Review of Bioenergy Potential in Jordan

Abstract

1. Introduction

- Increase in natural capital.

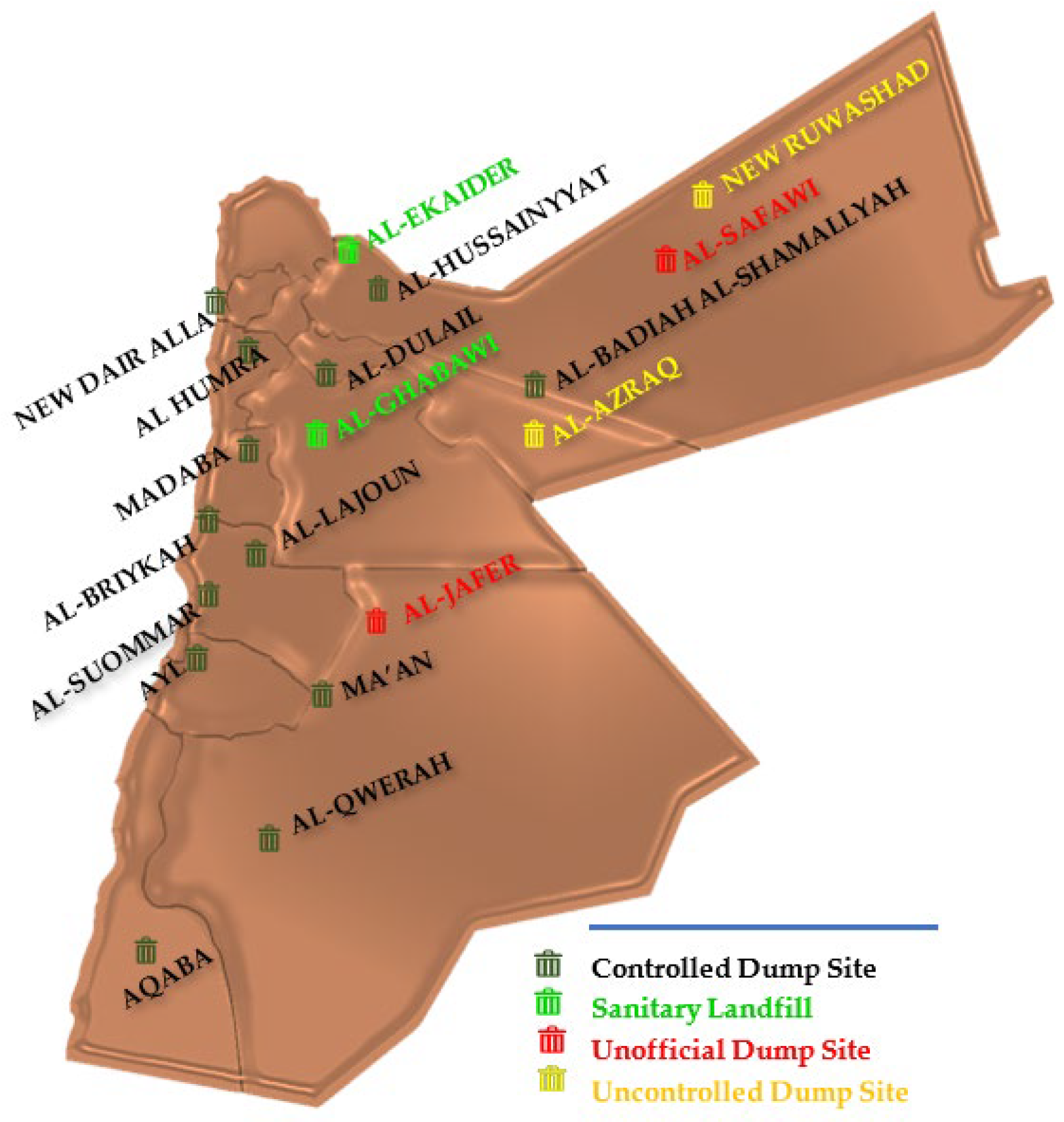

- Consistent economic growth.

- Poverty alleviation and social development.

- Effective use of resources.

- Mitigation and adaptation to climate change.

