1. Introduction

As “carbon neutrality and carbon peaking” have become a global consensus, new energy vehicles have become the main battlefield of energy transformation in various countries because they conform to the energy independence and security strategies of various countries and the long-term development goal of “carbon neutrality”. In order to reduce dependence on fossil fuels and improve energy efficiency, the entire electric vehicle industry is looking for solutions to electrify global transportation [

1]. Battery energy storage systems have been rapidly developed for the electric vehicles, the renewable energy generation, and the high-voltage pulsed energy storage [

2,

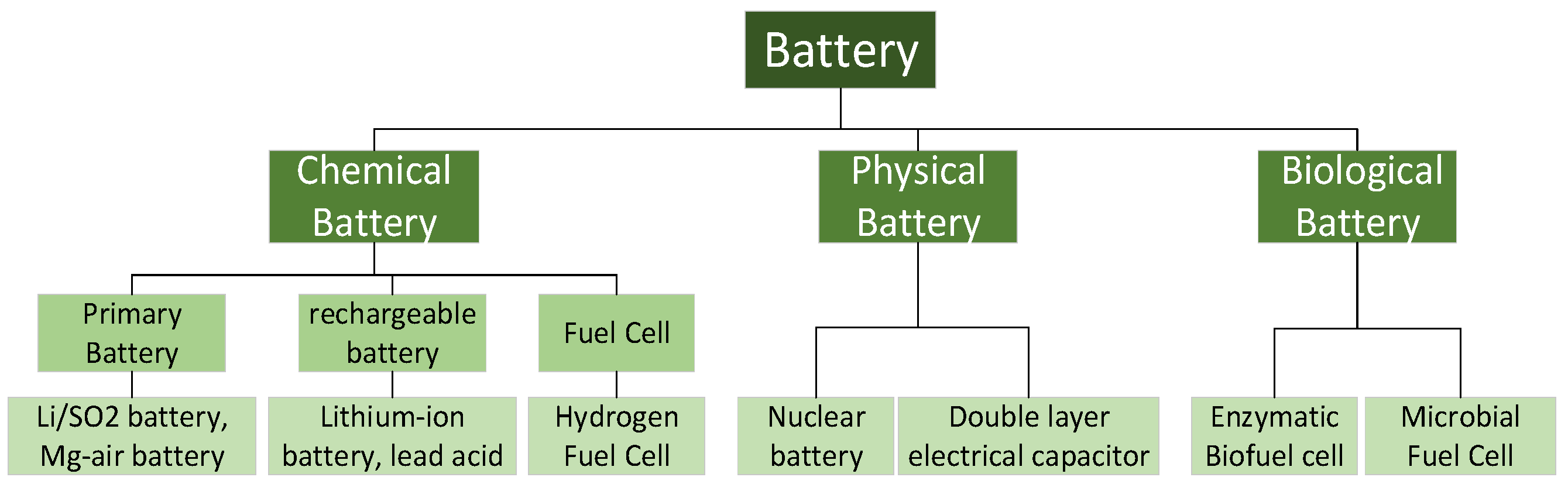

3]. Many different types of batteries have been developed, including chemical, physical, and biological batteries, as shown in

Figure 1.

Chemical battery can be further classified as primary battery [

4,

5], rechargeable battery [

6], and fuel cell [

7,

8,

9]. Among them, primary battery refers to the battery that cannot be recharged repeatedly, such as ”Li/SO

2 battery, Mg-air battery”; rechargeable battery refers to a battery that can be recharged repeatedly, such as ”lithium-ion, nickel-metal hydride, lead acid, vanadium redox flow, and sodium-sulfur batteries”. Compared with other batteries, lithium-ion batteries, as a new type of green battery, have many advantages, such as large energy density, high average output voltage, long service life, and no environmental pollution, and are widely used in various fields. Lithium-ion batteries are used mainly for the digital products in the traditional field and for power batteries and energy storage in the emerging field: (1) In the field of power systems, they are used mainly in aerospace vehicles, smart grids, and electric vehicles; (2) In the field of energy storage, they cover solar or wind energy power generation energy storage facilities, industrial enterprise energy storage, high-voltage pulse energy storage, and communication base station backup batteries; and (3) In the field of consumer electronics, they are used mainly in mobile phones, laptops, and other electronic digital products. Lithium-ion batteries are an important foundation to support the wide application of new energy in power, transportation, industry, communications, construction, military, and other fields, and have gradually become one of the most important sectors for countries around the world to implement the “dual carbon” strategy.

Fault diagnosis (FD) and RUL prediction are two key technologies in reliability and safety analysis, which detect faults in a timely fashion, quickly locate faults and forecast the faults, then formulate appropriate maintenance strategies to effectively avoid the occurrence of accidents. Therefore, they are widely used in industrial equipment [

10,

11,

12], power equipment [

13], auxiliary medicine [

14,

15], and industrial systems [

16,

17,

18]. Similarly, FD and RUL of lithium-ion batteries have been highly valued due to the specificity of the operating conditions of lithium-ion batteries. The performance of lithium-ion batteries declines throughout the entire process of use and maintenance. As the number of charges and discharge cycles of lithium-ion batteries increases, some irreversible chemical reactions often occur inside the battery, resulting in increased internal resistance and maximum available capacity as well as energy and peak power capacity decay, which significantly reduces the RUL of lithium-ion batteries and even brings various safety hazards, which may produce fatal failures, such as combustion and explosion.

In the field of energy storage, lithium-ion batteries are the essential energy storage source. Meanwhile, pulse capacitors and supercapacitors are also the common energy storage components. Pulsed energy storage systems composed of lithium-ion batteries and pulsed capacitors work under the complex operating conditions of pulsed repetitive discharge, and the accuracy of RUL prediction directly affects the engineering applications. Metalized thin film pulse capacitors are important components of pulsed energy storage applications, such as inertial confinement fusion laser devices, electromagnetic rail guns, and electromagnetic coil guns. RUL prediction is of great significance to the availability and operation and maintenance of the pulsed energy storage systems. In principle, lithium-ion batteries charge the pulsed capacitors by discharging at a large rate, together achieving rapid storage and instantaneous release of energy to form high currents of hundreds of kA levels. Pulse capacitors cannot be charged for long periods of time, and their complex “self-healing” process during charging has a significant impact on capacity. Supercapacitor performance is between the lithium-ion batteries and the metalized film capacitors and has the advantages of fast charging and discharging, high power density, and long cycle life, so they are used in series and parallel for large-scale energy storage, which is also widely used. Supercapacitors face serious challenges in terms of RUL due to the self-acceleration effect caused by series use.

Energy storage components operate in a complex environment and are a prerequisite for the good working operation of the load system. To ensure the proper operation of energy storage components, the study of RUL prediction is needed. Reliable RUL prediction can fully address users’ anxiety about the unknown RUL and the concerns about safety issues, guarantee the safe and efficient operation of energy storage components, and ensure their reliability and safety during use. After maintenance based on predictive information, we can reduce failure rate and operating cost, improve user experience, and avoid the accidents.

This paper briefly analyzes the operation mechanism and failure mechanism of several common energy storage components, conducts a generalization and research on the RUL prediction methods of energy storage components represented by lithium-ion batteries, summarizes the advantages and disadvantages of model-based methods, data-driven based methods, and data–model fusion-based methods for RUL prediction, and analyzes the application of the kalman filter (KF) and particle filter (PF) on the basis of data–model fusion methods for RUL prediction of lithium-ion batteries. Finally, the current problems and research outlook of energy storage component RUL prediction are proposed to provide theoretical support for the subsequent research work.

2. Failure Mechanism of Energy Storage Components

Common energy storage components include lithium-ion batteries, pulse capacitors, supercapacitors, etc. In the field of electromagnetic emission, with the power and energy demand of the power-using system as the traction and with the optimal volume and the weight suitability of the energy storage system as the goal, we can fully compare the various existing types of battery parameter indicators from the four aspects of safety, power density, energy density, and cycle life to determine the basic energy storage unit type for lithium-ion batteries. Lithium-ion batteries are subject to certain probability of failure during use or storage, including capacity decay, short cycle life, increased internal resistance, abnormal voltage, short circuit, deformation, thermal runaway, etc., which seriously reduces the performance, consistency, reliability, and safety of lithium-ion batteries [

19]. The failure of lithium-ion batteries is divided into two main categories: one is the performance failure and the other is safety failure. According to its working environment and conditions, different working conditions, combined with statistical analysis provide its failure threshold. Lithium-ion battery capacity should not be less than 90% of the initial value, and after reaching 1000 times, it should not be less than 80% of the initial value. If the capacity does not meet this standard, then the result is capacity decay failure.

