The Design of a Large-Scale Induction Heating Power Source for Organic Waste Digesters to Produce Fertilizer

Abstract

1. Introduction

2. Materials and Methods

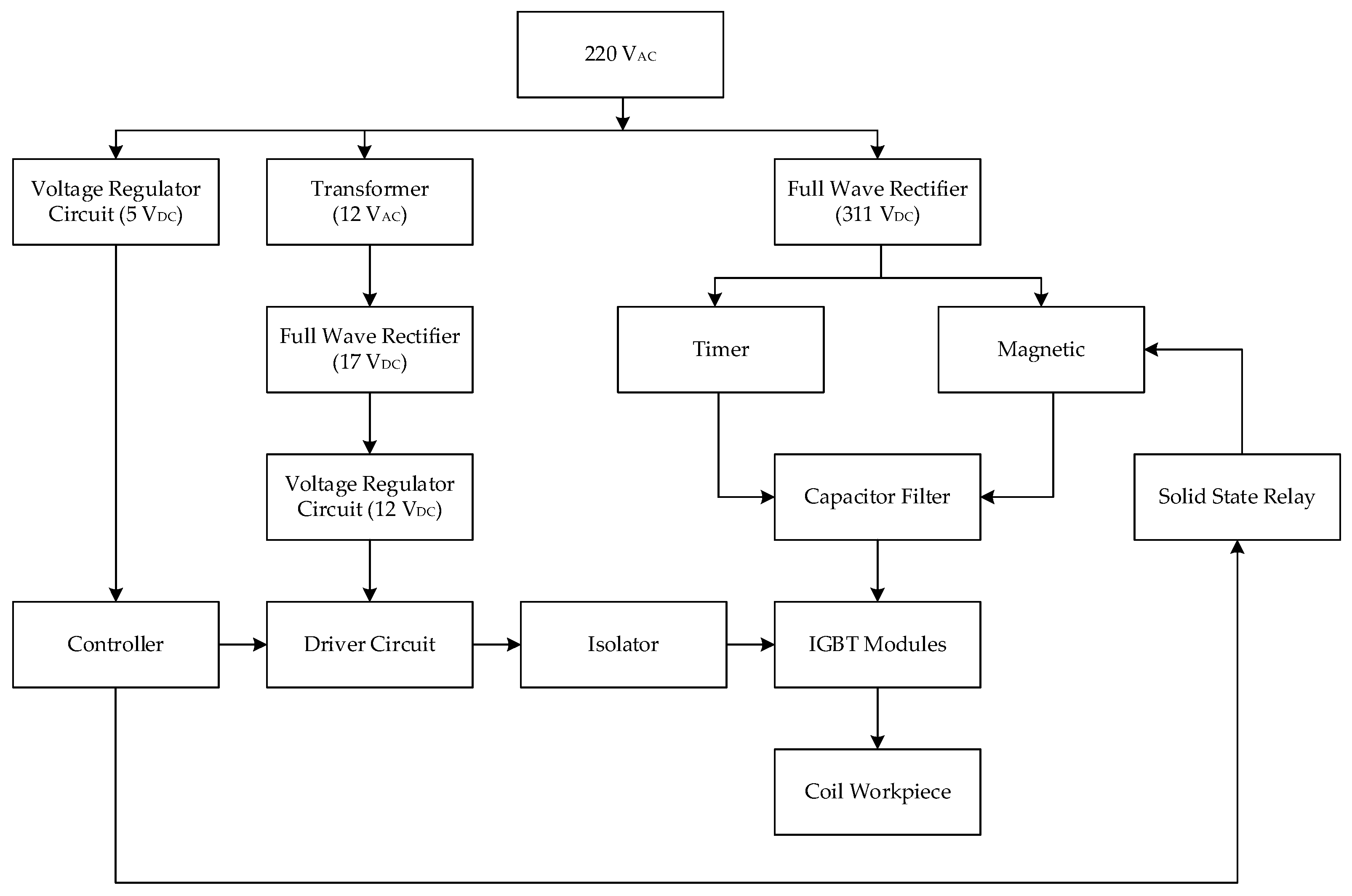

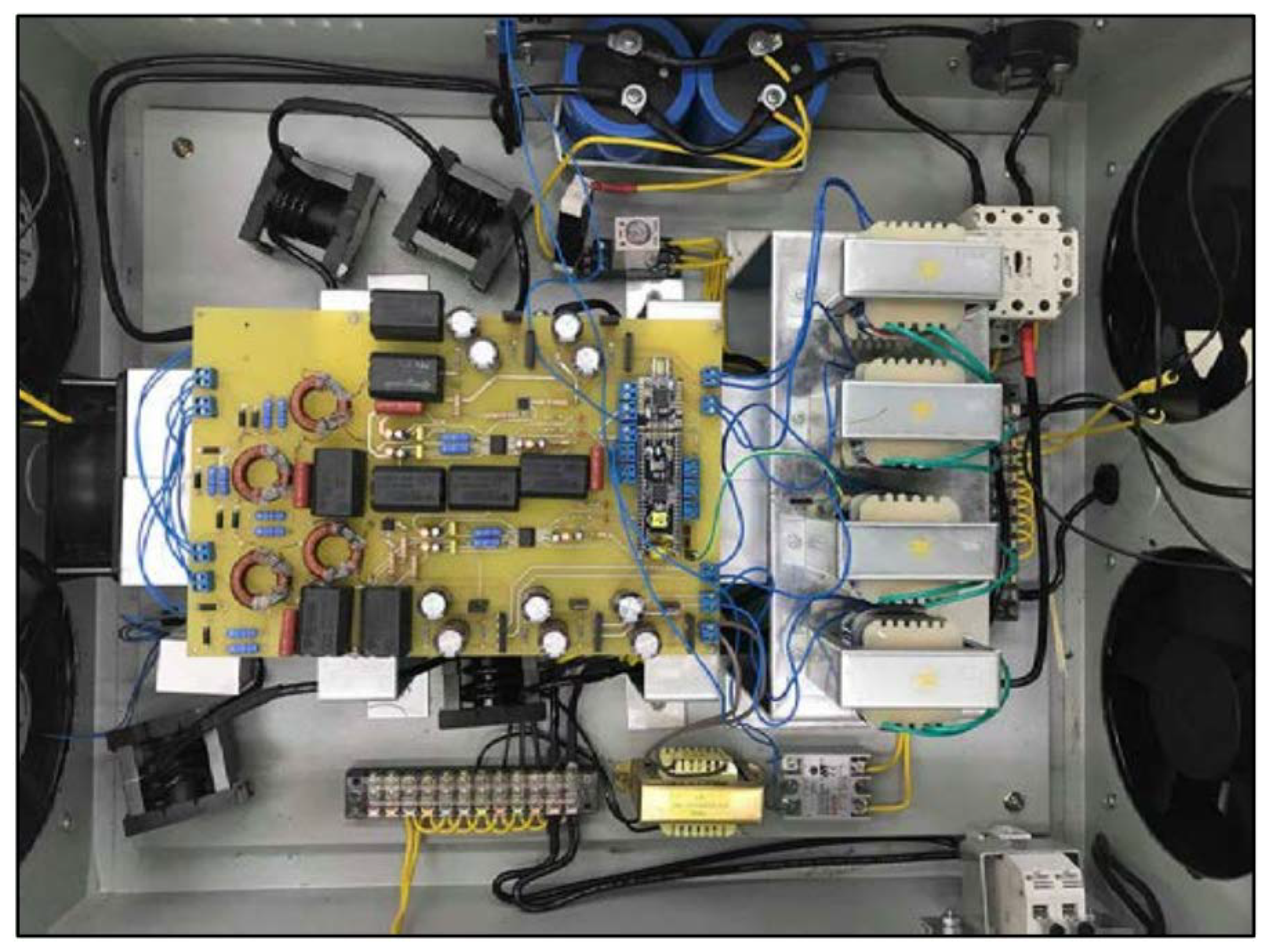

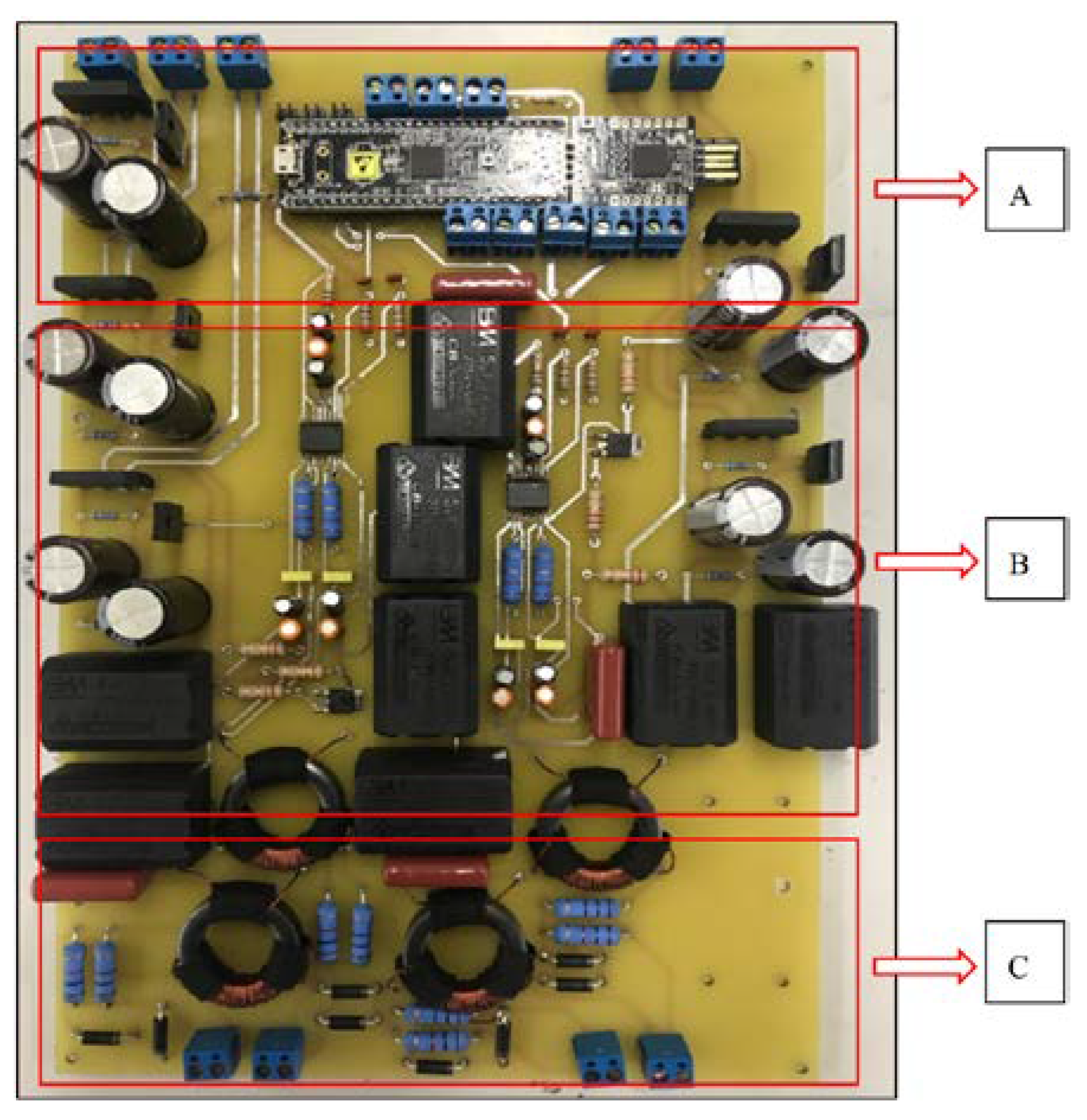

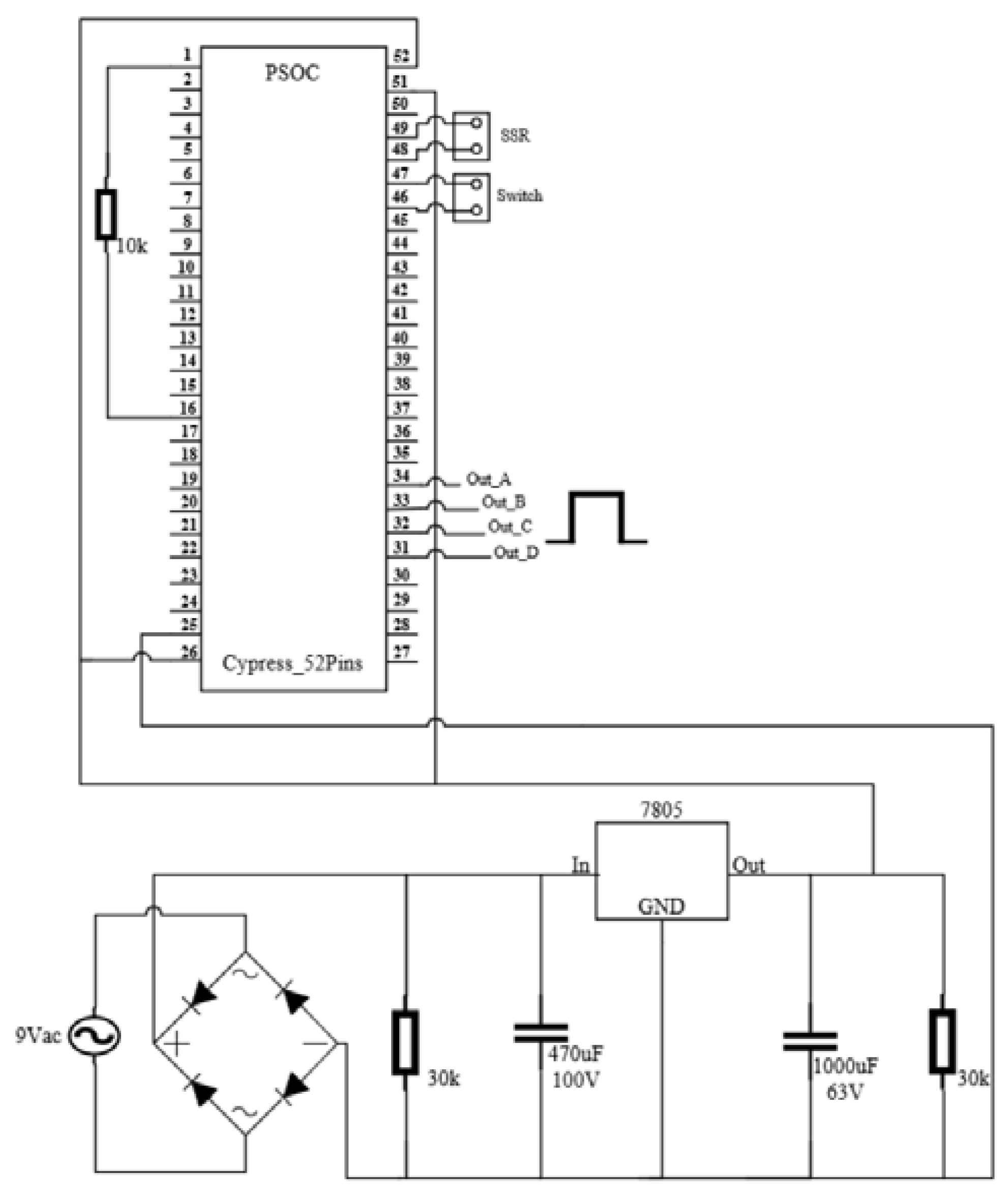

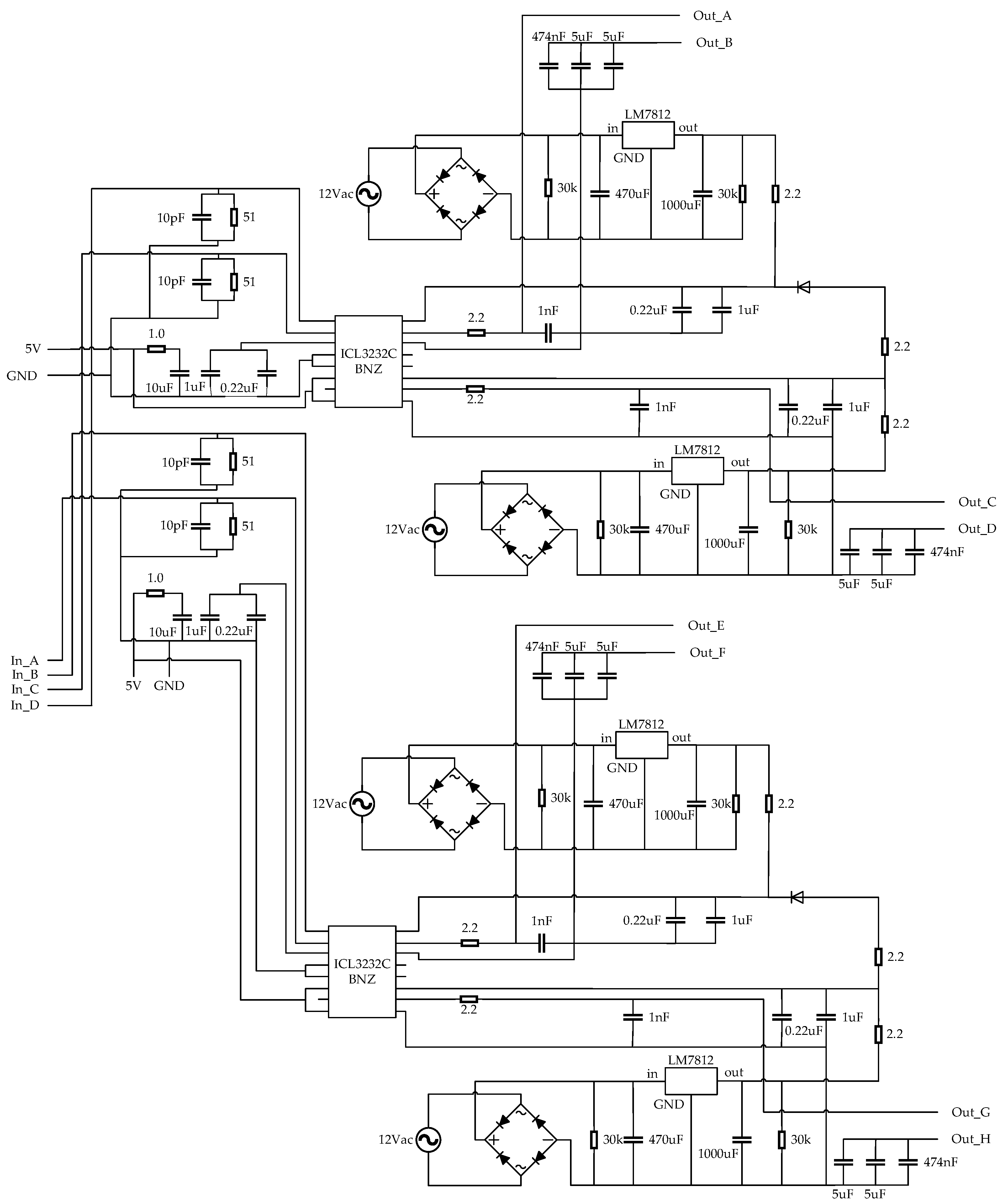

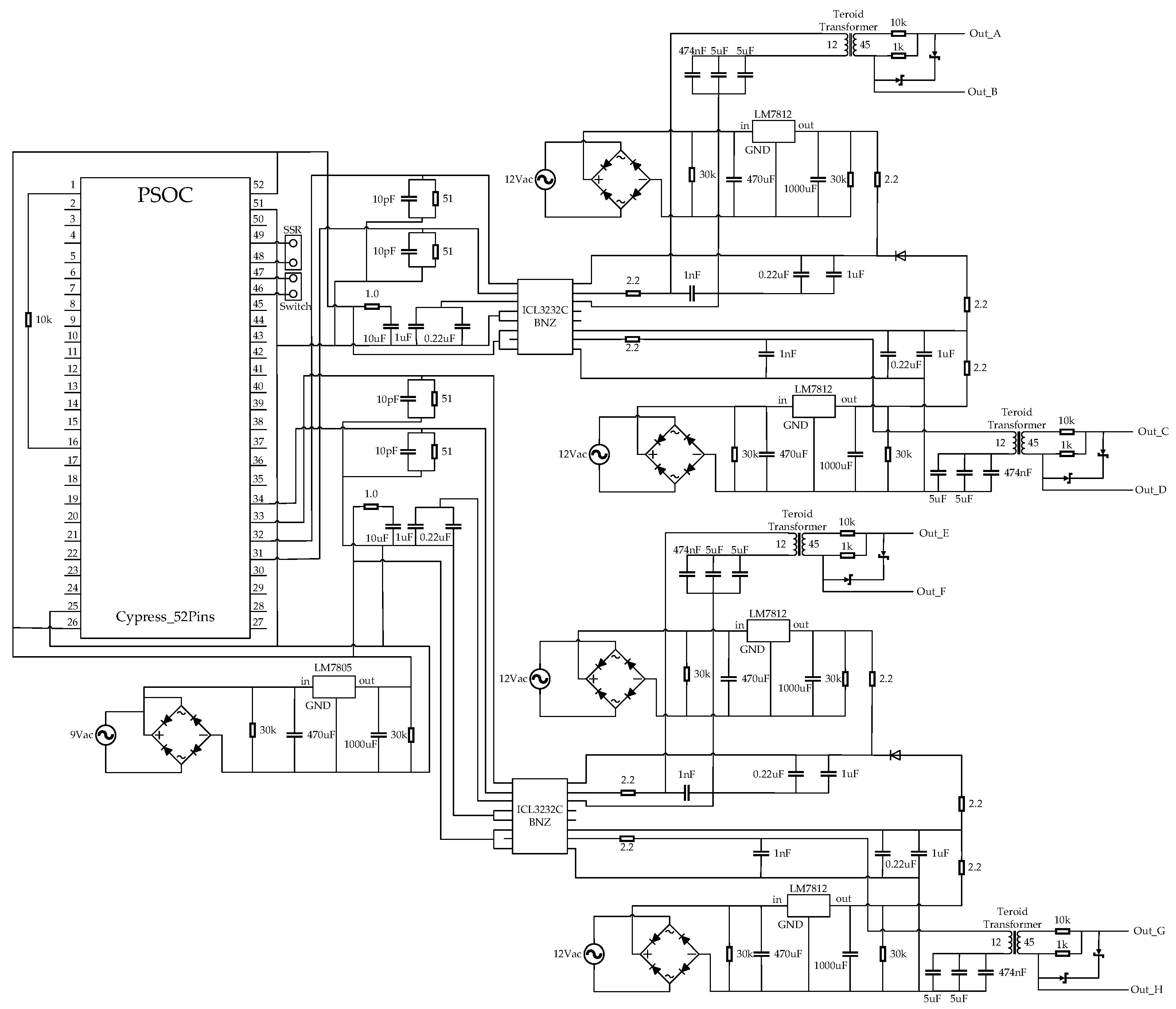

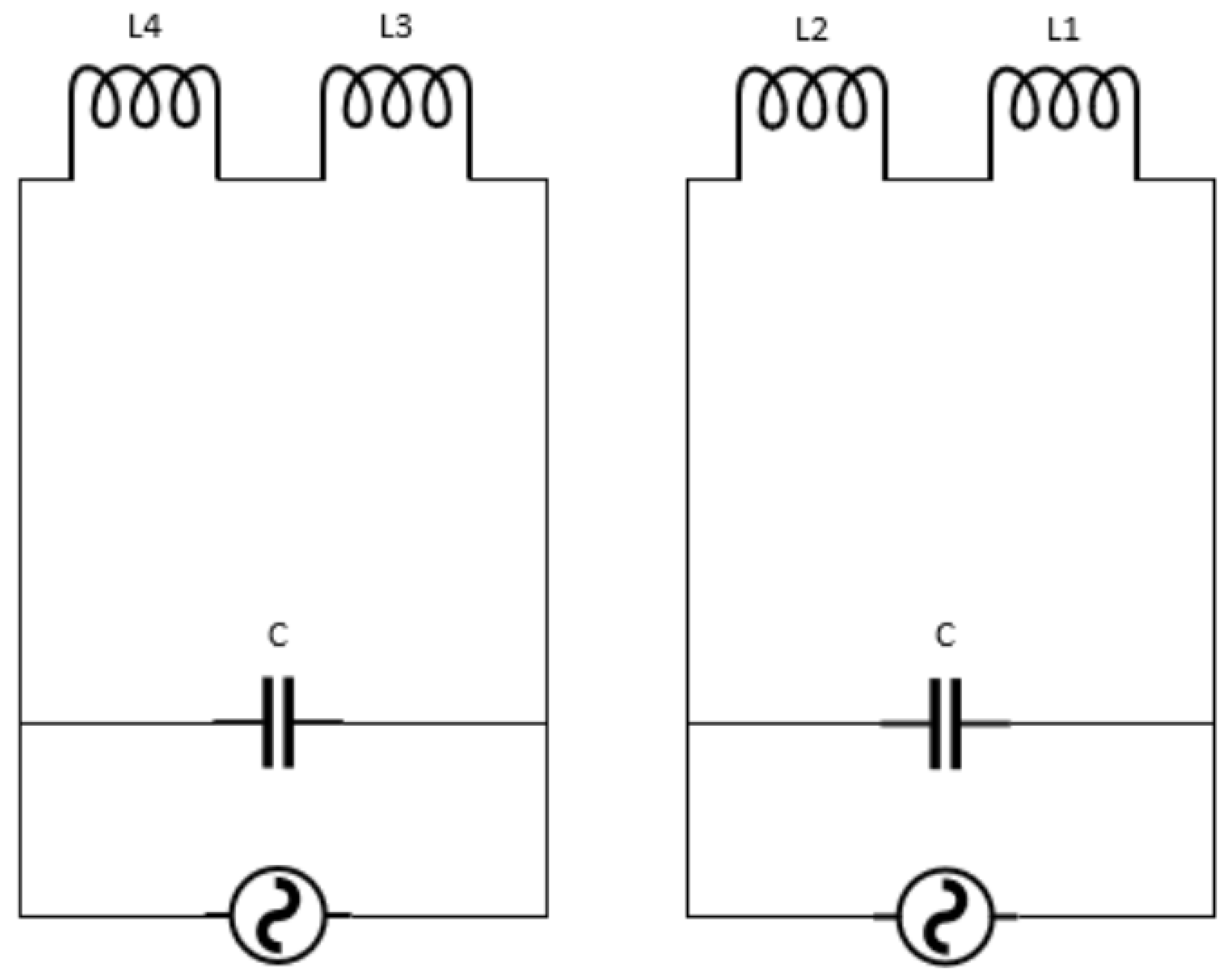

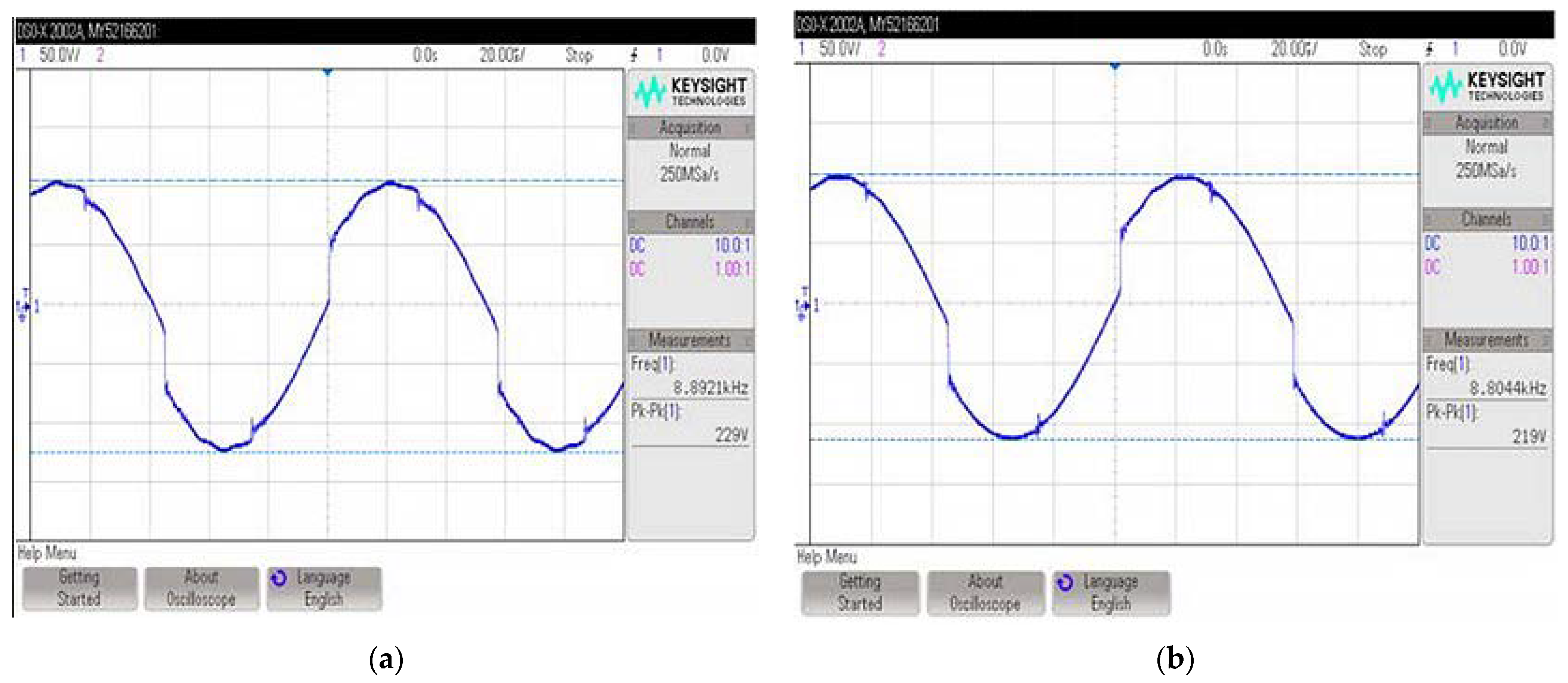

2.1. Thermal Induction Circuit Design

2.2. Temperature Analysis against Moisture and Thermal Energy of Organic Waste

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chiew, Y.L.; Spångberg, J.; Baky, A.; Hansson, P.-A.; Jönsson, H. Environmental impact of recycling digested food waste as a fertilizer in agriculture—A case study. Resour. Conserv. Recycl. 2015, 95, 1–14. [Google Scholar] [CrossRef]

