Component-Oriented Modeling Method for Real-Time Simulation of Power Systems

Abstract

1. Introduction

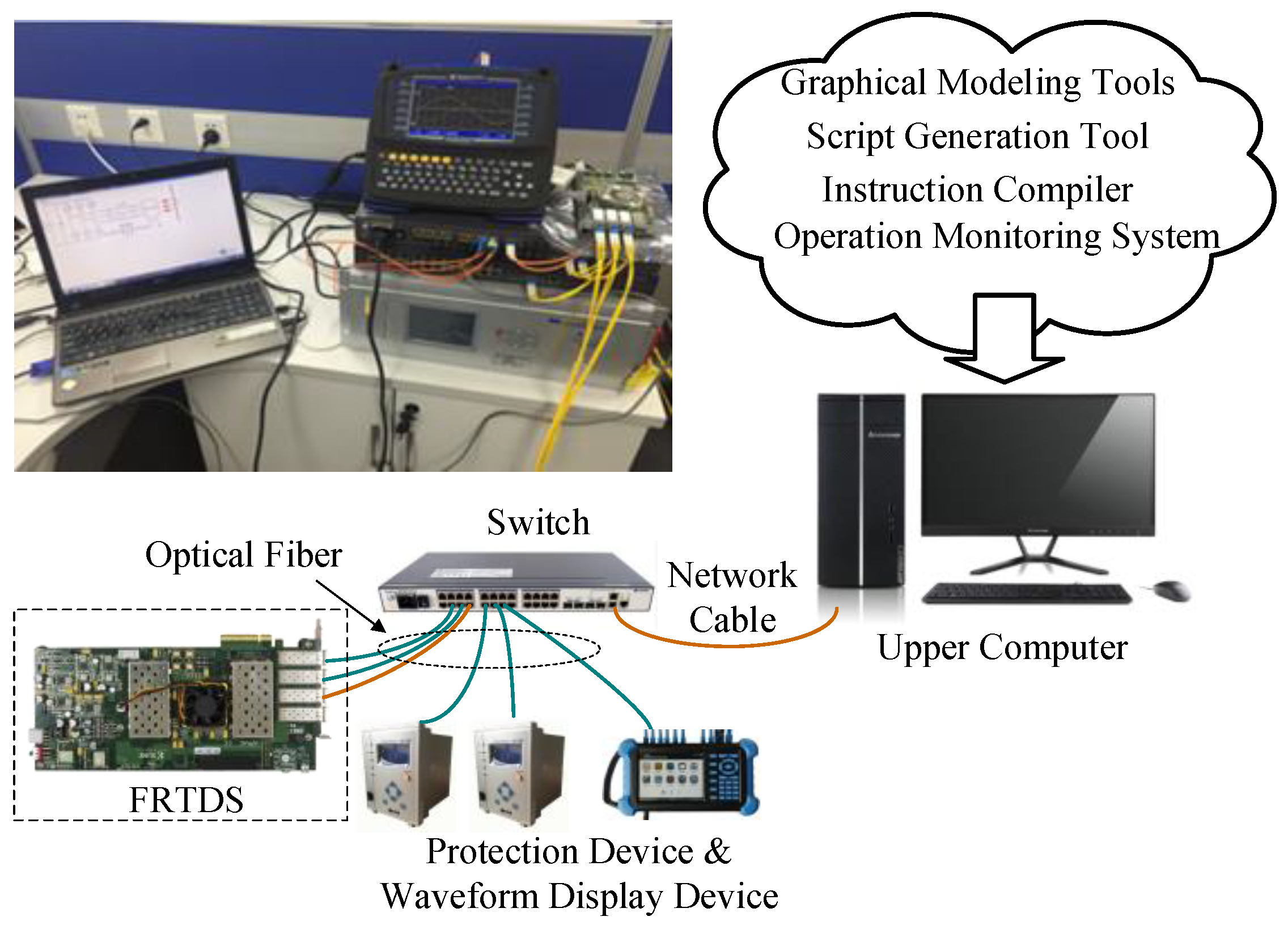

2. FRTDS

2.1. Overview of FRTDS

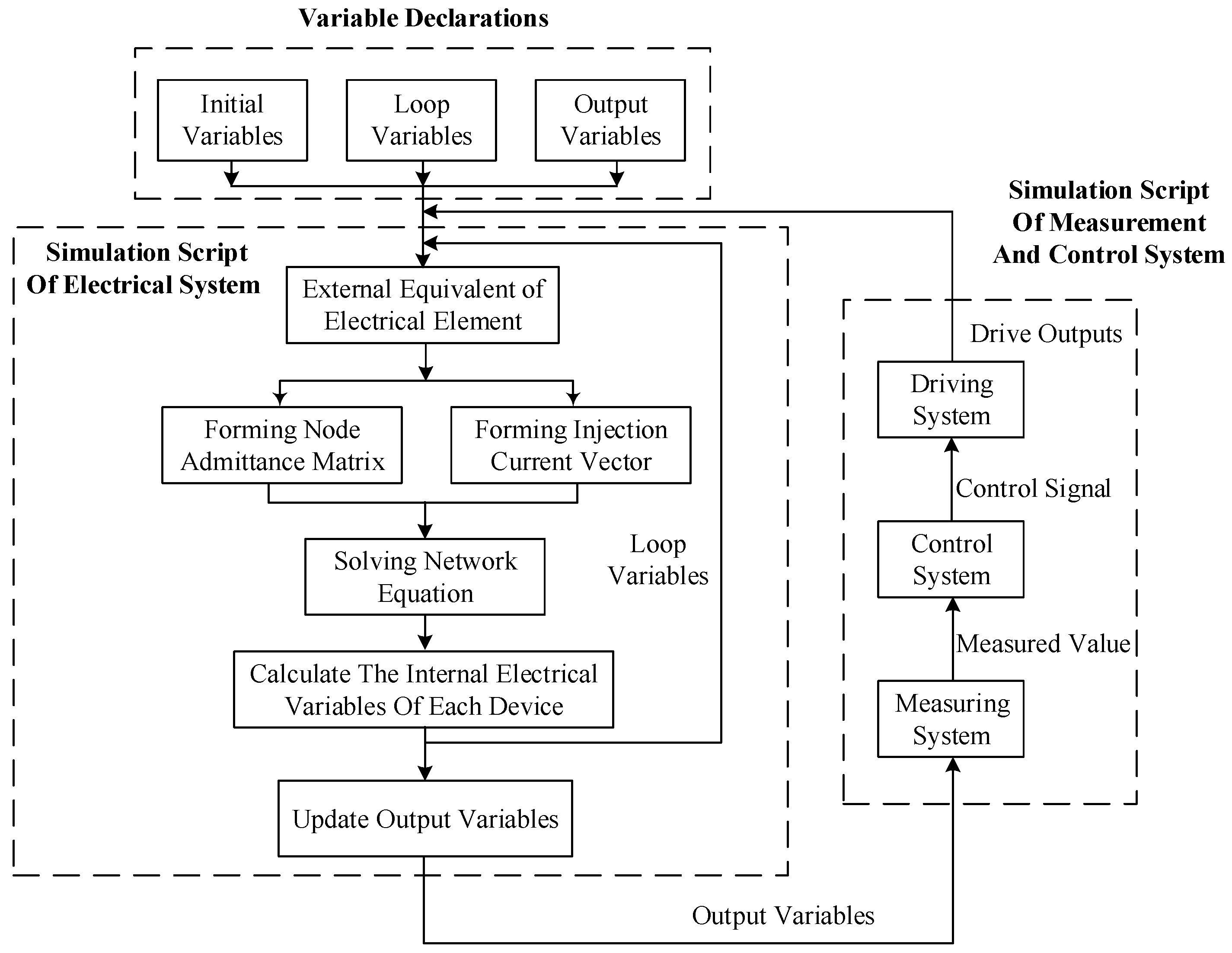

2.2. The Content and Limitations of the Simulation Script

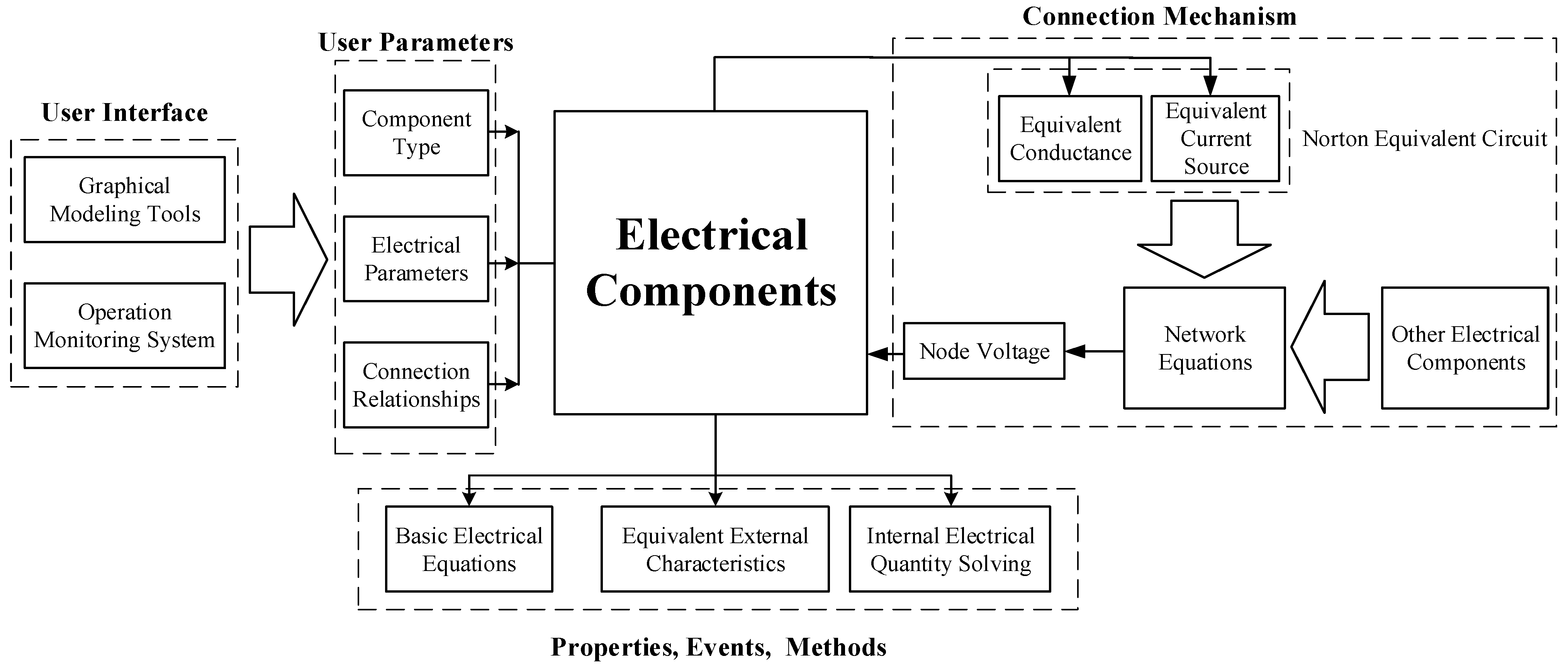