By fully grasping and analyzing the information on lithium-ion batteries failure, we can accurately obtain the root cause of lithium-ion batteries failure and guide the use of lithium-ion batteries throughout the life cycle. The failure of lithium-ion batteries is ultimately the failure of materials. Material failure refers mainly to abnormalities in material structure, properties, morphology, etc., and mismatches between materials. A variety of distinct effects may occur for a particular cause of failure, such as the precipitation of localized transition metals, which may produce gas and create a visual representation of bulging. Still, it may also be due to an internal short circuit that creates localized heat, which, in turn, causes the diaphragm to contract and creates a large area of thermal runaway. Failure analysis is divided into two directions: one is the diagnostic analysis based on lithium-ion batteries failure, which takes failure as the starting point and traces back to the failure mechanism of battery materials to achieve the purpose of analyzing the causes of failure; the other is the mechanism exploration analysis based on the cumulative failure cause database, which takes the failure point of design materials as the starting point and explores various influencing factors of the process of lithium-ion batteries failure to achieve the prevention-oriented purpose.

Supercapacitors, which emerged with the development of material science, are a new generation of power-based energy storage components and have a wide range of applications in electric vehicles, pulsed power systems, electrical energy weapons, uninterruptible power supply (UPS), and forklifts, which are a hot spot in the energy technology research [

20]. The aging factors of supercapacitors include external stresses, device material effects, and self-acceleration effects resulting from series use. The important parameters of supercapacitors are capacitance and equivalent series resistance, which should be constant and as high and low as possible, respectively, while the criterion for the end of life of supercapacitors is a 20% reduction in capacitance and a doubling of the equivalent series resistance [

21].

3. Current Research Status of Energy Storage Component Life Prediction

The remaining life, usually called the remaining active life, also known as the RUL, or residual life, is the time from the current moment that the energy storage components can continue to work properly. Life prediction refers to predicting how much time is left before the occurrence of one (or more) failures, given that the current state of the energy storage component and historical state data are known.

Current life prediction methods generally utilize only the product’s own performance degradation data. When the quantity of performance degradation data is small, the accuracy of the RUL prediction results is difficult to guarantee, which generally include model-based methods, data-driven based methods, and data-model fusion-based methods. Due to the limitation of aging test cost and time, the current life prediction has many problems, such as a small amount of sampled data and few measurement points of characteristic parameters. A support vector regression (SVR) [

22], suitable for this type of small sample that is used, and a deep belief network (DBN) [

23] are used to deeply extract the features of capacitor capacity degradation sequences without constructing a complex and unknown empirical degradation function, and a prediction model is established by fusing DBN and “dual channel” binary support vector regression (BSVR) prediction models to obtain the RUL prediction method on the basis of feature extraction and error compensation [

24].

For the small capacity of the training dataset and low learning rate of the RUL prediction model constructed on the basis of a neural network, a method to augment the training dataset based on the Akima method [

25] is proposed to build a salp swarm algorithm-extreme learning machine (SSA-ELM) lithium-ion battery full life-cycle remaining value prediction model on the basis of the improved extreme learning mechanism to further enhance the tracking capability of the model in the middle and late stages of the battery and to improve the accuracy and stability of the lithium-ion batteries RUL prediction results.

Supercapacitors have both the high-current and fast-charging and -discharging characteristics of traditional capacitors and the high energy-storage density characteristics of batteries. At present, the models established by domestic and foreign researchers that are based on the trend of parameter changes during the aging process of supercapacitors include mainly the aging model based on failure mechanism, electrochemical, and fractional-order, the supercapacitor trapezoidal equivalent circuit model, the Arrhenius model, and the supercapacitor aging model based on the Weibull failure statistical theory function [

26,

27]. Under the influence of complex coupling factors, the actual lifetime may not be consistent with the nominal lifetime measured in the laboratory. Therefore, on the basis of the variation law of capacitance and internal resistance, a prediction model of supercapacitor capacity decay, including temperature, current intensity, and cycle number factor, is established by the performance decay law exhibited by supercapacitors under different charging and discharging currents and temperature conditions using the classical Arrhenius model [

28]. The validation results show that the fitted results are in good agreement with the actual decay data.

Due to the complexity of the supercapacitor internals and the changing parameters during use, it is challenging to model the aging characteristics and health state in detail. If the relevant parameters are properly simplified, the prediction accuracy is reduced and limited in practical applications. In contrast, using a data-driven approach does not require physical modeling of components. It aims to simulate the relationship between measured data and component degradation, which can effectively solve this problem. An artificial neural network was used to construct a method for predicting the RUL of a hybrid battery–supercapacitor system [

29]. The key information needed for RUL prediction can be obtained in the discharge data itself, and experiments have shown that relying on only a small fraction of the discharge data (less than 4%), artificial neural networks can predict the health status of these devices and systems very accurately. Artificial neural networks themselves have some drawbacks, which are reflected in their inability to explain the physical relationship between the analysis of inputs and outputs and their tendency to overfit. Therefore, artificial neural networks are combined with fuzzy logic in order to obtain a neuro–fuzzy system and construct a health monitoring model for supercapacitors based on the neuro–fuzzy system model [

30]. The obtained results show that the introduction of temperature and voltage in this time series can be better for equivalent series resistance and capacitance prediction and, thus, for accurate estimation of the RUL, but the method requires a great deal of effort to build the database.

