A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy

Abstract

1. Introduction

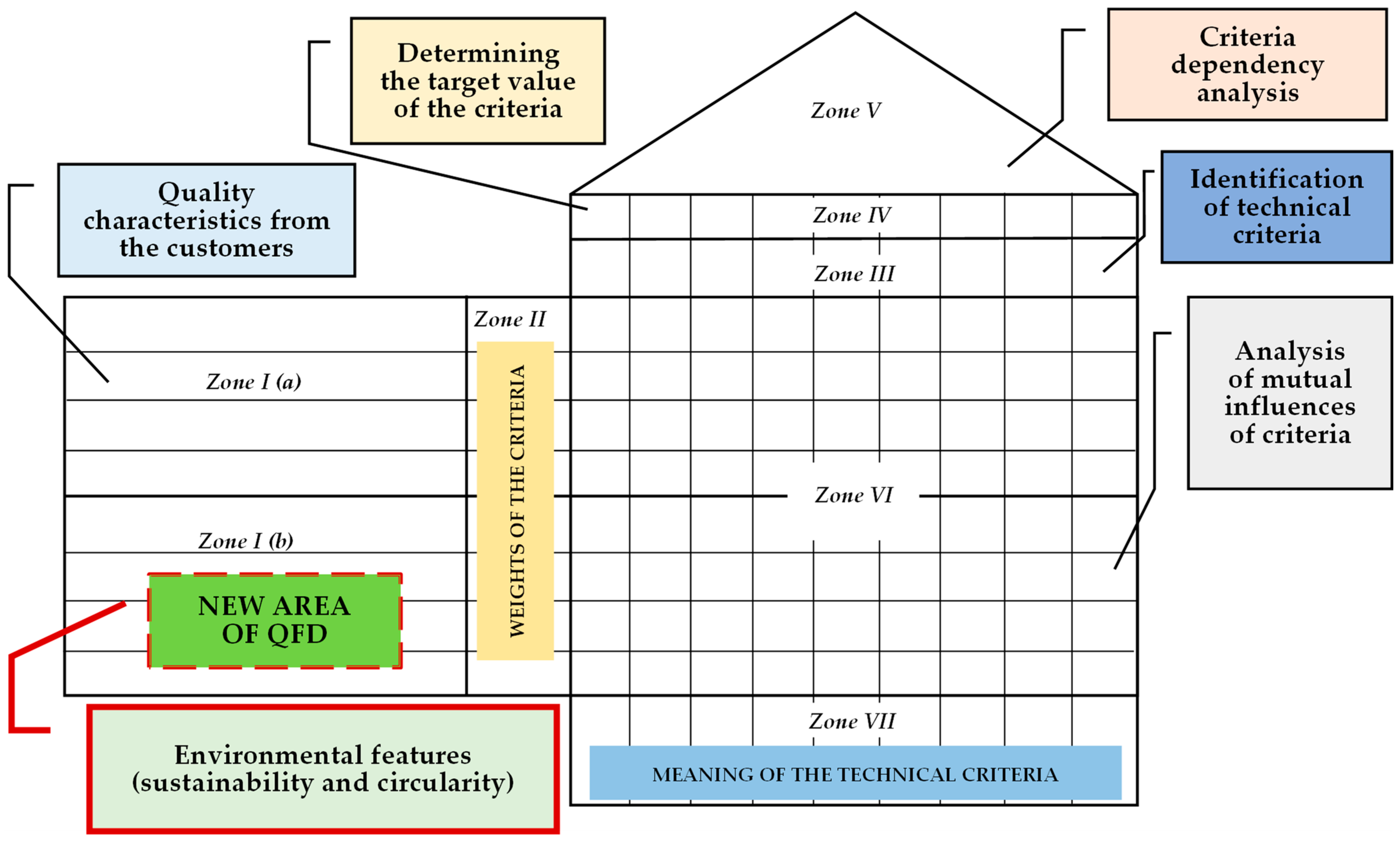

- The extension of the traditional quality house methodology to the area of sustainable development, including the circular economy (CE), which will be confronted with the expectations of customers (CE);

- Adding new blocks in the house of quality intended for the expectations in terms of the environment in relation to the newly designed product;

- Inclusion in one block (at one level) of weights not only for quality criteria (customers’ criteria), but also weights for environmental criteria (sustainable development and circularity), where these weights will be correlated with the weights of technical criteria;

- Implementation of other techniques supporting it in this method, mainly decision-making support;

- Determining purposes to design purposes according to customers’ expectations towards the products’ quality and its impact on the natural environment;

- Possible use of QFD-CE for any product, hence, this method can be useful for enterprises that want to design and improve products according to the idea of sustainable and continuous development.

