Effects of Numerical Schemes of Contact Angle on Simulating Condensation Heat Transfer in a Subcooled Microcavity by Pseudopotential Lattice Boltzmann Model

Abstract

1. Introduction

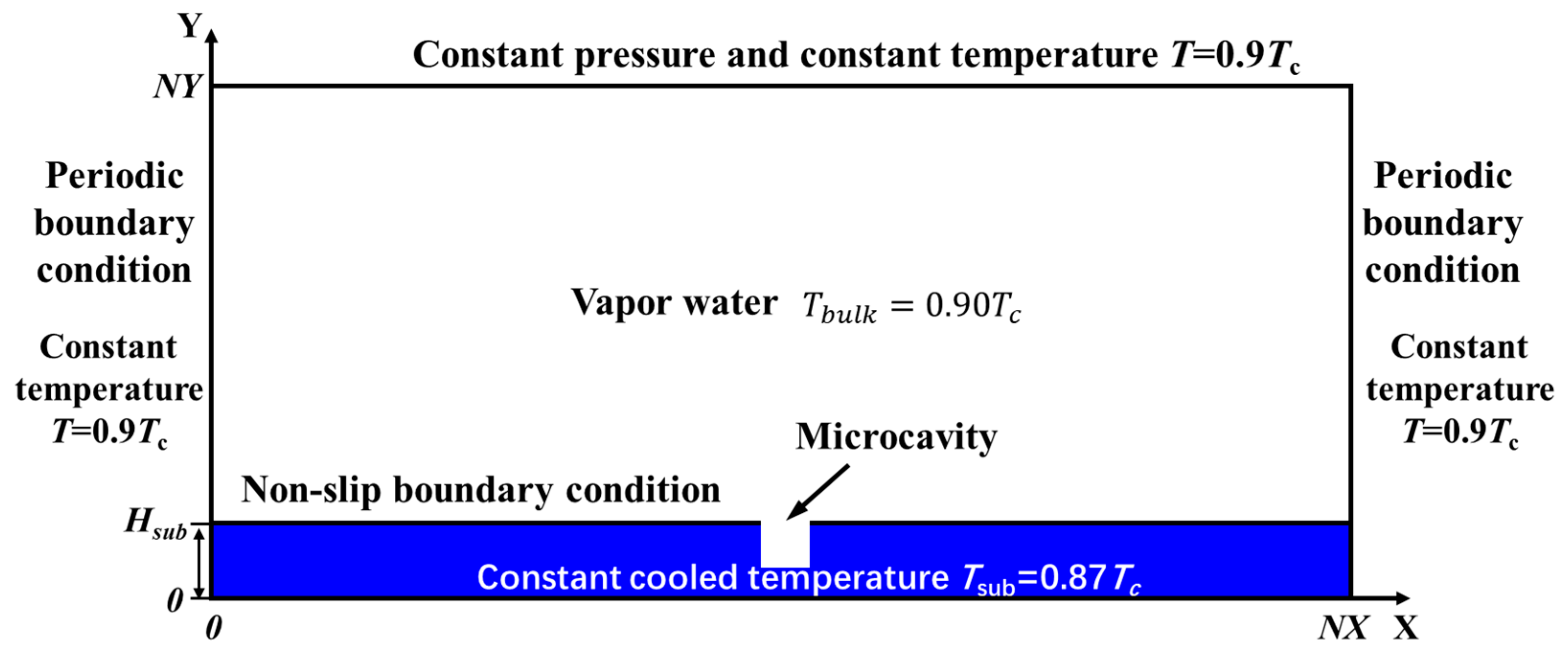

2. Pseudopotential Lattice Boltzmann Model

2.1. Fluid Dynamics Description

2.2. Heat Transfer Description

3. Simulation Settings

4. Results and Discussions

4.1. Effects of Subcooling Condition on Numerical Schemes of Contact Angle

4.2. Effects of Fluid Density Variation near Wall on Condensation

4.3. Effects of Numerical Schemes on Condensation Heat Transfer in a Microcavity

5. Conclusions

- The simulated contact angle of a subcooled substrate is smaller than that of an isothermal substrate by using different numerical schemes of contact angle in pseudopotential lattice Boltzmann model. The subcooling condition also destabilizes the algorithm incorporated with the pseudopotential-based scheme (Scheme #1) so that only an obtuse contact angle can be simulated by Scheme #1. However, such destabilization effect is eliminated by constructing a ghost fluid layer with weighted average density of surrounding fluid nodes (Scheme #2) or by using the geometric formulation scheme (Scheme #3).

