Abstract

In many countries, Heavy Fuel Oil (HFO) is still a common fuel in industrial applications due to its low price and high energy density. However, the complex and incomplete combustion of HFO results in high levels of emissions and low efficiency, which causes the search for additives to improve its properties without affecting its heating value. The present paper aims to use as an additive the liquid fraction from pyrolysis of the polystyrene for fuel oil, replacing conventional additives such as cutter stock, improving its fluidity without using heat to pump it. As for pyrolysis for obtaining pyrolytic oil, the effect of temperature on the chemical composition of the liquid fraction from the thermal pyrolysis of compact polystyrene was studied. PS pyrolysis was carried out in a temperature range between 350 to 450 °C at a heating rate of 15 °C min−1 in a batch type reactor, with a condensation system, in order to analyze the best fraction liquid yield. At 400 °C we obtained a liquid fraction of 81%. This product presented a kinematic viscosity of 1.026 mm2 s−1, a relative density of 0.935, a flash point of 24 °C, and a gross heating value of 48.5 MJ kg−1. Chromatographic analysis indicates that 75% by mass of the components corresponds to C6 to C20 hydrocarbons, showing the high generation of isomers of the polystyrene monomer and aromatic compounds. The product obtained is mixed with base fuel oil at 60 °C at 250 rpm for a period of one hour, in percentages of 10 to 50% by mass. The 10% mixture has properties very close to those required by the standard fuel oil, presenting a viscosity of 108 mm2 s−1 that adjusts to the requirements in burners for industrial applications; additionally, it has a Sulphur content lower than that of fuel oil without affecting its heating value.

1. Introduction

Currently, plastics have become an indispensable product in both daily and commercial human activities due to its low production cost, wide field of applications, and durability, among other useful characteristics. However, due to its large mass consumption and its natural long degradation time, along with poor disposal management, plastics constitute a relevant environmental problem [1]. Currently, plastics have become an indispensable product in both daily and business activities, due to its low production cost, wide range of applications, and durability. Hence, the massive consumption of plastics and the extended period of natural spoilage, along with the inadequate management at the final stage, make it into a relevant environmental issue [1].

Conventionally, used plastics end up as part of municipal solid waste around the world. They are mainly thermoplastics such as PET (polyethylene terephthalate), PP (polypropylene), PE (polyethylene), and PS (polystyrene) among others; plastics with different properties depending on their base structure (monomer) whose reusability and versatility make them very popular, representing 90% of all plastics. Plastic waste can be managed through various techniques including recycling, reuse, reduction of its use and management, disposal in landfills, and chemical recycling [2]. In recent years, chemical recycling through pyrolysis has been considered the most attractive technology to convert these residues into fuels. This type of recycling consists of thermal degradation of the material in the absence of oxygen. The product obtained is a mixture of linear organic compounds with different molecular weights; high molecular weight hydrocarbons behave as waxes, and light hydrocarbons can be used as liquid fuels in engines and boilers [3,4]. Pyrolysis transforms plastic waste into energy (liquid oils) through the controlled addition of heat with or without catalytic agents that selectively orient production towards conventional fuels [5,6]. The pyrolysis process generates three products: liquid fraction rich in organic compounds of molecular weight between C7 to C28 of aromatics, alkenes, alkanes, and cycles; a gaseous fraction consisting of H2, CO, CO2, CH4, and organic compounds of low molecular weight (C2-C7); a smaller solid residue, which mainly comprises carbon, also known as coke [7,8].

The reaction mechanism, which ensues the breakdown of the basic structures for most thermoplastics, occurs at random and implies that pyrolysis products would consist in a combination of hydrocarbons, whose distribution will depend on the plastic properties, or a mixture of it, temperature, type of reactor, heating rate, and catalysts, among other factors [9,10,11,12].

