Heat Recovery Using PCM in Decentralised Façade Ventilation

Abstract

1. Introduction

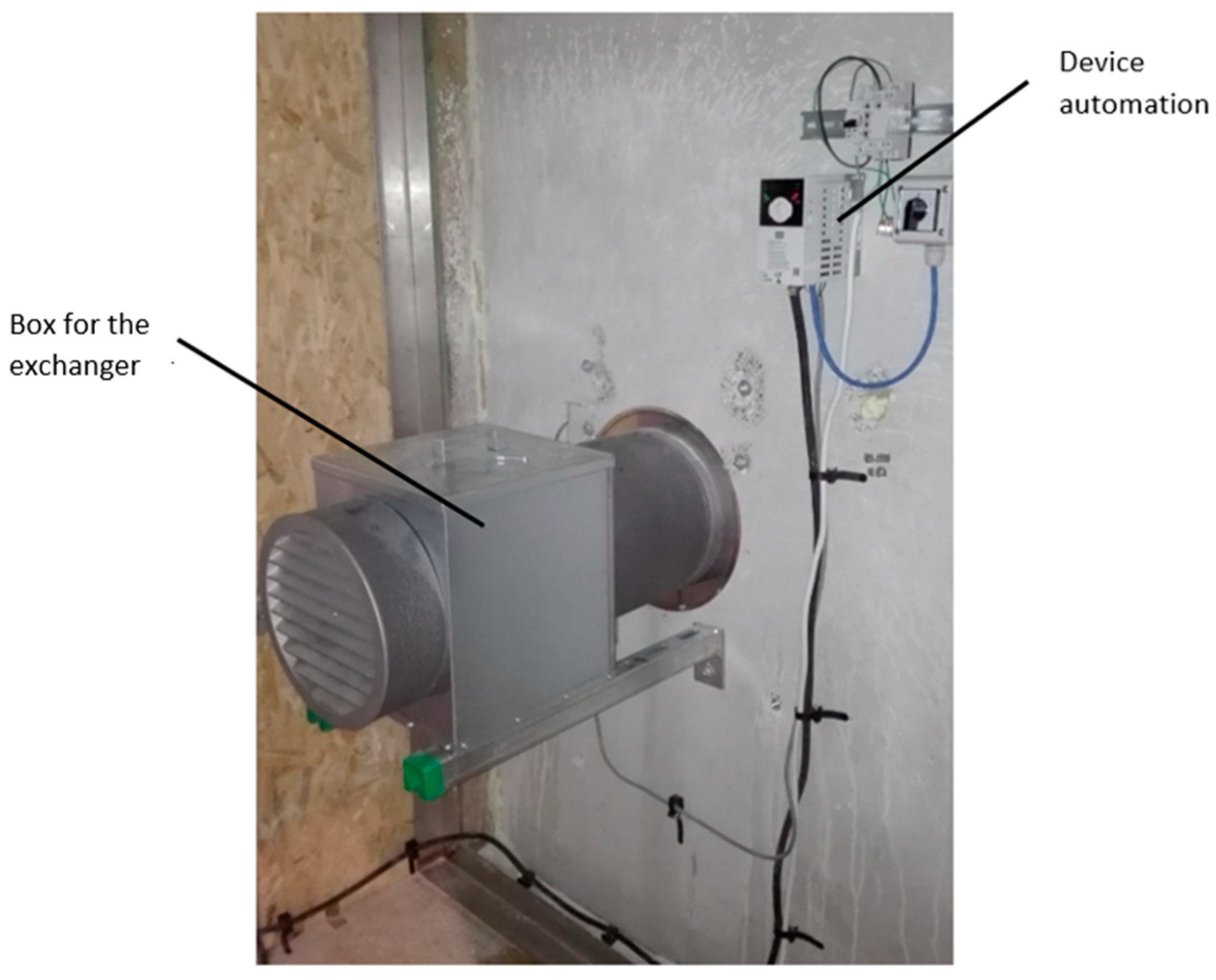

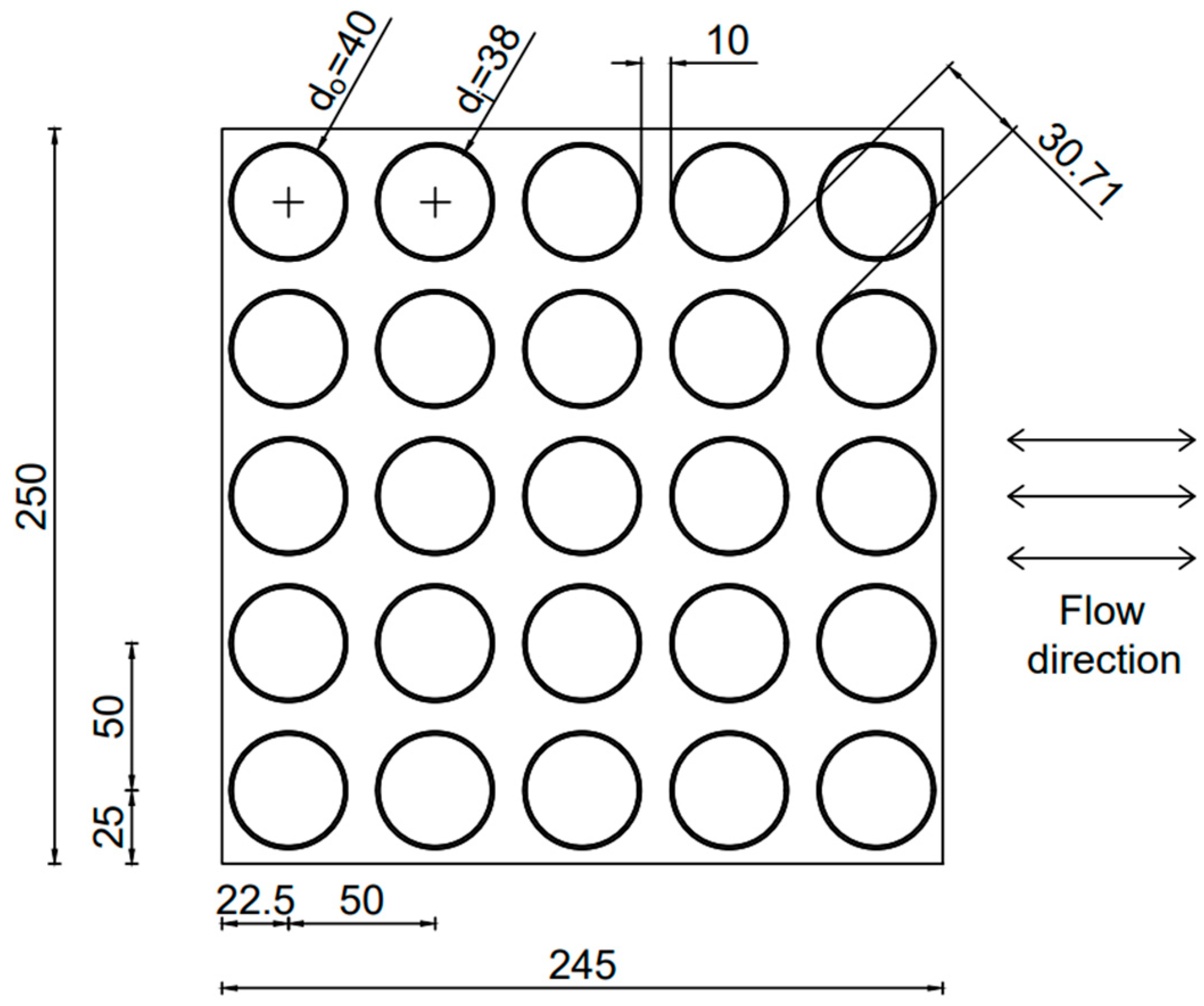

2. Materials and Methods

3. Calculation Method

4. Results

- There is a significant negative correlation between the efficiency results and the type of heat exchanger (r = −0.880, p < 0.001). The larger the diameter of the heat exchanger cylinders, the lower the efficiency.

- There is a significant negative correlation between efficiency results and duty cycle length (r = −0.330, p < 0.001). The longer the cycle, the lower the efficiency.

