Productivity Augmentation of Solar Stills by Coupled Copper Tubes and Parabolic Fins

Abstract

:1. Introduction

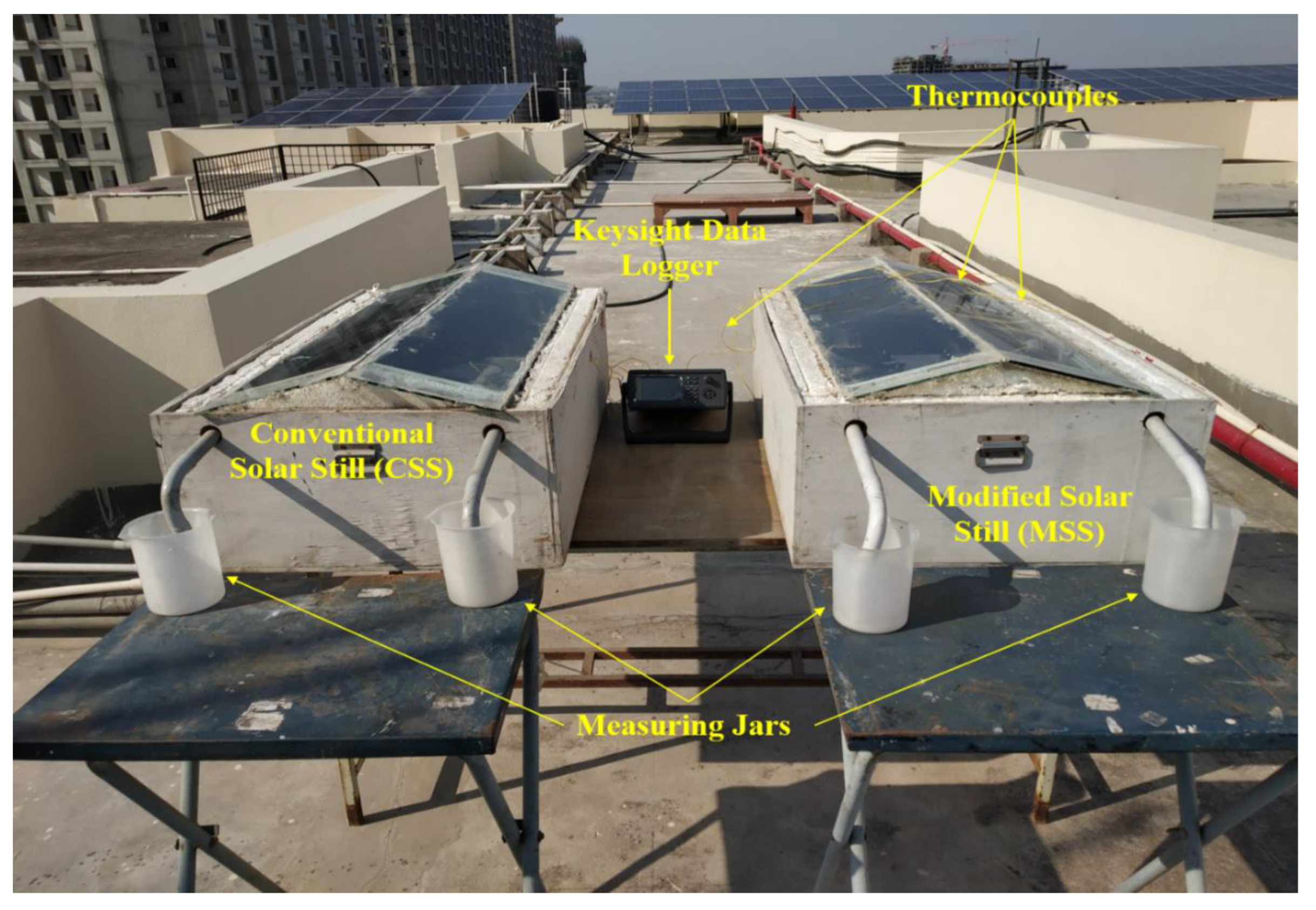

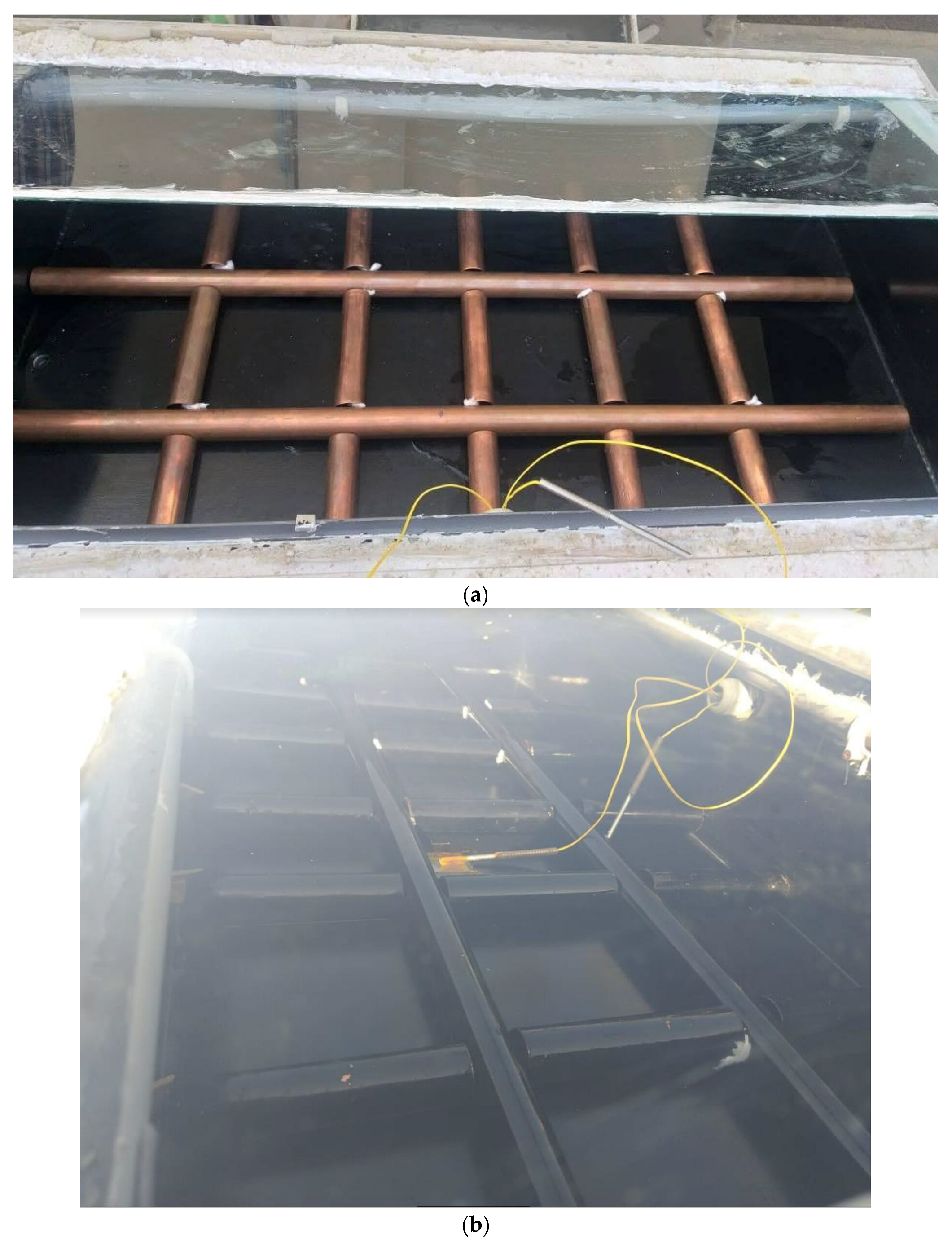

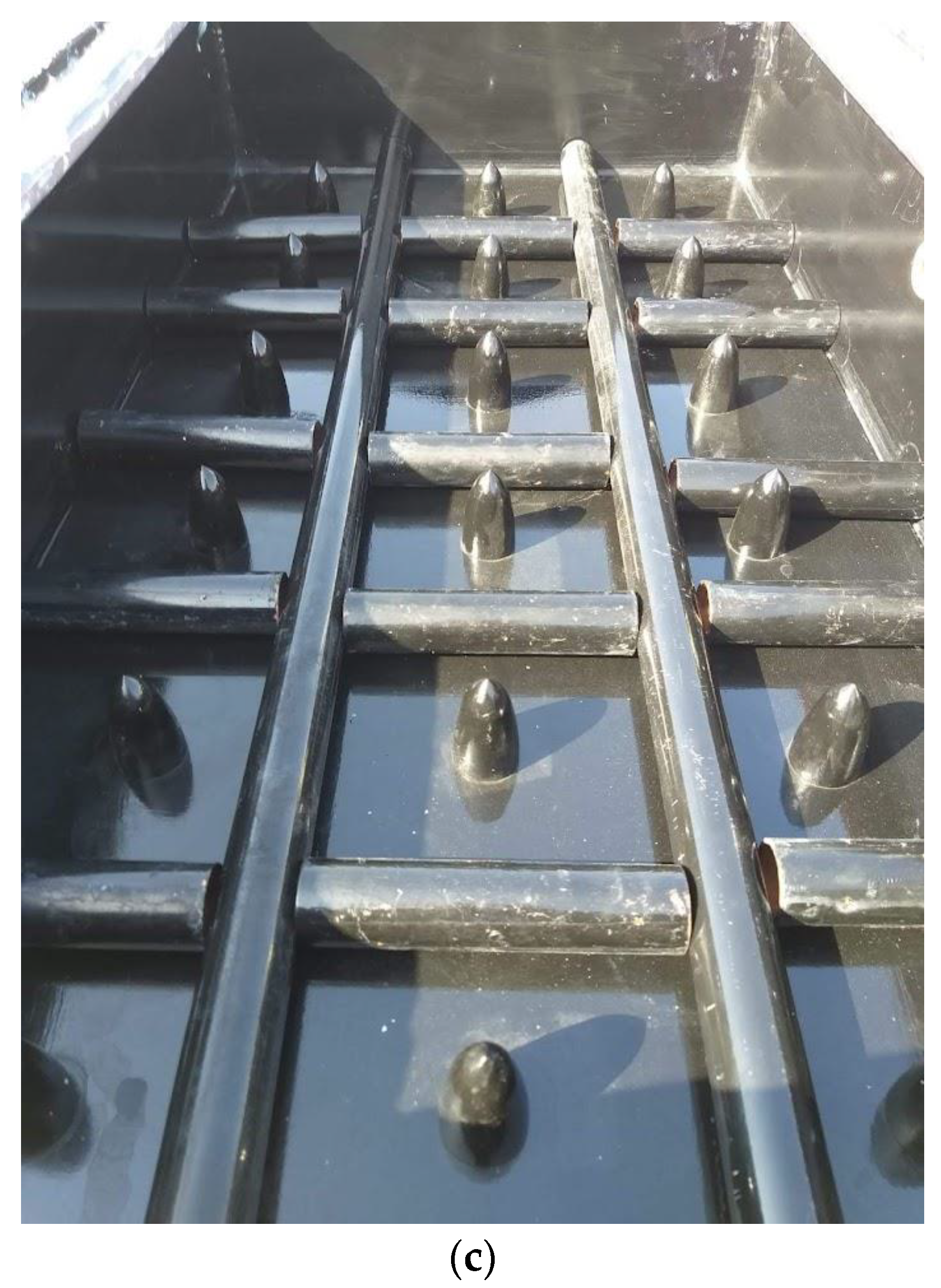

2. Materials and Experimental Framework

Uncertainty Analysis

3. Results and Discussions

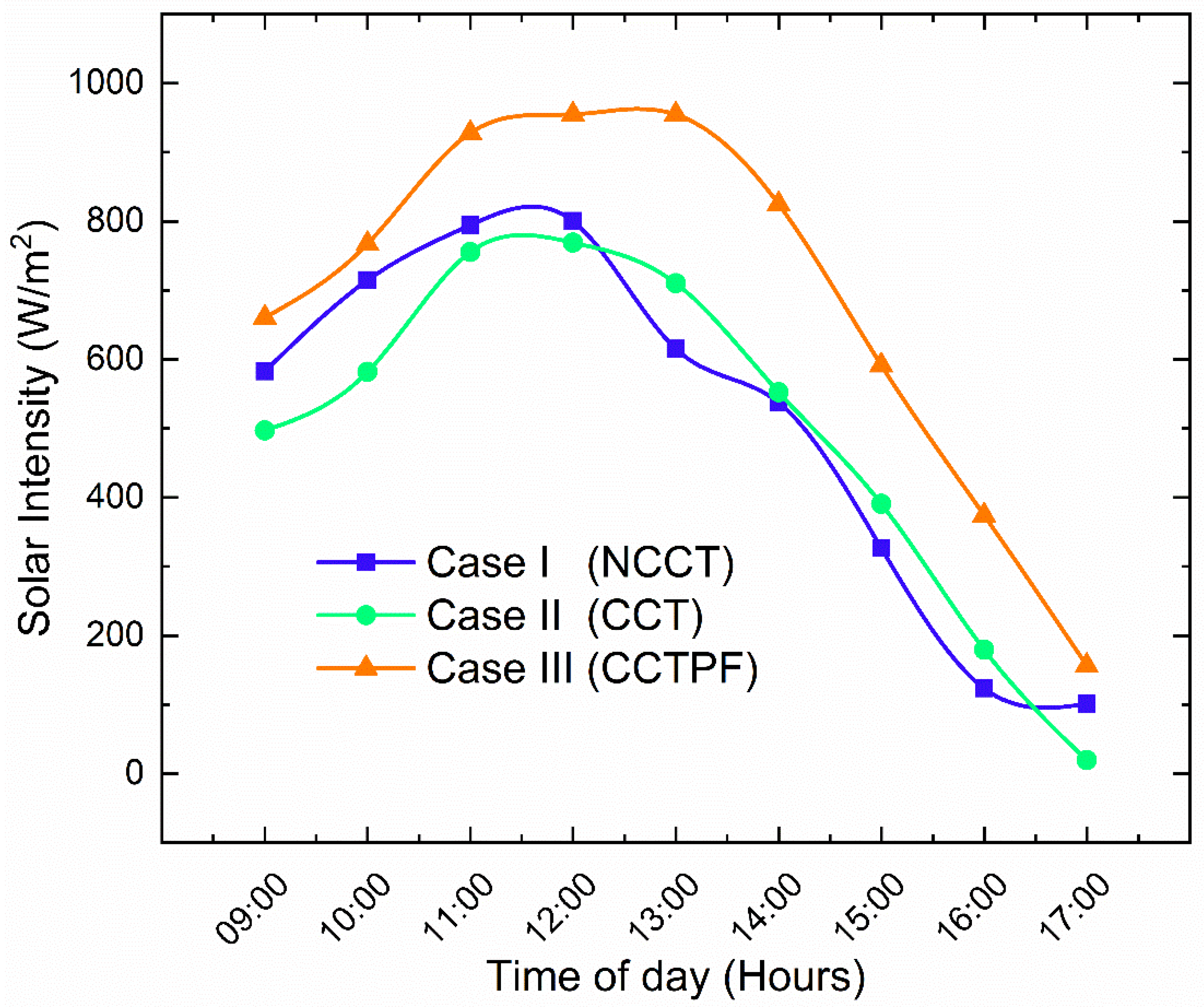

3.1. Solar Intensity

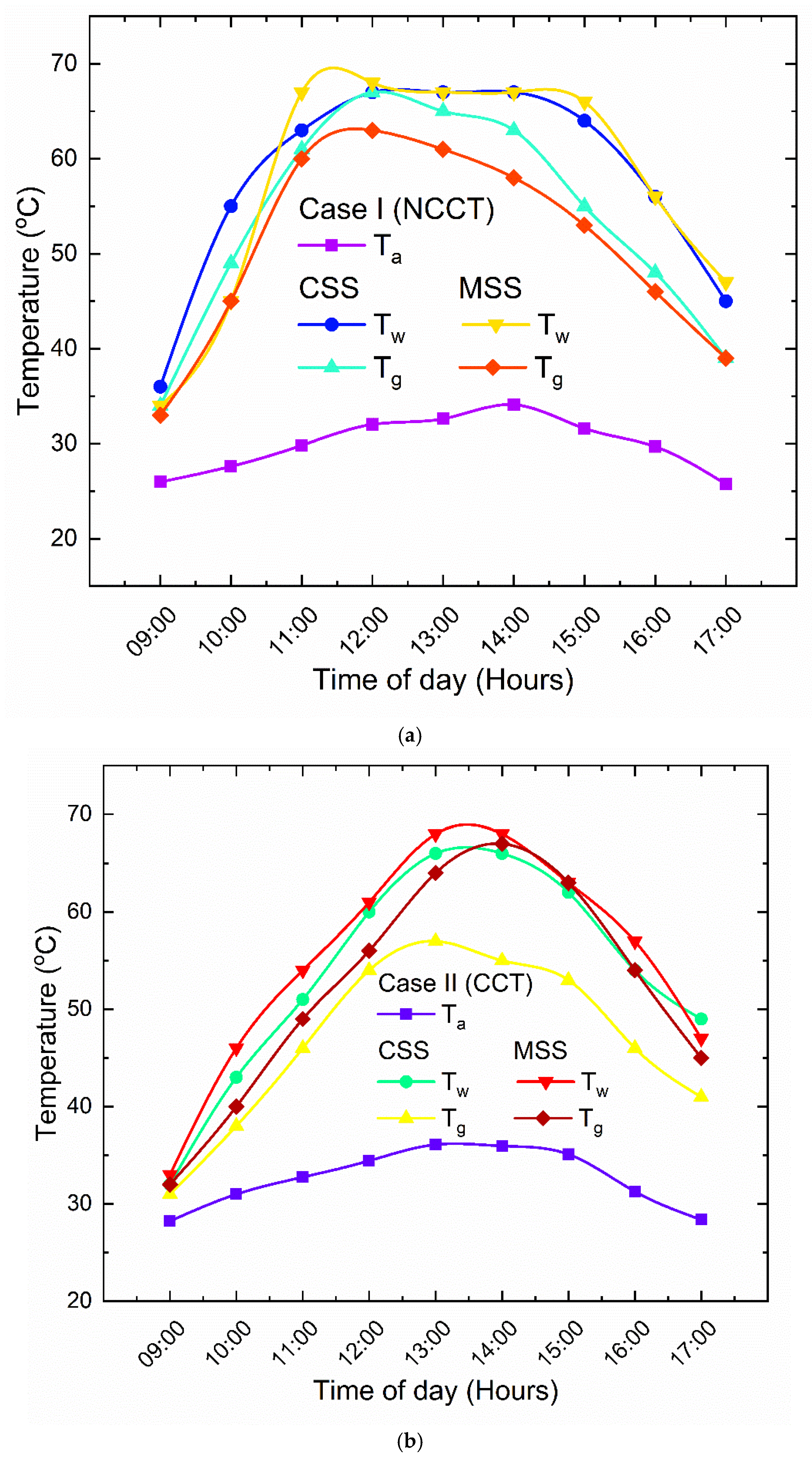

3.2. Temperature Profiles

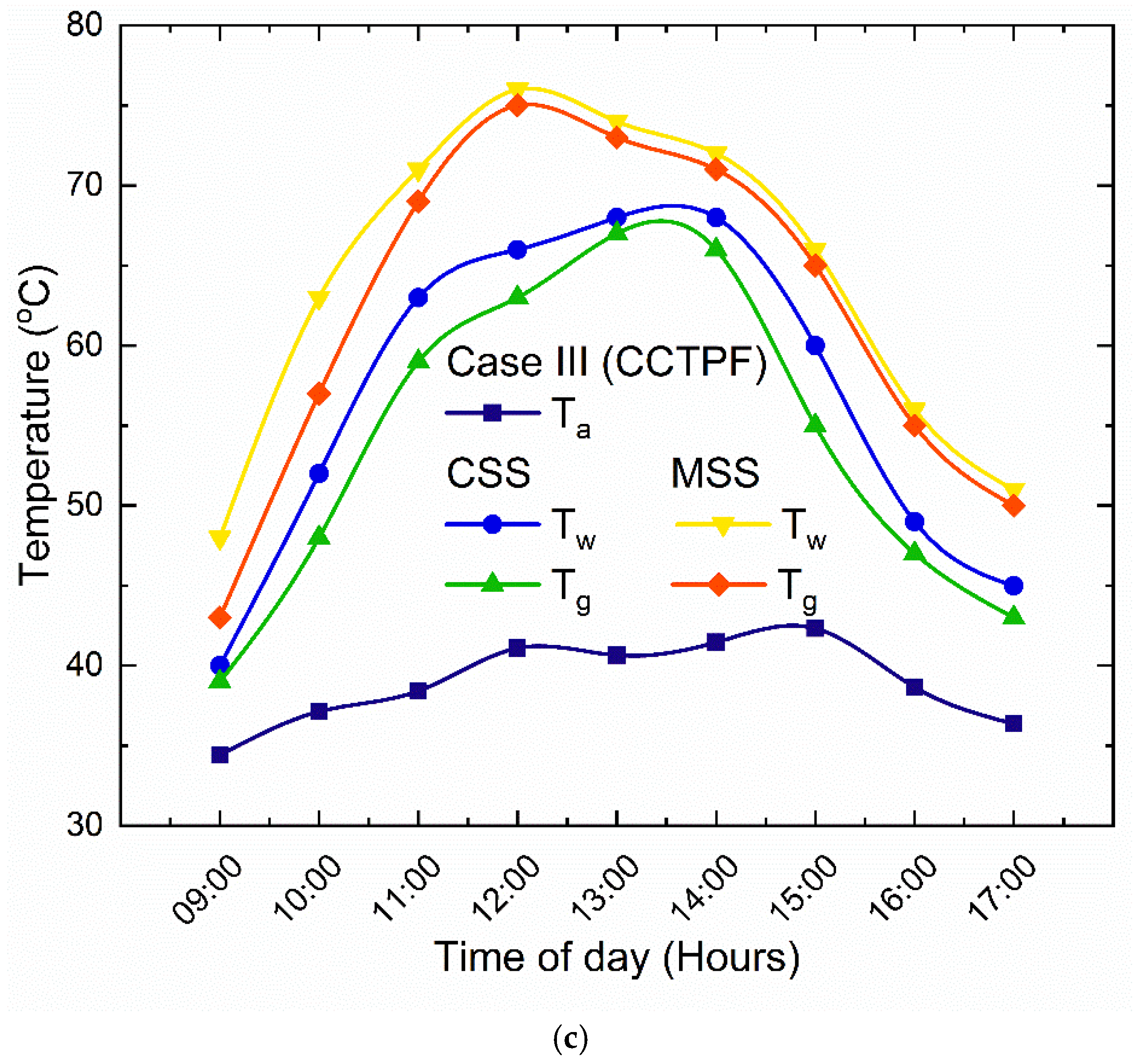

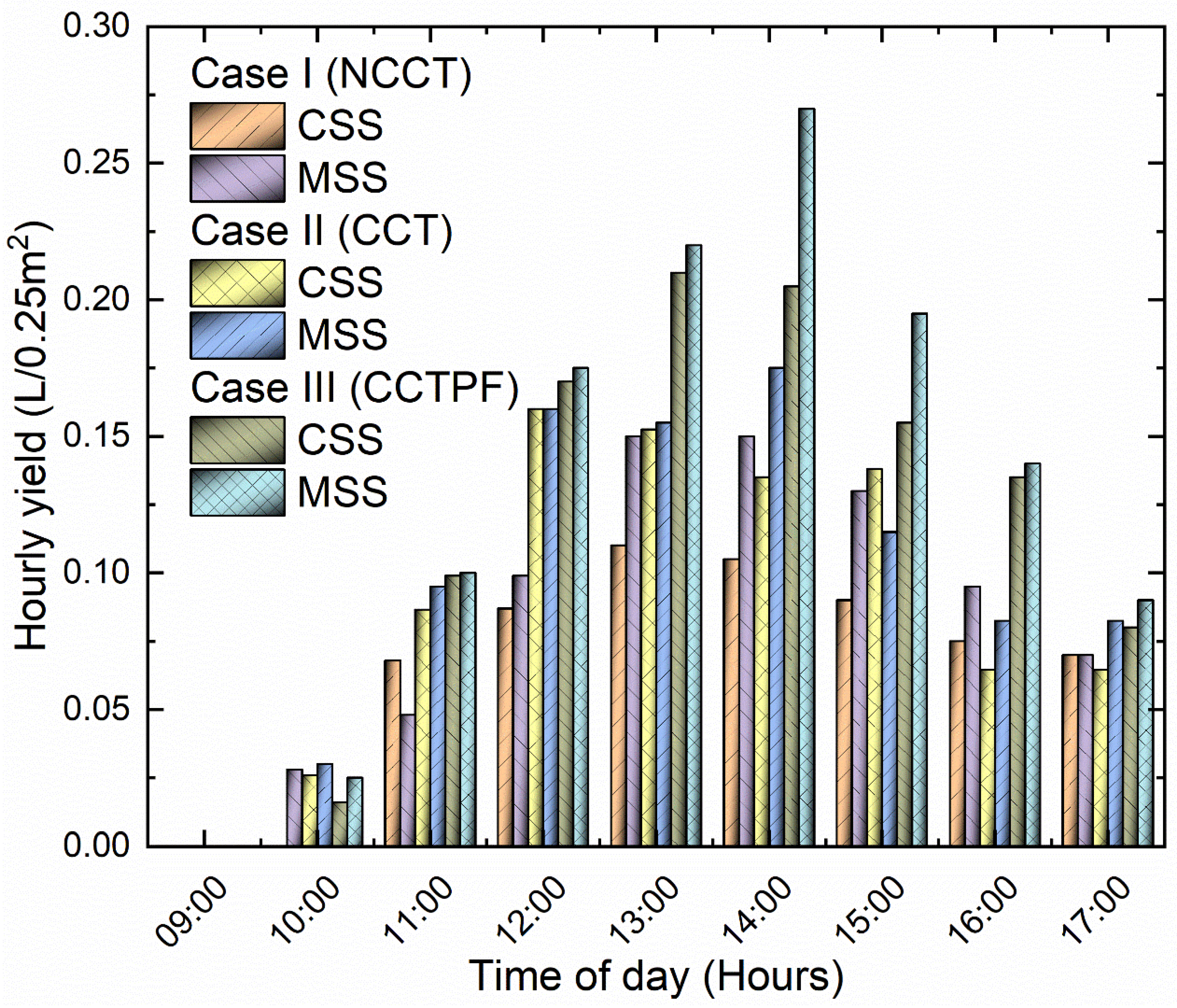