Another important factor is that pyrolysis can be carried out on a large-scale using equipment that has reached an adequate technological development whose operating conditions suggest the mandatory sorting of the waste to be fed to the process [13]. Among plastics in municipal solid waste, polystyrene is the most difficult thermoplastic to recycle due to its characterization and its aromatic composition, so that the pyrolysis technique applied to this kind of polymer is the proper one, as per the high recovery rates of the monomer (styrene), unlike the products obtained from other thermoplastics that, due to their structure (PP, PE), generate linear products of various molecular weight. The pyrolytic products of PS are distributed in mixtures of low molecular weight hydrocarbons, among which are hexane, benzene, heptane, toluene, octane, ethylbenzene, and styrene; these are compounds of high industrial interest for their different applications [14]. Thermal degradation (thermal pyrolysis) of PS occurs by radical formation, in which three steps are distinguished: (i) initiation; (ii) depolymerizing propagation; (iii) radical coupling [15,16]. The products obtained can be applied in mixtures with fossil fuels for engines or other energy use applications [17]. The additional products that are generated during pyrolysis, such as methyl styrene, benzene, or toluene, are of great interest as raw materials and other heavy components as they can be used in refineries, strengthening circular economy strategies [18,19].

On the other hand, cutter stock is a diluent with a flash point below 100 °C, obtained as a by-product of the catalytic cracking of naphtha or gas oil, resulting in a complex mixture of hydrocarbons; it has in its chemical structure chains of carbon—atoms in the range of C9 to C25 with a boiling point of 150 °C to 400 °C, such as kerosenes, olefins, diolefins, and bicyclic aromatic hydrocarbons. Such diluent is relevant to reduce viscosity of heavier oil and produce low Sulphur fuel oils, which are used to cut heavy oil in order to make it easier to freight. However, at the same time as the viscosity is reduced, the product loses its intrinsic stability due to the precipitation of asphaltenes. This phenomenon causes clogging of pipes, pumps, and burner nozzles in industrial furnaces. Previous research reports optimum diluent percentages in heavy fuel oil of 20% to achieve kinematic viscosities in the range of 400 to 510 mm2 s−1 for fuel oil No. 4, guaranteeing homogeneity and intrinsic stability [20].

At the industrial level, there are various techniques about handling heavy fuels such as fuel oil, which are mainly oriented to modify its viscosity in order to reduce the energy consumption used in its fluidization, above all without affecting the caloric power. It is important to emphasize the technique, which is based on the addition of light fractions with high diluent power, is very commonly applied, and depends to a great extent on the ease of acquiring such diluent compounds; otherwise it presents a major setback, like compatibility, since it can generate synergy and would entail transportation issues [21]. In accordance with the viscosity adjustment of heavy petroleum-derived fractions such as fuel oil, it is very common to use the solvent known as cutter stock, which is mixed directly with the base fuel oil for viscosity adjustment and entails a significant consumption of resources during the process [22].

The present paper aims to establish the effect of temperature on the characteristics and chemical composition of the liquid fraction of the thermal pyrolysis of compact polystyrene, a plastic sampled from urban solid waste under conditions of slow pyrolysis at low temperatures. The properties of the product obtained are analyzed for its potential use as a diluent or additive in mixture with fuel oil that helps to adjust its viscosity without reducing the caloric value of the initial fuel. The study also contemplates establishing optimal mixing conditions presented in the methodology.

2. Equipment and Methodology

2.1. Sample and Characterization of Recycled Polystyrene

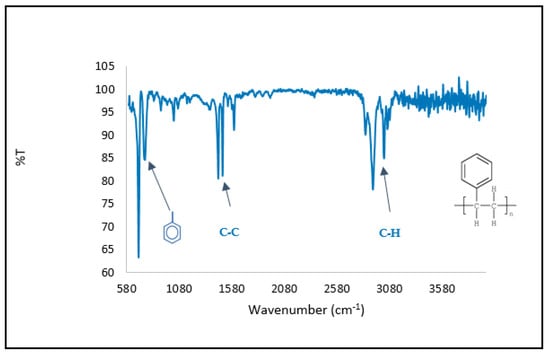

The employed polystyrene was collected from the urban solid waste of the city of Riobamba, Ecuador in a completely random sampling over a period of three months. The samples were crushed, washed, and rated. The classification was carried out with the objective of identifying and classifying by plastic family and selecting those samples only of compact polystyrene; this was done by using infrared spectrophotometry through Fourier correction (JASCO FT/IR-4100) and a wavenumber measuring range of 7800 to 350 cm−1 with a resolution of 0.9 cm−1, a high intensity ceramic source, and Quick Start System software.