- There is a significant positive correlation between the results and the external temperature (r = 0.162, p < 0.001). The higher the temperature of the external environment, the higher the efficiency.

5. Discussion

6. Summary and Conclusions

- The highest efficiency was achieved for heat exchanger 1, and at an external temperature of 0 °C it equals 76.29% for a 1 min cycle, 74.16% for a 2 min cycle, 73.45% for a 3 min cycle, and 70.63% for a 5 min cycle. The performance result is also influenced by a larger exchange surface of 214% and 123% compared to heat exchangers 2 and 3.

- The highest efficiency was achieved for the 1 min supply/exhaust cycle, and it was 76.29% at 0 °C, 75.72% at −10 °C, and 73.56% at −20 °C.

- The lowest efficiencies were obtained for heat exchanger 3, where the maximum obtained efficiency was 53.18% for the 1 min cycle, jojoba oil at 0 °C. Other variants of cycle length and external temperatures were associated with efficiencies below 50%. The performance result is also influenced by the lower exchange surface by 68% and 55% compared to heat exchangers 1 and 2.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cincinelli, A.; Martellini, T. Indoor Air Quality and Health. Int. J. Environ. Res. Public Health 2017, 14, 1286. [Google Scholar] [CrossRef] [PubMed]

- Telejko, M.; Zender-Świercz, E.; Zander-Świercz, E. Attempt to Improve Indoor Air Quality in Kindergartens. Procedia Eng. 2016, 161, 1704–1709. [Google Scholar] [CrossRef]

- Dodoo, A. Primary energy and economic implications of ventilation heat recovery for a multi-family building in a Nordic climate. J. Build. Eng. 2020, 31, 101391. [Google Scholar] [CrossRef]

- Mikola, A.; Kalamees, T.; Kõiv, T.-A. Performance of ventilation in Estonian apartment buildings. Energy Procedia 2017, 132, 963–968. [Google Scholar] [CrossRef]

- Alonso, M.J.; Liu, P.; Mathisen, H.M.; Ge, G.; Simonson, C. Review of heat/energy recovery exchangers for use in ZEBs in cold climate countries. Build. Environ. 2015, 84, 228–237. [Google Scholar] [CrossRef]

- Zhang, J.; Fung, A.S.; Jhingan, S. Analysis and feasibility study of residential integrated heat and energy recovery ventilator with built-in economizer using an excel spreadsheet program. Energy Build. 2014, 75, 430–438. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y. Heat and mass transfer in a membrane-based energy recovery ventilator. J. Membr. Sci. 1999, 163, 29–38. [Google Scholar] [CrossRef]

- Manz, H.; Huber, H.; Schälin, A.; Weber, A.; Ferrazzini, M.; Studer, M. Performance of single room ventilation units with recuperative or regenerative heat recovery. Energy Build. 2000, 31, 37–47. [Google Scholar] [CrossRef]

- Hurnik, M.; Specjal, A.; Popiolek, Z. On-site diagnosis of hybrid ventilation system in a renovated single-family house. Energy Build. 2017, 149, 123–132. [Google Scholar] [CrossRef]

- Ratajczak, K.; Szczechowiak, E. Energy consumption decreasing strategy for indoor swimming pools—Decentralized Ventilation system with a heat pump. Energy Build. 2020, 206, 109574. [Google Scholar] [CrossRef]

- Merzkirch, A.; Maas, S.; Scholzen, F.; Waldmann, D. A semi-centralized, valveless and demand controlled ventilation system in comparison to other concepts in field tests. Build. Environ. 2015, 93, 21–26. [Google Scholar] [CrossRef]

- Merzkirch, A.; Maas, S.; Scholzen, F.; Waldmann, D. Field tests of centralized and decentralized ventilation units in residential buildings—Specific fan power, heat recovery efficiency, shortcuts and volume flow unbalances. Energy Build. 2016, 116, 376–383. [Google Scholar] [CrossRef]

- Wulfinghoff, P.E. Multiple-zone HVAC: An Obsolete Template. Energy Eng. 2011, 108, 44–56. [Google Scholar] [CrossRef]

- Besant, R.; Simonson, C. Air-to-air exchangers. ASHRAE J. 2003, 45, 42. [Google Scholar]