- Palmiotto, M.; Fattore, E.; Paiano, V.; Celeste, G.; Colombo, A.; Davoli, E. Influence of a municipal solid waste landfill in the surrounding environment: Toxicological risk and odor nuisance effects. Environ. Int. 2014, 68, 16–24. [Google Scholar] [CrossRef]

- Frederickson, J.; Butt, K.R.; Morris, R.M.; Daniel, C. Combining vermiculture with traditional green waste composting systems. Soil Biol. Biochem. 1997, 29, 725–730. [Google Scholar] [CrossRef]

- Jiang, Y.; Ju, M.; Li, W.; Ren, Q.; Liu, L.; Chen, Y.; Yang, Q.; Hou, Q.; Liu, Y. Rapid production of organic fertilizer by dynamic high-temperature aerobic fermentation (DHAF) of food waste. Bioresour. Technol. 2015, 197, 7–14. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, F.; Liang, S.; Wang, Z.; Liu, Z.; Xiong, Y. Utilization of solar energy in sewage sludge composting: Fertilizer effect and application. Waste Manag. 2014, 34, 2014–2021. [Google Scholar] [CrossRef]

- Hou, J.; Li, M.; Xi, B.; Tan, W.; Ding, J.; Hao, Y.; Liu, D.; Liu, H. Short-duration hydrothermal fermentation of food waste: Preparation of soil conditioner for amending organic-matter-impoverished arable soils. Environ. Sci. Pollut. Res. 2017, 24, 21283–21297. [Google Scholar] [CrossRef]

- Matej, K.; Anze, Z.; Damijan, M.; Tomaz, J. Numerical analysis and thermographic investigation of induction heating. Int. J. Heat Mass Transf. 2010, 53, 3585–3591. [Google Scholar] [CrossRef]

- Lenka, J.; Andrej, G.; Peter, K.; Milan, S. Optimization of the Induction Heating Process in Order to Achieve Uniform Surface Temperature. Procedia Eng. 2016, 136, 125–131. [Google Scholar] [CrossRef]

