Non-Dominated Sorting-Based Hybrid Optimization Technique for Multi-Objective Hydrothermal Scheduling

Abstract

1. Introduction

- Initially, an initialization process is escalated over complete search space using the concept of oppositional-based learning.

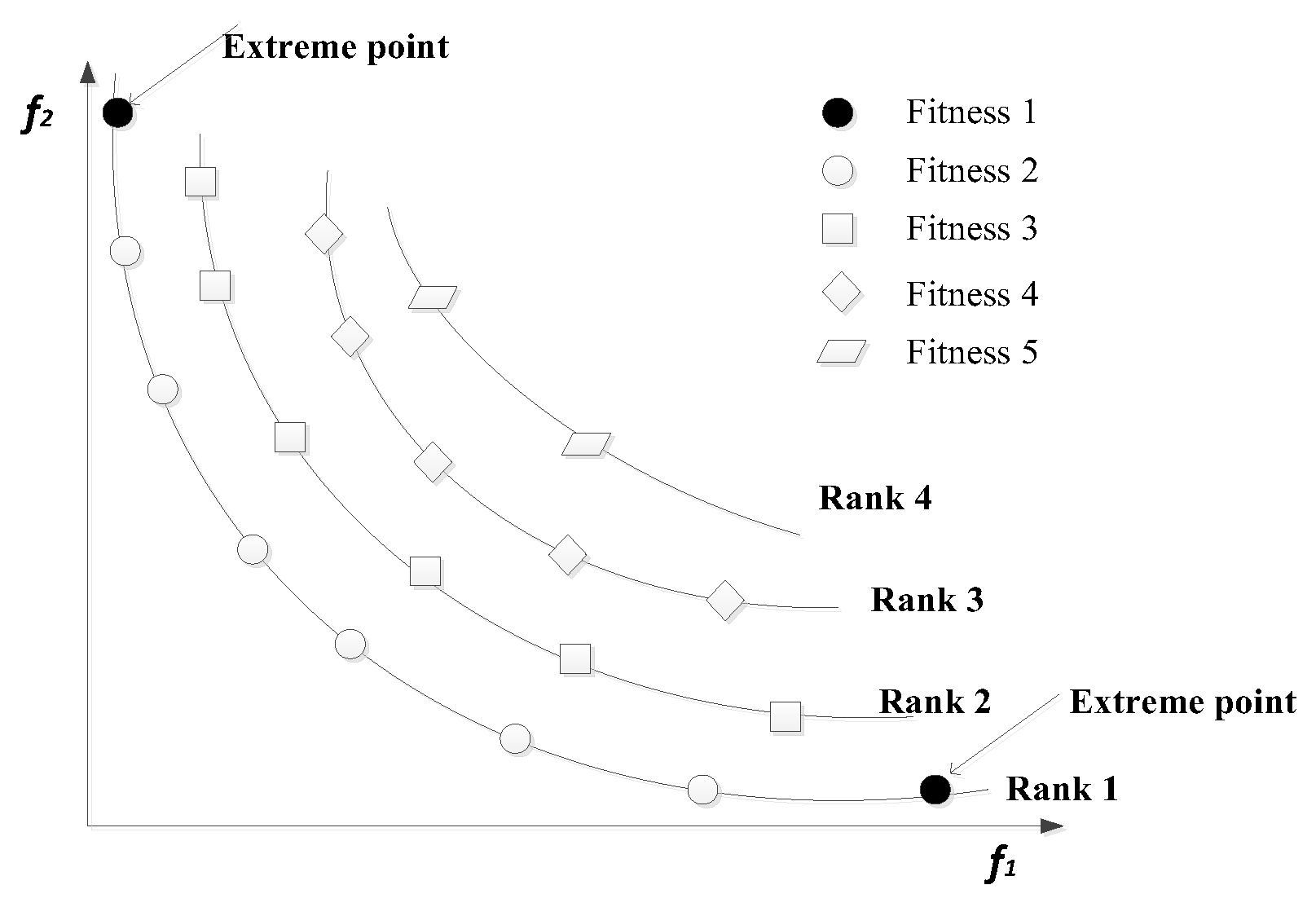

- Then, an integrated non-dominated sorting procedure deals with conflicting objective functions and attains a set of non-dominated solutions in a single run.

- The NS solutions are then stored in a limited length external archive, and a spread indicator metric is incorporated to update the archive. Once more, a disruption operator is used to update each agent’s position in order to prevent premature convergence.

- A fuzzy decision approach is also utilized to select better option from agent set. In addition, an effective constraint handling technique for dealing with load balancing limitations and end reservoir storage volumes in a hydrothermal scheduling problem is described.

- Finally, NSDOGGSA is carried out on two MSHTS test systems and results are compared with other existing techniques. Thus, the proposed approach attains feasible solutions effectively in terms of compromise solutions with less computational time for solving SHTS/MSHTS problems.