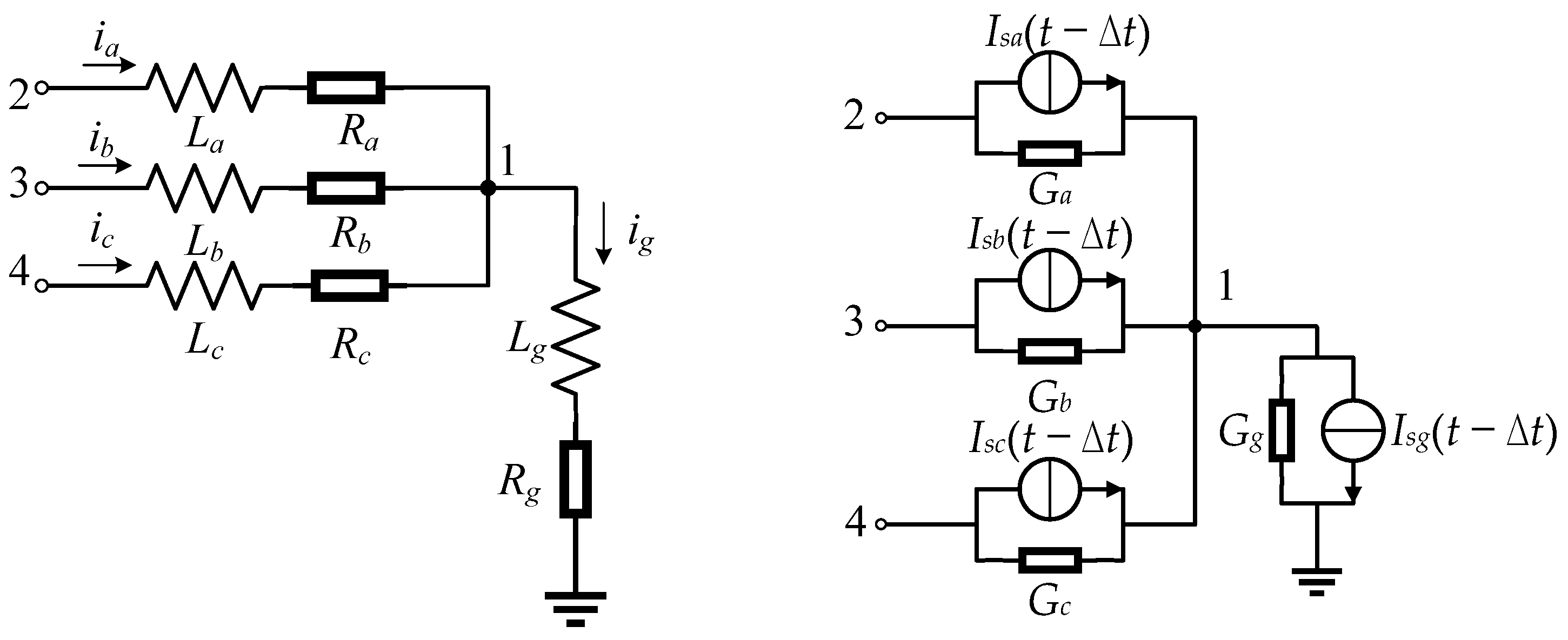

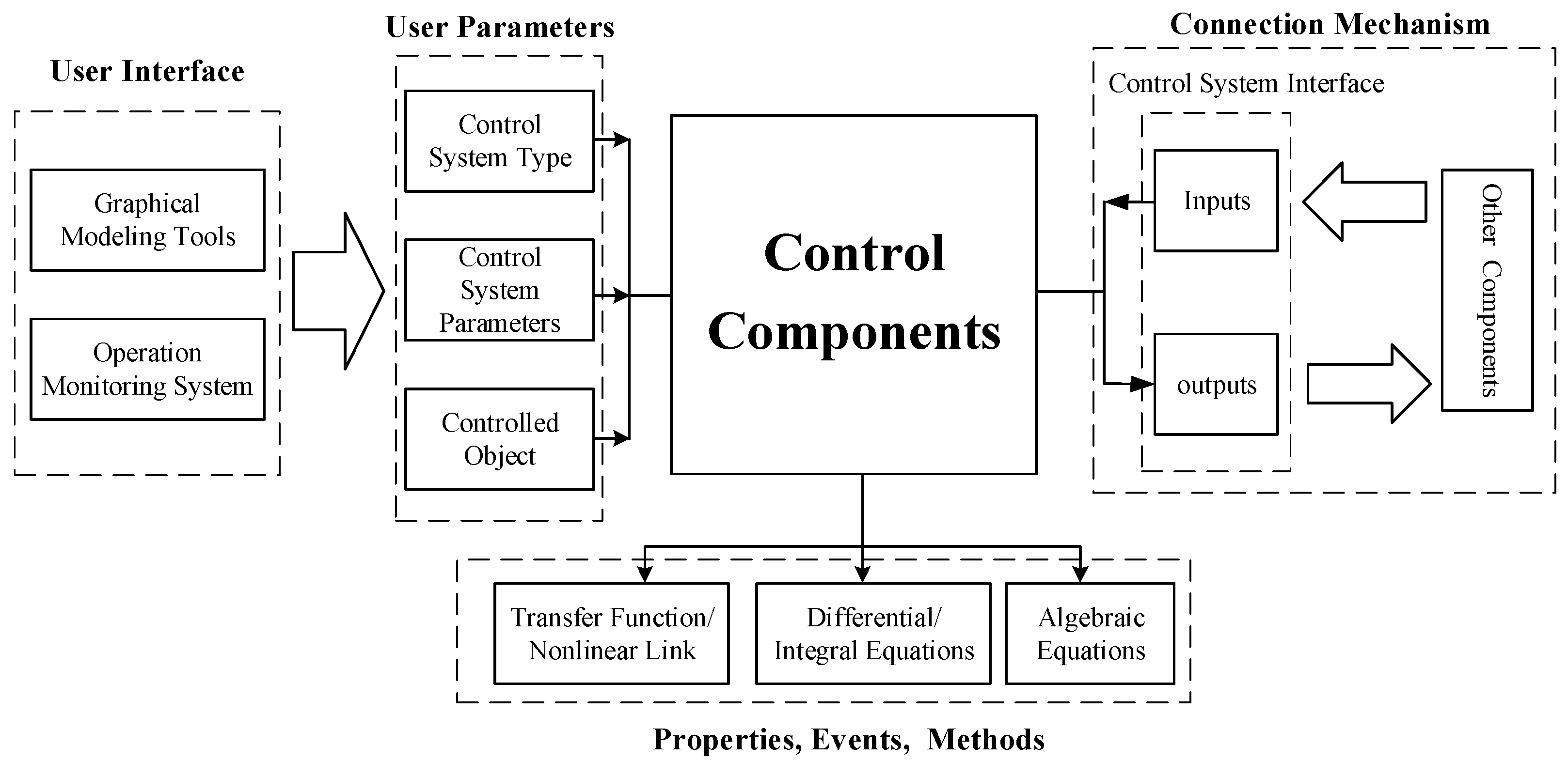

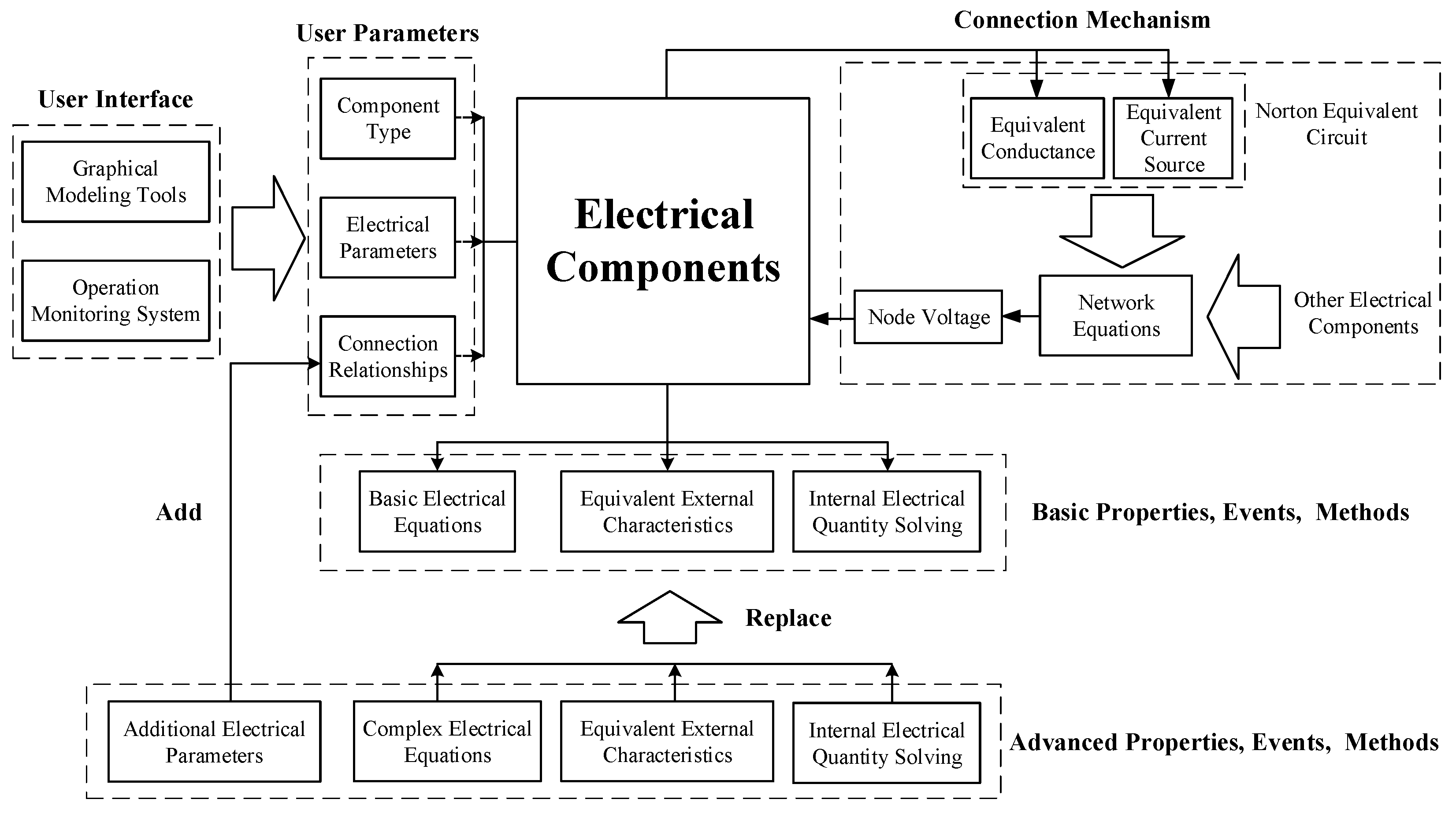

3. Component Modeling of Simulation Objects

4. Combination and Reconstruction of Electrical Components

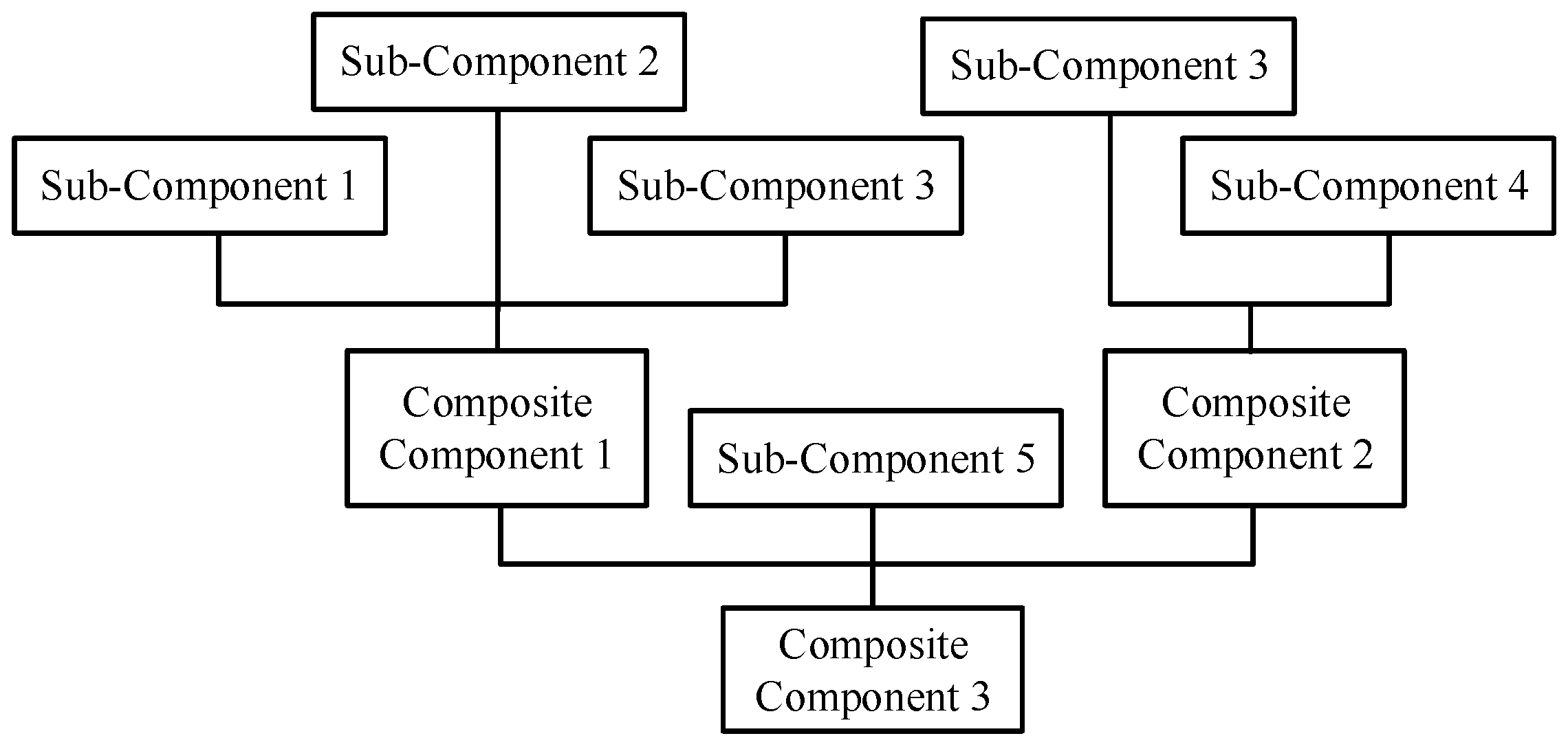

4.1. Composite Electrical Component