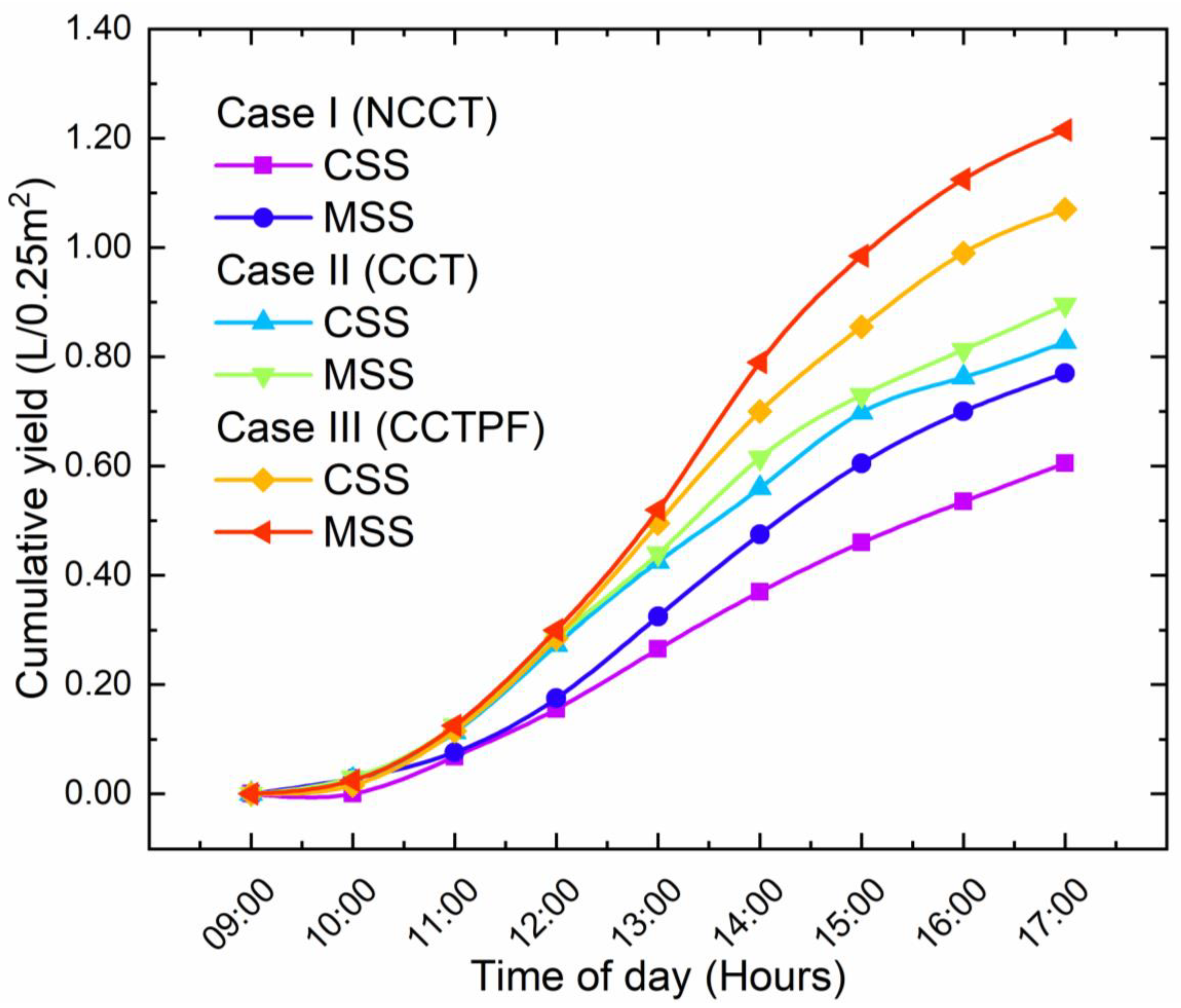

3.3. Hourly and Cumulative Yields

3.4. Water Quality Analysis

4. Monetary Analysis

- Number of sunny days (n) = 250;

- Interest rate (i) = 12%;

- Life of solar still (y) = 10 Years.

- c = Yield/day;

- n = sunny days/year.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akkala, S.R.; Kaviti, A.K. Impact of different fins designs on performance of solar still desalination system: A review. Environ. Dev. Sustain. 2023, 29, 1–42. [Google Scholar] [CrossRef]

