Techno-Economic Evaluation of Hydrogen-Based Cooking Solutions in Remote African Communities—The Case of Kenya

Abstract

1. Introduction

1.1. Framework and Concept

- (I)

- by supplying electricity via power-to-hydrogen-to-power (P2H2P) to serve electric cooking (e-cooking) appliances (hereinafter referred to as P2H2P-based e-cooking);

- (II)

- via direct combustion in hydrogen stoves;

- (III)

- via blending hydrogen into Liquid Petroleum Gas (LPG) by 20% on a volumetric basis for combustion in conventional LPG stoves.

- the higher hydrogen-air flame temperature allows for quick and flexible heating;

- the high diffusion coefficient is a great safety advantage;

- hydrogen can be ignited within a wide flammability range with low ignition energy required.

1.2. Definition of the Research Gap and Contribution to Research

- While the technical concepts of decentralized P2H2P-based e-cooking and decentralized hydrogen production for utilization via combustion have been proposed for different settings, a comparison of the systems is only possible when investigating the systems in the same setting. Further, decentralized hydrogen production for utilization via combustion has for now only been proposed as a stand-alone solution. However, potentially building on the same primary energy source as the local electricity supply system when considering renewable energy supply (e.g., PV), the effect of integrating hydrogen production in the electricity supply system must be investigated.

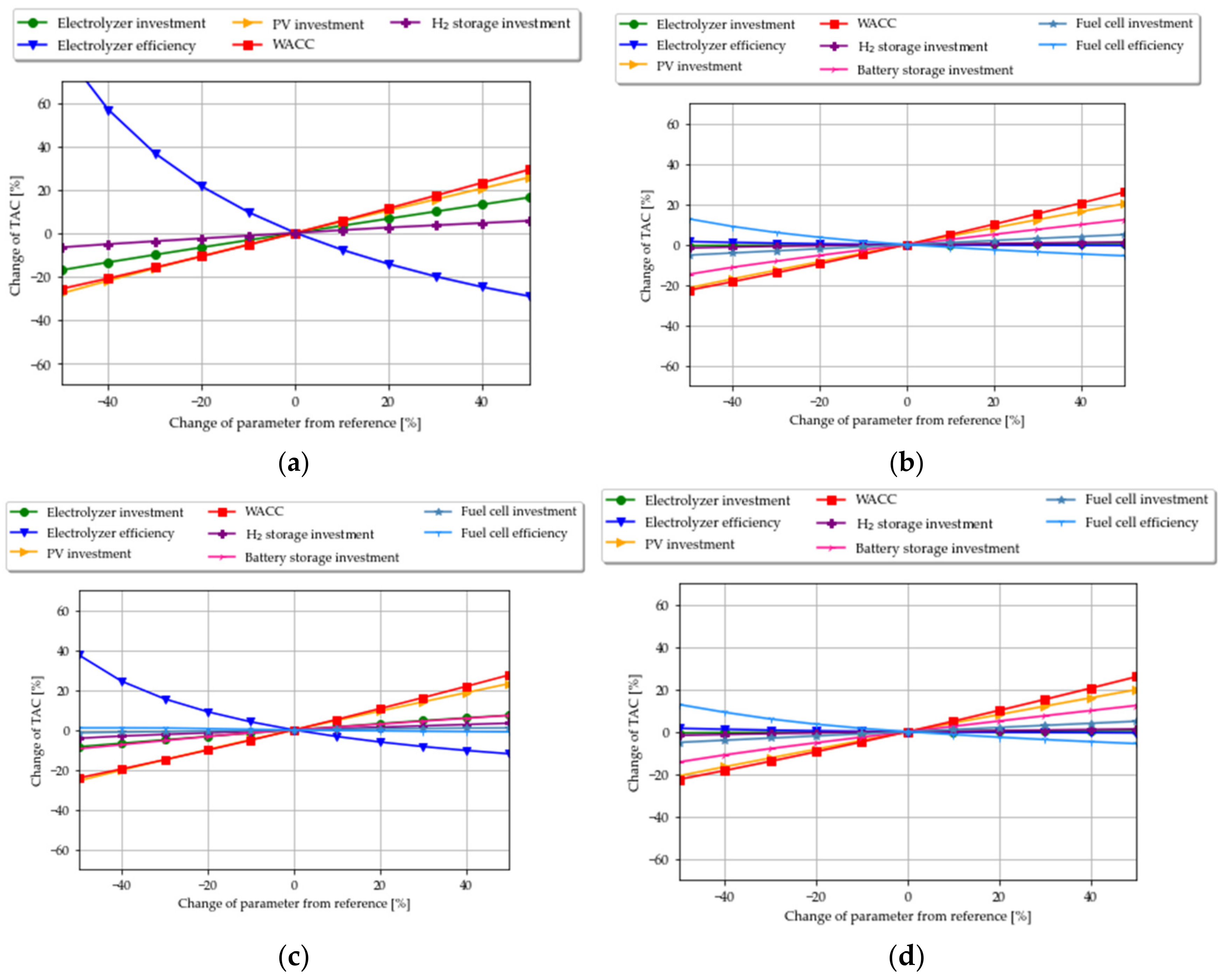

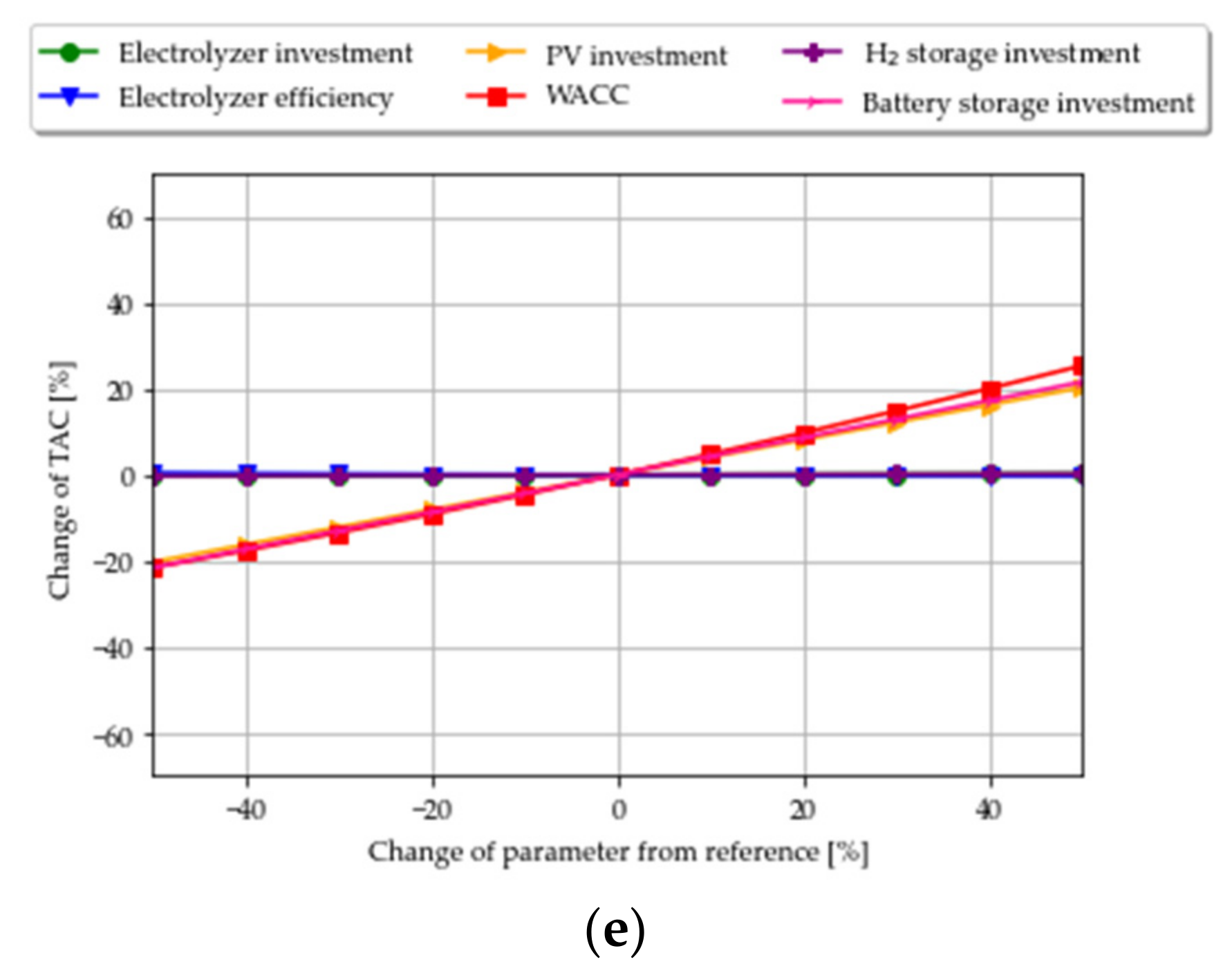

- In any of the previous works, the respective authors point out the substantial economic challenges of hydrogen-based cooking compared to traditional fuels. High investment costs of hydrogen technologies (e.g., [19,29]) pose a significant barrier to the uptake. However, the previous work did not explore the impact of changes in technical and economic parameters, jeopardizing the transferability of findings, and inclusion of possible future developments.

- The previous studies focus on hydrogen-based cooking solutions on an energy system level. However, when exploring clean cooking options, it is vital to include the end-user perspective in the analysis.

