Reduction in CO2 Emissions with Bivalent Heat Pump Systems

Abstract

1. Introduction

2. Methods

3. Results

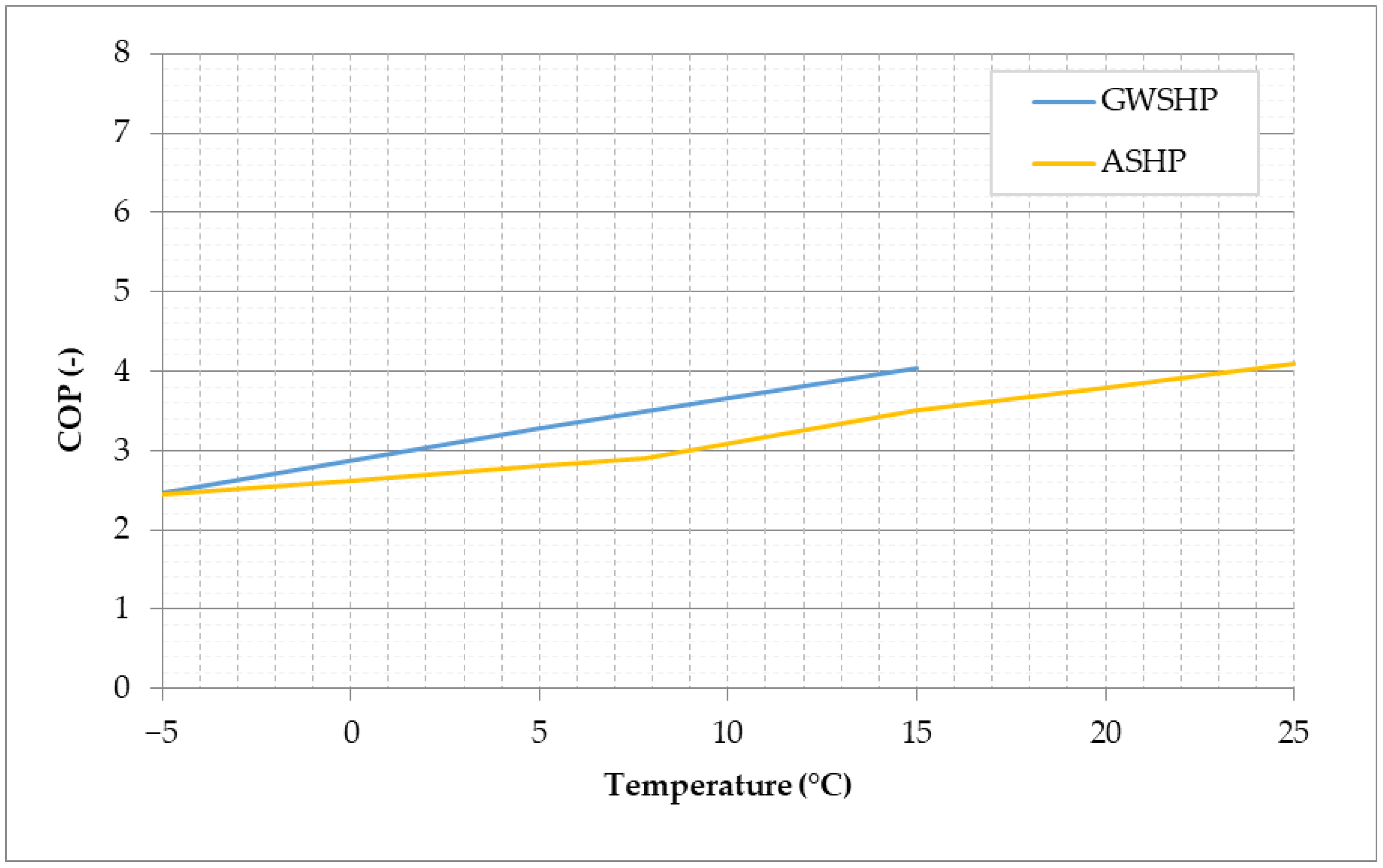

3.1. CO2 Emissions of Monovalent Heat Pump Systems during Heating Season

