Numerical Analysis of Heat Transfer within a Rotary Multi-Vane Expander

Abstract

1. Introduction

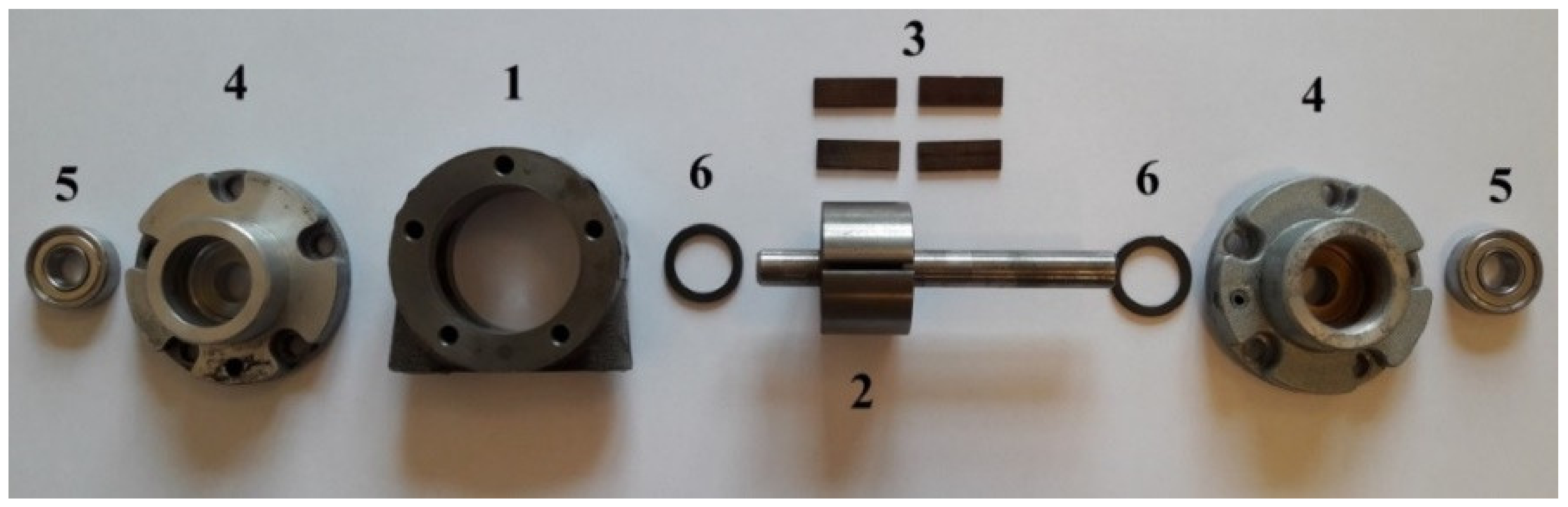

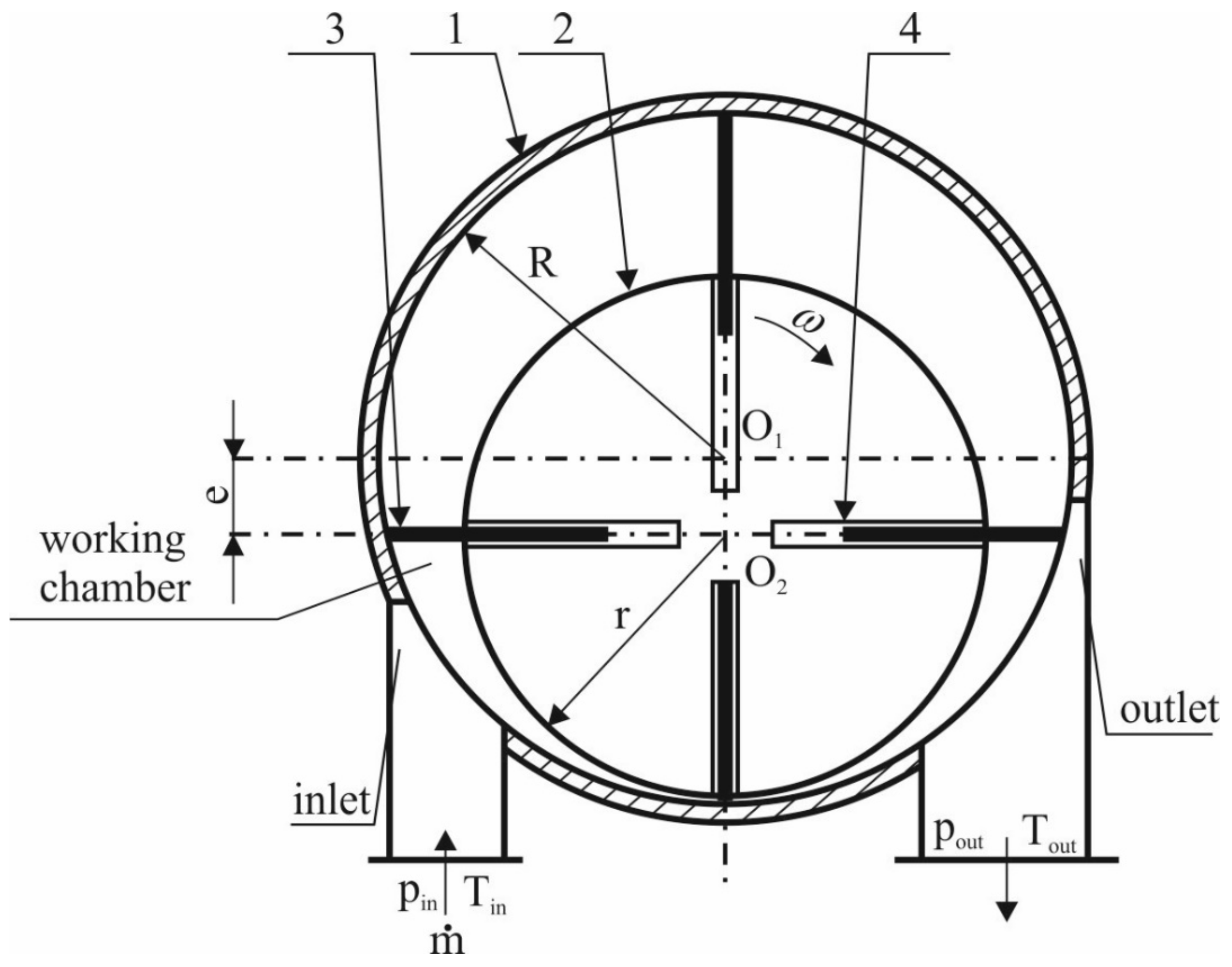

2. Description of the Multi-Vane Expander Assembly and Principle of Operation

- simple design,

- ease of installation and service,

- a small number of moving parts,

- the ability to work with a small flow of working fluid,

- large pressure drops that are possible to obtain in one stage,

- optimal expansion ratio in the range of 2–4,

- low weight and dimensions in relation to the power output,

- power range suitable for use in domestic micro power plants (the maximum power of currently manufactured expanders is about 10 kW),

- low rotational speed enabling the direct transmission of torque, to the generator as an example,

- lack of valves,

- the possibility of implementing oil-free and hermetic expanders,

- the possibility of using different working fluids, and

- insensitivity to wet gas expansion.

