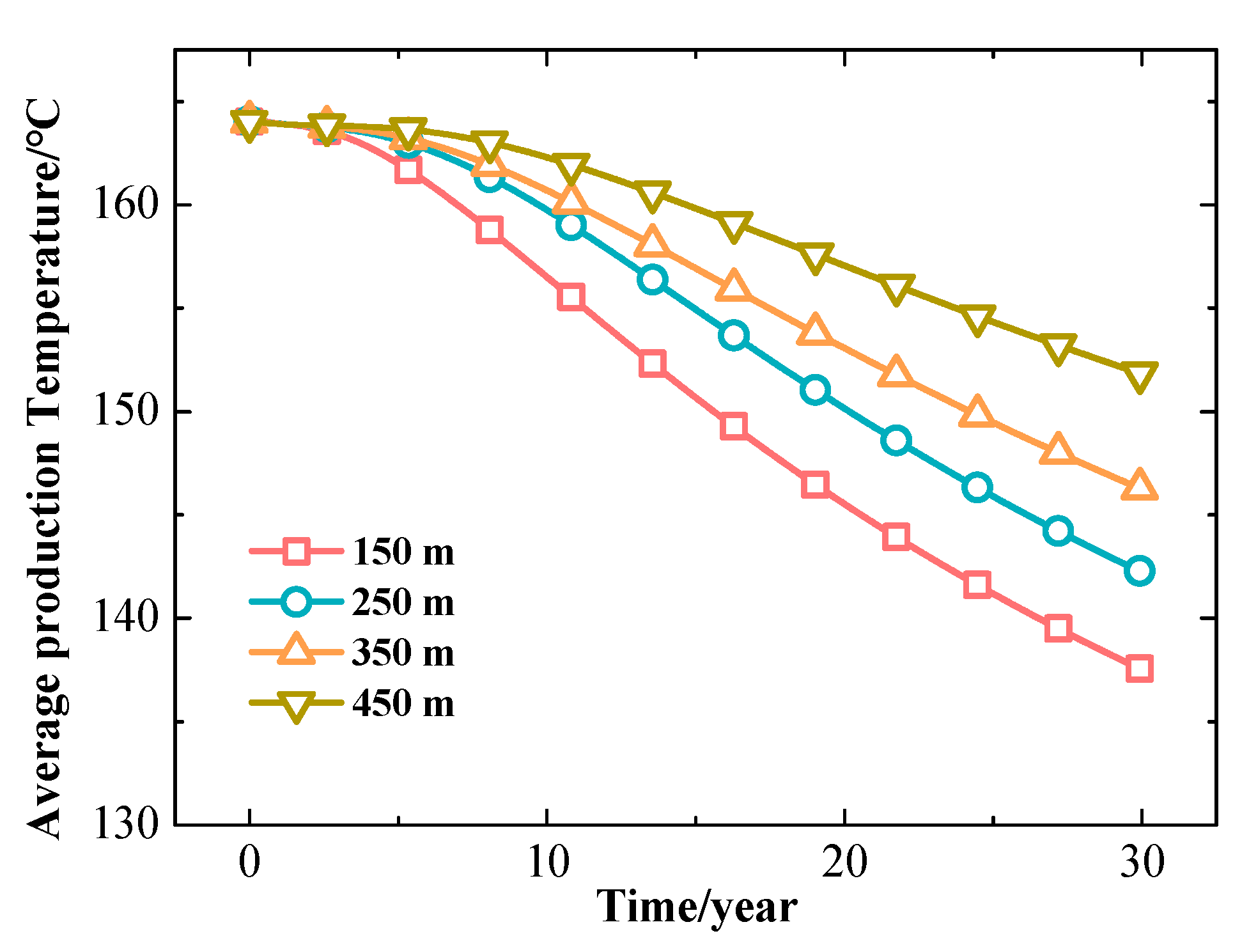

3.2.4. The Effect of the Injection–Production Well Spacing

4. Conclusions

- (1)

- The fracture networks form the main flow channels in the reservoir. At the mining stage, the low temperature and the low mean effective stress caused by the low temperature in reservoirs extend mainly along the fracture networks between the injection well and the production well. The effective stress increases mainly under the influence of pore pressure at the initial stage of mining and decreases at the later stage due to the effect of thermal stress. As the mining time increases, the local porosity and permeability parameters first decrease and then increase.

- (2)

- In the present studied cases, the vertical fractures and inclined fractures are not conducive to geothermal exploitation because they could accelerate thermal breakthrough.

- (3)

- The production temperature is not sensitive to the injection temperature of the cold flow, while the heat recovery capacity drops dramatically with the increase in injection temperature.

