1. Introduction

The United Nations World Water Development Report mentions that 3.7 billion people are currently affected by water scarcity and in 2050 this number could grow to 5.7 billion [

1]. This problem is caused by various factors, such as increasing population, urbanization, poor water management, climate change, pollution, etc., and is soon to be one of the most important challenges of humanity for the following years. Due to the vast abundance of seawater, water desalination, whose goal is to provide drinkable water from saline water with the expense of energy to power the associated units [

2], appears to be a viable solution to this problem and many countries have adopted this technique to satisfy their freshwater needs. By February 2020, the global desalination capacity for freshwater production was 114.9 million m

3/day [

3].

An exhaustive summary of the industrial water desalination plants around the world is presented by Ali et al. [

4], classifying the plants according to their desalination method: Multi-Effect Distillation (MED), Reverse Osmosis (RO), Multi-Stage Flash (MSF), Electrodialysis (ED) or Membrane Distillation (MD). Despite the large-scale desalination industry being settled in just three desalination methods (RO, MED and MSF) [

5], innovative techniques are being developed and pilot-tested in different research facilities every day. Lately, MD desalination has been foreseen as a promising alternative to conventional separation processes and has been intensively improved by different research groups globally [

6,

7,

8]. In their review, Pangarkar et al. [

9] compared the performance of the RO and MD desalination processes and concluded that, even though RO has been the preferred choice for new desalination plants due to many years of growth, MD is a better alternative for water desalination because of the lower operating temperature and pressure, the possibility of using solar heat, the higher product quality and better resistance to fouling.

Whether a long-used method or a newly born technique, any desalination process requires either electrical or thermal energy to function. Thus, great attention is being focused on renewable energy (RE) resources for their environmentally friendly nature in comparison with fossil fuels [

4]. Evidently, most countries that could face water scarcity are located in the so-called Global Sun Belt (within ±35° latitude from the equator) [

10], where the solar radiation is high, increasing the potential for the use of solar energy. For example, Mollahosseini et al. [

11] analyzed the potential of Iran, a country in the Global Sun Belt, for RE-driven desalination. They concluded that by combining solar and wind energies, the country could produce up to 28 billion m

3/year of freshwater.

The coexistence of solar resources with water shortages makes solar power an appropriate method to cover the energy requirements of any desalination process. Ali et al. [

4] classified the already pilot-tested solar desalination technologies into

direct or

indirect solar desalination. The first includes methods such as solar stills or the Humidification–Dehumidification process (HDH). Alternatively,

indirect solar desalination could be divided according to the type of energy generated from the sun: MSF, MED, Thermal Vapor Compression (TVC), MD and heat engine-driven RO and freezing methods obtain thermal energy from solar thermal collectors. Direct desalination produced by solar stills is one of the sustainable and economical technologies, but it has to improve its lower water productivity with advanced porous materials, nanoparticles or phase change materials [

12]. On the other hand, indirect membrane distillation is one of the most effective methods characterized by its high productivity particularly used in industrial plants [

13].

A solar collector is a device that transforms solar radiation energy into thermal energy by increasing the temperature of the Heat Transfer Fluid (HTF), the electrical energy produced by PV cells, or both in the case of hybrid PV/Thermal (PV-T) applications. Zhao et al. [

14] built a solar flat-plate PV-T system coupled with a Direct Contact MD (DCMD) module for energy generation and water desalination. The authors found that the hybrid system had a 4.44 times greater energy performance (including power density and energy efficiency) in comparison with the sole PV module. Moreover, Ma et al. [

15] reviewed the current status of solar-driven MD desalination and they identified that, alongside direct solar heating, the possible resolution to enhance solar energy utilization for higher water production is solar concentration, a hypothesis on which some authors have been working. Krnac et al. [

16] used the waste heat from the cooling system of a Concentrating Photovoltaic (CPV) solar dish to heat the feed water for a DCMD system, which produced a permeate flux of 7.1 L/m

2h. Elminshawy et al. [

17] proposed a cogeneration and solar desalination system powered by an earth-cooled solar concentrator. In their study, they varied the circulating water flow in the Concentrating Photovoltaic-Thermal (CPVT) and the inlet temperature of the feed water to find the combination of both that maximized the permeate flux production and energy performance of the system. In the end, their system was able to produce 19.58 m

3 of water at a cost of USD 22.48/m

3, with a thermal efficiency of 83%. Chen et al. [

18] compared the simulated performance of a solar MD system under the DCMD, Air Gap MD (AGMD) and Vacuum MD (VMD) configurations. The authors used an absorption plate to collect the solar energy and develop a two-stage design methodology to minimize the total annual cost using steady-state simulations and to maximize the permeate produced using a dynamic simulation. Their simulation showed that the costs per m

3 of freshwater under optimal operation conditions for the AGMD, DCMD and VMD configurations were USD 2.71, USD 5.38 and USD 10.41, respectively.

Among solar collectors, the Parabolic Trough Collector (PTC) is one of the most commonly used to produce Concentrated Solar Power (CSP) because of its high-temperature range and reduced cost as compared to two-axis tracking collectors, such as parabolic disk collectors. Some of the main applications for PTCs are CSP plants, industrial process heat, space heating, domestic hot water, refrigeration, air-conditioning, pumping water, solar chemistry and desalination [

19]. A clear example of the potential of PTCs is presented by Soomro and Kim [

20] where the technical and economic evaluation of a 50-MWe PTC plant with DCMD for electricity and freshwater production was performed. The plant produced up to 13.5 GWh of energy at a levelized cost of energy of 0.193833 USD/kWh during summer and 14.33 m

3 of freshwater per day at a cost of 0.64 USD/m

3. In recent years, an innovative CPVT system has been developed by Acosta-Pazmiño [

21], wherein an array of PV Si mono-crystalline cells was placed in the focus line of a PTC. The system was fabricated, characterized and experimentally evaluated using international standards. Moreover, a sensibility analysis found that the design parameter with the largest effect on the collector’s thermal and electrical efficiencies is the conversion efficiency of the PV cells, while the operating condition with the most influence is the incidence angle. A detailed presentation of the operating parameters and conditions for the evaluation is available in [

21].

A cogeneration plant involving CPVT-VMD technology was proposed and numerically evaluated by Chen et al. [

22]. They used a Fresnel lens to concentrate the sunlight into multi-junction cells (MJC) and a vacuum multi-effect MD (V-MEMD) system for water desalination and evaluated the system under typical weather conditions of Makkah, Saudi Arabia. The electrical and thermal efficiencies of the system remain constant at 24% and 45%, respectively; the annual permeate production reached 42m

3 of freshwater with a Specific Energy Consumption (SEC) of 205 kWh/m

3. Liu et al. [

23] numerically and experimentally analyzed a Vacuum Membrane Distillation seawater module coupled with a thermal/photovoltaic solar system. They reported the thermal and electrical performance of the system, as well as water harvesting. From the results, maximum thermal and electrical efficiencies of 56.2% and 15.9% were found, with a water yield of 0.579 L/m

2h obtained for the membrane distillation module.