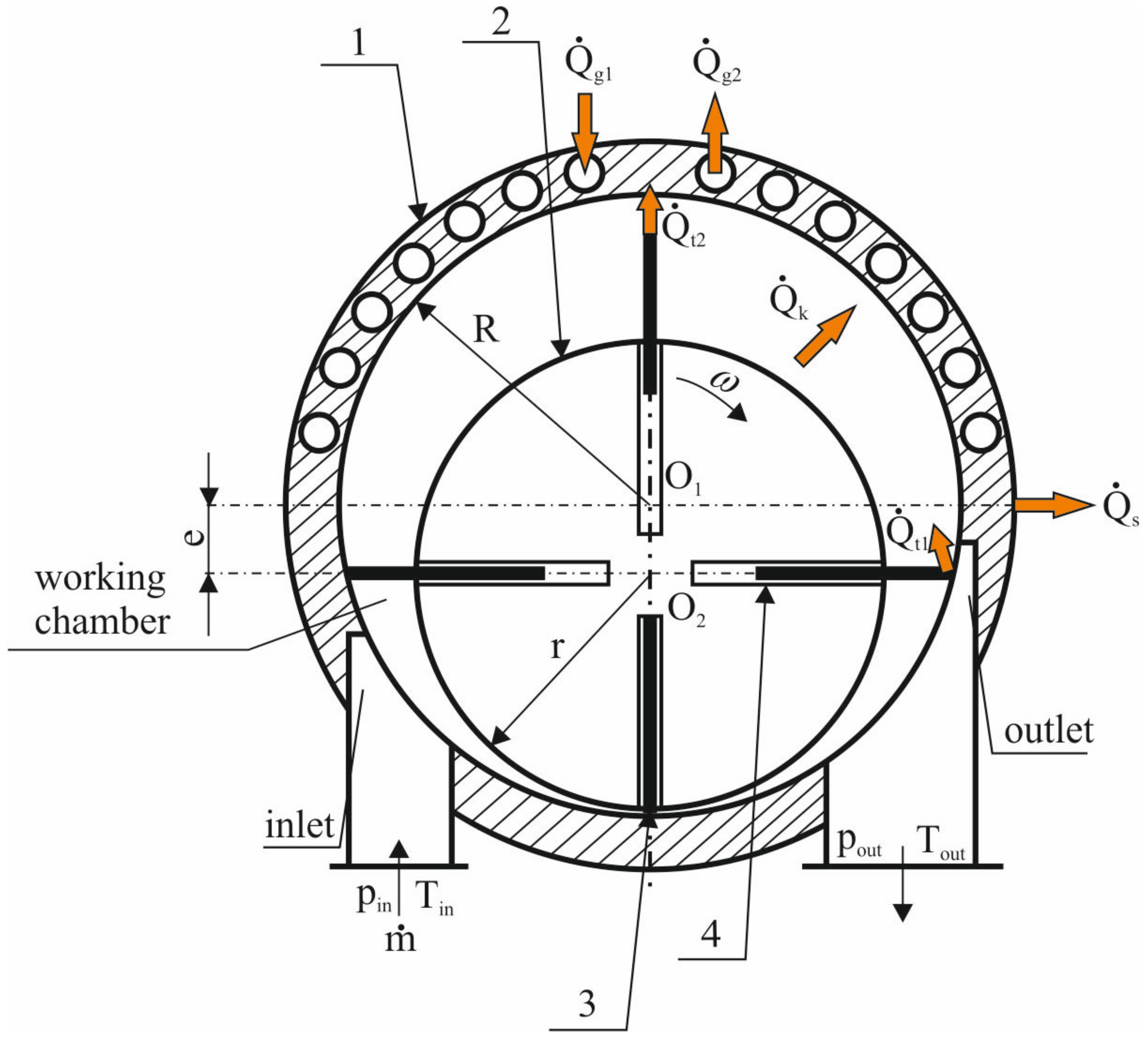

3. Heat Exchange Processes Occurring in a Multi-Vane Expander

- flow of working fluid through the working chambers,

- circulation of working fluid within working chambers and how its impact on machine parts,

- external and internal leakages of the working fluid,

- friction,

- temperature of the working fluid changes during processes (depending on the character of the machine operation, i.e., temperature drop when using cooled compressors and expanders to expand hot gasses, or temperature rise when using cold gas expanders, which expansion causes a further significant drop in gas temperature which can lead to, for example, the formation of hydrates [19]), and

- cooling (or heating) fluid to cool (or heat) the machine.

- g1 is the heat transfer rate at which heat from heated fluid is transferred to the working fluid,

- g2 is the heat transfer rate at which is taken from the working fluid by the cooling fluid,

- s is the heat transfer rate at which is dissipated from the surface of the machine to the surroundings,

- t = t1 + t2 describes the heat transfer rate at which is produced as the result of friction,

- t1 is the heat transfer rate that is generated as a result of friction and transferred to gas;

- t2 is the heat transfer rate that is generated as a result of friction and transferred to the parts of the machines, and

- k is the heat transfer rate at which is transferred by convection from (or taken by) gas to the walls of the working chamber.

