In this section, we propose a model for AC slow charging of EV batteries corresponding to Class 3 kW and Class 7–11 kW. This statistical model considers one-day charging of a vehicle, and other characteristics according to weekdays and weekends, seasons, and geographical regions can be extended based on a composite source model.

2.1. EV Charging Time

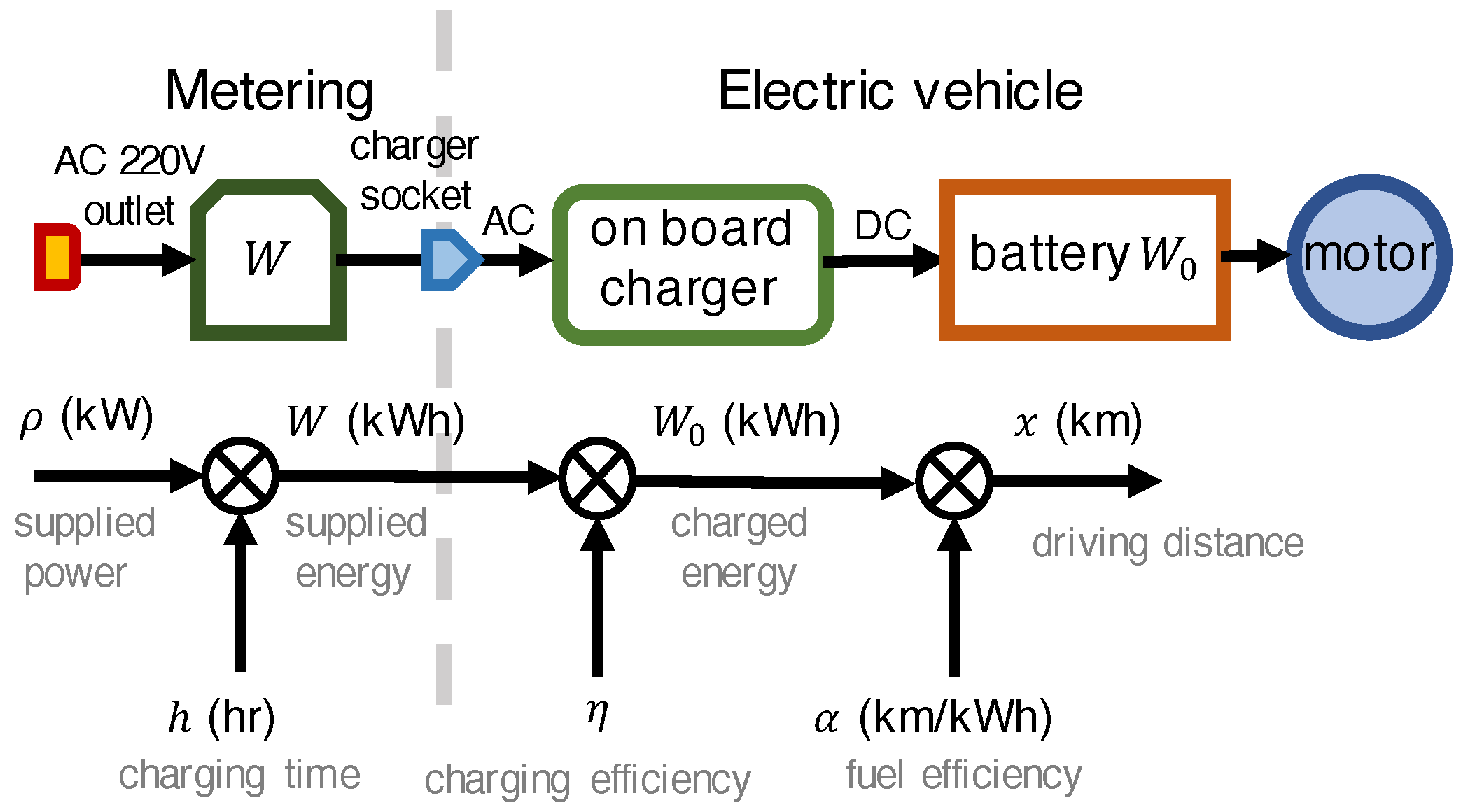

Let

(kWh) denote the amount of energy charged in the battery and

W (kWh) denote the energy to be supplied. The supplied energy

W, which is metered in a metering device, as shown in

Figure 1, serves as a basis for calculating electricity fees.