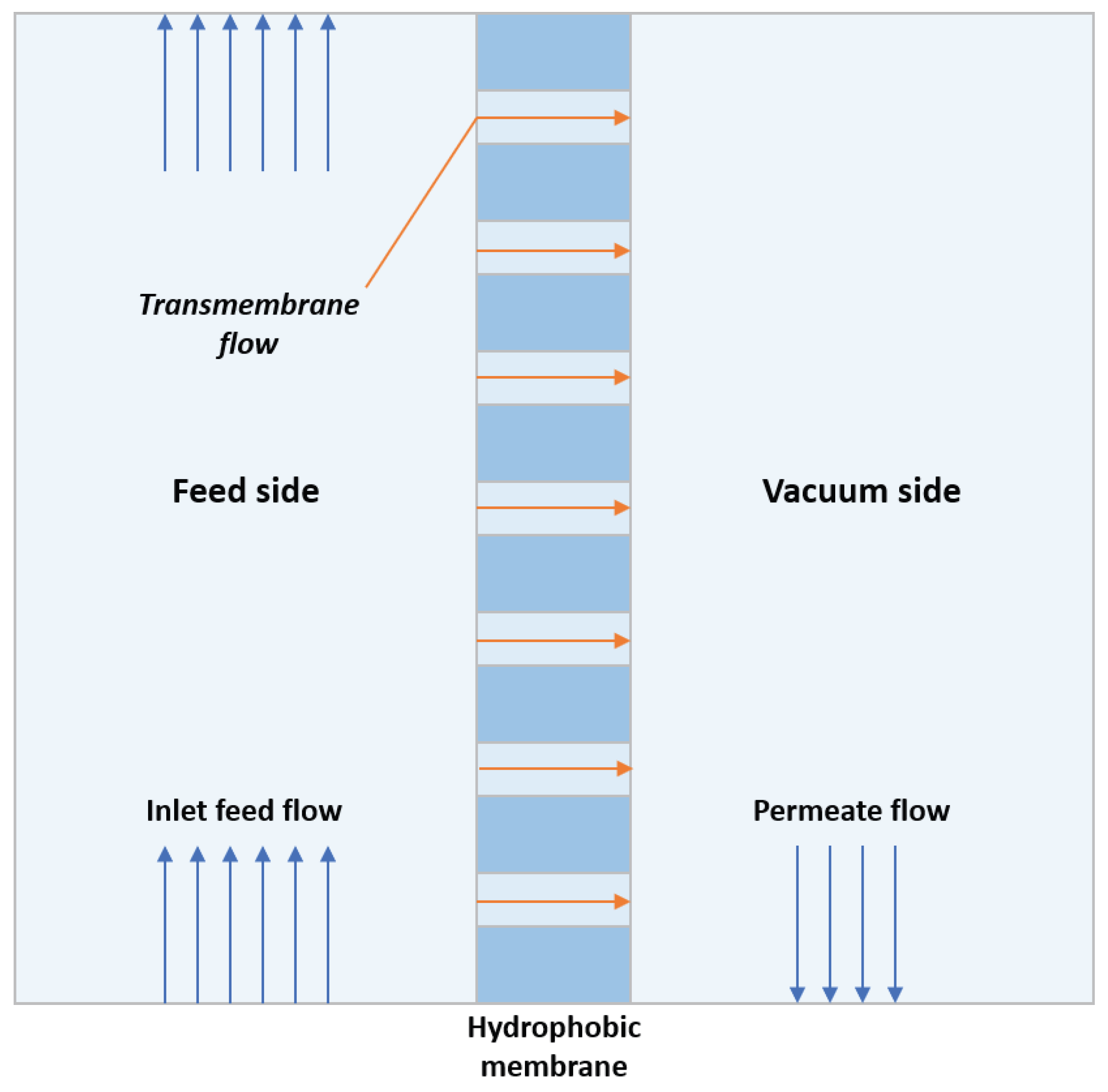

Despite there being already some research regarding the coupling of CPVT systems with MD technology, there remains an important gap in the literature for designing and performing parametric studies that assess the integration of hybrid solar desalination systems in different climate conditions. In addition, most of the research regarding solar desalination by MD is focused on the DCMD configuration because of its simplicity, paying little attention to other configurations, such as VMD, that could present a better performance under proper conditions. Therefore, VMD was selected in this study to be integrated with the hybrid solar collector because it is thermally more efficient and larger permeated flux production can be obtained. From the different types of solar collectors that can be used to provide thermal and electrical energy for the VMD system, the hybrid CPVT was selected because it can heat water at the required operating temperatures of the VMD and less capture solar area is required to produce heat and electricity compared with other technologies such as flat plate, vacuum tubes and PV collectors.

