Performance Evaluation of a Linear CPV/T System in Different Working Conditions

Abstract

1. Introduction

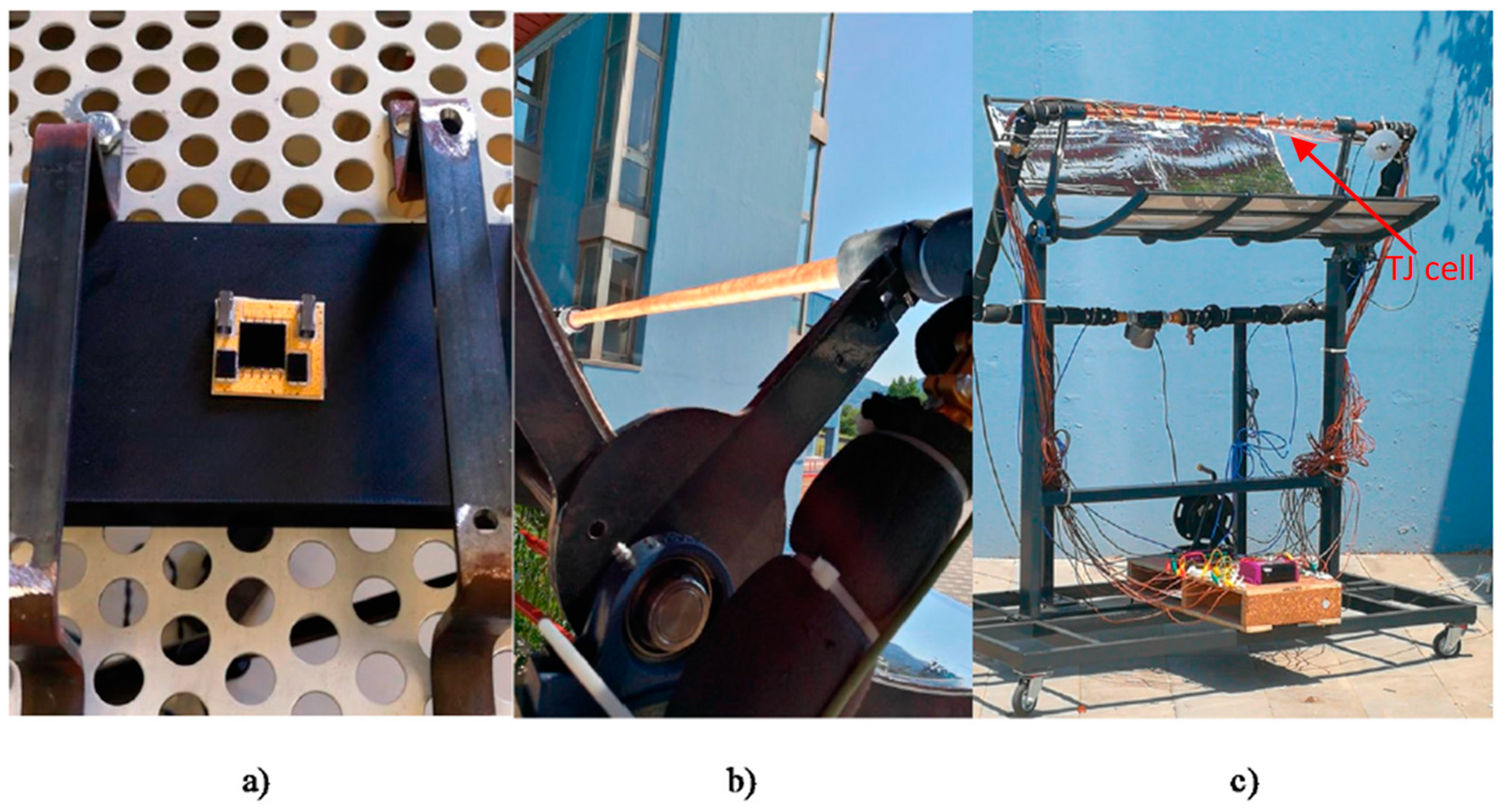

2. Experimental System

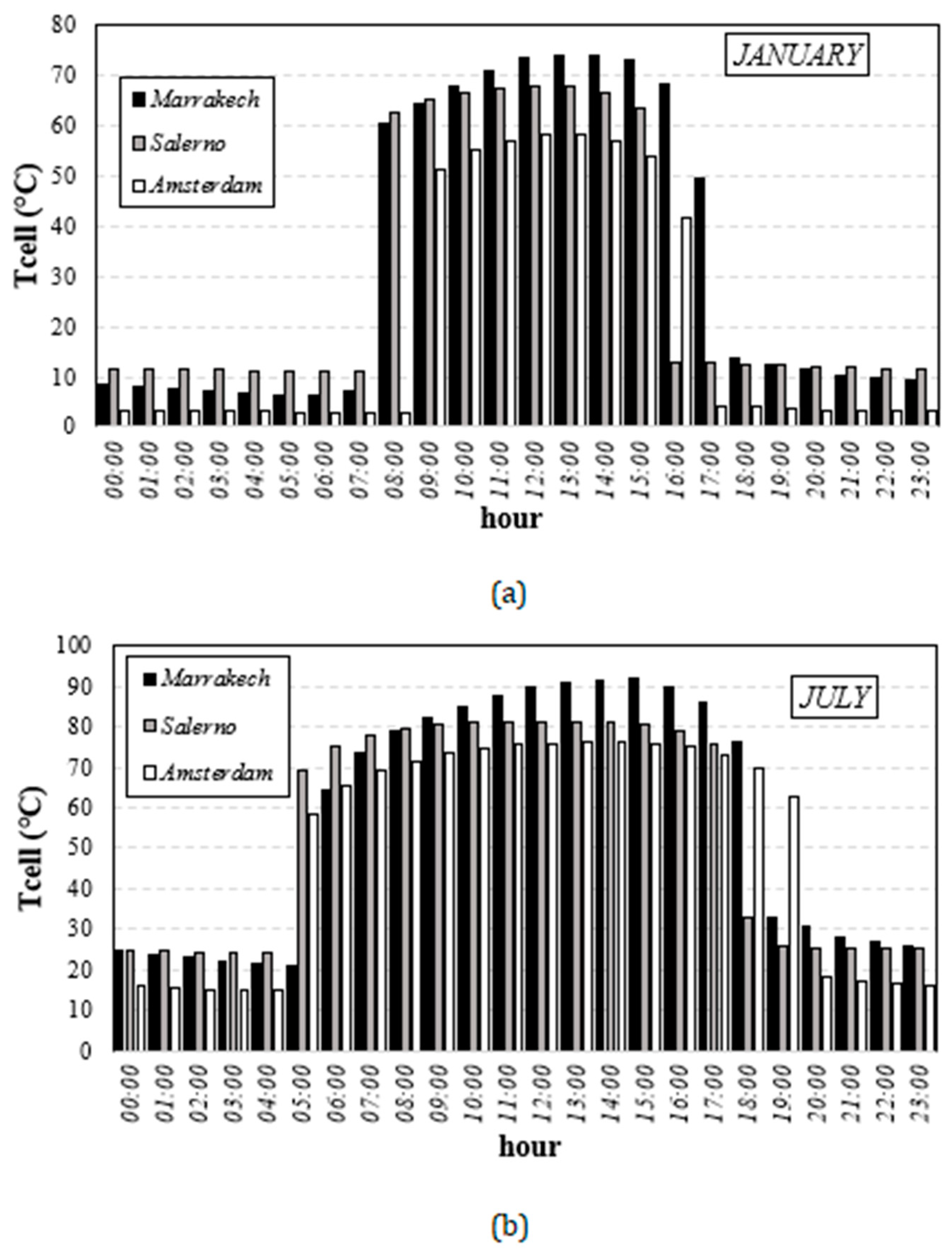

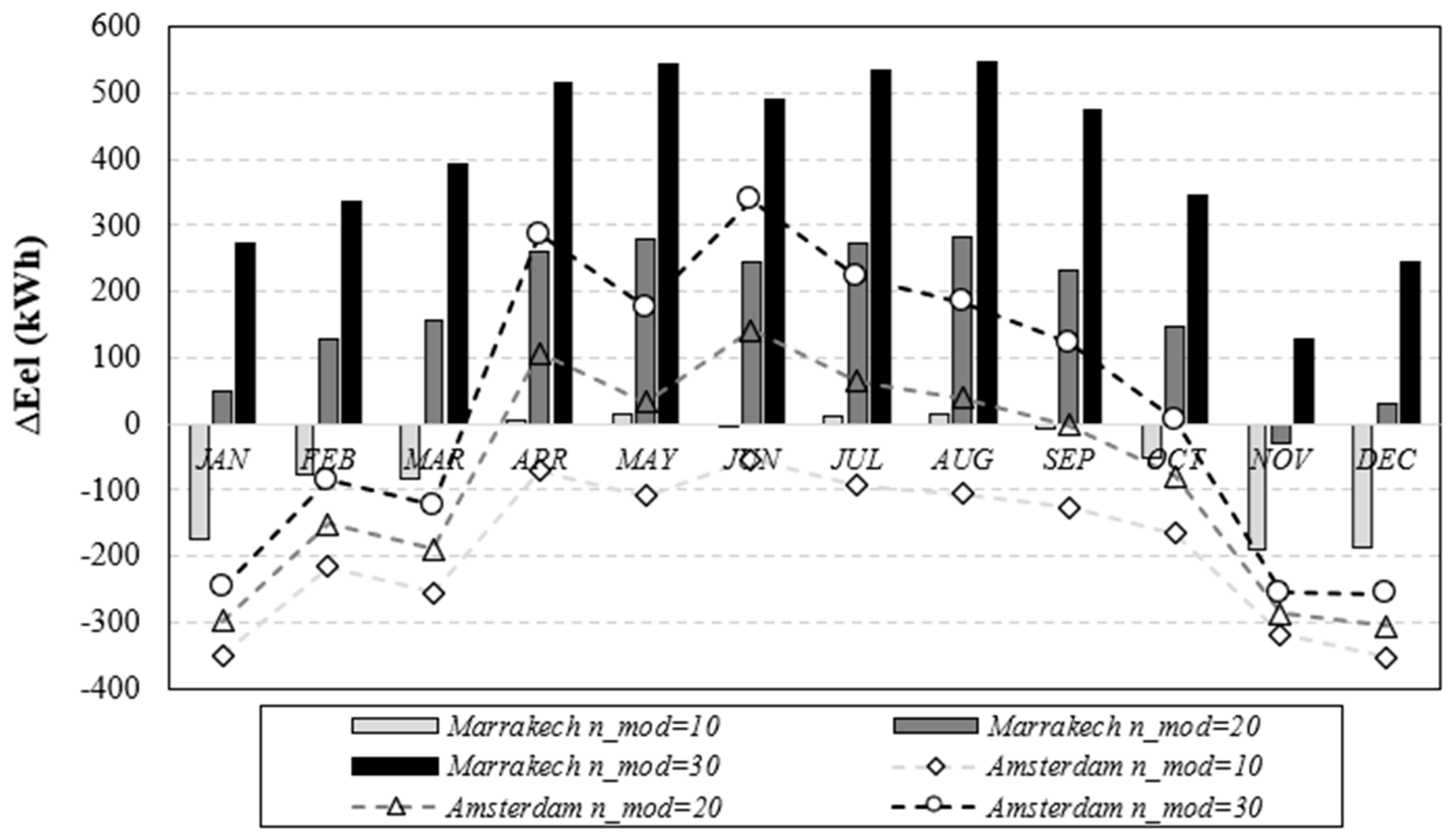

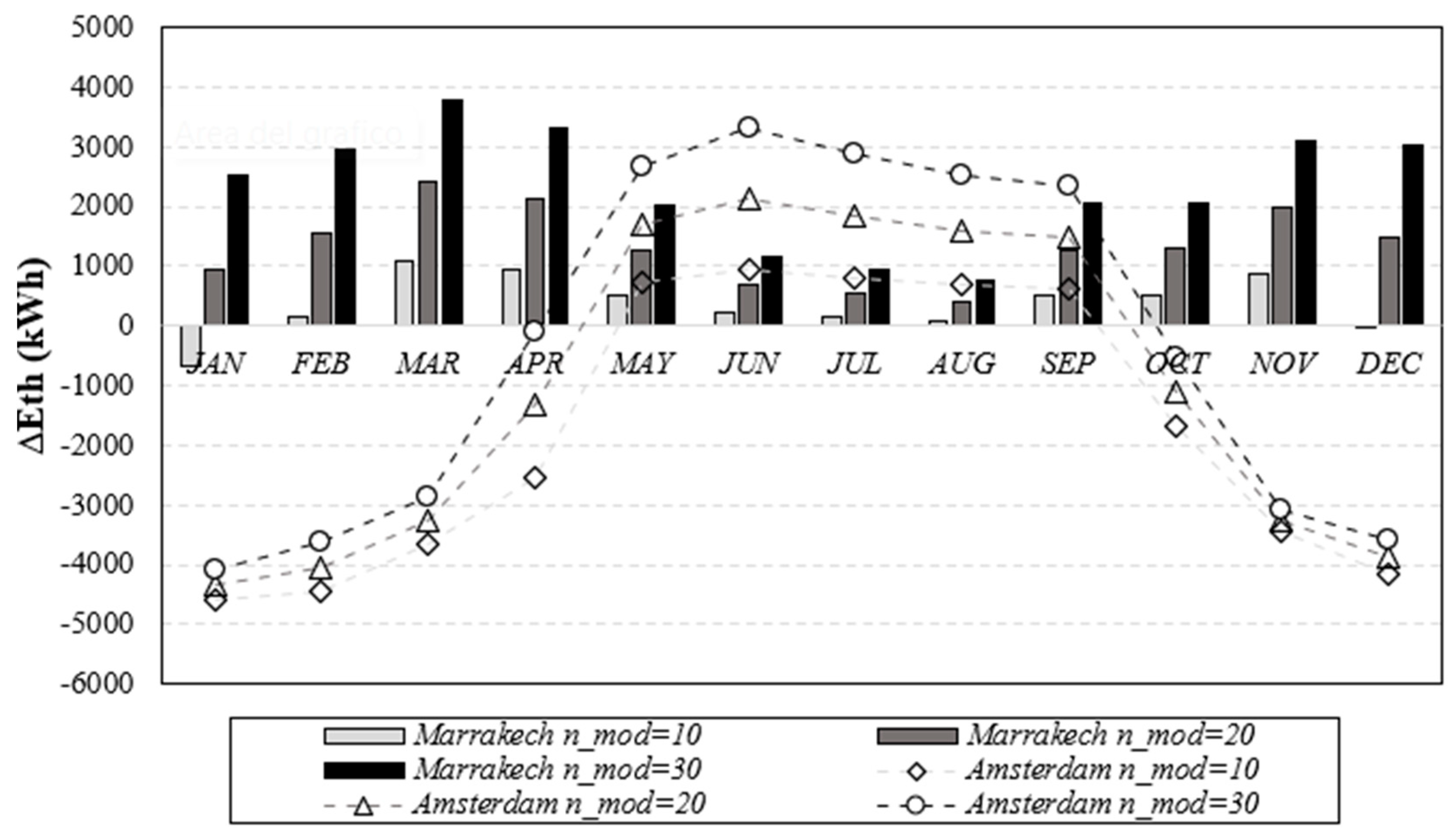

3. Energy and Economic Performance Evaluation

3.1. Energy Performance

- -

- low-temperature thermal power (LTQth) available at temperatures lower than 40 °C and then not utilizable;

- -

- middle-temperature thermal power (MTQth) available at temperatures included between 40 °C and 80 °C that can be adopted for winter heating (WH) and to produce domestic hot water (DHW);

- -

- high-temperature thermal power (HTQth) available at temperatures higher than 80 °C and usable in an Absorption Heat Pump (AHP) to obtain cooling power (Qcool).