- The fluid density near the wall simulated by the pseudopotential-based scheme (Scheme #1) fluctuates and deviates from the bulk fluid density, which plays the role of condensation nucleus. However, the simulated fluid density near the wall is uniform by constructing a ghost fluid layer with weighted average density of surrounding fluid nodes (Scheme #2) or by using the geometric formulation scheme (Scheme #3), so that condensation nucleation cannot occur spontaneously unless with a liquid film initialized in the microcavity.

- In the pseudopotential-based scheme (Scheme #1) the heat flux at the microcavity wall is unphysical before a liquid film is formed in the microcavity through “condensation nucleation”. Only after a liquid film forms in the microcavity, the temperature distribution and heat flux at the microcavity wall become reasonable in LB simulation by using the three numerical schemes of contact angle.

- Since an unphysical heat transfer phenomenon may occur in condensation simulation by pseudopotential LB model with the application of Scheme #1, it is recommended to use Scheme #2 or Scheme #3 in simulation. This study provides guidelines for researchers choosing the desirable numerical schemes of contact angle to ensure simulation accuracy on simulating the condensation process, so that much more efficient strategies or mechanisms for condensation heat transfer enhancement are expected to be revealed in the future from LB simulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El Fil, B.; Kini, G.; Garimella, S. A review of dropwise condensation: Theory, modeling, experiments, and applications. Int. J. Heat Mass Transf. 2020, 160, 120172. [Google Scholar] [CrossRef]

- Varanasi, K.K.; Hsu, M.; Bhate, N.; Yang, W.; Deng, T. Spatial control in the heterogeneous nucleation of water. Appl. Phys. Lett. 2009, 95, 094101. [Google Scholar] [CrossRef]

- Wu, Y.-L.; Zheng, J.-W.; Muneeshwaran, M.; Yang, K.-S.; Wang, C.-C. Moist air condensation heat transfer enhancement via superhydrophobicity. Int. J. Heat Mass Transf. 2022, 182, 121973. [Google Scholar] [CrossRef]

- Upot, N.V.; Fazle Rabbi, K.; Khodakarami, S.; Ho, J.Y.; Kohler Mendizabal, J.; Miljkovic, N. Advances in micro and nanoengineered surfaces for enhancing boiling and condensation heat transfer: A review. Nanoscale Adv. 2023, 5, 1232–1270. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ren, W. Numerical study of vapor condensation on patterned hydrophobic surfaces using the string method. Langmuir 2014, 30, 9567–9576. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Luo, K.H.; Kang, Q.J.; He, Y.L.; Chen, Q.; Liu, Q. Lattice Boltzmann methods for multiphase flow and phase-change heat transfer. Prog. Energy Combust. Sci. 2016, 52, 62–105. [Google Scholar] [CrossRef]

- Norouzi, S.; Soleimani, R.; Vasheghani Farahani, M.; Rasaei, M.R. Pore-scale simulation of capillary force effect in water-oil immiscible displacement process in porous media. In Proceedings of the 81st EAGE Conference and Exhibition, London, UK, 3–6 June 2019; pp. 1–5. [Google Scholar]

- Vasheghani Farahani, M.; Hassanpouryouzband, A.; Yang, J.; Tohidi, B. Heat transfer in unfrozen and frozen porous media: Experimental measurement and pore-scale modeling. Water Resour. Res. 2020, 56, e2020WR027885. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, J.; He, X.; Wang, Y. Thermal pseudo-potential lattice Boltzmann method for simulating cavitation bubbles collapse near a rigid boundary. Comput. Fluids 2021, 217, 104817. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, P. Lattice Boltzmann simulation for dropwise condensation of vapor along vertical hydrophobic flat plates. Int. J. Heat Mass Transf. 2013, 64, 1041–1052. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, P. 3D multiphase lattice Boltzmann simulations for morphological effects on self-propelled jumping of droplets on textured superhydrophobic surfaces. Int. Commun. Heat Mass Transf. 2015, 64, 7–13. [Google Scholar] [CrossRef]