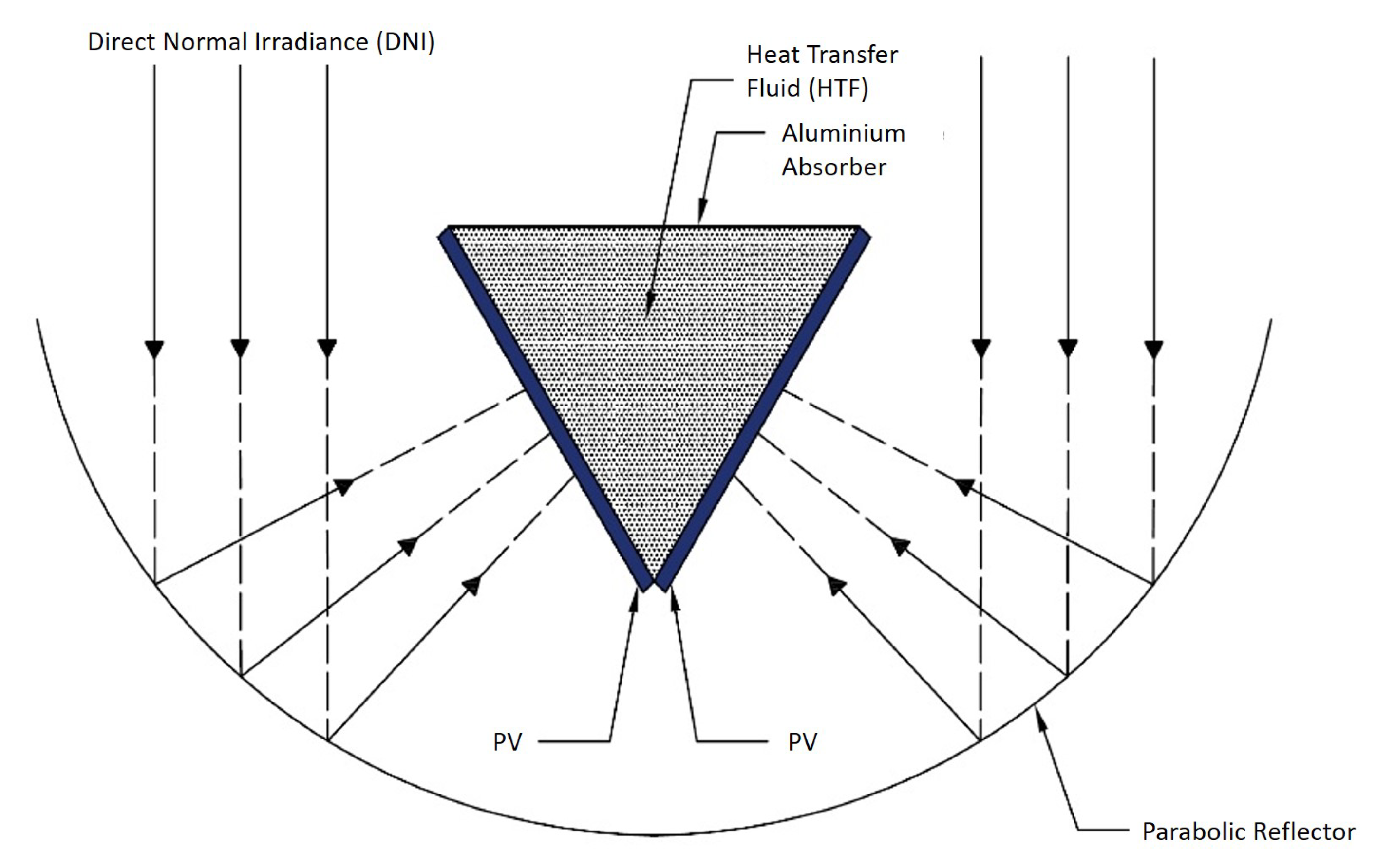

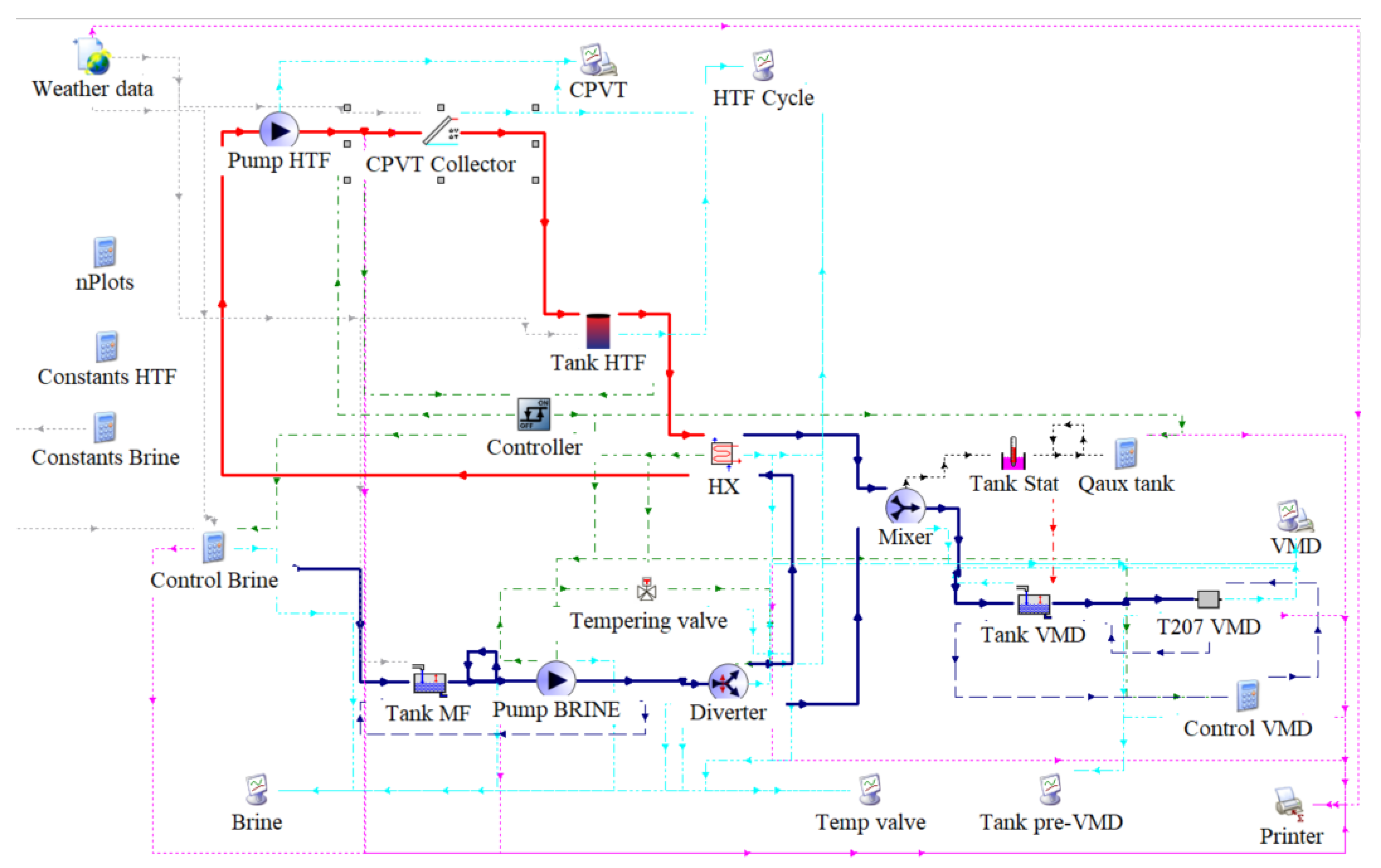

The purpose of this study is to numerically analyze the coupling of an innovative configuration of a CPVT-PTC module with a VMD module and evaluate the combined performance under real weather conditions for a year in four different coastal cities: La Paz, Mexico; Acapulco, Mexico; Nadi, Fiji; and Singapore, Singapore. The novelty and the contributions of this study can be summarized as follows: (1) the CPVT-PTC module used in the analysis consists of a commercial Parabolic Through Collector where the circular receiver has been replaced with a triangular receiver with PV cells in the two sides that are facing the reflecting surface. This type of hybrid collector has the advantage of requiring less PV area to produce more electricity due to the higher concentration ratio and at the same time providing thermal energy for the VMD process. Another advantage of this hybrid collector is the great potential to be industrially produced because conventional solar thermal plants with PTC can be easily hybridized by just replacing the receiver. (2) Design specifications and operating conditions based on annual simulations for different climate conditions of coastal cities are provided. These dynamics simulations were performed with TRNSYS to obtain the annual behavior of key parameters such as specific permeate production, thermal and electrical energy production, overall electrical consumption, etc. (3) The methodology employed to integrate the heat and mass transfer model of the VMD into the TRNSYS environment and the CPVT/PTC model using a modified version of the Type50f into the TRNSYS studio considering an incidence modifier angle of the system. To the best of our knowledge, energy annual simulations, for different coastal cities, of the coupling of the VMD module with the type of hybrid CPVT-PTC proposed have not been investigated. The results of this study are important for proving the technical and economic feasibility of the technology and for providing guides for the design of a prototype with potential to be commercialized.