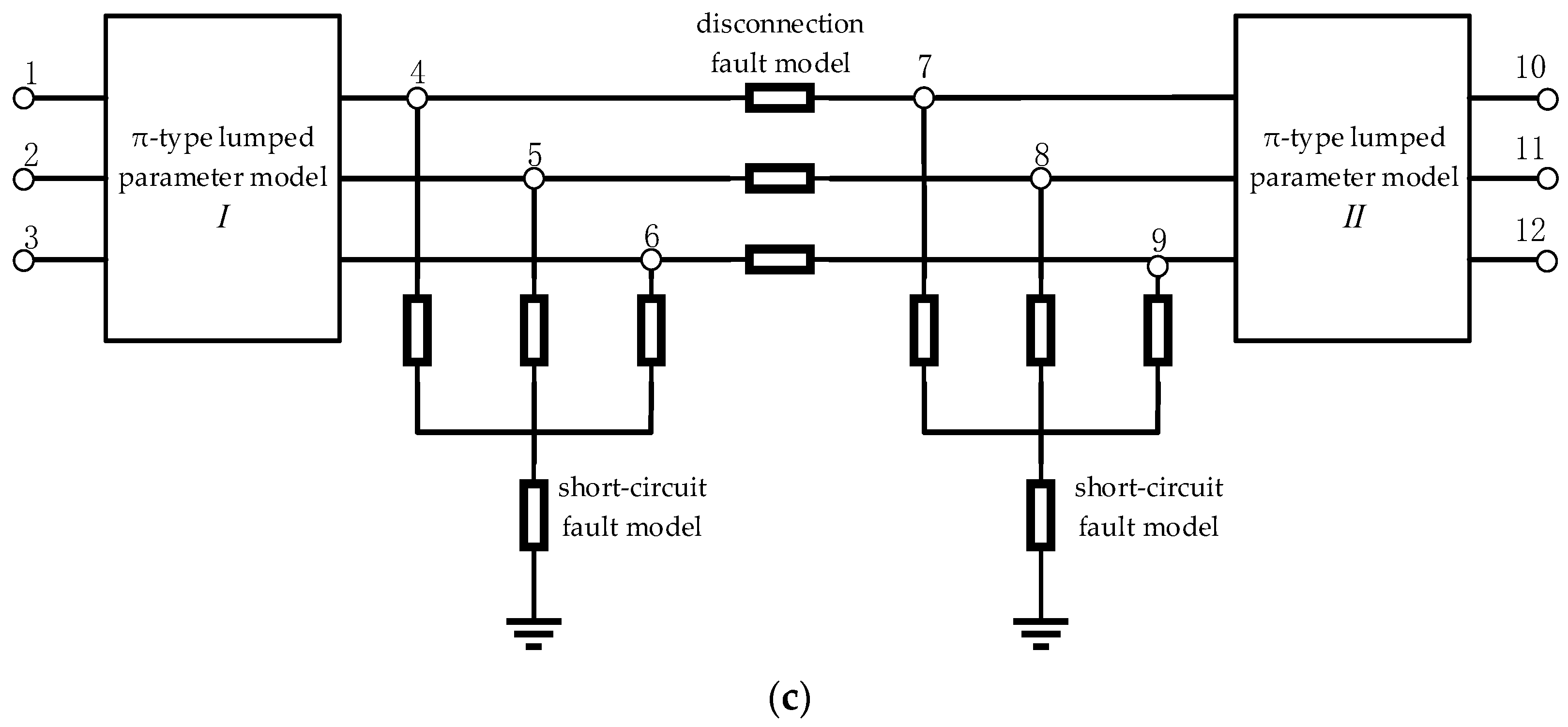

4.2. Reconstruction of Electrical Components

5. Optimization Method for a Simulation Script Based on the Component Modeling Method

5.1. Subscripts Based on the Component Modeling Method

5.2. Influence of Component Modeling on Node Elimination Strategy