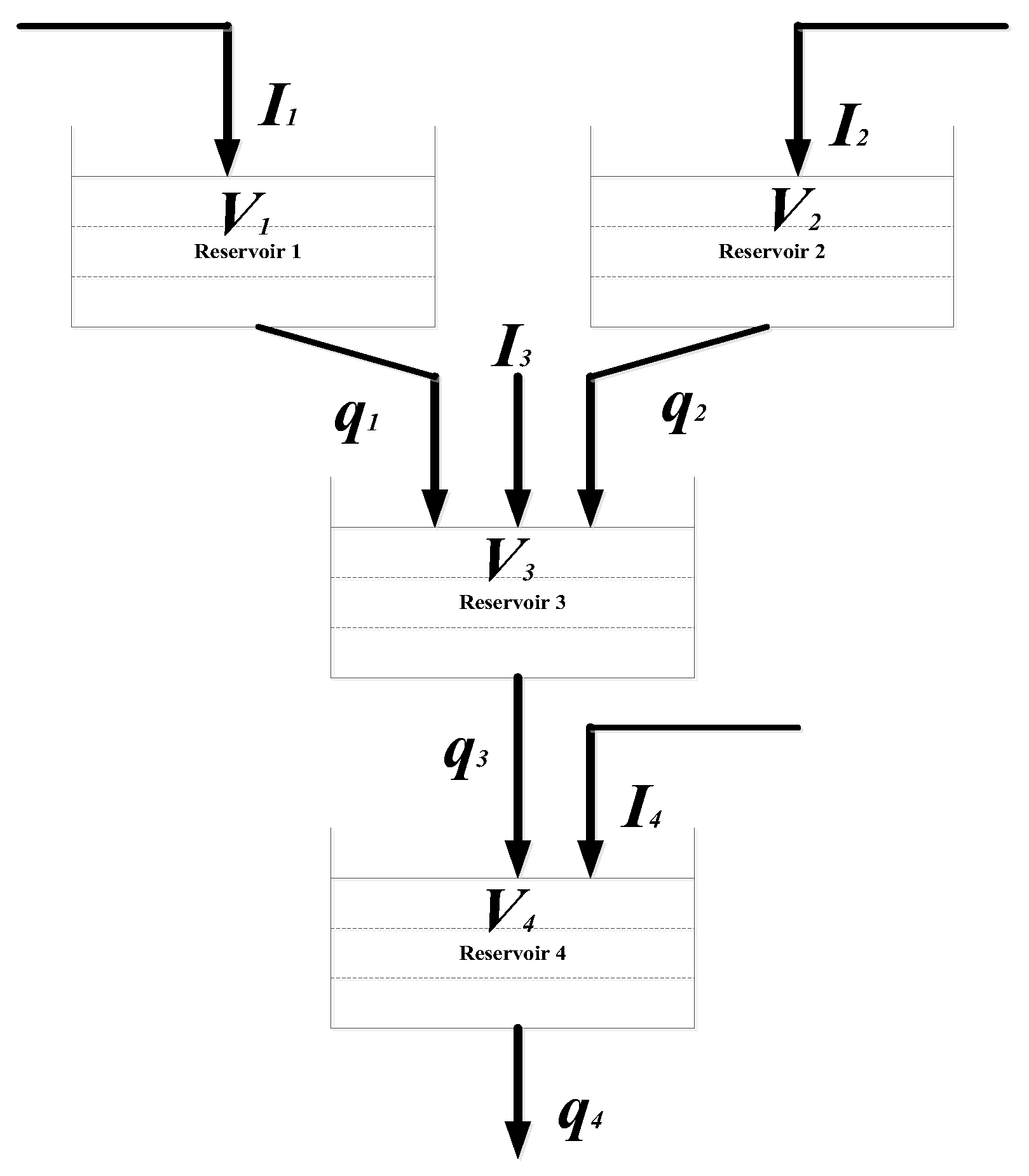

2. Problem Statement

2.1. Objective Functions

2.2. Constraints

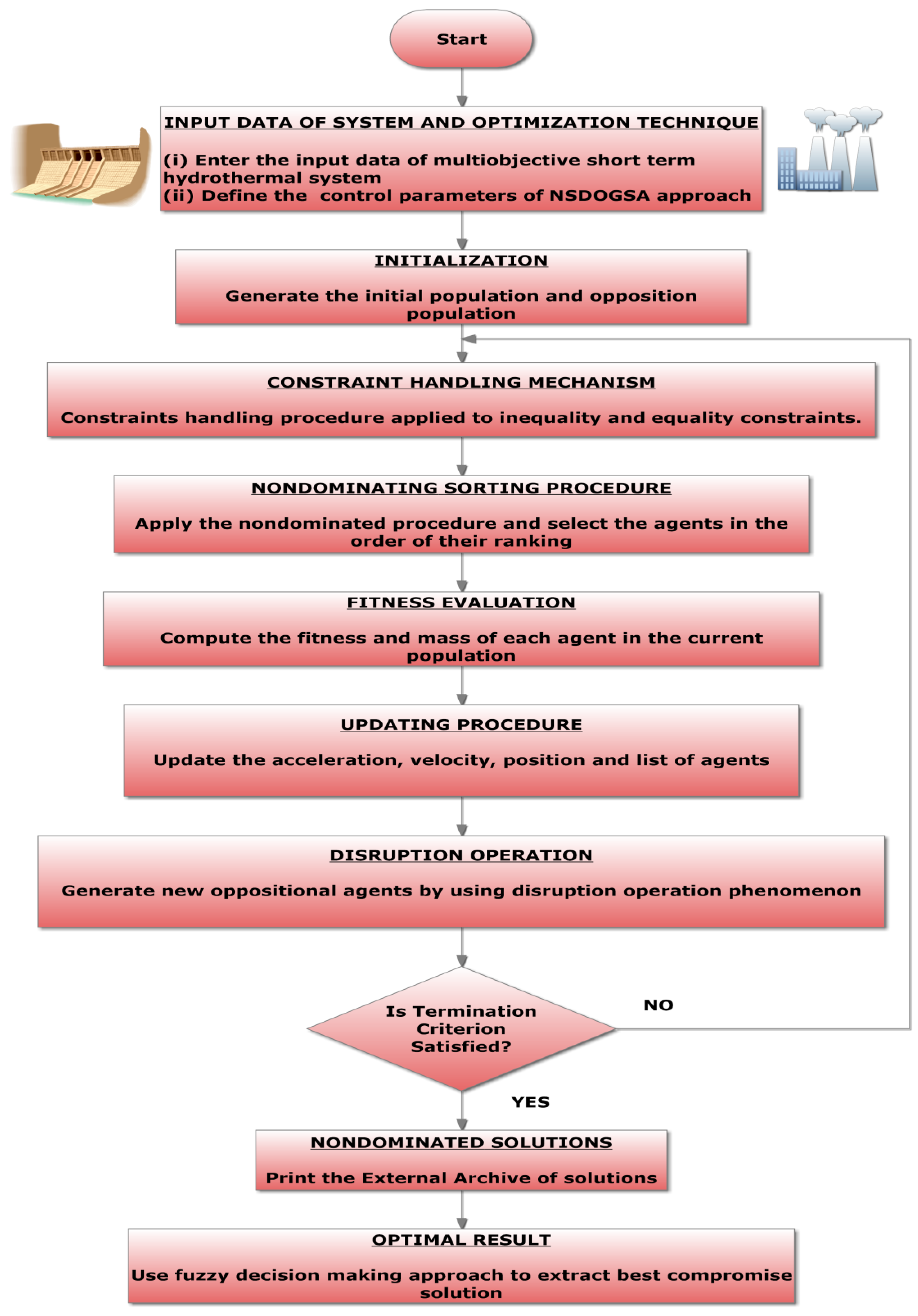

3. Proposed Methodology for Solving Multi-Objective Short-Term Hydrothermal Scheduling

3.1. Population Initialization

3.2. Update External Archive and Calculate Fitness and Mass

3.3. Update the Agent’s Acceleration, Velocity, and Position

3.4. Moving Agents with Disruption Operator

3.5. NSDOGSA Procedure for MSHTS Problem

- Step 1:

- Enter the data from the hydrothermal test system and define the NSDOGSA’s settings. Create an opposition-based population by randomly initializing the water discharges and thermal power generation outputs for each agent in the population.

- Step 2:

- Constraint handling procedure is performed to satisfy end reservoir volumes and system load balance constraints.

- Step 3:

- Apply the NS strategy and update an external archive group.

- Step 4:

- Update the agent’s acceleration, velocity, and position.

- Step 5:

- Moving agent’s updating using disruption operator.

- Step 6:

- When prescribed iteration number is reached, stop the operation and store the trade-off solutions in an external archive; otherwise, go to Step 2.

- Step 7:

- Identify the non-dominated solution from the trade-off solutions by using a fuzzy decision strategy.

4. Discussion and Simulation Studies

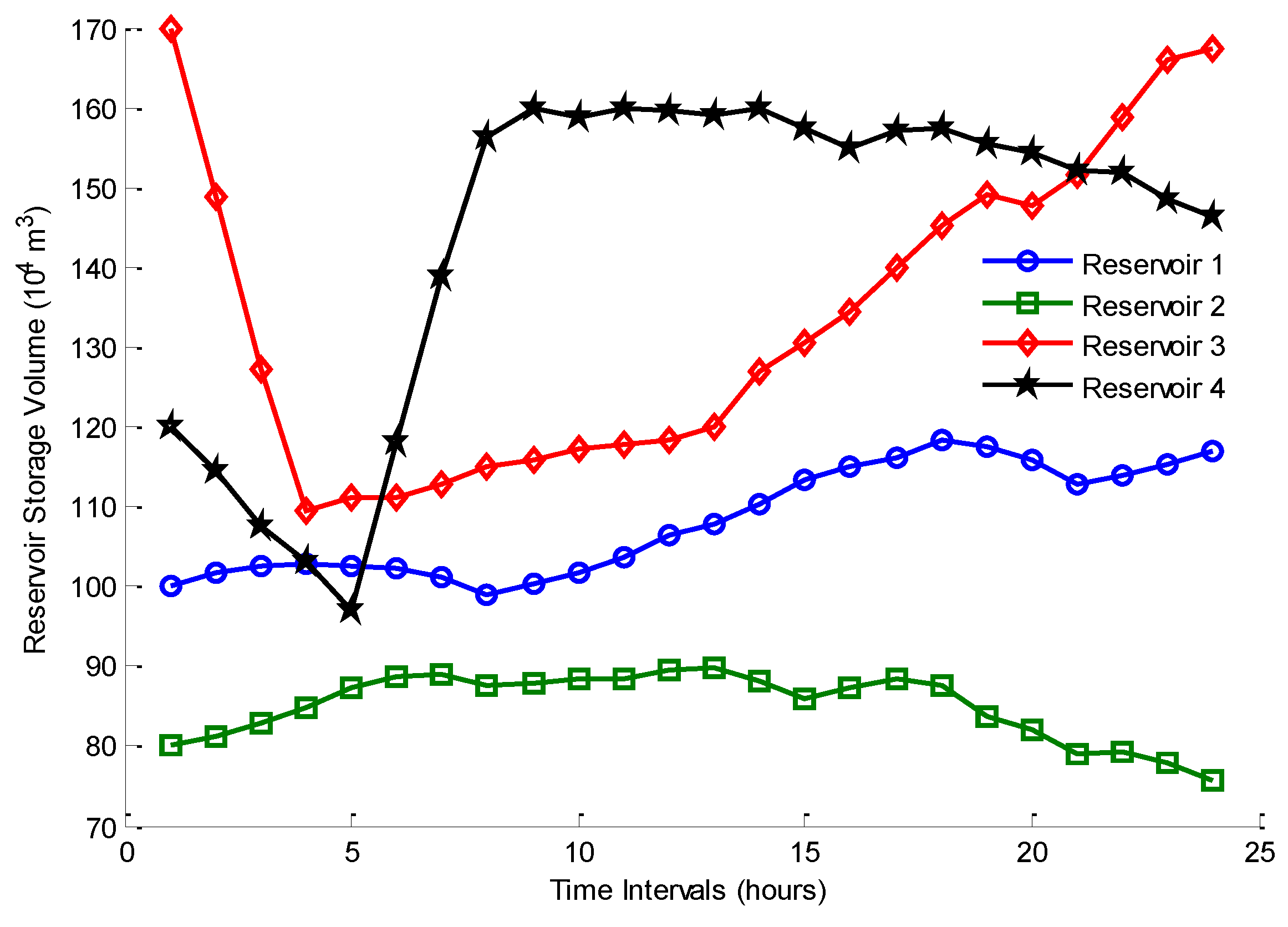

4.1. Test System-I

4.2. Test System-II

4.3. Statistical and Non-Parametric Analysis

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Hydro Plant | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 5 | 15 | 80 | 150 | 100 | 120 | 0 | 2 | 0 | 500 |

| 2 | 6 | 15 | 60 | 120 | 80 | 70 | 0 | 3 | 0 | 500 |

| 3 | 10 | 30 | 100 | 240 | 170 | 170 | 2 | 4 | 0 | 500 |

| 4 | 6 | 20 | 70 | 160 | 120 | 140 | 1 | 0 | 0 | 500 |

| Hydro Plant | ||||||

|---|---|---|---|---|---|---|

| 1 | −0.0042 | −0.42 | 0.030 | 0.90 | 10.0 | −50 |

| 2 | −0.0040 | −0.30 | 0.015 | 1.14 | 9.5 | −70 |

| 3 | −0.0016 | −0.30 | 0.014 | 0.55 | 5.5 | −40 |

| 4 | −0.0030 | −0.31 | 0.027 | 1.44 | 14.0 | −90 |

| Interval | Reservoir | Interval | Reservoir | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | ||

| 1 | 10 | 8 | 8.1 | 2.8 | 13 | 11 | 8 | 4 | 0 |

| 2 | 9 | 8 | 8.2 | 2.4 | 14 | 12 | 9 | 3 | 0 |

| 3 | 8 | 9 | 4 | 1.6 | 15 | 11 | 9 | 3 | 0 |

| 4 | 7 | 9 | 2 | 0 | 16 | 10 | 8 | 2 | 0 |

| 5 | 6 | 8 | 3 | 0 | 17 | 9 | 7 | 2 | 0 |

| 6 | 7 | 7 | 4 | 0 | 18 | 8 | 6 | 2 | 0 |

| 7 | 8 | 6 | 3 | 0 | 19 | 7 | 7 | 1 | 0 |

| 8 | 9 | 7 | 2 | 0 | 20 | 6 | 8 | 1 | 0 |

| 9 | 10 | 8 | 1 | 0 | 21 | 7 | 9 | 2 | 0 |

| 10 | 11 | 9 | 1 | 0 | 22 | 8 | 9 | 2 | 0 |

| 11 | 12 | 9 | 1 | 0 | 23 | 9 | 8 | 1 | 0 |

| 12 | 10 | 8 | 2 | 0 | 24 | 10 | 8 | 0 | 0 |

| Interval | Load Demand (MW) | Interval | Load Demand (MW) |

|---|---|---|---|

| 1 | 750 | 13 | 1110 |

| 2 | 780 | 14 | 1030 |

| 3 | 700 | 15 | 1010 |

| 4 | 650 | 16 | 1060 |

| 5 | 670 | 17 | 1050 |

| 6 | 800 | 18 | 1120 |

| 7 | 950 | 19 | 1070 |

| 8 | 1010 | 20 | 1050 |

| 9 | 1090 | 21 | 910 |

| 10 | 1080 | 22 | 860 |

| 11 | 1100 | 23 | 850 |

| 12 | 1150 | 24 | 800 |

| Thermal Plant | $/h | $/MWh | $/(MW)2h | $/h | 1/MW | lb/h | lb/MW h | lb/(MW)2h | lb/h | 1/MW | MW | MW |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 100 | 2.45 | 0.0012 | 160 | 0.038 | 60 | −1.355 | 0.0105 | 0.4968 | 0.01925 | 20 | 175 |

| 2 | 120 | 2.32 | 0.0010 | 180 | 0.037 | 45 | −0.600 | 0.0080 | 0.4860 | 0.01694 | 40 | 300 |

| 3 | 150 | 2.10 | 0.0015 | 200 | 0.035 | 30 | −0.555 | 0.0120 | 0.5035 | 0.01478 | 50 | 500 |