3. Results and Discussion

This section summarizes the main results as follows. First, the effects of the solar collector area and the inlet brine temperature of the VMD on the performance of the CPVT-VMD system are shown. Second, a performance analysis to compare the energy and permeate production for different coastal cities is presented. Finally, an economic analysis of the applications of the system in a coastal city for real weather conditions is performed.

3.1. Effect of Collector Area on the System’s Performance

Using the weather data from Acapulco, the first study included the variation in CPVT collector surface area (2-, 3- and 4-collector units) with an invariant set point temperature (60 °C) and its results are presented in

Figure 4.

As presented in

Figure 4a, the 4-collector unit (4U) scenario showed better performance, reaching a maximum freshwater production of 20.09 m

3/m

2VMD during May. Likewise, the peak-specific permeate production of the 3-collector unit (3U) and 2-collector unit (2U) systems were 16.35 and 8.13 m

3/m

2VMD, respectively, during April. One of the reasons why the peak productions did not occur during the same month is that the pump controller halts the system if the output temperature of the CPVT-PTC is higher than the brine set point temperature. Therefore, with the larger surface area of the 4-collector unit system, the operation stopped during the high-radiation days of April.

Regarding the adjusted thermal SF,

Figure 4b shows that the 4-collector unit system presented a better performance overall, reaching a maximum of 83%. Notably, all three systems presented their best performances during April, mainly due to the high solar incidence available. Alternatively, the lowest adjusted thermal SF was 46%, presented by the 2-collector unit system during October, with the 3-collector unit and the 4-collector unit systems presenting their lowest during this month as well with 58% and 67%, respectively.

Similarly, the 4-collect unit system presented the lowest SEC during any month of the year, even reaching negative values of −1.50 and −0.02 kWh/m

3 for April and May, respectively, as shown in

Figure 4c. This would mean that the energy production from the CPVT-PTC is larger than the energy consumption of the system during those months. Thus, the balance between the produced and consumed energies reached such values. Notably, the 3-collector unit and the 4-collector unit systems present a similar steady behaviour, with best (April) and worst (October) monthly performances of 5.72 and 5.41 kWh/m

3, respectively. Meanwhile, the 2-collector unit showed a more erratic behaviour with an analogous difference of 12.53 kWh/m

3 between the best and the worst monthly performances.

These findings define a significant parameter to size the coupled system and plan the production of a pilot plant. However, despite being outside the scope of this study, an economical assessment might demonstrate if the increment of the surface area in fact reduces the price of the specific permeate produced by the system.

3.2. Effect of VMD Set POINT Temperature on System’s Performance

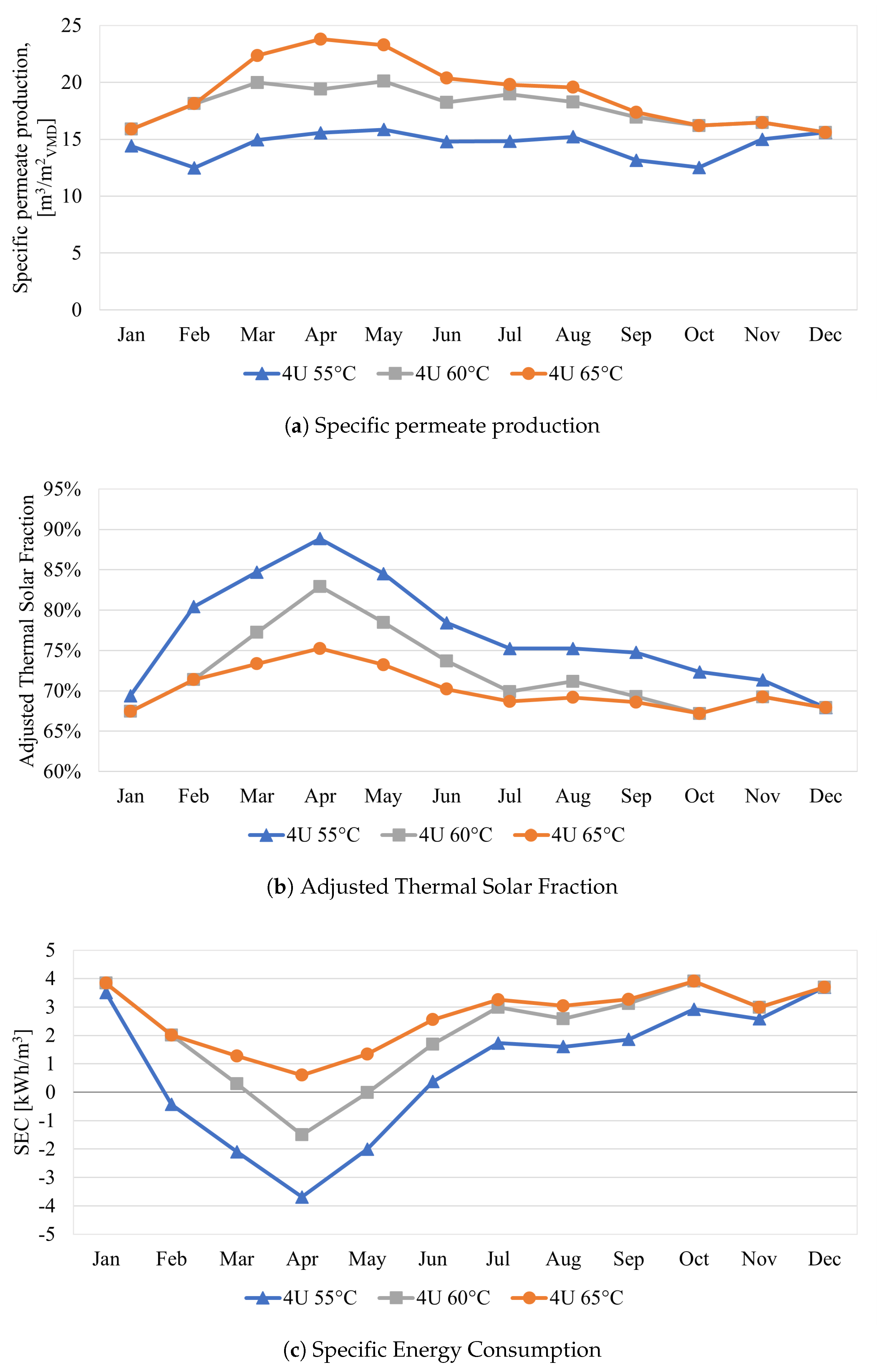

From the results of the previous parametric study, a surface area of 13 m2 (4-collector unit) was selected for the second study, where the effect of varying the set point temperature at which the brine reaches the VMD module was analyzed.