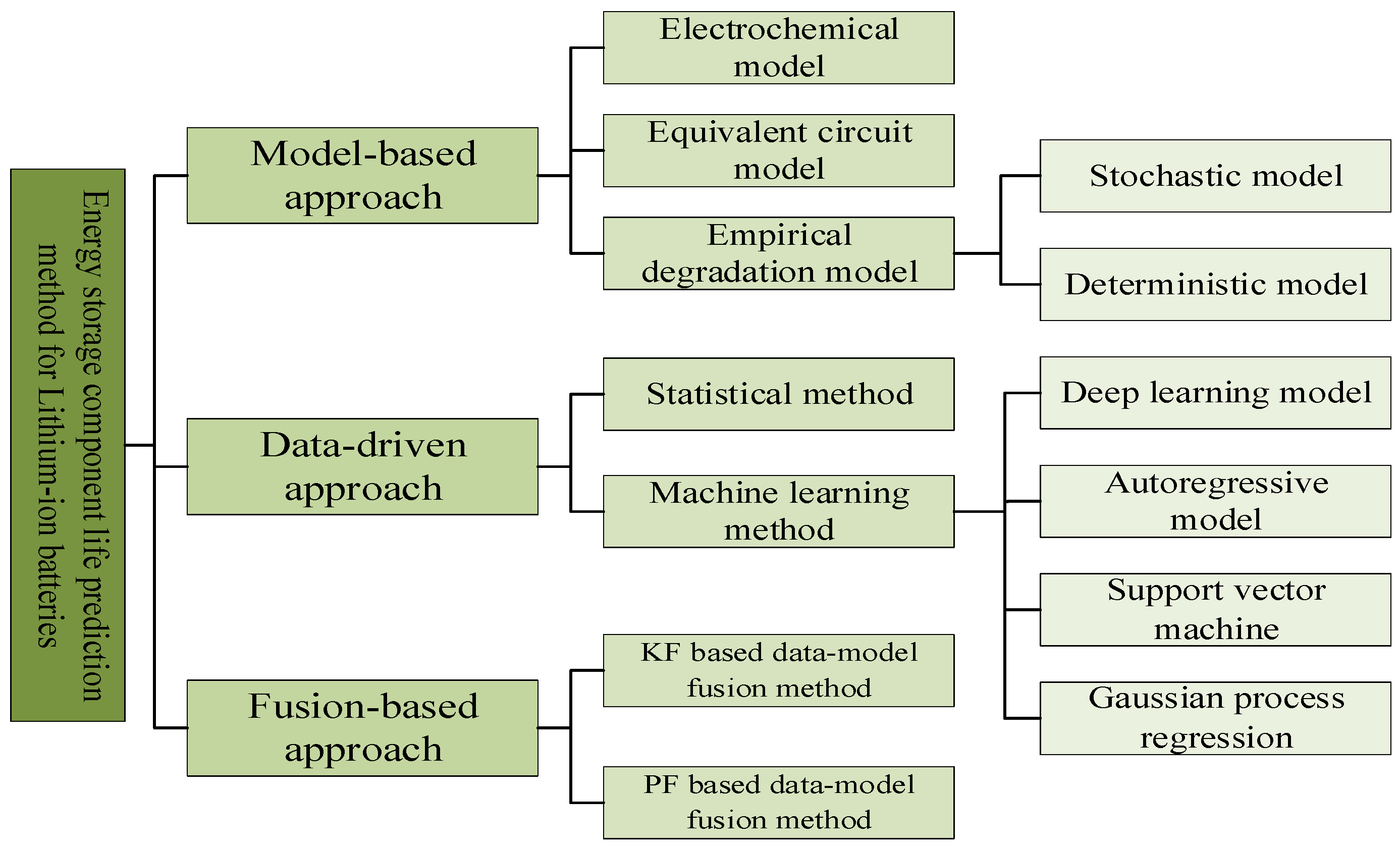

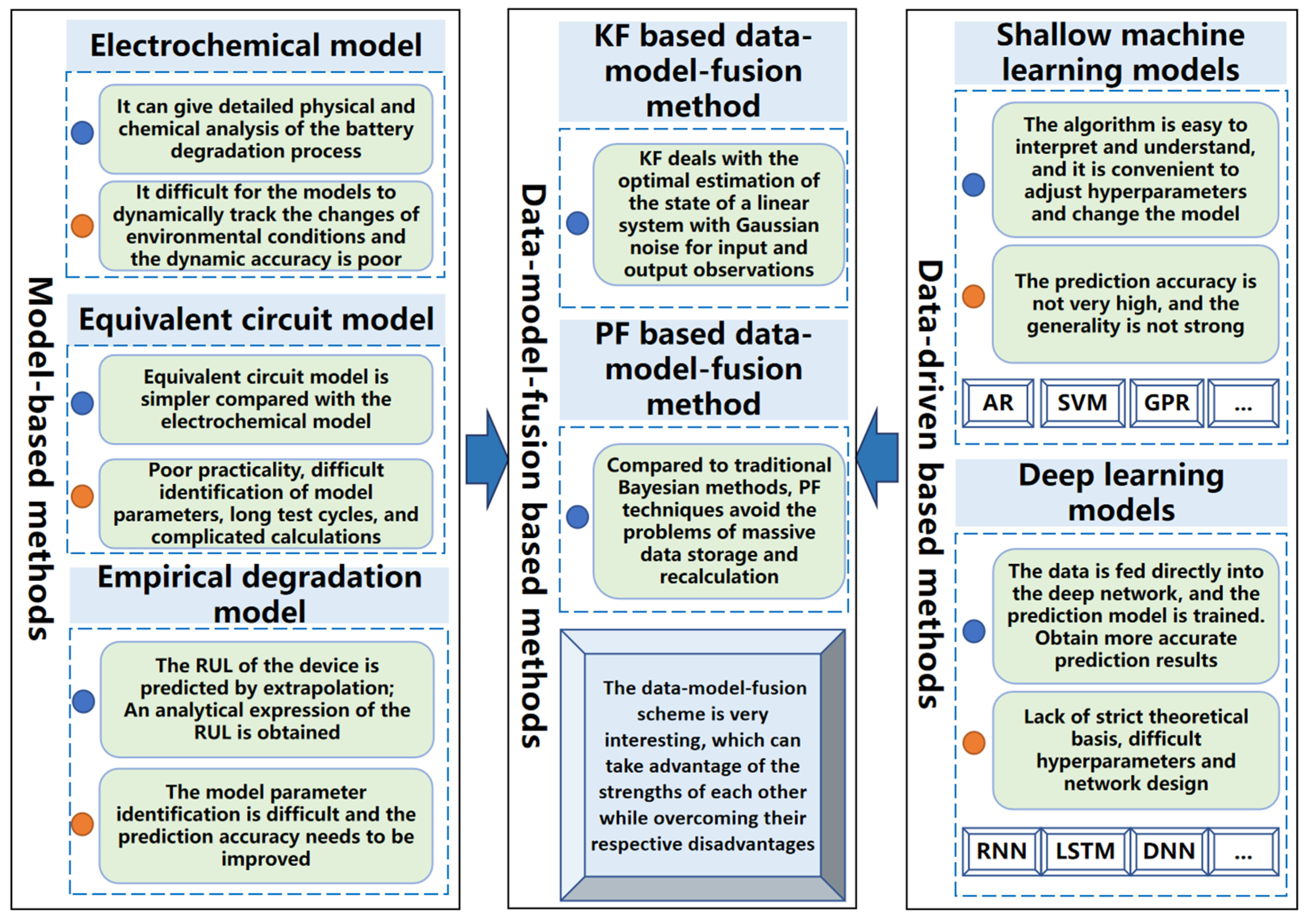

This paper summarizes the RUL prediction methods for energy storage components represented by lithium-ion batteries. The RUL prediction methods for lithium-ion batteries are broadly classified into three categories: model-based methods, data-driven based methods, and data–model fusion-based methods, as shown in

Figure 2.

3.1. Model-Based RUL Prediction Method

The model-based approach analyzes the battery operation mechanism and relies on the development of electrochemical, equivalent circuit, and empirical degradation models to describe the degradation mechanism of the system state from the perspective of the essential mechanism of the electrochemical reactions of lithium-ion batteries [

31].

3.1.1. Electrochemical Model

Electrochemical models can represent the transport processes between lithium-ion batteries, electrochemical kinetics, and material properties within the battery, and these unique advantages make them well-suited for electrode concentration estimation and charging strategy optimization for automotive batteries [

32]. To better accommodate real-time battery state estimation, a large body of literature has simplified and reconstructed various electrochemical models. Currently, there are four main types of electrochemical models for lithium-ion batteries: pseudo two-dimensional (P2D) models, single particle (SP) models, enhanced single particle (ESP) models, and multiphysics coupling (MC) models. All these models are reconstructed to reduce the computational complexity while maintaining acceptable model accuracy to enable the prediction of RUL based on electrochemical models.

In recent years, the P2D model has become an important tool used for battery design and aging mechanism analysis [

33]. With the application of emerging advanced numerical methods, simplified P2D models are beginning to be used in an attempt to solve lithium-ion batteries parameter optimization and state estimation problems. The literature [

34] describes in detail the finite volume method (FVM) for solving the P2D model so that it can be suitable for battery design, simulation, and control applications. The SP model has attracted a lot of attention from scholars because of its ability to capture the basic internal physicochemical reaction processes and also its low computational cost [

35]. In the literature [

36], the solid phase equations of the model were solved using the finite difference method (FDM) method, which helps to obtain the lithium-ion batteries concentration state at each layer within the cell electrode, and the parameters were identified on the basis of a simplified SP model. In response to the shortcomings of the conventional SP model at high multiplicative rates and dynamic conditions, research scholars have tried to integrate the electrolyte kinetic equations into the SP model to consider the effects of liquid phase concentration and liquid phase potential on the cell output voltage, thus constituting a new ESP model [

37]. In recent years, several scholars have reconstructed various MC models on the basis of simplified electrochemical models coupled with the effects of cell thermal and aging characteristics. In the literature [

38], a coupled electrochemical–thermal model was developed to simulate electrochemical reactions and heat transfer processes.

RUL prediction based on electrochemical models can give a detailed physical and chemical analysis of the battery degradation process, but the related models are based on specific battery materials, usage environment, and charging and discharging conditions, etc. The model parameters are generally obtained on the basis of the physical characteristics of the electrodes, which makes it difficult for the models to dynamically track the changes in environmental conditions, and the dynamic accuracy is poor. Moreover, the testing process for degradation factors is too complicated, and it is difficult to establish a perfect degradation model.

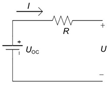

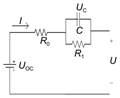

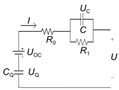

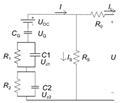

3.1.2. Equivalent Circuit Model

An equivalent circuit model is one in which a part of a circuit that is more complex is replaced with a simpler structure. Equivalence can be thought of as the equivalence of the outer ports of a network, but the two equivalent networks can have completely different structures inside. Although the structure of the equivalent circuit model is simple, its parameters have a clear physical meaning and can be estimated online, which can reflect the battery characteristics, making it of great interest to researchers in real-time applications. Currently, the main equivalent circuit models are the Rint model, Thevenin model, PNGV model, and GNL model. Several commonly used battery models are shown in

Table 1 [

39].

The RUL prediction method based on the equivalent circuit model is simpler compared with the electrochemical model, but the existing equivalent circuit models still have some defects, such as poor practicality, difficult identification of model parameters, long test cycles, and complicated calculations.