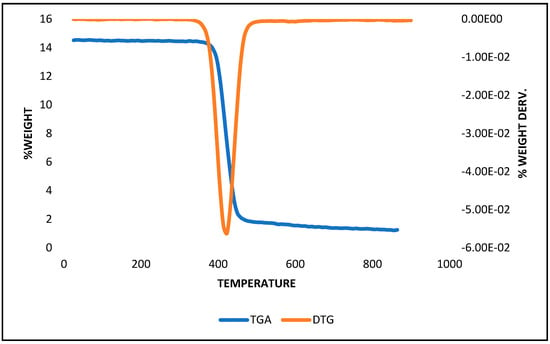

The characterization made by FTIR was verified through thermogravimetric analysis of the sample of plastic (TGA 1 STAR System METTLER TOLEDO) and dynamic analysis with nitrogen flow of 20 mL min−1 from an ambient temperature to a temperature of 900 °C. Additionally, the temperature range by TGA, which indicates the maximum degradation of plastic, was determined in order to establish the operating conditions in the pyrolysis reactor.

The samples used in both FTIR and TGA analysis were crushed to a particle size of approximately 1 mm, whereas the samples used in the pyrolysis reactor were approximately 1 cm in diameter size (mainly samples from containers used in the food industry); this actually represents an optimal size for pyrolysis because it improves mass and heat transfer within the reactor, generating a higher conversion rate. All tests were performed in triplicate to verify their repeatability.

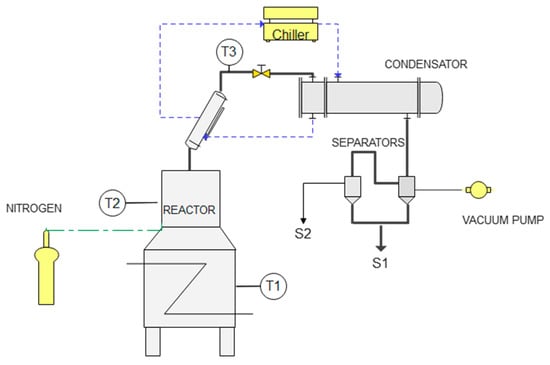

2.2. Pyrolysis Reactor

The pyrolysis experiments were carried out in a 5L capacity WEIHAI GLOBAL CHEMICAL MACHINERY MFG stainless steel Batch reactor, GSH-5 model, with a built-in stirrer and condensed system. The reactor was coupled to a cooling system that works at 10 °C, as shown in Figure 1. The plastic is placed into the reactor, which is heated by electrical heating elements; it has a temperature control system on the reactor jacket (T1), inside the reactor (T2), and at the condenser inlet (T3). The fraction liquid (condensable compounds) cooled in the condenser are collected in the biphasic separators of the equipment (S1), whereas the gaseous fraction (non-condensable compounds) can be collected at the outlet of the vacuum pump (S2). Table 1 describes the main characteristics of the reactor used for the pyrolysis.

Figure 1.

View of the pyrolysis reactor.

Table 1.

Main characteristics of the reactor.

2.2.1. Pyrolysis Process and Operating Conditions

The conditions of the pyrolysis experiments are shown in Table 2. For each test, the reactor is fed with 1000 g of recycled compact polystyrene in a size of approximately 1 cm in diameter, heated at a heating rate of 15 °C per minute. It is operated at five temperatures—350, 375, 400, 425, and 450 °C—established by thermogravimetric analysis and it can be observed that the degradation of the plastic starts at approximately 350 °C and ends near 450 °C. The stirring speed is at low rpm and, along with a slow heating rate and the right particle size, improves heat transfer within the reactor. The operating pressure for each test was −0.05 MPa; this value helped the work at relatively low pyrolysis temperatures, in addition to helping the transport of gases into the separation system. To verify the repeatability of the experiment, three repetitions were carried out at each temperature value.

Table 2.