2. Literature Review

3. Model of QFD-CE Method

3.1. General Concept

3.2. Assumptions

- Dependencies between technical criteria are determined for qualitative criteria (i.e., customer’s criteria, sustainable development, and circular economy criteria);

3.3. Description of QFD-CE Method

3.3.1. Stage 1: Selection of the Subject of Research and Definition of the Purpose

3.3.2. Stage 2: Selection of a Team of Experts

3.3.3. Stage 3: Choice of Key Criteria of Sustainable Development and Circular Economy

- Basic sustainable development criteria;

- Criteria for sustainable economic development, e.g., cost of energy production, cost of recycling activities, production cost, and lower energy consumption for raw materials, for example, use of waste (%), less use of materials (%), and machine set-up time for new products;

- Environmentally sustainable criteria, e.g., non-processing energy, emissions of CO2, energy consumption, number of machine settings to minimize waste, wastewater, greenhouse gases, less use of natural resources, non-toxic materials, modularity, and potential for reuse or recycling;

- Socially sustainable criteria, e.g., low labor utilization threshold, high employee learning rate, and low forgetting rate;

3.3.4. Stage 4: Obtaining Expectations from Customers

3.3.5. Stage 5: Identification of Technical Criteria

3.3.6. Stage 6: Determining the Target Value of the Criteria

3.3.7. Stage 7: Technical Criteria Dependency Analysis

3.3.8. Stage 8: Analysis of Mutual Influences of Criteria

3.3.9. Stage 9: Defining Design Goals

4. Results

4.1. Stage 1: Selection of the Subject of Research and Definition of the Purpose

4.2. Stage 2: Selection of a Team of Experts

4.3. Stage 3: Choice of Key Criteria of Sustainable Development and Circular Economy

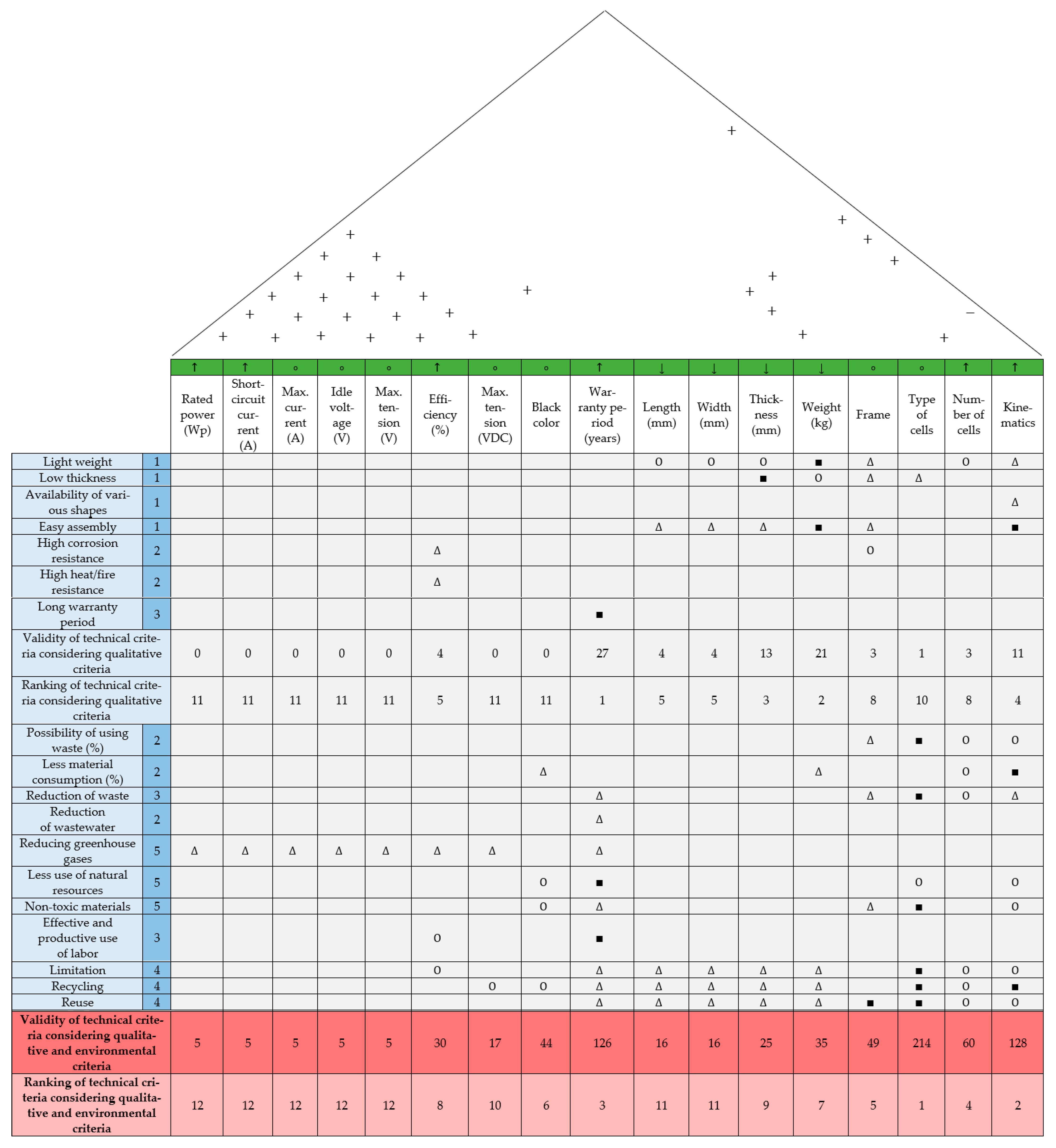

- Sustainable development criteria;