3.1.3. Empirical Degradation Model

Due to the complex chemical reactions inside the lithium-ion batteries, both electrochemical-model-based and equivalent-circuit-model-based approaches require analysis of the electrochemical characteristics of the lithium-ion batteries, which are too small in the application and cannot fully reflect the electrochemical reaction characteristics inside the battery. Therefore, empirical models are more often used to describe the degradation process of lithium-ion batteries in the field of RUL of lithium-ion batteries [

44]. Using battery capacity as the characteristic index to measure battery degradation, the empirical degradation model method combines battery use conditions, degradation mechanism, and failure mechanism to achieve RUL prediction, taking into account the battery charging and discharging electrochemical mechanism and the influence of battery aging on the external characteristics of the battery. Several common empirical degradation models include the polynomial model [

45], single exponential model [

46], double exponential model [

47], Fourier model [

48], ensemble model [

49], etc. The models are as follows:

where

,

,

, and

are the state parameter at the moment of

,

denotes the battery cycle period, and

is the battery capacity at the moment

, in units of

.

The model-based RUL prediction method also has some unavoidable drawbacks: (1) the established model is easily affected by noise and (2) when new observations are missing, it is impossible to continue updating the model parameters, which will lead to a decrease in the prediction effect. In summary, it can be seen that a single model-based method is difficult to predict battery RUL accurately in practical applications [

50].

The state degradation process of lithium-ion batteries exhibits significant uncertainty due to the influence of multi-source random factors, such as random fluctuations in load, uneven internal materials, and time-varying operating conditions. In order to describe the uncertain characteristics of the degradation process of lithium-ion batteries, a stochastic degradation model based on probability theory is considered for RUL prediction. The prediction methods of stochastic degradation model include mainly the Wiener process, gamma process, and Markov chain. Among them, the Wiener process [

51,

52] is widely used in the field of RUL prediction and health management as a non-monotonic degenerate process with good mathematical properties.

The Wiener process degradation model is a common model to describe stochastic degradation process. In general, the Wiener process

can be expressed as:

where

is the state at moment

,

is a function describing the instantaneous degradation rate,

is a time-varying function describing the magnitude of the variance of the random fluctuations, and

is the standard Brownian motion.

The key to predicting the RUL of the equipment based on the stochastic degradation process is to solve the PDF of life

, i.e.,

, which, in turn, enables the prediction of the probability distribution of the remaining life

. Lifetime

can be defined as:

Define the remaining lifetime

of the device at the current moment

as:

In recent years, most modeling approaches based on Werner process degradation generally assume that the system is a stochastic degradation model that follows a single stage in the degradation process. However, in engineering practice, due to the influence of internal factors (e.g., sudden changes in degradation mechanism) or external factors (e.g., dynamic environment, state switching, etc.), the degradation characteristics of many devices show two-stage or even multi-stage degradation characteristics [

53]. Therefore, it is necessary to divide different stages according to the degradation trend of the device and then use different Wiener process degradation models to portray them at different stages. In the literature [

54], a two-stage degradation model based on the Wiener process was established for the degradation process of batteries, and the analytical form of the RUL probability distribution was derived by fully considering the randomness of the change point and the randomness of the state at the change point.

3.2. Data-Driven RUL-Based Prediction Method

Data-driven approaches do not need to study the specific failure mechanism of the battery, which avoids building complex physicochemical models. Additionally, compared with the model-based approaches, the data-driven approach is simpler and more practical and can be used to handle complex systems. Data-driven RUL prediction methods fall into two main categories [

55]: statistical methods and machine learning methods. Machine learning methods can be broadly classified into two categories, shallow machine learning models and deep learning models, according to the strength of the learning ability of the models. Statistical methods are based on mathematical and statistical theories to establish statistics and perform RUL prediction, and such methods are subject to more constraints and are less applicable. In the following sections, shallow machine learning models and deep learning models are introduced.

3.2.1. Shallow Machine Learning Models

Shallow machine learning models include autoregression (AR), support vector machine (SVM), Gaussian process regression (GPR), and SVM and time series analysis fusion methods.

AR is a method of prediction that takes advantage of the dependence relationship (i.e., self-correlation) that exists between the historical time series of the prediction target’s values taken at different periods to establish a regression equation for prediction. The regression analysis is performed by using the past system state as input to obtain the model order and model parameters suitable for the current data characteristics. The literature [

56] proposed an AR-model-based RUL prediction method for lithium-ion batteries. A new method for RUL prediction combining empirical modal decomposition (EMD) and autoregressive integrated moving average (ARIMA) model was proposed in the literature [

57], which finally predicted the RUL of lithium-ion batteries. AR-type models have the advantages of few model parameters, low computational complexity, and short training time, and are generally used in application scenarios with a small amount of battery sample data. However, the autoregressive model cannot analyze the implied relationship among multiple input features, the confidence level and prediction accuracy of the results are low, and there may even be problems that the prediction results violate the actual physical laws.

SVM algorithm can solve machine learning problems in small sample cases, simplifying the usual problems, such as classification and regression. The literature [

58] applied SVM to the RUL prediction of lithium-ion batteries, and by experimental comparison, the prediction was more accurate and less computationally intensive than the traditional neural network. The effectiveness of the SVM algorithm is highly dependent on the choice of the kernel function, which often requires trying multiple kernel functions, and the penalty factor is difficult to determine. The number of vectors of the relevance vector machine (RVM) is much less than the number of support vectors used in SVM, and for classification task and regression task, the models generated by RVM are usually an order of magnitude more concise than those generated by the corresponding SVM, making the speed of processing test data greatly enhanced again. The literature [

59] proposes a framework for HI extraction and optimization of only the operating parameters of lithium-ion batteries for battery degradation modeling, where RVM is used as RUL estimation.

GPR is a probability estimation model based on a Bayesian framework with prior knowledge for regression analysis of system behavior processes. In the literature [

60], an energy-weighted GPR method based on EMD is proposed to address the problem that the capacity regeneration phenomenon affects the accuracy of lithium-ion batteries’ health state modeling, and the energy distribution of samples is obtained using EMD decomposition to establish an energy-weighted GPR-based SOH prediction model for lithium-ion batteries. To accurately predict the battery RUL, a multicore GPR model incorporating an adaptive feature fusion method was proposed in the literature [

61], and the effectiveness of the method was verified by simulation experiments on the National Aeronautics and Space Administration (NASA) battery dataset. In the literature [

62], the capacity increment curve of lithium-ion batteries was extracted, and the noise reduction process was performed by wavelet transform, then the peak and peak position features were selected as the input of GPR, and the conjugate gradient method was chosen to optimize the hyperparameters of Gaussian regression, and finally, the RUL of the battery was effectively predicted. GPR has the advantages of high model prediction accuracy and prediction results in the form of probability density. However, the inherent structure of its model leads to a high computational complexity when analyzing problems with large amounts of battery data. Meanwhile, the model has more hyperparameters, and the hyperparameter adjustment process is tedious during training.

In order to better describe the degradation process, research for RUL is gradually moving toward time-series-based prediction, while combining the learnability of machine learning algorithms to achieve good results in the RUL of batteries and bearings. The degradation trend of metallized film capacitors has a strong interpretability in time series, which is similar to that of batteries and bearings, and the change of parameters with time can show the change in capacitor lifetime.

3.2.2. Deep Learning Models

Deep learning, as a development of shallow neural networks, has become the main focus of current RUL prediction research, with its powerful data mining capability and efficient data processing performance. Deep learning, with its powerful nonlinear mapping capability and feature extraction, is increasingly used in the field of RUL prediction for lithium-ion batteries [

63]. Representative methods include recurrent neural network (RNN), long short-term memory (LSTM), deep neural networks (DNN), Prophet deep learning time series prediction methods, etc.

RNN is a class of neural networks with short-term memory capability. In recurrent neural networks, neurons can receive information not only from other neurons but also from themselves, forming a network structure with loops. The literature [

64] applied RNNs to the RUL prediction of lithium-ion batteries for electric and hybrid vehicles and obtained good prediction results. RNNs can make better use of information that cannot be modeled by traditional neural network structures, but they also pose a greater technical challenge, i.e., the problem of long-term dependencies. For this reason, the researchers turned their attention to the LSTM, a special network structure with three “gates” that can effectively alleviate the problem of long-term dependency. The three logic gates that control the information transfer are the input gate, the forget gate, and the output gate. In the literature [

65], a RUL prediction method based on LSTM model was proposed, and the model was validated using various experimental data of lithium-ion batteries at different currents and temperatures which did not rely on offline training data and achieved more satisfactory RUL prediction results. DNN can be understood as a neural network with many hidden layers and is also known as deep feedforward network (DFN), multi-layer perceptron (MLP). The literature [

66] used a DNN to predict SOH and RUL of batteries and compared it with other machine learning algorithms to achieve better prediction results.