3.2. Daily Energy Demand and CO2 Emissions of Bivalent Systems

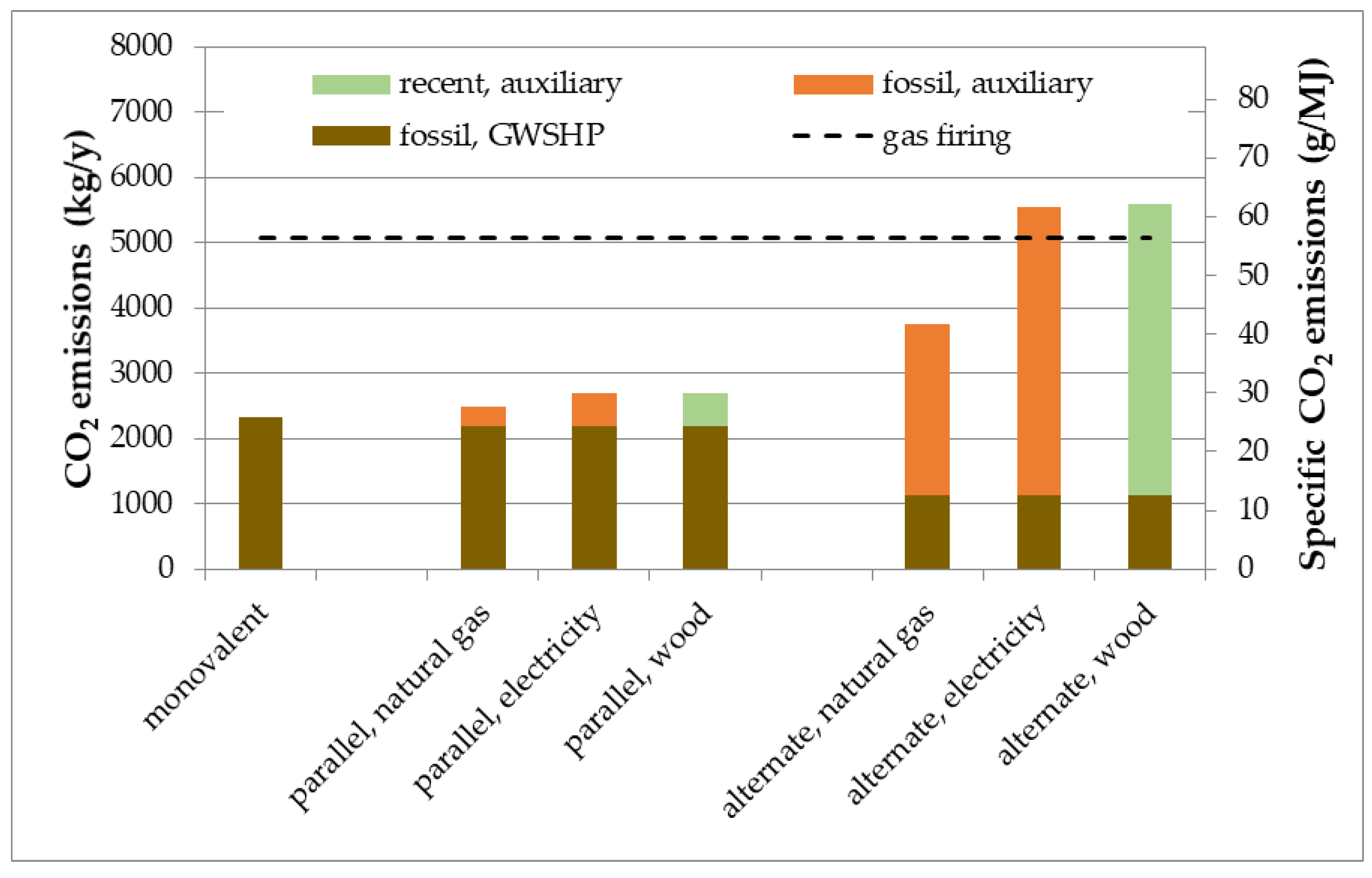

3.2.1. Daily Energy Demand and CO2 Emissions in Systems with Different Source Heat Pump Types: Alternate and Parallel Mode (TB = 2 °C)