- What are the respective least costly (optimal) energy system topologies and system operations to facilitate hydrogen-based cooking in off-grid villages?

- What is the least-cost energy system for hydrogen-based cooking in off-grid regions, presently and in the future?

- What are the main influencing parameters on the costs of the respective hydrogen-based cooking solutions?

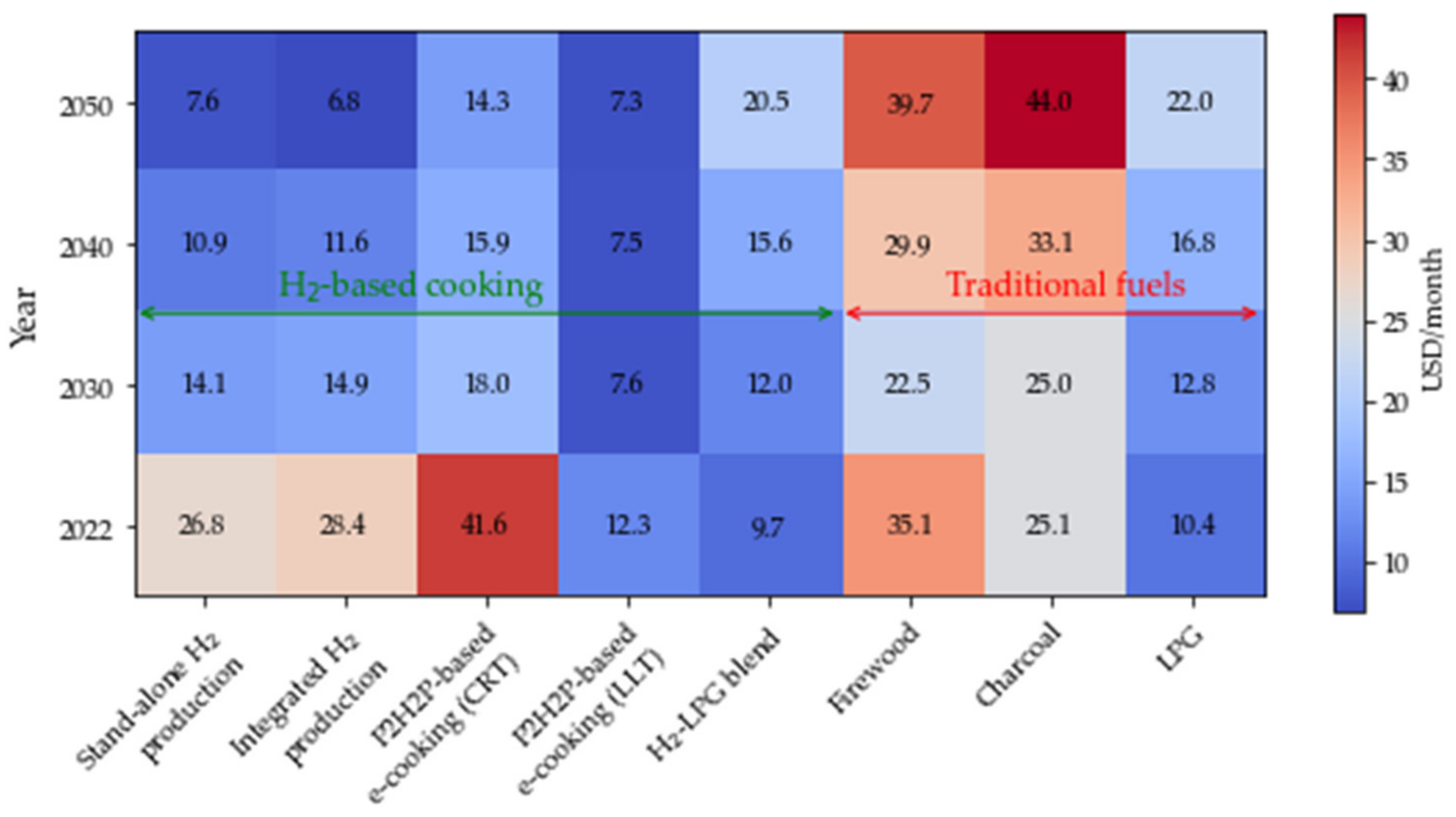

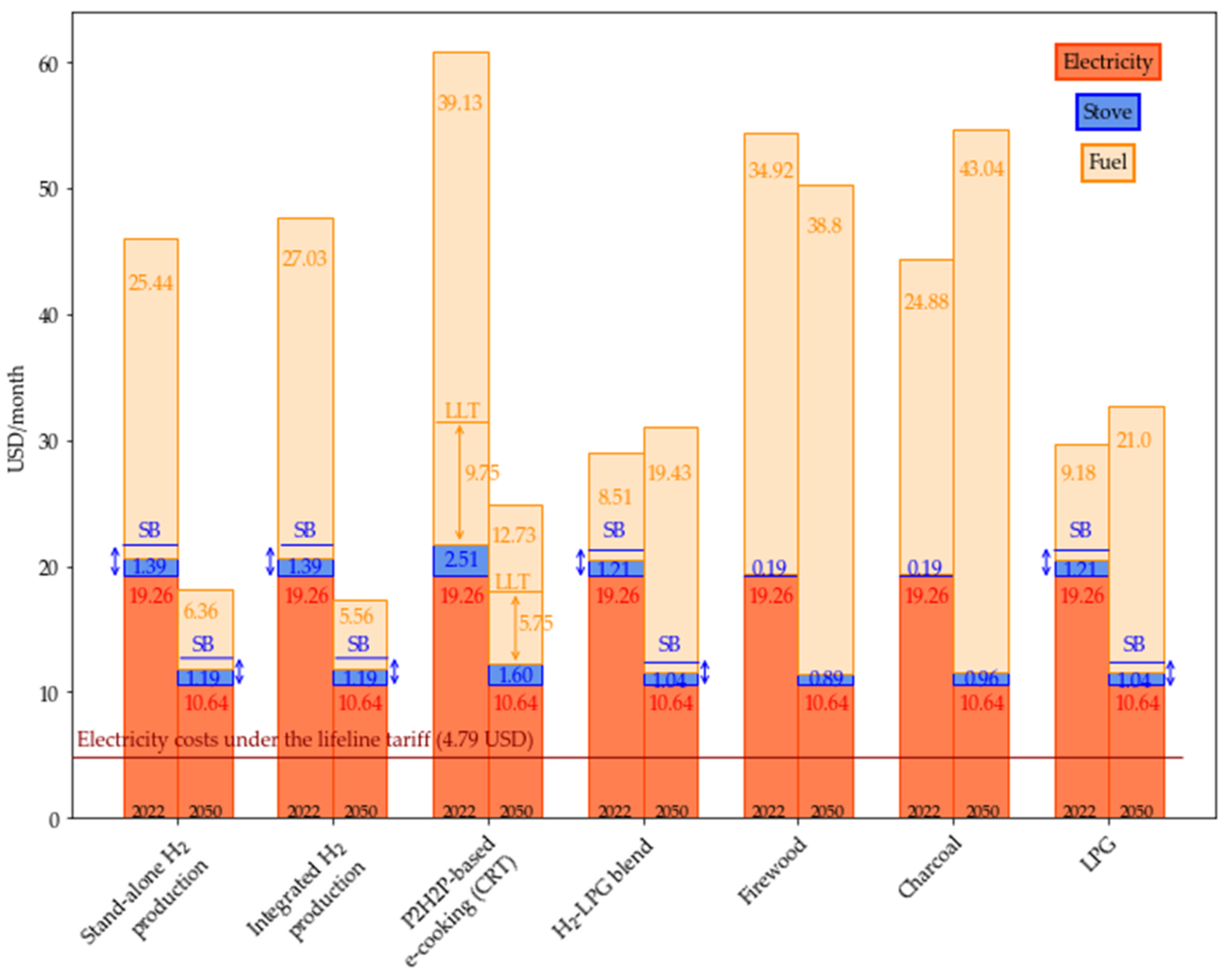

- What are the costs of hydrogen-based cooking in rural villages for the end user compared to traditional fuels, presently and in the future?