6. Case Study

- (1)

- The power source composite component, represented by components A1 and F1 in the figure, including an infinite bulk electric power source, CT, PT, transmission lines, and other components;

- (2)

- The interval unit composite component, represented by components A2, B1, E1, and F2 in the figure, including circuit breakers, isolation switches, CT, and grounding switches;

- (3)

- The bus coupler composite component, represented by component D in the figure, including circuit breakers, isolation switches, CT, and grounding switches, etc.;

- (4)

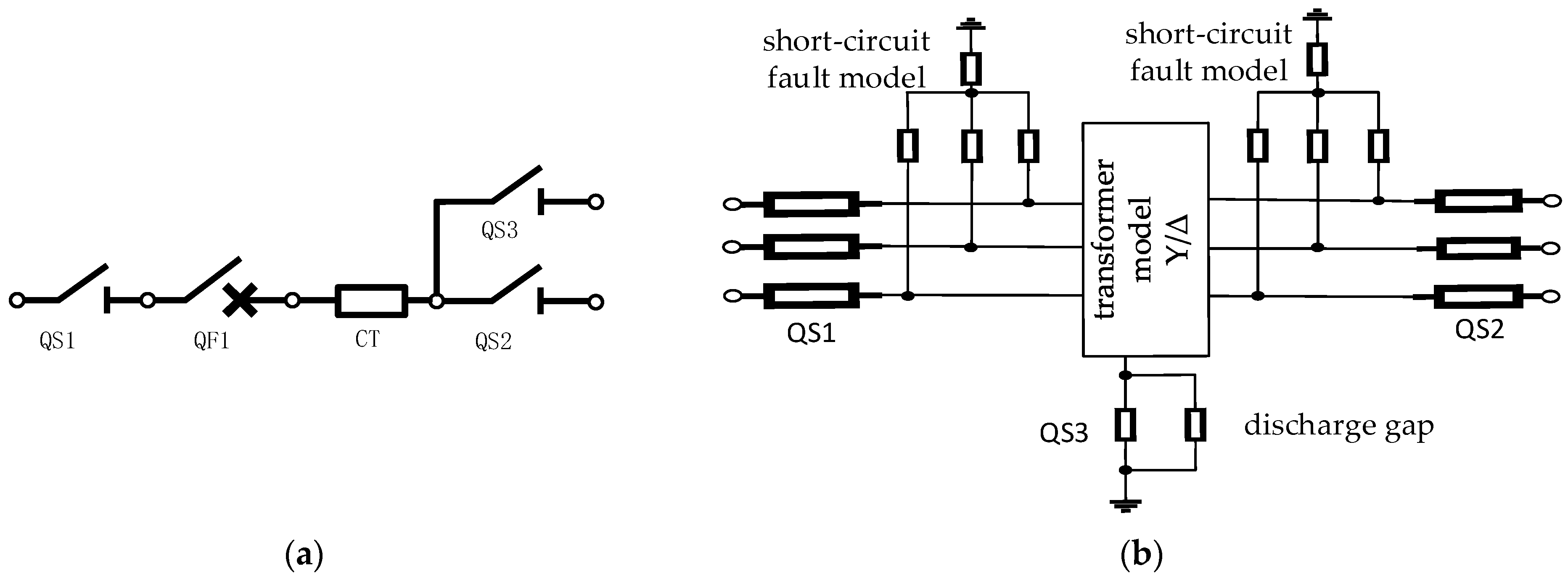

- The transformer composite component, represented by components B2 and E2 in the figure, including transformers, discharge gaps, and grounding switches;

- (5)

- The generator composite component, represented by component C in the figure, including multi-winding synchronous generators, PT, CT, circuit breakers, etc.