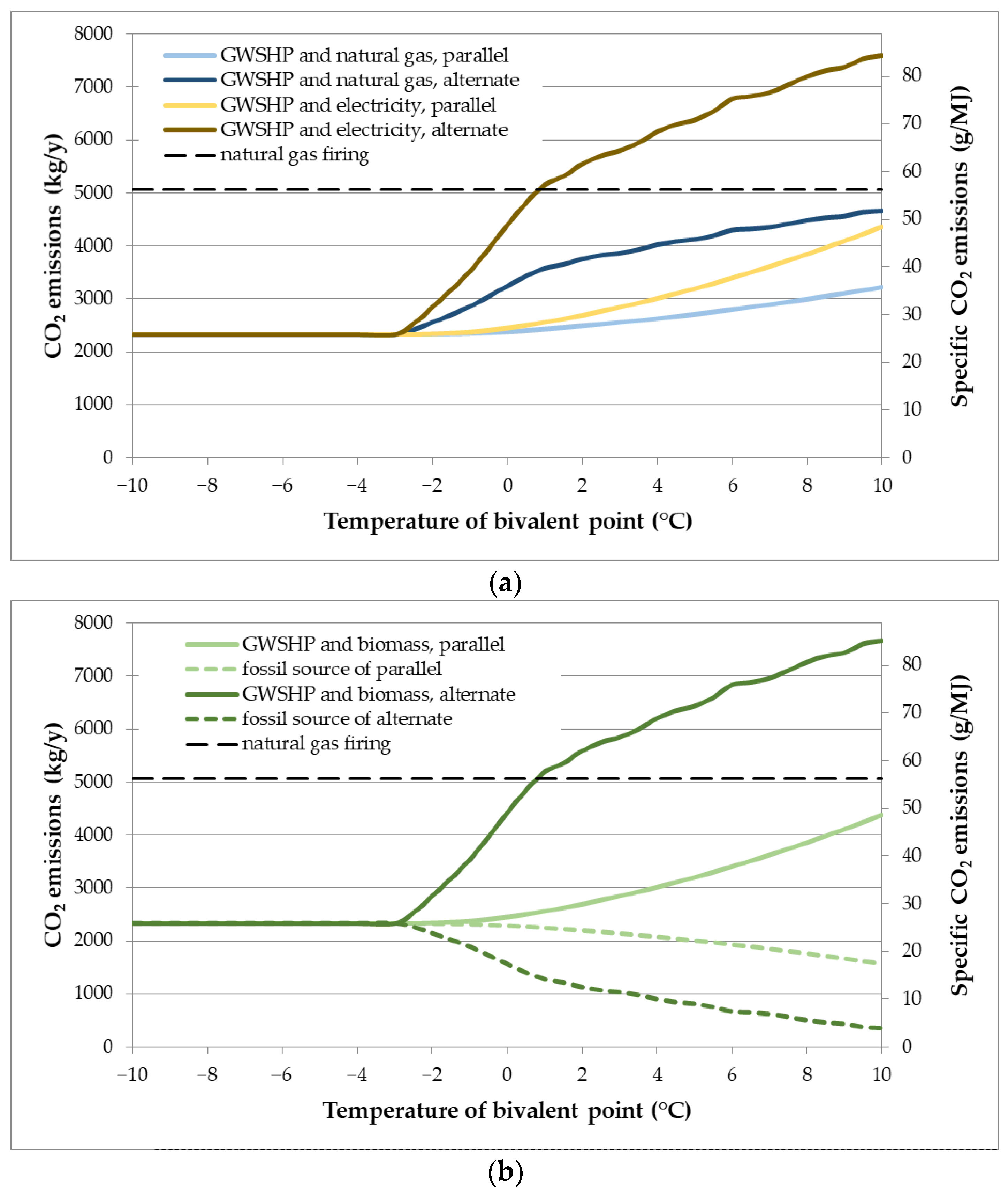

3.2.2. CO2 Emissions in HP Systems with Different Types of Auxiliary Energy in Alternate and Parallel Modes as the Function of the Bivalent Temperature