- Criteria for sustainable economic development, i.e., the possibility of using waste (%) and less material consumption (%);

- Environmentally sustainable criteria, i.e., energy consumption and number of machine settings to minimize, e.g., waste, sewage, greenhouse gases, less use of natural resources, and non-toxic materials;

- Socially sustainable criteria, i.e., effective and productive use of labor;

- Basic circular economy criteria [75];

- Reduce—reducing the amount of materials, resources, or waste generated as a result of increased production and consumption efficiency, while minimizing the amount of such waste and the negative impact on the natural environment;

- Reuse—reuse materials, products, or components that have not been wasted for the same purpose, where their use requires less resource and energy consumption than it does in the case of the need to produce them in a new state;

- Recycling—any recovery operation that ensures the reprocessing of waste into products, materials, or components, so that they can be used for the same or a different purpose; refers to the process by which used or waste materials are treated so that they can be reused.

4.4. Stage 4: Obtaining Expectations from Customers

- Efficiency of the photovoltaic panel;

- High power;

- High-level performance;

- Minimal energy loss;

- Appearance of the photovoltaic panel;

- Color;

- Small dimensions;

- Small dimensions;

- Small thickness;

- Availability of different shapes;

- Functionality of the photovoltaic panel;

- Easy assembly;

- High corrosion resistance;

- High heat/fire resistance;

- Long warranty period.

4.5. Stage 5: Identification of Technical Criteria

- Electrical criteria;

- Rated power (Wp);

- Short-circuit current (A);

- Maximum current (A);

- No-load voltage (V);

- Maximum voltage (V);

- Efficiency (%);

- Application criteria;

- Maximum system voltage (VDC);

- Color;

- Warranty period (years);

- Mechanical criteria;

- Length (mm);

- Width (mm);

- Thickness (mm);

- Weight (kg);

- Design criteria;

- Frame;

- Type of cells;

- Number of cells;

- Kinematics.

4.6. Stage 6: Determining the Target Value of the Criteria

4.7. Stage 7: Technical Criteria Dependency Analysis

4.8. Stage 8: Analysis of Mutual Influences of Criteria

4.9. Stage 9: Defining Design Goals

5. Discussion

- Simultaneously including qualitative criteria (customers’ criteria) and environmental criteria (sustainable development and the circular economy);

- Analysis of product design requirements in view of the importance of product criteria, which are determined simultaneously for customer criteria and environmental criteria;

- Adjusting products to the so-called “Voice of Customers” (VoC);

- Possibility of improving actions of products with taking care of the natural environment;

- Effectiveness at determining design purposes (or modifying) of products, which will be in accordance with customers’ expectations and simultaneously support making design actions or improving according to the sustainable development idea;

- Low-cost method that supports companies in the development of products in terms of quality and environment.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tunga, I.; Garcia-Teruel, A.; Noble, D.R.; Henderson, J. Addressing European Ocean Energy Challenge: The DTOceanPlus Structured Innovation Tool for Concept Creation and Selection. Energies 2021, 14, 5988. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Xia, S.; Li, B.; Zhang, X.; Wang, B.; Ye, T.; Zheng, W. A Review on the Policy, Technology and Evaluation Method of Low-Carbon Buildings and Communities. Energies 2023, 16, 1773. [Google Scholar] [CrossRef]

- Al-Sinan, M.A.; Bubshait, A.A.; Alamri, F. Saudi Arabia’s Journey toward Net-Zero Emissions: Progress and Challenges. Energies 2023, 16, 978. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Model Supporting Development Decisions by Considering Qualitative–Environmental Aspects. Sustainability 2021, 13, 9067. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Model to Predict Quality of Photovoltaic Panels Considering Customers’ Expectations. Energies 2022, 15, 1101. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Model of Choice Photovoltaic Panels Considering Customers’ Expectations. Energies 2021, 14, 5977. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednárová, L. Method of Choice: A Fluorescent Penetrant Taking into Account Sustainability Criteria. Sustainability 2020, 12, 5854. [Google Scholar] [CrossRef]

- Bogusz, M.; Matysik-Pejas, R.; Krasnodębski, A.; Dziekański, P. The Concept of Zero Waste in the Context of Supporting Environmental Protection by Consumers. Energies 2021, 14, 5964. [Google Scholar] [CrossRef]

- Goh, C.S.; Chong, H.-Y. Opportunities in the Sustainable Built Environment: Perspectives on Human-Centric Approaches. Energies 2023, 16, 1301. [Google Scholar] [CrossRef]

- Tsangas, M.; Papamichael, I.; Zorpas, A.A. Sustainable Energy Planning in a New Situation. Energies 2023, 16, 1626. [Google Scholar] [CrossRef]