3.2. Sizing and Economic Analysis

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area (m2) |

| AHP | Absorption Heat Pump |

| CF | Cash Flow (€/year) |

| COP | Coefficient of Performance |

| CPV | Concentrating Photovoltaic system |

| CPV/T | Concentrating Photovoltaic and Thermal system |

| Cost saving (€/year) | |

| C | Concentration factor |

| Copt | Optical concentration ratio |

| Unit purchase cost of cooling energy (€/kWh) | |

| Unit purchase cost of electrical energy (€/kWh) | |

| Unit purchase cost of thermal energy (€/kWh) | |

| Cost per module (€/mod) | |

| DNI | Direct Normal irradiance (W/m2) |

| DPBP | Discount Pay-Back Period (year) |

| Energy (kWh) | |

| Efficiency | |

| f | Non-ideal tracking system factor |

| G | Gains from the sale of surplus energy (€/year) |

| High Temperature | |

| Initial investment (€) | |

| Low Calorific Value (kWh/kg) | |

| Low Temperature | |

| Middle Temperature | |

| Number | |

| NPV | Net Present Value (€) |

| P | Electric power (W) |

| PV | Photovoltaic |

| Electrical energy selling price to the energy network (€/kWh) | |

| Q | Thermal power (W) |

| Rcell | Concentrated solar radiation incident on TJ cell (W/m2) |

| Discount rate | |

| T | Temperature (°C) |

| TJ | Triple-Junction cell |

| Profit Index | |

| CPV system Useful Life (year) | |

| Subscripts | |

| c | cell |

| el | electric |

| env | environmental |

| inv | inverter |

| loss | losses |

| monthly | |

| mod | module |

| opt | optical |

| th | thermal |

| tube | coolant flow tube |

| user | |

References

- Rejeb, O.; Shittu, S.; Ghenai, C.; Li, G.; Zhao, X.; Bettayeb, M. Optimization and Performance Analysis of a Solar Concentrated Photovoltaic-Thermoelectric (CPV-TE) Hybrid System. Renew. Energy 2020, 152, 1342–1353. [Google Scholar] [CrossRef]

- Burhan, M.; Shahzad, M.W.; Oh, S.J.; Ng, K.C. Long Term Electrical Rating of Concentrated Photovoltaic (CPV) Systems in Singapore. Energy Procedia 2019, 158, 73–78. [Google Scholar] [CrossRef]

- Renno, C.; D’Agostino, D.; Minichiello, F.; Petito, F.; Balen, I. Performance Analysis of a CPV/T-DC Integrated System Adopted for the Energy Requirements of a Supermarket. Appl. Therm. Eng. 2019, 149, 231–248. [Google Scholar] [CrossRef]

- Smil, V. Energy: A Beginner’s Guide. 2006. Available online: https://vaclavsmil.com/2017/02/21/energy-a-beginners-guide-beginners-guides-2nd-edition/ (accessed on 23 September 2022).

- Soni, M.S.; Gakkhar, N. Techno-Economic Parametric Assessment of Solar Power in India: A Survey. Renew. Sustain. Energy Rev. 2014, 40, 326–334. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Z.; Hu, P.; Cheng, X. Design and Optical Analysis of the Band-Focus Fresnel Lens Solar Concentrator. Appl. Therm. Eng. 2016, 102, 695–700. [Google Scholar] [CrossRef]

- Luque, A.; Sala, G.; Luque-Heredia, I. Photovoltaic Concentration at the Onset of Its Commercial Deployment. Prog. Photovolt. Res. Appl. 2006, 14, 413–428. [Google Scholar] [CrossRef]

- Baharoon, D.A.; Rahman, H.A.; Omar, W.Z.W.; Fadhl, S.O. Historical Development of Concentrating Solar Power Technologies to Generate Clean Electricity Efficiently–A Review. Renew. Sustain. Energy Rev. 2015, 41, 996–1027. [Google Scholar] [CrossRef]

- García-Domingo, B.; Piliougine, M.; Elizondo, D.; Aguilera, J. CPV Module Electric Characterisation by Artificial Neural Networks. Renew. Energy 2015, 78, 173–181. [Google Scholar] [CrossRef]

- Wang, G.; Yao, Y.; Chen, Z.; Hu, P. Thermodynamic and Optical Analyses of a Hybrid Solar CPV/T System with High Solar Concentrating Uniformity Based on Spectral Beam Splitting Technology. Energy 2019, 166, 256–266. [Google Scholar] [CrossRef]