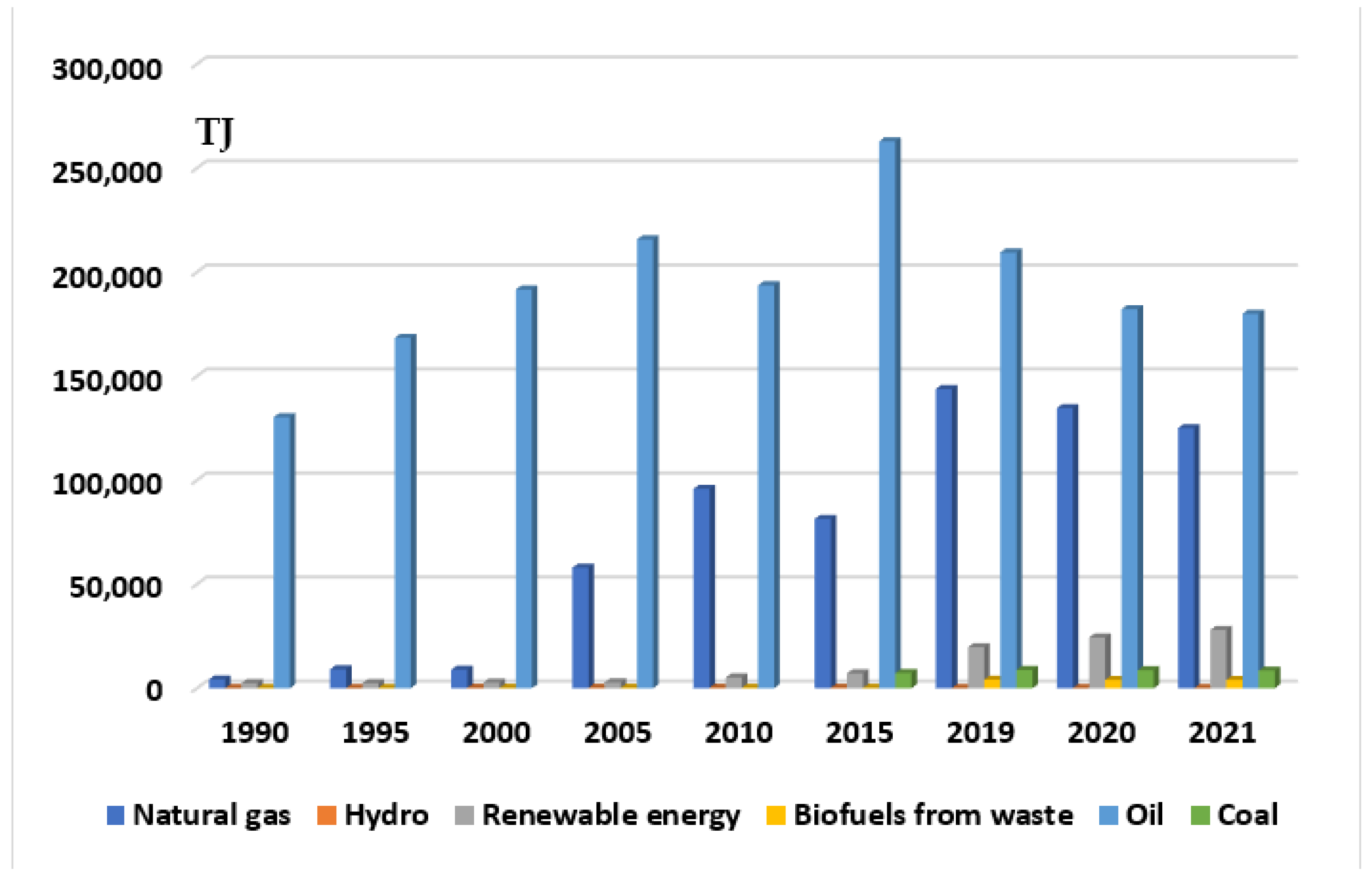

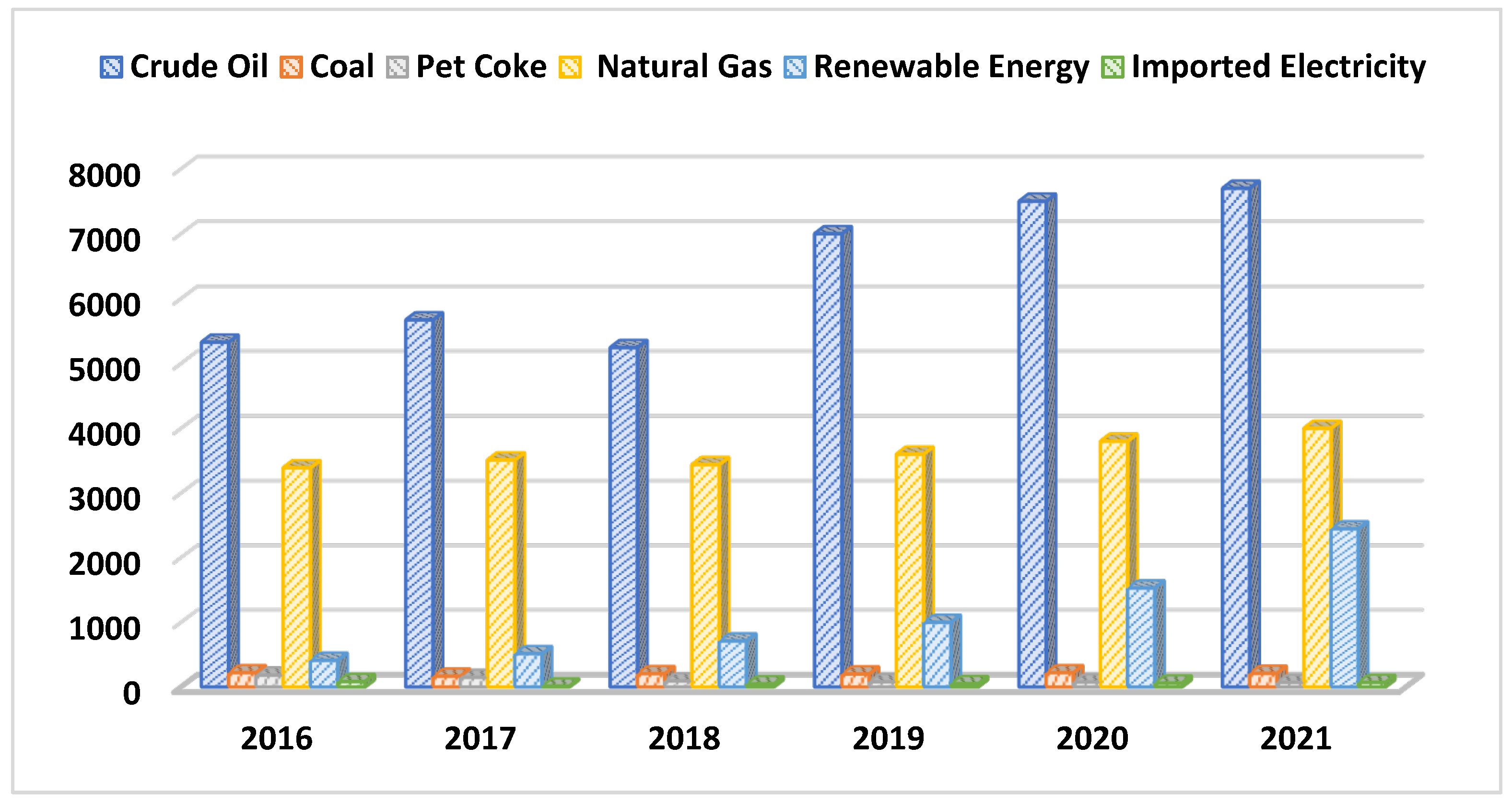

2. The Energy Sector in Jordan: Current Situation

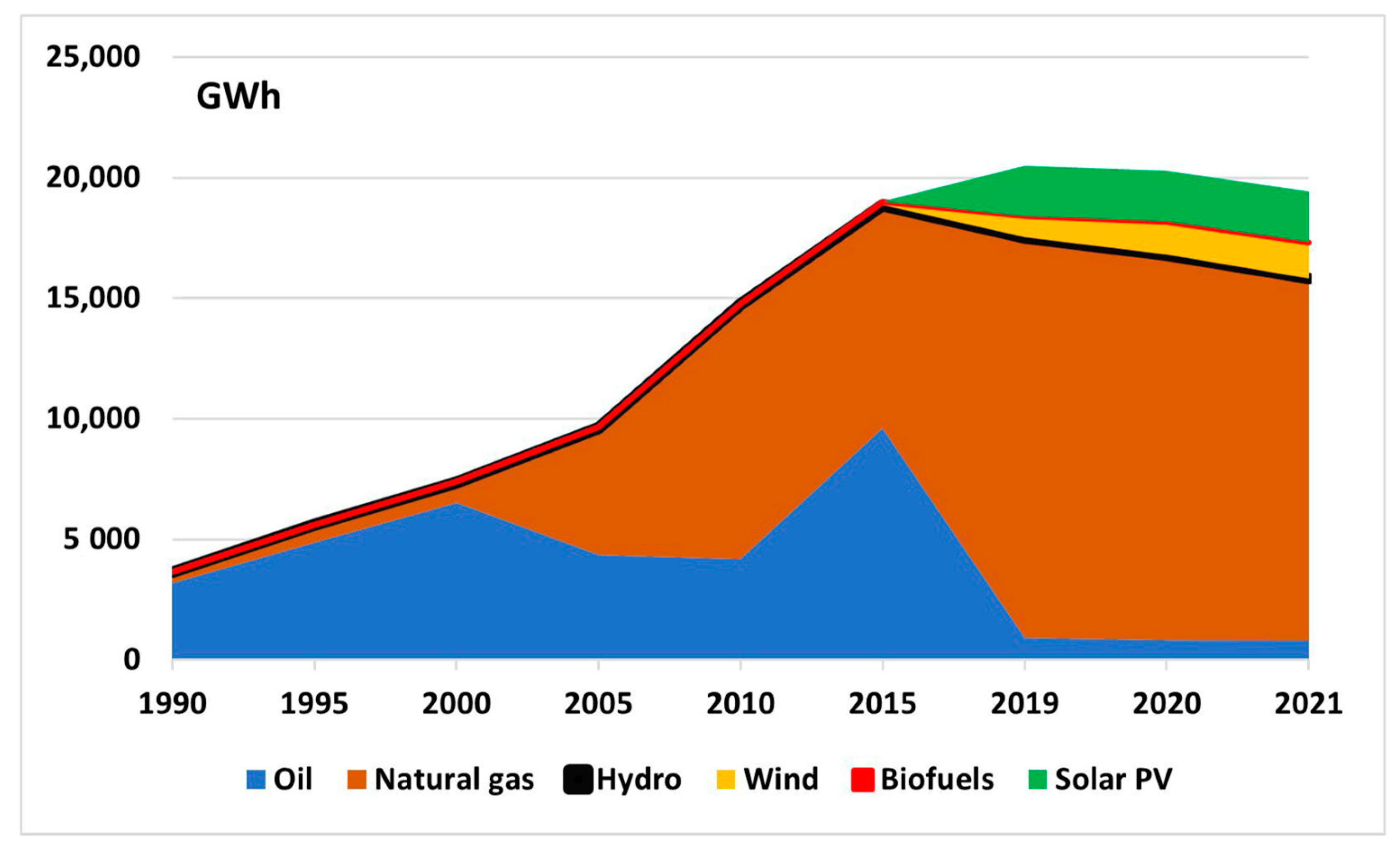

2.1. Electricity Generation in Jordan

2.2. Renewables Energy Status in Jordan

3. Potential Bioenergy from Targeted Biomass

3.1. Solid Biomass (Wood, Agricultural Residue, and Strong Waste)

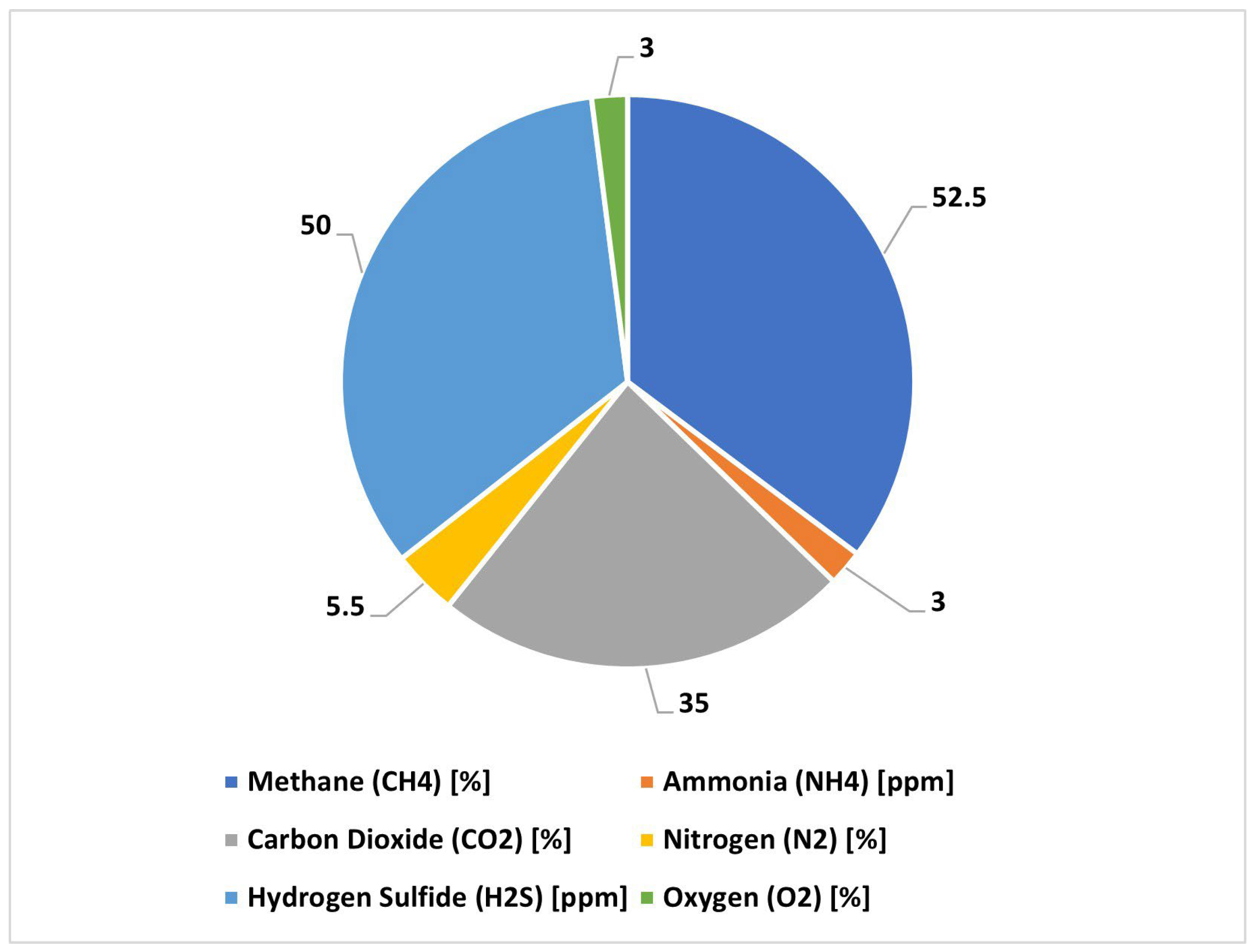

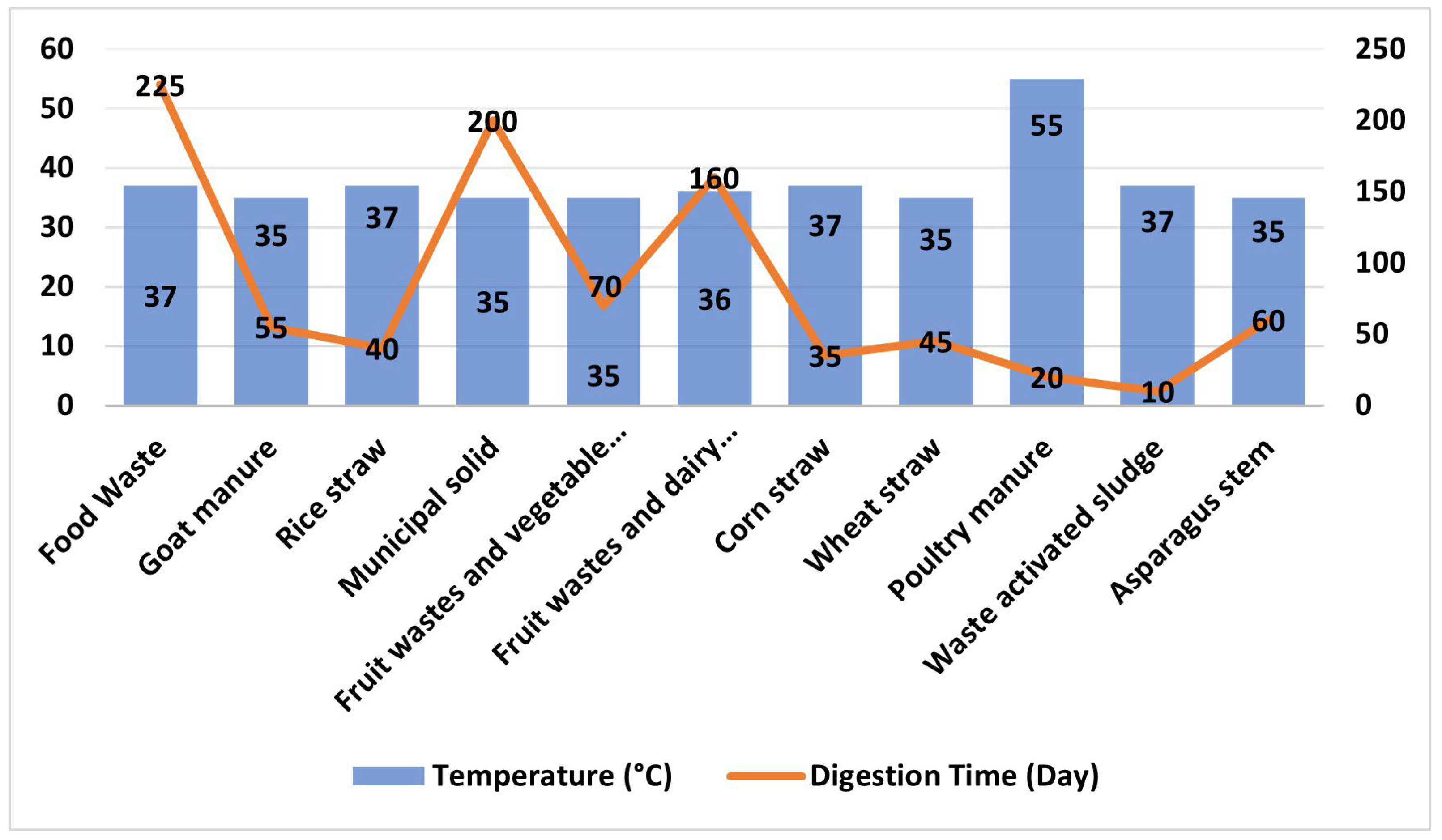

3.2. Biogas Energy (Decay and Rot, By-Products of Animals, and Manure and Human Waste)

3.3. Liquid Biofuel Energy (Ethanol and Biodiesel)

- Sugar-containing raw materials include sugar beet, sugar cane, molasses, whey, and sweet sorghum.

- Grains such as corn and wheat are examples of raw materials that contain starch and crops with roots, such as cassava.

- Lignocellulosic biomass includes straw, crop waste, and wood waste [64].