2. Materials and Methods

2.1. Energy Systems for Hydrogen-Based Clean Cooking Services

2.2. Materials and Case Study

2.2.1. Case Study

Renewable Energy Supply

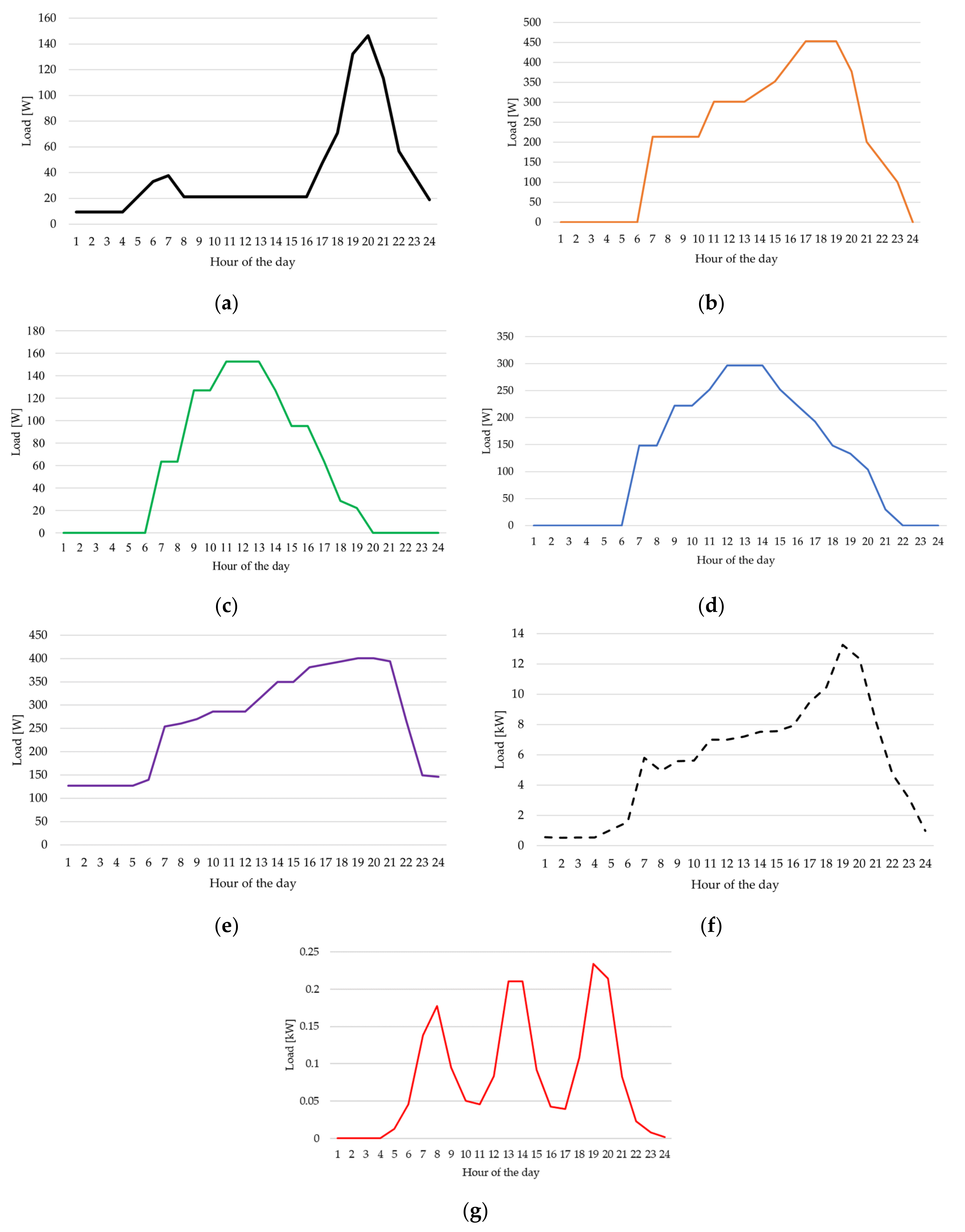

Electricity Demand

Cooking Demand

2.2.2. Component Assumptions

Cooking Systems

| Parameter | Fuelwood | Charcoal | LPG | Hydrogen | AC EPC + Hot Plate |

|---|---|---|---|---|---|

| Stove efficiency [%] [25] | Traditional: 17 Improved: 35 | Traditional: 31 Improved: 41 | 54 | 58 [29] | AC EPC: 24–150 (Av. 62.5) [17] Hot plate: 0.5 [52] |

| Stove investment [USD] | Basic: 2–10 [49] Improved: 30–50 [49]; 15–50 [25] | Single burner: 20–60; Double burner:30–90 [52]; “Meko”: 37.65 [25] | Assumption of LPG stove refit: 50 USD single burner | Hot plate: 10–30 [49] AC EPC 50–100 [49], 58 [17] | |

| Storage investment [USD] | / | / | 6 kg: 21,8 USD 13 kg: 39.36 USD [53] | 0.5 kg: 25 USD (assumption) | / |

Hydrogen System

Electricity System

2.3. Methods

2.3.1. Model Objective

2.3.2. Economic Measures of Result

Economic Energy System Evaluation

Economic Impact for End Users

2.3.3. Scenario Assumptions

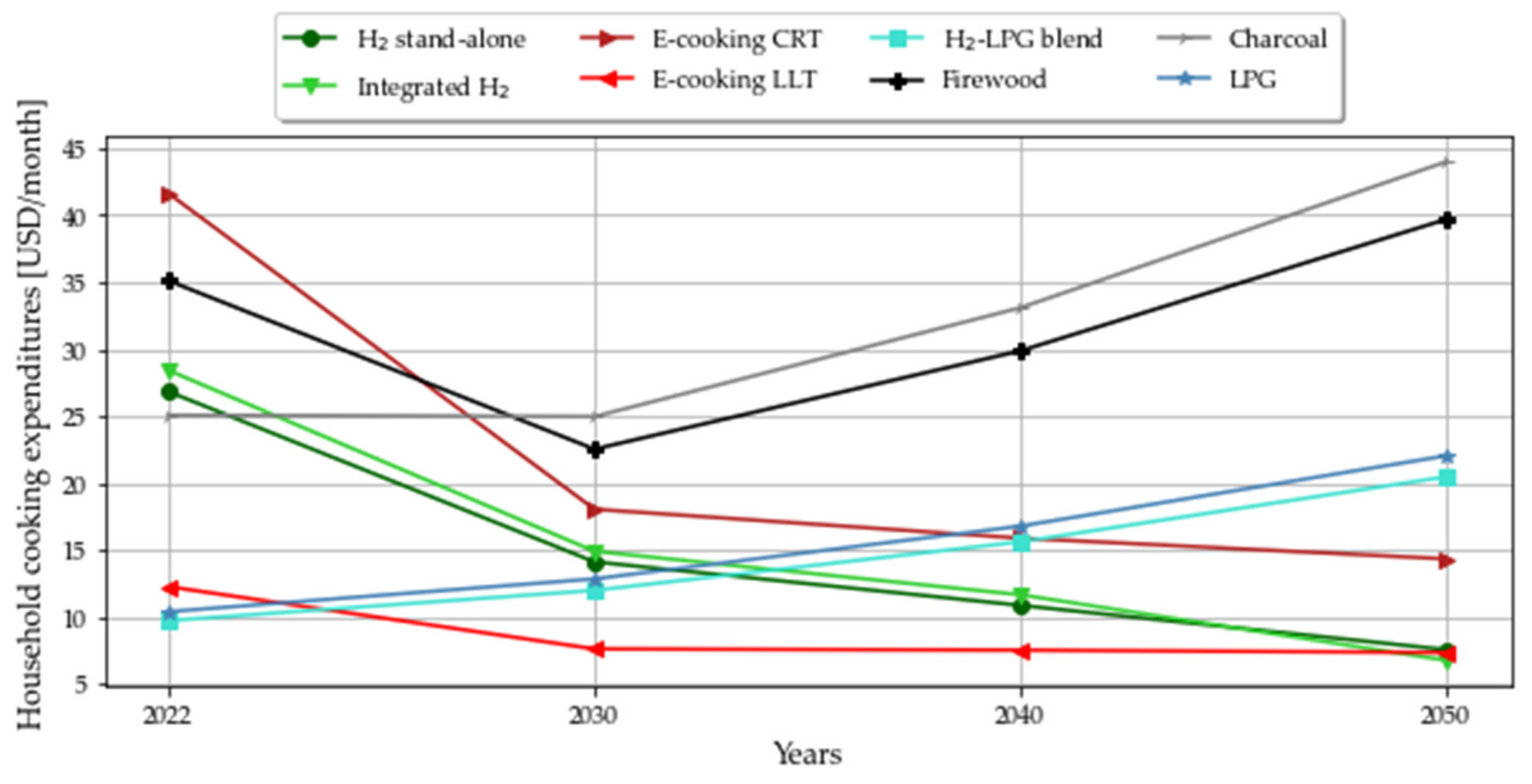

- Improvement of renewable energies and hydrogen technologies: with ongoing research and increased production, renewable energy technologies and hydrogen technologies are expected to improve in efficiency and simultaneously decline in costs. In reference to current prices, PV module prices may fall by approximately 60% until 2030 and 75% by 2050 according to the International Renewable Energy Agency (IRENA) [73]. Similarly, electrolysis is expected to decline in CAPEX by 40% by 2030 and by more than 80% by 2050 [74]. Simultaneously, efficiency improvements of ELs of at least up to 73% are expected for low-temperature electrolysis until 2050 [74]. As analogous expectations for the FC are vague in the literature, we assume similar trends for the FC. We assume 70% efficiency for a PEMFC to be reachable in the future, referring to t maximum of 65% [74].

- Increase in fuel costs: traditional (fossil) cooking fuel resources in Sub-Saharan Africa are limited. In Kenya, an increase in firewood prices has already been reported. In alignment with assumptions from the ESMAP, we assume a 3% annual increase in traditional and fossil fuel prices [49].

- Switch in stoves: the government and other organizations promote the diffusion of improved efficient cooking in Kenya. Likely, improved cookstoves (ICS) (notably, there is no universally accepted definition of the term “improved cookstove”, thus we rely on the definition of ESMAP adopted by the Ministry of Energy of the Republic of Kenya [25]) are successively used even by the rural population. We assume the substitution of traditional firewood and charcoal stoves by ICSs with higher efficiencies, but notably increased costs, as stated under Cooking Systems, by 2030. We further assume more efficient DC EPCs (efficiency of 70%) to substitute AC EPC and electric hotplates from 2030 onwards [49]. Notably, this impacts the electricity demand profile; see Cooking Demand. For any cookstove, we estimate a linear cost decline of 5% between 2030 and 2040 and 10% between 2040 and 2050. In the reference case, we assume a Meko-stove for hydrogen and LPG, but analyze the costs for a more expensive conventional single-burner.