- Jiang, S.; Hu, P.; Mo, S.; Chen, Z. Optical Modeling for a Two-Stage Parabolic Trough Concentrating Photovoltaic/Thermal System Using Spectral Beam Splitting Technology. Sol. Energy Mater. Sol. Cells 2010, 94, 1686–1696. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Han, X.; Du, X.; Wei, G.; Yang, Y. A Review of the Concentrated Photovoltaic/Thermal (CPVT) Hybrid Solar Systems Based on the Spectral Beam Splitting Technology. Appl. Energy 2017, 187, 534–563. [Google Scholar] [CrossRef]

- Algareu, A.O.; Mahmoud, S.; Al-Dadah, R.K. Electrical Characterization of Photovoltaic Cell with Low-Concentration Ratio Square Aperture Concentrator. Int. J. Energy Res. 2017, 41, 2332–2344. [Google Scholar] [CrossRef]

- Lokeswaran, S.; Mallick, T.K.; Reddy, K.S. Design and Analysis of Dense Array CPV Receiver for Square Parabolic Dish System with CPC Array as Secondary Concentrator. Sol. Energy 2020, 199, 782–795. [Google Scholar] [CrossRef]

- Xu, N.; Ji, J.; Sun, W.; Han, L.; Chen, H.; Jin, Z. Outdoor Performance Analysis of a 1090× Point-Focus Fresnel High Concentrator Photovoltaic/Thermal System with Triple-Junction Solar Cells. Energy Convers. Manag. 2015, 100, 191–200. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F.; Gatto, A. Artificial Neural Network Models for Predicting the Solar Radiation as Input of a Concentrating Photovoltaic System. Energy Convers. Manag. 2015, 106, 999–1012. [Google Scholar] [CrossRef]

- Burhan, M.; Shahzad, M.W.; Ng, K.C. Sustainable Cooling with Hybrid Concentrated Photovoltaic Thermal (CPVT) System and Hydrogen Energy Storage. Int. J. Comput. Phys. Ser. 2018, 12, 40–51. [Google Scholar] [CrossRef]

- Li, M.-F.; Tang, X.-P.; Wu, W.; Liu, H.-B. General Models for Estimating Daily Global Solar Radiation for Different Solar Radiation Zones in Mainland China. Energy Convers. Manag. 2013, 70, 139–148. [Google Scholar] [CrossRef]

- Renno, C. Theoretical and Experimental Evaluation of the Working Fluid Temperature Levels in a CPV/T System. Energies 2020, 13, 3077. [Google Scholar] [CrossRef]

- Alves, P.; Fernandes, J.F.P.; Torres, J.P.N.; Costa Branco, P.J.; Fernandes, C.; Gomes, J. From Sweden to Portugal: The Effect of Very Distinct Climate Zones on Energy Efficiency of a Concentrating Photovoltaic/Thermal System (CPV/T). Sol. Energy 2019, 188, 96–110. [Google Scholar] [CrossRef]

- Yang, F.; Wang, H.; Zhang, X.; Tian, W.; Hua, Y.; Dong, T. Design and Experimental Study of a Cost-Effective Low Concentrating Photovoltaic/Thermal System. Sol. Energy 2018, 160, 289–296. [Google Scholar] [CrossRef]

- Han, X.; Xu, C.; Ju, X.; Du, X.; Yang, Y. Energy Analysis of a Hybrid Solar Concentrating Photovoltaic/Concentrating Solar Power (CPV/CSP) System. Sci. Bull. 2015, 60, 460–469. [Google Scholar] [CrossRef]

- Han, X.; Zhao, G.; Xu, C.; Ju, X.; Du, X.; Yang, Y. Parametric Analysis of a Hybrid Solar Concentrating Photovoltaic/Concentrating Solar Power (CPV/CSP) System. Appl. Energy 2017, 189, 520–533. [Google Scholar] [CrossRef]

- Ben Youssef, W.; Maatallah, T.; Menezo, C.; Ben Nasrallah, S. Modeling and Optimization of a Solar System Based on Concentrating Photovoltaic/Thermal Collector. Sol. Energy 2018, 170, 301–313. [Google Scholar] [CrossRef]

- Renno, C. Experimental and Theoretical Analysis of a Linear Focus CPV/T System for Cogeneration Purposes. Energies 2018, 11, 2960. [Google Scholar] [CrossRef]

- Burhan, M.; Shahzad, M.W.; Ng, K.C. Long-Term Performance Potential of Concentrated Photovoltaic (CPV) Systems. Energy Convers. Manag. 2017, 148, 90–99. [Google Scholar] [CrossRef]

- Aprea, C.; Renno, C. An Air Cooled Tube-Fin Evaporator Model for an Expansion Valve Control Law. Math. Comput. Model. 1999, 30, 135–146. [Google Scholar] [CrossRef]

- Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#MR (accessed on 23 September 2022).

- Renno, C.; Petito, F. Triple-Junction Cell Temperature Evaluation in a CPV System by Means of a Random-Forest Model. Energy Convers. Manag. 2018, 169, 124–136. [Google Scholar] [CrossRef]

- Matlab R2019, The MathWorks. Available online: https://it.mathworks.com/products/matlab.html (accessed on 23 September 2022).