Pyrolysis process conditions.

2.2.2. Characterization of Pyrolysis Products

Both the condensable and non-condensable products pass through a heat exchanger at 10 °C. The liquid fraction is collected in amber containers kept at low temperatures to avoid the loss of volatiles; the gaseous fraction is gathered in Tedslar bags for further analysis. The chemical characterization of the pyrolytic oil is carried out by GC-MC chromatography with a total retention time of 37.5 min. Helium was used as carrier gas with a flow rate of 1 mL/min, at an injector and detector temperature of 250 °C in a capillary column (50 m × 200 μm × 0.50 μm). On the other hand, the physical-chemical characterization of the liquid fraction measures density, viscosity, and flash point among other parameters, according to the corresponding ASTM standards.

2.2.3. Preparation and Characterization of Mixtures with Fuel-Oil

The bio-oil samplings are made in a composite sample, which is distilled in order to separate heavy compounds such as waxes or gums that may be present in it. The distilled product is mixed at 50, 40, 20, and 10% by mass with base fuel oil called M50, M40, M20, and M10, respectively. Due to the high viscosity of the fuel oil, an automatic Glasco brand shaker is used at a temperature of 60 °C, stirring at 250 rpm for a period of one hour to achieve a homogeneous emulsion.

The main physicochemical properties of the bio-oil and fuel-oil mixtures such as viscosity, density, flash point, Sulphur, and water content are analyzed according to the corresponding ASTM standards. Additionally, the pour point is determined to measure the stability of the fuel oil with the PS product.

3. Results and Discussion

3.1. Characterization of the Recycled Polystyrene

The FTIR spectrum of the compact PS (Figure 2) presents four groups of pronounced bands belonging to the multiple stress movements: CH bonds at 2919.7 cm−1, CC bonds between 1400–1600 cm−1 of the aromatic ring with a bending movement of –CH2; aromatic ring stresses with values of 748.2 cm−1; out-of-plane ring deformation vibrations at a length of 1027 cm−1, which confirms the high presence of styrene in the polymer structure. The band at 1341 cm−1 shows the presence of N–C and N-H bonds corresponding to nitrogenous compounds, which is attributed to the presence of acrylonitrile additives that are used as UV protectors or antistatic additives, which are very common in the manufacture of plastics. The band at 1027 cm−1 corresponds to the vibration of the methyl benzene bonds, which are characteristic of plasticizing agents used in the processing of hard plastics, such as the case of compact PS [9,23]. These additives, due to their small structure when compared to the polymer, at the early thermal degradation of PS, undergo cracking, as do volatile substances at relatively low temperatures (<150 °C) [12,24], producing the progressive increase of the pressure in the reactor. It is important to mention, as shown in the spectrum, that the PS, due to its structure, is a plastic which does not denote the presence of chlorine or any component which could generate corrosive atmospheres for the equipment or harmful emissions.

Figure 2.

FTIR spectroscopic results of the plastic sample.

Figure 3 represents the TGA (Thermogravimetric analysis) and DTG (Differential Thermogravimetric Analysis) curves with reference to the recycled compact polystyrene sample that was handled. The single curve shown indicates that the degradation reaction under the applied conditions was carried out in a single stage—a step that was replicated in the reactor. Furthermore, it is possible to observe the temperature range at which the loss of mass occurs, which is between 350 °C and 450 °C; 425 °C being the temperature at which the maximum degradation takes place.

Figure 3.

TGA and DTG curves for Polystyrene.