- (1)

- Scheme 1: Regardless of the relative independence of the calculation process between components and the privacy of the component data, all variables of the simulation system are centrally declared and evenly distributed to four micro-processing cores and then evenly distributed into the four data areas. The node elimination strategy uses only the minimum degree–maximum independent set method.

- (2)

- Scheme 2: Considering the relative independence of the calculation process between components and the privacy of component data, the variables of the simulation system are declared using the component-oriented modeling method. The variables of branches A and D are assigned to microprocessor core 1, the variables of branches B and G are assigned to microprocessor core 2, the variables of branches E and F are assigned to microprocessor core 3, and the variables of branch C are assigned to microprocessor core 4. Inside each microprocessor core, variables belonging to the same component are arranged in the same data area as much as possible. This node elimination strategy uses only the minimum degree–maximum independent set method.

- (3)

- Scheme 3: This variable arrangement scheme is the same as scheme 2. For the external equivalent process of each component, the minimum degree method is used for node elimination; for the external network equation solution process, the minimum degree–maximum independent set method is used for node elimination.

7. Conclusions

- (1)

- When users employ FRTDS for real-time simulations, the component-oriented modeling method makes the simulation modeling process more convenient, especially when the simulation example is replaced, or secondary development of the element model is performed.

- (2)

- The concept of subscripts and the hierarchical structure of scripts generated after component modeling enable the compiler to fully consider the compatibility between tasks and data when arranging computing tasks, thereby reducing the occurrence of data transfer and helping to reduce the simulation calculation time.

- (3)

- The proposed node elimination strategy using a combination of the minimum degree method and the minimum degree–maximum independent set method for different stages of simulation can reduce the computational workload and match the degree of algorithm parallelism with the actual parallel computing capacity of hardware, further reducing the simulation calculation time.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FPGA | Field-Programmable Gate Array |

| FRTDS | FPGA-based Real Time Digital Simulator |

| CPU | Central Processing Unit |

| GOOSE | Generic Object-Oriented Substation Event |

| SV | Sampled Value |

| CT | Current Transformer |

| PT | Potential Transformer |

References

- Subedi, S.; Rauniyar, M.; Ishaq, S.; Hansen, T.M.; Tonkoski, R.; Shirazi, M.; Wies, R.; Cicilio, P. Review of Methods to Accelerate Electromagnetic Transient Simulation of Power Systems. IEEE Access 2021, 9, 89714–89731. [Google Scholar] [CrossRef]

- Zhou, Z.; Dinavahi, V. Fine-Grained Network Decomposition for Massively Parallel Electromagnetic Transient Simulation of Large Power Systems. IEEE Power Energy Technol. Syst. J. 2017, 4, 51–64. [Google Scholar] [CrossRef]

- Strasser, T.I.; Rohjans, S.; Burt, G.M. Methods and Concepts for Designing and Validating Smart Grid Systems. Energies 2019, 12, 1861. [Google Scholar] [CrossRef]

- Yadav, G.; Liao, Y.; Burfield, A.D. Hardware-in-the-Loop Testing for Protective Relays Using Real Time Digital Simulator (RTDS). Energies 2023, 16, 1039. [Google Scholar] [CrossRef]

- Han, J.; Hong, Q.; Feng, Z.; Syed, M.H.; Burt, G.M.; Booth, C.D. Design and Implementation of a Real-Time Hardware-in-the-Loop Platform for Prototyping and Testing Digital Twins of Distributed Energy Resources. Energies 2022, 15, 6629. [Google Scholar] [CrossRef]

- Estrada, L.; Vázquez, N.; Vaquero, J.; de Castro, Á.; Arau, J. Real-Time Hardware in the Loop Simulation Methodology for Power Converters Using LabVIEW FPGA. Energies 2020, 13, 373. [Google Scholar] [CrossRef]

- Matar, M.; Karimi, H.; Etemadi, A.; Iravani, R. A High Performance Real-Time Simulator for Controllers Hardware-in-the-Loop Testing. Energies 2012, 5, 1713–1733. [Google Scholar] [CrossRef]

- Song, J.; Hur, K.; Lee, J.; Lee, H.; Lee, J.; Jung, S.; Shin, J.; Kim, H. Hardware-in-the-Loop Simulation Using Real-Time Hybrid-Simulator for Dynamic Performance Test of Power Electronics Equipment in Large Power System. Energies 2020, 13, 3955. [Google Scholar] [CrossRef]

- Sidwall, K.; Forsyth, P. Advancements in Real-Time Simulation for the Validation of Grid Modernization Technologies. Energies 2020, 13, 4036. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Elsayed, Y.; Isham, M.; Elshora, A.; Siddique, A.B.; Esteves, O.L.A. Demonstration of Resilient Microgrid with Real-Time Co-Simulation and Programmable Loads. Technologies 2022, 10, 83. [Google Scholar] [CrossRef]