4. Bioenergy Situation in Jordan

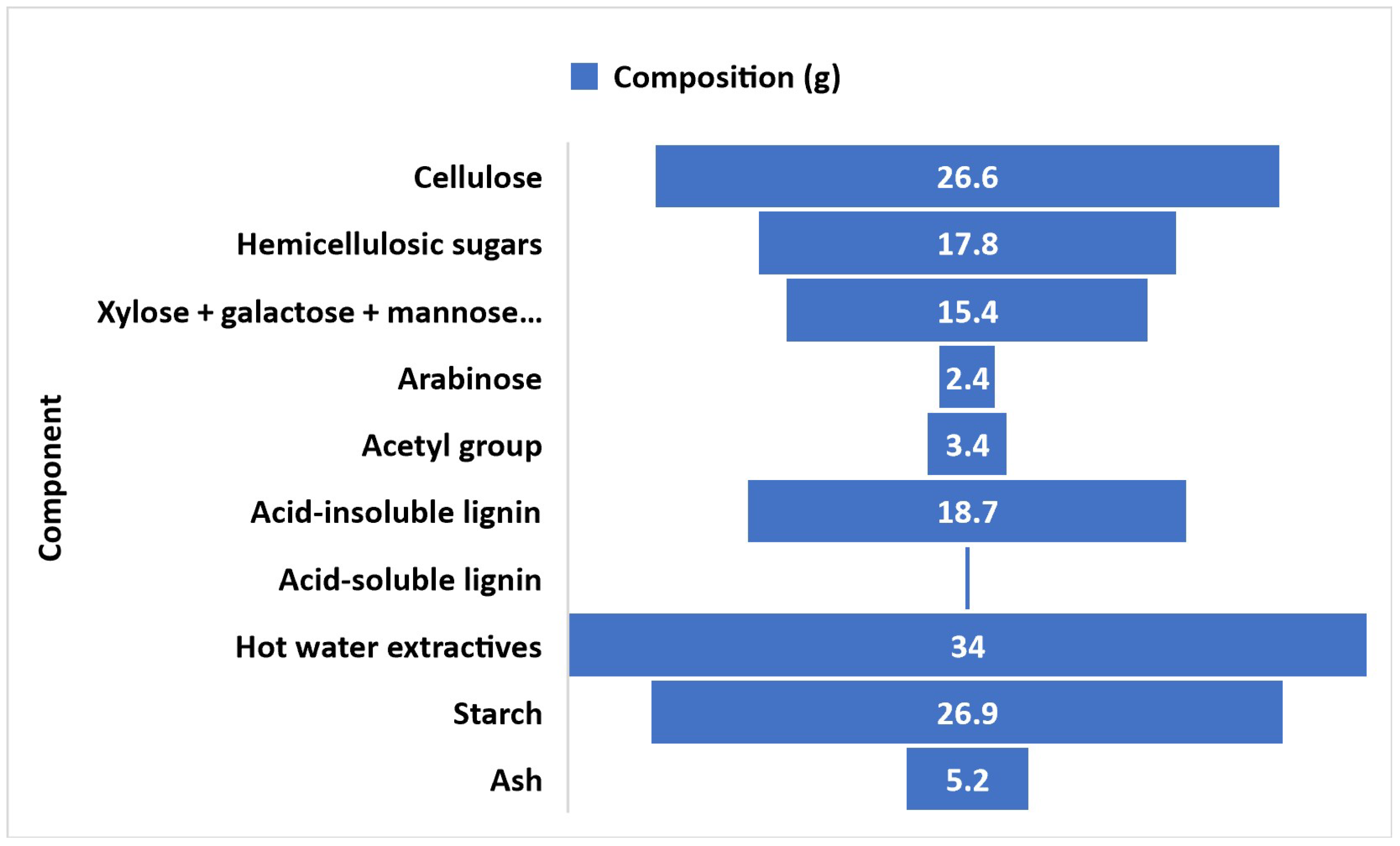

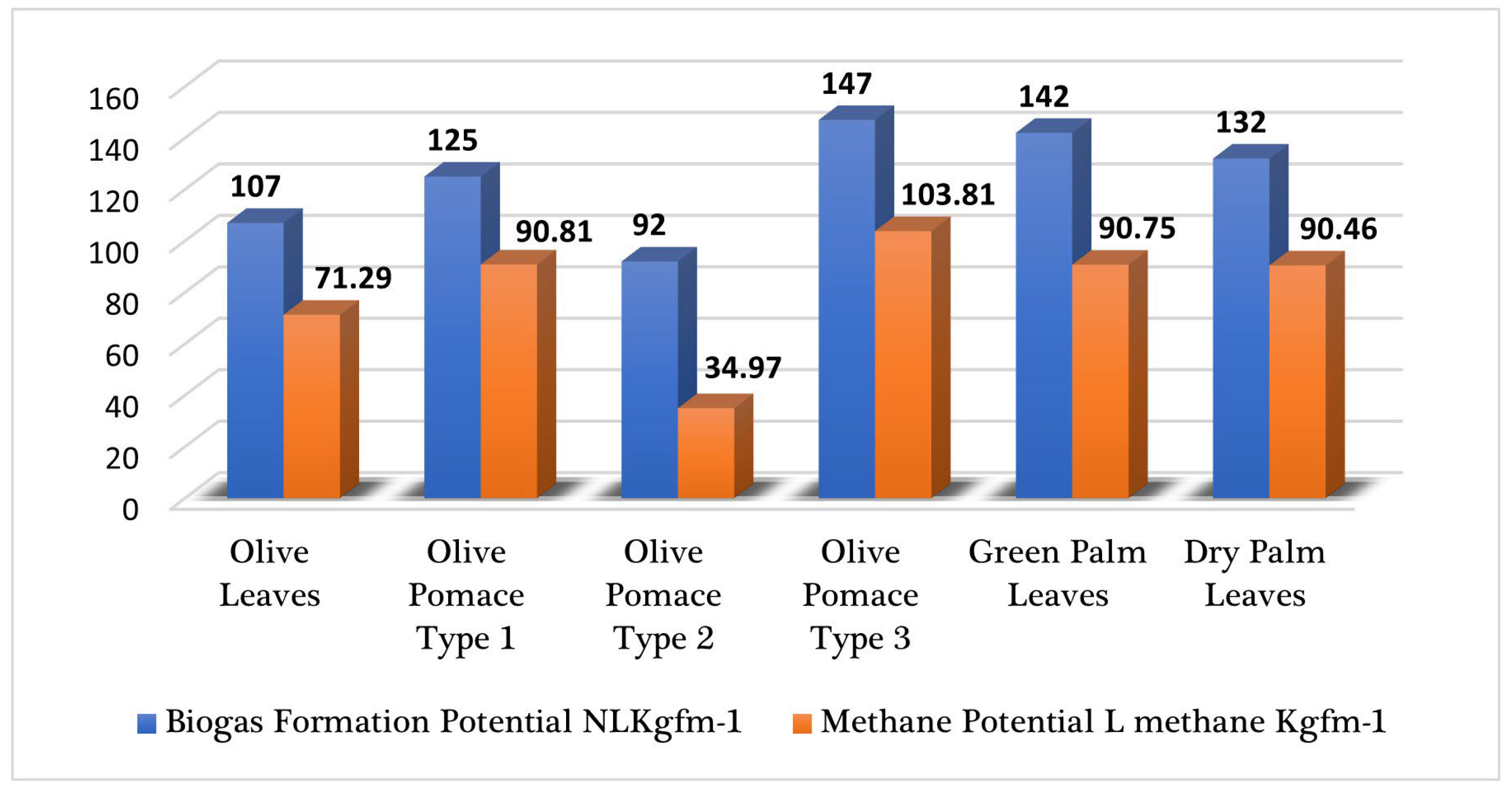

4.1. Energy Production from Palm Farms and Olive Groves in Jordan

- Most of the generated olive pomace was dried and burned directly in homes as heat.

- 35% of pomace, 17% of oil, and 48% of pomace are all included in one ton of olive pellets [79].

- In 2018, nearly 200 tons of pomace were generated by each olive oil milling line [80].

- Most facilities and companies that produce olive oil have several milling lines.

4.2. Human Waste Sources in Jordan

- Organic waste from grocery stores, motels, and restaurants.

- Animal waste, primarily from chickens and cows.

- Agro-industrial organic waste.

- Industrial organic waste.

- Garbage accumulated in cities.

- Septic and sewage sludge.

- Olive mills.

4.3. Slaughter Field Waste in Jordan

- Agriculture Ministry for slaughterhouses.

- The Ministry of Local Administration.

- The slaughterhouse in the Greater Amman Municipality.

4.4. Current Biogas Projects in Jordan

4.4.1. Al-Samra WWTP Biogas

4.4.2. Wadi Shallala WWTP Biogas

4.4.3. Al-Russaifah Landfill Biogas

5. Economic Analysis

6. Biomass Exergy Balance

7. Barriers in Society, Behavior and Education

- The most significant societal hurdles to attaining sustainable renewable energy development are population expansion and unsustainable consumption and production habits.

- The persistent lack of understanding regarding renewable energy production has stymied progress.

- There is a scarcity of innovative research in the educational sector.

- Data are difficult to obtain for consultants, investors, institutions, and researchers, posing a barrier to progress and innovation.

- There is an insufficient connection between civil society and government.

8. Recommendations and Discussion

- The Jordanian government must design and incorporate goals for sustainable development, combating climate change, and green growth within its sectoral policy frameworks. This would encourage the development of greener initiatives and rules that enhance the favorable environment for greener investment and private sector growth.

- Complementary technical assistance programs must be activated, and support for small and medium-sized enterprises that use recyclable products that are environmentally and climatically sustainable and enhance collaboration across sectors must be provided for the responsible institution to be more successful in obtaining funding for implementation, whether from the general budget or from private investors or donors.

- Creating training programs to prepare garbage collectors for formal and institutional integration into the recycling value chain by teaching them best practices for recycling in addition to core business and soft skills and issuing necessary regulatory directives in areas where business activity is concentrated companies and enterprises that minimize trash creation or recycle it, as well as organizations that separate the source and carry out waste recycling activities, can all participate in a program of financial and moral grants and incentives.