- Besant, R.W.; Simonson, C.J. Air-to-air energy recovery. ASHRAE J. 2000, 42, 31–43. [Google Scholar]

- Dieckmann, J.; Roth, K.W.; Brodrick, J. Air-to-air energy recovery heat exchangers. ASHRAE J. 2003, 45, 57. [Google Scholar]

- Zender–Świercz, E. A Review of Heat Recovery in Ventilation. Energies 2021, 14, 1759. [Google Scholar] [CrossRef]

- Mahdi, J.M.; Mohammed, H.I.; Talebizadehsardari, P. A new approach for employing multiple PCMs in the passive thermal management of photovoltaic modules. Sol. Energy 2021, 222, 160–174. [Google Scholar] [CrossRef]

- Krasoń, J. Możliwości zastosowania materiałów zmiennofazowych w pasywnych rozwiązaniach ściennych elementów murowych, JCEEA, t. Czas. Inżynierii Lądowej Sr. Archit. 2014, 61, 297–306. [Google Scholar]

- Hatamleh, R.I.; Abu-Hamdeh, N.H.; Bantan, R.A. Integration of a solar air heater to a building equipped with PCM to reduce the energy demand. J. Build. Eng. 2022, 48, 103948. [Google Scholar] [CrossRef]

- Kasaeian, A.; Bahrami, L.; Pourfayaz, F.; Khodabandeh, E.; Yan, W.-M. Experimental studies on the applications of PCMs and nano-PCMs in buildings: A critical review. Energy Build. 2017, 154, 96–112. [Google Scholar] [CrossRef]

- Ning, M.; Jingyu, H.; Dongmei, P.; Shengchun, L.; Mengjie, S. Investigations on thermal environment in residential buildings with PCM embedded in external wall. Energy Procedia 2017, 142, 1888–1895. [Google Scholar] [CrossRef]

- Melcer, A.; Klugmann-Radziemska, E.; Lewandowski, W.; Iwaniak-Lewandowska, W. Materiały zmiennofazowe dostępne na rynku. Właściwości i zastosowanie. Przemysł Chem. 2012, 91, 1733–1742. [Google Scholar]

- Nemati, H.; Souriaee, V.; Habibi, M.; Vafai, K. Design and Taguchi-based optimization of the latent heat thermal storage in the form of structured porous-coated pipe. Energy 2023, 263, 125947. [Google Scholar] [CrossRef]

- Koç, A.; Yağlı, H.; Bilgic, H.H.; Koç, Y.; Özdemir, A. Performance analysis of a novel organic fluid filled regenerative heat exchanger used heat recovery ventilation (OHeX-HRV) system. Sustain. Energy Technol. Assess. 2020, 41, 100787. [Google Scholar] [CrossRef]

- Pekdogan, T.; Tokuç, A.; Ezan, M.A.; Başaran, T. Experimental investigation of a decentralized heat recovery ventilation system. J. Build. Eng. 2021, 35, 102009. [Google Scholar] [CrossRef]

- Chang, C.-C.; Lai, C.-H.; Yang, C.-M.; Chiang, Y.-C.; Chen, S.-L. Thermal performance enhancement of a periodic total heat exchanger using energy-storage material. Energy Build. 2013, 67, 579–586. [Google Scholar] [CrossRef]

- Al-Zubaydi, A.Y.T.; Hong, G. Experimental investigation of counter flow heat exchangers for energy recovery ventilation in cooling mode. Int. J. Refrig. 2018, 93, 132–143. [Google Scholar] [CrossRef]

- Eisapour, A.H.; Eisapour, M.; Mohammed, H.I.; Shafaghat, A.; Ghalambaz, M.; Talebizadehsardari, P. Optimum design of a double elliptical latent heat energy storage system during the melting process. J. Energy Storage 2021, 44, 103384. [Google Scholar] [CrossRef]