- Gupta, K.; Sahoo, S.; Panigrahi, B.K.; Blaabjerg, F.; Popovski, P. On the Assessment of Cyber Risks and Attack Surfaces in a Real-Time Co-Simulation Cybersecurity Testbed for Inverter-Based Microgrids. Energies 2021, 14, 4941. [Google Scholar] [CrossRef]

- Abusalah, A.; Saad, O.; Mahseredjian, J.; Karaagac, U.; Gerin-Lajoie, L.; Kocar, I. CPU based parallel computation of electromagnetic transients for large power grids. Electr. Power Syst. Res. 2018, 160, 57–63. [Google Scholar] [CrossRef]

- Omar Faruque, M.D.; Strasser, T.; Lauss, G. Real-time simulation technologies for power systems design, testing, and analysis. IEEE Power Energy Technol. Syst. J. 2015, 2, 63–73. [Google Scholar] [CrossRef]

- Tavana, N.R.; Dinavahi, V. A General Framework for FPGA-Based Real-Time Emulation of Electrical Machines for HIL Applications. IEEE Trans. Ind. Electron. 2015, 62, 2041–2053. [Google Scholar] [CrossRef]

- Bai, H.; Luo, H.; Liu, C.; Paire, D.; Gao, F. A Device-Level Transient Modeling Approach for the FPGA-Based Real-Time Simulation of Power Converters. IEEE Trans. Power Electron. 2020, 35, 1282–1292. [Google Scholar] [CrossRef]

- Matar, M.; Iravani, R. Massively Parallel Implementation of AC Machine Models for FPGA-Based Real-Time Simulation of Electromagnetic Transients. IEEE Trans. Power Del. 2011, 26, 830–840. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, S.; Jin, Z.; Hu, R. A Novel FPGA-Based Real-Time Simulator for Micro-Grids. Energies 2017, 10, 1239. [Google Scholar] [CrossRef]

- Zhang, B.; Jin, X.; Tu, S.; Jin, Z.; Zhang, J. A New FPGA-Based Real-Time Digital Solver for Power System Simulation. Energies 2019, 12, 4666. [Google Scholar] [CrossRef]

- Zhang, B.; Wu, Y.; Jin, Z.; Wang, Y. A Real-Time Digital Solver for Smart Substation Based on Orders. Energies 2017, 10, 1795. [Google Scholar] [CrossRef]

- Guan, Y.; Zhang, B.; Jin, Z. An FRTDS Real-Time Simulation Optimized Task Scheduling Algorithm Based on Reinforcement Learning. IEEE Access 2020, 8, 155797. [Google Scholar] [CrossRef]

- Wang, L. Component-based performance-sensitive real-time embedded software. IEEE Aerosp. Electron. Syst. Mag. 2008, 23, 28–34. [Google Scholar] [CrossRef]

- Tibermacine, C.; Sadou, S.; That, M.T.; Dony, C. Software architecture constraint reuse-by-composition. Future Gener. Comput. Syst. 2016, 61, 37–53. [Google Scholar] [CrossRef]

- Lu, K.S.; Chang, C.K. ALTA: Automatic Load-Time Adaptation Technique for Refactoring-Based Evolution of Software Component. In Proceedings of the 2012 IEEE 36th Annual Computer Software and Applications Conference, Izmir, Turkey, 16–20 July 2012; pp. 203–212. [Google Scholar] [CrossRef]

- Alsac, O.; Stott, B.; Tinney, W. Sparsity-oriented compensation methods for modified network solutions. IEEE Trans. Power Appar. Syst. 1983, 102, 1050–1060. [Google Scholar] [CrossRef]

- Zhang, B.; Zhao, D.; Jin, Z.; Wu, Y. Multivalued Coefficient Prestorage and Block Parallel Method for Real-Time Simulation of Microgrid on FRTDS. Energies 2017, 10, 1248. [Google Scholar] [CrossRef]

| Parameter Name | Parameter Type | Unit | Setting Range |

|---|---|---|---|

| Rated voltage (UB) | Floating point number | KV | 0~2000 |

| Rated active power (P) | Floating point number | MW | 0~100 |

| Rated reactive power (Q) | Floating point number | MVar | 0~100 |

| Ground resistance (Rg) | Floating point number | Ω | 0~106 |

| Grounding inductance (Lg) | Floating point number | H | 0~106 |

| Associated node | Positive integer | / | 0~100 |

| Scheme | Computational Load | Number of Data Transfers | Number of Instructions | Actual Time Used |

|---|---|---|---|---|

| Scheme 1 | 16,627 | 2802 | 6267 | 50.14 μs |

| Scheme 2 | 16,627 | 1680 | 5905 | 47.24 μs |

| Scheme 3 | 15,301 | 1513 | 5424 | 43.39 μs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Z.; Zhang, J.; Wang, S.; Zhang, B. Component-Oriented Modeling Method for Real-Time Simulation of Power Systems. Energies 2023, 16, 2731. https://doi.org/10.3390/en16062731

Jin Z, Zhang J, Wang S, Zhang B. Component-Oriented Modeling Method for Real-Time Simulation of Power Systems. Energies. 2023; 16(6):2731. https://doi.org/10.3390/en16062731

Chicago/Turabian StyleJin, Zhao, Jie Zhang, Shuyuan Wang, and Bingda Zhang. 2023. "Component-Oriented Modeling Method for Real-Time Simulation of Power Systems" Energies 16, no. 6: 2731. https://doi.org/10.3390/en16062731

APA StyleJin, Z., Zhang, J., Wang, S., & Zhang, B. (2023). Component-Oriented Modeling Method for Real-Time Simulation of Power Systems. Energies, 16(6), 2731. https://doi.org/10.3390/en16062731