- Wu, S.; Xu, X.; Yang, N.; Jin, Y.; Jin, Z.; Xie, Z. Non-Conventional Induction Heat Treatment: Effect of Design and Electrical Parameters on Apple Juice Safety and Quality. Foods 2022, 11, 3937. [Google Scholar] [CrossRef]

- Jeerasak, W.; Jirasak, S.; Wanchai, S. Innovative of induction heating. J. Humanit. Soc. Sci. Thonburi Univ. 2014, 8. Available online: https://so03.tci-thaijo.org/index.php/trujournal/article/view/56692 (accessed on 18 February 2023).

- Elepaño, A.R.; Satairapan, K.T.; Darmian, C.E. Chapter 472—Development of a Rice Hull Cyclonic Furnace for Drying Applications. In World Renewable Energy Congress VI; Sayigh, A.A.M., Ed.; Pergamon: Oxford, UK, 2000; pp. 2190–2193. [Google Scholar] [CrossRef]

- Karunanithy, C.; Shafer, K. Heat transfer characteristics and cooking efficiency of different sauce pans on various cooktops. Appl. Therm. Eng. 2016, 93, 1202–1215. [Google Scholar] [CrossRef]

- Energy in buildings. Available online: https://www.open.edu/openlearn/nature-environment/energy-buildings/content-section-0?active-tab=description-tab (accessed on 24 August 2015).

- Ye, Q.; Zeng, J.; Li, Y.; TYuan, P.; Wang, F. Heat Integration for Phenols and Ammonia Recovery Process of Coal Gasification Wastewater Considering Optimization of Process Parameters. Energies 2022, 15, 9258. [Google Scholar] [CrossRef]

- Tudbury, C.A. Electric and magnetic conditions inside an induction-heated workpiece. Trans. Am. Inst. Electr. Eng. Part II: Appl. Ind. 1959, 78, 79–83. [Google Scholar] [CrossRef]

- Watanabe, T.; Nagaya, S.; Hirano, N.; Fukuri, S. Elemental Development of Metal Melting by Electromagnetic Induction Heating Using Superconductor Coils. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Han, Y.; Wen, H.; Yu, E. Study on electromagnetic heating process of heavy-duty sprockets with circular coils and profile coils. Appl. Therm. Eng. 2016, 100, 861–868. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, L.; Mu, L.; Zhu, K.; Li, A. Thermally assisted bio-drying of food waste: Synergistic enhancement and energetic evaluation. Waste Manag. 2018, 80, 327–338. [Google Scholar] [CrossRef]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 86, 131–137. [Google Scholar] [CrossRef]

- Sarkar, S.; Pal, S.; Chanda, S. Optimization of a Vegetable Waste Composting Process with a Significant Thermophilic Phase. Procedia Environ. Sci. 2016, 35, 435–440. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, D.-H.; Yun, Y.-M. Effect of operation temperature on anaerobic digestion of food waste: Performance and microbial analysis. Fuel 2017, 209, 598–605. [Google Scholar] [CrossRef]