- Renno, C. Thermal and Electrical Modelling of a CPV/T System Varying Its Configuration. J. Therm. Sci. 2019, 28, 123–132. [Google Scholar] [CrossRef]

- Shakouri, M.; Ghadamian, H.; Hoseinzadeh, S.; Sohani, A. Multi-objective 4E analysis for a building integrated photovoltaic thermal double skin Façade system. Solar Energy 2022, 233, 408–420. [Google Scholar] [CrossRef]

- Renno, C.; Petito, F.; D’Agostino, D.; Minichiello, F. Modeling of a CPV/T-ORC combined system adopted for an industrial user. Energies 2020, 13, 33476. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Material | InGaP/GaAs/Ge |

| Dimensions | 10 mm × 10 mm |

| ηr (at 25 °C, 50 W/cm2–1000 suns) | 39.0% |

| Temperature coefficient (σt) | −0.04%/K |

| Equation | R2 | ||||

|---|---|---|---|---|---|

| Equation (2) | 12.481 | 0.9794 | - | - | 0.9552 |

| Equation (3) | - | - | 1.4193 | 500.51 | 0.9479 |

| January | July | |

|---|---|---|

| Marrakech | 1199 | 1336 |

| Salerno | 964 | 1500 |

| Amsterdam | 755 | 1644 |

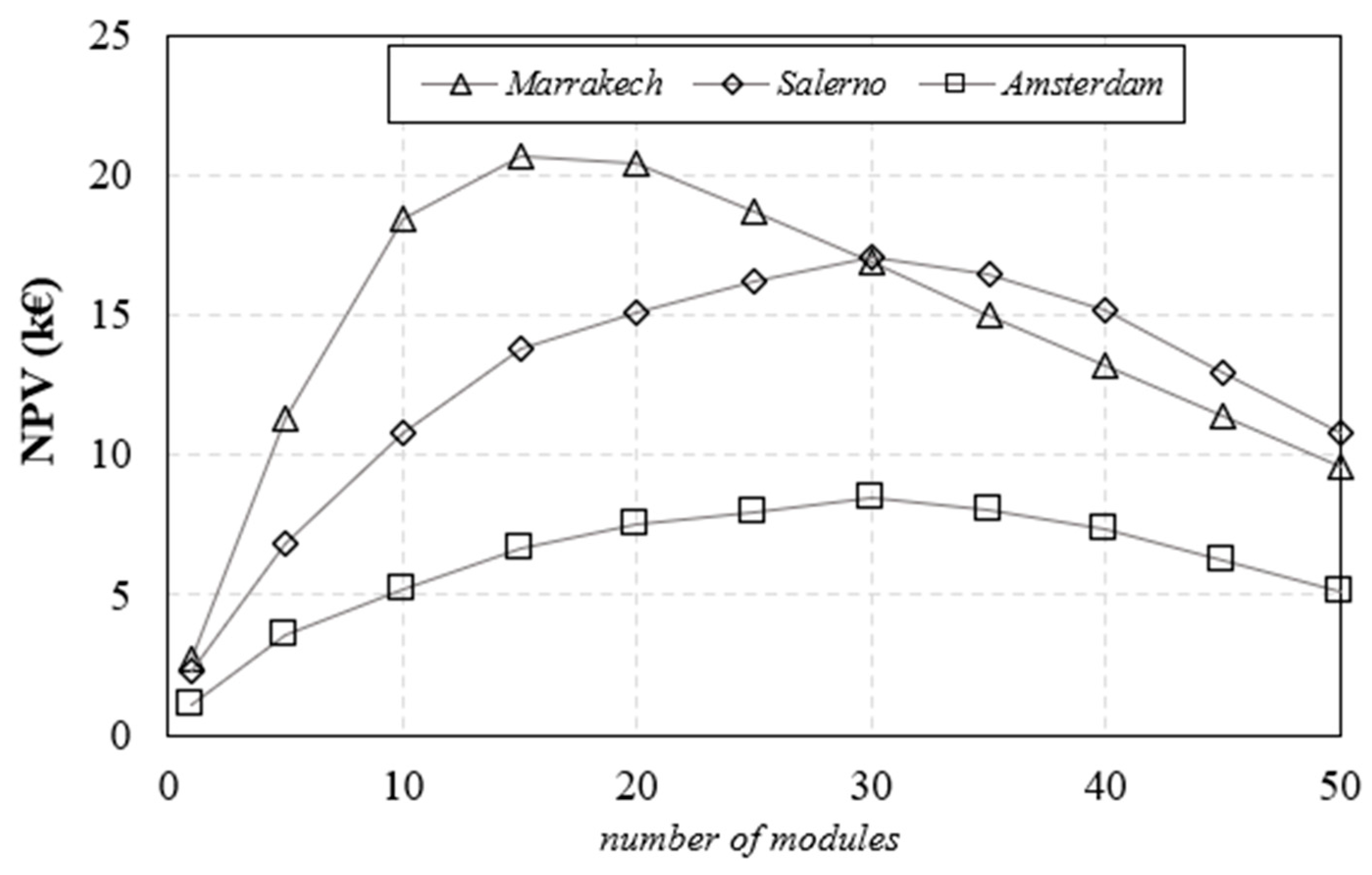