- Electricity tariff: the regulated electricity tariffs for grid-connected customers in Kenya have slightly declined over the last years. However, a continuation of this trend is questionable and hard to predict. Thus, we maintain the uniform electricity tariff in our scenarios. Individual cost-based tariffs for isolated grids, however, will likely fall alongside the estimated cost decline of energy supply technologies. We adjust the mini-grid tariff according to the LCOE reduction observed in our analysis of a stand-alone electricity supply system (see Figure 1b).

3. Results and Implications

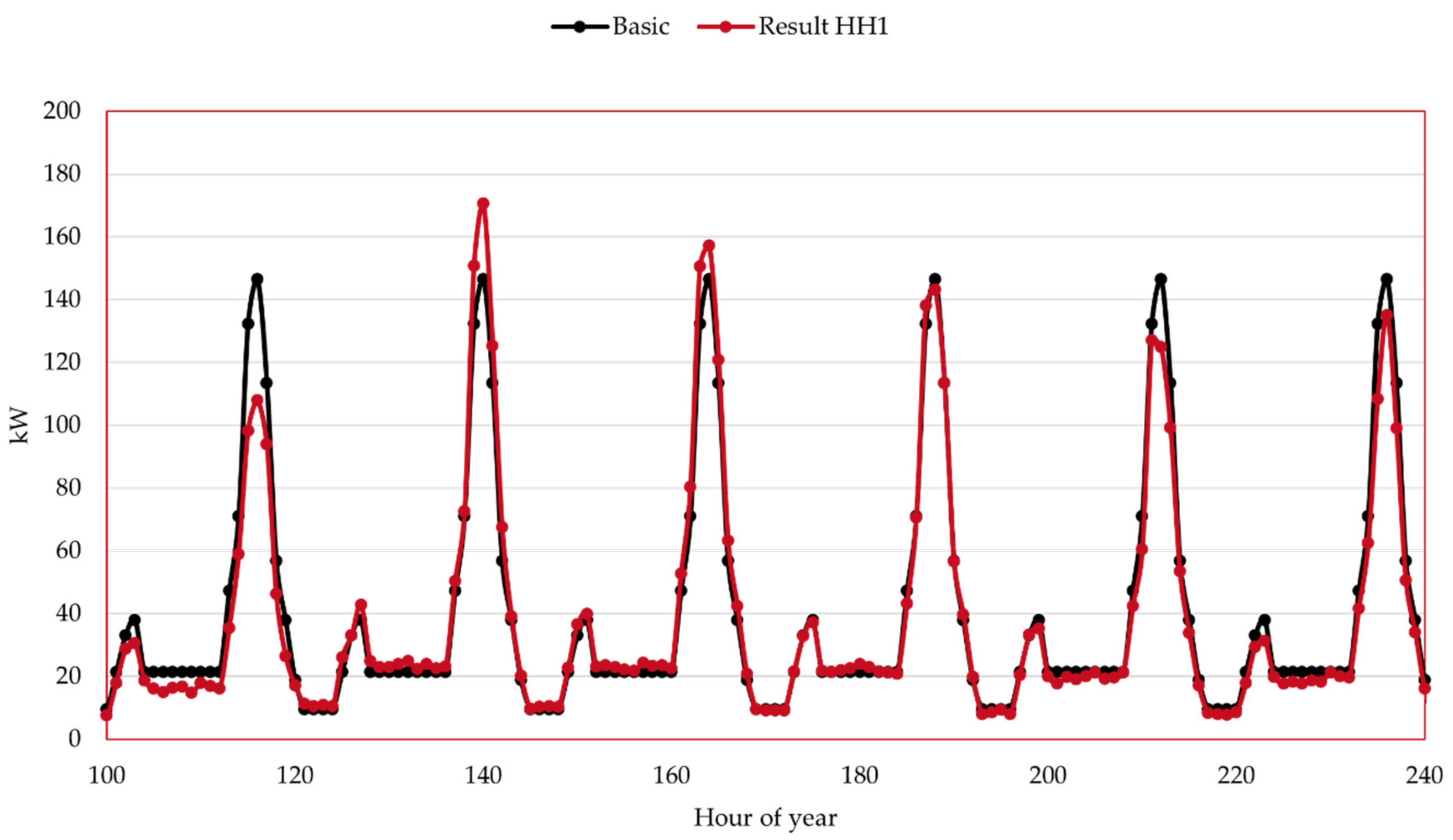

3.1. Energy System Results

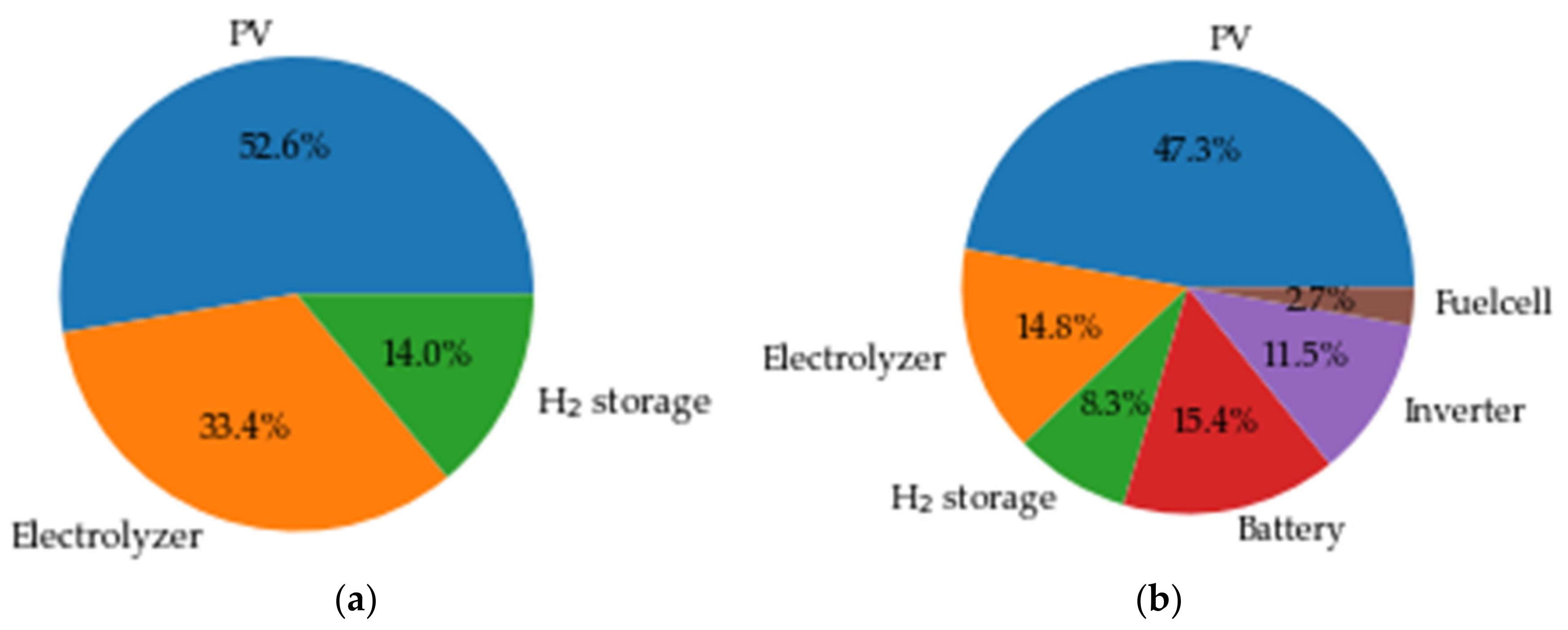

3.1.1. Optimal Energy System Topology

- System integration: when integrating the EL to produce hydrogen for utilization via combustion into the electricity supply system, the resulting PV and EL component sizes are less than the sum of the respective component sizes when considering stand-alone hydrogen combustion and electricity supply. This suggests that synergies in the operation of the subsystems and co-utilization of infrastructures can be unlocked by the integration.

- Electricity supply system: we observe that the FC becomes smaller in the optimal energy system topology in scenarios 2030 and 2040 when integrating the hydrogen production into the electricity supply system. Currently, this is explained by studying the operational behavior of the systems. Under present conditions, the FC operates during evening peaks and after days with low solar irradiation, as the hydrogen storage associated with low energy losses is a suitable long-term storage. When decreasing the investment costs of the PV in 2030 and 2040 scenarios, more of such rare events are covered directly by larger-sized PV and short-term battery storage (note that the share of excess electricity increases by 50% from 2030 to 2040). However, the expected decline in CAPEX of the EL and FC and respective efficiency increase expected by 2050 suggest to exclusively include P2H2P as back-up complementing PV, and the battery is excluded from the optimal energy system. The same trend is reflected in the stand-alone electricity supply system and hydrogen-based e-cooking system.

- Hydrogen–LPG blend: while we suggest harnessing excess electricity of an existing PV-battery mini-grid, the excess electricity share is only reduced by 4% (10% of the total excess) when integrating the electrolyzer. An optimal electrolyzer size of <1 kW is sufficient to produce the required amount of hydrogen cooking fuel when blended into LPG by 20% on a volumetric basis. This suggests that the potential of the blending solution to decrease excess electricity of mini-grids is limited when considering the market size for cooking fuel to be restricted to the local residentials (see [75] for a related discussion of utilizing excess electricity from over-sized mini-grids in Africa).