In the literature [

67], an RUL prediction method based on the Prophet algorithm was used, which can introduce contextualized knowledge to adjust the prediction results and has advantages for seasonal and periodic time series data prediction. The Prophet algorithm can be configured with model parameters and combined with deep learning algorithm to achieve temporal prediction. Contextualized knowledge can be added, which, in turn, adjusts the prediction results.

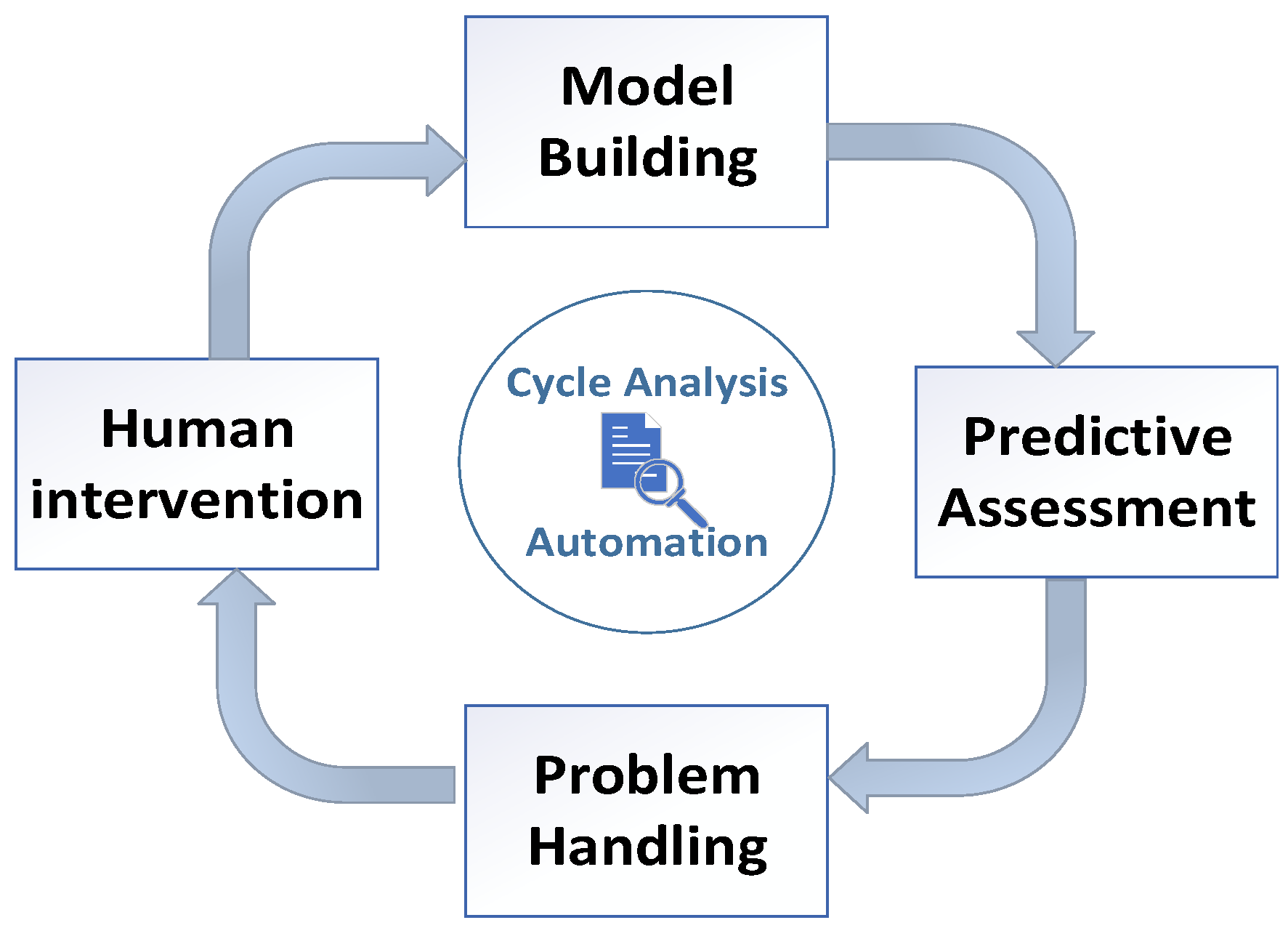

Figure 3 shows the flow of the Prophet algorithm. First, the capacitance and the internal resistance obtained by using the working condition data are modeled, and the corresponding parameters are set with the background knowledge of the problem. By calculating the historical data, the optimal model is automatically selected for prediction. At the end of the prediction, the Prophet algorithm can give the data points with large deviations so that they can be checked manually. Then, the model can be adjusted on the basis of the results, and the cycle can be repeated several times until a suitable model is obtained, depending on the scenario used.

3.3. Fusion-Based RUL Prediction Method

To compensate for the shortcomings of model-based approaches and single data-driven approaches, hybrid models that integrate multiple approaches make full use of the respective advantages of different model approaches to obtain better performance. Currently, the fusion of RUL prediction includes mainly different models [

68], different data-driven methods [

69,

70], and the fusion of model- and data-driven methods [

44,

71]. In recent years, fusion methods based on mathematical models and data-driven techniques have been a hot research topic for RUL prediction of lithium-ion batteries. The data–model fusion method combines the advantages of both data-driven and traditional models, which can not only reflect the physical degradation mechanism of the battery but also obtain updated information and evolutionary laws of the battery health state from the data set. The method of data–model fusion usually uses the stochastic filtering (KF/EKF/UKF/PF) method as a bridge to achieve the complementary advantages of data-model methods and improve the prediction accuracy based on the extracted health indicators and the selection of a suitable degradation model.

3.3.1. KF-Based Data–Model Fusion Method

KF is suitable for solving the optimal state estimation problem of dynamic systems. Even if the observed the system state parameters contain noise and the observed values are inaccurate, KF can still accomplish the optimal estimation of the true values of the states. In particular, the recursive structure of KF overcomes the application limitations of methods such as Wiener filtering, so KF is widely used in several fields, such as navigation guidance, target localization, weather forecasting, and fault diagnosis. The classical KF process can be roughly divided into two update phases, i.e., time update and observation update. In addition, its computation process is a continuous “prediction–correction” process. With known initial states and and covariance matrix , new filter predictions can be computed immediately whenever new data are observed, which is why KF is easy to implement. The following is the computational flow of the KF algorithm.

KF is able to estimate the optimal state of the target under the condition of linear Gaussian model, but there are always different degrees of nonlinearity in the real system. In order to achieve accurate state estimation, filtering methods applicable to nonlinear systems must be established. Both extended Kalman filter (EKF) and unscented Kalman filter (UKF) can handle nonlinear problems, but the ideas used in each are different. The EKF is an extension of the standard KF in the nonlinear case; the EKF algorithm linearizes the nonlinear function by Taylor expansion, omitting the higher-order terms and retaining the first-order terms of the expansion, and finally approximates the state estimate and variance estimate of the system by the KF algorithm to achieve filtering of the signal. UKF uses the probability distributions of nonlinear functions instead of the traditional linearization of nonlinear objects and employs the unscented transform (UT) to handle the nonlinear transfer of the mean and the covariance of the prediction equations through deterministic sampling. The UKF is built on the Kalman linear filtering framework, which does not require derivation of the Jacobi matrix nor does it ignore higher-order terms and, therefore, has a good filtering effect on nonlinear systems. However, the UKF converges slowly during improper initialization and cannot achieve accurate state estimation, and it may even diverge.

In order to perform accurate state estimation under complex operating conditions and to avoid scattering of the filtering algorithm due to improper initialization, a weight optimization unscented Kalman filter (WOUKF) algorithm based on weight optimization was proposed in the literature [

48]. The WOUKF algorithm optimizes the sampling points by resampling them during the prediction phase. This algorithm updates the sigma points generated in the UT transform while being able to retain the sigma points close to the true value. However, the filtering algorithm cannot update after the prediction points due to the lack of input from the observations, so the BiLSTM–Attention Mechanism algorithm is chosen to predict the residual values as a substitute for the true observations and input to the filtering algorithm for further updating.