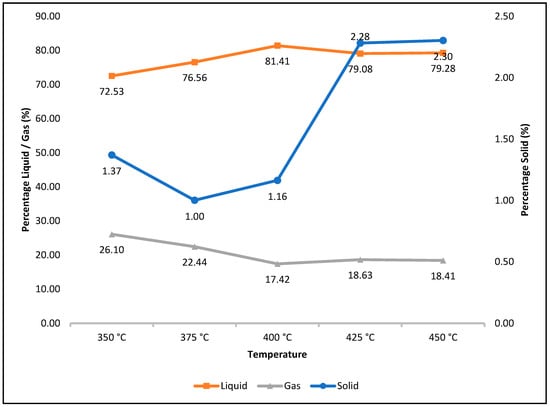

3.2. Process Performance

To achieve repeatability of the experiment, the temperature of the reactor, the jacket, and the condenser were controlled in all the tests. In all cases, the liquid fraction showed a minimum deviation between the experimental data. In previous studies, it was determined that the reaction time does not significantly affect the yield of the liquid fraction under the operating conditions in which this study was carried out, so only the effect of temperature is analyzed. Polystyrene, which is one of the most difficult plastics to recycle, accounts for 16% of the total plastic generated locally [25,26]. The yield of each of the three products is closely related to the process temperature.

Figure 4 showed that the liquid fraction slightly decreases, whereas the fraction of gaseous increases at a higher temperature of more than 400 °C, which causes the C–C bonds to break more easily and generate lighter hydrocarbons with a short chain. The gas fraction mainly comprises compounds between C1 and C4, in which ethylene, butadienes, and methane predominate, as explained by Artetxe et al. (2015) [18]. Moreover, an increase in the gaseous fraction can be seen at 425 °C; beyond this temperature, the percentage of each fraction is almost constant. As a matter of fact, exceeding such maximum degradation temperature, certain secondary reactions, for instance poly aromatic formation reactions, are initiated so that it maintains the almost constant production of oils [27,28]. The highest liquid fraction was achieved at 400 °C with a mass recovery of 814 g (81.41%) and with a standard deviation of ±0.209. Similar values described in Park’s study (2020) [16] revealed a yield between 86% and 89% in two stages; instead, in this study, a single stage was conducted with equal recovery of the styrene monomer.

Figure 4.

Distribution of liquid, solid, and gas mass fractions obtained from the pyrolysis of PS.

Figure 4 also shows the behavior of the gaseous fraction and the solid fraction. Pyrolysis gases show a slight decrease with increasing temperature, whereas biochar generation shows a slight increase; this is because slow pyrolysis conditions tend to produce a higher solid fraction.

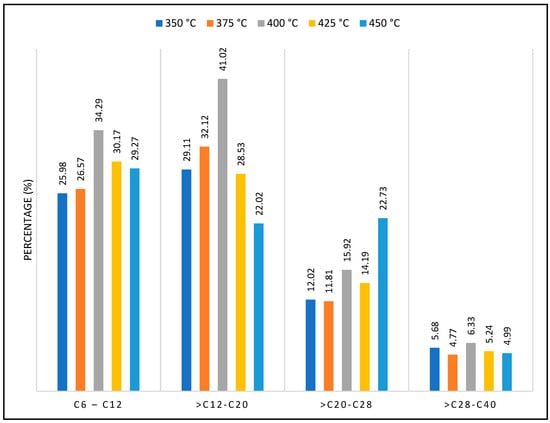

Figure 5 shows the distribution according to the number of carbons of the products obtained. The presence of a high percentage of compounds between C6 and C20 is due to the fact that pyrolysis, in this type of plastics, forms radicals in the main chain without affecting the aromatic ring. As a consequence, it mainly generates the depolymerization of polystyrene so that the temperature increases, as well as the amount of this type of compounds, until reaching a maximum level (400 °C). After that, there will be a decrease in the fraction because at higher temperatures the radicals formed in the main chain increase, giving rise to the union of several of them in compounds of various aromatic rings [28,29].

Figure 5.

Distribution of the liquid fraction composition after 10 min of reaction.

It is important to mention that the gaseous fraction obtained is a mixture of low molecular weight hydrocarbons, and it is mainly distributed between C1 to C4 hydrocarbons; for this reason, this fraction can be used as a gaseous fuel in other applications or in the pyrolysis process itself to supply the heat necessary to the degradation of the plastic. This process is very common in industrial pyrolysis plants that work continuous flows. On the other hand, the solid fraction is presented as a solid in the form of a powder with a porous structure that can be considered a “biochar”, which can be used as a filtering or absorbent material when activated by chemical or physical mechanisms. Some works have been presented where this biochar is used for retention of heavy metals, organic compounds, or even used as a retention agent for carbon monoxide due to its retention capacity [19].