3.2.3. CO2 Emissions in GSHP Systems with Different Electricity Mixes

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| List of Symbols with Description and Unit | |

| c | specific heat capacity (kJ/(kg°C)) |

| COPi | coefficient of performance of the heat pump on the i-th day |

| E | annual heat pump-related CO2 emissions (g/year) |

| eaux | specific CO2 emissions of the auxiliary heating (g/MJ) |

| ee | power generation-related specific CO2 emissions (g/MJ) |

| HDDi | daily heating degree days of the i-th day (°C·d) |

| HDDi,max | daily heating degree days of the coldest day (°C·d) |

| i | count of the day |

| m | mass (kg) |

| P | power of the heat pump (MW) |

| Q | annual heat demand (MJ) |

| q | specific heat demand (MJ/°C) |

| Qaux,i | heat demand supplied by auxiliary energy on the i-th day (MJ) |

| QDWH,i | daily energy demand of DHW production on the i-th day (MJ) |

| Qext,i | external energy needed for the heat pump on the i-th day (MJ) |

| QHP,i | energy delivered by the heat pump on the i-th day (MJ) |

| Qi | daily heat demand on the i-th day (MJ) |

| Qi,B | daily heat demand at the bivalent point (MJ) |

| Qi,max | maximum daily heat demand (MJ) |

| Tb | base temperature (°C) |

| TB | temperature of the bivalent point (°C) |

| Tin | indoor temperature (°C) |

| To,i | daily outdoor temperature on the i-th day (°C) |

| To,min | daily outdoor temperature on the coldest day (°C) |

| ΔT | temperature difference (°C) |

| τ | one day in seconds (s/d) |

| Abbreviations | |

| ASHP | air source heat pump |

| BW | Baden-Württemberg |

| CO2 | carbon dioxide |

| COP | coefficient of performance |

| DHW | domestic hot water |

| EU | European Union |

| GSHP | ground-source heat pump |

| GWSHP | groundwater-source heat pump |

| HDD | heating degree day |

| HP | heat pump |

| LCA | life cycle analysis |

| SPF | seasonal performance factor |

| TRNSYS | transient system simulation tool |

| UK | United Kingdom |

References

- Energy Statistics Data Browser 2022, IEA, Paris. Available online: https://www.iea.org/data-and-statistics/data-tools/energy-statistics-data-browser (accessed on 27 February 2023).

- European Commission. Heating and Cooling. 2021. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/heating-and-cooling_en (accessed on 27 February 2023).

- European Commission, Directorate-General for Communication. European Green Deal: Delivering on Our Targets. 2021. Available online: https://data.europa.eu/doi/10.2775/373022 (accessed on 25 February 2023).

- Lund, J.W.; Tóth, A.N. Direct utilization of geothermal energy 2020 worldwide review. Geothermics 2021, 90, 101915. [Google Scholar] [CrossRef]

- Ochsner, K. Geothermal Heat Pumps. A Guide for Planning and Installing, 1st ed.; Earthscan from Routledge: London, UK, 2007; 146p. [Google Scholar]

- Rybach, L. Geothermal Heat Pump Production Sustainability—The Basis of the Swiss GHP Success Story. Energies 2022, 15, 7870. [Google Scholar] [CrossRef]

- Bayer, P.; Attard, G.; Blum, P.; Menberg, K. The geothermal potential of cities. Renew. Sustain. Energy Rev. 2019, 106, 17–30. [Google Scholar] [CrossRef]