- Akkala, S.R.; Kumar Kaviti, A. Advanced design techniques in passive and active tubular solar stills: A review. Environ. Sci. Pollut. Res. 2022, 29, 48020–48056. [Google Scholar] [CrossRef] [PubMed]

- Kaviti, A.K.; Akkala, S.R.; Ali, M.A.; Anusha, P.; Kaviti, A.K. Amplification of productivity of distillate using cerium oxide nanofluid in solar powered desalination. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 1226–1240. [Google Scholar] [CrossRef]

- Ram, S.; Kumar, A.; Arunkumar, T.; Singh, V. Progress on suspended nanostructured engineering materials powered solar distillation—A review. Renew. Sustain. Energy Rev. 2021, 143, 110848. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Akkala, S.R.; Ali, M.A.; Anusha, P.; Sikarwar, V.S. Performance Improvement of Solar Desalination System Based on CeO2-MWCNT Hybrid Nanofluid. Sustainability 2023, 15, 4268. [Google Scholar] [CrossRef]

- Irshad, M.S.; Hao, Y.; Arshad, N.; Alomar, M.; Lin, L.; Li, X.; Wageh, S.; Al-Hartomy, O.A.; Al-Sehemi, A.G.; Dao, V.-D.; et al. Highly charged solar evaporator toward sustainable energy transition for in-situ freshwater & power generation. Chem. Eng. J. 2023, 458, 141431. [Google Scholar] [CrossRef]