- Najim, F.T.; Bahlekeh, A.; Mohammed, H.I.; Dulaimi, A.; Abed, A.M.; Ibrahem, R.K.; Al-Qrimli, F.A.; Mahmoud, M.Z.; Awrejcewicz, J.; Pawłowski, W. Evaluation of Melting Mechanism and Natural Convection Effect in a Triplex Tube Heat Storage System with a Novel Fin Arrangement. Sustainability 2022, 14, 10982. [Google Scholar] [CrossRef]

- Tiji, M.E.; Al-Azzawi, W.K.; Mohammed, H.I.; Dulaimi, A.; Rashid, F.L.; Mahdi, J.M.; Majdi, H.S.; Talebizadehsardari, P.; Ali, H.M. Thermal Management of the Melting Process in a Latent Heat Triplex Tube Storage System Using Different Configurations of Frustum Tubes. J. Nanomater. 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Han, H.; Kwon, Y.-I. Inhaling/Exhaling Heat Recovery Ventilator Using the Concept of Alternating-Current Ventilation. HVACR Res. 2006, 12, 843–859. [Google Scholar] [CrossRef]

- Zender-Świercz, E. Utility Model Number P.432536 Accumulation Heat Exchanger Especially for Facade Ventilation; 2022; p. 432536. [Google Scholar]

- PN-EN 16798-1: 2019-06; Energy Performance of Buildings—Ventilation for Buildings—Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality. Thermal Environment, Lighting and Acoustics. Polish Committee for Standardization: Warsaw, Poland, 2019.

- PN-EN 12831:2017-08; Charakterystyka energetyczna budynków—Metoda obliczania projektowego obciążenia cieplnego—Część 1: Obciążenie cieplne. Polish Committee for Standardization: Warsaw, Poland, 2017.

- Ciulla, G.; Brano, V.L.; Cellura, M.; Franzitta, V.; Milone, D. A Finite Difference Model of a PV-PCM System. Energy Procedia 2012, 30, 198–206. [Google Scholar] [CrossRef]

- Pekdogan, T.; Tokuç, A.; Ezan, M.A.; Başaran, T. Experimental investigation on heat transfer and air flow behavior of latent heat storage unit in a facade integrated ventilation system. J. Energy Storage 2021, 44, 103367. [Google Scholar] [CrossRef]

- Zemitis, J.; Bogdanovics, R. Heat recovery efficiency of local decentralized ventilation device at various pressure differ-ences. Mag. Civ. Eng. 2020, 2, 120–128. [Google Scholar]

| Chamber Simulating an Indoor Environment | Chamber Simulating an External Environment | |

|---|---|---|

| Temperature range | −5 to +50 °C | −30 to 80 °C |

| Setting step | 0.1 K | 0.1 K |

| Length | 2.15 m | 2.65 m |

| Width | 1.8 m | 1.8 m |

| Height | 2.3 m | 2.3 m |

| Heat Exchanger 1 | Heat Exchanger 2 | Heat Exchanger 3 | |

|---|---|---|---|

| Tube external diameter—do (mm) | 10 | 25 | 40 |

| Tube inside diameter—di (mm) | 8 | 23 | 38 |

| Transverse tube pitch—St (mm) | 20 | 35 | 50 |

| Row pitch—Sl (mm) | 10 | 30 | 50 |

| Tube layout | staggered | staggered | inline |

| Number of rows—N | 25 | 8 | 5 |

| Number of tubes—n | 313 | 56 | 25 |

| Tube height—H (mm) | 300 | 300 | 300 |

| Surface area of a heat exchanger—A (m2) | 2.95 | 1.32 | 0.94 |

| Volume of PCM—V (dm3) | 4.72 | 6.98 | 8.51 |

| Phase Change Material | Specific Heat J/gK | Heat Melting J/g | Heat Clotting J/g | Temperature Melting °C | Capacity Thermal J/K |

|---|---|---|---|---|---|

| coconut oil | 1.67 | 103.02 | 86.68 | 25 | 0.0156 |

| jojoba oil | 10.81 | 130.7 | 132.6 | 14.7 | 0.1046 |

| water | 19.88 | 330.4 | 258.9 | 0.3 | 0.260 |

| Resistance temperature detectors—Pt100 | |

|---|---|

| Measuring range | −200.00 °C to +400.00 °C |

| Resolution | 0.01 K |

| Linearisation accuracy | ±0.05 K |

| Connector programming | ZA 9030 FS2 |

| Time | Material | External Temperature | Internal Temperature | Device Efficiency |