- Li, X.; Cheng, P. Lattice Boltzmann simulations for transition from dropwise to filmwise condensation on hydrophobic surfaces with hydrophilic spots. Int. J. Heat Mass Transf. 2017, 110, 710–722. [Google Scholar] [CrossRef]

- Guo, Q.; Cheng, P. 3D lattice Boltzmann investigation of nucleation sites and dropwise-to-filmwise transition in the presence of a non-condensable gas on a biomimetic surface. Int. J. Heat Mass Transf. 2019, 128, 185–198. [Google Scholar] [CrossRef]

- Wang, X.; Chen, Z.; Xu, B. Coalescence-induced jumping of condensate droplets on microstructured surfaces with different gravitational fields by lattice Boltzmann method. Comput. Fluids 2019, 188, 60–69. [Google Scholar] [CrossRef]

- Shan, X.; Chen, H. Lattice Boltzmann model for simulating flows with multiple phases and components. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 1993, 47, 1815–1819. [Google Scholar] [CrossRef] [PubMed]

- Martys, N.S.; Chen, H. Simulation of multicomponent fluids in complex three-dimensional geometries by the lattice Boltzmann method. Phys. Rev. E Stat. Phys. Plasmas Fluids Relat. Interdiscip. Top. 1996, 53, 743–750. [Google Scholar] [CrossRef] [PubMed]

- Sukop, M.C.; Thorne, D.T. Lattice Boltzmann Modeling: An introduction for Geoscientists and Engineers; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Li, Q.; Luo, K.H.; Kang, Q.J.; Chen, Q. Contact angles in the pseudopotential lattice Boltzmann modeling of wetting. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2014, 90, 053301. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Yu, Y.; Luo, K.H. Implementation of contact angles in pseudopotential lattice Boltzmann simulations with curved boundaries. Phys. Rev. E 2019, 100, 053313. [Google Scholar] [CrossRef] [PubMed]

- Qin, F.; Zhao, J.; Kang, Q.; Derome, D.; Carmeliet, J. Lattice Boltzmann modeling of drying of porous media considering contact angle hysteresis. Transp. Porous Media 2021, 140, 395–420. [Google Scholar] [CrossRef]

- Ding, H.; Spelt, P.D. Wetting condition in diffuse interface simulations of contact line motion. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2007, 75, 046708. [Google Scholar] [CrossRef]

- Hu, A.; Li, L.; Uddin, R.; Liu, D. Contact angle adjustment in equation-of-state-based pseudopotential model. Phys. Rev. E 2016, 93, 053307. [Google Scholar] [CrossRef]

- Wang, D.; Lin, G. Numerical stability and accuracy of contact angle schemes in pseudopotential lattice Boltzmann model for simulating static wetting and dynamic wetting. Comput. Model. Eng. Sci. 2023, in press. [Google Scholar]

- Wang, D.; Cheng, P. Constructing a ghost fluid layer for implementation of contact angle schemes in multiphase pseudopotential lattice Boltzmann simulations for non-isothermal phase-change heat transfer. Int. J. Heat Mass Transf. 2023, 201, 123618. [Google Scholar] [CrossRef]

- Ranathunga, D.T.S.; Shamir, A.; Dai, X.; Nielsen, S.O. Molecular Dynamics Simulations of Water Condensation on Surfaces with Tunable Wettability. Langmuir 2020, 36, 7383–7391. [Google Scholar] [CrossRef] [PubMed]

- Bhatnagar, P.L.; Gross, E.P.; Krook, M. A model for collision processes in gases. I. Small amplitude processes in charged and neutral one-component systems. Phys. Rev. Lett. 1954, 94, 511. [Google Scholar] [CrossRef]