- Muthu Saravanan, N.; Rajakumar, S.; Moshi, A.A.M. Experimental investigation on the performance enhancement of single basin double slope solar still using kanchey marbles as sensible heat storage materials. Mater. Today Proc. 2020, 39, 1600–1604. [Google Scholar] [CrossRef]

- Alawee, W.H.; Dhahad, H.A.; Mohamed, T.A. An experimental study on improving the performance of a double slope solar still. In Proceedings of the 7 th International Conference on Sustainable Agriculture for Food, Energy and Industry in Regional and Global Context, Kuala Lumpur, Malaysia, 25–27 August 2015; Volume 5, pp. 1–11. [Google Scholar]

- Panchal, P.H.N. Effect of Different parameters on double slope solar still productivity. Int. J. Adv. Sci. Eng. 2011, 1, 17–21. [Google Scholar]

- Irshad, M.S.; Arshad, N.; Zhang, J.; Song, C.; Mushtaq, N.; Alomar, M.; Shamim, T.; Dao, V.-D.; Wang, H.; Wang, X.; et al. Wormlike Perovskite Oxide Coupled with Phase-Change Material for All-Weather Solar Evaporation and Thermal Storage Applications. Adv. Energy Sustain. Res. 2023, 4, 2200158. [Google Scholar] [CrossRef]