- Analyzing current processes and outlining procedures are important to make sure Jordan’s biogas potential is realized. Planning and implementing a standard laboratory; creating, running, and assessing a hybrid biogas pilot plant; as well as designing and executing a biogas inventory for the Jordanian landfills.

- Jordan’s government should pursue a stronger role for renewables in the future energy mix because of the significant cost reductions in renewable energy technology over the past ten years.

9. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Description | Symbol | Description |

| GHG | Greenhouse Gas | TES | Total Energy Supply |

| CO2 | Carbon Dioxide | KWh | Kilowatt-hour |

| N2O | Nitrous Oxide | USD | United States Dollar |

| CH4 | Methane | NDC | Nationally Determined Contribution |

| AFOLU’s | Agriculture, Forestry, And Other Land Use | Toe/Cap | Ton Of Oil/Capacity Market Programs |

| N | Nitrogen | Ca | Calcium |

| TWh | Ton Watt-hour | Mg | Magnesium |

| GW | Giga Watt | MEMR | Minister of Energy and Mineral Resources |

| PJ | Petajoule | MENA | Middle East and North Africa. |

| GWh | Giga Watt hour | kg | Kilograms |

| FDI | Foreign Direct Investment | WWTP | Wastewater Treatment Plant. |

| TCI | Total Capital Investment | CHP | Combined Heat and Power |

| NLKgfm−1 | Cumulative biogas formation and methane yield volume produced per kg | L methane kgfm−1 | Cumulative methane yield formation potential. |

| t/a | Ton/annum | FDS | Final Disposal Site |

| JSC | Joint Service Councils |

References

- Alhassany, H.D.; Abbas, S.M.; Tostado-Véliz, M.; Vera, D.; Kamel, S.; Jurado, F. Review of Bioenergy Potential from the Agriculture Sector in Iraq. Energies 2022, 15, 2678. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2022. 2022. Available online: https://www.iea.org/news/world-energy-outlook-2022- (accessed on 25 May 2022).

- Smith, P.; Clark, H.; Dong, H.; Elsiddig, E.A.; Haberl, H.; Harper, R.; House, J.; Jafari, M.; Masera, O.; Mbow, C.; et al. Ecosystems Services and Management (ESM). In Climate Change 2014; Cambridge University Press: Cambridge, UK, 2014; Chapter 11. [Google Scholar]

- Jaganmohan, M. Production of Bioenergy Worldwide from 2009 to 2020. Available online: https://www.statista.com/statistics/1032907/bioenergy-production-globally/ (accessed on 3 June 2022).

- Global Bioenergy Statistics; World Bioenergy Association: Stockholm, Sweden, 2021.

- Buchspies, B.; Kaltschmitt, M. The Influence of Co-product Handling Methodology on Greenhouse Gas Savings of Biofuels in the European Context. BioEnergy Res. 2016, 10, 167–182. [Google Scholar] [CrossRef]

- Jaganmohan, M. Leading Consumer of Solid Biomass Energy in the European Union (EU) in 2020. Available online: https://www.statista.com/statistics/799370/solid-biomass-energy-production-european-union-eu/ (accessed on 15 June 2022).

- Asia Pacific Biomass Energy Market. EMR Expert Market Research, USA & Canada. 2022. Available online: https://www.expertmarketresearch.com/pressrelease/asia-pacific-biomass-energy-market (accessed on 17 July 2022).