- Wurster, S.; Heß, P.; Nauruschat, M.; Jütting, M. Sustainable Circular Mobility: User-Integrated Innovation and Specifics of Electric Vehicle Owners. Sustainability 2020, 12, 7900. [Google Scholar] [CrossRef]

- Muerza, V.; Urciuoli, L.; Zapata Habas, S. Enabling the Circular Economy of Bio-Supply Chains Employing Integrated Biomass Logistics Centers—A Multi-Stage Approach Integrating Supply and Production Activities. J. Clean. Prod. 2023, 384, 135628. [Google Scholar] [CrossRef]

- Ncube, A.; Mtetwa, S.; Bukhari, M.; Fiorentino, G.; Passaro, R. Circular Economy and Green Chemistry: The Need for Radical Innovative Approaches in the Design for New Products. Energies 2023, 16, 1752. [Google Scholar] [CrossRef]

- Yontar, E. Critical Success Factor Analysis of Blockchain Technology in Agri-Food Supply Chain Management: A Circular Economy Perspective. J. Environ. Manag. 2023, 330, 117173. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, B.d.S.M.; Carvalho, F.L.d.; Fiorini, P.d.C. Circular Economy and Financial Aspects: A Systematic Review of the Literature. Sustainability 2022, 14, 3023. [Google Scholar] [CrossRef]

- Scarpellini, S.; Marín-Vinuesa, L.M.; Aranda-Usón, A.; Portillo-Tarragona, P. Dynamic Capabilities and Environmental Accounting for the Circular Economy in Businesses. Sustain. Account. Manag. Policy J. 2020, 11, 1129–1158. [Google Scholar] [CrossRef]

- Aranda-Usón, A.; Portillo-Tarragona, P.; Marín-Vinuesa, L.; Scarpellini, S. Financial Resources for the Circular Economy: A Perspective from Businesses. Sustainability 2019, 11, 888. [Google Scholar] [CrossRef]

- Lee, D.D.; Faff, R.W.; Langfield-Smith, K. Revisiting the Vexing Question: Does Superior Corporate Social Performance Lead to Improved Financial Performance? Aust. J. Manag. 2009, 34, 21–49. [Google Scholar] [CrossRef]

- Nag, U.; Sharma, S.K.; Padhi, S.S. Evaluating Value Requirement for Industrial Product-Service System in Circular Economy for Wind Power-Based Renewable Energy Firms. J. Clean. Prod. 2022, 340, 130689. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Method of Improve the Level of Product Quality. Prod. Eng. Arch. 2021, 27, 1–7. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Universal Model to Support the Quality Improvement of Industrial Products. Materials 2021, 14, 7872. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. A Pro-Environmental Method of Sample Size Determination to Predict the Quality Level of Products Considering Current Customers’ Expectations. Sustainability 2021, 13, 5542. [Google Scholar] [CrossRef]

- Shen, Y.; Zhou, J.; Pantelous, A.A.; Liu, Y.; Zhang, Z. A Voice of the Customer Real-Time Strategy: An Integrated Quality Function Deployment Approach. Comput. Ind. Eng. 2022, 169, 108233. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, L.; Wang, G.A.; Li, Y.; He, S. Using Neutral Sentiment Reviews to Improve Customer Requirement Identification and Product Design Strategies. Int. J. Prod. Econ. 2022, 254, 108641. [Google Scholar] [CrossRef]

- Jie, Y.; Ji, X.; Yue, A.; Chen, J.; Deng, Y.; Chen, J.; Zhang, Y. Combined Multi-Layer Feature Fusion and Edge Detection Method for Distributed Photovoltaic Power Station Identification. Energies 2020, 13, 6742. [Google Scholar] [CrossRef]

- Puglieri, F.N.; Ometto, A.R.; Salvador, R.; Barros, M.V.; Piekarski, C.M.; Rodrigues, I.M.; Diegoli Netto, O. An Environmental and Operational Analysis of Quality Function Deployment-Based Methods. Sustainability 2020, 12, 3486. [Google Scholar] [CrossRef]

- Papamichael, I.; Zorpas, A.A. End-of-Waste Criteria in the Framework of End-of-Life PV Panels Concerning Circular Economy Strategy. Waste Manag. Res. J. A Sustain. Circ. Econ. 2022, 40, 1677–1679. [Google Scholar] [CrossRef]

- Curtis, T.; Heather, B.; Ligia, S. A Circular Economy for Solar Photovoltaic System Materials: Drivers, Barriers, Enablers, and U.S. Policy Considerations; NREL/TP-6A20-74550; National Renewable Energy Laboratory: Golden, CO, USA, 2021; pp. 1–89. [Google Scholar]

- Ziemińska-Stolarska, A.; Pietrzak, M.; Zbiciński, I. Application of LCA to Determine Environmental Impact of Concentrated Photovoltaic Solar Panels—State-of-the-Art. Energies 2021, 14, 3143. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, T.; Gupta, A.K. End-of-Life Management of Solar PV Waste in India: Situation Analysis and Proposed Policy Framework. Renew. Sustain. Energy Rev. 2022, 153, 111774. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Jeguirim, M.; Argirusis, N.; Jellali, S.; Sourkouni, G.; Argirusis, C.; Zorpas, A.A. End-of-Life Management and Recycling on PV Solar Energy Production. Energies 2022, 15, 6430. [Google Scholar] [CrossRef]