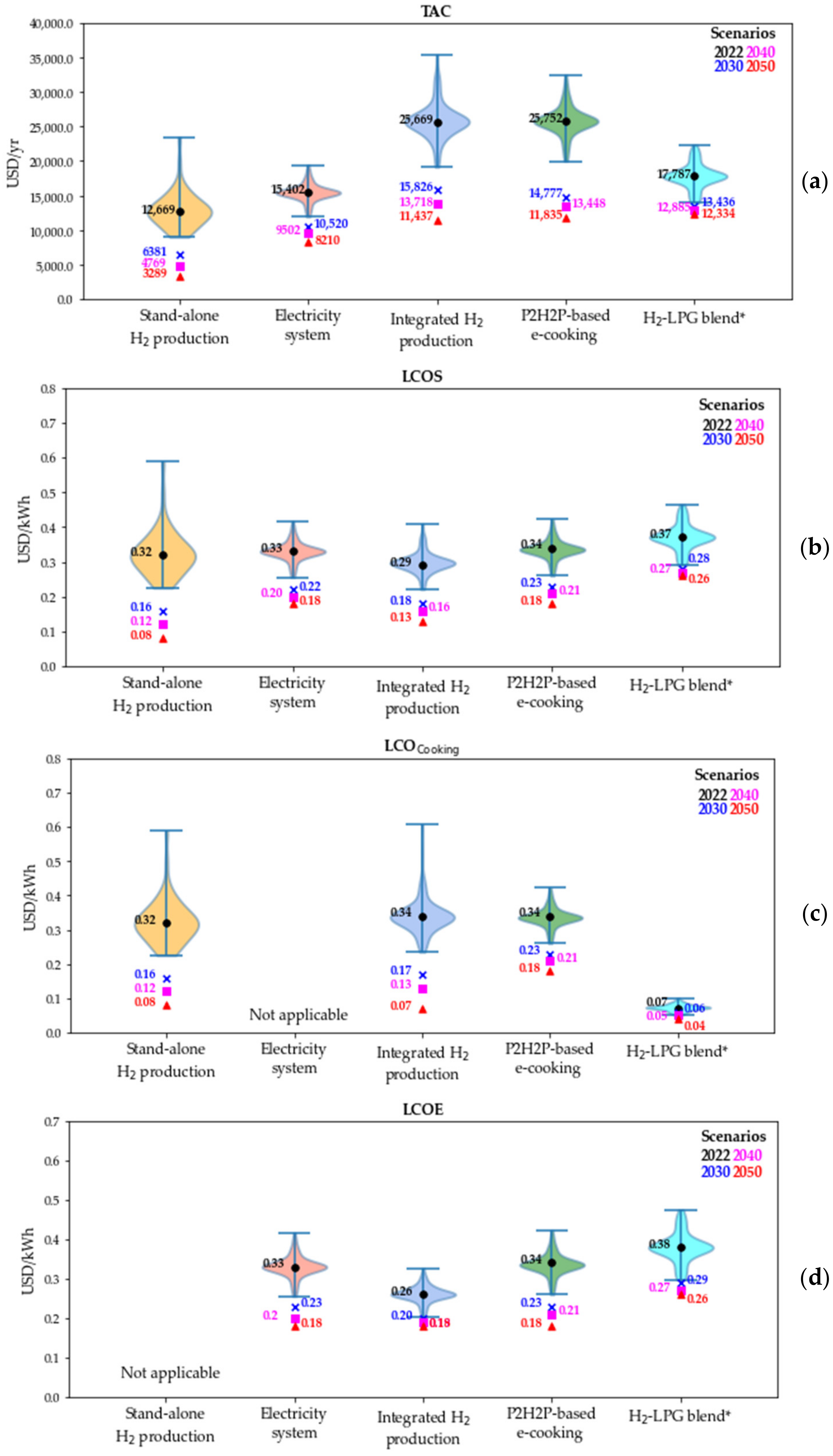

3.1.2. Economic Energy System Results

3.2. Economic Results for End Users

4. Discussion

| Cooking Fuel | Firewood | Charcoal | LPG |

|---|---|---|---|

| CO2 [g/kg] | 1548 [87] | 2385 [87] | 2728 [84] |

| CH4 [g/kg] | 4.86 [87] | 5.29 [87] | 134.5 [84] |

| N2O | 35.6 [84] | 0.24 [87] | 28.82 [84] |

| CO2-equivalents [g/kg] | 12,278 | 2588 | 14,678 [84] |

| Total household annual emissions [kg CO2-eq./yr] | 15,685 | 1653 | 1232 |

| Annual village emissions [t CO2-eq./yr] | 658.79 | 69.45 | 51.75 |

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AC | Alternating current |

| AEL | Alkaline electrolysis |

| CAPEX | Capital expenditure |

| DC | Direct current |

| DG | Diesel generator |

| EL | Electrolysis |

| EPRA | Energy and Petroleum Regulatory Authority |

| ESMAP | Energy Sector Management Assistance Program |

| FC | Fuel cell |

| H2 | Hydrogen |

| IRENA | International Renewable Energy Agency |

| LCOCooking | Levelized costs of cooking energy |

| LCOE | Levelized costs of electricity |

| LEAP | Long term Europe Africa Partnership |

| MECS | Modern Energy Cooking Services |

| OPEX | Operational expenditure |

| PV | Photovoltaic |

| PEMFC | Polymer membrane exchange fuel cell |

| P2H2P | Power-to-hydrogen-to-power |

| SOEL | Solid oxide electrolysis |

| SOFC | Solid oxide fuel cell |

| WACC | Weighted average costs of capital |

| WHO | World Health Organization |

Appendix A

Appendix B

- 1.

- Levelized costs of system (LCOS): average costs per kWh of useful energy produced by the system to serve energy as

- 2.

- Levelized Costs of Electricity (LCOE): we define the levelized costs of electricity (LCOE) as the average cost per kWh of useful electricity energy produced by the system to serve electric loads. Thereby, we divide the annualized costs of producing electricity (notably excluding any cost associated with the potential cooking system loads) by the total electric load served.

References

- United Nations. Sustainable Development Goals Knowledge Platform. Available online: https://sustainabledevelopment.un.org (accessed on 11 July 2022).

- Kurmi, O.P.; Semple, S.; Simkhada, P.; Smith, W.C.S.; Ayres, J.G. COPD and Chronic Bronchitis Risk of Indoor Air Pollution from Solid Fuel: A Systematic Review and Meta-Analysis. Thorax 2010, 65, 221–228. [Google Scholar] [CrossRef] [PubMed]

- Yu, K.; Qiu, G.; Chan, K.-H.; Lam, K.-B.H.; Kurmi, O.P.; Bennett, D.A.; Yu, C.; Pan, A.; Lv, J.; Guo, Y.; et al. Association of Solid Fuel Use With Risk of Cardiovascular and All-Cause Mortality in Rural China. JAMA 2018, 319, 1351–1361. [Google Scholar] [CrossRef] [PubMed]

- James, B.S.; Shetty, R.S.; Kamath, A.; Shetty, A. Household cooking fuel use and its health effects among rural women in southern India-A cross-sectional study. PLoS ONE 2020, 27, e0231757. [Google Scholar] [CrossRef] [PubMed]

- Bond, T.C.; Doherty, S.J.; Fahey, D.W.; Forster, P.M.; Berntsen, T.; DeAngelo, B.J.; Flanner, M.G.; Ghan, S.; Kärcher, B.; Koch, D.; et al. Bounding the Role of Black Carbon in the Climate System: A Scientific Assessment: Black Carbon in the Climate System. J. Geophys. Res. Atmos. 2013, 118, 5380–5552. [Google Scholar] [CrossRef]

- Grieshop, A.P.; Marshall, J.D.; Kandlikar, M. Health and Climate Benefits of Cookstove Replacement Options. Energy Policy 2011, 39, 7530–7542. [Google Scholar] [CrossRef]

- IEA—International Energy Agency. World Energy Outlook 2018; IEA: Washington, DC, USA, 2019; p. 661. [Google Scholar]

- IEA; IRENA; UNSD; WB; WHO. Tracking SDG7: The Energy Progress Report 2022; IEA: Washington, DC, USA, 2022. [Google Scholar]

- Shupler, M.; O’Keefe, M.; Puzzolo, E.; Nix, E.; de Cuevas, R.A.; Mwitari, J.; Gohole, A.; Sang, E.; Čukić, I.; Menya, D.; et al. Pay-as-You-Go Liquefied Petroleum Gas Supports Sustainable Clean Cooking in Kenyan Informal Urban Settlement during COVID-19 Lockdown. Appl. Energy 2021, 292, 116769. [Google Scholar] [CrossRef]

- Schöne, N.; Heinz, B. Semi-Systematic Literature Review on the Contribution of Hydrogen to Universal Access to Energy in the Rationale of Sustainable Development Goal Target 7.1. Energies 2023, 16, 1658. [Google Scholar] [CrossRef]

- Maestre, V.M.; Ortiz, A.; Ortiz, I. Challenges and Prospects of Renewable Hydrogen-Based Strategies for Full Decarbonization of Stationary Power Applications. Renew. Sustain. Energy Rev. 2021, 152, 111628. [Google Scholar] [CrossRef]