References

- Basu, M. Goal-attainment method based on simulated annealing technique for economic-environmental dispatch of hydrothermal power systems with cascaded reservoirs. Electr. Power Compon. Syst. 2004, 32, 1269–1286. [Google Scholar] [CrossRef]

- Basu, M. An interactive fuzzy satisfying method based on evolutionary programming technique for multi-objective short-term hydrothermal scheduling. Electr. Power Syst. Res. 2004, 69, 277–285. [Google Scholar] [CrossRef]

- Lakshminarasimman, L.; Subramanian, S. Short-term scheduling of hydrothermal power system with cascaded reservoirs by using modified differential evolution. IET Gener. Transm. Distrib. 2006, 53, 693–700. [Google Scholar] [CrossRef]

- Mandal, K.K.; Chakraborty, N. Short-term combined economic emission scheduling of hydrothermal power systems with cascaded reservoirs using differential evolution. Energy Convers. Manag. 2009, 50, 97–104. [Google Scholar] [CrossRef]

- Mandal, K.K.; Chakraborty, N. Short-term combined economic emission scheduling of hydrothermal systems with cascaded reservoirs using particle swarm optimization technique. Appl. Soft Comput. 2011, 11, 1295–1302. [Google Scholar] [CrossRef]

- Sun, C.; Lu, S. Short-term combined economic emission hydrothermal scheduling using improved quantum-behaved particle swarm optimization. Expert Syst. Appl. 2010, 37, 4232–4241. [Google Scholar] [CrossRef]

- Lu, S.; Sun, C.; Lu, Z. An improved quantum-behaved particle swarm optimization method for short-term combined economic emission hydrothermal scheduling. Energy Convers. Manag. 2010, 51, 561–571. [Google Scholar] [CrossRef]

- Lu, S.; Sun, C. Quadratic approximation based differential evolution with valuable trade off approach for bi-objective short-term hydrothermal scheduling. Expert Syst. Appl. 2011, 38, 13950–13960. [Google Scholar] [CrossRef]

- Narang, N.; Dhillon, J.S.; Kothari, D.P. Multi-objective short-term hydrothermal generation scheduling using predator–prey optimization. Electr. Power Compon. Syst. 2012, 40, 1708–1730. [Google Scholar] [CrossRef]

- Narang, N.; Dhillon, J.S.; Kothari, D.P. Weight pattern evaluation for multiobjective hydrothermal generation scheduling using hybrid search technique. Electr. Power Energy Syst. 2014, 62, 665–678. [Google Scholar] [CrossRef]

- Mandal, K.K.; Chakraborty, N. Daily combined economic emission scheduling of hydrothermal systems with cascaded reservoirs using self-organizing hierarchical particle swarm optimization technique. Expert Syst. Appl. 2012, 39, 3438–3445. [Google Scholar] [CrossRef]

- Roy, P.K. Hybrid chemical reaction optimization approach for combined economic emission short-term hydrothermal scheduling. Electr. Power Compon. Syst. 2014, 42, 1647–1660. [Google Scholar] [CrossRef]

- Nguyena, T.T.; Dieu, V.N. An efficient cuckoo bird inspired meta-heuristic algorithm for short-term combined economic emission hydrothermal scheduling. Ain Shams Eng. Journal 2018, 9, 483–497. [Google Scholar] [CrossRef]

- Arnel, G.; Ales, Z. Short-term combined economic and emission hydrothermal optimization by surrogate differential evolution. Appl. Energy 2015, 141, 42–56. [Google Scholar]

- Qin, H.; Zhou, J.; Lu, Y.; Wang, Y.; Zhang, Y. Multi-objective differential evolution with adaptive Cauchy mutation for short-term multi-objective optimal hydro-thermal scheduling. Energy Convers. Manag. 2010, 51, 788–794. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Zhang, Y.; Fang, N.; Zhang, R. Short term hydrothermal scheduling using multi-objective differential evolution with three chaotic sequences. Electr. Power Energy Syst. 2013, 47, 85–99. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Zhang, Y.; Lu, Y.; Wang, Y. Culture belief based multi-objective hybrid differential evolutionary algorithm in short term hydrothermal scheduling. Energy Convers. Manag. 2013, 65, 173–184. [Google Scholar] [CrossRef]

- Rui, Z.; Zhou, J.; Wang, Y. Multi-objective optimization of hydrothermal energy system considering economic and environmental aspects. Electr. Power Energy Syst. 2012, 42, 384–395. [Google Scholar]

- Lu, Y.; Zhou, J.; Qin, H.; Wang, Y.; Zhang, Y. A hybrid multi-objective cultural algorithm for short-term environmental/economic hydrothermal scheduling. Energy Convers. Manag. 2011, 52, 2121–2134. [Google Scholar] [CrossRef]

- Zhou, J.; Liao, X.; Ouyang, S.; Zhang, R.; Zhang, Y. Multi-objective artificial bee colony algorithm for short-term scheduling of hydrothermal system. Electr. Power Energy Syst. 2014, 55, 542–553. [Google Scholar] [CrossRef]

- Ahmadi, A.; Kaymanesh, A.; Siano, P.; Janghorbani, M.; Nezhade, A.E.; Sarno, D. Evaluating the effectiveness of normal boundary intersection method for short-term environmental/economic hydrothermal self-scheduling. Electr. Power Syst. Res. 2015, 123, 192–204. [Google Scholar] [CrossRef]

- Zhong-kai, F.; Wen-jing, N.; Chun-tian, C. Multi-objective quantum-behaved particle swarm optimization for economic environmental hydrothermal energy system scheduling. Energy 2017, 131, 165–178. [Google Scholar] [CrossRef]

- Feng, Z.K.; Niu, W.J.; Zhou, J.Z.; Cheng, C.T.; Zhang, Y.C. Scheduling of short-term hydrothermal energy system by parallel multi-objective differential evolution. Appl. Soft Comput. 2017, 61, 58–71. [Google Scholar] [CrossRef]

- Rashedi, E.; Nezamabadi-pour, H.; Saryazdi, S. GSA: A gravitational search algorithm. Inf. Sci. 2009, 179, 2232–2248. [Google Scholar] [CrossRef]

- Gouthamkumar, N.; Sharma, V.; Naresh, R. Disruption based gravitational search algorithm for short term hydrothermal scheduling. Expert Syst. Appl. 2015, 42, 7000–7011. [Google Scholar] [CrossRef]

- Gouthamkumar, N.; Sharma, V.; Naresh, R. Hybridized gravitational search algorithm for short term hydrothermal scheduling. IETE J. Res. 2015, 62, 1–11. [Google Scholar] [CrossRef]

- Nobahari, H.; Nikusokhan, M.; Siarry, P.A. Multi objective gravitational search algorithm based on nondominated sorting. Int. J. Swarm Intell. Res. 2012, 3, 32–49. [Google Scholar] [CrossRef]

- Tian, H.; Yuan, X.; Ji, B.; Chen, Z. Multi-objective optimization of short-term hydrothermal scheduling using nondominated sorting gravitational search algorithm with chaotic mutation. Energy Convers. Manag. 2014, 81, 504–519. [Google Scholar] [CrossRef]

- Tian, H.; Yuan, X.; Huang, Y.; Wu, X. An improved gravitational search algorithm for solving short-term economic/environmental hydrothermal scheduling. Soft Comput. 2015, 19, 2783–2797. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J.; Lu, P.; Wang, C. Short-term economic environmental hydrothermal scheduling using improved multi-objective gravitational search algorithm. Energy Convers. Manag. 2015, 89, 1227–1236. [Google Scholar] [CrossRef]

- Gouthamkumar, N.; Sharma, V.; Naresh, R. Nondominated sorting disruption based gravitational search algorithm with mutation scheme for multiobjective short term hydrothermal scheduling. Electr. Power Compon. Syst. 2016, 52, 1–15. [Google Scholar]

- Gouthamkumar, N.; Sharma, V.; Naresh, R. Application of nondominated sorting gravitational search algorithm with disruption operator for stochastic multiobjective short term hydrothermal scheduling. IET Gener. Transm. Distrib. 2016, 10, 862–872. [Google Scholar]

- Gouthamkumar, N.; Balusu, S.; Bathina, V. Nondominated sorting-based disruption in oppositional gravitational search algorithm for stochastic multiobjective short-term hydrothermal scheduling. Soft Comput. 2019, 23, 7229–7248. [Google Scholar]

- Coello, C.A.C.; Pulido, G.T.; Lechuga, M.S. Handling multiple objectives with particle swarm optimization. IEEE Trans. Evol. Comput. 2004, 8, 256–279. [Google Scholar] [CrossRef]

- Deb, K.; Amrit, P.; Sameer, A.; Meyarivan, T. A fast and elitist multi-objective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Tizhoosh, H.R. Opposition-based learning: A new scheme for machine intelligence. In Proceedings of the International Conference on Computational Intelligence for Modelling, Control and Automation and International Conference on Intelligent Agents, Web Technologies and Internet Commerce, Vienna, Austria, 28–30 November 2005; pp. 695–701. [Google Scholar]

- Liu, H.; Ding, G.; Sun, H. An improved opposition-based disruption operator in gravitational search algorithm. In Proceedings of the 2012 Fifth International Symposium on Computational Intelligence and Design, Vienna, Austria, 28–29 October 2012; pp. 123–126. [Google Scholar]

- Marcel, F.; Lorca, Á.; Matías, N.P. Multistage adaptive robust optimization for the hydrothermal scheduling problem. Comput. Oper. Res. 2023, 150, 106051. [Google Scholar] [CrossRef]

- Sakthivel, V.P.; Thirumal, K.; Sathya, P.D. Quasi-oppositional turbulent water flow-based optimization for cascaded short term hydrothermal scheduling with valve-point effects and multiple fuels. Energy 2022, 251, 123905. [Google Scholar] [CrossRef]

- Paulo, V.L.; Renata, P.; Felipe, B.; Gabriel, T.; Erlon, C.F.; Lucas, B.P. Dealing with negative inflows in the long-term hydrothermal scheduling problem. Energies 2022, 15, 1115. [Google Scholar] [CrossRef]

- Saqib, A.; Muhammad, S.F.; Syed, A.R.K.; Ghulam, A.; Nasim, U.; Alsharef, M.; Mohamed, E.F. Introducing adaptive machine learning technique for solving short-term hydrothermal scheduling with prohibited discharge zones. Sustainability 2022, 14, 11673. [Google Scholar] [CrossRef]

- Muhammad, A.I.; Muhammad, S.F.; Noor, U.A.; Ahsen, T.; Irfan, A.K.; Ghulam, A.; Syed, A.R.K. A new fast deterministic economic dispatch method and statistical performance evaluation for the cascaded short-term hydrothermal scheduling problem. Sustainability 2023, 15, 1644. [Google Scholar] [CrossRef]