|---|---|---|---|---|

| 1 min | jojoba oil | 0 °C | 20 °C | 76.29% |

| 1 min | coconut oil | 0 °C | 20 °C | 75.10% |

| 1 min | empty | 0 °C | 20 °C | 72.70% |

| 1 min | water | 0 °C | 20 °C | 72.15% |

| 2 min | jojoba oil | 0 °C | 20 °C | 74.19% |

| 2 min | coconut oil | 0 °C | 20 °C | 72.61% |

| 2 min | empty | 0 °C | 20 °C | 69.49% |

| 2 min | water | 0 °C | 20 °C | 70.78% |

| 3 min | jojoba oil | 0 °C | 20 °C | 73.45% |

| 3 min | coconut oil | 0 °C | 20 °C | 71.29% |

| 3 min | empty | 0 °C | 20 °C | 66.20% |

| 3 min | water | 0 °C | 20 °C | 69.90% |

| 5 min | jojoba oil | 0 °C | 20 °C | 70.63% |

| 5 min | coconut oil | 0 °C | 20 °C | 68.96% |

| 5 min | empty | 0 °C | 20 °C | 60.53% |

| 5 min | water | 0 °C | 20 °C | 68.55% |

| 1 min | jojoba oil | −10 °C | 20 °C | 75.72% |

| 1 min | coconut oil | −10 °C | 20 °C | 70.56% |

| 1 min | empty | −10 °C | 20 °C | 72.92% |

| 1 min | water | −10 °C | 20 °C | 71.30% |

| 2 min | jojoba oil | −10 °C | 20 °C | 71.94% |

| 2 min | coconut oil | −10 °C | 20 °C | 68.08% |

| 2 min | empty | −10 °C | 20 °C | 69.05% |

| 2 min | water | −10 °C | 20 °C | 69.61% |

| 3 min | jojoba oil | −10 °C | 20 °C | 70.45% |

| 3 min | coconut oil | −10 °C | 20 °C | 66.49% |

| 3 min | empty | −10 °C | 20 °C | 65.59% |

| 3 min | water | −10 °C | 20 °C | 68.73% |

| 5 min | jojoba oil | −10 °C | 20 °C | 67.83% |

| 5 min | coconut oil | −10 °C | 20 °C | 64.25% |

| 5 min | empty | −10 °C | 20 °C | 59.12% |

| 5 min | water | −10 °C | 20 °C | 67.27% |

| 1 min | jojoba oil | −20 °C | 20 °C | 73.56% |

| 1 min | coconut oil | −20 °C | 20 °C | 69.69% |

| 1 min | empty | −20 °C | 20 °C | 72.16% |

| 1 min | water | −20 °C | 20 °C | 70.17% |

| 2 min | jojoba oil | −20 °C | 20 °C | 71.05% |

| 2 min | coconut oil | −20 °C | 20 °C | 67.38% |

| 2 min | empty | −20 °C | 20 °C | 68.14% |

| 2 min | water | −20 °C | 20 °C | 69.29% |

| 3 min | jojoba oil | −20 °C | 20 °C | 69.39% |

| 3 min | coconut oil | −20 °C | 20 °C | 65.82% |

| 3 min | empty | −20 °C | 20 °C | 64.67% |

| 3 min | water | −20 °C | 20 °C | 67.70% |

| 5 min | jojoba oil | −20 °C | 20 °C | 67.22% |

| 5 min | coconut oil | −20 °C | 20 °C | 63.48% |

| 5 min | empty | −20 °C | 20 °C | 57.98% |

| 5 min | water | −20 °C | 20 °C | 65.93% |

| Time | Material | External Temperature | Internal Temperature | Device Efficiency |