3.3. Bio-Oil Characteristics

Table 3 shows the physicochemical characteristics of the pyrolytic oil or bio-oil. The content of styrene and other aromatic compounds generate a fluid with a low viscosity and flash point, but with high heating value. The direct use as fuel would be difficult. However, due to the high content of light compounds, especially styrene, according to Barbarias et al. (2016) [15], this fraction could be used as an additive to conventional fuels such as gasoline and diesel or as a solvent or additive in the chemical industry or industrial applications. That would help to reduce the viscosity of heavy fuels without reducing its heating value [13,17].

Table 3.

Characteristics of the bio-oil obtained at 400 °C.

3.4. Bio-Oil/Fuel Oil Mixtures

Table 4 shows the properties of the different bio-oil/fuel-oil mixtures compared with the properties required by the standard Fuel Oil #4. The M10 mixture (10% by mass of bio-oil) reveals the best results. The kinematic viscosity was 108.4 mm2 s−1, which is below the lower limit of 400 °C because of the large number of aromatic components in the liquid fraction of the PS pyrolysis and the good diluting cut of these compounds. Additionally, for the pumping of fuel oil in some industrial applications such as in burners, a maximum viscosity of 350 °C is needed. Thus, this solvent allows to directly adjust the operating viscosity, avoiding the preheating process of the fuel that is normally used. It is important to mention that the other mixtures show low viscosities with respect to the standard, but the other properties are not significantly affected.

Table 4.

Characteristics of the new bio-oil/Fuel-oil mixtures.

The atomizers used in industrial burners have different viscosity requirements. For example, steam-assisted atomization burners always need a less viscous fuel oil than that required by rotary cup atomization burners. Even the latter can atomize fuels with a viscosity of up to 45 mm2 s−1. As additional data, there is a pour point of 11 °C for the M10 mixture and an equivalent toluene percentage of 14%, which indicates a good stability without the presence of sedimentation of asphaltenes or similar compounds. This is an important property for the storage and pumping of the fuel. On the other hand, another advantage in the use of pyrolysis products as an additive is that this does not increase the sulfur (max. 1.324%) content and it keeps it under the limit set by the ASTM D-4294-16e1 standard (max 1.5%). Furthermore, the caloric value is not affected by the dilution made. The caloric value of the mixture M10 is 39.84 MJ kg−1 and the minimum is 39 MJ kg−1 [30].

4. Conclusions

The recovery of the liquid fraction from the pyrolysis of polystyrene plastic waste presented a higher percentage at 400 °C with a recovery of 81.4%, which decreases as the reactor temperature increases, generating a higher gaseous fraction. Moreover, the reaction time does not influence the percentage of the product obtained after the main chain has been broken. In this way, the characterization of the liquid product obtained presents a mixture of low molecular weight hydrocarbons with high caloric power and high diluent power due to the presence of the recovered styrene and other aromatic components as a result of the thermal cracking carried out. As for the blends with fuel oil, the M10 blend presents optimum performance characteristics for industrial applications, decreasing the viscosity of the fuel oil to a value of almost 75% of the initial viscosity. Therefore, this work may be promising for the use of bio-oil in other future industrial applications.

Author Contributions

Conceptualization, P.P.; methodology, P.P. and C.H.; software, P.P.; validation C.P. and P.P.; formal analysis, C.H., C.P. and P.P.; investigation, C.H. and P.P.; resources, C.P. and P.P.; data curation, J.C.B., P.P. and A.C.; writing—original draft preparation, P.P.; writing—review and editing, P.P. and J.C.B.; visualization, P.P.; supervision, P.P., A.C. and J.C.B.; funding acquisition, P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Compa, M.; Alomar, C.; Wilcox, C.; van Sebille, E.; Lebreton, L.; Hardesty, B.D.; Deudero, S. Risk assessment of plastic pollution on marine diversity in the Mediterranean Sea. Sci. Total Environ. 2019, 678, 188–196. [Google Scholar] [CrossRef] [PubMed]