- Nunes, A.M.M.; Coelho Junior, L.M.; Abrahão, R.; Santos Júnior, E.P.; Simioni, F.J.; Rotella, P., Jr.; Rocha, L.C.S. Public Policies for Renewable Energy: A Review of the Perspectives for a Circular Economy. Energies 2023, 16, 485. [Google Scholar] [CrossRef]

- Wolniak, R. Metoda qfd w Projektowaniu Jakości. Teoria i Praktyka; Politechnika Śląska: Gliwice, Poland, 2016; Volume 1. [Google Scholar]

- Kiran, D.R. Quality Function Deployment. In Total Quality Management; Elsevier: Amsterdam, The Netherlands, 2017; pp. 425–437. [Google Scholar]

- Wolniak, E.R.; Sȩdek, A. Using QFD Method for the Ecological Designing of Products and Services. Qual. Quant. 2009, 43, 695–701. [Google Scholar] [CrossRef]

- Wolniak, R. The Use of QFD Method Advantages and Limitation. Prod. Eng. Arch. 2018, 18, 14–17. [Google Scholar] [CrossRef]

- Kravchenko, M.; Pigosso, D.C.A.; McAloone, T.C. A Trade-Off Navigation Framework as a Decision Support for Conflicting Sustainability Indicators within Circular Economy Implementation in the Manufacturing Industry. Sustainability 2020, 13, 314. [Google Scholar] [CrossRef]

- Alarcón, F.; Cortés-Pellicer, P.; Pérez-Perales, D.; Sanchis, R. Sustainability vs. Circular Economy from a Disposition Decision Perspective: A Proposal of a Methodology and an Applied Example in SMEs. Sustainability 2020, 12, 10109. [Google Scholar] [CrossRef]

- Shah, W.U.H.; Hao, G.; Yasmeen, R.; Kamal, M.A.; Khan, A.; Padda, I.U.H. Unraveling the Role of China’s OFDI, Institutional Difference and B&R Policy on Energy Efficiency: A Meta-Frontier Super-SBM Approach. Environ. Sci. Pollut. Res. 2022, 29, 56454–56472. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.Q.; Zhang, F.Y. Energy-Saving Design for Hydraulic Cylinder Reciprocating Seal Based on QFD. Appl. Mech. Mater. 2010, 44–47, 1146–1150. [Google Scholar] [CrossRef]

- Leba, M.; Ionica, A.; Dobra, R.; Pasculescu, V.M. Quality function deployment (QFD) based expert system for renewable energy structures. a wind turbine case study. Environ. Eng. Manag. J. 2014, 13, 1365–1370. [Google Scholar] [CrossRef]

- Runliang, D.; Hui, Z. Model of Design for Energy Saving of Products Based on the Integration of TRIZ/AD/QFD. In Proceedings of the 2009 16th International Conference on Industrial Engineering and Engineering Management, Beijing, China, 21–23 October 2009; pp. 171–175. [Google Scholar]

- Yong, P.; Wenhui, Y.; Heng, W. The Study on Energy Saving and Output Enhancement of Pumping Well Based on the Theory of QFD/TRIZ. In Proceedings of the 2009 International Conference on Energy and Environment Technology, Guilin, China, 16–18 October 2009; pp. 449–453. [Google Scholar]

- Caligiana, G.; Liverani, A.; Francia, D.; Frizziero, L.; Donnici, G. Integrating QFD and TRIZ for Innovative Design. J. Adv. Mech. Des. Syst. Manuf. 2017, 11, JAMDSM0015. [Google Scholar] [CrossRef]

- Yang, W.; Cao, G.; Peng, Q.; Sun, Y. Effective Radical Innovations Using Integrated QFD and TRIZ. Comput. Ind. Eng. 2021, 162, 107716. [Google Scholar] [CrossRef]

- Haiyun, C.; Zhixiong, H.; Yüksel, S.; Dinçer, H. Analysis of the Innovation Strategies for Green Supply Chain Management in the Energy Industry Using the QFD-Based Hybrid Interval Valued Intuitionistic Fuzzy Decision Approach. Renew. Sustain. Energy Rev. 2021, 143, 110844. [Google Scholar] [CrossRef]

- Yamakawa, E.K.; Aoki, A.R.; Siebert, L.C.; Klinguelfus, G.; Cauchick Miguel, P.A. A Fuzzy-QFD Decision Making Approach for Selecting Industry Energy Efficiency Indicators. In Proceedings of the 2013 IEEE PES Conference on Innovative Smart Grid Technologies (ISGT Latin America), Sao Paulo, Brazil, 15–17 April 2013; pp. 1–5. [Google Scholar]