- Miglani, S.; Orehounig, K.; Carmeliet, J. A methodology to calculate longterm shallow geothermal energy potential for an urban neighbourhood. Energy Build. 2018, 159, 462–473. [Google Scholar] [CrossRef]

- Schiel, K.; Baume, O.; Caruso, G.; Leopold, U. GIS-based modelling of shallow geothermal energy potential for CO2 emission mitigation in urban areas. Renew. Energy 2016, 86, 1023–1036. [Google Scholar] [CrossRef]

- Kammen, D.M.; Sunter, D.A. City-integrated renewable energy for urban sustainability. Science 2016, 352, 922–928. [Google Scholar] [CrossRef]

- Sarbu, I.; Mirza, M.; Muntean, D. Integration of Renewable Energy Sources into Low-Temperature District Heating Systems: A Review. Energies 2022, 15, 6523. [Google Scholar] [CrossRef]

- Rose, J.; Thomsen, K.E.; Balslev-Olesen, O. The Balance between Energy Efficiency and Renewable Energy for District Renovations in Denmark. Sustainability 2022, 14, 13605. [Google Scholar] [CrossRef]

- Kerényi, A.; McIntosh, R.W. Sustainable Development in Changing Complex Earth Systems, 1st ed.; Springer: Cham, Switzerland, 2020; 292p. [Google Scholar]

- Ruhnau, O.; Hirth, L.; Praktiknjo, A. Time series of heat demand and heat pump efficiency for energy system modeling. Sci. Data 2019, 6, 189. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 6, 3559–3573. [Google Scholar] [CrossRef]

- Scoccia, R.; Toppi, T.; Aprile, M.; Motta, M. Absorption and compression heat pump systems for space heating and DHW in European buildings: Energy, environmental and economic analysis. J. Build. Eng. 2018, 16, 94–105. [Google Scholar] [CrossRef]

- Weeratunge, H.; Aditya, G.R.; Dunstall, S.; de Hoog, J.; Narsilio, G.; Halgamuge, S. Feasibility and performance analysis of hybrid ground source heat pump systems in fourteen cities. Energy 2021, 234, 121254. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Smith, M.; Bevacqua, A.; Tembe, S.; Lal, P. Life cycle analysis (LCA) of residential ground source heat pump systems: A comparative analysis of energy efficiency in New Jersey. Sustain. Energy Technol. Assess. 2021, 47, 101364. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

- Sevindik, S.; Spataru, C.; Domenech Aparisi, T.; Bleischwitz, R. A Comparative Environmental Assessment of Heat Pumps and Gas Boilers towards a Circular Economy in the UK. Energies 2021, 14, 3027. [Google Scholar] [CrossRef]

- Jenkins, D.P.; Tucker, R.; Rawlings, R. Modelling the carbon-saving performance of domestic ground-source heat pumps. Energy Build. 2009, 41, 587–595. [Google Scholar] [CrossRef]

- Blum, P.; Campillo, G.; Münch, W.; Kölbel, T. CO2 savings of ground source heat pump systems—A regional analysis. Renew. Energy 2010, 35, 122–127. [Google Scholar] [CrossRef]

- Bayer, P.; Saner, D.; Bolay, S.; Rybach, L.; Blum, P. Greenhouse gas emission savings of ground source heat pump systems in Europe: A review. Renew. Sustain. Energy Rev. 2012, 16, 1256–1267. [Google Scholar] [CrossRef]

- Leerbeck, K.; Bacher, P.; Junker, R.G.; Tveit, A.; Corradi, O.; Madsen, H.; Ebrahimy, R. Control of Heat Pumps with CO2 Emission Intensity Forecasts. Energies 2020, 13, 2851. [Google Scholar] [CrossRef]

- Sewastianik, S.; Gajewski, A. An Environmental Assessment of Heat Pumps in Poland. Energies 2021, 14, 8104. [Google Scholar] [CrossRef]

- Fidorów-Kaprawy, N.; Stefaniak, Ł. Potential of CO2 Emission Reduction via Application of Geothermal Heat Exchanger and Passive Cooling in Residential Sector under Polish Climatic Conditions. Energies 2022, 15, 8531. [Google Scholar] [CrossRef]