First, as shown in

Figure 5a, the 55 °C system presented a lower specific permeate production, mainly since a lower brine temperature at the VMD produces a lower pressure difference between the vapor pressure of the feed side and the vacuum pressure of the permeate side of the membrane. Moreover, it is clear from the results of the 60 and 65 °C runs that a higher brine set point temperature generates a larger specific permeate production, especially from March to June, when the solar radiation available is higher. Notably, from October to February, the production is the same for both cases. This could be occasioned by the low availability of solar radiation, insufficient to rise the brine temperature up to the set point temperature and turning on the auxiliary heater to compensate for the missing energy input similarly in both cases, thus generating the same permeate output during those months.

Despite a larger permeate production, a higher brine set point temperature results in a much lower adjusted thermal SF, as presented in

Figure 5b. Except for December, where the adjusted thermal SF for any brine set point temperature is the same, the 55 °C scenario showed a better performance for each month, reaching a top SF of 89% during April in comparison to the 83% and 75% peak-adjusted thermal SFs reached by the 60 and 65 °C scenarios, respectively. Moreover, despite the differences in performance, it is important to observe that the lowest adjusted thermal SF for the systems presented was 67%, occurring during October for both the 60 and 65 °C systems. However, this low performance is also present during December and January for all three systems. Therefore, an additional energy source could be used seasonally to enhance the performance of the system only during the months with low incident solar radiation.

Similarly to the metric previously discussed, the 55 °C system showed a lower SEC than the 60 and 65 °C systems, as displayed in

Figure 5c. Moreover, it presented negative SECs from February to May, reaching down to −3.69 kWh/m

3 during April. In particular, the 60 °C system also reached negative SEC values during April and May, achieving an SEC of −1.50 kWh/m

3 during the former month. Additionally, independent of the brine set point temperature, the SEC does not vary much from November to January, even reaching the same value during December. As mentioned for the specific permeate production, this is due to the use of the same auxiliary heater to increase the temperature of the underheated brine coming from the heat exchanger during months with low solar radiation and the use of an additional heating element during this period could enhance the performance of the system.

Since it is intended for this system to be developed as a stand-alone unit able to run without much support from the local electricity grid, a higher SF is more attractive and from the results of the second parametric study, the set point temperature of the brine at the entrance of the VMD module was defined as 55 °C for the performance study of the system under different weather conditions.

3.3. Multi-CITY Performance Analysis

The electrical and thermal conversion efficiencies for the CPVT module averaged 8.2% and 41.4%, respectively, and did not change significantly among the different cities. These values show that the CPVT system can convert practically half of the solar radiation it receives into useful energy for any desired application, which herein is the desalination process.

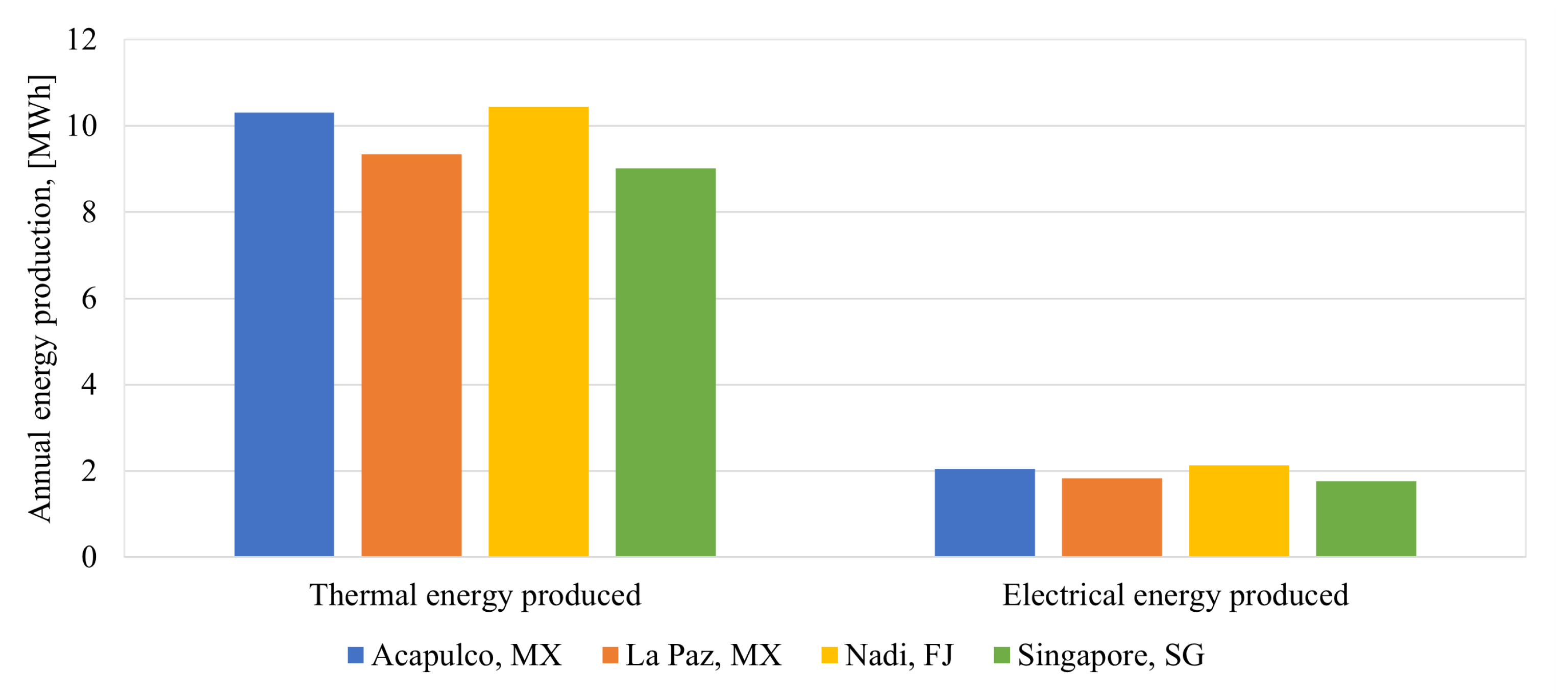

Figure 6 shows the annual thermal and electrical energies produced by the system under the weather conditions of each of the cities. Regardless of the location, the thermal energy production was significantly greater than the electrical output. The thermal and electrical energy production of Acapulco and Nadi cities was approximately 10% higher than the one of La Paz and Singapore. This behavior is expected due to the higher annual solar radiation of the Acapulco and Nadi cities.