4. Numerical Modeling

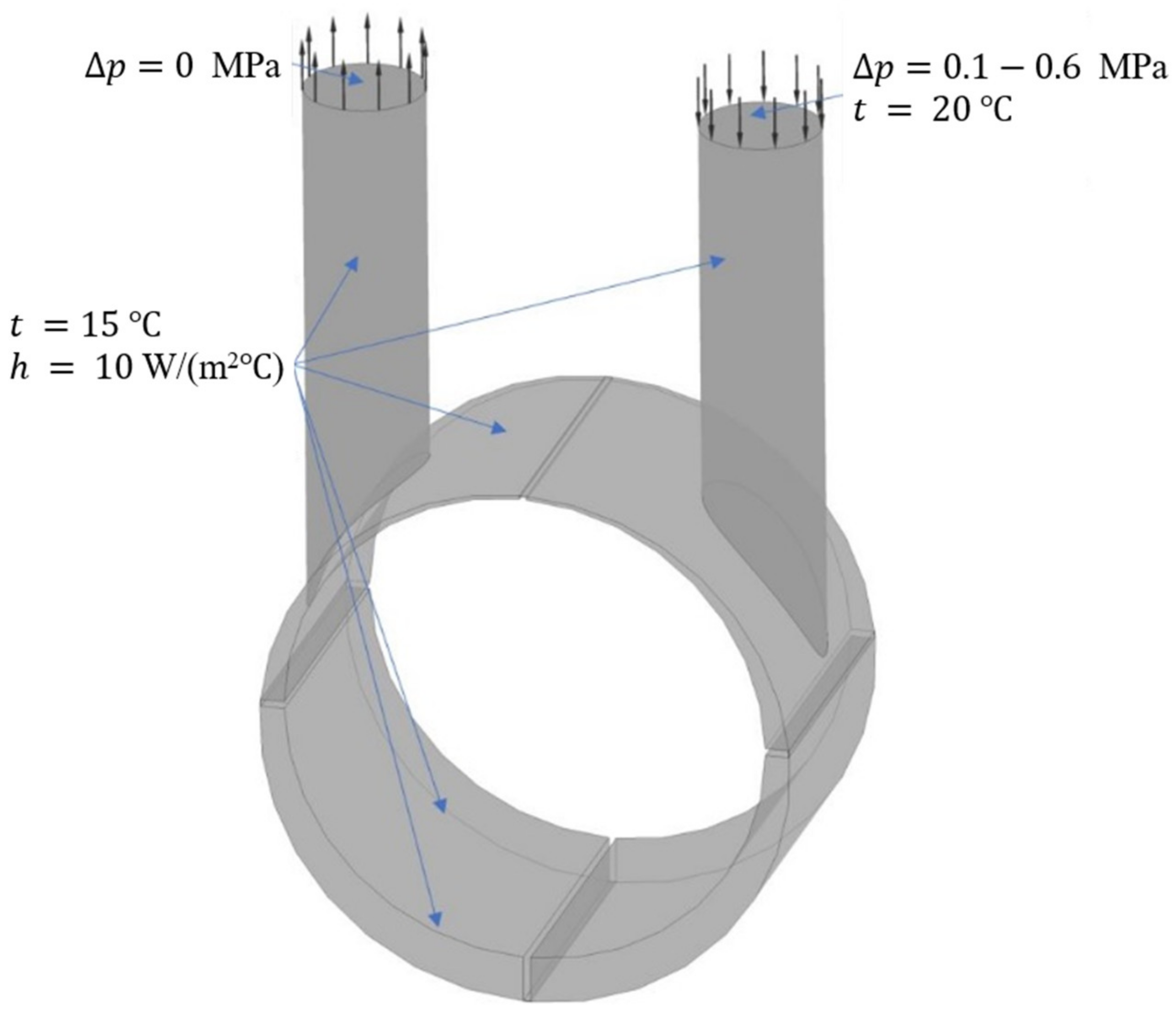

4.1. Physical Model

4.2. Governing Equations

4.3. Boundary Conditions and Simulation Settings

4.4. Numerical Detail

5. Results

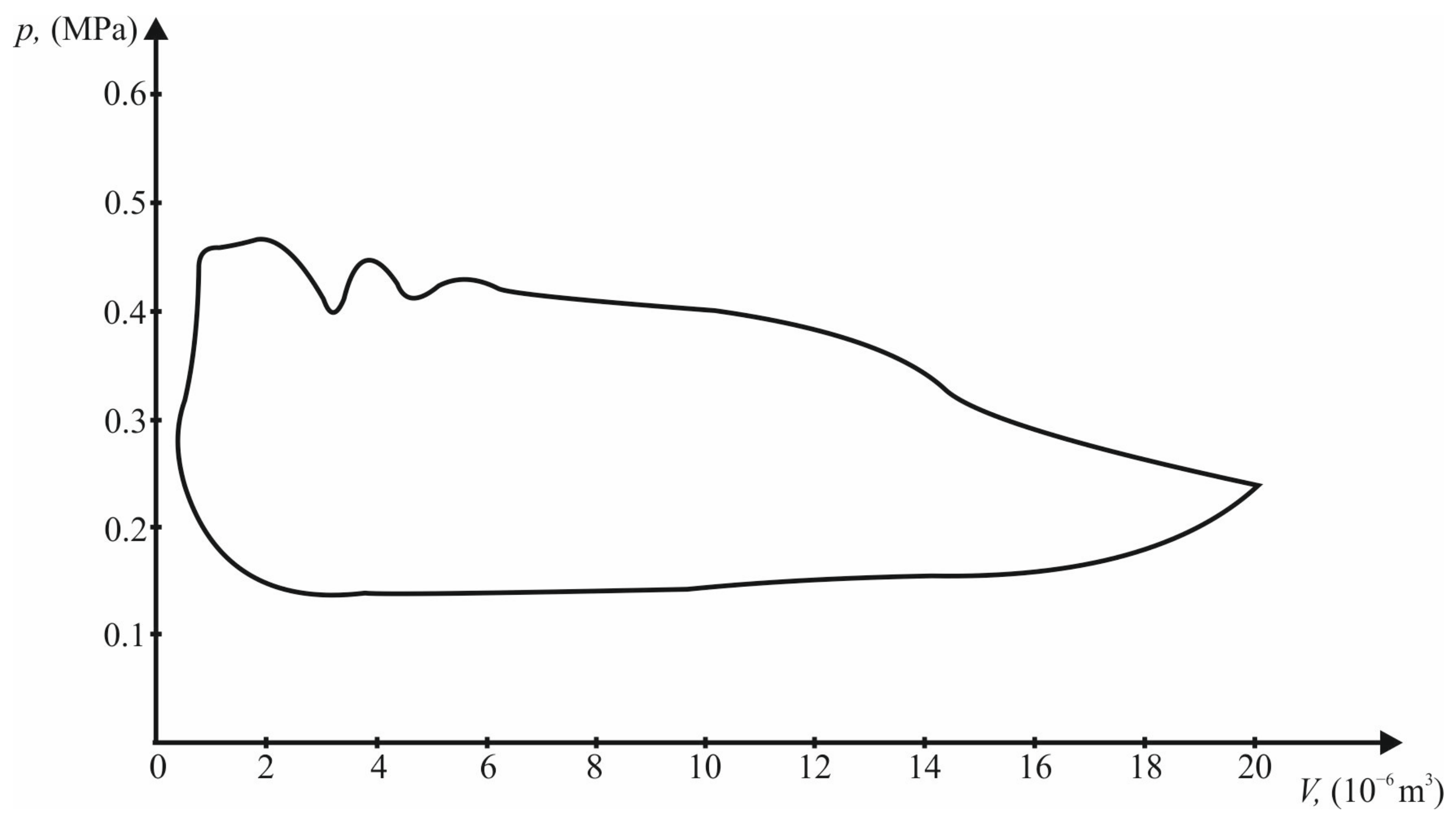

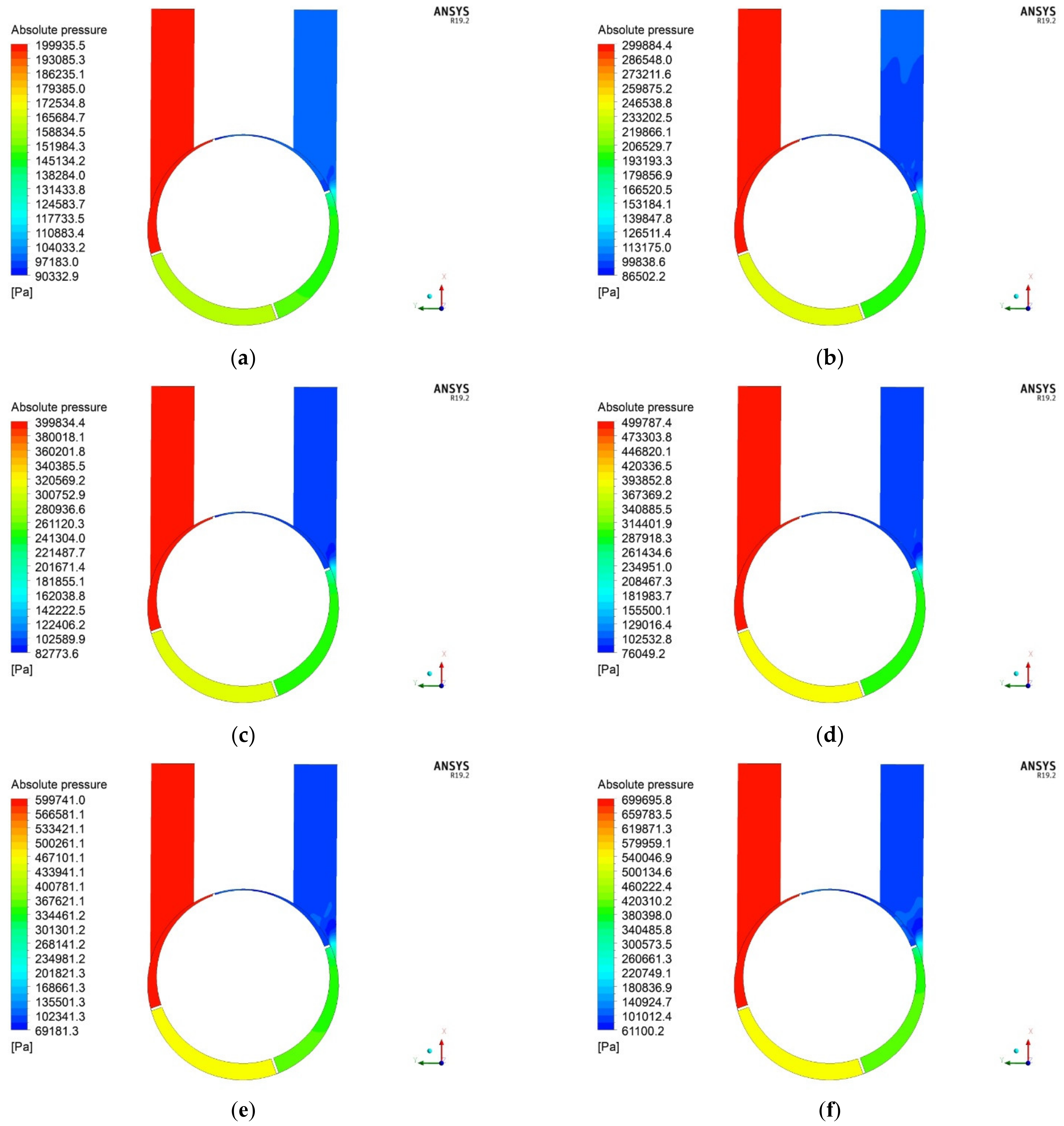

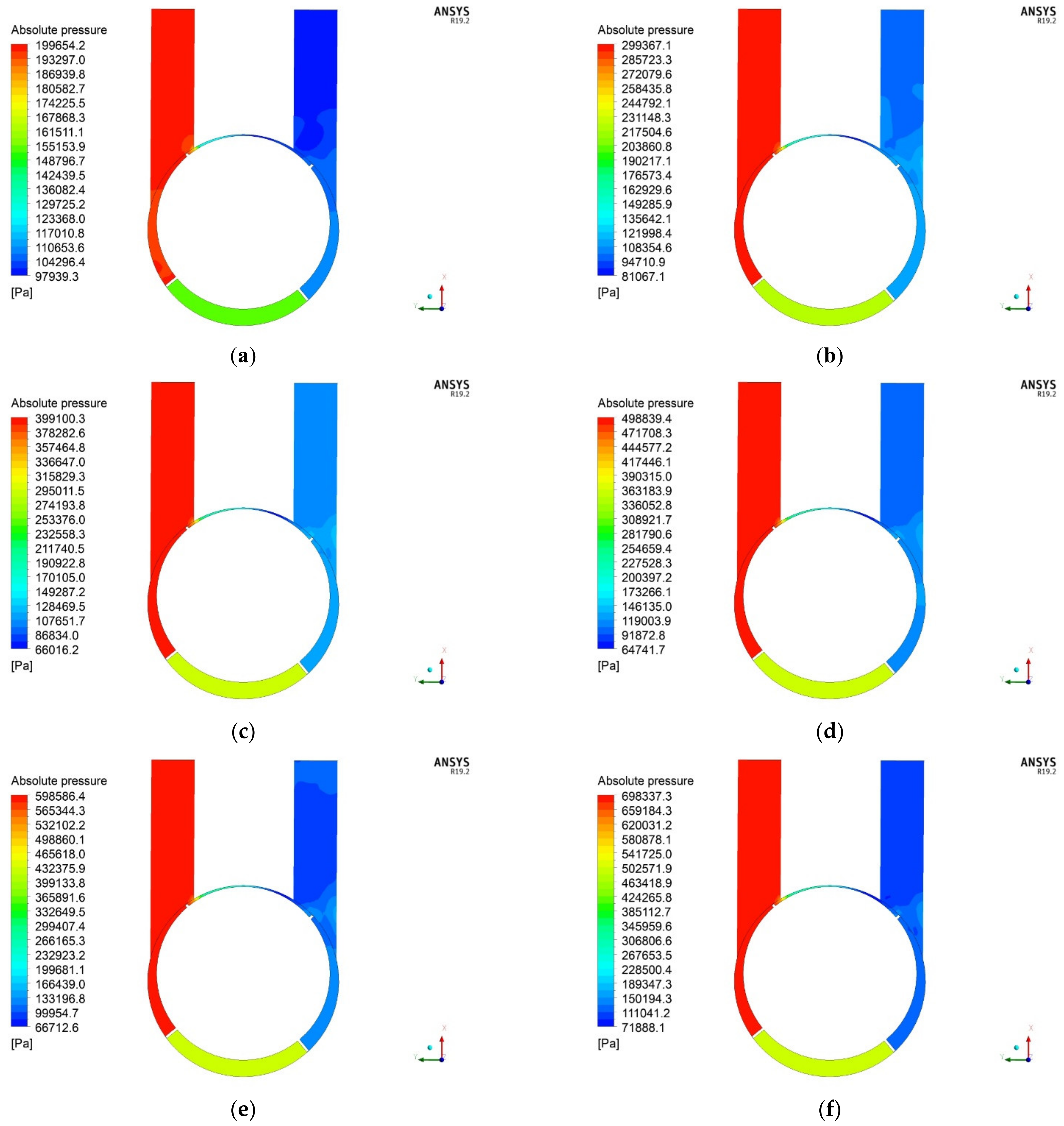

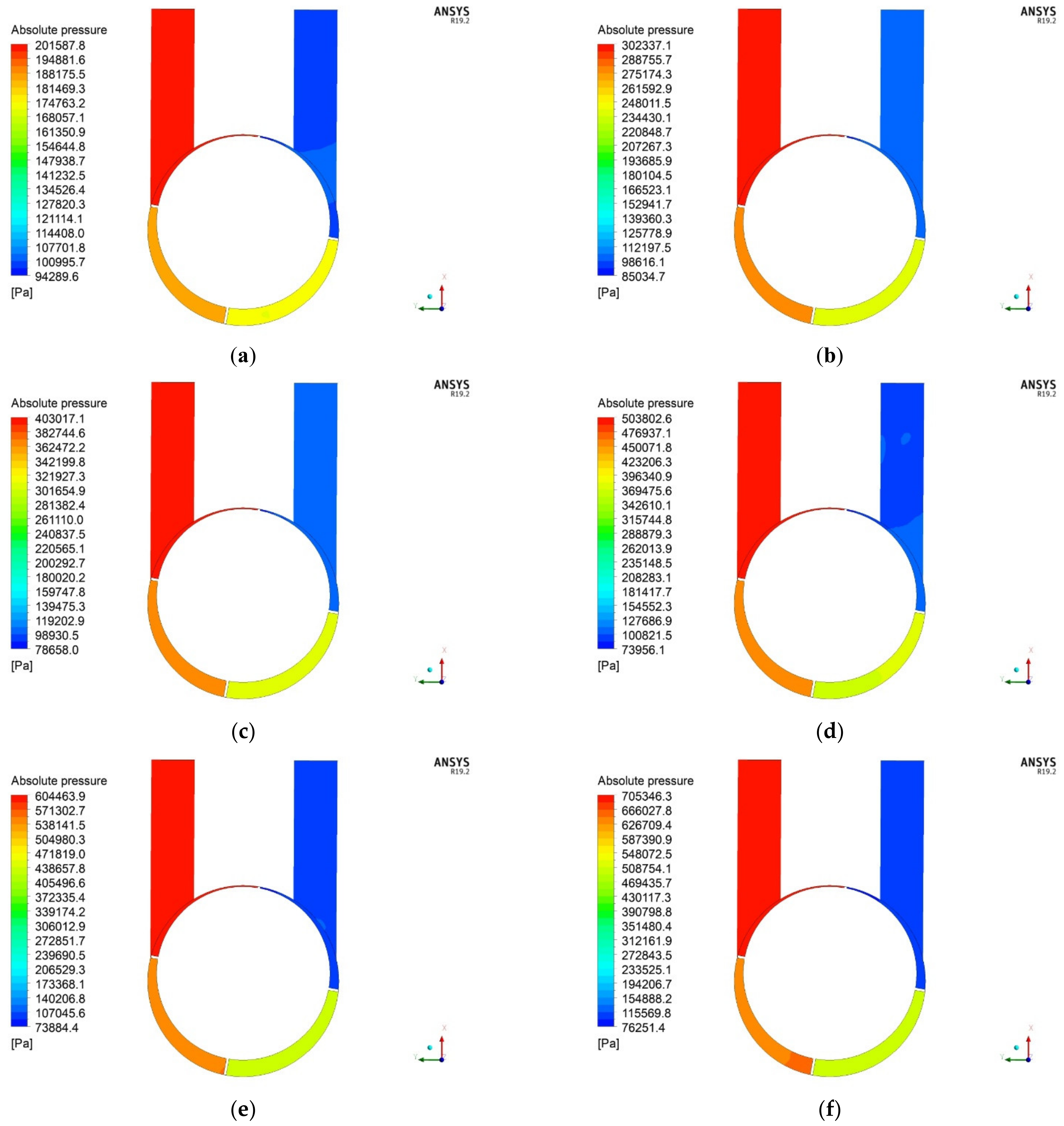

5.1. Distributions of Pressure

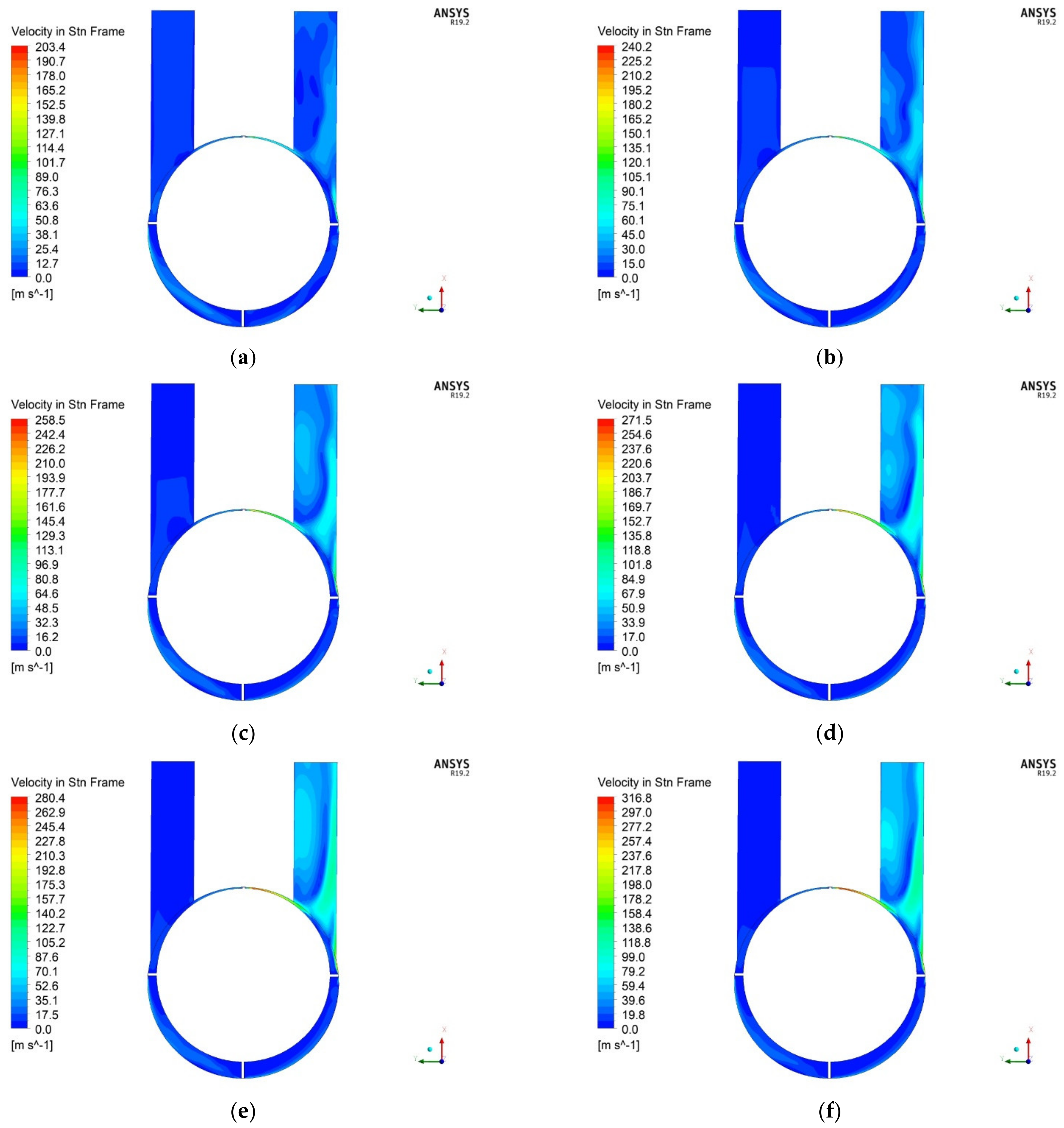

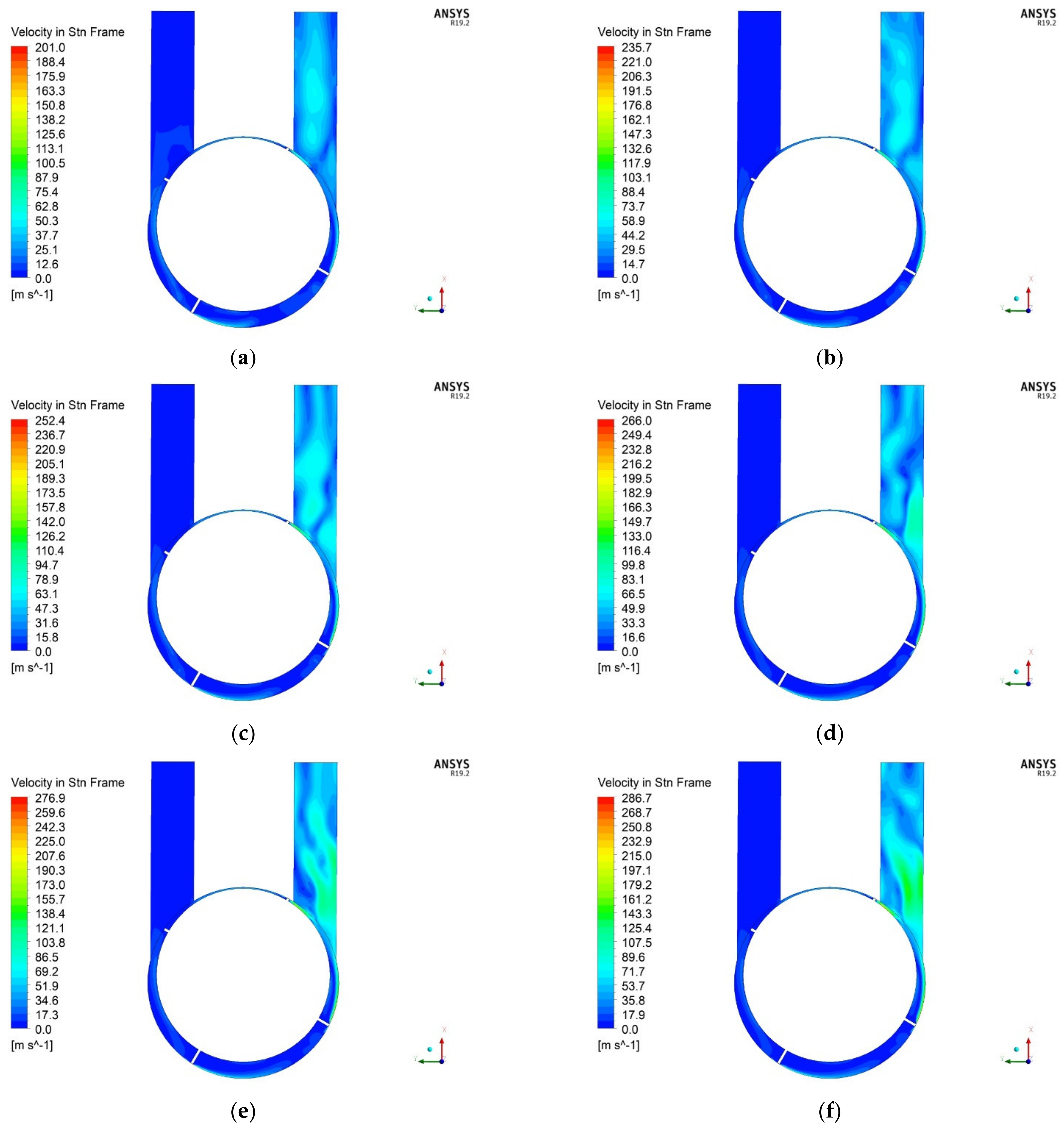

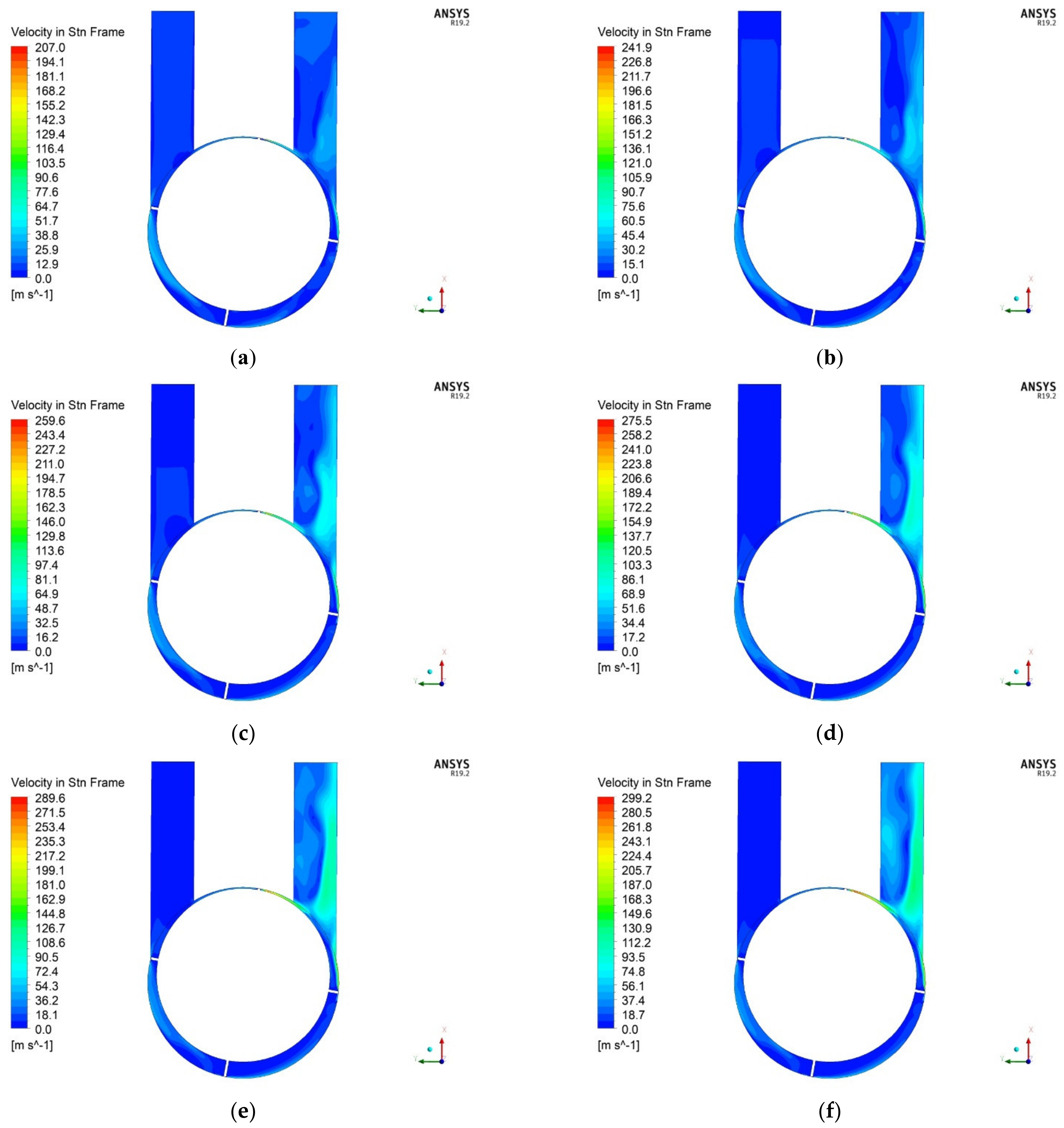

5.2. Distributions of Velocity

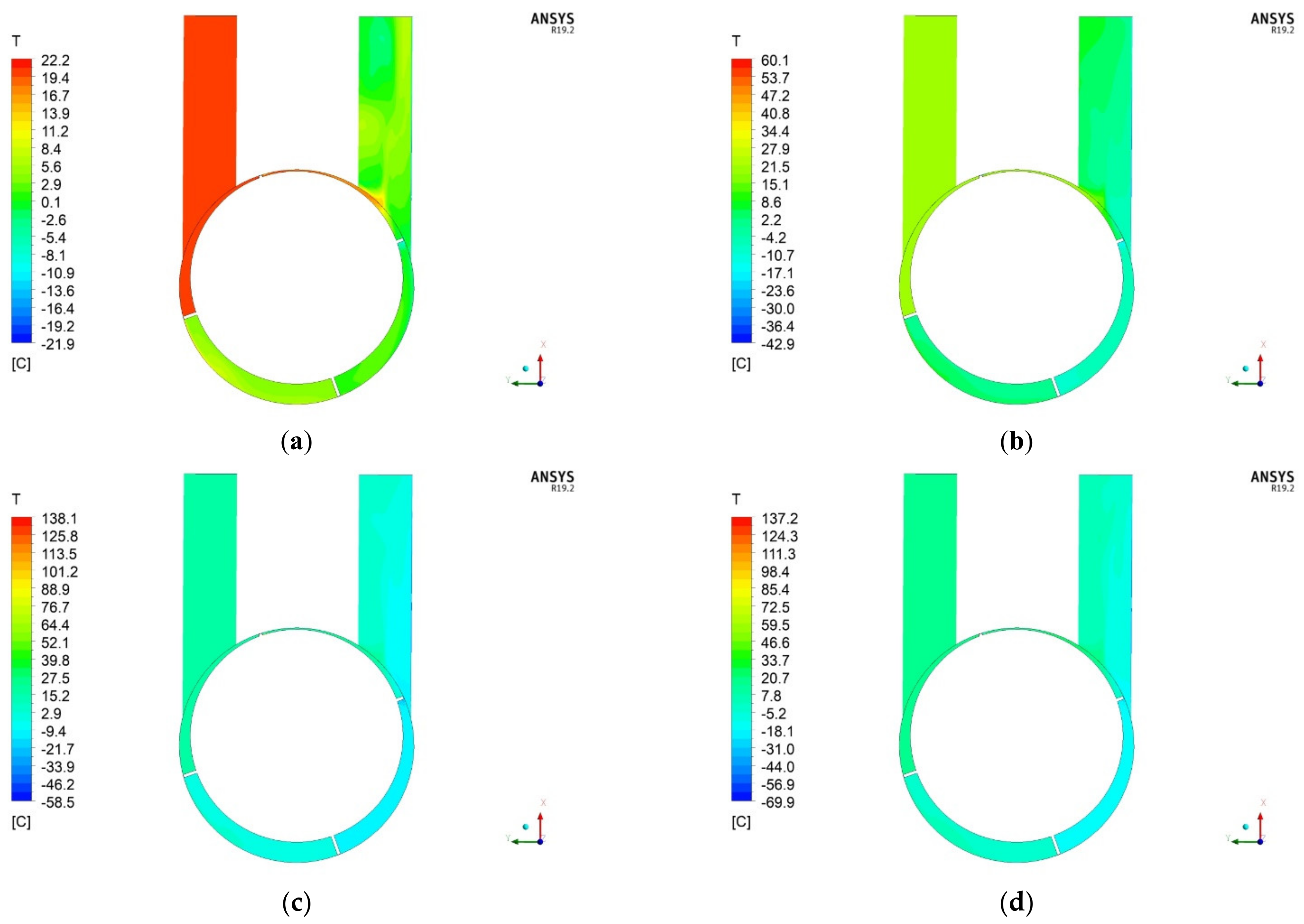

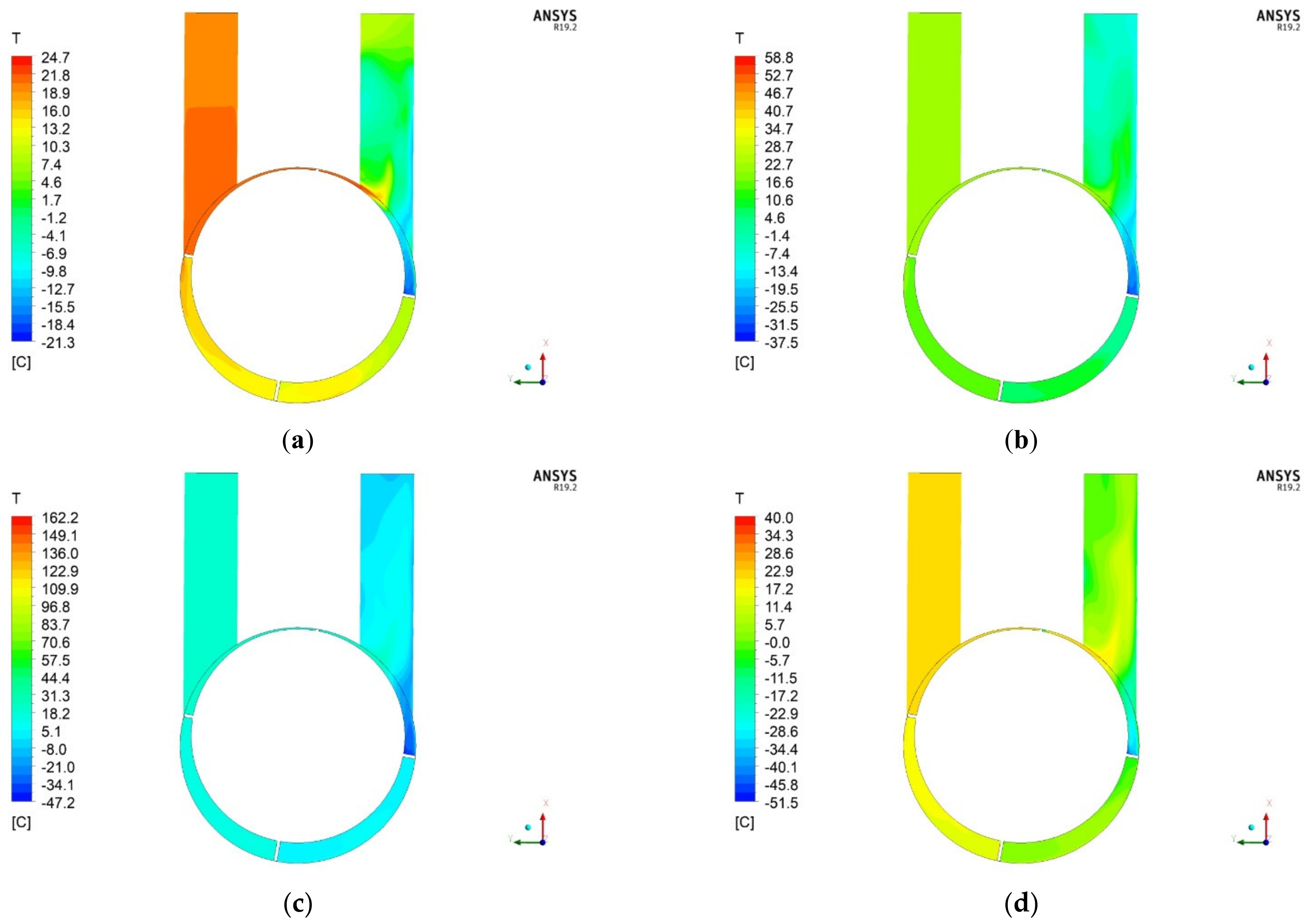

5.3. Distributions of Temperature

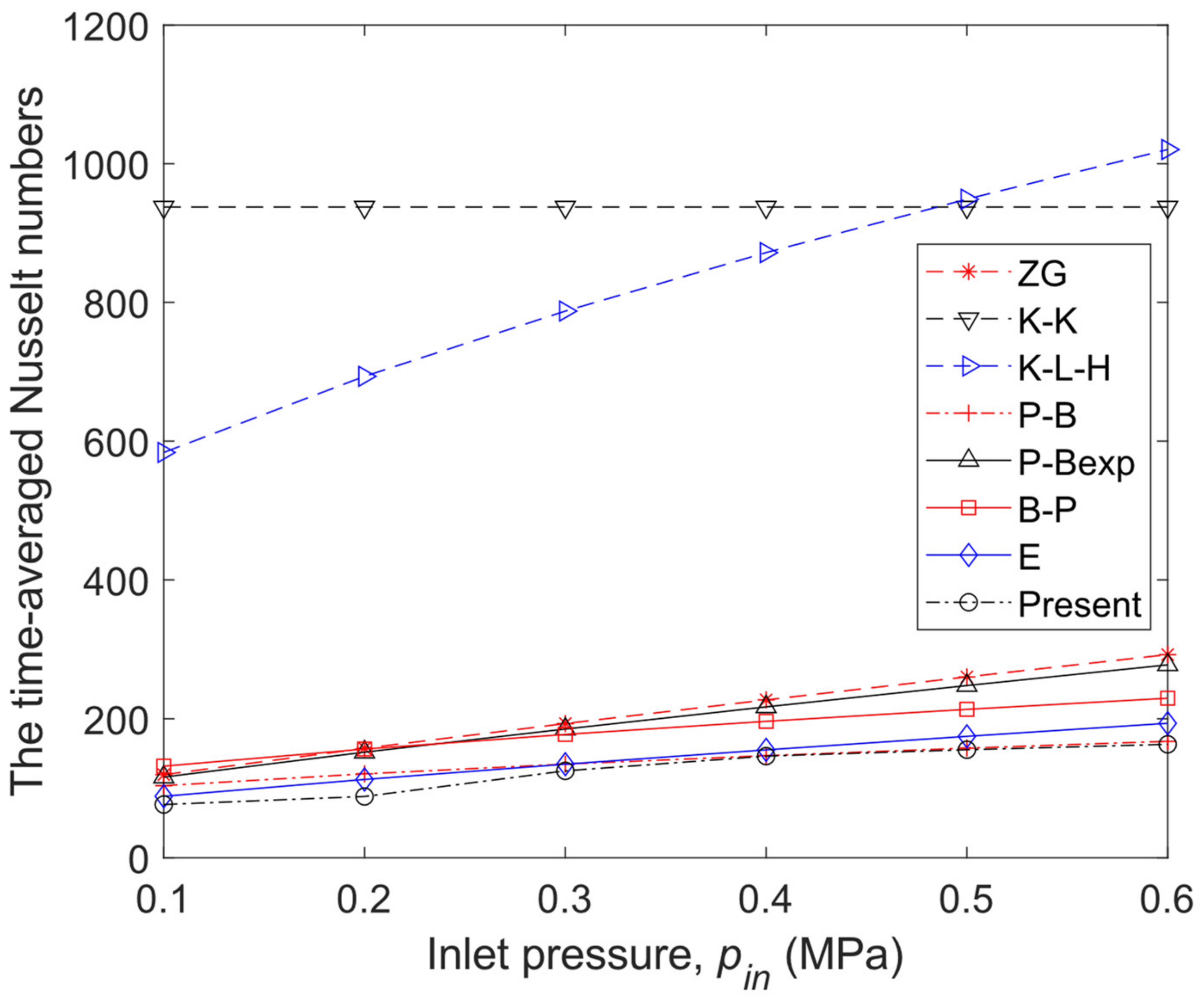

5.4. Comparison of the Nusselt Number with Available Correlations

6. Conclusions

- The transient results of the Nusselt number showed a periodic maximum that occurs near 30° of rotor rotation.