- Das, H.S.; Tan, C.W.; Yatim, A.H.M.; Lau, K.Y. Feasibility Analysis of Hybrid Photovoltaic/Battery/Fuel Cell Energy System for an Indigenous Residence in East Malaysia. Renew. Sust. Energ. Rev. 2017, 76, 1332–1347. [Google Scholar] [CrossRef]

- Jahangiri, M.; Haghani, A.; Shamsabadi, A.A.; Mostafaeipour, A.; Pomares, L.M. Feasibility Study on the Provision of Electricity and Hydrogen for Domestic Purposes in the South of Iran Using Grid-Connected Renewable Energy Plants. Energy Strategy Rev. 2019, 23, 23–32. [Google Scholar] [CrossRef]

- Brenna, M.; Foiadelli, F.; Longo, M.; Abegaz, T.D. Integration and Optimization of Renewables and Storages for Rural Electrification. Sustainibility 2016, 8, 982. [Google Scholar] [CrossRef]

- Schöne, N.; Khairallah, J.; Heinz, B. Model-Based Techno-Economic Evaluation of Power-to-Hydrogen-to-Power for the Electrification of Isolated African off-Grid Communities. Energy Sustain. Dev. 2022, 70, 592–608. [Google Scholar] [CrossRef]

- ESMAP; SE4All. Beyond Connections: Energy Access Redefined; World Bank: Washington, DC, USA, 2016. [Google Scholar]

- Efficiency for Access Coalition. Solar Appliance Technology Brief: Electric Pressure Cookers. Available online: https://storage.googleapis.com/e4a-website-assets/EforA_Solar_Appliance_Technology_Brief_EPCs_July-2021.pdf (accessed on 24 January 2023).

- Luta, D.N.; Raji, A.K. Decision-Making between a Grid Extension and a Rural Renewable off-Grid System with Hydrogen Generation. Int. J. Hydrogen Energy 2018, 43, 9535–9548. [Google Scholar] [CrossRef]

- Hailu Kebede, M.; Bekele Beyene, G. Feasibility Study of PV-Wind-Fuel Cell Hybrid Power System for Electrification of a Rural Village in Ethiopia. J. Electr. Comput. Eng. 2018, 2018, 4015354. [Google Scholar] [CrossRef]

- Leary, J.; Scott, N.; Sago, S.; Minja, A.; Batchelor, S.; Chepkurui, K.; Sawe, E. eCook Tanzania Cooking Diaries—October 2019 Working Paper; EAM, Loughborough University, University of Surrey & Gamos Ltd. supported by Innovate UK, UK Aid (DfID) & Gamos Ltd. 2019. Available online: https://mecs.org.uk/wp-content/uploads/2020/12/eCook-Tanzania-Cooking-Diaries-Working-Paper-13-10-19-JL-COMPRESSED.pdf (accessed on 12 December 2022).

- Singh, V.K.; Chauhan, N.S. Fundamentals and Use of Hydrogen as a Fuel. J. Mech. Eng. 2015, 6, 63–68. [Google Scholar]

- Kobayashi, H.; Hayakawa, A.; Somarathne, K.; Okafor, E.C. Science and Technology of Ammonia Combustion. Proc. Combust. Inst. 2019, 37, 109–133. [Google Scholar] [CrossRef]

- de Vries, H.; Mokhov, A.; Levinsky, H. The Impact of Natural Gas/Hydrogen Mixtures on the Performance of End-Use Equipment: Interchangeability Analysis for Domestic Appliances. Appl. Energy 2017, 208, 1007–1019. [Google Scholar] [CrossRef]

- The Engineering ToolBox. Fuels—Higher and Lower Calorific Values. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 23 January 2023).

- Ministry of Energy Kenya. Kenya Cooking Sector Study Compressed; Ministry of Energy Kenya: Nairobi, Kenya, 2019. [Google Scholar]

- Young, D.; Mill, G.; Wall, R. Feasibility of Renewable Energy Storage Using Hydrogen in Remote Communities in Bhutan. Int. J. Hydrogen Energy 2007, 32, 997–1009. [Google Scholar] [CrossRef]

- WLPGA; GLPGP. Sustainable Development Goals: Contributions of LPG; WLPGA: Neuilly-sur-Seine, France, 2019. [Google Scholar]

- Puzzolo, E.; Cloke, J.; Evans, A.; Pope, D. National Scaling Up of LPG to Achieve SDG 7: Implications for Policy, Implementation, Public Health and Environment; MECS. 2020. Available online: https://mecs.org.uk/wp-content/uploads/2020/02/MECS-LPG-Briefing-Paper_Jan-2020.pdf (accessed on 12 December 2022).

- Topriska, E.; Kolokotroni, M.; Dehouche, Z.; Wilson, E. Solar Hydrogen System for Cooking Applications: Experimental and Numerical Study. Renew. Energy 2015, 83, 717–728. [Google Scholar] [CrossRef]

- Topriska, E. Experimental and Computational Study of a Solar Powered Hydrogen Production System for Domestic Cooking Applications in Developing Economies. Ph.D. Thesis, Brunel University London, Uxbridge, UK, 2016. [Google Scholar]

- University of Technology, Jamaica. Sustainable Hydrogen Cooking Gas. Available online: https://www.utech.edu.jm/cseii/event-3.html (accessed on 25 November 2022).

- Jamaica Information Service. Utech Launches Project to Develop Hydrogen Gas for Cooking. Available online: https://jis.gov.jm/utech-launches-project-to-develop-hydrogen-gas-for-cooking/ (accessed on 25 November 2022).

- Schmidt Rivera, X.C.; Topriska, E.; Kolokotroni, M.; Azapagic, A. Environmental Sustainability of Renewable Hydrogen in Comparison with Conventional Cooking Fuels. J. Clean. Prod. 2018, 196, 863–879. [Google Scholar] [CrossRef]

- Topolski, K.; Reznicek, E.; Erdener, B.; San Marchi, C.; Ronevich, J.; Fring, L.; Simmons, K.; Fernandez, O.; Gidge, B.-M.; Chung, M. Hydrogen Blending into Natural Gas Pipeline Infrastructure: Review of the State of Technology; NREL: Golden, CO, USA, 2022. Available online: https://www.nrel.gov/docs/fy23osti/81704.pdf2022 (accessed on 30 January 2023).

- Makaryan, I.A.; Sedov, I.V.; Salgansky, E.A.; Arutyunov, A.V.; Arutyunov, V.S. A Comprehensive Review on the Prospects of Using Hydrogen–Methane Blends: Challenges and Opportunities. Energies 2022, 15, 2265. [Google Scholar] [CrossRef]

- Foell, W.; Pachauri, S.; Spreng, D.; Zerriffi, H. Household Cooking Fuels and Technologies in Developing Economies. Energy Policy 2011, 39, 7487–7496. [Google Scholar] [CrossRef]

- Buttler, A.; Spliethoff, H. Current Status of Water Electrolysis for Energy Storage, Grid Balancing and Sector Coupling via Power-to-Gas and Power-to-Liquids: A Review. Renew. Sust. Energ. Rev. 2018, 82, 2440–2454. [Google Scholar] [CrossRef]

- Akinyele, D.; Olabode, E.; Amole, A. Review of Fuel Cell Technologies and Applications for Sustainable Microgrid Systems. Inventions 2020, 5, 42. [Google Scholar] [CrossRef]

- Carbon Africa Limited. Kenya Market Assessment for Off-Grid Electrification; Carbon Africa Limited: Nairobi, Kenya, 2014. [Google Scholar]

- Moner-Girona, M.; Bódis, K.; Morrissey, J.; Kougias, I.; Hankins, M.; Huld, T.; Szabó, S. Decentralized Rural Electrification in Kenya: Speeding up Universal Energy Access. Energy Sustain. Dev. 2019, 52, 128–146. [Google Scholar] [CrossRef]

- Lorenzoni, L.; Cherubini, P.; Fioriti, D.; Poli, D.; Micangeli, A.; Giglioli, R. Classification and Modeling of Load Profiles of Isolated Mini-Grids in Developing Countries: A Data-Driven Approach. Energy Sustain. Dev. 2020, 59, 208–225. [Google Scholar] [CrossRef]

- Pfenninger, S.; Staffell, I. Long-Term Patterns of European PV Output Using 30 Years of Validated Hourly Reanalysis and Satellite Data. Energy 2016, 114, 1251–1265. [Google Scholar] [CrossRef]

- Renewables. Ninja. Simulations of the Hourly Power Output from Wind and Solar Power Plants. Available online: https://www.renewables.ninja (accessed on 11 July 2022).

- Jacobson, M.Z.; Jadhav, V. World Estimates of PV Optimal Tilt Angles and Ratios of Sunlight Incident upon Tilted and Tracked PV Panels Relative to Horizontal Panels. Sol. Energy 2018, 169, 55–66. [Google Scholar] [CrossRef]

- Scott, N.; Coley, W. Understanding Load Profiles of Mini-Grid Customers in Tanzania. Energies 2021, 14, 4207. [Google Scholar] [CrossRef]

- Blechinger, P.; Cader, C.; Bertheau, P. Least-Cost Electrification Modeling and Planning—A Case Study for Five Nigerian Federal States. Proc. IEEE 2019, 107, 1923–1940. [Google Scholar] [CrossRef]

- HOMER Energy. Generating Synthetic Load Data, HOMER Pro. Available online: https://www.homerenergy.com/products/grid/docs/1.4/generating_synthetic_load_data.html (accessed on 11 July 2022).