- Gradziuk, P.; Siudek, A.; Klepacka, A.M.; Florkowski, W.J.; Trocewicz, A.; Skorokhod, I. Heat Pump Installation in Public Buildings: Savings and Environmental Benefits in Underserved Rural Areas. Energies 2022, 15, 7903. [Google Scholar] [CrossRef]

- Beccali, M.; Bonomolo, M.; Martorana, F.; Catrini, P.; Buscemi, A. Electrical hybrid heat pumps assisted by natural gas boilers: A review. Appl. Energy 2022, 322, 119466. [Google Scholar] [CrossRef]

- Vering, C.; Wüllhorst, F.; Mehrfeld, P.; Müller, D. Towards an integrated design of heat pump systems: Application of process intensification using two-stage optimization. Energy Convers. Manag. 2021, 250, 114888. [Google Scholar] [CrossRef]

- Vering, C.; Maier, L.; Breuer, K.; Krützfeldt, H.; Streblow, R.; Müller, D. Evaluating heat pump system design methods towards a sustainable heat supply in residential buildings. Appl. Energy 2022, 308, 118204. [Google Scholar] [CrossRef]

- Klein, K.; Huchtemann, K.; Müller, D. Numerical study on hybrid heat pump systems in existing buildings. Energy Build. 2014, 69, 193–201. [Google Scholar] [CrossRef]

- Bagarella, G.; Lazzarin, R.; Noro, M. Annual simulation, energy and economic analysis of hybrid heat pump systems for residential buildings. Appl. Therm. Eng. 2016, 99, 485–494. [Google Scholar] [CrossRef]

- Mondot, M.; Caillet, J.; Tang, C. Design optimization of hybrid heat pumps for new and existing buildings in France. In Proceedings of the 12th IEA Heat Pump Conference 2017, Rotterdam, The Netherlands, 15–18 May 2017. [Google Scholar]

- Neubert, D.; Glück, C.; Schnitzius, J.; Marko, A.; Wapler, J.; Bongs, C.; Felsmann, C. Analysis of the Operation Characteristics of a Hybrid Heat Pump in an Existing Multifamily House Based on Field Test Data and Simulation. Energies 2022, 15, 5611. [Google Scholar] [CrossRef]

- Dongellini, M.; Naldi, C.; Morini, G.L. Influence of sizing strategy and control rules on the energy saving potential of heat pump hybrid systems in a residential building. Energy Convers. Manag. 2021, 235, 114022. [Google Scholar] [CrossRef]

- Hackel, S.; Pertzborn, A. Effective design and operation of hybrid ground-source heat pumps: Three case studies. Energy Build. 2011, 43, 3497–3504. [Google Scholar] [CrossRef]

- Buday, T.; Szabó, G.; Fazekas, I.; Paládi, M.; Szabó, S.; Szabó, G.; Kerényi, A. Annual pattern of the coefficient of performance considering several heat pump types and its environmental consequences. Int. Rev. Appl. Sci. Eng. 2014, 5, 173–179. [Google Scholar] [CrossRef]

- Paládi, M.; Szabó, S.; Megyeriné Runyó, A.; Kerényi, A. Firewood consumption and CO2 emission of detached houses in rural environment, NE-Hungary. Carpathian J. Earth Environ. Sci. 2014, 9, 199–208. [Google Scholar]

- Verbai, Z.; Lázár, I.; Kalmár, F. Heating degree day in Hungary. Environ. Eng. Manag. J. 2014, 13, 6. [Google Scholar] [CrossRef]

- Szalai, S.; Auer, I.; Hiebl, J.; Milkovich, J.; Radim, T.; Stepanek, P.; Zahradnicek, P.; Bihari, Z.; Lakatos, M.; Szentimrey, T.; et al. Climate of the Greater Carpathian Region. Final Technical Report. 2003. Available online: www.carpatclim-eu.org (accessed on 12 October 2022).