is then defined as

where a positive constant

represents the charging efficiency that considers both the charger and the battery and is less than 1. According to the 2022 data from the Korea Energy Agency (KEA), for the cases of the 100 kW-class DCFC, the charging efficiency for the charger alone is approximately 95%, and it is planned to increase to 98% in the future. In addition, the battery also has its own efficiency. Slow chargers, such as Class 3 kW and Class 7–11 kW, usually have a higher charging efficiency than fast chargers. Hence, in the statistical analysis, we set the efficiency as

. In the case of Class 3 kW, the metering device generally receives power from the conventional AC 220 V outlet and supplies energy to EV through a connector, such as the DC combo, as shown in

Figure 1. A wireless charging system can also be considered for slow chargers [

19].

In South Korea, there is a performance measure for EVs called the government-approved electric-vehicle fuel efficiency. This measure is divided into two parts for urban and high-speed driving conditions, similar to the fuel efficiency for internal combustion engine vehicles, and there is also a combined fuel efficiency that takes into account both parts. As of September 2022, the latest Hyundai Ioniq 6 has the best-combined fuel efficiency of 6.2 km/kWh in South Korea.

In general, EVs have higher fuel efficiency in urban areas compared to high-speed driving conditions. For instance, the Hyundai Ioniq 6 has fuel efficiencies of 6.8 km/kWh in urban areas and 5.5 km/kWh in high-speed driving conditions.

Let us denote the fuel efficiency of an EV as

(km/kWh). Then, as illustrated in

Figure 1, the daily driving distance

x that can be derived with the charged energy

is given as

Here,

represents a discharging efficiency. From (

1) and (

2), the supplied energy

W can be written as

, a function of the driving distance

x. Therefore, the longer the distance traveled, the more energy required. According to a survey conducted by the Korea Electric Power Research Institute (KEPRI) in 2022, the average daily driving distance of approximately 10,000 households with EVs was 60.9 km, which is higher than the average of 39.6 km of conventional vehicles reported by the Korea Statistics Office (KOSIS) in 2022.

Now, let us derive a simple model of the charging time of a slow charger. Let the supplied power be denoted as

. The supplied energy to charge the EV

W then satisfies

where

h implies the charging time, and the supplied power

satisfies the condition that

for

, and

is 0 elsewhere. Let the time average of

be denoted by

and be defined as

Then, the supplied energy is expressed as

, and using (

1) and (

2), the daily charging time can be written as

From (

5), we observe that the charging time is directly proportional to the driving distance

x. Assume that Lithium-ion batteries are initially charged to approximately 85% of the state of charge (SOC) with a constant current and then charged to 100% with a constant voltage. Hence, the supplied power

tends to increase gradually during the constant current charging step. In the case of slow chargers, we observe that the change in supplied power

is very small when charging from 35% to 80%. In other words, we can assume that the supplied power is constant during the charging period, i.e.,

[

20]. Note that this charging scenario on SOC can maximize the battery life. In the case of a 3 kW-class slow charger, the supplied power

can be selected at the start of charging, and it is assumed that the supplied power remains unchanged during the charging period. In contrast, for the fast chargers, supplied power changes can be significant.

Considering Hyundai Ioniq 5, which has a combined fuel efficiency of

km/kWh, the daily charging time is

h from (

5) as an example. Here, we assume that the charging efficiency is

, the average supplied power is

kW, and the daily driving distance is

km (KEPRI, 2022). In other words, we need to charge this EV for about 4 h every day. The supplied energy

W calculated is

kWh, and the energy stored in the battery is

kWh.