- Popp, A.; Calvin, K.; Fujimori, S.; Havlik, P.; Humpenöder, F.; Stehfest, E.; Bodirsky, B.L.; Dietrich, J.P.; Doelmann, J.C.; Gusti, M.; et al. Land-use futures in the shared socio-economic pathways. Glob. Environ. Change 2017, 42, 331–345. [Google Scholar] [CrossRef]

- Kang, Y.; Yang, Q.; Bartocci, P.; Wei, H.; Liu, S.S.; Wu, Z.; Zhou, H.; Yang, H.; Fantozzi, F.; Chen, H. Bioenergy in China: Evaluation of domestic biomass resources and the associated greenhouse gas mitigation potentials. Renew. Sustain. Energy Rev. 2020, 127, 109842. [Google Scholar] [CrossRef]

- World Bank. 2022. Available online: https://www.data.worldbank.org (accessed on 1 July 2022).

- Addustour. Disclosure of the cost of Jordan’s import of energy in 2021. Available online: https://www.addustour.com/articles/1289785 (accessed on 4 August 2022).

- Glada Lahn, S. Refugees and Energy Resilience in Jordan; Chatham House: London, UK, 2016. [Google Scholar]

- Ministry of Environment. Waste Sector—Green Growth National Action Plan 2021–2025; Ministry of Environment: Amman, Jordan, 2020. [Google Scholar]

- Ministry to Issue $20m Tender to Handle Medical, Hazardous Waste. Jordan News, 27 October 2022.

- Da’aja, K. The Strategic Plan of the Greater Amman Municipality. 2022. Available online: https://amman.jo/ (accessed on 29 October 2022).

- Jordan News. Available online: https://www.petra.gov.jo/Include/InnerPage.jsp?ID=105545&lang=ar&name=news (accessed on 30 October 2022).

- Ministry of Energy and Mineral Resources Annual Report. 2021. Available online: https://www.memr.gov.jo (accessed on 1 November 2022).

- Energy Data Intelligent and Consulting. 2022. Available online: www.enerdata.net (accessed on 2 November 2022).

- Myyas, R.N.; Almajali, M.R. Effect of COVID-19 on Energy Sector in Jordan. Int. J. Energy Econ. Policy 2022, 12, 20–29. [Google Scholar] [CrossRef]

- International Energy Agency. 2022. Available online: www.iea.org (accessed on 3 November 2022).

- International Energy Agency. Natural Gas Information. 2022. Available online: http://wds.iea.org/wds/pdf/gas_documentation.pdf (accessed on 3 November 2022).

- Economist Intelligence (EIU). Energy Outlook Surviving the Energy Crisis. 2023. Available online: www.eiu.com (accessed on 4 November 2022).

- Abu-Rumman, G.; Khdair, A.I.; Khdair, S.I. Current status and future investment potential in renewable energy in Jordan: An overview. Heliyon 2020, 6, e03346. [Google Scholar] [CrossRef] [PubMed]

- Global Petrol Prices. 2022. Available online: https://www.globalpetrolprices.com/ (accessed on 5 November 2022).

- Zaidan, R. Natural Gas Accounts for 73% of Electricity Generation; Alghad: Amman, Jordan, 2022. [Google Scholar]

- Jordan News. 2022. Available online: https://www.jordannews.jo (accessed on 5 November 2022).

- MEMR. Summary of Jordan Energy Strategy 2020–2030.; Ministry of Energy & Mineral Resources: Amman, Jordan, 2020. [Google Scholar]

- Khalifeh, A. Jordan Imports JD2.8 Billion Worth of Energy in 2021. Jordan News, 3 July 2022.

- Attaqa. Jordan’s Production of Oil and Gas Records 177.3 Thousand Tons in 2021. Available online: https://attaqa.net/ (accessed on 6 November 2022).

- Myyas, R.N.; Al-Dabbasa, M.; Tostado-Véliz, M.; Jurado, F. A novel solar panel cleaning mechanism to improve performance and harvesting rainwater. Sol. Energy 2022, 237, 19–28. [Google Scholar] [CrossRef]

- IRENA. Renewable Readiness Assessment: The Hashemite Kingdom of Jordan; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Ababneh, S. The Climate Effect of Biomass and a Roadmap for Development of Bioenergy Projects in Jordan_sa-0; Royal Scientific Society: Amman, Jordan, 2019. [Google Scholar]

- The Jordan Times. 2022. Available online: https://www.jordantimes.com (accessed on 7 November 2022).

- Hosseini, F. Case Study on Policy Reforms to Promote Renewable Energy in Jordan; Economic and Social Commission for Western Asia: Beirut, Lebanon, 2018. [Google Scholar]

- Anderson, R.; Keshwani, D.; Guru, A.; Yang, H.; Irmak, S.; Subbiah, J. An integrated modeling framework for crop and biofuel systems using the DSSAT and GREET models. Environ. Model. Softw. 2018, 108, 40–50. [Google Scholar] [CrossRef]

- De Souza, N.R.D.; Fracarolli, J.; Junqueira, T.L.; Chagas, M.F.; Cardoso, T.F.; Watanabe, M.D.; Cavalett, O.; Filho, S.V.; Dale, B.E.; Bonomi, A.; et al. Sugarcane ethanol and beef cattle integration in Brazil. Biomass-Bioenergy 2019, 120, 448–457. [Google Scholar] [CrossRef]

- Corré, W.; Conijn, J.; Meesters, K.; Bos, H. Accounting for co-products in energy use, greenhouse gas emission savings and land use of biodiesel production from vegetable oils. Ind. Crop. Prod. 2016, 80, 220–227. [Google Scholar] [CrossRef]

- Mumm, R.H.; Rausch, K.D.; Stein, H.H. Land usage attributed to corn ethanol production in the United States: Sensitivity to technological advances in corn grain yield, ethanol conversion, and co-product utilization. Biotechnol. Biofuels 2014, 7, 61. [Google Scholar] [CrossRef] [PubMed]

- Egeskog, A.; Berndes, G.; Freitas, F.; Gustafsson, S.; Sparovek, G. Integrating bioenergy and food production—A case study of combined ethanol and dairy production in Pontal, Brazil. Energy Sustain. Dev. 2011, 15, 8–16. [Google Scholar] [CrossRef]

- De Oliveira Silva, R.; Barioni, L.G.; Hall, J.A.J.; Moretti, A.C.; Fonseca Veloso, R.; Alexander, P.; Crespolini, M.; Moran, D. Sustainable intensification of Brazilian livestock production through optimized pasture restoration. Agric. Syst. 2017, 153, 201–211. [Google Scholar] [CrossRef]

- De Souza, N.R.D.; Cavalett, O.; Junqueira, T.L. Techno-economic and environmental assessment of bioenergy and livestock integrated systems in Brazil. Sustain. Prod. Consum. 2022, 32, 580–592. [Google Scholar] [CrossRef]

- Biomass at a Glance. National Energy Education Development Project. 2019. Available online: https://www.need.org (accessed on 12 November 2022).