- Stiebel Eltron Magyarország. Available online: https://www.stiebel-eltron.hu/content/dam/ste/cdbassets/historic/bedienungs-_u_installationsanleitungen/WPL_13-23_E_cool__e74043d2-34ab-11e7-a4d3-005056a95add.pdf (accessed on 24 October 2022).

- Stiebel Eltron Magyarország. Available online: https://www.stiebel-eltron.hu/content/dam/ste/cdbassets/current/bedienungs-_u_installationsanleitungen/instructionandinstallationmanual_doc-00082424.pdf (accessed on 24 October 2022).

- EUROSTAT Data Browser. Gross and Net Production of Electricity and Derived Heat by Type of Plant and Operator. Available online: https://ec.europa.eu/eurostat/databrowser/view/NRG_IND_PEH__custom_5175824/default/table?lang=en (accessed on 26 February 2023).

- Greenhouse Gas Inventories (UNFCCC). EEA. Available online: https://www.eea.europa.eu/data-and-maps/data/national-emissions-reported-to-the-unfccc-and-to-the-eu-greenhouse-gas-monitoring-mechanism-18/national-greenhouse-gas-inventories-ipcc-common-reporting-format-sector-classification/microsoft-access-format-zip-2/at_download/file (accessed on 25 February 2023).

- Szabó, G.; Fazekas, I.; Szabó, S.; Szabó, G.; Buday, T.; Paládi, M.; Kisari, K.; Kerényi, A. The carbon footprint of a biogas power plant. Environ. Eng. Manag. J. 2014, 13, 2867–2874. [Google Scholar] [CrossRef]

- Verbai, Z.; Lakatos, Á.; Kalmár, F. Prediction of energy demand for heating of residential buildings using variable degree day. Energy 2014, 76, 780–787. [Google Scholar] [CrossRef]

- Kurylyk, B.L.; Kerry, T.B.; Jeffrey, M.M. McKenzie Climate change impacts on groundwater and soil temperatures in cold and temperate regions: Implications, mathematical theory, and emerging simulation tools. Earth Sci. Rev. 2014, 138, 313–334. [Google Scholar] [CrossRef]

- Headon, J.; Banks, D.; Waters, A.; Robinson, V.K. Regional distribution of ground temperature in the Chalk aquifer of London, UK. Q. J. Eng. Geol. Hydrogeol. 2009, 42, 313–323. [Google Scholar] [CrossRef]

- Deroubaix, A.; Labuhn, I.; Camredon, M.; Gaubert, B.; Monerie, P.-A.; Popp, M.; Ramarohetra, J.; Ruprich-Robert, Y.; Silvers, L.G.; Siour, G. Large uncertainties in trends of energy demand for heating and cooling under climate change. Nat. Commun. 2021, 12, 5197. [Google Scholar] [CrossRef]

- Menberg, K.; Bayer, P.; Zosseder, K.; Rumohr, S.; Blum, P. Subsurface urban heat islands in German cities. Sci. Total Environ. 2013, 442, 123–133. [Google Scholar] [CrossRef]

- Buday, T.; Buday-Bódi, E.; Csákberényi-Nagy, G.; Kovács, T. Subsurface Urban Heat Island Investigation in Debrecen, Hungary Based on Archive and Recently Measured Data. In Proceedings of the European Geothermal Congress 2019, Den Haag, The Netherlands, 11–14 June 2019. [Google Scholar]

| e, Specific CO2 Emissions (g/MJ) | Carbon Savings Compared with Gas Firing (g/MJ) | |||