- Murugavel, K.K.; Sivakumar, S.; Ahamed, J.R.; Chockalingam, K.K.S.K.; Srithar, K. Single basin double slope solar still with minimum basin depth and energy storing materials. Appl. Energy 2010, 87, 514–523. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Ram, A.S.; Thakur, A.K. Influence of fully submerged permanent magnets in the evaluation of heat transfer and performance analysis of single slope glass solar still. J. Power Energy 2021, 236, 109–123. [Google Scholar] [CrossRef]

- Dhivagar, R.; Sundararaj, S. A Review on Methods of Productivity Improvement in Solar Desalination. Appl. Mech. Mater. 2018, 877, 414–429. [Google Scholar] [CrossRef]

- Ullah, I.; Rasul, M.G. Recent developments in solar thermal desalination technologies: A review. Energies 2019, 12, 119. [Google Scholar] [CrossRef]

- Li, C.; Goswami, Y.; Stefanakos, E. Solar assisted sea water desalination: A review. Renew. Sustain. Energy Rev. 2013, 19, 136–163. [Google Scholar] [CrossRef]

- Mevada, D.; Panchal, H.; Kumar Sadasivuni, K.; Israr, M.; Suresh, M.; Dharaskar, S.; Thakkar, H. Effect of fin configuration parameters on performance of solar still: A review. Groundw. Sustain. Dev. 2020, 10, 100289. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Mary, B.; Ram, A.S. Effect of Truncated Conic Fins in Distillate of Double Slope Solar Still. In Innovations in Mechanical Engineering: Select Proceedings of ICIME 2021; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Jani, H.K.; Modi, K.V. Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol. Energy 2019, 179, 186–194. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Naike, V.R.; Ram, A.S.; Thakur, A.K. Energy and exergy analysis of a truncated and parabolic finned double slope solar stills. Int. J. Ambient. Energy 2021, 43, 6210–6223. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-maghlany, W.M.; Abdelgaied, M.; Abdel-aziz, M.M. Performance enhancement of pyramid-shaped solar stills using hollow circular fins and phase change materials. J. Energy Storage 2020, 31, 101610. [Google Scholar] [CrossRef]

- Kateshia, J.; Lakhera, V.J. Analysis of solar still integrated with phase change material and pin fins as absorbing material. J. Energy Storage 2021, 35, 102292. [Google Scholar] [CrossRef]

- Modi, K.V.; Patel, U.N.; Patel, S.J.; Patel, J.N.; Patel, S.R. Efficacy of partially and fully submerged circular cross-section metal hollow-fins and black cotton cloth wick-segments on a single-basin dual-slope solar still. J. Clean. Prod. 2022, 344, 131059. [Google Scholar] [CrossRef]

- Mevada, D.; Panchal, H.; Ahmadein, M.; Zayed, M.E.; Alsaleh, N.A.; Djuansjah, J.; Moustafa, E.B.; Elsheikh, A.H.; Sadasivuni, K.K. Investigation and performance analysis of solar still with energy storage materials: An energy-exergy efficiency analysis. Case Stud. Therm. Eng. 2022, 29, 101687. [Google Scholar] [CrossRef]

- Balachandran, G.B.; David, P.W.; Mariappan, R.K.; Kabeel, A.E.; Athikesavan, M.M.; Sathyamurthy, R. Improvising the efficiency of single-sloped solar still using thermally conductive nano-ferric oxide. Environ. Sci. Pollut. Res. 2020, 27, 32191–32204. [Google Scholar] [CrossRef] [PubMed]

- Rabbi, H.M.F.; Sahin, A.Z. Performance improvement of solar still by using hybrid nanofluids. J. Therm. Anal. Calorim. 2021, 143, 1345–1360. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Akkala, S.R.; Sikarwar, V.S. Productivity enhancement of stepped solar still by loading with magnets and suspended micro charcoal powder. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1–19. [Google Scholar] [CrossRef]

- Kabeel, A.E.; El-Agouz, E.S.; Athikesavan, M.M.; Duraisamy Ramalingam, R.; Sathyamurthy, R.; Prakash, N.; Prasad, C. Comparative analysis on freshwater yield from conventional basin-type single slope solar still with cement-coated red bricks: An experimental approach. Environ. Sci. Pollut. Res. 2020, 27, 32218–32228. [Google Scholar] [CrossRef]

- Singh, J.; Mittal, M.K.; Khullar, V. Nanofluid-based wick-type integrated solar still for improved diurnal and nocturnal distillate production. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 10094–10115. [Google Scholar] [CrossRef]

- Kaviti, A.K.; Akkala, S.R.; Sikarwar, V.S.; Snehith, P.S.; Mahesh, M. Camphor-Soothed Banana Stem Biowaste in the Productivity and Sustainability of Solar-Powered Desalination. Appl. Sci. 2023, 13, 1652. [Google Scholar] [CrossRef]

- Panchal, H.; Sathyamurthy, R.; Kabeel, A.E.; El-Agouz, S.A.; Rufus, D.; Arunkumar, T.; Manokar, A.M.; Winston, D.P.; Sharma, A.; Thakar, N.; et al. Annual performance analysis of adding different nanofluids in stepped solar still. J. Therm. Anal. Calorim. 2019, 138, 3175–3182. [Google Scholar] [CrossRef]

- Panchal, H.; Sadasivuni, K.K.; Shanmugan, S.; Pandya, N. Performance analysis of waste brick magnesia as a storage material in a solar still. Heat Transf. 2021, 50, 1799–1811. [Google Scholar] [CrossRef]

- Afzal, S.; Kumar, A.; Rao, S.; Sakthivel, S.; Harish, T.; Kumar, K.V.; Rao, T.S.; Thaker, A.; Reddy, K.V.; Naga Sai, A.M.; et al. Performance analysis of non-contact nanostructure solar desalination system by varying water depth at a constant air gap. Sol. Energy 2022, 247, 485–498. [Google Scholar] [CrossRef]