- Smarajit, G.; Manvir, K.; Suman, B.; Vinod, K. Hybrid ABC-BAT for solving short-term hydrothermal scheduling problems. Energies 2019, 12, 551. [Google Scholar] [CrossRef]

- Cui, Z.; Ali, T.H.; Ali, N.K.; Mingxin, J.; Muamer, N.M.; Nallapaneni, M.K. A rigid cuckoo search algorithm for solving short-term hydrothermal scheduling problem. Sustainability 2021, 13, 4277. [Google Scholar] [CrossRef]

| Method | Minimum EPC ($) | Minimum EEP (lb) | MSHTS | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EPC ($) | EEP (lb) | Time (s) | EPC ($) | EEP (lb) | Time (s) | EPC ($) | EEP (lb) | Time (s) | |

| SAGA [1] | 45,305.00 | 33,851.00 | - | 49,330.00 | 16,554.00 | - | 45,956.00 | 17,447.00 | - |

| Fuzzy EP [2] | 45,063.04 | 48,797.00 | - | 59,228.00 | 16,554.00 | - | 47,906.00 | 26,234.00 | 4582.0 |

| MDE [3] | 42,611.00 | 33,323.00 | 125.00 | 48,714.00 | 15,730.00 | - | 43,198.00 | 20,385.00 | - |

| DE [4] | 43,500.00 | 21,092.00 | 72.95 | 51,449.00 | 18,257.00 | 72.73 | 44,914.00 | 19,615.00 | 74.96 |

| PSO [5] | 42,474.00 | 28,132.00 | 123.52 | 48,263.00 | 16,928.00 | 124.66 | 43,280.00 | 17,899.00 | 132.45 |

| IQPSO [6] | 42,359.00 | 31,298.00 | - | 45,271.00 | 17,767.00 | - | 44,259.00 | 18,229.00 | - |

| QPSO [7] | 42,545.00 | 31,205.00 | - | 46,288.00 | 17,735.00 | - | 44,122.00 | 18,102.00 | - |

| QPSO-DM [7] | 41,909.00 | 30,724.00 | - | 45,392.00 | 17,659.00 | - | 43,507.00 | 18,183.00 | - |

| QADEVT [8] | 41,762.00 | 30,710.00 | - | 45,971.00 | 16,654.00 | - | 42,939.00 | 17,918.00 | - |

| PSO [9] | 43,076.00 | 25,384.00 | 77.31 | 48,570.00 | 16,199.00 | 75.21 | 45,906.00 | 18,621.00 | 79.21 |

| PPO [9] | 42,042.00 | 27,961.00 | 30.71 | 48,913.00 | 15,728.00 | 30.62 | 44,111.00 | 17,473.00 | 31.62 |

| PSO [10] | 43,251.00 | 24,042.00 | 40.35 | 46,046.00 | 16,720.00 | 41.43 | 44,330.00 | 19,589.00 | 44.52 |

| PPO [10] | 42,170.00 | 26,177.00 | 29.31 | 49,072.00 | 15,805.00 | 29.40 | 43,146.00 | 17,009.00 | 29.31 |

| PSO with PPS [10] | 42,056.00 | 27,532.00 | 31.56 | 48,006.00 | 15,801.00 | 31.83 | 43,005.00 | 17,054.00 | 32.31 |

| PPO with PPS [10] | 41,530.00 | 28,757.00 | 28.32 | 48,920.00 | 15,716.00 | 29.12 | 42,836.00 | 17,254.00 | 29.19 |

| SOHPSO-TVAC [11] | 41,983.00 | 24,482.00 | 112.00 | 44,432.00 | 16,803.00 | 112.56 | 43,045.00 | 17,003.00 | 120.00 |

| HCRO-DE [12] | 42,398.51 | 24,087.36 | - | 48,446.94 | 16,142.73 | - | 42,801.55 | 17,622.99 | - |

| CBIA [13] | 41,223.00 | - | 94.00 | - | 16,303.00 | 96.00 | 42,990.00 | 17,311.00 | 98.00 |

| NPdynejDE [14] | 40,859.84 | 22,767.78 | 26.24 | 49,717.22 | 16,495.62 | 26.25 | 41,697.23 | 17,981.40 | 26.27 |

| MODE-ACM [15] | 42,417.00 | 16,706.00 | - | 44,962.00 | 16,242.00 | - | 43,289.00 | 16,382.00 | 27.03 |

| MODE [16] | 42,198.00 | 17,711.00 | - | 45,157.00 | 16,241.00 | - | 43,250.00 | 16,803.00 | - |

| LM-MODE [16] | 41,872.00 | 17,726.00 | - | 45,049.00 | 16,221.00 | - | 43,277.00 | 16,684.00 | 27.00 |

| CM-MODE [16] | 42,309.00 | 17,697.00 | - | 45,084.00 | 16,248.00 | - | 43,279.00 | 16,603.00 | 27.40 |

| TM-MODE [16] | 42,051.00 | 17,861.00 | - | 45,040.00 | 16,091.00 | - | 43,377.00 | 16,517.00 | 27.20 |

| MODE [17] | - | - | - | - | - | - | 43,694.00 | 16,524.00 | - |

| CB-MOHDE [17] | - | - | - | - | - | - | 43,122.00 | 16,503.00 | 24.40 |

| MOCA-PSO [18] | 42,009.00 | 16,842.00 | - | 47,085.00 | 15,858.00 | - | 43,873.00 | 16,222.00 | - |

| NSGA-II [19] | 42,126.00 | 16,763.00 | - | 46,744.00 | 15,914.00 | - | 43,606.00 | 16,270.00 | - |

| HMOCA [19] | 41,805.00 | 16,841.00 | - | 48,191.00 | 15,746.00 | - | 43,593.00 | 16,204.00 | - |

| MOABC [20] | - | - | - | - | - | - | 43,972.57 | 16,132.29 | - |

| NBIM [21] | 41,549.99 | 17,076.52 | 1.92 | 48,921.93 | 15,666.61 | 1.61 | 43,501.89 | 16,146.54 | 40.95 |

| MODE-ACM [22] | 42,417.00 | 16,706.00 | - | 44,962.00 | 16,242.00 | - | 43,289.00 | 16,382.00 | - |

| NSGA-II [22] | 42,126.00 | 16,763.00 | - | 46,744.00 | 15,914.00 | - | 43,606.00 | 16,270.00 | - |

| MOQPSO [22] | 41,981.00 | 16,868.00 | - | 48,803.00 | 15,710.00 | - | 44,149.00 | 16,123.00 | - |

| MODE [23] | 42,474.00 | 17,175.00 | - | 47,644.00 | 15,939.00 | - | 44,091.00 | 16,297.00 | - |

| PMODE [23] | 41,901.00 | 16,966.00 | - | 48,147.00 | 15,790.00 | - | 44,060.00 | 16,177.00 | 67.90 |

| NSPSO [28] | 43,625.00 | - | - | - | 16,371.00 | - | 44,638.00 | 16,694.00 | - |

| NSPSO-CM [28] | 42,977.00 | - | - | - | 16,245.00 | - | 44,248.00 | 16,651.00 | - |

| NSGSA [28] | 43,707.00 | - | - | - | 16,136.00 | - | 44,519.00 | 16,574.00 | - |

| NSGSA-CM [28] | 42,841.00 | 16,789.00 | - | 46,335.00 | 16,092.00 | - | 43,207.00 | 16,564.00 | - |

| GSA [29] | - | - | - | - | - | - | 44,857.43 | 18,091.98 | - |

| IGSA [29] | - | - | - | - | - | - | 43,299.89 | 17,868.74 | - |

| IMOGSA [30] | - | - | - | - | - | - | 44,245.63 | 16,149.17 | - |

| NSGA-II | - | - | - | - | - | - | 43,684.00 | 17,048.00 | 169.00 |

| MOPSO | - | - | - | - | - | - | 43,281.00 | 17,123.00 | 97.00 |

| GSA | 42,032.35 | 24,852.78 | 32.29 | 50,318.67 | 16,523.80 | 28.61 | - | - | - |

| OGSA | 41,844.69 | 24,108.97 | 18.12 | 49,667.05 | 16,482.66 | 20.37 | - | - | - |

| DGSA | 41,751.15 | 23,717.71 | 31.99 | 49,998.83 | 16,403.20 | 31.49 | - | - | - |

| DOGSA | 40,865.79 | 23,456.90 | 14.59 | 48,384.75 | 15,984.44 | 17.54 | - | - | - |

| NSGSA | - | - | - | - | - | - | 44,084.68 | 17,125.60 | 64.23 |

| NSOGSA | - | - | - | - | - | - | 43,928.05 | 17,107.98 | 68.37 |

| NSDGSA | - | - | - | - | - | - | 43,400.08 | 16,993.80 | 67.39 |

| NSDOGSA | - | - | - | - | - | - | 42,853.70 | 16,899.86 | 70.49 |

| Hour | Water Discharges of Hydro (104 m3) | Generation of Hydropower (MW) | Generation of Thermal Power (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | |

| 1 | 8.57 | 7.20 | 29.35 | 7.77 | 78.57 | 57.11 | 0.00 | 154.90 | 103.78 | 126.12 | 229.52 |

| 2 | 8.47 | 7.94 | 29.53 | 10.50 | 78.40 | 62.14 | 0.00 | 181.35 | 102.68 | 125.94 | 229.49 |

| 3 | 8.76 | 7.47 | 29.20 | 12.57 | 80.28 | 59.29 | 0.00 | 192.93 | 101.84 | 125.90 | 139.76 |

| 4 | 7.31 | 6.72 | 18.45 | 8.02 | 70.94 | 55.37 | 29.28 | 133.68 | 96.28 | 124.70 | 139.75 |

| 5 | 7.16 | 7.29 | 17.40 | 9.54 | 69.81 | 60.40 | 32.82 | 141.46 | 102.48 | 123.27 | 139.76 |

| 6 | 7.29 | 7.96 | 16.91 | 10.30 | 70.34 | 64.99 | 35.41 | 171.56 | 102.46 | 125.75 | 229.49 |

| 7 | 10.43 | 6.89 | 13.78 | 13.12 | 87.69 | 57.67 | 42.79 | 219.82 | 102.67 | 209.83 | 229.53 |

| 8 | 7.38 | 6.55 | 16.54 | 11.16 | 70.15 | 54.87 | 38.56 | 215.38 | 102.50 | 209.27 | 319.27 |

| 9 | 8.18 | 8.61 | 15.11 | 16.06 | 75.83 | 67.93 | 41.93 | 268.73 | 102.74 | 213.57 | 319.27 |

| 10 | 10.5 | 7.88 | 15.14 | 13.94 | 88.38 | 63.32 | 43.49 | 251.43 | 104.35 | 209.80 | 319.23 |