In addition, EKF/UKF is often used in conjunction with some other machine learning methods in order to obtain a high prediction accuracy. In the literature [

72], an integrated algorithm was proposed to establish a double exponential state space model to describe the degradation of lithium-ion batteries, introduce an adaptive UKF algorithm to update the covariance of process noise and observation noise adaptively, and optimize the key parameters of SVR using genetic algorithm to finally achieve multi-step prediction. In the literature [

73], a method for predicting the RUL of lithium-ion batteries based on the idea of error correction was proposed by combining UKF, complete ensemble empirical mode decomposition (CEEMD), and RVM.

3.3.2. PF-Based Data–Model Fusion Method

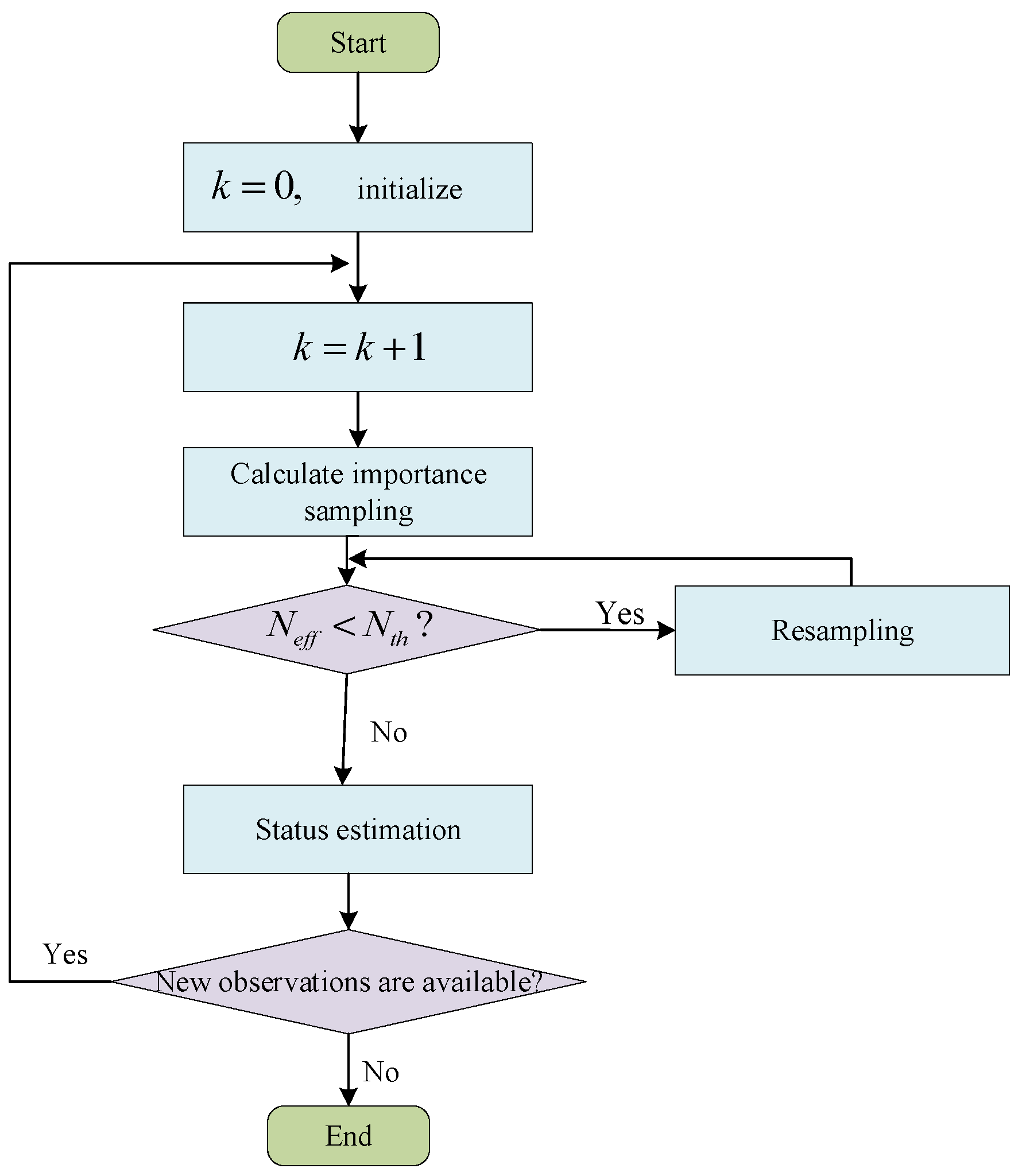

PF is a state estimation algorithm whose core idea is the Monte Carlo simulation method and the recursive Bayesian estimation. The core idea of PF is to approximate the probability distribution of the system states using discrete random states composed of sets of particles with weights and to obtain the minimum variance distribution of the states by replacing the integration operation with the particle mean. The main advantages of PF are unlimited noise model, unlimited system model, and accuracy advantage, so it can be applied to nonlinear systems that cannot be handled by KF.

Currently, PF methods have been widely used in the fields of target localization and tracking, pattern recognition, image processing, communication, and signal processing. PF uses statistical Bayesian inference to estimate and update the parameters of the model by calculating the probability density function. The PF method is known as a sequential Monte Carlo method with Bayesian update parameters. When new measurements are obtained, the posterior probability information of the previous moment is taken as the prior probability information of this moment. The PF contains the following assumptions: (1) the system state is the one describing the degradation process of the system, which can be updated by the initial distribution of the Markov process and the transformation equation and (2) the observed state is the state of the system with noise shown. The PF process is divided into two steps. One step is the state prediction, and the other step is updating the prediction model parameters. The specific algorithm is as follows [

74]:

| Algorithm 1: Principle of PF Algorithm |

| Step 1. | Initialization: Let , the particle set is obtained by sampling from the prior distribution , and the weights are initialized to . |

| Step 2. | Importance sampling: Two steps of -moment prediction and weight update.

For , sampling from the proposed distribution function at moment , , and setting .

For , weight update, calculate the weight of each particle: , and weight normalization: . |

| Step 3. | Resampling phase: When is less than , resampling is carried out. Generate a particle set with each weight of from the previous particle set according to the weights. |

| Step 4. | Output: The posterior distribution is obtained by weighting the output particles, and the system state can be found by calculating the sample mean . |

| Step 5. | Determine whether there is a new observation; if so, set and move to Step 2, otherwise end. |