- Hartvigsson, E.; Ahlgren, E. Comparison of Load Profiles in a Mini-Grid: Assessment of Performance Metrics Using Measured and Interview-Based Data. Energy Sustain. Dev. 2018, 43, 186–195. [Google Scholar] [CrossRef]

- ESMAP. Cooking with Electricity: A Cost Perspective; World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Lindgren, S.A. Clean Cooking for All? A Critical Review of Behavior, Stakeholder Engagement, and Adoption for the Global Diffusion of Improved Cookstoves. Energy Res. Soc. Sci. 2020, 68, 101539. [Google Scholar] [CrossRef]

- Leach, M.; Mullen, C.; Lee, J.; Soltowski, B.; Wade, N.; Galloway, S.; Coley, W.; Keddar, S.; Scott, N.; Batchelor, S. Modelling the Costs and Benefits of Moving to Modern Energy Cooking Services—Methods & Application to Three Case Studies; Modern Energy Cooking Services 2021. Available online: https://mecs.org.uk/wp-content/uploads/2021/05/Modelling-the-costs-and-benefits-of-moving-to-Modern-Energy-Cooking-Services-–-methods-application-to-three-case-studies.pdf (accessed on 12 December 2022).

- Couture, T.; Jacobs, D. Beyond Fire; E3 Analytics, International Energy Transition GmbH: Berlin, Germany, 2019; p. 83. [Google Scholar]

- Total Energies. Total Energies Gas Prices Cylinders & Accessories. Available online: https://totalenergies.ke/products/totalenergies-gas/totalenergies-gas-prices-cylinders-accessories (accessed on 28 March 2023).

- Ambition to Action. The Kenyan Cooking Sector Opportunities for Climate Action and Sustainable Development; New Climate Institute: Berlin, Germany, 2021. [Google Scholar]

- Jäger-Waldau, A. PV-Status Report 2019; Joint Reseearch Centre: Luxembourg, 2019. [Google Scholar]

- Moner-Girona, M.; Solano-Peralta, M.; Lazopoulou, M.; Ackom, E.K.; Vallve, X.; Szabó, S. Electrification of Sub-Saharan Africa through PV/Hybrid Mini-Grids: Reducing the Gap between Current Business Models and on-Site Experience. Renew. Sust. Energ. Rev. 2018, 91, 1148–1161. [Google Scholar] [CrossRef]

- ESMAP. Mini Grids for Half a Billion People: Market Outlook and Handbook for Decision Makers; World Bank: Washington, DC, USA, 2019. [Google Scholar]

- Se4all. State of the Global Mini-Grids Market Report 2020; Se4all: Washington, DC, USA, 2020. [Google Scholar]

- Ghandi, O.; Srinivasan, D. Sustainable Energy Solutions for Remote Areas in the Tropics (Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2020; ISBN 978-3-030-41951-6. [Google Scholar]

- Sen, R. A Detailed Manual on Lead Acid Battery Operation and Maintenance for Solar PV Plants; USAID: Washington, DC, USA, 2018. [Google Scholar]

- Spataru, C.; Bouffaron, P. Chapter 22—Off-Grid Energy Storage. In Storing Energy; Letcher, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Agenbroad, J.; Carlin, K.; Ernst, K.; Doig, S. Minigrids in the Money: Six Ways to Reduce Minigrid Costs by 60% for Rural Electrification; Rocky Mountain Institute: Basalt, CO, USA, 2018. [Google Scholar]

- Louie, H. Off-Grid Renewable Energy Systems in Developing Countries; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Reber, T.; Booth, S.; Cutler, D.; Li, X.; Salasovich, J. Tariff Considerations for Micro-Grids in Sub-Saharan Africa; NREL USAID Power Africa: Bryanston, South Africa, 2018; p. 30. [Google Scholar]

- Hilpert, S.; Kaldemeyera, C.; Krien, U.; Günther, S.; Wingenbach, C.; Plessmann, G. The Open Energy Modelling Framework (Oemof)—A New Approach to Facilitate Open Science in Energy System Modelling. Energy Strategy Rev. 2018, 22, 16–25. [Google Scholar] [CrossRef]

- Krien, U.; Schönfeldt, P.; Launer, J.; Hilpert, S.; Kaldemeyer, C.; Pleßmann, G. Oemof.Solph—A Model Generator for Linear and Mixed-Integer Linear Optimisation Ofenergy Systems. Softw. Impacts 2020, 6, 100028. [Google Scholar] [CrossRef]

- Benderes, S.; Bertheau, P.; Blechinger, P. Sizing and Optimization of Hybrid Mini-Grids with MicrOgridS—An Open-Source Modelling Tool. In Proceedings of the 3rd International Hybrid Power Systems Workshop, Tenerife, Spain, 8–9 May 2018. [Google Scholar]

- IRENA. Renewable Power Generation Costs in 2019, Technical Report; IRENA: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Kibet, H. Association for Microfinance Institutions—AMFI Kenya Sector Report; AMFI: Mumbai, India, 2021. [Google Scholar]

- Stima. Electricity Cost in Kenya. Available online: https://www.stimatracker.com (accessed on 30 January 2023).

- The World Bank; ESMAP. Mini Grids in Kenya: A Case Study of a Market at a Turning Point; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Meister Consultants Group, Inc. Exploring Africa’s Mini-Grid Tariff Methodologies; U.S. AID: Washington, DC, USA, 2020. [Google Scholar]

- IRENA. Future of Solar PV; IRENA: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- IRENA. Green Hydrogen Cost Reduction—Scaling up Electrolysers to Meet the 1.5 °C Climate Goal; IRENA: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Louie, H.; Dauenhauer, P. Effects of Load Estimation Error on Small-Scale off-Grid Photovoltaic System Design, Cost and Reliability. Energy Sustain. Dev. 2016, 34, 30–43. [Google Scholar] [CrossRef]

- Smolinka, T.; Günther, M.; Garche, J. Stand Und Entwicklungspotenzial Der Wasserelektrolyse Zur Herstellung von Wasserstoff Aus Regenerativen Energien; Fraunhofer ISE, FCBAT: Breisgau, Germany, 2011. [Google Scholar]

- Hsu, E.; Forougi, N.; Gan, M.; Muchiri, E.; Pope, D.; Puzzolo, E. Microfinance for Clean Cooking: What Lessons Can Be Learned for Scaling up LPG Adoption in Kenya through Managed Loans? Energy Policy 2021, 154, 112263. [Google Scholar] [CrossRef]

- Little, M.; Blanchard, R. Pre-Feasibility Methodology to Compare Productive Uses of Energy Supplied by Stand-Alone Solar Photovoltaic Systems: A Tanzanian Case Study. Energy Sustain. Dev. 2022, 70, 497–510. [Google Scholar] [CrossRef]

- Matthey-Junod, A. Leaving No Aspect of Sustainability behind: A Framework for Designing Sustainable Energy Interventions Applied to Refugee Camps. Energy Res. Soc. Sci. 2022, 90, 102636. [Google Scholar] [CrossRef]

- Shuma, J.C.; Sawe, E.; Clements, A.; Meena, S.B.; Aloyce, K.; Ngaya, A.E. ECooking Delivery Models: Approach to Designing Delivery Models for Electric Pressure Cookers with Case Study for Tanzania. Energies 2022, 15, 771. [Google Scholar] [CrossRef]

- Bisaga, I.; To, L.S. Funding and Delivery Models for Modern Energy Cooking Services in Displacement Settings: A Review. Energies 2021, 14, 4176. [Google Scholar] [CrossRef]

- Stritzke, S.; Sakyi-Nyarko, C.; Bisaga, I.; Bricknell, M.; Leary, J.; Brown, E. Results-Based Financing (RBF) for Modern Energy Cooking Solutions: An Effective Driver for Innovation and Scale? Energies 2021, 14, 4559. [Google Scholar] [CrossRef]

- Bricknell, M.; Stritzke, S.; Brown, E.; Batchelor, S.; Weston, P.; Gopalan, A. Modern Energy Cooking: Review of the Funding Landscape—Reports of 5 Clean Cooking Series. Energy 4 Impact, MECS. 2022. Available online: https://energy4impact.org/modern-energy-cooking-review-funding-landscape-0 (accessed on 12 December 2022).

- EPA. Emission Factors for Greenhouse Gas Inventories. Available online: https://www.epa.gov/sites/default/files/2018-03/documents/emission-factors_mar_2018_0.pdf (accessed on 24 January 2022).