| 11 | 7.54 | 9.18 | 15.24 | 17.10 | 72.39 | 71.32 | 43.36 | 281.12 | 102.67 | 209.85 | 319.29 |

| 12 | 7.69 | 8.28 | 16.12 | 13.40 | 74.59 | 66.27 | 41.61 | 245.91 | 102.57 | 210.03 | 409.02 |

| 13 | 8.06 | 9.74 | 15.74 | 17.27 | 77.55 | 73.90 | 44.35 | 282.22 | 103.25 | 209.46 | 319.27 |

| 14 | 7.92 | 10.02 | 14.35 | 18.04 | 77.29 | 74.14 | 48.02 | 285.62 | 105.59 | 209.81 | 229.53 |

| 15 | 8.14 | 7.30 | 15.81 | 18.00 | 79.59 | 58.48 | 47.41 | 282.35 | 102.84 | 209.82 | 229.51 |

| 16 | 7.27 | 9.14 | 14.91 | 12.77 | 73.92 | 70.18 | 50.16 | 235.41 | 102.31 | 208.76 | 319.26 |

| 17 | 7.70 | 7.44 | 15.86 | 12.15 | 77.38 | 59.71 | 49.98 | 232.02 | 102.27 | 209.36 | 319.28 |

| 18 | 9.39 | 9.74 | 13.27 | 16.21 | 88.49 | 72.23 | 54.26 | 273.10 | 102.84 | 209.80 | 319.28 |

| 19 | 6.37 | 6.51 | 14.80 | 15.80 | 67.13 | 51.12 | 53.9 | 268.02 | 102.58 | 207.97 | 319.28 |

| 20 | 8.53 | 11.93 | 14.36 | 18.42 | 83.11 | 79.28 | 55.17 | 287.63 | 105.48 | 209.81 | 229.52 |

| 21 | 7.56 | 8.35 | 13.66 | 15.96 | 76.10 | 60.30 | 56.51 | 265.91 | 101.83 | 209.59 | 139.76 |

| 22 | 9.15 | 10.62 | 14.23 | 17.80 | 86.43 | 71.91 | 57.19 | 279.62 | 100.06 | 125.04 | 139.75 |

| 23 | 9.54 | 8.67 | 15.67 | 18.09 | 88.38 | 61.36 | 56.16 | 276.87 | 102.65 | 124.82 | 139.76 |

| 24 | 6.08 | 10.59 | 18.39 | 14.67 | 64.32 | 70.14 | 50.96 | 247.27 | 102.67 | 124.88 | 139.76 |

| EPC ($) 40,865.79 EEP (lb) 23,456.90 | |||||||||||

| Hour | Water Discharges of Hydro (104 m3) | Generation of Hydropower (MW) | Generation of Thermal Power (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | |

| 1 | 9.23 | 6.03 | 29.8 | 6.87 | 82.21 | 49.24 | 0.00 | 143.47 | 143.06 | 193.17 | 138.85 |

| 2 | 8.24 | 6.57 | 29.22 | 8.16 | 76.85 | 54.11 | 0.00 | 155.71 | 158.16 | 197.80 | 137.36 |

| 3 | 7.92 | 6.14 | 29.89 | 6.40 | 75.07 | 51.95 | 0.00 | 128.2 | 133.77 | 178.59 | 132.42 |

| 4 | 6.43 | 6.00 | 16.58 | 6.45 | 64.64 | 52.54 | 35.67 | 124.18 | 124.71 | 148.33 | 99.93 |

| 5 | 6.11 | 6.83 | 17.83 | 7.73 | 62.29 | 59.95 | 31.42 | 133.45 | 128.8 | 133.64 | 120.45 |

| 6 | 8.77 | 6.08 | 18.50 | 8.89 | 80.37 | 55.28 | 28.68 | 169.25 | 123.76 | 200.90 | 141.75 |

| 7 | 9.05 | 6.07 | 12.95 | 13.25 | 81.32 | 55.71 | 41.25 | 235.26 | 174.51 | 212.25 | 149.70 |

| 8 | 8.19 | 7.29 | 17.39 | 14.70 | 76.09 | 64.04 | 32.92 | 264.07 | 174.63 | 230.53 | 167.71 |

| 9 | 9.25 | 8.14 | 17.38 | 18.34 | 82.31 | 69.19 | 33.05 | 295.14 | 174.49 | 251.01 | 184.81 |

| 10 | 8.79 | 7.10 | 16.22 | 17.83 | 80.07 | 62.58 | 36.05 | 291.06 | 174.26 | 254.16 | 181.82 |

| 11 | 9.87 | 8.87 | 14.55 | 13.75 | 86.42 | 74.29 | 39.33 | 256.9 | 174.83 | 267.46 | 200.77 |

| 12 | 10.22 | 10.52 | 16.81 | 17.56 | 88.75 | 82.76 | 35.24 | 288.92 | 174.44 | 266.33 | 213.57 |

| 13 | 10.08 | 10.29 | 16.74 | 17.15 | 88.06 | 80.26 | 36.35 | 285.7 | 174.46 | 249.93 | 195.24 |

| 14 | 8.85 | 8.33 | 15.11 | 15.49 | 81.90 | 68.68 | 42.03 | 272.37 | 174.74 | 227.84 | 162.44 |

| 15 | 8.71 | 8.23 | 17.79 | 15.03 | 81.93 | 68.47 | 37.58 | 268.94 | 174.94 | 217.88 | 160.26 |

| 16 | 8.02 | 9.03 | 15.80 | 16.92 | 78.13 | 73.44 | 45.34 | 284.39 | 174.6 | 245.09 | 159.02 |

| 17 | 8.06 | 9.04 | 16.07 | 16.92 | 78.75 | 72.91 | 46.62 | 284.24 | 174.82 | 241.70 | 150.96 |

| 18 | 9.68 | 10.31 | 15.41 | 18.76 | 88.62 | 78.06 | 48.92 | 297.4 | 174.88 | 249.90 | 182.23 |

| 19 | 7.78 | 10.68 | 15.34 | 18.65 | 76.71 | 77.02 | 49.95 | 293.02 | 174.77 | 242.45 | 156.08 |

| 20 | 7.73 | 10.06 | 13.88 | 18.63 | 76.27 | 71.86 | 52.61 | 292.05 | 174.56 | 224.16 | 158.50 |

| 21 | 5.91 | 8.90 | 13.49 | 18.18 | 62.14 | 64.73 | 54.45 | 286.14 | 173.47 | 160.86 | 108.21 |

| 22 | 7.08 | 10.40 | 12.48 | 18.73 | 71.49 | 72.06 | 56.18 | 287.61 | 143.13 | 133.91 | 95.61 |

| 23 | 6.02 | 11.36 | 13.69 | 15.76 | 63.31 | 75.04 | 57.80 | 262.62 | 128.46 | 164.51 | 98.25 |

| 24 | 5.00 | 9.72 | 13.87 | 20.00 | 54.72 | 65.67 | 58.41 | 291.26 | 124.83 | 123.75 | 81.36 |

| EPC ($) 48,384.75 EEP (lb) 15,984.44 | |||||||||||

| Scheme Index | NSDOGSA | NSDGSA | NSOGSA | NSGSA | ||||

|---|---|---|---|---|---|---|---|---|

| EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | |

| 1 | 42,757.12 | 16,952.40 | 43,232.16 | 17,069.73 | 43,923.55 | 17,127.19 | 43,981.68 | 17,163.86 |

| 2 | 42,759.40 | 16,947.06 | 43,236.95 | 17,065.58 | 43,923.75 | 17,125.28 | 43,983.92 | 17,161.99 |

| 3 | 42,772.48 | 16,940.42 | 43,245.13 | 17,062.87 | 43,928.05 | 17,107.98 | 43,994.53 | 17,157.44 |

| 4 | 42,781.36 | 16,934.94 | 43,246.66 | 17,059.15 | 43,930.54 | 17,107.04 | 44,017.77 | 17,155.2 |

| 5 | 42,788.52 | 16,931.99 | 43,263.44 | 17,053.18 | 43,943.3 | 17,102.65 | 44,031.34 | 17,148.20 |

| 6 | 42,794.50 | 16,930.20 | 43,270.04 | 17,049.55 | 43,943.53 | 17,100.96 | 44,033.99 | 17,142.63 |

| 7 | 42,800.10 | 16,926.27 | 43,275.30 | 17,046.75 | 43,945.66 | 17,099.67 | 44,052.06 | 17,134.13 |

| 8 | 42,806.36 | 16,923.62 | 43,282.97 | 17,045.66 | 43,947.87 | 17,099.33 | 44,075.11 | 17,131.71 |

| 9 | 42,810.19 | 16,921.27 | 43,288.77 | 17,040.76 | 43,950.71 | 17,097.66 | 44,084.68 | 17,125.60 |

| 10 | 42,823.55 | 16,914.99 | 43,290.53 | 17,040.07 | 43,951.46 | 17,096.93 | 44,139.67 | 17,116.22 |

| 11 | 42,826.71 | 16,909.40 | 43,298.41 | 17,035.64 | 43,953.51 | 17,096.85 | 44,171.75 | 17,112.51 |

| 12 | 42,853.70 | 16,899.86 | 43,321.00 | 17,025.12 | 43,960.36 | 17,094.56 | 44,187.41 | 17,110.25 |

| 13 | 42,913.92 | 16,881.42 | 43,400.08 | 16,993.80 | 43,963.36 | 17,094.43 | 44,203.95 | 17,108.70 |

| 14 | 42,919.34 | 16,879.90 | 43,516.27 | 16,955.06 | 43,966.55 | 17,093.03 | 44,234.28 | 17,103.18 |

| 15 | 42,925.84 | 16,877.80 | 43,530.27 | 16,953.23 | 43,969.06 | 17,092.92 | 44,252.79 | 17,100.96 |

| 16 | 42,936.49 | 16,875.81 | 43,555.32 | 16,950.78 | 43,974.31 | 17,090.93 | 44,280.84 | 17,097.77 |

| 17 | 43,000.56 | 16,860.49 | 43,561.82 | 16,947.97 | 43,977.86 | 17,090.3 | 44,293.20 | 17,095.67 |

| 18 | 43,022.16 | 16,856.33 | 43,570.16 | 16,943.07 | 43,980.24 | 17,089.61 | 44,317.36 | 17,093.68 |

| 19 | 43,032.77 | 16,854.48 | 43,581.51 | 16,939.80 | 43,984.07 | 17,088.03 | 44,317.86 | 17,092.71 |

| 20 | 43,042.87 | 16,852.86 | 43,593.79 | 16,936.27 | 43,987.24 | 17,087.68 | 44,369.93 | 17,087.18 |