- Haktanır, E.; Kahraman, C. A Novel Interval-Valued Pythagorean Fuzzy QFD Method and Its Application to Solar Photovoltaic Technology Development. Comput. Ind. Eng. 2019, 132, 361–372. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Gong, C.; Dinçer, H.; Yüksel, S. An Integrated Hesitant 2-Tuple Pythagorean Fuzzy Analysis of QFD-Based Innovation Cost and Duration for Renewable Energy Projects. Energy 2022, 248, 123561. [Google Scholar] [CrossRef]

- Das, A. Shabbiruddin Renewable Energy Source Selection Using Analytical Hierarchy Process and Quality Function Deployment: A Case Study. In Proceedings of the 2016 Second International Conference on Science Technology Engineering and Management (ICONSTEM), Chennai, India, 30–31 March 2016; pp. 298–302. [Google Scholar]

- Servert, J.; Labanda, A.; Fuentealba, E.; Cortes, M.; Pérez, R. Quality Function Deployment Analysis for the Selection of Four Utility-Scale Solar Energy Projects in Northern Chile. Energy Procedia 2014, 49, 1896–1905. [Google Scholar] [CrossRef]

- Haber, N.; Fargnoli, M. Sustainable Product-Service Systems Customization: A Case Study Research in the Medical Equipment Sector. Sustainability 2021, 13, 6624. [Google Scholar] [CrossRef]

- Neramballi, A.; Sakao, T.; Willskytt, S.; Tillman, A.-M. A Design Navigator to Guide the Transition towards Environmentally Benign Product/Service Systems Based on LCA Results. J. Clean Prod. 2020, 277, 124074. [Google Scholar] [CrossRef]

- Li, Y.; Ghazilla, R.A.R.; Abdul-Rashid, S.H. QFD-Based Research on Sustainable User Experience Optimization Design of Smart Home Products for the Elderly: A Case Study of Smart Refrigerators. Int. J. Environ. Res. Public Health 2022, 19, 13742. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Liu, C.; Mahmoodi, R.; Li, Q.; Ghandehari Ferdowsi, M.R.; Naebe, M. A Sustainable Approach to the Low-Cost Recycling of Waste Glass Fibres Composites towards Circular Economy. Sustainability 2020, 12, 641. [Google Scholar] [CrossRef]

- Zarte, M.; Pechmann, A.; Nunes, I.L. Problems, Needs, and Challenges of a Sustainability-Based Production Planning. Sustainability 2022, 14, 4092. [Google Scholar] [CrossRef]

- Lawor, B.; Hornyak, M. Smart goals: How the application of smart goals can contribute to achievement of student learning outcomes. Dev. Bus. Simul. Exp. Learn. 2012, 39, 259–267. [Google Scholar]

- PUTMAN, V.L.; PAULUS, P.B. Brainstorming, Brainstorming Rules and Decision Making. J. Creat Behav. 2009, 43, 29–40. [Google Scholar] [CrossRef]

- Ulewicz, R.; Nový, F. Quality Management Systems in Special Processes. Transp. Res. Procedia 2019, 40, 113–118. [Google Scholar] [CrossRef]

- Dudek, F.; Baker, K. The Constant-Sum Method Applied to Scaling Subjective Dimensions. Am. J. Psychol. 1956, 69, 616–624. [Google Scholar] [CrossRef]

- Sullivan, G.M.; Artino, A.R. Analyzing and Interpreting Data From Likert-Type Scales. J. Grad. Med. Educ. 2013, 5, 541–542. [Google Scholar] [CrossRef] [PubMed]

- Ostasz, G.; Siwiec, D.; Pacana, A. Universal Model to Predict Expected Direction of Products Quality Improvement. Energies 2022, 15, 1751. [Google Scholar] [CrossRef]

- Ulewicz, R.; Siwiec, D.; Pacana, A.; Tutak, M.; Brodny, J. Multi-Criteria Method for the Selection of Renewable Energy Sources in the Polish Industrial Sector. Energies 2021, 14, 2386. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. A New Model Supporting Stability Quality of Materials and Industrial Products. Materials 2022, 15, 4440. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Method of Determining Sequence Actions of Products Improvement. Materials 2022, 15, 6321. [Google Scholar] [CrossRef] [PubMed]

- Serra, V.; Ledda, A.; Ruiu, M.G.G.; Calia, G.; de Montis, A. Integrating Adaptation to Climate Change into Sustainable Development Policy and Planning. Sustainability 2022, 14, 7634. [Google Scholar] [CrossRef]

- Ivascu, L. Measuring the Implications of Sustainable Manufacturing in the Context of Industry 4.0. Processes 2020, 8, 585. [Google Scholar] [CrossRef]

- Harris, S.; Martin, M.; Diener, D. Circularity for Circularity’s Sake? Scoping Review of Assessment Methods for Environmental Performance in the Circular Economy. Sustain. Prod. Consum. 2021, 26, 172–186. [Google Scholar] [CrossRef]

- Koszewska, M.; Bielecki, M. How to Make Furniture Industry More Circular? The Role of Component Standardisation in Ready-to-Assemble Furniture. Entrep. Sustain. Issues 2020, 7, 1688–1707. [Google Scholar] [CrossRef]