- (4)

- Within the first 10 years of mining, the effect of the injection flow rates on the production temperature is insignificant. As time goes by, the production temperature decreases with the increase in injection flow rates. Because the heat recovery capacity is proportional to the flow rate, the heat recovery capacity in this study increases as the flow rate increases within 30 years.

- (5)

- Injection and production well spacing is one of the most critical factors that significantly influence the production temperature. In the test cases, the production temperature and heat recovery amount increase as the well spacing increases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Jiang, F. Designing multi-well layout for enhanced geothermal system to better exploit hot dry rock geothermal energy. Renew.. Energy 2015, 74, 37–48. [Google Scholar] [CrossRef]

- Salimzadeh, S.; Nick, H.M.; Zimmerman, R.W. Thermoporoelastic effects during heat extraction from low-permeability reservoirs. Energy 2018, 142, 546–558. [Google Scholar] [CrossRef]

- Wei, X.; Feng, Z.; Zhao, Y. Numerical simulation of thermo hydro-mechanical coupling effect in mining fault-mode hot dry rock geothermal energy. Renew. Energy 2019, 139, 120–135. [Google Scholar] [CrossRef]

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; Damico, S.; Liarte, I.A. Enhanced geothermal systems (EGS): A review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Leontidis, V.; Niknam, P.H.; Durgut, I.; Talluri, L.; Manfrida, G.; Fiaschi, D.; Akin, S.; Gainville, M. Modelling reinjection of two-phase non-condensable gases and water in geothermal wells. Appl. Therm. Eng. 2023, 223, 120018. [Google Scholar] [CrossRef]

- Niknam, P.H.; Talluri, L.; Fiaschi, D.; Manfrida, G. Sensitivity analysis and dynamic modelling of the reinjection process in a binary cycle geothermal power plant of Larderello area. Energy 2021, 214, 118869. [Google Scholar] [CrossRef]

- Zhang, J.; Xie, J.X. Effect of reservoir’s permeability and porosity on the performance of cellular development model for enhanced geothermal system. Renew. Energy 2020, 148, 824–838. [Google Scholar] [CrossRef]

- Schoenball, M.; Dorbath, L.; Gaucher, E.; Wellmann, F.; Kohl, T. Change of stress regime during geothermal reservoir stimulation. Geophys. Res. Lett. 2014, 41, 1163–1170. [Google Scholar] [CrossRef]

- Egert, R.; Nitschke, F.; Gholami Korzani, M.; Kohl, T. Stochastic 3D Navier-Stokes Flow in Self-Affine Fracture Geometries Controlled by Anisotropy and Channeling. Geophys. Res. Lett. 2021, 48, e2020GL092138. [Google Scholar] [CrossRef]

- Marchand, S.; Mersch, O.; Selzer, M.; Nitschke, F.; Schoenball, M.; Schmittbuhl, J.; Nestler, B.; Kohl, T. A Stochastic Study of Flow Anisotropy and Channelling in Open Rough Fractures. Rock Mech. Rock Eng. 2019, 53, 233–249. [Google Scholar] [CrossRef]

- Jiang, F.; Chen, J.; Huang, W.; Luo, L. A three-dimensional transient model for EGS subsurface thermo-hydraulic process. Energy 2014, 72, 300–310. [Google Scholar] [CrossRef]

- Luo, F.; Xu, R.N.; Jiang, P.X. Numerical investigation of fluid flow and heat transfer in a doublet enhanced geothermal system with CO2 as the working fluid (CO2-EGS). Energy 2014, 64, 307–322. [Google Scholar] [CrossRef]

- Aliyu, M.D.; Chen, H.P. Enhanced geothermal system modelling with multiple pore media: Thermo-hydraulic coupled processes. Energy 2018, 165, 931–948. [Google Scholar] [CrossRef]

- Yin, T.; Li, Q.; Hu, Y.; Yu, S.; Liang, G. Coupled thermo-hydro-mechanical analysis of valley narrowing deformation of high arch dam: A case study of the xiluodu project in China. Appl. Sci. 2020, 10, 524. [Google Scholar] [CrossRef]

- Vik, S.H.; Salimzadeh, S.; Nick, H.M. Heat recovery from multiple-fracture enhanced geothermal systems: The effect of thermoelastic fracture interactions. Renew. Energy 2018, 121, 606–622. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, X.; Sun, Z.; Huang, Z.; Liu, J.; Li, Y.; Xin, Y.; Yan, X.; Liu, W. Numerical simulation of the heat extraction in 3D-EGS with thermal-hydraulic-mechanical coupling method based on discrete fractures model. Geothermics 2018, 74, 19–34. [Google Scholar] [CrossRef]