| Hour | Water Discharges of Hydro (104 m3) | Generation of Hydropower (MW) | Generation of Thermal Power (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | |

| 1 | 8.31 | 6.81 | 29.4 | 8.34 | 77.02 | 54.55 | 0.00 | 161.81 | 108.41 | 207.26 | 140.95 |

| 2 | 8.25 | 6.44 | 29.82 | 9.29 | 77.17 | 52.75 | 0.00 | 167.58 | 131.38 | 210.99 | 140.13 |

| 3 | 7.69 | 7.04 | 29.95 | 6.12 | 73.79 | 57.68 | 0.00 | 122.05 | 101.59 | 205.37 | 139.52 |

| 4 | 7.11 | 6.52 | 15.29 | 6.16 | 69.95 | 55.31 | 38.43 | 118.13 | 103.20 | 125.20 | 139.79 |

| 5 | 6.25 | 6.51 | 17.08 | 8.22 | 63.45 | 56.65 | 34.41 | 137.00 | 112.14 | 126.61 | 139.74 |

| 6 | 8.33 | 6.84 | 16.65 | 9.05 | 77.88 | 59.67 | 35.73 | 168.38 | 107.73 | 210.90 | 139.72 |

| 7 | 10.05 | 7.33 | 13.64 | 12.58 | 86.60 | 63.00 | 42.41 | 226.32 | 173.72 | 216.61 | 141.33 |

| 8 | 7.75 | 6.55 | 15.9 | 11.50 | 73.26 | 57.11 | 39.24 | 230.26 | 174.59 | 209.8 | 225.74 |

| 9 | 8.63 | 7.54 | 16.58 | 18.38 | 78.99 | 63.84 | 37.85 | 295.6 | 174.35 | 209.91 | 229.45 |

| 10 | 8.98 | 9.03 | 15.56 | 15.51 | 81.41 | 72.81 | 40.93 | 272.02 | 174.26 | 209.81 | 228.77 |

| 11 | 9.33 | 7.93 | 15.45 | 13.96 | 83.91 | 66.52 | 41.38 | 258.73 | 174.55 | 287.72 | 187.2 |

| 12 | 8.56 | 7.67 | 16.92 | 16.26 | 80.33 | 65.47 | 37.89 | 279.05 | 174.37 | 284.01 | 228.87 |

| 13 | 8.47 | 9.67 | 15.35 | 15.74 | 80.14 | 76.93 | 42.47 | 274.35 | 174.12 | 233.50 | 228.48 |

| 14 | 9.06 | 11.08 | 15.86 | 18.22 | 84.30 | 82.49 | 44.01 | 294.46 | 174.41 | 209.93 | 140.4 |

| 15 | 9.17 | 7.67 | 15.33 | 17.95 | 85.60 | 63.62 | 46.38 | 289.94 | 174.75 | 209.87 | 139.84 |

| 16 | 8.97 | 7.06 | 15.32 | 14.61 | 84.80 | 60.46 | 47.70 | 260.52 | 174.54 | 212.02 | 219.96 |

| 17 | 6.74 | 7.76 | 16.75 | 15.00 | 69.68 | 65.45 | 46.38 | 266.10 | 174.33 | 207.59 | 220.47 |

| 18 | 8.73 | 9.72 | 14.93 | 17.86 | 83.94 | 75.90 | 51.76 | 289.47 | 174.89 | 227.55 | 216.48 |

| 19 | 8.72 | 8.75 | 16.07 | 16.54 | 83.79 | 68.60 | 50.87 | 277.59 | 174.47 | 274.96 | 139.72 |

| 20 | 9.07 | 11.05 | 13.56 | 17.33 | 85.60 | 78.59 | 53.81 | 282.49 | 174.02 | 210.40 | 165.08 |

| 21 | 5.95 | 8.71 | 13.31 | 17.03 | 62.84 | 65.41 | 54.94 | 278.20 | 174.14 | 135.18 | 139.29 |

| 22 | 6.54 | 10.51 | 12.57 | 18.37 | 67.77 | 74.48 | 56.68 | 287.48 | 109.42 | 124.83 | 139.33 |

| 23 | 7.29 | 10.26 | 16.76 | 18.19 | 73.72 | 72.37 | 54.08 | 282.74 | 102.73 | 124.84 | 139.51 |

| 24 | 7.06 | 13.57 | 12.56 | 19.99 | 72.27 | 82.37 | 58.41 | 291.53 | 102.13 | 128.06 | 65.24 |

| EPC ($) 42,853.70 EEP (lb) 16,899.86 | |||||||||||

| Approach | Minimum EPC ($) | Minimum EEP (lb) | Mshts | ||||||

|---|---|---|---|---|---|---|---|---|---|

| EPC ($) | EEP (lb) | Time (s) | EPC ($) | EEP (lb) | Time (s) | EPC ($) | EEP (lb) | Time (s) | |

| MDE [3] | - | - | - | - | - | - | 44,435.68 | 20,622.43 | - |

| MODE [16] | 43,053.00 | 20,860.00 | - | 45,152.00 | 18,409.00 | - | 44,149.00 | 19,250.00 | - |

| LM-MODE [16] | 42,819.00 | 20,464.00 | - | 45,888.00 | 18,134.00 | - | 43,978.00 | 19,017.00 | 41.57 |

| CM-MODE [16] | 42,992.00 | 20,754.00 | - | 45,574.00 | 18,215.00 | - | 43,748.00 | 19,039.00 | 42.06 |

| TM-MODE [16] | 42,782.00 | 20,444.00 | - | 45,446.00 | 18,183.00 | - | 43,889.00 | 18,914.00 | 41.73 |

| MODE [17] | 43,249.00 | 19,794.00 | - | 45,922.00 | 17,782.00 | - | 44,434.00 | 18,654.00 | - |

| CB-MOHDE [17] | 42,722.00 | 19,816.00 | - | 45,797.00 | 17,601.00 | - | 43,894.00 | 18,384.00 | 34.30 |

| NSGA-II [18] | 43,489.00 | 18,332.00 | - | 47,251.00 | 17,054.00 | - | 44,847.00 | 17,415.00 | - |

| MOCA-PSO [18] | 42,656.00 | 18,125.00 | - | 47,956.00 | 16,881.00 | - | 44,627.00 | 17,364.00 | - |

| NSGA-II [19] | 43,489.00 | 18,332.00 | - | 47,251.00 | 17,054.00 | - | 44,643.00 | 17,457.00 | - |

| HMOCA [19] | 43,278.00 | 17,984.00 | - | 47,871.00 | 17,019.00 | - | 44,344.00 | 17,408.00 | - |

| MOABC [20] | 42,234.35 | 18,061.29 | - | 49,791.95 | 16,672.27 | - | 44,817.59 | 17,194.43 | - |

| NSGA-II [22] | 43,489.00 | 18,332.00 | - | 47,251.00 | 17,054.00 | - | 44,847.00 | 17,415.00 | - |

| HMOCA [22] | 43,278.00 | 17,984.00 | - | 47,871.00 | 17,019.00 | - | 45,026.00 | 17,306.00 | - |

| MOQPSO [22] | 43,032.00 | 17,960.00 | - | 48,350.00 | 16,803.00 | - | 44,852.00 | 17,280.00 | - |

| MODE [23] | 44,355.00 | 18,009.00 | - | 49,396.00 | 16,854.00 | - | 45,680.00 | 17,436.00 | - |

| PMODE [23] | 43,128.00 | 17,868.00 | - | 49,387.00 | 16,715.00 | - | 44,673.00 | 17,246.00 | - |

| HMOCA [30] | 43,278.00 | 17,984.00 | - | 47,871.00 | 17,019.00 | - | 45,026.00 | 17,306.00 | - |

| NSGA-II [30] | 43,489.00 | 18,332.00 | - | 47,251.00 | 17,054.00 | - | 44,847.00 | 17,415.00 | - |

| IMOGSA [30] | 42,914.00 | 18,041.00 | - | 47,276.00 | 16,950.00 | - | 44,492.37 | 17,354.44 | - |

| NSGA-II | - | - | - | - | - | - | 44,958.00 | 18,458.00 | 213.47 |

| MOPSO | - | - | - | - | - | - | 44,653.00 | 18,190.00 | 137.63 |

| GSA | 43,590.29 | 21,443.91 | 41.63 | 49,399.43 | 18,038.89 | 42.14 | - | - | - |

| OGSA | 43,178.95 | 20,299.15 | 36.45 | 49,641.62 | 17,434.50 | 35.61 | - | - | - |

| DGSA | 42,825.61 | 20,421.52 | 32.74 | 49,572.92 | 17,111.71 | 34.92 | - | - | - |

| DOGSA | 42,738.57 | 20,617.73 | 28.14 | 49,472.11 | 16,939.41 | 29.68 | - | - | - |

| NSGSA | - | - | - | - | - | - | 45,085.08 | 18,502.98 | 69.52 |

| NSOGSA | - | - | - | - | - | - | 44,942.17 | 18,320.67 | 73.31 |

| NSDGSA | - | - | - | - | - | - | 43,891.31 | 18,419.36 | 71.23 |

| NSDOGSA | - | - | - | - | - | - | 43,664.12 | 18,211.05 | 75.97 |

| Hour | Hydro Water Discharges (104 m3) | Hydropower Generation (MW) | Thermal Power Generation (MW) | Loss (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | ||

| 1 | 8.78 | 6.80 | 28.59 | 9.11 | 79.77 | 54.49 | 0.00 | 170.92 | 101.77 | 124.26 | 229.25 | 10.45 |

| 2 | 6.94 | 6.64 | 28.88 | 6.38 | 68.31 | 54.12 | 0.00 | 131.23 | 101.62 | 207.47 | 228.79 | 11.55 |

| 3 | 7.9 | 6.31 | 28.55 | 6.22 | 75.39 | 52.67 | 0.00 | 125.42 | 102.35 | 125.37 | 229.21 | 10.41 |

| 4 | 5.51 | 7.61 | 13.29 | 7.22 | 57.63 | 62.75 | 42.88 | 133.6 | 94.81 | 124.61 | 139.50 | 5.77 |

| 5 | 7.75 | 6.46 | 15.45 | 8.46 | 74.84 | 55.99 | 40.54 | 140.77 | 102.63 | 122.38 | 138.95 | 6.10 |

| 6 | 6.5 | 7.70 | 12.92 | 9.86 | 65.48 | 64.96 | 44.81 | 177.43 | 103.40 | 124.87 | 229.49 | 10.42 |

| 7 | 9.93 | 9.15 | 14.24 | 13.79 | 86.93 | 72.91 | 44.56 | 236.13 | 173.45 | 208.12 | 139.71 | 11.82 |