- Cerutti, P.O.; Sola, P.; Chenevoy, A.; Iiyama, M.; Yila, J.; Zhou, W.; Djoudi, H.; Atyi, R.E.; Gautier, D.J.; Gumbo, D.; et al. The Socioeconomic and Environmental Impacts of Wood Energy Value Chains in Sub-Saharan Africa: A Systematic Map Protocol. Environ. Evid. 2015, 4, 12. [Google Scholar] [CrossRef]

- Forrister, H.; Liu, J.; Scheuer, E.; Dibb, J.; Ziemba, L.; Thornhill, K.L.; Anderson, B.; Diskin, G.; Perring, A.E.; Schwarz, J.P.; et al. Evolution of Brown Carbon in Wildfire Plumes. Geophys. Res. Lett. 2015, 42, 4623–4630. [Google Scholar] [CrossRef]

- Akagi, S.K.; Yokelson, R.J.; Wiedinmyer, C.; Alvarado, M.; Reid, J.S.; Karl, T.; Crounse, J.D.; Wennberg, P.O. Emission Factors for Open and Domestic Biomass Burning for Use in Atmospheric Models. Atmos. Chem. Phys. 2011, 11, 4039–4072. [Google Scholar] [CrossRef]

- Lewis, A.C. Optimising Air Quality Co-Benefits in a Hydrogen Economy: A Case for Hydrogen-Specific Standards for NO x Emissions. Environ. Sci. Atmos. 2021, 1, 201–207. [Google Scholar] [CrossRef]

- Scott, N.; Barnard-Tallier, M.; Clements, A.; Inston, R.; Lapworth, S.; Price, M. Landscaping Study—Modern Foods (Working Paper). Modern Energy Cooking Services. Available online: https://mecs.org.uk/wp-content/uploads/2020/12/Landscape-Study-Modern-Foods-and-Eating-Habits.pdf (accessed on 8 February 2023).

- Gordon, J.A.; Balta-Ozkan, N.; Nabavi, S.A. Beyond the Triangle of Renewable Energy Acceptance: The Five Dimensions of Domestic Hydrogen Acceptance. Appl. Energy 2022, 324, 119715. [Google Scholar] [CrossRef]

- Flynn, R.; Bellaby, P.; Ricci, M. Environmental Citizenship and Public Attitudes to Hydrogen Energy Technologies. Environ. Politics 2008, 17, 766–783. [Google Scholar] [CrossRef]

- Scott, M.; Powells, G. Towards a New Social Science Research Agenda for Hydrogen Transitions: Social Practices, Energy Justice, and Place Attachment. Energy Res. Soc. Sci. 2020, 61, 101346. [Google Scholar] [CrossRef]

- Efficiency for Access; 60 Decibels. Uses and Impacts of Electric Pressure Cookers—Insights from Kenya. 2021. Available online: https://efficiencyforaccess.org/publications/uses-impacts-of-electric-pressure-cookers (accessed on 8 February 2023).

- Clements, A.; Fodio Todd, J. Tanzania ECooking Market Assessment. MECS. 2022. Available online: https://mecs.org.uk/wp-content/uploads/2022/08/Tanzania-eCooking-Market-Assessment-2022-Final.pdf (accessed on 8 February 2023).

- Modern Energy Cooking Services; UK Aid. Cooking with Electricity in Kenya—A Culinary Tour of a Transformative Opportunity. Available online: https://mecs.org.uk/blog/cooking-with-electricity-in-kenya-a-culinary-tour-of-a-transformative-opportunity/ (accessed on 8 February 2023).

| Property | Unit | Hydrogen (H2) | Propane (C3H8) | Methane (CH4) |

|---|---|---|---|---|

| Molecular weight | u | 2.01594 [21] | 44.1 | 16.4 |

| Gravimetric energy content | MJ/kg | 120 [22] | 46.4 [22] | 50 [22] |

| Higher heating value (HHV) | MJ/Nm3 (MJ/l Propane) | 12.75 [23] | 26.5 [24] | 39.82 [23] |

| Flammability range (Equivalence ratio) | 0.1~7.1 [22] | 0.51~2.5 [22] | 0.5~1.7 [22] | |

| Max. laminar burning velocity | m/s | 2.91 [22] | 0.43 [22] | 0.37 [22] |

| Adiabatic flame temperature in air | °C | 2.110 [22] | 2.000 [22] | 1.950 [22] |

| Diffusion coefficient in air | Cm2/s | 0.61 [21] | 0.1318 [S] | 0.221 [S] |

| Minimum auto ignition temperature | °C | 520 [22] | 450 [22] | 630 [22] |

| Parameter | Fuelwood | Charcoal | LPG | Hydrogen | EPC + Hot Plate |

|---|---|---|---|---|---|

| Calorific value [kWh/kg] | 4.12 | 8.61 | 13.14 | 39.4 | / |

| Fuel costs [USD/kg] 1 [25] | 0.33 | 0.47 | 1.31 | See analysis | Lifeline tariff (<100 kWh/m): 0.17 USD/kWh Domestic ordinary tariff: 0.23 USD/kWh [49] Average cost reflective mini-grid tariff: 0.67–0.8 USD/kWh |

| Daily fuel demand per household [kg] 1 [49] | 3.5 | 1.75 | 0.23 | 0.066 | 1.92 |

| Parameter | Unit | AEL | H2 Storage | PEMFC |

|---|---|---|---|---|

| Specific investment costs | USD/kWel | 1000 | 20 USD/kWh | 2600 |

| O&M costs | % invest | 3 | 0.3 USD/kWh/a | 3 |

| Lifetime | y | 10 (stack) 20 (system) | 20 | 10 (stack) 20 (system) |

| Efficiency | % | 60 (LHV) | 0.88 1 | 55 (LHV) |

| Year | CAPEX [USD/kWel] | Efficiency [% System, LHV] | PV CAPEX [USD/kW] | Firewood Price [USD/kg] | Charcoal Price [USD/kg] | LPG Price [USD/kg] | Lifeline Tariff [USD/kWh] | CRF Tariff [USD/kWh] | ||

|---|---|---|---|---|---|---|---|---|---|---|

| EL | FC | EL | FC | |||||||

| 2022 | 1000 | 2600 | 60 | 55 | 1000 | 0.33 | 0.47 | 1.31 | 0.167 | 0.67 |

| 2030 | 600 | 1560 | 64.5 | 59 | 400 | 0.42 | 0.59 | 1.66 | 0.167 | 0.47 |

| 2040 | 400 | 1040 | 69 | 63.25 | 325 | 0.56 | 0.8 | 2.23 | 0.167 | 0.41 |

| 2050 | 200 | 520 | 73 | 67 | 250 | 0.75 | 1.07 | 3.0 | 0.167 | 0.37 |

| Parameter | Year | Stand-Alone H2 Production | Stand-Alone Electricity Supply | Integrated H2 Production | P2H2P-Based e-Cooking * | H2–LPG Blend ** |

|---|---|---|---|---|---|---|

| PV power [kWp] | 2022 | 50.25 | 48.81 | 91.11 | 80.17 | 54.46 |

| 2030 | 53.51 | 53.45 | 105.22 | 72.11 | 54.46 | |

| 2040 | 53.49 | 52.45 | 100.73 | 69.81 | 54.46 | |

| 2050 | 54.82 | 68.02 | 121.4 | 93.23 | 54.46 | |

| Battery capacity [kWh] | 2022 | 140.79 | 134.72 | 234.24 | 272.72 | |

| 2030 | 117.88 | 136.83 | 174.63 | 272.72 | ||

| 2040 | 117.39 | 135.43 | 173.6 | 272.72 | ||

| 2050 | 0 | 0 | 0 | 272.72 | ||

| Electrolyzer power [kWel] | 2022 | 25.02 | 0.97 | 24.35 | 1.72 | 0.29 |

| 2030 | 22.53 | 2.08 | 22.85 | 2.16 | 0.27 | |

| 2040 | 22.52 | 1.95 | 21.7 | 2.04 | 0.25 | |

| 2050 | 24.07 | 21.27 | 46.55 | 29.51 | 0.24 | |

| Fuel cell power [kWel] | 2022 | 1.98 | 0.67 | 3.23 | ||

| 2030 | 2.2 | 0.3 | 2.82 | |||

| 2040 | 2.24 | 0.44 | 2.93 | |||

| 2050 | 13.98 | 13.99 | 20.28 | |||

| H2 storage capacity [kWh] | 2022 | 648.53 | 164.21 | 801.69 | 272.36 | 17.81 |

| 2030 | 482.27 | 143.21 | 437.73 | 189.83 | 17.64 | |

| 2040 | 360.69 | 144.33 | 447.71 | 204.98 | 17.63 | |

| 2050 | 251.59 | 230.4 | 408.02 | 314.93 | 17.62 | |

| Excess electricity share [%] | 2022 | 15.2 | 31.2 | 19.02 | 30.89 | 35.6 |

| 2030 | 26.07 | 36.25 | 31.34 | 34.96 | 35.86 | |

| 2040 | 31.09 | 34.58 | 30.61 | 32.69 | 36.04 | |

| 2050 | 36.8 | 33.37 | 35.56 | 33.19 | 36.19 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schöne, N.; Dumitrescu, R.; Heinz, B. Techno-Economic Evaluation of Hydrogen-Based Cooking Solutions in Remote African Communities—The Case of Kenya. Energies 2023, 16, 3242. https://doi.org/10.3390/en16073242

Schöne N, Dumitrescu R, Heinz B. Techno-Economic Evaluation of Hydrogen-Based Cooking Solutions in Remote African Communities—The Case of Kenya. Energies. 2023; 16(7):3242. https://doi.org/10.3390/en16073242

Chicago/Turabian StyleSchöne, Nikolas, Raluca Dumitrescu, and Boris Heinz. 2023. "Techno-Economic Evaluation of Hydrogen-Based Cooking Solutions in Remote African Communities—The Case of Kenya" Energies 16, no. 7: 3242. https://doi.org/10.3390/en16073242

APA StyleSchöne, N., Dumitrescu, R., & Heinz, B. (2023). Techno-Economic Evaluation of Hydrogen-Based Cooking Solutions in Remote African Communities—The Case of Kenya. Energies, 16(7), 3242. https://doi.org/10.3390/en16073242