- Ouda, O.K.M.; Raza, S.A.; Nizami, A.S.; Rehan, M.; Al-Waked, R.; Korres, N.E. Waste to energy potential: A case study of Saudi Arabia. Renew. Sustain. Energy Rev. 2016, 61, 328–340. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.; Rehan, M.; Aburiazaiza, A.; Ismail, I.; Nizami, A. Plastic waste to liquid oil through catalytic pyrolysis using natural and synthetic zeolite catalysts. Waste Manag. 2017, 69, 66–78. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Basu, S.; Shetti, N.P.; Kamali, M.; Walvekar, P.; Aminabhavi, T.M. Waste-to-energy nexus: A sustainable development. Environ. Pollut. 2020, 267, 115501. [Google Scholar] [CrossRef]

- Lee, D.-J.; Lu, J.-S.; Chang, J.-S. Pyrolysis synergy of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 318, 123912. [Google Scholar] [CrossRef]

- Rathore, D.; Nizami, A.-S.; Singh, A.; Pant, D. Key issues in estimating energy and greenhouse gas savings of biofuels: Challenges and perspectives. Biofuel Res. J. 2016, 3, 380–393. [Google Scholar] [CrossRef]

- Colantonio, S.; Cafiero, L.; De Angelis, D.; Ippolito, N.M.; Tuffi, R.; Ciprioti, S.V. Thermal and catalytic pyrolysis of a synthetic mixture representative of packaging plastics residue. Front. Chem. Sci. Eng. 2019, 14, 288–303. [Google Scholar] [CrossRef]

- Zhang, Y.; Ji, G.; Chen, C.; Wang, Y.; Wang, W.; Li, A. Liquid oils produced from pyrolysis of plastic wastes with heat carrier in rotary kiln. Fuel Process. Technol. 2020, 206, 106455. [Google Scholar] [CrossRef]

- Athapaththu, A.; Thushari, G.; Dias, P.; Abeygunawardena, A.; Egodauyana, K.; Liyanage, N.; Pitawala, H.; Senevirathna, J. Plastics in surface water of southern coastal belt of Sri Lanka (Northern Indian Ocean): Distribution and characterization by FTIR. Mar. Pollut. Bull. 2020, 161, 111750. [Google Scholar] [CrossRef]

- Ding, K.; Liu, S.; Huang, Y.; Liu, S.; Zhou, N.; Peng, P.; Wang, Y.; Chen, P.; Ruan, R. Catalytic microwave-assisted pyrolysis of plastic waste over NiO and HY for gasoline-range hydrocarbons production. Energy Convers. Manag. 2019, 196, 1316–1325. [Google Scholar] [CrossRef]

- Miskolczi, N.; Juzsakova, T.; Sója, J. Preparation and application of metal loaded ZSM-5 and y-zeolite catalysts for thermo-catalytic pyrolysis of real end of life vehicle plastics waste. J. Energy Inst. 2019, 92, 118–127. [Google Scholar] [CrossRef]

- Quesada, L.; Calero, M.; Martín-Lara, M.Á.; Pérez, A.; Blázquez, G. Production of an Alternative Fuel by Pyrolysis of Plastic Wastes Mixtures. Energy Fuels 2020, 34, 1781–1790. [Google Scholar] [CrossRef]

- Veses, A.; Martínez, J.D.; Callén, M.S.; Murillo, R.; García, T. Application of Upgraded Drop-In Fuel Obtained from Biomass Pyrolysis in a Spark Ignition Engine. Energies 2020, 13, 2089. [Google Scholar] [CrossRef]

- Nisar, J.; Ali, G.; Shah, A.; Iqbal, M.; Khan, R.A.; Sirajuddin; Anwar, F.; Ullah, R.; Akhter, M.S. Fuel production from waste polystyrene via pyrolysis: Kinetics and products distribution. Waste Manag. 2019, 88, 236–247. [Google Scholar] [CrossRef]

- Barbarias, I.; Lopez, G.; Artetxe, M.; Arregi, A.; Santamaria, L.; Bilbao, J.; Olazar, M. Pyrolysis and in-line catalytic steam reforming of polystyrene through a two-step reaction system. J. Anal. Appl. Pyrolysis 2016, 122, 502–510. [Google Scholar] [CrossRef]