- The time-averaged Nusselt number was compared with available correlations from the literature, and the results were most comparable to the results modeled using E and P-B models (especially for inlet pressure higher than 0.2 MPa), that the MAPE of E and P-B models, with regard to the presented study, indicate 15% and 14%, respectively.

- A comparison of the modeling results suggested that the applicability of models which are available in the literature and are applied for modeling the heat transfer in other machines and devices with rotating vanes (e.g., scraped surface heat exchangers) is limited in the case of estimating the heat transfer processes in a multi-vane machine. This can be caused by the different intensities of the thermal and flow processes that occur during the expansion of gas in the expander working chambers and the higher rotational speeds of the shaft.

- The numerical results indicated that the flow is characterized by high velocities and intensive mixing of the working fluid.

- Leakages of the working fluid between adjacent working chambers influence the flow of the working fluid and, therefore, the heat transfer conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gnutek, Z.; Kolasiński, P. The Application of Rotary Vane Expanders in Organic Rankine Cycle Systems—Thermodynamic Description and Experimental Results. J. Eng. Gas Turbines Power 2013, 135, 061901. [Google Scholar] [CrossRef]

- Kolasinski, P. Application of the Multi-Vane Expanders in Orc Systems—A Review on the Experimental and Modeling Research Activities. Energies 2019, 12, 2975. [Google Scholar] [CrossRef]

- Hanson, K. Prototype Solar Heating and Combined Heating and Cooling Systems (Quarterly Report No. 3); DTIE (Divison of Technical Information Extension, US Atomic Energy Commission): Washington, DC, USA, 1977. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Hussein, M.; Probert, S.D. Multi-Vane Expanders as Prime Movers for Low-Grade Energy Organic Rankine-Cycle Engines. Appl. Energy 1984, 16, 129–146. [Google Scholar] [CrossRef]

- Badr, O.; Probert, S.D.; O’Callaghan, P. Performances of Multi-Vane Expanders. Appl. Energy 1985, 20, 207–234. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Probert, S.D. Rankine-Cycle Systems for Harnessing Power from Low-Grade Energy Sources. Appl. Energy 1990, 36, 263–292. [Google Scholar] [CrossRef]