| 8 | 7.73 | 6.98 | 14.64 | 12.37 | 73.87 | 58.23 | 45.46 | 235.93 | 174.59 | 208.60 | 229.17 | 15.84 |

| 9 | 6.41 | 7.00 | 18.47 | 13.88 | 64.77 | 58.35 | 35.28 | 251.73 | 174.36 | 208.40 | 319.23 | 22.13 |

| 10 | 8.46 | 9.49 | 14.33 | 17.55 | 79.82 | 73.47 | 46.08 | 284.07 | 174.15 | 209.17 | 229.35 | 16.11 |

| 11 | 7.76 | 7.51 | 20.43 | 15.18 | 75.89 | 61.95 | 28.20 | 260.71 | 174.86 | 286.72 | 229.48 | 17.82 |

| 12 | 9.58 | 7.64 | 12.11 | 16.50 | 87.88 | 63.57 | 46.78 | 270.65 | 174.92 | 210.00 | 318.41 | 22.21 |

| 13 | 5.32 | 7.08 | 12.68 | 15.82 | 57.47 | 60.18 | 48.40 | 263.35 | 174.12 | 209.43 | 319.14 | 22.09 |

| 14 | 6.72 | 8.35 | 15.63 | 13.87 | 69.90 | 68.60 | 47.82 | 248.72 | 173.58 | 207.76 | 229.45 | 15.82 |

| 15 | 11.54 | 9.34 | 18.92 | 18.34 | 99.55 | 74.41 | 39.77 | 285.19 | 174.91 | 208.85 | 139.62 | 12.30 |

| 16 | 8.19 | 9.45 | 17.67 | 15.19 | 81.23 | 74.78 | 43.11 | 263.08 | 174.57 | 209.79 | 229.50 | 16.06 |

| 17 | 7.31 | 8.33 | 18.54 | 16.60 | 74.98 | 67.83 | 39.42 | 271.68 | 174.75 | 208.08 | 229.32 | 16.05 |

| 18 | 6.03 | 9.07 | 12.91 | 14.55 | 64.57 | 71.13 | 51.81 | 250.76 | 174.74 | 209.81 | 319.30 | 22.12 |

| 19 | 8.01 | 9.60 | 17.57 | 17.31 | 80.40 | 71.99 | 46.18 | 274.13 | 174.38 | 209.54 | 229.46 | 16.08 |

| 20 | 6.18 | 8.66 | 12.42 | 16.31 | 65.88 | 65.43 | 53.70 | 268.17 | 174.60 | 209.04 | 229.14 | 15.95 |

| 21 | 8.30 | 9.28 | 13.57 | 17.09 | 82.37 | 68.30 | 54.20 | 275.49 | 174.49 | 126.17 | 139.67 | 10.70 |

| 22 | 8.55 | 10.93 | 13.64 | 18.05 | 83.93 | 75.73 | 55.56 | 283.84 | 102.09 | 126.16 | 139.76 | 7.07 |

| 23 | 10.83 | 8.34 | 13.48 | 17.43 | 96.79 | 61.79 | 56.62 | 274.18 | 102.15 | 126.27 | 139.19 | 6.99 |

| 24 | 14.78 | 14.29 | 11.23 | 17.96 | 108.29 | 84.54 | 56.77 | 278.03 | 102.42 | 125.33 | 50.03 | 5.41 |

| EPC ($) 42,738.57 EEP (lb) 20,617.73 | ||||||||||||

| Hour | Water Discharges (104 m3) | Hydropower Generation (MW) | Thermal Power Generation (MW) | Transmission Loss (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | ||

| 1 | 7.58 | 6.25 | 29.96 | 7.27 | 72.39 | 50.74 | 0.00 | 148.55 | 166.45 | 191.46 | 130.95 | 10.53 |

| 2 | 8.19 | 6.44 | 29.57 | 6.87 | 77.00 | 53.12 | 0.00 | 139.35 | 164.36 | 212.41 | 145.06 | 11.3 |

| 3 | 7.88 | 6.14 | 29.41 | 6.81 | 75.27 | 51.92 | 0.00 | 134.32 | 141.91 | 182.08 | 123.00 | 8.51 |

| 4 | 6.85 | 6.43 | 16.26 | 7.01 | 68.19 | 55.54 | 35.85 | 131.73 | 131.06 | 110.36 | 124.00 | 6.74 |

| 5 | 6.18 | 6.32 | 16.42 | 6.27 | 63.08 | 56.15 | 35.47 | 115.28 | 137.77 | 157.25 | 112.39 | 7.39 |

| 6 | 6.43 | 6.63 | 14.72 | 10.16 | 65.00 | 59.18 | 39.77 | 185.21 | 149.52 | 179.69 | 130.75 | 9.12 |

| 7 | 8.29 | 6.27 | 16.66 | 14.03 | 78.07 | 56.83 | 36.15 | 243.11 | 174.43 | 223.20 | 150.77 | 12.56 |

| 8 | 10.34 | 6.81 | 17.36 | 14.3 | 88.78 | 60.44 | 33.48 | 259.82 | 174.41 | 237.33 | 169.45 | 13.71 |

| 9 | 8.79 | 6.96 | 15.56 | 16.3 | 80.55 | 61.54 | 37.48 | 279.18 | 174.39 | 276.89 | 195.80 | 15.84 |

| 10 | 8.24 | 9.77 | 15.22 | 14.22 | 77.60 | 78.57 | 38.38 | 260.94 | 174.79 | 262.68 | 202.84 | 15.8 |

| 11 | 10.15 | 8.00 | 16.34 | 16.56 | 88.8 | 68.34 | 36.66 | 281.89 | 174.49 | 266.26 | 199.38 | 15.83 |

| 12 | 8.95 | 9.23 | 15.58 | 17.44 | 83.11 | 75.85 | 38.67 | 288.80 | 174.90 | 286.80 | 219.26 | 17.39 |

| 13 | 11.68 | 8.27 | 15.69 | 16.86 | 95.95 | 69.82 | 39.10 | 284.32 | 174.42 | 267.01 | 195.06 | 15.67 |

| 14 | 9.76 | 8.49 | 17.47 | 14.67 | 87.57 | 70.97 | 37.45 | 264.41 | 174.50 | 237.65 | 171.28 | 13.83 |

| 15 | 8.06 | 8.49 | 16.79 | 15.51 | 78.27 | 71.21 | 40.50 | 272.44 | 174.80 | 236.68 | 149.10 | 12.99 |

| 16 | 8.55 | 8.51 | 13.39 | 17.17 | 82.00 | 71.59 | 49.04 | 286.76 | 174.54 | 241.56 | 168.39 | 13.88 |

| 17 | 9.76 | 9.88 | 16.03 | 14.60 | 89.22 | 78.67 | 47.39 | 263.58 | 174.92 | 241.71 | 168.33 | 13.82 |

| 18 | 9.44 | 10.84 | 15.84 | 18.47 | 87.36 | 81.45 | 48.62 | 295.72 | 174.75 | 276.75 | 170.23 | 14.87 |

| 19 | 8.99 | 11.19 | 15.36 | 18.01 | 84.47 | 79.90 | 50.52 | 291.55 | 174.38 | 240.60 | 162.24 | 13.67 |

| 20 | 8.10 | 11.52 | 15.43 | 18.54 | 78.54 | 78.41 | 51.58 | 294.03 | 174.72 | 227.72 | 158.26 | 13.27 |

| 21 | 6.43 | 7.67 | 13.64 | 17.24 | 66.09 | 57.21 | 54.93 | 279.69 | 173.19 | 181.43 | 108.01 | 10.55 |

| 22 | 5.29 | 10.12 | 13.23 | 18.69 | 56.74 | 71.11 | 57.03 | 288.48 | 146.49 | 147.43 | 100.98 | 8.26 |

| 23 | 6.07 | 11.47 | 15.29 | 18.86 | 63.71 | 75.92 | 57.28 | 286.60 | 136.60 | 144.78 | 92.65 | 7.54 |

| 24 | 5.00 | 10.29 | 15.14 | 20.00 | 54.72 | 68.64 | 58.26 | 289.54 | 126.98 | 125.33 | 83.14 | 6.62 |

| EPC ($) 49,472.11 EEP (lb) 16,939.41 | ||||||||||||

| Scheme Index | NSDOGSA | NSDGSA | NSOGSA | NSGSA | ||||

|---|---|---|---|---|---|---|---|---|

| EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | EPC ($) | EEP (lb) | |

| 1 | 43,570.08 | 18,270.29 | 43,816.72 | 18,500.01 | 44,697.82 | 18,455.36 | 44,578.08 | 18,715.46 |

| 2 | 43,584.03 | 18,254.88 | 43,822.06 | 18,468.71 | 44,727.58 | 18,438.35 | 44,582.70 | 18,711.37 |

| 3 | 43,594.84 | 18,248.13 | 43,859.69 | 18,440.95 | 44,763.7 | 18,424.36 | 44,590.81 | 18,703.52 |

| 4 | 43,601.49 | 18,243.94 | 43,872.52 | 18,428.78 | 44,773.88 | 18,415.21 | 44,635.47 | 18,685.50 |

| 5 | 43,614.08 | 18,240.17 | 43,884.56 | 18,426.01 | 44,783.26 | 18,408.02 | 44,652.56 | 18,679.12 |

| 6 | 43,630.18 | 18,230.82 | 43,884.83 | 18,424.13 | 44,797.29 | 18,404.00 | 44,690.48 | 18,667.34 |

| 7 | 43,646.56 | 18,224.12 | 43,891.31 | 18,419.36 | 44,800.26 | 18,390.26 | 44,710.03 | 18,659.53 |

| 8 | 43,654.43 | 18,217.42 | 43,906.46 | 18,417.44 | 44,837.87 | 18,371.36 | 44,733.37 | 18,648.93 |

| 9 | 43,664.12 | 18,211.05 | 43,911.22 | 18,414.28 | 44,858.87 | 18,359.31 | 44,744.73 | 18,642.28 |

| 10 | 43,677.60 | 18,206.40 | 43,912.25 | 18,410.02 | 44,867.97 | 18,357.54 | 45,085.08 | 18,502.98 |

| 11 | 43,694.22 | 18,201.37 | 43,928.05 | 18,403.01 | 44,873.94 | 18,347.25 | 45,098.55 | 18,498.36 |

| 12 | 43,722.34 | 18,187.66 | 43,957.77 | 18,392.01 | 44,903.54 | 18,342.53 | 45,117.49 | 18,491.32 |

| 13 | 43,732.99 | 18,185.34 | 44,057.74 | 18,357.99 | 44,931.15 | 18,328.18 | 45,131.72 | 18,485.27 |