- Peter, A.P.; Chew, K.W.; Koyande, A.K.; Munawaroh, H.S.H.; Bhatnagar, A.; Tao, Y.; Sun, C.; Sun, F.; Ma, Z.; Show, P.L. Integrated microalgae culture with food processing waste for wastewater remediation and enhanced biomass productivity. Chin. Chem. Lett. 2023, 34, 107721. [Google Scholar] [CrossRef]

- Pulingam, T.; Lakshmanan, M.; Chuah, J.-A.; Surendran, A.; Zainab-L, I.; Foroozandeh, P.; Uke, A.; Kosugi, A.; Sudesh, K. Oil palm trunk waste: Environmental impacts and management strategies. Ind. Crop. Prod. 2022, 189, 115827. [Google Scholar] [CrossRef]

- Abanades, H.S.; Ahmadi, A.; Das, B.; Ehyaei, M.A.; Esmaeilion, F.; El Haj Assad, M.; Hajilounezhad, T.; Jamali, D.H.; Hmida, A.; Ozgoli, H.A.; et al. A critical review of biogas production and usage with legislations framework across the globe. Int. J. Environ. Sci. Technol. 2022, 19, 3377–3400. [Google Scholar] [CrossRef]

- Herbes, C.; Halbherr, V.; Braun, L. Factors Influencing prices for heat from biogas plants. Appl. Energy 2018, 221, 308–318. [Google Scholar] [CrossRef]

- Damyanova, S.; Beschkov, V. Biogas as a Source of Energy and Chemicals. In Biorefinery Concepts; IntechOpen: London, UK, 2020. [Google Scholar]

- Kapoor, R.; Ghosh, P.; Kumar, M.; Vijay, V.K. Evaluation of biogas upgrading technologies and future perspectives. Environ. Sci. Pollut. Res. 2019, 26, 11631–11661. [Google Scholar] [CrossRef]

- Yang, L.; Ge, X.; Wan, C.; Yu, F.; Li, Y. Progress and perspectives in converting biogas to transportation fuels. Renew. Sustain. Energy 2014, 40, 1133–1152. [Google Scholar] [CrossRef]

- Minh, D.P.; Siang, T.J.; Vo, D.V.; Phan, T.S.; Ridart, C.; Nzihou, A.; Grouset, D. Hydrogen Production from Biogas Reforming: An Overview of Steam Reforming, Dry Reforming, Dual Reforming, and Tri-Reforming of Methane. In Hydrogen Supply Chains; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Wasajja, H.; Lindeboom, R.E.; van Lier, J.B.; Aravind, P.V. Techno-economic review of biogas cleaning technologies for small scale off-grid solid oxide fuel cell applications. Fuel Process. Technol. 2020, 197, 106215. [Google Scholar] [CrossRef]

- Floudas, D.; Binder, M.; Riley, R.; Barry, K.; Blanchette, R.A.; Henrissat, B.; Martínez, A.T.; Otillar, R.; Spatafora, J.W.; Yadav, J.S.; et al. The Paleozoic Origin of Enzymatic Lignin Decomposition Reconstructed from 31 Fungal Genomes. Science 2012, 336, 1715–1719. [Google Scholar] [CrossRef] [PubMed]

- Park, G.W.; Gong, G.; Joo, J.C.; Song, J.; Lee, J.; Lee, J.-P.; Kim, H.T.; Ryu, M.H.; Sirohi, R.; Zhuang, X.; et al. Recent progress and challenges in biological degradation and biotechnological valorization of lignin as an emerging source of bioenergy: A state-of-the-art review. Renew. Sustain. Energy Rev. 2022, 157, 112025. [Google Scholar] [CrossRef]

- Rouches, E.; Zhou, S.; Steyer, J.; Carrere, H. White-Rot Fungi pretreatment of lignocellulosic biomass for anaerobic digestion: Impact of glucose supplementation. Process. Biochem. 2016, 51, 1784–1792. [Google Scholar] [CrossRef]

- Börjesson, P. Biogas as a resource-efficient vehicle fuel. Trends Biotechnol. 2008, 26, 7–13. [Google Scholar] [CrossRef] [PubMed]

- Hung, H.; Chen, H.-Y. Renewable coffee waste-derived porous carbons as anode materials for high-performance sustainable microbial fuel cells. ACS Sustain. Chem. Eng. 2019, 7, 16991–16999. [Google Scholar] [CrossRef]

- Alrbai, M.; Ahmad, A.D.; Al-Dahidi, S.; Ayadi, O.; Hjouj, D.; Al-Ghussain, L. Optimization of energy production from biogas fuel in a closed landfill using artificial neural networks: A case study of Al Ghabawi Landfill, Jordan. Waste Manag. 2022, 150, 218–226. [Google Scholar] [CrossRef]

- Woertz, I.; Feffer, A.; Lundquist, T.; Nelson, Y. Algae Grown on Dairy and Municipal Wastewater for Simultaneous Nutrient Removal and Lipid Production for Biofuel Feedstock. J. Environ. Eng. 2009, 135, 1115–1122. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Rasul, M.G.; Chowdhury, A.A.; Ashwath, N. Biofuels Production through Biomass Pyrolysis —A Technological Review. Energies 2012, 5, 4952–5001. [Google Scholar] [CrossRef]

- Borges, L.D. Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions. Renew. Sustain. Energy 2012, 16, 2839–2849. [Google Scholar] [CrossRef]

- Ramos, M.; Dias, A.P.S.; Puna, J.F.; Gomes, J.; Bordado, J.C. Biodiesel Production Processes and Sustainable Raw Materials. Energies 2019, 12, 4408. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Dragone, G.; Guimarães, P.M.; Silva, J.P.; Carneiro, L.M.; Roberto, I.C.; Vicente, A.; Domingues, L.; Teixeira, J.A. Technological trends, global market, and challenges of bio-ethanol production. Biotechnol. Adv. 2010, 28, 817–830. [Google Scholar] [CrossRef] [PubMed]

- Bušić, A.; Marđetko, N.; Kundas, S.; Morzak, G.; Belskaya, H.; Šantek, M.I.; Komes, D.; Novak, S.; Šantek, B. Bioethanol Production from Renewable Raw Materials and its Separation and Purification: A Review. Food Technol. Biotechnol. 2018, 56, 289–311. [Google Scholar] [CrossRef]

- He, R.; Men, Y.; Liu, J.; Wang, J.; An, W.; Huang, X.; Song, W.; Liu, J.; Dai, S. Tailoring the Selectivity of Bio-Ethanol Transformation by Tuning the Size of Gold Supported on ZnZr10 Ox Catalysts. Chemcatchem 2018, 10, 3969–3973. [Google Scholar] [CrossRef]

- Small, L. Highly active iron and cobalt catalysts for the polymerization of ethylene. J. Am. Chem. Soc. 1988, 120, 4049–4050. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, J.; Zhu, Z.; Zhang, Y.; Zhao, Y.; Li, R.; Watson, J.; Li, B.; Liu, Z. Simultaneous production of biocrude oil and recovery of nutrients and metals from human feces via hydrothermal liquefaction. Energy Convers. Manag. 2017, 134, 340–346. [Google Scholar] [CrossRef]

- Branduardi, P.; Berterame, N.; Rossi, G.; Porro, D.; Longo, V.; Porro, D. A novel pathway to produce butanol and isobutanol in Saccharomyces cerevisiae. Biotechnol. Biofuels 2013, 6, 68. [Google Scholar] [CrossRef]

- Komendantova, N.; Marashdeh, L.; Al-Salaymeh, A.; Al Twassi, S.; AlBeek, R.; Hassouneh, K. On the crossroad—Renewable energy sources or shale oil? Understanding patterns of social attitudes in Jordan. OPEC Energy Rev. 2021, 46, 3–30. [Google Scholar] [CrossRef]

- Al-Kurdi, M. Biofuels in Jordan: Perspectives; Echoing Sustainability in MENA: Amman, Jordan, 2021. [Google Scholar]

- Ayodele, B.V.; Mustapa, S.I.; Alsaffar, M.A.; Cheng, C.K.; Patinvoh, R.J. Thermochemical Valorization of Oil Palm Biomass to Value-Added Products: A Biorefinery Concept. In Innovations in Thermochemical Technologies for Biofuel Processing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 177–197. [Google Scholar]