|---|---|---|---|---|

| 1 min | jojoba oil | 0 °C | 20 °C | 61.00% |

| 1 min | coconut oil | 0 °C | 20 °C | 56.82% |

| 1 min | empty | 0 °C | 20 °C | 59.76% |

| 1 min | water | 0 °C | 20 °C | 61.57% |

| 2 min | jojoba oil | 0 °C | 20 °C | 57.22% |

| 2 min | coconut oil | 0 °C | 20 °C | 54.19% |

| 2 min | empty | 0 °C | 20 °C | 56.56% |

| 2 min | water | 0 °C | 20 °C | 55.22% |

| 3 min | jojoba oil | 0 °C | 20 °C | 55.05% |

| 3 min | coconut oil | 0 °C | 20 °C | 52.22% |

| 3 min | empty | 0 °C | 20 °C | 53.20% |

| 3 min | water | 0 °C | 20 °C | 56.35% |

| 5 min | jojoba oil | 0 °C | 20 °C | 51.68% |

| 5 min | coconut oil | 0 °C | 20 °C | 49.28% |

| 5 min | empty | 0 °C | 20 °C | 47.00% |

| 5 min | water | 0 °C | 20 °C | 54.64% |

| 1 min | jojoba oil | −10 °C | 20 °C | 58.46% |

| 1 min | coconut oil | −10 °C | 20 °C | 52.41% |

| 1 min | empty | −10 °C | 20 °C | 56.56% |

| 1 min | water | −10 °C | 20 °C | 59.48% |

| 2 min | jojoba oil | −10 °C | 20 °C | 54.69% |

| 2 min | coconut oil | −10 °C | 20 °C | 49.91% |

| 2 min | empty | −10 °C | 20 °C | 53.13% |

| 2 min | water | −10 °C | 20 °C | 54.65% |

| 3 min | jojoba oil | −10 °C | 20 °C | 52.79% |

| 3 min | coconut oil | −10 °C | 20 °C | 48.19% |

| 3 min | empty | −10 °C | 20 °C | 49.97% |

| 3 min | water | −10 °C | 20 °C | 55.59% |

| 5 min | jojoba oil | −10 °C | 20 °C | 49.62% |

| 5 min | coconut oil | −10 °C | 20 °C | 45.40% |

| 5 min | empty | −10 °C | 20 °C | 44.07% |

| 5 min | water | −10 °C | 20 °C | 50.64% |

| 1 min | jojoba oil | −20 °C | 20 °C | 56.68% |

| 1 min | coconut oil | −20 °C | 20 °C | 55.08% |

| 1 min | empty | −20 °C | 20 °C | 56.60% |

| 1 min | water | −20 °C | 20 °C | 58.72% |

| 2 min | jojoba oil | −20 °C | 20 °C | 52.68% |

| 2 min | coconut oil | −20 °C | 20 °C | 51.94% |

| 2 min | empty | −20 °C | 20 °C | 52.98% |

| 2 min | water | −20 °C | 20 °C | 56.22% |

| 3 min | jojoba oil | −20 °C | 20 °C | 50.41% |

| 3 min | coconut oil | −20 °C | 20 °C | 49.39% |

| 3 min | empty | −20 °C | 20 °C | 49.29% |

| 3 min | water | −20 °C | 20 °C | 54.63% |

| 5 min | jojoba oil | −20 °C | 20 °C | 47.57% |

| 5 min | coconut oil | −20 °C | 20 °C | 45.84% |

| 5 min | empty | −20 °C | 20 °C | 42.56% |

| 5 min | water | −20 °C | 20 °C | 52.48% |

| Time | Material | External Temperature | Internal Temperature | Device Efficiency |