- Qian, Y.-H.; d’Humières, D.; Lallemand, P. Lattice BGK models for Navier-Stokes equation. EPL Europhys. Lett. 1992, 17, 479. [Google Scholar] [CrossRef]

- Hou, S.; Zou, Q.; Chen, S.; Doolen, G.; Cogley, A.C. Simulation of cavity flow by the lattice Boltzmann method. J. Comput. Phys. 1995, 118, 329–347. [Google Scholar] [CrossRef]

- Kupershtokh, A.L.; Medvedev, D.A. Lattice Boltzmann equation method in electrohydrodynamic problems. J. Electrostat. 2006, 64, 581–585. [Google Scholar] [CrossRef]

- Kupershtokh, A.L.; Medvedev, D.A.; Karpov, D.I. On equations of state in a lattice Boltzmann method. Comput. Math. Appl. 2009, 58, 965–974. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, P. Numerical investigation of droplet motion and coalescence by an improved lattice Boltzmann model for phase transitions and multiphase flows. Comput. Fluids 2012, 53, 93–104. [Google Scholar] [CrossRef]

- Yuan, P.; Schaefer, L. Equations of state in a lattice Boltzmann model. Phys. Fluids 2006, 18, 042101. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, P. A lattice Boltzmann method for simulation of liquid–vapor phase-change heat transfer. Int. J. Heat Mass Transf. 2012, 55, 4923–4927. [Google Scholar] [CrossRef]

- Yang, J.; Fei, L.; Zhang, X.; Ma, X.; Luo, K.H.; Shuai, S. Improved pseudopotential lattice Boltzmann model for liquid water transport inside gas diffusion layers. Int. J. Hydrogen Energy 2021, 46, 15938–15950. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, P.; Yan, H.J. Improved thermal lattice Boltzmann model for simulation of liquid-vapor phase change. Phys. Rev. E 2017, 96, 063303. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Cheng, P. Mesoscale simulations of boiling curves and boiling hysteresis under constant wall temperature and constant heat flux conditions. Int. J. Heat Mass Transf. 2017, 110, 319–329. [Google Scholar] [CrossRef]

- Wang, D.; Cheng, P. Nanoparticles deposition patterns in evaporating nanofluid droplets on smooth heated hydrophilic substrates: A 2D immersed boundary-lattice Boltzmann simulation. Int. J. Heat Mass Transf. 2021, 168, 120868. [Google Scholar] [CrossRef]

| Scheme | Description |

|---|---|

| #1 | Pseudopotential-based scheme [17] |

| #2 | Pseudopotential-based scheme with a special ghost fluid layer [24] |

| #3 | Geometric formulation scheme [20,21] |

| tn | 36,400 | 36,400 | 36,300 | 36,300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Lin, G.; Zhao, Y.; Gao, M. Effects of Numerical Schemes of Contact Angle on Simulating Condensation Heat Transfer in a Subcooled Microcavity by Pseudopotential Lattice Boltzmann Model. Energies 2023, 16, 2622. https://doi.org/10.3390/en16062622

Wang D, Lin G, Zhao Y, Gao M. Effects of Numerical Schemes of Contact Angle on Simulating Condensation Heat Transfer in a Subcooled Microcavity by Pseudopotential Lattice Boltzmann Model. Energies. 2023; 16(6):2622. https://doi.org/10.3390/en16062622

Chicago/Turabian StyleWang, Dongmin, Gaoshuai Lin, Yugang Zhao, and Ming Gao. 2023. "Effects of Numerical Schemes of Contact Angle on Simulating Condensation Heat Transfer in a Subcooled Microcavity by Pseudopotential Lattice Boltzmann Model" Energies 16, no. 6: 2622. https://doi.org/10.3390/en16062622

APA StyleWang, D., Lin, G., Zhao, Y., & Gao, M. (2023). Effects of Numerical Schemes of Contact Angle on Simulating Condensation Heat Transfer in a Subcooled Microcavity by Pseudopotential Lattice Boltzmann Model. Energies, 16(6), 2622. https://doi.org/10.3390/en16062622