- Sun, Z.-X.; Zhang, X.; Xu, Y.; Yao, J.; Wang, H.-X.; Lv, S.; Huang, Y.; Cai, M.-Y.; Huang, X. Numerical simulation of the heat extraction in EGS with thermal-hydraulic-mechanical coupling method based on discrete fractures model. Energy 2017, 120, 20–33. [Google Scholar] [CrossRef]

- Gan, Q.; Elsworth, D. Production optimization in fractured geothermal reservoirs by coupled discrete fracture network modeling. Geothermics 2016, 62, 131–142. [Google Scholar] [CrossRef]

- Shi, Y.; Song, X.; Li, J.; Wang, G.; Zheng, R.; YuLong, F. Numerical investigation on heat extraction performance of a multilateral-well enhanced geothermal system with a discrete fracture network. Fuel 2019, 244, 207–226. [Google Scholar] [CrossRef]

- Lee, S.H.; Jensen, C.L.; Lough, M.F. An efficient finite difference model for flow in a reservoir with multiple length-scale fractures. SPE J. 2000, 5, 268–275. [Google Scholar] [CrossRef]

- Lee, S.H.; Lough, M.F.; Jensen, C.L. Hierarchical modeling of flow in naturally fractured formations with multiple length scales. Water Resour. Res. 2001, 37, 443–455. [Google Scholar] [CrossRef]

- Praditia, T.; Helmig, R.; Hajibeygi, H. Multiscale formulation for coupled flow-heat equations arising from single-phase flow in fractured geothermal reservoirs. Comput. Geosci. 2018, 22, 1305–1322. [Google Scholar] [CrossRef]

- Wang, C.; Winterfeld, P.; Johnston, B.; Wu, Y.S. An embedded 3D fracture modeling approach for simulating fracture-dominated fluid flow and heat transfer in geothermal reservoirs. Geothermics 2020, 86, 101831. [Google Scholar] [CrossRef]

- Li, T.; Han, D.; Yang, F.; Li, J.; Wang, D.; Yu, B.; Wei, J. Modeling study of the thermal-hydraulic-mechanical coupling process for EGS based on the framework of EDFM and XFEM. Geothermics 2020, 89, 101953. [Google Scholar] [CrossRef]

- Yu, S.; Song, X.J.; Feng, Y.J. Effects of lateral-well geometries on multilateral-well EGS performance based on a thermal-hydraulic-mechanical coupling model. Geothermics 2021, 89, 101939. [Google Scholar]

- Pruess, K.; Oldenburg, C.; Moridis, G. TOUGH2 User’s Guide Version 2; Office of Scientific & Technical Information Technical Reports; University of California: Berkeley, CA, USA, 1999. [Google Scholar]

- Huang, X.; Zhu, J.; Li, J.; Lan, C.; Jin, X. Parametric study of an enhanced geothermal system based on thermo-hydro-mechanical modeling of a prospective site in Songliao Basin. Appl. Therm. Eng. 2016, 105, 1–7. [Google Scholar] [CrossRef]

- Rutqvist, J.; Wu, Y.S.; Tsang, C.F. A Modeling Approach for Analysis of Coupled Multiphase Fluid Flow, Heat Transfer, and Deformation in Fractured Porous Rock. Int. J. Rock Mech. Min. Sci. 2002, 39, 429–442. [Google Scholar] [CrossRef]

- Biot, M.A.; Willis, D.G. The Elastic Coefficients of the Theory of Consolidation. J. Appl. Mech. 1957, 24, 594–601. [Google Scholar] [CrossRef]

- Leverett, M.C. Capillary behavior in porous media. AIME Trans. 1941, 142, 341–358. [Google Scholar] [CrossRef]

- Pluimers, S.B. Hierarchical Fracture Modeling Approach. Master’s thesis, TU Delft, Delft University of Technology, Delft, The Netherlands, 2015. [Google Scholar]

- Bai, B. One-dimensional thermal consolidation characteristics of geotechnical media under non-isothermal condition. Eng. Mech. 2005, 22, 186–191. [Google Scholar]

- Fakcharoenphol, P.; Xiong, Y.; Hu, L.; Winterfeld, P.H.; Xu, T.; Wu, Y.S. User’s Guide of TOUGH2-EGS: A Coupled Geomechanical and Reactive Geochemical Simulator for Fluid and Heat Flow in Enhanced Geothermal Systems. Version 1.0; Petroleum Engineering Department of Colorado School of Mines: Golden, CO, USA, 2013. [Google Scholar]