The month-specific permeate production of each city is presented in

Figure 7. The largest annual production is presented in Acapulco, with 218.410 m

3/m

2VMD of permeate, followed by Nadi, with 209.415 m

3/m

2VMD, La Paz, with 185.886 m

3/m

2VMD and Singapore, with 170.365 m

3/m

2VMD. These values are coherent with those obtained from the literature [

18], further confirming the results obtained from these simulations.

The lowest monthly SEC among the cities was

kWh/m

3, reached in Acapulco, followed by Nadi with

kWh/m

3, La Paz with

kWh/m

3 and Singapore with

kWh/m

3. However, it is important to notice that the performance of the system in Singapore is the steadiest of the four, while in the other cities it varies considerably between seasons. Furthermore, as shown in

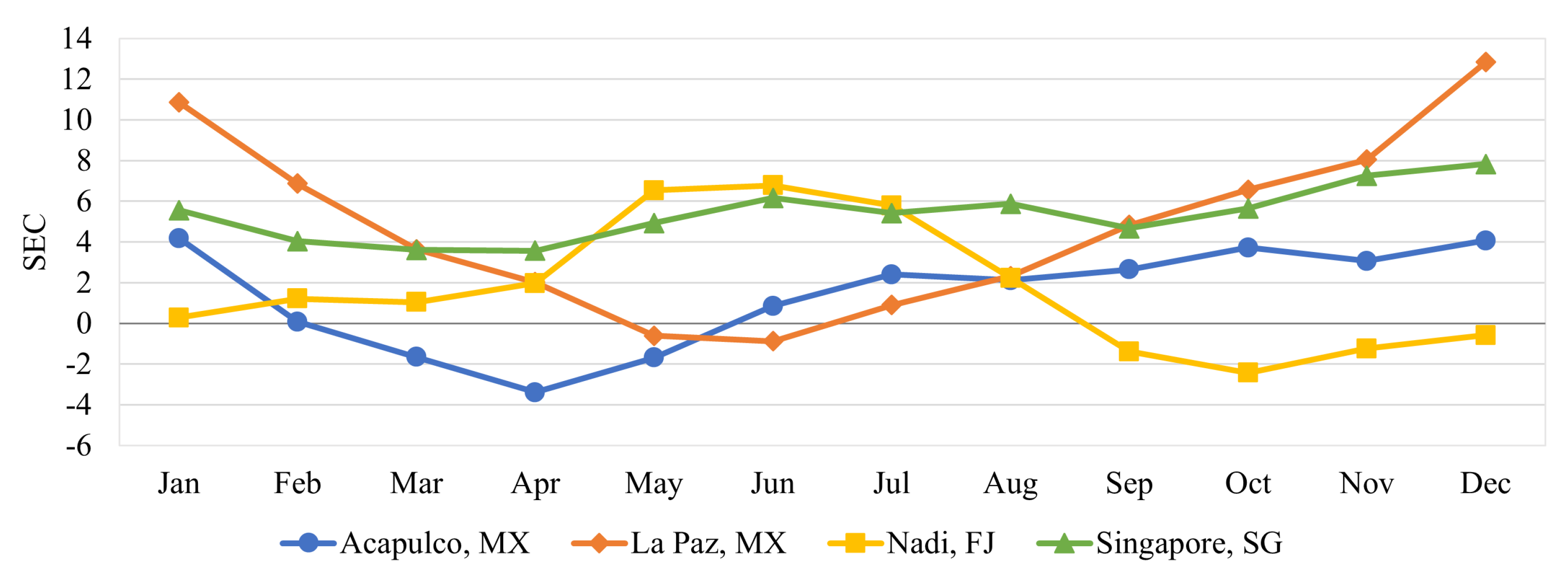

Figure 8, the coupled system reached negative SECs from March to May, in Acapulco; during May and June, in La Paz; and from September to December, in Nadi. This shows the great potential for desalination during the months with high solar radiation in each city.

As mentioned in

Section 2.4, one relevant metric to evaluate the performance of the integrated system is the solar fraction, which is directly related to the solar radiation in the city. Notably, since the electrical SF is larger than 100% throughout the year for every city, for the thermal SF, Equation (

18) will be implemented.