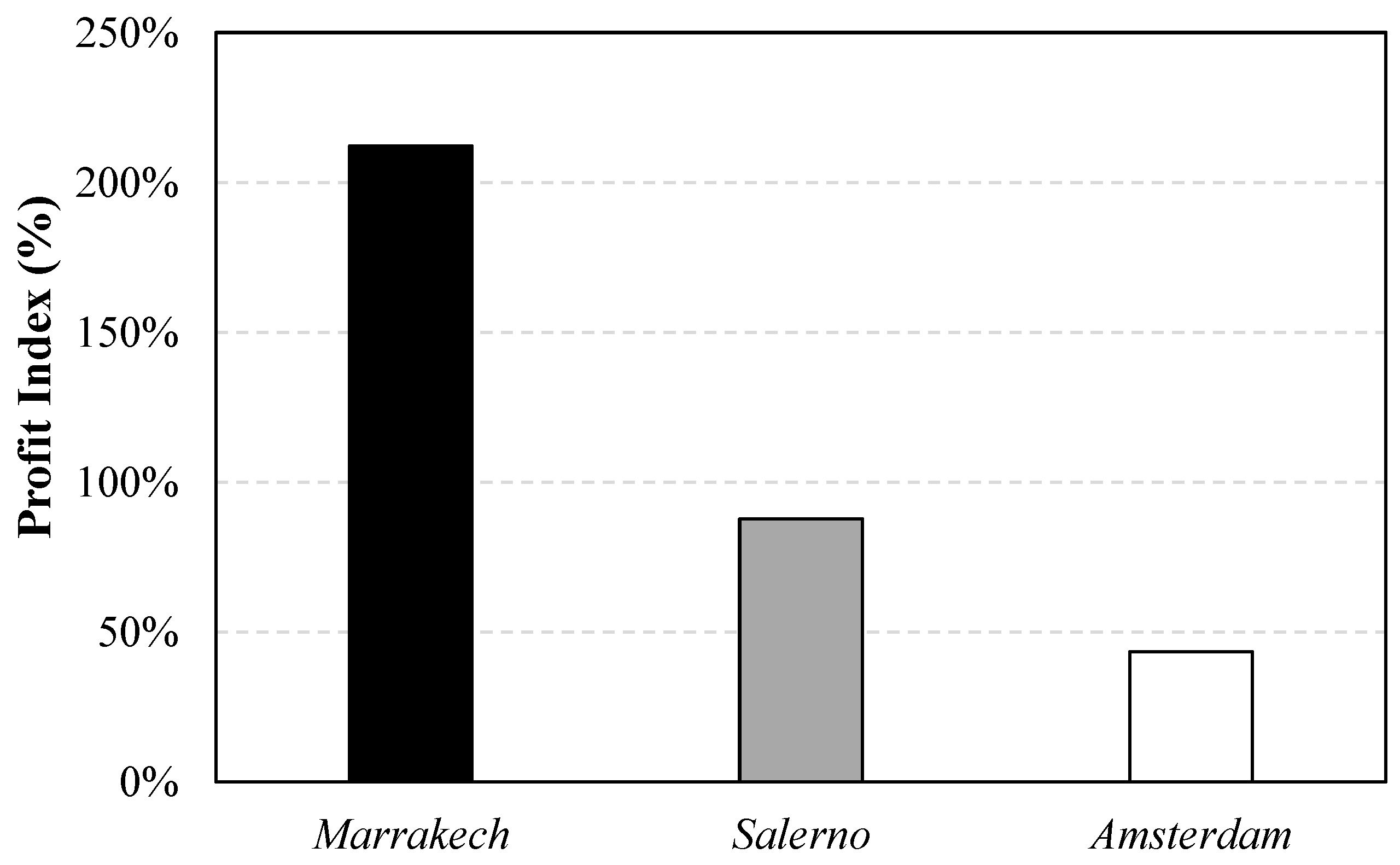

| Parameter | Value |

|---|---|

| Useful life for a CPV system: | 20 years |

| Cost per module: | 650 €/mod |

| Purchase cost of electricity: | 0.20 €/kWh |

| Electricity selling price: | 0.06 €/kWh |

| LCV Methane: | 9.60 kWh/Sm3 |

| η Boiler: | 0.900 |

| Methan price: | 0.800 €/Sm3 |

| Thermal energy cost: | 0.0926 €/kWh |

| COPf | 3.00 |

| Cooling energy cost: | 0.0667 €/kWh |

| COPf of AHP | 0.700 |

| discount index: | 0.015 |

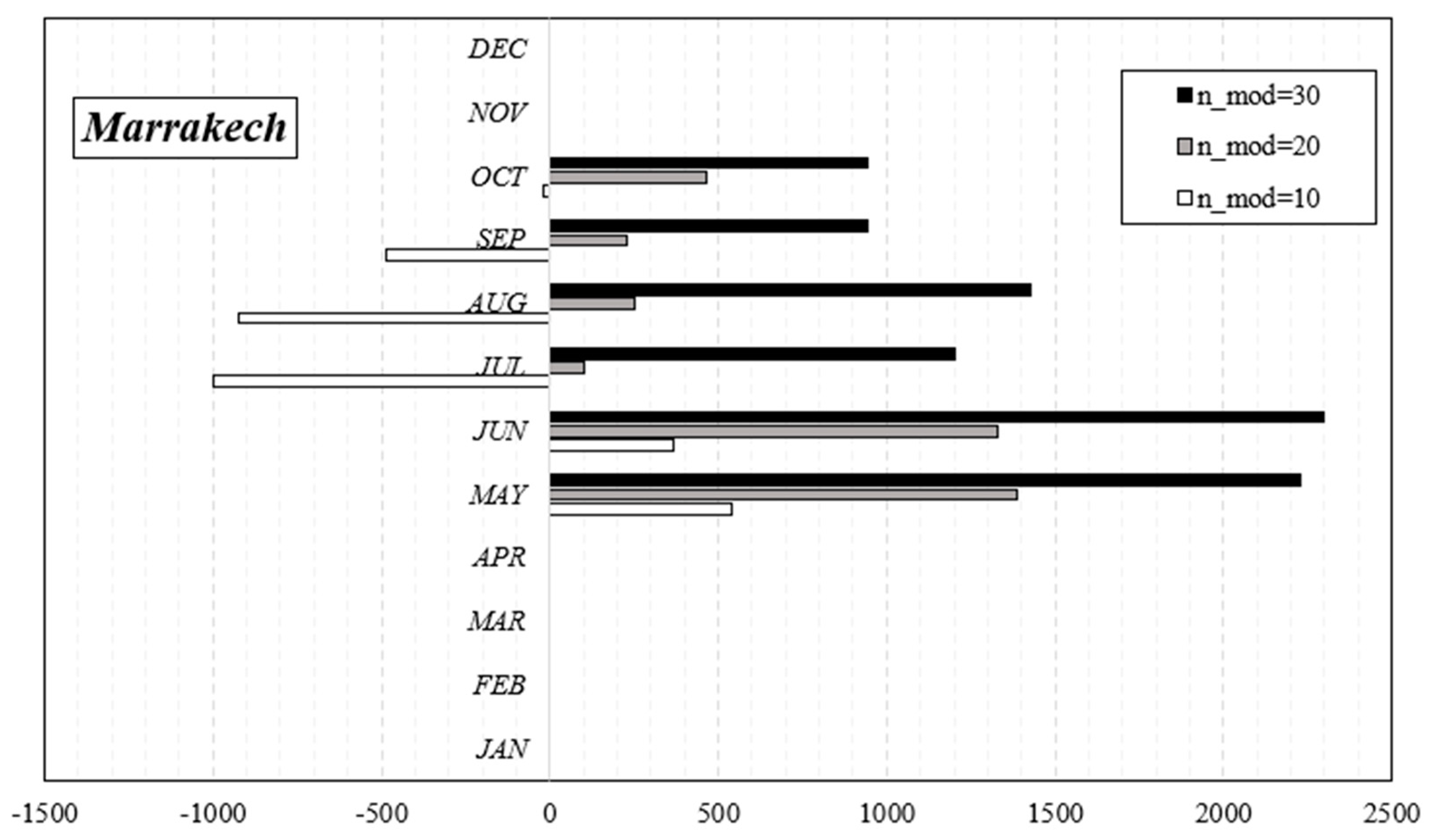

| Marrakech | Amsterdam | |||||

|---|---|---|---|---|---|---|

| Month | Eel (kWh) | Eth (kWh) | Ecool (kWh) | Eel (kWh) | Eth (kWh) | Ecool (kWh) |

| January | 400 | 2250 | 0 | 400 | 4850 | 0 |

| February | 280 | 1250 | 0 | 280 | 4850 | 0 |

| March | 320 | 250 | 0 | 320 | 4050 | 0 |

| April | 250 | 250 | 0 | 250 | 3750 | 0 |

| May | 250 | 250 | 300 | 250 | 250 | 0 |

| June | 250 | 250 | 600 | 250 | 250 | 0 |

| July | 250 | 250 | 2100 | 250 | 250 | 0 |

| August | 250 | 250 | 2100 | 250 | 250 | 0 |

| September | 250 | 250 | 1200 | 250 | 250 | 0 |

| October | 250 | 250 | 500 | 250 | 2250 | 0 |

| November | 350 | 250 | 0 | 350 | 3650 | 0 |

| December | 400 | 1550 | 0 | 400 | 4450 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renno, C.; Perone, A.; D’Agostino, D.; Minichiello, F. Performance Evaluation of a Linear CPV/T System in Different Working Conditions. Energies 2023, 16, 2115. https://doi.org/10.3390/en16052115

Renno C, Perone A, D’Agostino D, Minichiello F. Performance Evaluation of a Linear CPV/T System in Different Working Conditions. Energies. 2023; 16(5):2115. https://doi.org/10.3390/en16052115

Chicago/Turabian StyleRenno, Carlo, Alessandro Perone, Diana D’Agostino, and Francesco Minichiello. 2023. "Performance Evaluation of a Linear CPV/T System in Different Working Conditions" Energies 16, no. 5: 2115. https://doi.org/10.3390/en16052115

APA StyleRenno, C., Perone, A., D’Agostino, D., & Minichiello, F. (2023). Performance Evaluation of a Linear CPV/T System in Different Working Conditions. Energies, 16(5), 2115. https://doi.org/10.3390/en16052115