- Barends, F.B.J. Complete solution for transient heat transport in porous media, following Lauwerier’s concept. Proc. SPE Annu. Tech. Conf. Exhib. 2010, 4, 3139–3150. [Google Scholar]

- Shi, Y.; Song, X.; Wang, G.; Li, J.; Geng, L.; Li, X. Numerical study on heat extraction performance of a multilateral-well enhanced geothermal system considering complex hydraulic and natural fractures. Renew. Energy 2019, 141, 950–963. [Google Scholar] [CrossRef]

- Yan, X.; Huang, Z.; Yao, J.; Li, Y.; Fan, D. An efficient embedded discrete fracture model based on mimetic finite difference method. J. Pet. Sci. Eng. 2016, 145, 11–21. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, Y.; Yu, Z.; Hu, Z.; Lan, C.; Xu, T. Hot dry rock geothermal potential of the Xujiaweizi area in Songliao Basin, northeastern China. Environ. Earth Sci. 2016, 75, 1–22. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Elastic modulus (GPa) | 14.40 |

| Poisson ratio | 0.20 |

| Porosity | 0.01 |

| Conductivity (W/m·K) | 2.34 |

| Heat capacity (J/kg·K) | 690 |

| Thermal expansion (K−1) | 1.5 × 10−6 |

| Initial mean stress (MPa) | 3.0 |

| Parameters | Value |

|---|---|

| Rock density (kg/m3) | 14.40 |

| Heat capacity (J/kg·K) | 1000 |

| Conductivity (W/m·K) | 3.0 |

| Matrix porosity | 0.01 |

| Fracture porosity | 1.0 |

| Matrix permeability (m2) | 3.2 × 10−18 |

| Fracture permeability (m2) | 3.2 × 10−9 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Rock density (kg/m3) | 2600 | Young’s module (GPa) | 14.4 |

| Heat capacity (J/kg·K) | 1000 | Poisson ratio | 0.2 |

| Thermal conductivity (W/m·K) | 2.0 | Coefficient of Biot | 1 |

| Matrix porosity | 0.1 | Linear thermal expansion (°C−1) | 4.14 × 10−6 |

| Fracture porosity | 0.3 | Productivity index | 1.03 × 10−12 |

| Matrix permeability (m2) | 3.2 × 10−14 | Water injection rate (kg/s) | 8 |

| Fracture permeability (m2) | 3.2 × 10−9 | Bottomhole production pressure (MPa) | 33.25 |

| Models | The Volume of the Total Fractures | The Fraction of Vertical Fractures | The Fraction of Horizontal Fractures | The Fraction of Inclined Fractures |

|---|---|---|---|---|

| Model 1 | 6656.25 m3 | 45% | 55% | 0.0% |

| Model 2 | 6712.50 m3 | 55% | 45% | 0.0% |

| Model 3 | 6434.61 m3 | 33.3% | 33.3% | 33.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, X.-Y.; Huang, D.; Lei, W.-X.; Chen, S.-C.; Huang, Z.-Q.; Zhu, C.-Y. Investigation of Heat Extraction in an Enhanced Geothermal System Embedded with Fracture Networks Using the Thermal–Hydraulic–Mechanical Coupling Model. Energies 2023, 16, 3758. https://doi.org/10.3390/en16093758

Duan X-Y, Huang D, Lei W-X, Chen S-C, Huang Z-Q, Zhu C-Y. Investigation of Heat Extraction in an Enhanced Geothermal System Embedded with Fracture Networks Using the Thermal–Hydraulic–Mechanical Coupling Model. Energies. 2023; 16(9):3758. https://doi.org/10.3390/en16093758

Chicago/Turabian StyleDuan, Xin-Yue, Di Huang, Wen-Xian Lei, Shi-Chao Chen, Zhao-Qin Huang, and Chuan-Yong Zhu. 2023. "Investigation of Heat Extraction in an Enhanced Geothermal System Embedded with Fracture Networks Using the Thermal–Hydraulic–Mechanical Coupling Model" Energies 16, no. 9: 3758. https://doi.org/10.3390/en16093758

APA StyleDuan, X.-Y., Huang, D., Lei, W.-X., Chen, S.-C., Huang, Z.-Q., & Zhu, C.-Y. (2023). Investigation of Heat Extraction in an Enhanced Geothermal System Embedded with Fracture Networks Using the Thermal–Hydraulic–Mechanical Coupling Model. Energies, 16(9), 3758. https://doi.org/10.3390/en16093758