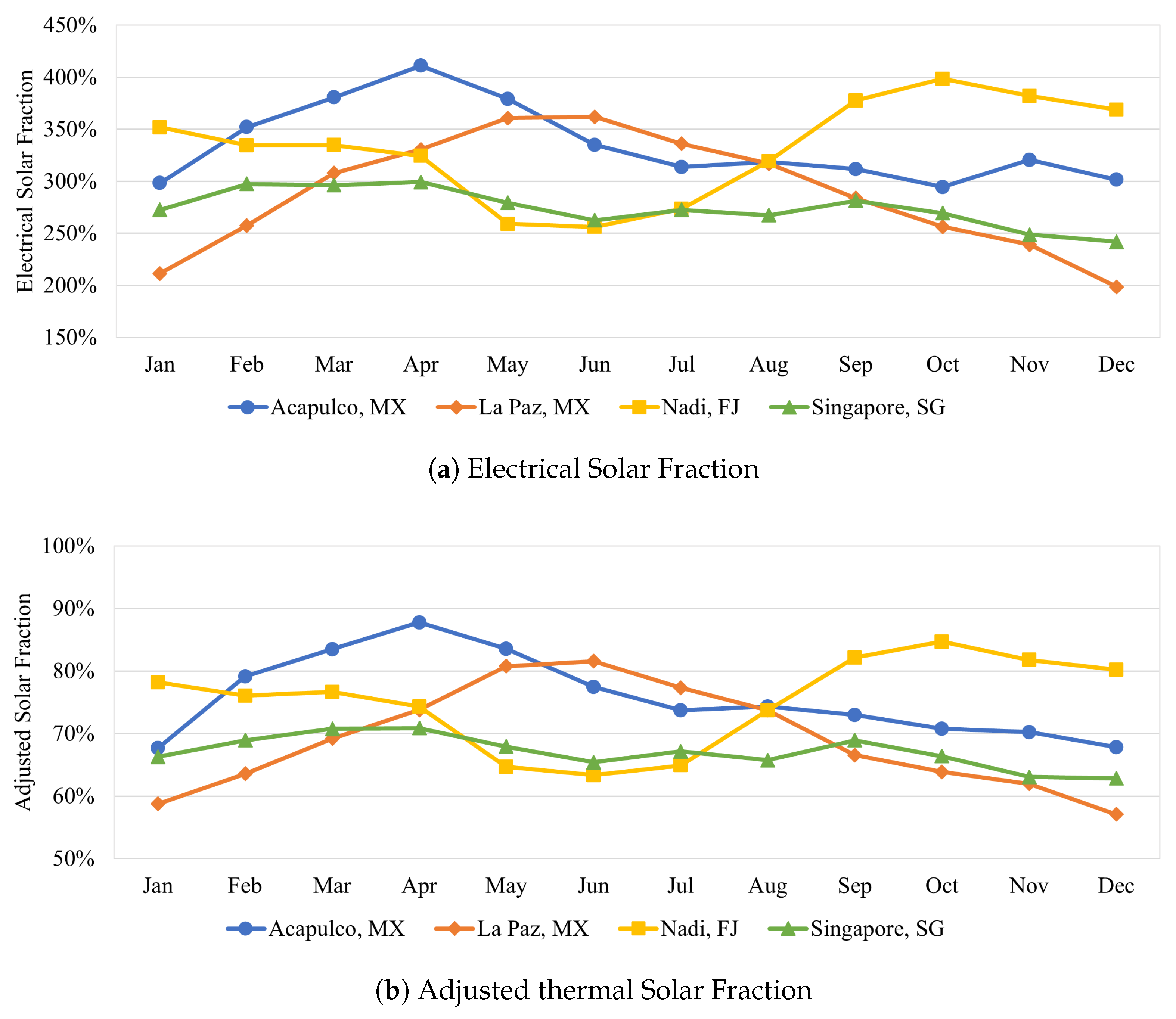

Figure 9 shows the monthly averaged daily solar radiation received by the system in each city and

Figure 10 presents a comparison of the monthly SF achieved by the system under the different weather conditions, showing a clear correlation between the amount of solar radiation received and the performance of the system. Importantly, despite the thermal energy production being larger than the electrical, the electrical SF, depicted in

Figure 10a, is over four times larger than its thermal counterpart, presented in

Figure 10b, due to the high thermal energy required by the system to increase the brine temperature before reaching the VMD module. In other words, the electrical requirement for running the pumps integrated into the system can be easily covered by the electricity produced by the CPVT module; however, the thermal energy produced is insufficient to cover the energy required to heat the brine to the set point temperature and it is necessary to supplement it with an additional external energy source.

Moreover, the location of each city with respect to the equator influences the system’s performance. As expected, a better performance is presented in the months with a higher incident solar radiation and vice versa: La Paz, the northernmost city in this analysis (Lat.: 24.1426 N), presents its peak performance during the summer months in the northern hemisphere, while Nadi, the southernmost city (Lat.: 17.7765 S), presents the opposite behaviour and Singapore, practically sitting on the equator (Lat.: 1.3521 N), remains mostly stable throughout the whole year but produces less permeate and electrical energy.

3.4. Economic Analysis

In order to have an estimation of the cost of the proposed system, an economic analysis is performed. The data and results of Acapulco, MX, are for this analysis.

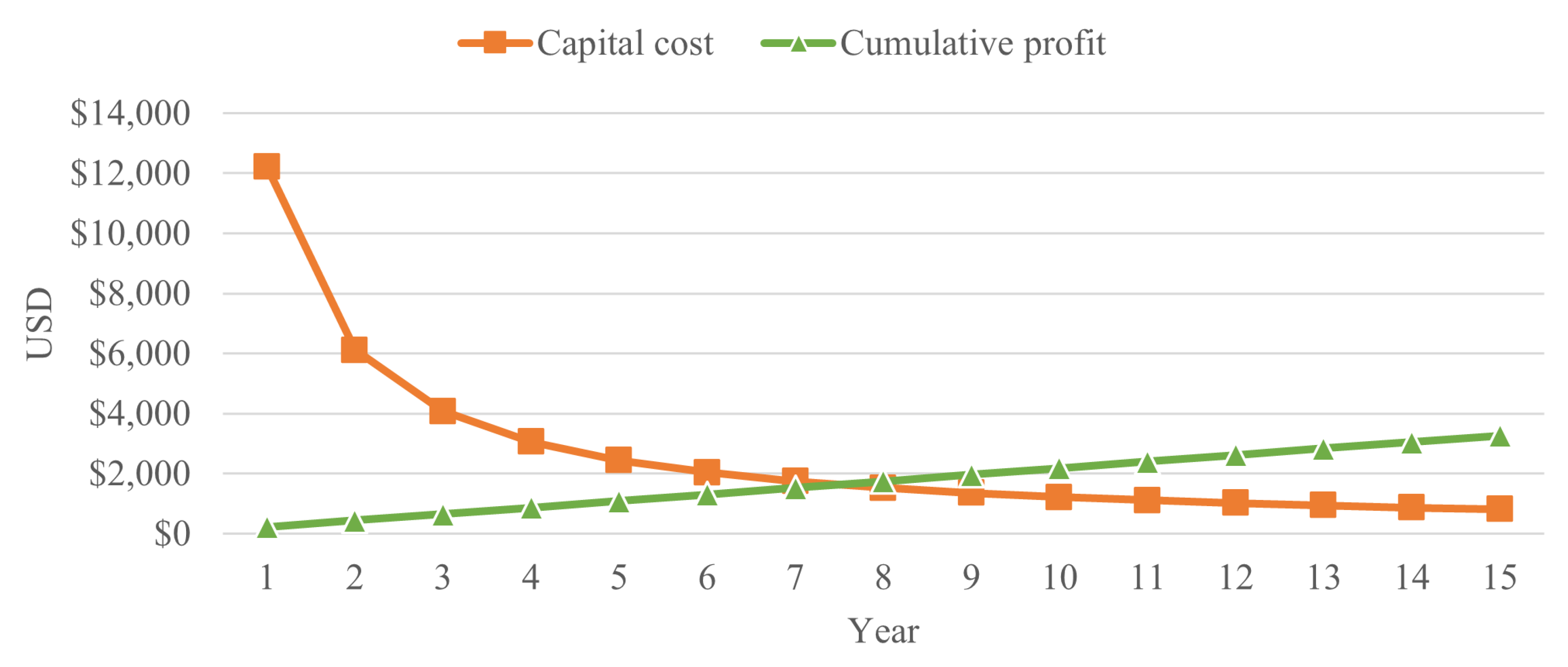

Table A2 presents a list of all the components required to assemble the CPVT-VMD system with their respective prices. From this calculation, a subtotal capital cost of USD 10,186.11 was estimated for the whole system. Moreover, an estimated installation cost of 20% [

26] was selected for this analysis, reaching a total capital cost of USD 12,223.33.