- Badr, O.; Probert, S.D.; O’Callaghan, P.W. Selecting a Working Fluid for a Rankine-Cycle Engine. Appl. Energy 1985, 21, 1–42. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Probert, S.D. Thermodynamic and Thermophysical Properties of Organic Working Fluids for Rankine-Cycle Engines. Appl. Energy 1985, 19, 1–40. [Google Scholar] [CrossRef]

- Badr, O.; Hussein, M.; Probert, S.D.; O’Callaghan, P.W. Thermal Stabilities of Mixtures of Trichlorofluoroethane and Lubricating Fluids Contained in Copper Sealed Tubes. Appl. Energy 1984, 16, 41–52. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Probert, S.D. Performances of Rankine-Cycle Engines as Functions of Their Expanders’ Efficiencies. Appl. Energy 1984, 18, 15–27. [Google Scholar] [CrossRef]

- Badr, O.; Probert, S.D.; O’Callaghan, P. Multi-Vane Expanders: Vane Dynamics and Friction Losses. Appl. Energy 1985, 20, 253–285. [Google Scholar] [CrossRef]

- Badr, O.; Probert, S.D.; O’Callaghan, P.W. Multi-Vane Expanders: Internal-Leakage Losses. Appl. Energy 1985, 20, 1–46. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Probert, S.D. Multi-Vane Expander Performance: Breathing Characteristics. Appl. Energy 1985, 19, 241–271. [Google Scholar] [CrossRef]

- Badr, O.; O’Callaghan, P.W.; Probert, S.D. Multi-Vane Expanders: Geometry and Vane Kinematics. Appl. Energy 1985, 19, 159–182. [Google Scholar] [CrossRef]

- Gnutek, Z.; Kalinowski, E. Application of Rotary Vane Expanders in Systems Utilizing the Waste Heat. In Proceedings of the International Compressor Engineering Conference, Purdue University, West Lafayette, IN, USA, 19–22 July 1994. [Google Scholar]

- Gnutek, Z. Sliding-Vane Rotary Machinery. Developing Selected Issues of One-Dimensional Theory; Wrocław University of Technology Publishers: Wrocław, Poland, 1997. [Google Scholar]

- Rak, J.; Błasiak, P.; Kolasiński, P. Influence of the Applied Working Fluid and the Arrangement of the Steering Edges on Multi-Vane Expander Performance in Micro ORC System. Energies 2018, 11, 892. [Google Scholar] [CrossRef]