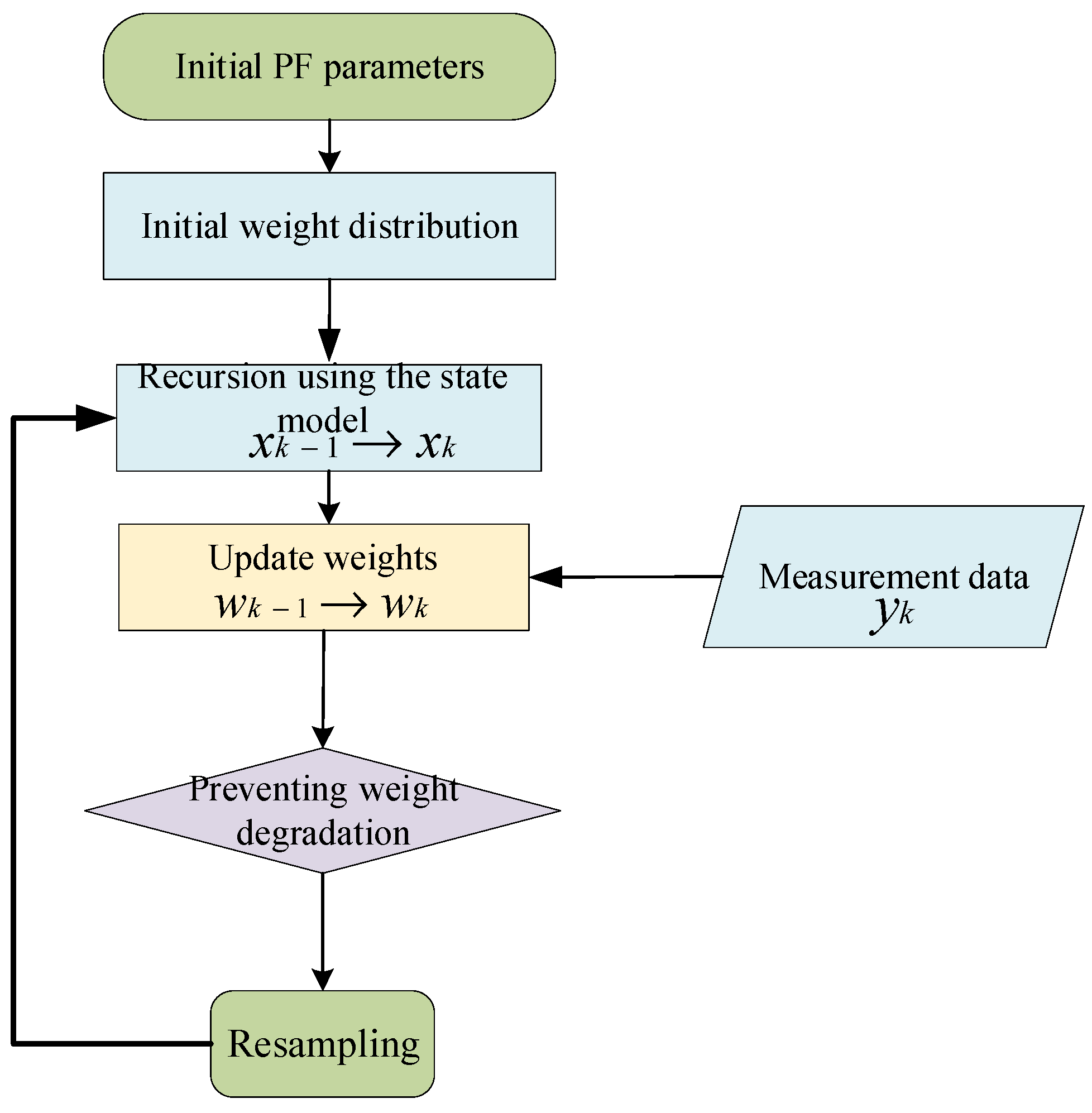

The flow chart of the standard PF algorithm is shown in

Figure 4.

In the prediction process, the capacitance-valued states at future moments

(

= 1, 2, 3, …) can be explained by incorporating a dynamic state model,

which can be derived from the state at the current moment

and the state transfer probability distribution function

. This requires establishing the initial conditional probabilities with all possible future probabilities, i.e.,

where

is to perform

charge–discharge followed by

charge–discharge. The algorithm flow of the entire prediction process is shown in

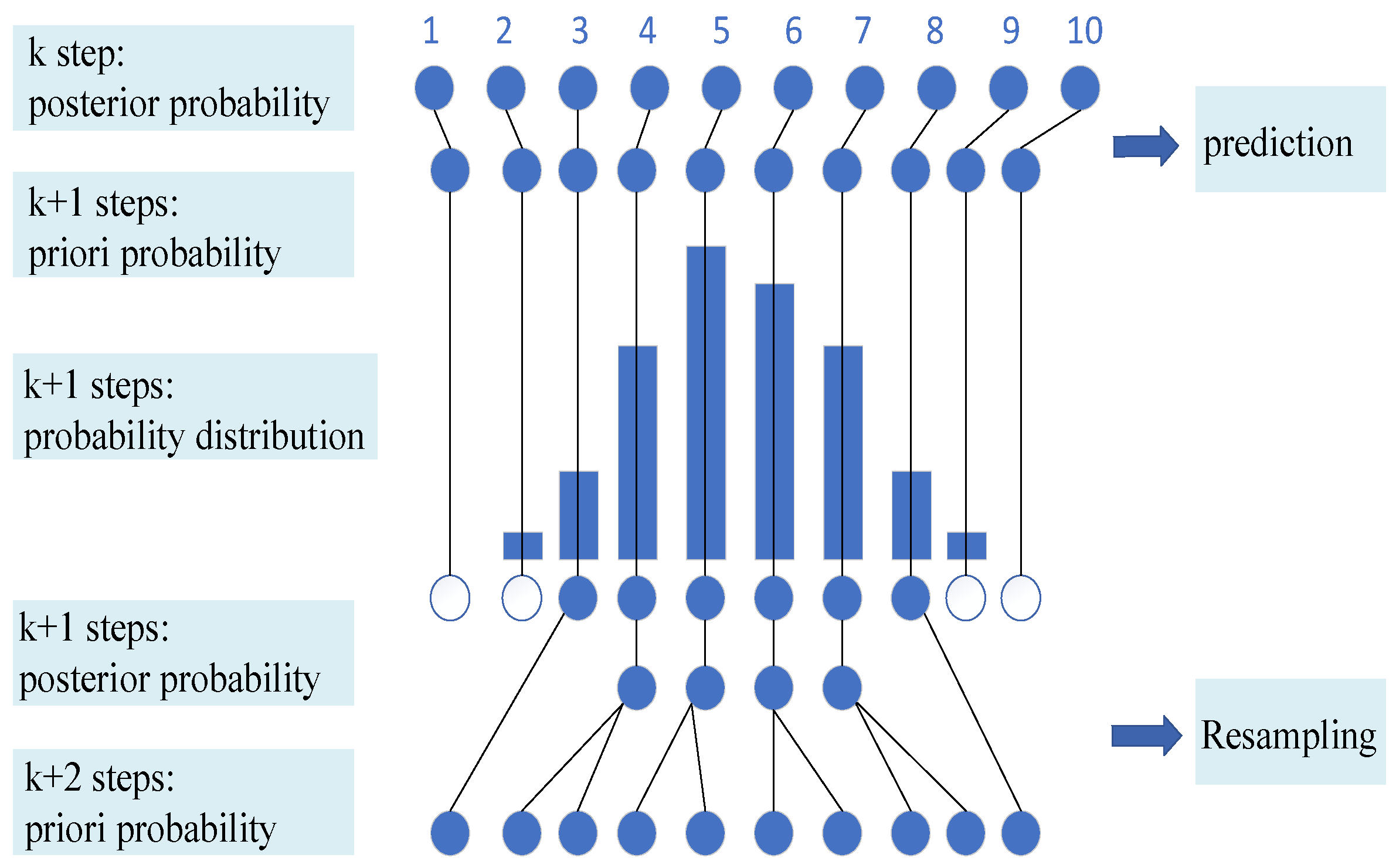

Figure 5, where

is the particle weight. The empirical model for predicting object degradation is first determined by the known capacitance value change curve of the degraded capacitor, the PF parameters are initialized, and then the initial weight setting of each particle is performed. Usually, the initial weight distribution of all particles is averaged and then recursively extrapolated through the state model. After each recursion, the predicted values of multiple particles are compared with the actual measured values; the larger particles are kept, and the smaller ones are removed, a process called updating the weights. Resampling is required to prevent the weights from degenerating.

Figure 6 shows the resampling schematic of Step

in the PF prediction method, where each solid origin represents a particle, and the hollow origin represents the rejected particle. The resampling process keeps the particles with higher probability and removes the particles with lower probability, thus updating the model of PF so that the model parameters satisfy individual capacitors with individual differences. The Weibull distribution method and the Birnbaum–Saunders distribution method cannot accomplish this.