- Park, K.-B.; Jeong, Y.-S.; Guzelciftci, B.; Kim, J.-S. Two-stage pyrolysis of polystyrene: Pyrolysis oil as a source of fuels or benzene, toluene, ethylbenzene, and xylenes. Appl. Energy 2020, 259, 114240. [Google Scholar] [CrossRef]

- Shadangi, K.P.; Mohanty, K. Co-pyrolysis of Karanja and Niger seeds with waste polystyrene to produce liquid fuel. Fuel 2015, 153, 492–498. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Barbarias, I.; Arregi, A.; Aguado, R.; Bilbao, J.; Olazar, M. Styrene recovery from polystyrene by flash pyrolysis in a conical spouted bed reactor. Waste Manag. 2015, 45, 126–133. [Google Scholar] [CrossRef]

- Baena-González, J.; Santamaria-Echart, A.; Aguirre, J.L.; González, S. Chemical recycling of plastic waste: Bitumen, solvents, and polystyrene from pyrolysis oil. Waste Manag. 2020, 118, 139–149. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.; Aburiazaiza, A.S.; Rehan, M.; Ismail, I.; Nizami, A. Effect of plastic waste types on pyrolysis liquid oil. Int. Biodeterior. Biodegrad. 2016, 119, 239–252. [Google Scholar] [CrossRef]

- Li, Q.; Faramarzi, A.; Zhang, S.; Wang, Y.; Hu, X.; Gholizadeh, M. Progress in catalytic pyrolysis of municipal solid waste. Energy Convers. Manag. 2020, 226, 113525. [Google Scholar] [CrossRef]

- Quesada, L.; Pérez, A.; Godoy, V.; Peula, F.; Calero, M.; Blázquez, G. Optimization of the pyrolysis process of a plastic waste to obtain a liquid fuel using different mathematical models. Energy Convers. Manag. 2019, 188, 19–26. [Google Scholar] [CrossRef]

- Miandad, R.; Nizami, A.; Rehan, M.; Barakat, M.; Khan, M.; Mustafa, A.; Ismail, I.; Murphy, J. Influence of temperature and reaction time on the conversion of polystyrene waste to pyrolysis liquid oil. Waste Manag. 2016, 58, 250–259. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Yang, Y.; Li, W.; Shi, Y.; Jin, L.; Zhang, Z.; Wang, G. Free radical reaction model for n -pentane pyrolysis. Chin. J. Chem. Eng. 2018, 26, 514–520. [Google Scholar] [CrossRef]

- Mo, Y.; Zhao, L.; Wang, Z.; Chen, C.-L.; Tan, G.-Y.A.; Wang, J.-Y. Enhanced styrene recovery from waste polystyrene pyrolysis using response surface methodology coupled with Box–Behnken design. Waste Manag. 2014, 34, 763–769. [Google Scholar] [CrossRef]

- Sogancioglu, M.; Yel, E.; Ahmetli, G. Investigation of the Effect of Polystyrene (PS) Waste Washing Process and Pyrolysis Temperature on (PS) Pyrolysis Product Quality. Energy Procedia 2017, 118, 189–194. [Google Scholar] [CrossRef]

- Verma, A.; Sharma, S.; Pramanik, H. Pyrolysis of waste expanded polystyrene and reduction of styrene via in-situ multiphase pyrolysis of product oil for the production of fuel range hydrocarbons. Waste Manag. 2020, 120, 330–339. [Google Scholar] [CrossRef]

- Aljabri, N.M.; Lai, Z.; Hadjichristidis, N.; Huang, K.W. Renewable aromatics from the degradation of polysty-rene under mild conditions. J. Saudi Chem. Soc. 2017, 21, 983–989. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation kinetics of plastics and model selection. Thermochim. Acta 2017, 654, 191–202. [Google Scholar] [CrossRef]

- Dubdub, I.; Al-Yaari, M. Thermal behavior of mixed plastics at different heating rates: I. pyrolysis kinetics. Polymers 2021, 13, 3413. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).