- Kolasiński, P.; Błasiak, P.; Rak, J. Experimental and Numerical Analyses on the Rotary Vane Expander Operating Conditions in a Micro Organic Rankine Cycle System. Energies 2016, 9, 606. [Google Scholar] [CrossRef]

- Kolasiński, P.; Pomorski, M.; Błasiak, P.; Rak, J. Use of Rolling Piston Expanders for Energy Regeneration in Natural Gas Pressure Reduction Stations—Selected Thermodynamic Issues. Appl. Sci. 2017, 7, 535. [Google Scholar] [CrossRef]

- Błasiak, P.; Kolasiński, P.; Daniarta, S. Analysis of Heat Transfer within Rotary Vane Expander. In Proceedings of the 6th International Seminar on ORC Power Systems, Munich, Germany, 11–13 October 2021. [Google Scholar] [CrossRef]

- Gnutek, Z. Gazowe Objętościowe Maszyny Energetyczne—Podstawy; Wrocław University of Science and Technology Publishing: Wrocław, Poland, 2004. [Google Scholar]

- Mamontow, M. Voprosy Termodynamiki Tiela Pieremiennoj Massy; Obrongiz: Moscow, Russia, 1961. [Google Scholar]

- Błasiak, P.; Pietrowicz, S. Towards a Better Understanding of 2D Thermal-Flow Processes in a Scraped Surface Heat Exchanger. Int. J. Heat Mass Transf. 2016, 98, 240–256. [Google Scholar] [CrossRef]

- Błasiak, P.; Pietrowicz, S. An Experimental Study on the Heat Transfer Performance in a Batch Scraped Surface Heat Exchanger under a Turbulent Flow Regime. Int. J. Heat Mass Transf. 2017, 107, 379–390. [Google Scholar] [CrossRef]

- Błasiak, P. Wpływ Zmiennych Warunków Ruchu Płynu w Pobliżu Ścianki Na Wymianę Ciepła. Ph.D. Thesis, Wrocław University of Science and Technology, Wrocław, Poland, 2015. [Google Scholar]

- Kern, D.Q.; Karakas, H.J. Mechanically Aided Heat Transfer; Chemical Automatics Design Bureau: Voronezh, Russia, 1958. [Google Scholar]

- Kool, J. Heat Transfer in Scraped Vessels and Pipes Handing Viscous Materials. Trans. Inst. Chem. Engrs. 1958, 36, 259. [Google Scholar]

- Skelland, A.H. Discussion of the Paper “Correlation of Scraped Film Heat Transfer in the Votator”. Chem. Eng. Sci. 1959, 9, 263–266. [Google Scholar] [CrossRef]

- Harriott, P. Heat Transfer in Scraped-Surface Heat Exchangers. In Chemical Engineering Progress Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1959; Volume 55, p. 137. [Google Scholar]

- Penney, W.R.; Bell, K.J. Close-Clearance Agitators—Part 2. Heat Transfer Coefficients. Ind. Eng. Chem. 1967, 59, 47–54. [Google Scholar] [CrossRef]

- Penney, W.R.; Bell, K.J. Heat Transfer in a Thermal Processor Agitated with a Fixed Clearance Thin Flat Blade. In Chemical Engineering Progress Symposium Series; American Institute of Chemical Engineers: New York, NY, USA, 1969; Volume 65, pp. 1–11. [Google Scholar]

- ANSYS Ansys®. CFX-Solver Theory Guide, Version 14.5.; ANSYS: Canonsburg, PA, USA, 2014.

- ANSYS Ansys®. ICEM CFD, Help System, V14.5.; ANSYS: Canonsburg, PA, USA, 2014.

| Model | Correlation for the Nu | Notes | Refs. |

|---|---|---|---|

| ZG | Rel > 105 | [21] | |

| K-K | - | [26] | |

| K-L-H | [27,28,29] | ||

| P-B | - | [30] | |

| P-Bexp | Rer > 400 ethylene, glycol | [31] | |

| B-P | Pr < 1 | [24] | |

| E | - | [21] |

| Thermal Conductivity [W/(m·K)] | Dynamic Viscosity [Pa·s] | Specific Heat [J/(kg·K)] | Density [kg/m3] |

|---|---|---|---|

| 0.0261 | 0.00001831 | 1004.4 | Ideal gas law |

| Parameter | Value | Remarks |

|---|---|---|

| Inlet temperature | 20 °C | static temperature |

| Inlet relative total pressure | 0.1–0.6 MPa | with a step of 0.1 MPa |

| Outlet relative pressure | 0 MPa | - |

| Operating absolute pressure | 0.1 MPa | - |

| Ambient temperature | 15 °C | - |

| Heat transfer coefficient | 10 W/(m2·K) | at the outer wall surface |

| Time duration | 0.06 s | 3 full revolutions |

| Time step | 5.55 × 10−6 s | 0.1° of revolution |

| Rotational speed | 3000 rpm | - |

| Turbulence model | SST | standard model |

| Turbulence intensity | 5% | at the inlet |

| Vane-to-wall clearance | 40 μm | constant |

| Mesh No. | Inlet Pressure (MPa) 1 | y+ Mean (−) | y+ Max (−) |

|---|---|---|---|

| 0 | 0.6 | 1.382 | 1.679 |

| 1 | 0.6 | 1.386 | 1.690 |

| 0.5 | 1.224 | 1.467 | |

| 0.4 | 1.024 | 1.237 | |

| 0.3 | 0.827 | 1.004 | |

| 0.2 | 0.613 | 0.749 | |

| 0.1 | 0.383 | 0.466 | |

| 2 | 0.6 | 1.411 | 1.701 |

| 3 | 0.6 | 1.400 | 1.695 |

| 4 | 0.6 | 1.112 | 1.300 |

| Mesh No. | Number of Elements | ||||

|---|---|---|---|---|---|

| Axially | Circumferentially | Gap | Vane | Total | |

| 0 | 9 | 76 | 22 | 22 | 29,304 |

| 1 | 9 | 76 | 19 | 19 | 25,308 |

| 2 | 9 | 76 | 16 | 16 | 21,312 |

| 3 | 9 | 76 | 13 | 13 | 17,316 |

| 4 | 9 | 44 | 10 | 10 | 6120 |

| Model | ||||||||

|---|---|---|---|---|---|---|---|---|

| Inlet Pressure (MPa) | ZG [20] | K-K [20] | K-L-H [20] | P-B [20] | P-Bexp [20] | B-P [20] | E [20] | Present |

| 0.1 | 119.6 | 937.5 | 583.6 | 103.8 | 116.1 | 131.9 | 88.5 | 76.6 |

| 0.2 | 157.6 | 937.5 | 693.4 | 120.8 | 152.0 | 156.5 | 112.7 | 88.2 |

| 0.3 | 193.2 | 937.5 | 787.5 | 134.8 | 185.3 | 177.6 | 134.7 | 125.1 |

| 0.4 | 227.3 | 937.5 | 871.8 | 147.0 | 217.2 | 196.4 | 155.3 | 146.3 |

| 0.5 | 260.4 | 937.5 | 948.9 | 157.8 | 247.9 | 213.7 | 174.8 | 155.5 |

| 0.6 | 292.5 | 937.5 | 1020.5 | 167.6 | 277.7 | 229.7 | 193.6 | 163.3 |

| Parameter | ZG | K-K | K-L-H | P-B | P-Bexp | B-P | E |

|---|---|---|---|---|---|---|---|

| MAPE | 65% | 709% | 568% | 14% | 58% | 51% | 15% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Błasiak, P.; Kolasiński, P.; Daniarta, S. Numerical Analysis of Heat Transfer within a Rotary Multi-Vane Expander. Energies 2023, 16, 2794. https://doi.org/10.3390/en16062794

Błasiak P, Kolasiński P, Daniarta S. Numerical Analysis of Heat Transfer within a Rotary Multi-Vane Expander. Energies. 2023; 16(6):2794. https://doi.org/10.3390/en16062794

Chicago/Turabian StyleBłasiak, Przemysław, Piotr Kolasiński, and Sindu Daniarta. 2023. "Numerical Analysis of Heat Transfer within a Rotary Multi-Vane Expander" Energies 16, no. 6: 2794. https://doi.org/10.3390/en16062794

APA StyleBłasiak, P., Kolasiński, P., & Daniarta, S. (2023). Numerical Analysis of Heat Transfer within a Rotary Multi-Vane Expander. Energies, 16(6), 2794. https://doi.org/10.3390/en16062794