- Raut, M.P.; Prince Williams, S.P.M.; Bharttacharyya, J.K.; Chakrabarti, T.; Devotta, S. Microbial dynamics and enzyme activities during rapid composting of municipal solid waste—A compost maturity analysis perspective. Bioresour. Technol. 2008, 99, 6512–6519. [Google Scholar] [CrossRef]

- Nair, J.; Okamitsu, K. Microbial inoculants for small scale composting of putrescible kitchen wastes. Waste Manag. 2010, 30, 977–982. [Google Scholar] [CrossRef]

- Chang, J.I.; Hsu, T.-E. Effects of compositions on food waste composting. Bioresour. Technol. 2008, 99, 8068–8074. [Google Scholar] [CrossRef]

- Sin, S.-J.; Zahed, I. Ampere’s law and energy loss in AdS/CFT duality. Phys. Lett. B 2007, 648, 318–322. [Google Scholar] [CrossRef]

- Nian, S.-C.; Huang, M.-S.; Tsai, T.-H. Enhancement of induction heating efficiency on injection mold surface using a novel magnetic shielding method. Int. Commun. Heat Mass Transf. 2014, 50, 52–60. [Google Scholar] [CrossRef]

- Vonsovskii, S.V. Ferromagnetic Resonance, 1st ed.; Pergamon Press: New York, NY, USA, 1966. [Google Scholar]

- Nian, S.-C.; Tsai, S.-W.; Huang, M.-S.; Huang, R.-C.; Chen, C.-H. Key parameters and optimal design of a single-layered induction coil for external rapid mold surface heating. Int. Commun. Heat Mass Transf. 2014, 57, 109–117. [Google Scholar] [CrossRef]

- Li, Z.-F.; Hu, J.-C.; Huang, M.-S.; Lin, Y.-L.; Lin, C.-W.; Meng, Y.-M. Load Estimation for Induction Heating Cookers Based on Series RLC Natural Resonant Current. Energies 2022, 15, 1294. [Google Scholar] [CrossRef]

- Leelachariyakul, B.; Yutthagowith, P. Accurate Circuit Parameter Determination of a Resonant Power Frequency Converter for High-Voltage and Partial Discharge Tests. Energies 2022, 15, 5497. [Google Scholar] [CrossRef]

- Gwóźdź, M. The Application of Tuned Inductors in Electric Power Systems. Energies 2022, 15, 8481. [Google Scholar] [CrossRef]

- Cha, K.-H.; Ju, C.-T.; Kim, R.-Y. Analysis and Evaluation of WBG Power Device in High Frequency Induction Heating Application. Energies 2020, 13, 5351. [Google Scholar] [CrossRef]

| Induction Heating | Inductor (µH) | Resistor (Ω) | Frequency (kHz) | The Current the Load Pulls When the Voltage Value Increases (A) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 30 | 150 | 250 | 310 | 320 | 340 | ||||

| 1 | 160 | 3.9 | 8.569 | 4.36 | 14.96 | 25.78 | 34.80 | 36.38 | 39.62 |

| 2 | 195 | 3.6 | 8.965 | 4.42 | 15.20 | 25.82 | 34.22 | 35.42 | 38.66 |

| 3 | 190 | 3.4 | 8.906 | 4.24 | 15.30 | 25.98 | 34.10 | 35.64 | 38.66 |

| 4 | 197.6 | 3.5 | 8.645 | 4.24 | 15.26 | 26.26 | 34.90 | 36.32 | 39.46 |

| Heating Time (Minutes) | The Loaded Current Required (A) | Coil Temperature (°C) | Temperature Inside the Tank at the Coil Area (°C) |

|---|---|---|---|

| 5 | 32 | 37 | 70 |

| 15 | 27 | 60 | 92 |

| 30 | 25 | 65 | 115 |

| 45 | 23 | 68 | 125 |

| 60 | 22 | 75 | 147 |

| 90 | 22 | 75 | 150 |

| Induction Heating | Inductor (µH) | Resistor (Ω) | Frequency (kHz) | The Current the Load Pulls When the Voltage Value Increases (A) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 30 | 150 | 250 | 310 | 320 | 340 | ||||

| 1 | 207.4 | 3.672 | 8.892 | 4.64 | 13.16 | 20.92 | 33.84 | 34.18 | 36.52 |

| 2 | 218.8 | 3.549 | 8.804 | 4.82 | 16.24 | 28.38 | 35.32 | 37.98 | 39.52 |

| Heating Time (Minutes) | The Loaded Current Pulls to Use (A) | Coil Temperature (°C) | Temperature Inside the Tank at the Coil Area (°C) |