- Boorsma, N.; Polat, E.; Bakker, C.; Peck, D.; Balkenende, R. Development of the Circular Product Readiness Method in Circular Design. Sustainability 2022, 14, 9288. [Google Scholar] [CrossRef]

- Campbell-Johnston, K.; Calisto Friant, M.; Thapa, K.; Lakerveld, D.; Vermeulen, W.J.V. How Circular Is Your Tyre: Experiences with Extended Producer Responsibility from a Circular Economy Perspective. J. Clean Prod. 2020, 270, 122042. [Google Scholar] [CrossRef]

- Saidani, M.; Yannou, B.; Leroy, Y.; Cluzel, F.; Kendall, A. A Taxonomy of Circular Economy Indicators. J. Clean Prod. 2019, 207, 542–559. [Google Scholar] [CrossRef]

- Ortner, P.; Tay, J.Z.; Wortmann, T. Computational Optimization for Circular Economy Product Design. J. Clean Prod. 2022, 362, 132340. [Google Scholar] [CrossRef]

- Schoden, F.; Schnatmann, A.K.; Blachowicz, T.; Manz-Schumacher, H.; Schwenzfeier-Hellkamp, E. Circular Design Principles Applied on Dye-Sensitized Solar Cells. Sustainability 2022, 14, 15280. [Google Scholar] [CrossRef]

- Calvo-Porral, C.; Lévy-Mangin, J.-P. The Circular Economy Business Model: Examining Consumers’ Acceptance of Recycled Goods. Adm. Sci. 2020, 10, 28. [Google Scholar] [CrossRef]

- Mu, E.; Pereyra-Rojas, M. Practical Decision Making, 1st ed.; Springer International Publishing: Cham, Swizterland, 2017; Volume 1, ISBN 978-3-319-33860-6. [Google Scholar]

- Libby, R.; Blashfield, R.K. Performance of a Composite as a Function of the Number of Judges. Organ. Behav. Hum. Perform. 1978, 21, 121–129. [Google Scholar] [CrossRef]

- Wang, L.; Chu, J.; Wu, J. Selection of Optimum Maintenance Strategies Based on a Fuzzy Analytic Hierarchy Process. Int. J. Prod. Econ. 2007, 107, 151–163. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N. Global Supplier Development Considering Risk Factors Using Fuzzy Extended AHP-Based Approach. Omega (Westport) 2007, 35, 417–431. [Google Scholar] [CrossRef]

- Hwangbo, Y.; Yang, Y.-S.; Kim, M.-S.; Kim, Y. The Effectiveness of Kano-QFD Approach to Enhance Competitiveness of Technology-Based SMEs through Transfer Intention Model. Sustainability 2020, 12, 7885. [Google Scholar] [CrossRef]

- Neira-Rodado, D.; Ortíz-Barrios, M.; de la Hoz-Escorcia, S.; Paggetti, C.; Noffrini, L.; Fratea, N. Smart Product Design Process through the Implementation of a Fuzzy Kano-AHP-DEMATEL-QFD Approach. Appl. Sci. 2020, 10, 1792. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D.; Bednarova, L. Analysis of the incompatibility of the product with fluorescent method. Metalurgija 2019, 58, 337–340. [Google Scholar]

- Shah, W.U.H.; Hao, G.; Yan, H.; Yasmeen, R.; Lu, Y. Energy Efficiency Evaluation, Changing Trends and Determinants of Energy Productivity Growth across South Asian Countries: SBM-DEA and Malmquist Approach. Environ. Sci. Pollut. Res. 2022, 30, 19890–19906. [Google Scholar] [CrossRef] [PubMed]

- Shah, W.U.H.; Hao, G.; Yan, H.; Yasmeen, R.; Jie, Y. The Role of Energy Policy Transition, Regional Energy Efficiency, and Technological Advancement in the Improvement of China’s Environmental Quality. Energy Rep. 2022, 8, 9846–9857. [Google Scholar] [CrossRef]

- Shah, W.U.H.; Hao, G.; Yan, H.; Yasmeen, R.; Padda, I.U.H.; Ullah, A. The Impact of Trade, Financial Development and Government Integrity on Energy Efficiency: An Analysis from G7-Countries. Energy 2022, 255, 124507. [Google Scholar] [CrossRef]

- Ostasz, G.; Siwiec, D.; Pacana, A. Model to Determine the Best Modifications of Products with Consideration Customers’ Expectations. Energies 2022, 15, 8102. [Google Scholar] [CrossRef]

- Pacana, J. The Impact of the Structural Form on the Stress Distribution in a Flexspline of a Hermetic Harmonic Driver. J. Theor. Appl. Mech. 2020, 58, 1049–1060. [Google Scholar] [CrossRef]

- Borgianni, Y.; Maccioni, L.; Dignös, A.; Basso, D. A Framework to Evaluate Areas of Interest for Sustainable Products and Designs. Sustainability 2022, 14, 7931. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Method of Fuzzy Analysis of Qualitative-Environmental Threat in Improving Products and Processes (Fuzzy QE-FMEA). Materials 2023, 16, 1651. [Google Scholar] [CrossRef]