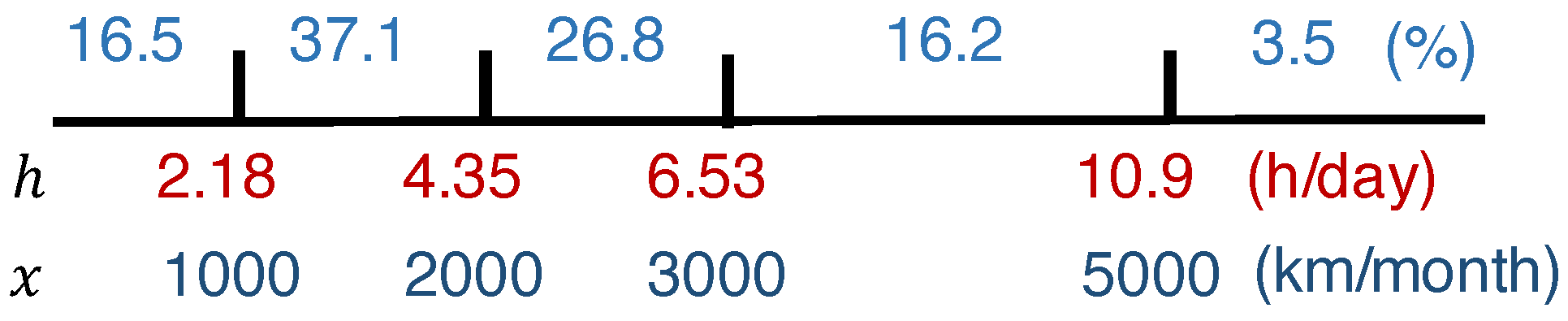

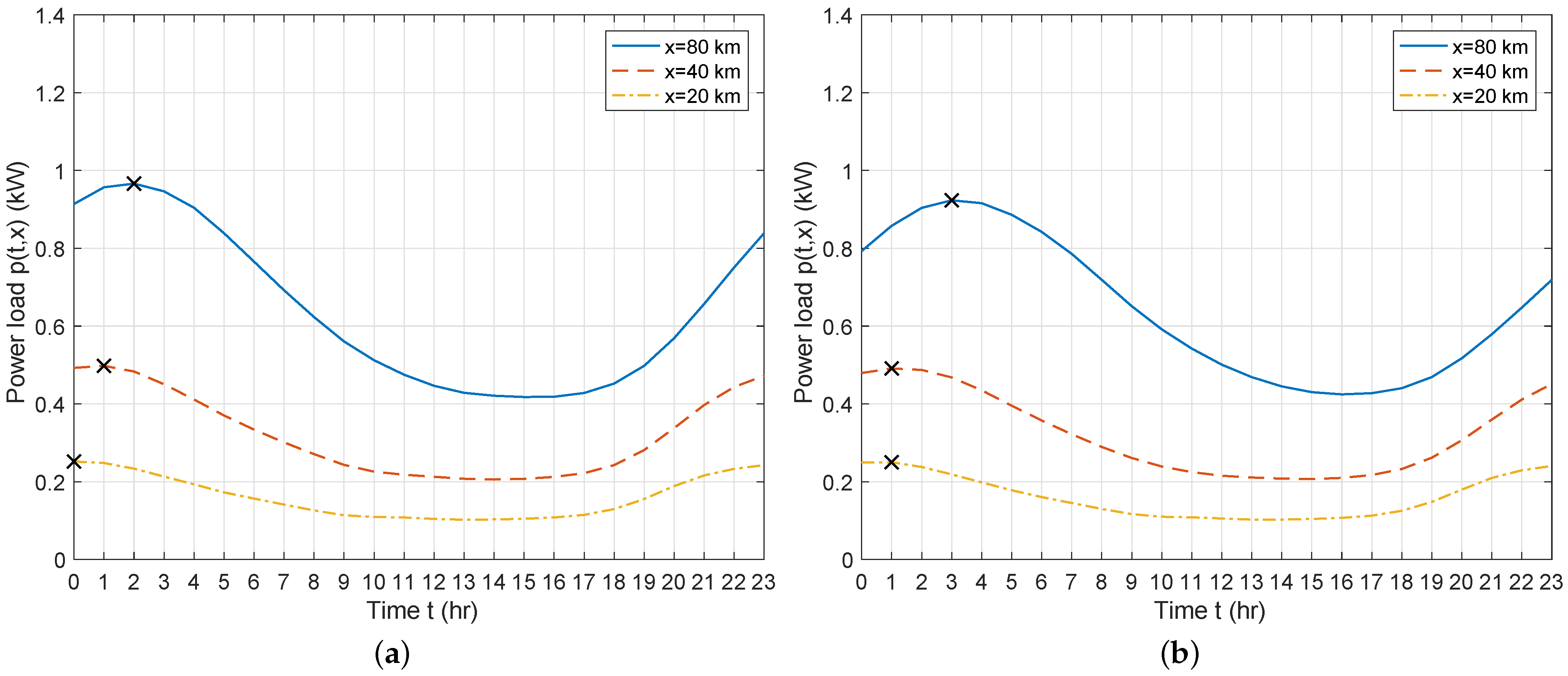

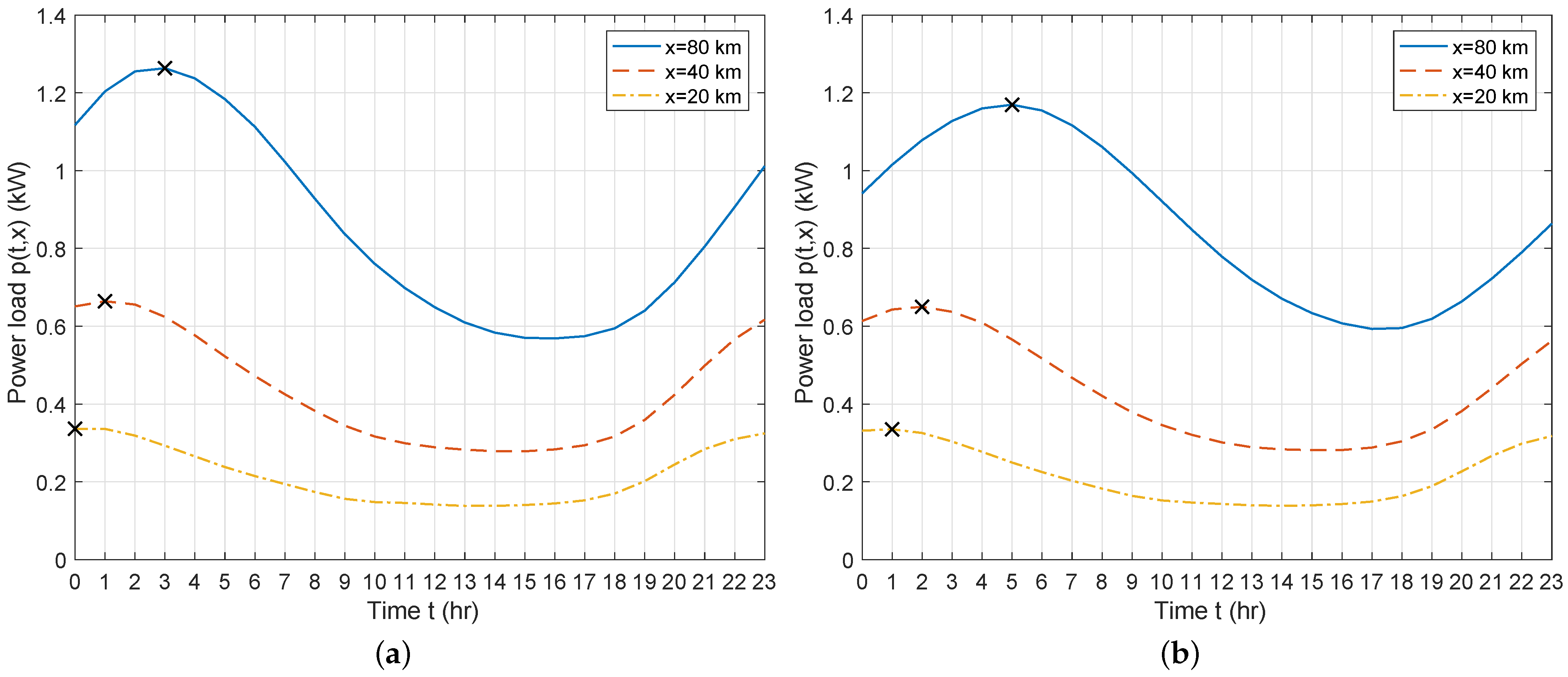

Figure 2 shows the charging time per day according to the driving distance distribution for one month. In total, 37.1% of the monthly driving range falls between 1000 and 2000 km, and the charging time ranges from 2.18 to 4.35 h.