Once the capital costs were determined, a financial run spanning 15 years was performed to identify how this seemingly heavy initial investment is deferred with every year the system operates. Not only that, but this was used to calculate the Return of Investment (ROI) period and the Specific production cost for every m

3 of permeate produced. A cost of USD 1 per m

3 of supplied water is considered based on the site of the local water supplier of Acapulco, MX [

43]. Additionally, as presented in the previous section, a constant annual production of 218 m

3 of permeate was considered for this run.

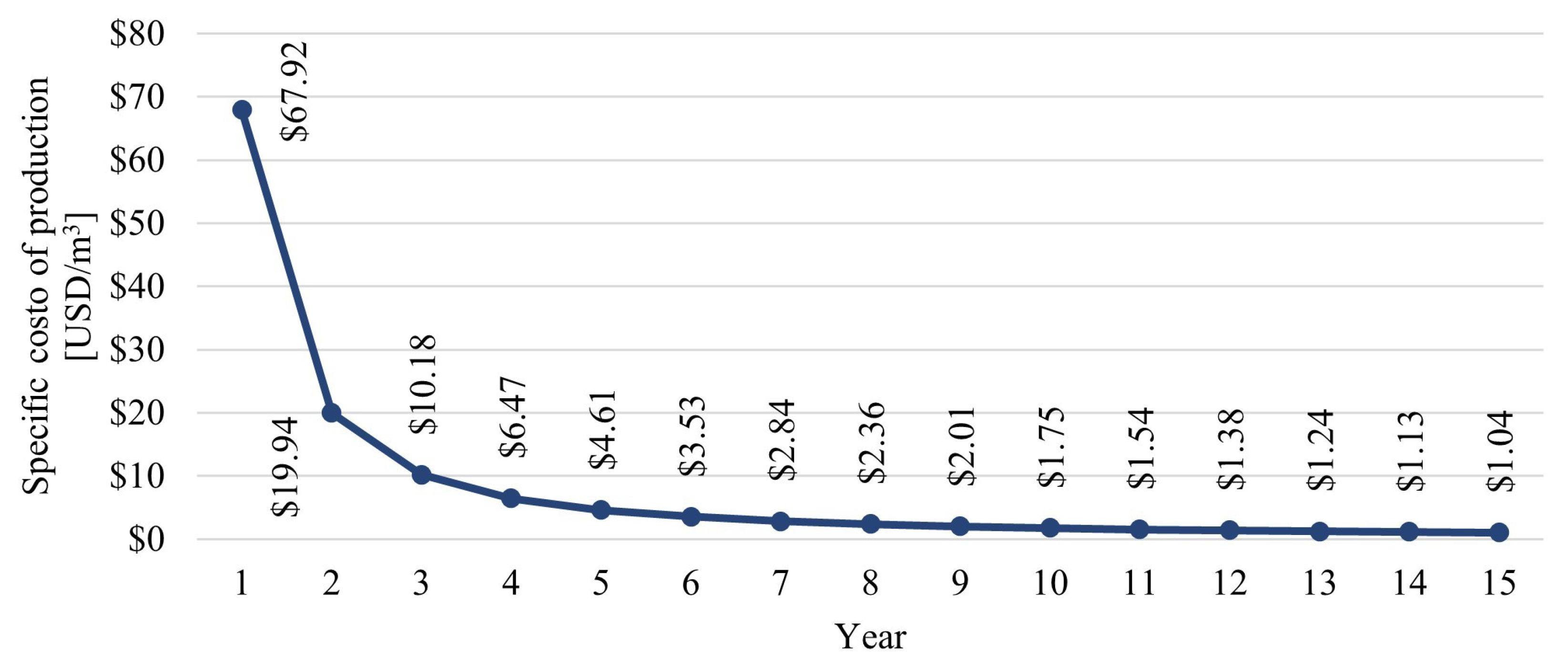

Figure 11 depicts the results of the ROI analysis for this system. It is noticeable that the deferment of the capital cost of the system has an exponential reduction with every year that the system is operating, reaching a break-even point after 7 years, achieving its first profits on the eighth. On the other hand, as shown in

Figure 12, the cost of producing 1 m

3 of permeate via the proposed system also decreases exponentially with every year the system operates. In this case, even after 15 years of operation, the cost per m

3 is not able to match the local supplier price of USD 1 per m

3 but it is still a more competitive cost than those presented by other authors in the literature such as Elminshawy et al. (22.48 USD/m

3) [

17] or Chen et al. (2.71 USD/m

3) [

18]. A larger VMD membrane area could reduce the capital and variable costs of the system, achieving lower price for every m

3 of permeate produced.

In summary, from the energy and economic analysis, the results show the potential of this coupled system for the production of electrical energy and fresh water. Possible applications could involve the development of a low-cost prototype, which could aid remote coastal communities by supplying clean energy and water for their inhabitants. Future work must focus on the development of the prototype system required to experimentally validate the simulations.

4. Conclusions

The dynamic behavior of the coupled CPVT-VMD solar desalination system was studied under the weather conditions of Acapulco, MX, La Paz, MX, Nadi, FJ, and Singapore, SG, throughout a whole year. A transient simulation was developed in TRNSYS to evaluate the system performance and parametric studies help to identify the optimal operating conditions for the test. The CPVT model was previously developed by [

21] and is represented in the simulation by a modified Type 50f component. Similarly, the VMD model was previously developed by [

33] and a new Type was written using TypeStudo to include it in the simulation.

From the results of the parametric studies, the operating conditions considered for the multi-city system’s evaluation were 4-collector units (13 m2) and a set point temperature of 55 °C. The results showed that independent of the city evaluated, the system could fully cover the electrical energy requirements for its operation and a significant part of the thermal requirements and also that the performance of the system is strongly related to the solar radiation received in the city, i.e., a higher solar radiation results in a better performance. Additionally, the CPVT system can convert almost 50% of the received solar radiation into useful energy (8% into electricity and 41% into heat). The permeate production varied from 170.365 m3/m2VMD in Singapore, SG, to 218.410 m3/m2VMD in Acapulco, MX, with 185.885 and 209.415 m3/m2VMD produced in La Paz, MX, and Nadi, FJ, respectively, similar to other values presented in the literature regarding the solar-assisted VMD permeate production. From the economical analysis, it was determined that for the city of Acapulco, after 7 years a profit can be obtained with the proposed solar desalination system. The cost of producing 1 m3 of permeate approaches exponentially the low local supplier price and it is competitive with others costs reported in the literature with similar solar membrane distillation systems.

This work provides relevant information for the development of a functional prototype, which could further be scaled up to a pilot plant.