- Rufuss DD, W.; Suganthi, L.; Iniyan, S.; Davies, P.A. Effects of nanoparticle-enhanced phase change material (NPCM) on solar still productivity. J. Clean. Prod. 2018, 192, 9–29. [Google Scholar] [CrossRef]

- Fath, H.E.S.; El-Samanoudy, M.; Fahmy, K.; Hassabou, A. Thermal-economic analysis and comparison between pyramid-shaped and single-slope solar still configurations. Desalination 2003, 159, 69–79. [Google Scholar] [CrossRef]

| Measuring Device | Accuracy | Percentage Error | Standard Uncertainty |

|---|---|---|---|

| Anemometer | ±0.1 m/s | 10 | 0.06 m/s |

| Keysight data logger | ±0.1 °C | 1.3 | 0.06 °C |

| Thermocouple sensors | 0.5 °C | 0.25 | ±0.8 °C |

| Measuring jars | ±5 mL | 5 | 3 mL |

| pyranometer | 5.77 W/m2 | 10 | ±10 W/m2 |

| S. No. | Author | Material Type | Desalination Percentage | Distillate Yield (L/m2) |

|---|---|---|---|---|

| 1. | Mevada et al. [23] | Marbles stones & Black granite | 72.6% | 2.50 |

| 2. | Balachandran et al. [24] | Nano-Fe2O3 | 68% | 4.39 |

| 3. | Hossain and Sahin [25] | Hybrid nanofluid (Al2O3-water-SiO2) | 37.76% | 4.99 |

| 4. | Kumar et al. [26] | Magnets and charcoal | 104.54% | 6.3 |

| 5. | Kabeel et al. [27] | Cement coated red bricks coated | 45% | 6.3 |

| 6. | Singh al. [28] | Wicks and nanofluid | 89.9% | NA |

| 7. | Kaviti et al. [29] | Camphor soothed stems | 36.35% | 3.7 |

| 8. | Panchal et al. [30] | TiO2 and MgO nanofluids | 20.4% & 45.8% | 3.5 & 2.7 |

| 9. | Hitesh et al. [31] | Magnesia Waste brick | NA | 2.07 |

| 10. | Present study | Case I—NCCT | 3.08 | |

| Case II—CCT | 3.58 | |||

| Case III—CCTPF | 4.86 |

| Parameters of Water Quality | Prior to Desalination | After Desalination (MSS) | After Desalination (CSS) | Maximum Permitted Quantities in Drinkable Water (WHO and BIS Standards) [32] |

|---|---|---|---|---|

| Hardness (mg/L) | 380 | 140 | 160 | 200 |

| pH | 8.18 | 7.23 | 7.64 | 8.5 |

| Fluoride (mg/L) | 0.734 | 0.428 | 0.569 | 1.5 |

| Chloride (mg/L) | 75.6 | 10.58 | 15.73 | 250 |

| TDS (ppm) | 440 | 20 | 55 | 500 |

| S. No | Service/Material | Quantity/Area/per Still | CSS (USD) | MSS (USD) |

|---|---|---|---|---|

| 1. | Aluminum basin | 2.5 m2 | 15 | 15 |

| 2. | PVC channel | 2 | 3 | 3 |

| 3. | Black powder coating | 0.5 m2 | 2 | 2 |

| 4. | Glass cover, 0.4 cm | 0.5 m2 | 1 | 1 |

| 5. | Double-side tape | 1.5 m | 1 | 1 |

| 6. | Silicon glue | 1 | 2 | 2 |

| 7. | Copper tubes | 17 | - | 12 |

| 8. | Fins | 18 | - | 15 |

| 9. | Thermocol | - | 2 | 2 |

| 10. | Fabrication charges | - | 30 | 30 |

| Total cost | - | 56$ | 83$ |

| Parameters in USD | Conventional Still (CSS) | Modified Still (MSS) |

|---|---|---|

| P | 56 | 83 |

| CRF | 0.177 | 0.177 |

| FAC | 9.91 | 14.69 |

| S | 11.2 | 16.6 |

| SFF | 0.05698 | 0.05698 |

| ASV | 0.6381 | 0.9458 |

| AMC | 1.48 | 2.20 |

| AC | 10.75 | 15.94 |

| M | 267.5 | 300 |

| CPL | 0.040 | 0.053 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaviti, A.K.; Teja, M.; Madhukar, O.; Teja, P.B.; Aashish, V.; Gupta, G.S.; Sivaram, A.; Sikarwar, V.S. Productivity Augmentation of Solar Stills by Coupled Copper Tubes and Parabolic Fins. Energies 2023, 16, 6606. https://doi.org/10.3390/en16186606

Kaviti AK, Teja M, Madhukar O, Teja PB, Aashish V, Gupta GS, Sivaram A, Sikarwar VS. Productivity Augmentation of Solar Stills by Coupled Copper Tubes and Parabolic Fins. Energies. 2023; 16(18):6606. https://doi.org/10.3390/en16186606

Chicago/Turabian StyleKaviti, Ajay Kumar, Magadapalli Teja, Oruganti Madhukar, Polaboina Bhanu Teja, Vakapalli Aashish, Gembali Srinivasa Gupta, Akkala Sivaram, and Vineet Singh Sikarwar. 2023. "Productivity Augmentation of Solar Stills by Coupled Copper Tubes and Parabolic Fins" Energies 16, no. 18: 6606. https://doi.org/10.3390/en16186606

APA StyleKaviti, A. K., Teja, M., Madhukar, O., Teja, P. B., Aashish, V., Gupta, G. S., Sivaram, A., & Sikarwar, V. S. (2023). Productivity Augmentation of Solar Stills by Coupled Copper Tubes and Parabolic Fins. Energies, 16(18), 6606. https://doi.org/10.3390/en16186606