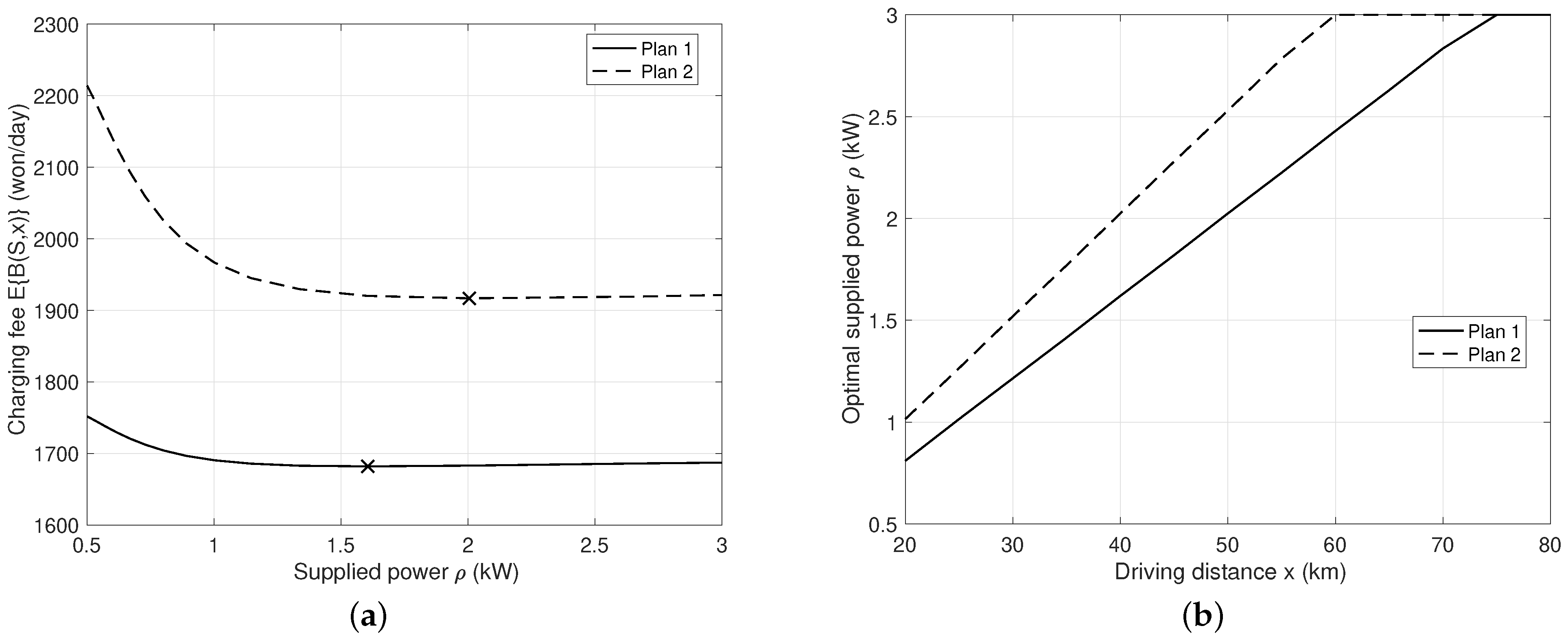

2.2. EV Charging Fee

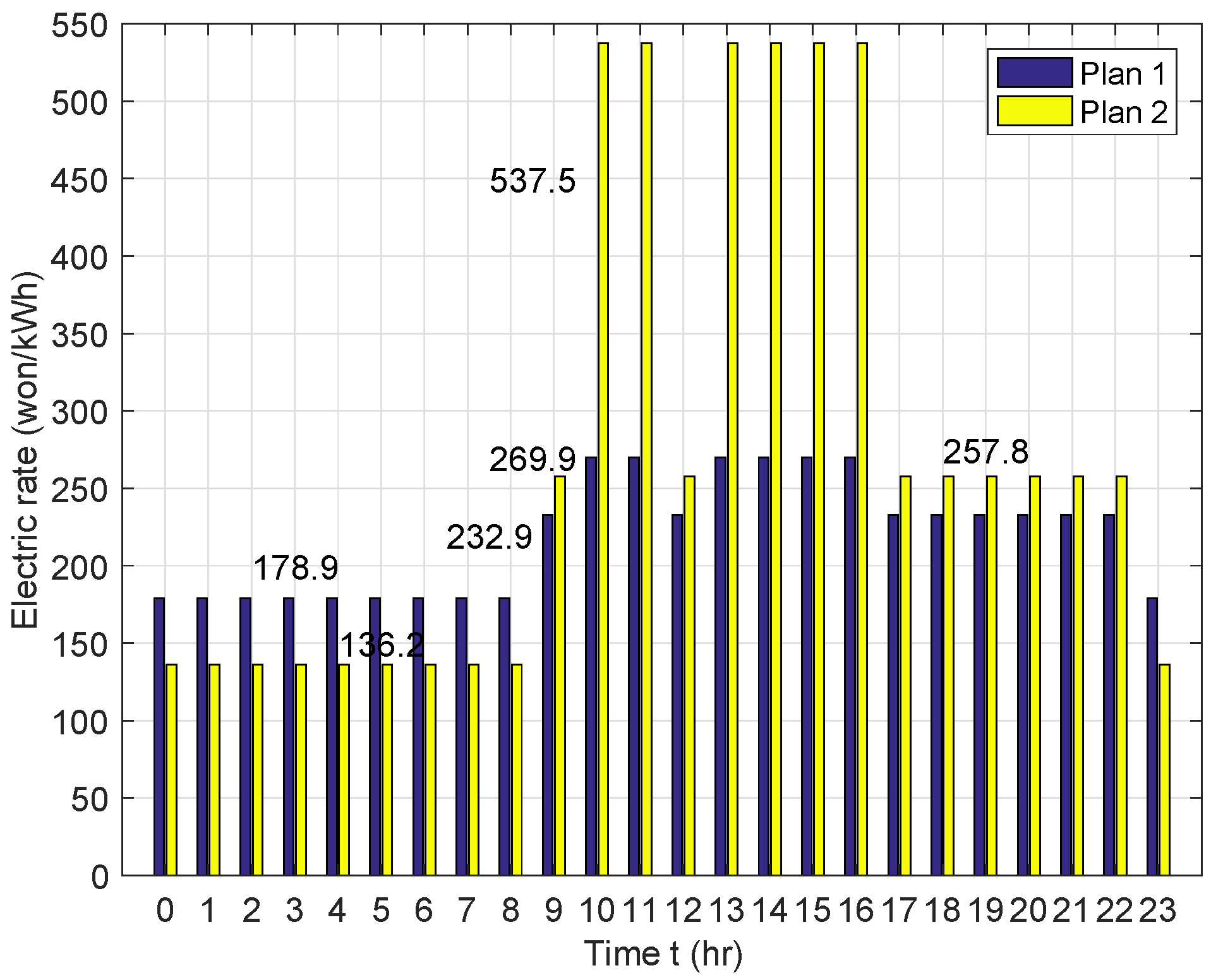

Dynamic rate plans that implement price-based demand response (DR) systems are widely used to reduce the power demand during peak hours or shift it to off-peak hours. A common example of such a plan is the time-of-use (TOU) rate plan, where peak hours of high electricity consumption have higher prices compared to off-peak hours [

21]. In this subsection, we analyze the charging fees under a dynamic rate plan using the EV charging model presented in

Section 2.

Let

s denote the starting time of the charging in hours and

denote the charging fee for a driving distance

x. Then,

can be expressed as

In (

6),

, where

, represents a dynamic rate plan that has varying rates for 24 h a day. If the rate plan

is a constant of

during the charging interval of

, then, by using (

5), the charging fee in (

6) can be rewritten as

We now derive the mean of the charging fee. First, the starting time of the charging has irregular characteristics, so let us set it as a random variable

S instead of a fixed value

s. Here, assume that

S has a continuous probability density of

. Furthermore, assume that the driving distance

x is set as a random variable

X and has a continuous probability density of

. When the driving distance is given by

, a mean charging fee is given as the following conditional mean:

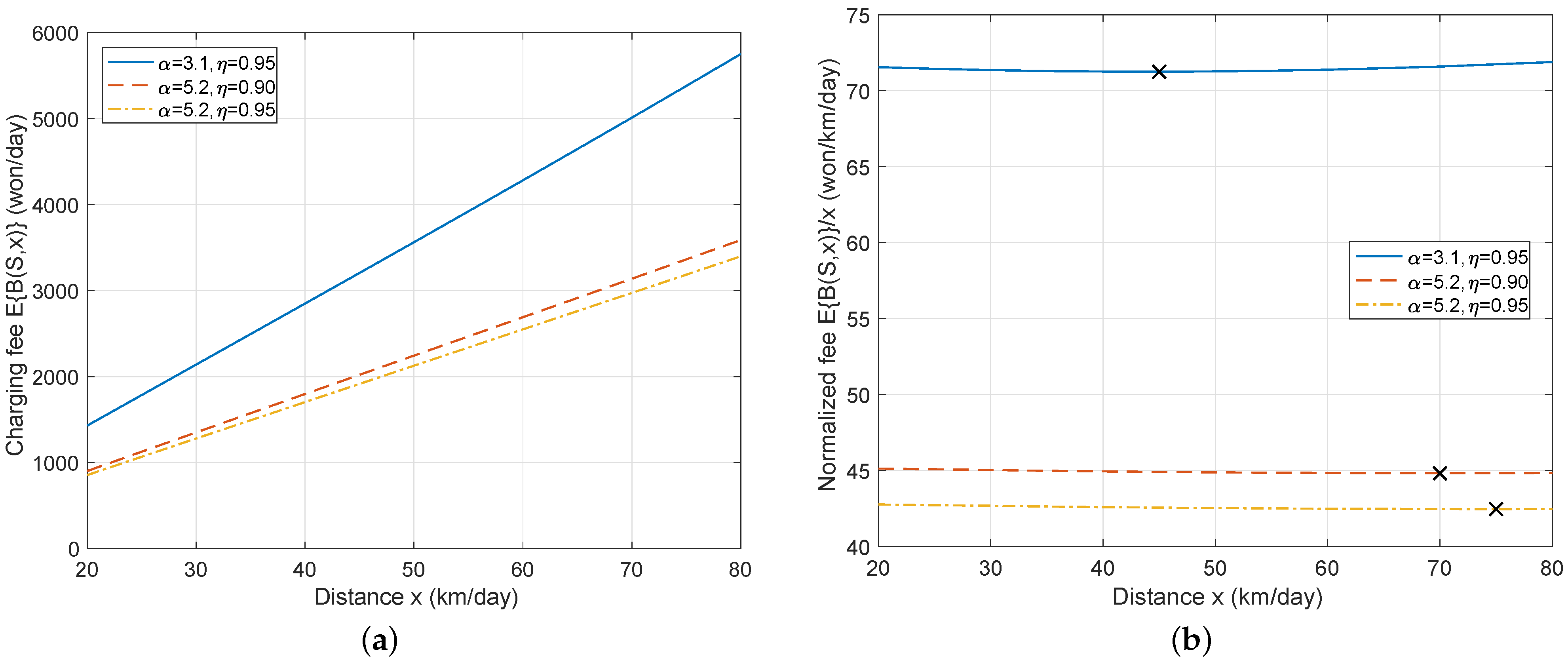

For a given driving distance

x, we can calculate the daily charging fee using this conditional mean of (

8).

The mean daily charging fee is given as

If the rate plan

is a constant of

during a charging interval of

t in a similar manner to (

7), then the mean charging fee is given as

Assume charging takes place between 23:00 and 09:00. For example, KEPCO provides a fixed rate

KRW/kWh. Note that, as of February 2023, 1000 Korean Won (KRW) is approximately equal to 0.83 US Dollars (USD). For the fuel efficiency of

km/kWh and the charging efficiency of

, the mean charging fee is calculated to be KRW 2524. Here, the mean driving distance is

km from

Figure 2 (KEPRI, 2022). For a membership case of the Korea Electric Vehicle Infrastructure Technology (KEBVIT), the rate is 110 KRW/kWh, and thus, the mean charging fee is KRW 1357.