|---|---|---|---|---|

| Total | From Fossil Fuels | From Carbon-Neutral Fuels | ||

| gas firing | 56.35 | 56.35 | 0.00 | - |

| electric heating (“low”) | 10.99 | 10.99 | 0.00 | 45.36 |

| electric heating (“middle”) | 94.91 | 94.91 | 0.00 | no savings |

| electric heating (“high”) | 265.77 | 265.77 | 0.00 | no savings |

| electric heat pump (COP = 3.67, “low”) | 2.99 | 2.99 | 0.00 | 53.36 |

| electric heat pump (COP = 3.67, “middle”) | 25.86 | 25.86 | 0.00 | 30.49 |

| electric heat pump (COP = 3.67, “high”) | 72.42 | 72.42 | 0.00 | no savings |

| wood firing | 95.82 | 0.00 | 95.82 | 56.35 |

| biogas firing | 96.61 | 1.85 | 94.76 | 54.50 |

| Fossil CO2 Emissions (kg/y) | Recent CO2 Emissions (kg/y) | CO2 Reduction (Compared with Gas Firing) | |

|---|---|---|---|

| gas firing | 5071.56 | 0.00 | 0.0% |

| electric heating (“low”) | 988.91 | 0.00 | 80.5% |

| electric heating (“middle”) | 8541.88 | 0.00 | no savings |

| electric heating (“high”) | 23920.05 | 0.00 | no savings |

| biomass firing | 0.00 | 8624.02 | 100.00% |

| biogas firing | 166.67 | 8528.79 | 96.71% |

| CO2 Emissions of Electricity | CO2 Emissions (kg/y) | CO2 Reduction (Compared with Gas Firing) | |

|---|---|---|---|

| CO2 emissions, electric GWSHP (kg/y) | “low” | 269.45 | 94.7% |

| “middle” | 2327.43 | 54.1% | |

| “high” | 6517.56 | no savings | |

| CO2 emissions, electric ASHP (kg/y) | “low” | 355.69 | 93.0% |

| “middle” | 3072.30 | 39.4% | |

| “high” | 8603.44 | no savings |

| ASHP | GSHP | |||

|---|---|---|---|---|

| Parallel | Alternate | Parallel | Alternate | |

| +natural gas | 3174.0 kg/y | 4001.9 kg/y | 2485.2 kg/y | 3748.7 kg/y |

| 35.27 g/MJ | 44.46 g/MJ | 27.61 g/MJ | 41.65 g/MJ | |

| +electricity | 3373.4 kg/y | 5799.2 kg/y | 2684.6 kg/y | 5546.0 kg/y |

| 37.48 g/MJ | 64.43 g/MJ | 29.83 g/MJ | 61.62 g/MJ | |

| +wood | 3378.1 kg/y | 5841.6 kg/y | 2689.3 kg/y | 5588.4 kg/y |

| 37.53 g/MJ | 64.90 g/MJ | 29.88 g/MJ | 62.09 g/MJ | |

| “Middle” | “Low” | “High” | ||

|---|---|---|---|---|

| monovalent | 54.1% | 94.7% | no savings | |

| bivalent-parallel TB = 2 °C | +natural gas | 51.0% | 89.2% | no savings |

| +electricity | 47.1% | 93.9% | no savings | |

| +wood | 47.0% (56.7% *) | 85.2% (95.0% *) | no savings | |

| bivalent-alternate TB = 2 °C | +natural gas | 26.1% | 45.6% | no savings |

| +electricity | no savings | 87.6% | 0 | |

| +wood | no savings (77.9% *) | 9.4% (97.4% *) | no savings (38.0% *) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buday, T.; Buday-Bódi, E. Reduction in CO2 Emissions with Bivalent Heat Pump Systems. Energies 2023, 16, 3209. https://doi.org/10.3390/en16073209

Buday T, Buday-Bódi E. Reduction in CO2 Emissions with Bivalent Heat Pump Systems. Energies. 2023; 16(7):3209. https://doi.org/10.3390/en16073209

Chicago/Turabian StyleBuday, Tamás, and Erika Buday-Bódi. 2023. "Reduction in CO2 Emissions with Bivalent Heat Pump Systems" Energies 16, no. 7: 3209. https://doi.org/10.3390/en16073209

APA StyleBuday, T., & Buday-Bódi, E. (2023). Reduction in CO2 Emissions with Bivalent Heat Pump Systems. Energies, 16(7), 3209. https://doi.org/10.3390/en16073209