- Boral, S.; Howard, I.; Chaturvedi, S.K.; McKee, K.; Naikan, V.N.A. A Novel Hybrid Multi-Criteria Group Decision Making Approach for Failure Mode and Effect Analysis: An Essential Requirement for Sustainable Manufacturing. Sustain. Prod. Consum. 2020, 21, 14–32. [Google Scholar] [CrossRef]

- Olejarz, T.; Siwiec, D.; Pacana, A. Method of Qualitative–Environmental Choice of Devices Converting Green Energy. Energies 2022, 15, 8845. [Google Scholar] [CrossRef]

- Guzzo, D.; Trevisan, A.H.; Echeveste, M.; Costa, J.M.H. Circular Innovation Framework: Verifying Conceptual to Practical Decisions in Sustainability-Oriented Product-Service System Cases. Sustainability 2019, 11, 3248. [Google Scholar] [CrossRef]

- Jonšta, P.; Jonšta, Z.; Brožová, S.; Ingaldi, M.; Pietraszek, J.; Klimecka-Tatar, D. The Effect of Rare Earth Metals Alloying on the Internal Quality of Industrially Produced Heavy Steel Forgings. Materials 2021, 14, 5160. [Google Scholar] [CrossRef]

- Grabowski, M.; Gawlik, J.; Krajewska-Śpiewak, J.; Skoczypiec, S.; Tyczyński, P. Technological Possibilities of the Carbide Tools Application for Precision Machining of WCLV Hardened Steel. Adv. Sci. Technol. Res. J. 2022, 16, 141–148. [Google Scholar] [CrossRef]

- el Badaoui, M.; Touzani, A. AHP QFD Methodology for a Recycled Solar Collector. Prod. Eng. Arch. 2022, 28, 30–39. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Kandasamy, J.; Aravind Raj, S.; Baghdadi, M.A.; Shahzad, M.A. Sustainable Product Development Using FMEA ECQFD TRIZ and Fuzzy TOPSIS. Sustainability 2022, 14, 14345. [Google Scholar] [CrossRef]

| Name of Criteria | Type of Criteria |

|---|---|

| Customers’ criteria | Criteria determined by customers |

| Environmental criteria | Circular economy criteria and sustainable development criteria |

| Qualitative criteria | Criteria determined by customers + environmental criteria |

| Technical criteria | Measurable criteria which are selected based on catalogue of product |

| No. | Type/Group of Criterion | Criteria of Photovoltaic Panels (Qualitative and Environmental) | Sum of Values from Customers | Criteria Weight |

|---|---|---|---|---|

| 1 | Efficiency of the photovoltaic panel | High power | 82 | 5 |

| 2 | High-level performance | 78 | ||

| 3 | Environmentally sustainable criteria | Non-toxic materials | 78 | |

| 4 | Reducing greenhouse gases | 76 | ||

| 5 | Less use of natural resources | 72 | ||

| 6 | Basic circular economy criteria | Limitation | 62 | 4 |

| 7 | Reuse | 62 | ||

| 8 | Recycling | 58 | ||

| 9 | Socially sustainable criteria | Effective and productive use of labor | 52 | 3 |

| 10 | Environmentally sustainable criteria | Reduction of waste | 50 | |

| 11 | Functionality of the photovoltaic panel | Long warranty period | 42 | |

| 12 | Efficiency of the photovoltaic panel | Minimal energy loss | 40 | |

| 13 | Environmentally sustainable criteria | Reduction of wastewater | 36 | 2 |

| 14 | Sustainable economic development | Possibility of using waste (%) | 32 | |

| 15 | Functionality of the photovoltaic panel | High corrosion resistance | 30 | |

| 16 | High heat/fire resistance | 30 | ||

| 17 | Sustainable economic development | Less material consumption (%) | 30 | |

| 18 | Appearance of the photovoltaic panel | Light weight | 24 | 1 |

| 19 | Color | 22 | ||

| 20 | Availability of various shapes | 12 | ||

| 21 | Functionality of the photovoltaic panel | Easy assembly | 12 | |

| 22 | Appearance of the photovoltaic panel | Small dimensions | 10 | |

| 23 | Low thickness | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siwiec, D.; Pacana, A.; Gazda, A. A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies 2023, 16, 2474. https://doi.org/10.3390/en16052474

Siwiec D, Pacana A, Gazda A. A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies. 2023; 16(5):2474. https://doi.org/10.3390/en16052474

Chicago/Turabian StyleSiwiec, Dominika, Andrzej Pacana, and Andrzej Gazda. 2023. "A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy" Energies 16, no. 5: 2474. https://doi.org/10.3390/en16052474

APA StyleSiwiec, D., Pacana, A., & Gazda, A. (2023). A New QFD-CE Method for Considering the Concept of Sustainable Development and Circular Economy. Energies, 16(5), 2474. https://doi.org/10.3390/en16052474