|---|---|---|---|---|

| 1 min | jojoba oil | 0 °C | 20 °C | 53.18% |

| 1 min | coconut oil | 0 °C | 20 °C | 49.13% |

| 1 min | empty | 0 °C | 20 °C | 49.32% |

| 1 min | water | 0 °C | 20 °C | 53.09% |

| 2 min | jojoba oil | 0 °C | 20 °C | 50.19% |

| 2 min | coconut oil | 0 °C | 20 °C | 51.89% |

| 2 min | empty | 0 °C | 20 °C | 46.8% |

| 2 min | water | 0 °C | 20 °C | 50.68% |

| 3 min | jojoba oil | 0 °C | 20 °C | 48.34% |

| 3 min | coconut oil | 0 °C | 20 °C | 49.99% |

| 3 min | empty | 0 °C | 20 °C | 44.34% |

| 3 min | water | 0 °C | 20 °C | 48.82% |

| 5 min | jojoba oil | 0 °C | 20 °C | 44.50% |

| 5 min | coconut oil | 0 °C | 20 °C | 43.98% |

| 5 min | empty | 0 °C | 20 °C | 39.86% |

| 5 min | water | 0 °C | 20 °C | 48.65% |

| 1 min | jojoba oil | −10 °C | 20 °C | 50.88% |

| 1 min | coconut oil | −10 °C | 20 °C | 50.79% |

| 1 min | empty | −10 °C | 20 °C | 45.89% |

| 1 min | water | −10 °C | 20 °C | 52.83% |

| 2 min | jojoba oil | −10 °C | 20 °C | 47.71% |

| 2 min | coconut oil | −10 °C | 20 °C | 47.77% |

| 2 min | empty | −10 °C | 20 °C | 43.41% |

| 2 min | water | −10 °C | 20 °C | 49.16% |

| 3 min | jojoba oil | −10 °C | 20 °C | 45.86% |

| 3 min | coconut oil | −10 °C | 20 °C | 45.63% |

| 3 min | empty | −10 °C | 20 °C | 40.85% |

| 3 min | water | −10 °C | 20 °C | 47.82% |

| 5 min | jojoba oil | −10 °C | 20 °C | 43.13% |

| 5 min | coconut oil | −10 °C | 20 °C | 42.55% |

| 5 min | empty | −10 °C | 20 °C | 36.39% |

| 5 min | water | −10 °C | 20 °C | 45.55% |

| 1 min | jojoba oil | −20 °C | 20 °C | 49.83% |

| 1 min | coconut oil | −20 °C | 20 °C | 48.28% |

| 1 min | empty | −20 °C | 20 °C | 44.88% |

| 1 min | water | −20 °C | 20 °C | 48.99% |

| 2 min | jojoba oil | −20 °C | 20 °C | 46.97% |

| 2 min | coconut oil | −20 °C | 20 °C | 46.31% |

| 2 min | empty | −20 °C | 20 °C | 42.05% |

| 2 min | water | −20 °C | 20 °C | 47.33% |

| 3 min | jojoba oil | −20 °C | 20 °C | 45.09% |

| 3 min | coconut oil | −20 °C | 20 °C | 44.37% |

| 3 min | empty | −20 °C | 20 °C | 39.14% |

| 3 min | water | −20 °C | 20 °C | 45.89% |

| 5 min | jojoba oil | −20 °C | 20 °C | 42.48% |

| 5 min | coconut oil | −20 °C | 20 °C | 41.21% |

| 5 min | empty | −20 °C | 20 °C | 34.45% |

| 5 min | water | −20 °C | 20 °C | 44.68% |

| Variable | Measurement | |

|---|---|---|

| Heat exchanger | spearman correlation coefficient (r) | −0.880 |

| materiality level (p) | 0.000 | |

| sample size (N) | 1440 | |

| Cycle | spearman correlation coefficient (r) | −0.330 |

| materiality level (p) | 0.000 | |

| sample size (N) | 1440 | |

| External temperature | spearman correlation coefficient (r) | 0.162 |

| materiality level (p) | 0.000 | |

| sample size (N) | 1440 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galiszewska, B.; Zender-Świercz, E. Heat Recovery Using PCM in Decentralised Façade Ventilation. Energies 2023, 16, 3310. https://doi.org/10.3390/en16083310

Galiszewska B, Zender-Świercz E. Heat Recovery Using PCM in Decentralised Façade Ventilation. Energies. 2023; 16(8):3310. https://doi.org/10.3390/en16083310

Chicago/Turabian StyleGaliszewska, Beata, and Ewa Zender-Świercz. 2023. "Heat Recovery Using PCM in Decentralised Façade Ventilation" Energies 16, no. 8: 3310. https://doi.org/10.3390/en16083310

APA StyleGaliszewska, B., & Zender-Świercz, E. (2023). Heat Recovery Using PCM in Decentralised Façade Ventilation. Energies, 16(8), 3310. https://doi.org/10.3390/en16083310