|---|---|---|---|

| 5 | 35 | 37 | 60 |

| 15 | 27 | 65 | 82 |

| 30 | 25 | 80 | 95 |

| 45 | 24 | 85 | 115 |

| 60 | 24 | 95 | 126 |

| 90 | 24 | 95 | 128 |

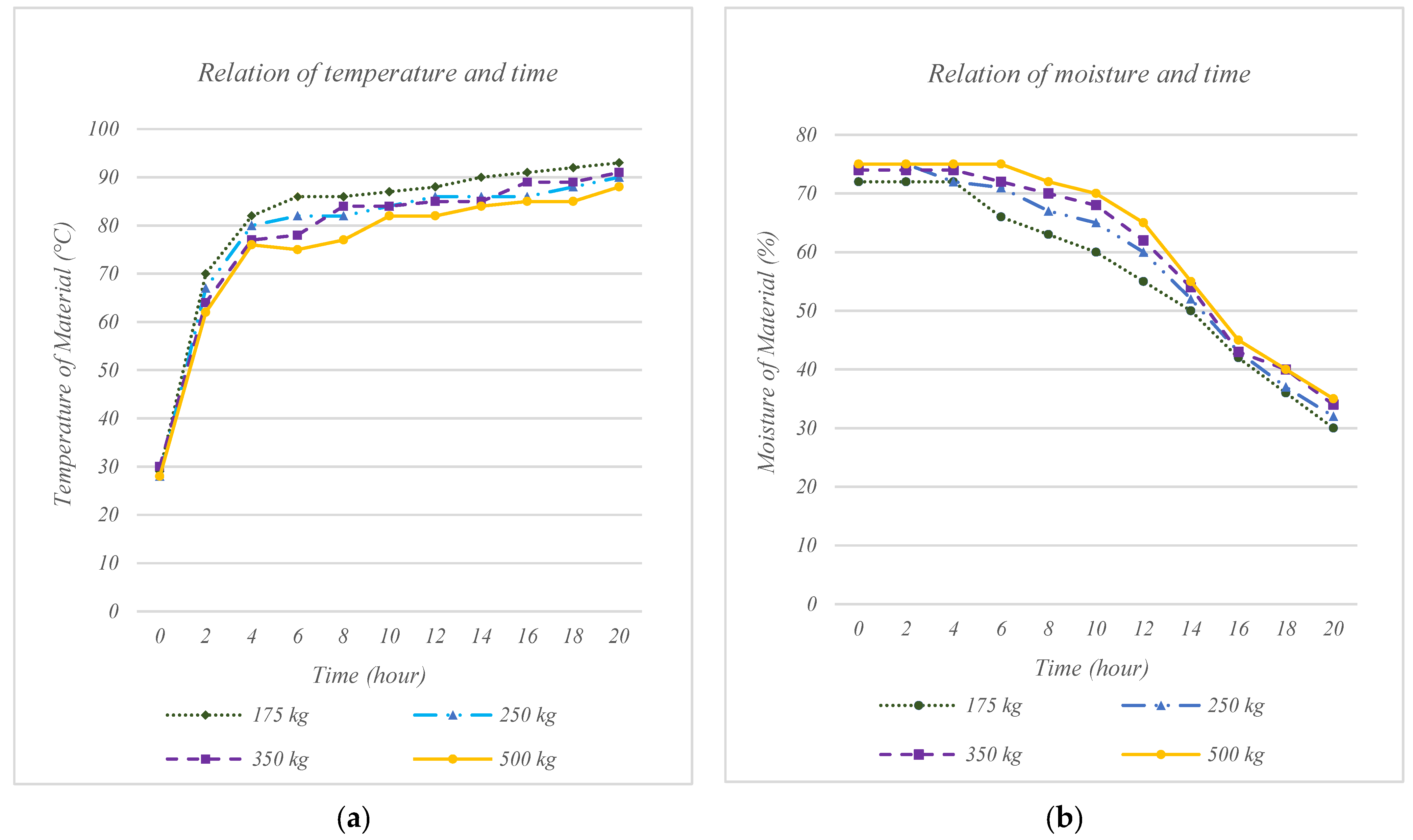

| Starting Weight (kg) | Parameter | Test Time | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | Average | ||

| 175 | Temperature (°C) | 92 | 93 | 92 | 91 | 92 | 92 |

| Moisture (%) | 30 | 28 | 30 | 32 | 30 | 30 | |

| Weight (kg) | 75 | 72 | 73 | 76 | 74 | 74 | |

| 250 | Temperature (°C) | 89 | 88 | 90 | 90 | 89 | 89 |

| Moisture (%) | 32 | 34 | 31 | 31 | 32 | 32 | |

| Weight (kg) | 116 | 118 | 113 | 112 | 114 | 115 | |

| 350 | Temperature (°C) | 90 | 90 | 93 | 92 | 90 | 91 |

| Moisture (%) | 34 | 35 | 32 | 33 | 36 | 34 | |

| Weight (kg) | 163 | 163 | 160 | 162 | 164 | 162 | |

| 500 | Temperature (°C) | 88 | 86 | 87 | 85 | 89 | 87 |

| Moisture (%) | 33 | 36 | 35 | 38 | 33 | 35 | |

| Weight (kg) | 227 | 232 | 229 | 233 | 227 | 230 | |

| Types of Heating | Heating Efficiency (%) | Advantages/Disadvantages |

|---|---|---|

| Induction heating | >80 | Highest efficiency and uses electricity to heat, which is easy to source, and cheap. |

| Biomass furnaces | 70 | High efficiency, but the materials used, such as rice husks or corn husks, are rare and expensive. |

| Tungsten coil | 51.8 | Uses the same amount of electricity as induction heating. However, the heating efficiency is lower, and the cost of tungsten coils is relatively high. |

| Gas | 50 | The heating efficiency is not high, and the cost is expensive. |

| Coal | 32 | Easy to find but difficult to control the quantity. It also has the lowest heating efficiency. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thosdeekoraphat, T.; Tanthai, K.; Lhathum, K.; Kotchapradit, S.; Santalunai, S.; Thongsopa, C. The Design of a Large-Scale Induction Heating Power Source for Organic Waste Digesters to Produce Fertilizer. Energies 2023, 16, 2123. https://doi.org/10.3390/en16052123

Thosdeekoraphat T, Tanthai K, Lhathum K, Kotchapradit S, Santalunai S, Thongsopa C. The Design of a Large-Scale Induction Heating Power Source for Organic Waste Digesters to Produce Fertilizer. Energies. 2023; 16(5):2123. https://doi.org/10.3390/en16052123

Chicago/Turabian StyleThosdeekoraphat, Thanaset, Kittisak Tanthai, Kachaporn Lhathum, Supawat Kotchapradit, Samran Santalunai, and Chanchai Thongsopa. 2023. "The Design of a Large-Scale Induction Heating Power Source for Organic Waste Digesters to Produce Fertilizer" Energies 16, no. 5: 2123. https://doi.org/10.3390/en16052123

APA StyleThosdeekoraphat, T., Tanthai, K., Lhathum, K., Kotchapradit, S., Santalunai, S., & Thongsopa, C. (2023). The Design of a Large-Scale Induction Heating Power Source for Organic Waste Digesters to Produce Fertilizer. Energies, 16(5), 2123. https://doi.org/10.3390/en16052123