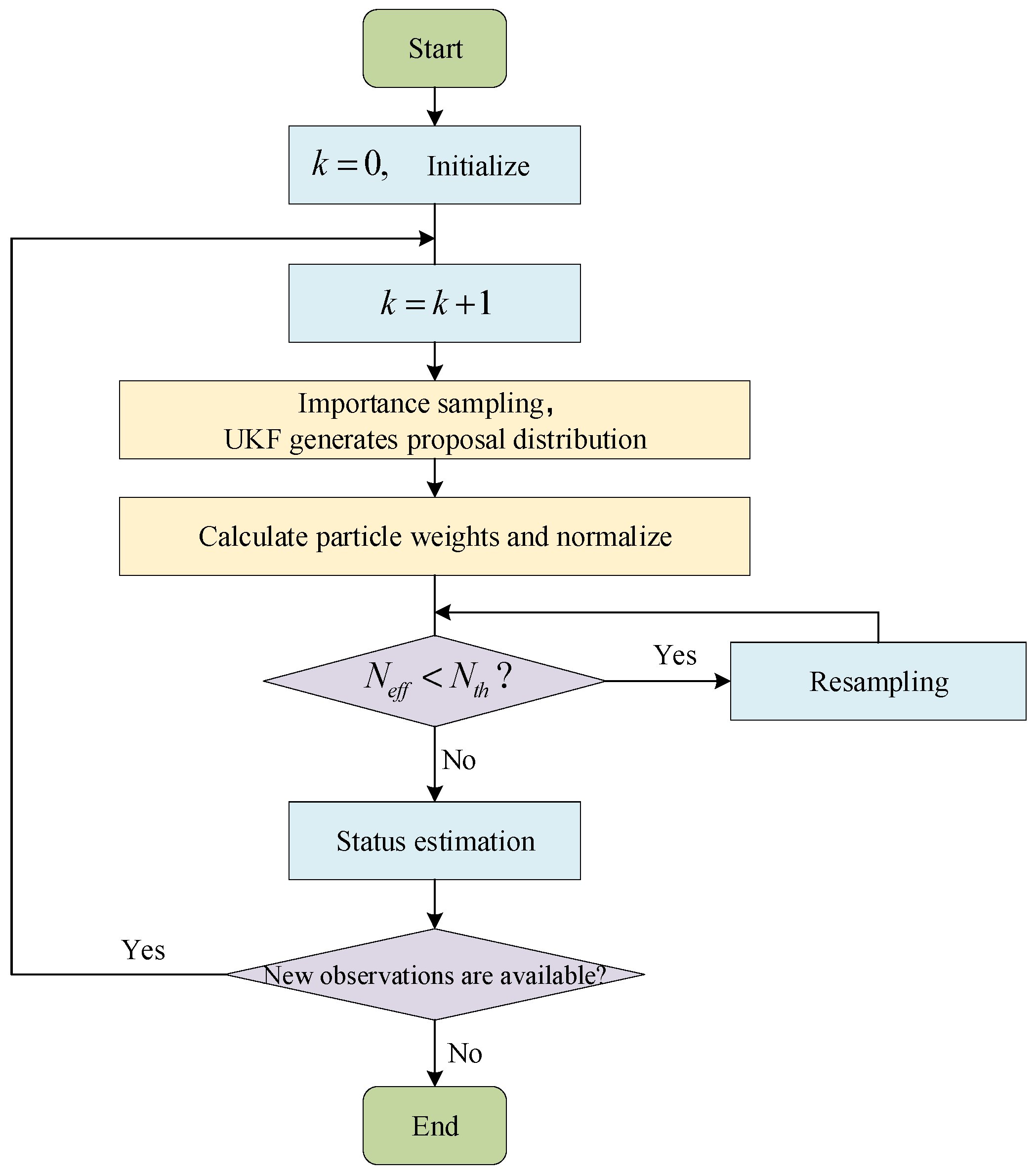

In PF, it is not enough to reduce the impact of particle degradation by introducing resampling algorithms. There are three main improvement methods to address the problems of PF particle degradation and lack of particle diversity. In addition to directly increasing the number of particles, the other two most effective methods are choosing a reasonable importance distribution function and improving the particle resampling method, respectively. Finding the optimal proposed probability density distribution function and ensuring an efficient resampling step can directly and effectively guarantee the effectiveness of particles and improve the accuracy of PF. Unscented particle filter (UPF) is an improved PF method based on the optimized importance density function, which uses the proposed distribution obtained by UKF as the importance function to guide the PF for sampling. The UKF conveys the state mean and variance of the nonlinear system through a set of sigma points obtained by a traceless transformation, making the particle distribution closer to the system posterior distribution. At the same time, the introduction of UKF can also combine the latest observations of the system, which can make the particle distribution guiding the PF sampling closer to the real state. The flow chart of the UPF algorithm is shown in

Figure 7.

In order to attenuate the effects of unavoidable observation errors generated in the filtering iterative prediction process, a fusion of UPF and GA-SVR for the RUL prediction algorithm of lithium-ion batteries was proposed in the literature [

75], where a scheme of using GA-SVR for observation error correction based on the UPF algorithm was introduced, and the fusion method was experimentally verified to have better filtering effects. The literature [

76] proposed a hybrid framework to improve the prediction accuracy of lithium-ion batteries using adaptive Levy flight (ALF)-optimized grain PF and LSTM networks. In the literature [

77], an interactive multi-model framework based on PF and SVR was proposed to achieve multi-step prediction of battery capacity and RUL. In the literature [

78], a dynamic UPF model is proposed to describe the degradation of a single battery, from which the uncertainty of the capacity and the RUL during degradation can be represented. Furthermore, the noise variables in the UPF model can be well estimated adaptively on the basis of EM algorithm. In [

79], a grey neural network (GNN)-fused grey model (GM) and BPNN are proposed to estimate the capacity online with the inputs of new health indicators. Additionally, the sliding-window grey model (SGM) is employed to track the degradation trend of the battery, and the trend equation is set as the state transition equation of PF algorithm. Meanwhile, the estimation values by GNN model are used as observation values of the PF to construct the GNN-fused sliding-window grey model on the basis of PF framework (GNN-SGMPF) for prediction of battery RUL. To facilitate the comparison of the three categories of RUL prediction methods for lithium-ion batteries, we summarize the advantages and disadvantages of the different methods mentioned above in a block diagram, as shown in

Figure 8.

5. Research Prospect

5.1. Lithium-Ion Battery Capacity Regeneration Problem

The capacity regeneration phenomenon occurs in lithium-ion batteries during cycling, and the capacity regeneration phenomenon interferes with the trend of the capacity prediction curve and affects the performance of the prediction model. In view of the capacity regeneration phenomenon of lithium batteries during degradation, the local capacity regeneration model of lithium-ion batteries is considered, and the research on the RUL prediction method of lithium-ion batteries based on the fusion-type algorithm is carried out to predict the global trend of battery capacity degradation using the data-driven method, which enables the PF to track the local capacity regeneration phenomenon during the prediction process.

5.2. Predictive Modeling of Thermal Runaway Response in Lithium-Ion Batteries

When exposed to abusive conditions or when manufacturing defects exist, an exothermic reaction may occur inside the lithium-ion battery, which eventually leads to thermal runaway. For the heat release, toxic gas emission, fire, and explosion that usually accompany the thermal runaway reaction of lithium-ion batteries, a method based on the fusion of stochastic filtering and traditional thermal models is considered to model the prediction of thermal runaway reaction of lithium-ion batteries, coupling the possible heat-generating side reactions inside the battery to simulate the process of thermal runaway and finally achieve a more accurate prediction.

5.3. A Study to Consider Personalized Lithium-Ion Batteries Health Management

Personalized prediction of battery health status remains challenging due to the varying usage interests, the dynamic operating patterns, and the limited historical data. Real-time and personalized lithium-ion batteries health management facilitates end-user safety improvements. Practical applications also require consideration of customized and personalized battery health status prediction for each discharge protocol. Personalized lithium-ion batteries health management on a variety of unknown usage protocols uses cycling knowledge from completely different usage protocols, charge and discharge configurations, and battery packs.

5.4. Energy Storage Component Module RUL Prediction Considering Consistency

Most of the energy storage components in practical applications are in the form of modules, while most of the current studies are for single components. In order to make better prediction of energy storage components by RUL in real scenarios, consistent research on RUL prediction of energy storage component modules should be considered in future research. Meanwhile, considering different working conditions of application scenarios, such as electric vehicles and pulsed energy storage, research on energy storage component module RUL prediction should be carried out to improve the generalization of the prediction model and ensure that a high prediction effect can be achieved in practical applications.

5.5. Verification of Failure Mechanism Based on Computational Simulation

The energy storage components belong to the grey box (grey system) of modern cybernetics, i.e., the internal physical and chemical change mechanisms and thermodynamic and kinetic processes are not fully understood. The failure phenomena of the design controllable variables are used as a starting point for further forward verification process analysis. On the basis of the conclusions of the reverse diagnostic analysis, the verification of the failure mechanism is finally achieved through the simulated use (storage) of the physical energy storage components, or theoretical computational simulation.

5.6. RUL Prediction Method for Energy Storage Components Applicable to Pulsed Repetitive Discharge Scenarios

In the pulsed repetitive discharge scenario applications, energy storage components operate under extreme operating conditions. Energy storage components for extreme applications are faced with extremely complex physical parameter variation situations. It is important to consider not only the consistency of the module-based energy storage system during discharge and the prevention of backflow of the faulty module current to other normal modules under abnormal conditions but also the online estimation of the overall life of the module for continuous high-voltage pulse energy storage repetitive discharge scenarios to overcome the influence of extreme environments, improve prediction accuracy, and support reliable and safe cyclic discharge of the pulse energy storage system. In summary, the RUL prediction method based on the stochastic filtering method is applicable to the RUL prediction of energy storage components in pulsed repetitive discharge scenarios. It should be combined with deep learning methods to model the failure law in the process of successive discharges and carry out state accurate estimation fusion to ensure the control model of module discharge consistency, together to improve the cycle discharge life of pulsed energy storage system.