| 14 | 43,830.42 | 18,150.56 | 44,077.13 | 18,355.48 | 44,942.17 | 18,320.67 | 45,167.70 | 18,484.80 |

| 15 | 43,870.55 | 18,136.63 | 44,088.09 | 18,351.00 | 44,953.95 | 18,318.36 | 45,190.99 | 18,467.46 |

| 16 | 43,883.72 | 18,135.89 | 44,132.21 | 18,341.47 | 44,980.61 | 18,310.85 | 45,212.60 | 18,464.32 |

| 17 | 43,884.10 | 18,134.97 | 44,139.95 | 18,338.58 | 45,016.21 | 18,305.82 | 45,216.08 | 18,460.96 |

| 18 | 43,901.07 | 18,129.38 | 44,159.20 | 18,335.46 | 45,032.58 | 18,301.31 | 45,253.05 | 18,448.54 |

| 19 | 43,969.55 | 18,106.21 | 44,164.92 | 18,328.03 | 45,043.33 | 18,293.21 | 45,263.07 | 18,444.63 |

| 20 | 43,980.60 | 18,101.12 | 44,197.01 | 18,321.55 | 45,325.12 | 18,276.06 | 45,318.81 | 18,427.51 |

| Hour | Water Discharges (104 m3) | Hydropower Generation (MW) | Thermal Power Generation (MW) | Transmission Loss (MW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Hydro 1 | Hydro 2 | Hydro 3 | Hydro 4 | Plant 1 | Plant 2 | Plant 3 | ||

| 1 | 10.6 | 6.36 | 29.85 | 8.31 | 88.6 | 51.49 | 0.00 | 161.43 | 106.29 | 209.99 | 139.94 | 7.74 |

| 2 | 8.75 | 6.10 | 29.8 | 7.25 | 79.39 | 50.66 | 0.00 | 143.22 | 165.96 | 211.9 | 140.11 | 11.24 |

| 3 | 6.89 | 6.75 | 29.84 | 6.81 | 67.57 | 56.21 | 0.00 | 132.89 | 106.71 | 124.91 | 221.86 | 10.15 |

| 4 | 7.03 | 6.14 | 13.81 | 6.38 | 68.87 | 53.26 | 41.70 | 122.32 | 105.07 | 125.28 | 139.71 | 6.20 |

| 5 | 7.98 | 6.73 | 17.42 | 7.89 | 75.18 | 58.94 | 34.79 | 134.43 | 101.74 | 131.40 | 139.71 | 6.20 |

| 6 | 8.70 | 7.53 | 15.91 | 8.94 | 78.91 | 64.82 | 38.56 | 168.90 | 107.54 | 209.20 | 139.75 | 7.68 |

| 7 | 9.32 | 8.19 | 13.56 | 14.52 | 81.64 | 68.64 | 43.39 | 246.48 | 173.56 | 208.75 | 139.39 | 11.85 |

| 8 | 7.41 | 6.48 | 16.53 | 13.55 | 69.97 | 56.41 | 39.16 | 251.63 | 174.73 | 209.77 | 223.99 | 15.66 |

| 9 | 6.26 | 7.15 | 15.41 | 14.72 | 62.26 | 61.21 | 42.21 | 262.97 | 174.05 | 282.59 | 221.85 | 17.13 |

| 10 | 10.35 | 9.45 | 13.96 | 15.13 | 87.94 | 75.12 | 45.45 | 269.07 | 174.78 | 215.19 | 228.64 | 16.19 |

| 11 | 6.95 | 7.86 | 16.67 | 13.58 | 68.50 | 65.92 | 41.12 | 255.18 | 174.01 | 284.65 | 228.14 | 17.52 |

| 12 | 8.99 | 8.18 | 13.26 | 16.92 | 82.95 | 68.5 | 46.03 | 284.72 | 174.07 | 282.63 | 228.77 | 17.67 |

| 13 | 8.02 | 7.66 | 16.87 | 15.00 | 77.30 | 65.22 | 41.81 | 268.21 | 174.02 | 274.12 | 226.58 | 17.25 |

| 14 | 7.26 | 7.15 | 19.86 | 15.24 | 72.73 | 62.15 | 32.13 | 270.77 | 173.83 | 209.85 | 224.29 | 15.75 |

| 15 | 10.86 | 8.34 | 13.61 | 16.41 | 94.61 | 70.50 | 48.99 | 279.51 | 174.74 | 212.57 | 141.40 | 12.33 |

| 16 | 6.57 | 8.87 | 16.70 | 16.71 | 68.25 | 73.92 | 45.55 | 282.17 | 173.77 | 209.15 | 222.86 | 15.68 |

| 17 | 8.12 | 7.66 | 14.80 | 15.02 | 80.14 | 66.27 | 49.48 | 264.74 | 174.46 | 289.12 | 139.57 | 13.78 |

| 18 | 9.53 | 12.24 | 15.47 | 18.73 | 88.95 | 88.33 | 50.03 | 295.34 | 174.50 | 209.91 | 229.22 | 16.28 |

| 19 | 9.55 | 10.03 | 13.78 | 18.96 | 88.83 | 75.40 | 52.60 | 297.96 | 174.79 | 211.99 | 182.41 | 13.98 |

| 20 | 6.70 | 9.01 | 12.83 | 16.50 | 69.36 | 68.37 | 54.16 | 274.95 | 173.50 | 287.19 | 136.04 | 13.56 |

| 21 | 6.38 | 9.96 | 12.29 | 17.80 | 66.69 | 72.48 | 55.42 | 284.88 | 174.49 | 126.95 | 139.83 | 10.74 |

| 22 | 5.99 | 8.63 | 16.94 | 14.91 | 63.57 | 65.09 | 53.41 | 259.01 | 101.14 | 198.66 | 126.30 | 7.18 |

| 23 | 8.96 | 11.32 | 16.97 | 17.48 | 85.27 | 77.96 | 53.80 | 280.20 | 102.33 | 127.05 | 130.15 | 6.77 |

| 24 | 7.83 | 14.24 | 12.17 | 20.00 | 77.98 | 84.39 | 58.04 | 292.40 | 103.93 | 120.55 | 68.27 | 5.56 |

| EPC ($) 43,664.12 EEP (lb) 18,211.05 | ||||||||||||

| Technique | Scheduling Problem | Superlative Value | Middling Value | Wickedest Value | Standard Deviation |

|---|---|---|---|---|---|

| GSA | Optimization of EPC ($) | 42,032.35 | 42,292.38 | 42,561.94 | 9.43 |

| Optimization of EEP (lb) | 16,523.80 | 16,534.76 | 16,683.23 | 4.53 | |

| OGSA | Optimization of EPC ($) | 41,844.69 | 42,051.67 | 42,395.45 | 5.94 |

| Optimization of EEP (lb) | 16,482.66 | 16,495.34 | 16,509.23 | 3.85 | |

| DGSA | Optimization of EPC ($) | 41,751.15 | 41,821.65 | 41,989.78 | 8.54 |

| Optimization of EEP (lb) | 16,403.20 | 16,439.34 | 16,489.23 | 2.85 | |

| DOGSA | Optimization of EPC ($) | 40,865.79 | 40,978.56 | 41,219.57 | 3.02 |

| Optimization of EEP (lb) | 15,984.44 | 16,039.30 | 16,187.45 | 1.24 | |

| NSGSA | MSHTS | 0.055593 | 0.052142 | 0.047392 | 0.00476 |

| NSOGSA | 0.058393 | 0.056843 | 0.048684 | 0.00352 | |

| NSDGSA | 0.053160 | 0.050326 | 0.048051 | 0.00263 | |

| NSDOGSA | 0.054031 | 0.051594 | 0.049493 | 0.00207 |

| Technique | Scheduling Problem | Superlative Value | Middling Value | Wickedest Value | Standard Deviation |

|---|---|---|---|---|---|

| GSA | Optimization of EPC ($) | 43,590.29 | 43,658.23 | 43,833.42 | 7.49 |

| Optimization of EEP (lb) | 18,038.89 | 18,295.34 | 18,639.60 | 8.23 | |

| OGSA | Optimization of EPC ($) | 43,178.95 | 43,385.02 | 43,730.95 | 4.16 |

| Optimization of EEP (lb) | 17,434.50 | 17,623.52 | 18,049.28 | 5.27 | |

| DGSA | Optimization of EPC ($) | 42,825.61 | 43,101.79 | 43,503.07 | 3.75 |

| Optimization of EEP (lb) | 17,111.71 | 17,293.34 | 17,693.42 | 4.28 | |

| DOGSA | Optimization of EPC ($) | 42,738.57 | 42,846.09 | 42,965.95 | 2.07 |

| Optimization of EEP (lb) | 16,939.41 | 17,023.52 | 17,124.53 | 2.18 | |

| NSGSA | MSHTS | 0.051433 | 0.050532 | 0.046230 | 0.01359 |

| NSOGSA | 0.055553 | 0.052394 | 0.048304 | 0.00934 | |

| NSDGSA | 0.054226 | 0.051053 | 0.047597 | 0.00862 | |

| NSDOGSA | 0.052525 | 0.050906 | 0.049394 | 0.00673 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nadakuditi, G.; Pulluri, H.; Dahiya, P.; Murthy, K.S.R.; Varma, P.S.; Bajaj, M.; Altameem, T.; El-Shafai, W.; Fouda, M.M. Non-Dominated Sorting-Based Hybrid Optimization Technique for Multi-Objective Hydrothermal Scheduling. Energies 2023, 16, 2316. https://doi.org/10.3390/en16052316

Nadakuditi G, Pulluri H, Dahiya P, Murthy KSR, Varma PS, Bajaj M, Altameem T, El-Shafai W, Fouda MM. Non-Dominated Sorting-Based Hybrid Optimization Technique for Multi-Objective Hydrothermal Scheduling. Energies. 2023; 16(5):2316. https://doi.org/10.3390/en16052316

Chicago/Turabian StyleNadakuditi, Gouthamkumar, Harish Pulluri, Preeti Dahiya, K. S. R. Murthy, P. Srinivasa Varma, Mohit Bajaj, Torki Altameem, Walid El-Shafai, and Mostafa M. Fouda. 2023. "Non-Dominated Sorting-Based Hybrid Optimization Technique for Multi-Objective Hydrothermal Scheduling" Energies 16, no. 5: 2316. https://doi.org/10.3390/en16052316

APA StyleNadakuditi, G., Pulluri, H., Dahiya, P., Murthy, K. S. R., Varma, P. S., Bajaj, M., Altameem, T., El-Shafai, W., & Fouda, M. M. (2023). Non-Dominated Sorting-Based Hybrid Optimization Technique for Multi-Objective Hydrothermal Scheduling. Energies, 16(5), 2316. https://doi.org/10.3390/en16052316