- Corley, R. Where Do All the Nutrients Go? Planter 2009, 85, 133–174. [Google Scholar]

- Khalid, H.; Zakaria, Z.Z.; Anderson, J.M. Nutrient cycling in an oil palm plantation: The effects of residue management practices during replanting on dry matter and nutrient uptake of young palms. J. Oil Palm Res. 2000, 12, 29–37. [Google Scholar]

- Kala, D.; Fauziah, C.; Thohirah, L. Composting oil palm wastes and sewage sludge for use in potting media of ornamental plants. Malays. J. Soil Sci. 2009, 13, 77–91. [Google Scholar]

- Eom, I.-Y.; Yu, J.-H.; Jung, C.-D.; Hong, K.-S. Efficient ethanol production from dried oil palm trunk treated by hydrothermolysis and subsequent enzymatic hydrolysis. Biotechnol. Biofuels 2015, 8, 83. [Google Scholar] [CrossRef] [PubMed]

- Maaita, A.M.; Shdefat, S. The Official Journal of the International Olive Council—International Olive Council. 2022. Available online: https://www.internationaloliveoil.org/ (accessed on 15 November 2022).

- Al-Addous, M.; Alnaief, M.; Class, C.; Nsair, A.; Kuchta, K.; Alkasrawi, M. Technical possibilities of biogas production from olive and date waste in Jordan. BioResources 2017, 12, 9383–9395. [Google Scholar] [CrossRef]

- Al-Fayez, E. General Syndicate of Contemporaries and Jordanian Olive Producers. 2021. Available online: www.civilsociety-jo.net (accessed on 15 November 2022).

- Luc Reuter, B. National Strategy and Action Plan for Sustainable Consumption and Production in Jordan. 2021. Available online: https://www.greengrowthknowledge.org/sites/default/files/downloads/resource/National%20Strategy%20and%20Action%20Plan%20for%20Sustainable%20Consumption%20and%20Production%20in%20Jordan%20%282016-2025%29.pdf (accessed on 16 November 2022).

- Raya Taher, S.; Perrin, J.P. The Impacts of Waste Disposal Sites on Communities in Jordan. 2021. Available online: https://oxfamilibrary.openrepository.com/bitstream/handle/10546/621201/rr-not-in-my-backyard-waste-jordan-070721-en.pdf?sequence=1&isAllowed=y (accessed on 16 November 2022).

- Zafar, S. EcoMENA Echoing Sustainability in MENA. 2020. Biomass Energy, Middle East, Renewable Energy. Available online: www.ecomena.org (accessed on 17 November 2022).

- Suhartini, S.; Nurika, I.; Paul, R.; Melville, L. Estimation of Biogas Production and the Emission Savings from Anaerobic Digestion of Fruit-based Agro-industrial Waste and Agricultural crops residues. BioEnergy Res. 2021, 14, 844–859. [Google Scholar] [CrossRef]

- Zabermawi, N.M.; Alsulaimany, F.A.; El-Saadony, M.T.; El-Tarabily, K.A. New eco-friendly trends to produce biofuel and bioenergy from microorganisms: An updated review. Saudi J. Biol. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Formentini, D.F.; Marques, C.A.; Fracaro, G.D.P.M.; Constanzi, R.N.; De Souza, S.N.M. Electricity generation from biogas of poultry slaughterhouse biomass in Matelandia Brazil. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011; pp. 8–13. [Google Scholar]

- Saidan, M. Waste Management in Jordan; Jordan Green Building Council. 2016. Available online: https://mena.fes.de/fileadmin/user_upload/pdf (accessed on 6 June 2022).

- Laith Al-Junaidi. Arab Countries, Reports, Jordan, Environment and Climate; Anadolu Agency: Amman, Jordan, 2021; Available online: https://www.aa.com.tr/ar (accessed on 18 November 2022).

- ALRai. Biogas Production from Rusifa Landfill. Available online: https://alrai.com/article/573789.html (accessed on 19 November 2022).

- Zeren, F.G.; Karaca, S.S. Biomass energy consumption and foreign direct investments: Evidence ffrom developed and developing countries. Electron. J. Soc. Sci. 2021, 20, 494–507. [Google Scholar]

- Yasmeen, R.; Zhaohui, C.; Shah, W.U.H.; Kamal, M.A.; Khan, A. Exploring the role of biomass energy consumption, ecological footprint through FDI and technological innovation in B&R economies: A simultaneous equation approach. Energy 2022, 244, 122703. [Google Scholar]

- Orhan, M.; Dincer, I.; Naterer, G. Cost analysis of a thermochemical Cu–Cl pilot plant for nuclear-based hydrogen production. Int. J. Hydrogen Energy 2008, 33, 6006–6020. [Google Scholar] [CrossRef]

- Wang, Y.; Li, G.; Liu, Z.; Cui, P.; Zhu, Z.; Yang, S. Techno-economic analysis of biomass-to-hydrogen process in comparison with coal-to-hydrogen process. Energy 2019, 185, 1063–1075. [Google Scholar] [CrossRef]

- Xiang, D.; Liu, X.; Mai, Z. Techno-economic performance of the coal-to-olefins process with CCS. Chem. Eng. J. 2014, 240, 45–54. [Google Scholar] [CrossRef]

- Li, G.; Wang, S.; Zhao, J.; Qi, H.; Ma, Z.; Cui, P.; Zhu, Z.; Gao, J.; Wang, Y. Life cycle assessment and techno-economic analysis of biomass-to-hydrogen production with methane tri-reforming. Energy 2020, 199, 117488. [Google Scholar] [CrossRef]

- Dewulf, J.; Van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its Potential and Limitations in Environmental Science and Technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Rupesh, S.; Muraleedharan, C.; Arun, P. Energy and exergy analysis of syngas production from different biomasses through air-steam gasification. Front. Energy 2016, 14, 607–619. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, B.; Gao, X.; Jiang, B. Energy and exergy characteristics of syngas produced from air gasification of walnut sawdust in an entrained flow reactor. Int. J. Exergy 2017, 23, 244–262. [Google Scholar] [CrossRef]

- Cengel, A. Thermodynamics: An Engineering Approach; McGraw-Hill: New York, NY, USA, 2009. [Google Scholar]

- Song, G.; Chen, L.; Xiao, J.; Shen, L. Exergy evaluation of biomass steam gasification via interconnected fluidized beds. Int. J. Energy Res. 2013, 37, 1743–1751. [Google Scholar] [CrossRef]

- Taha, A.S.; Zaid, I.A.; Alim, A.A.; Fathi, M.E.; Morsi, H. Renewable Energy and Its Role in Achieving Sustainable Development in the Light of International Experiences—A Case Study of “Egypt”; Democratic Arabic Center for Strategic, Political & Economic Studies: Egypt, 2018. [Google Scholar]

| Biomass Feedstock | Amount of Production (%) |

|---|---|

| Animal Manure | 96.5 |

| Olive Oil Pomace | 1.8 |

| Slaughterhouse Waste | 0.1 |

| Blood | 0.5 |

| Sludge | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nahar Myyas, R.; Tostado-Véliz, M.; Gómez-González, M.; Jurado, F. Review of Bioenergy Potential in Jordan. Energies 2023, 16, 1393. https://doi.org/10.3390/en16031393

Nahar Myyas R, Tostado-Véliz M, Gómez-González M, Jurado F. Review of Bioenergy Potential in Jordan. Energies. 2023; 16(3):1393. https://doi.org/10.3390/en16031393

Chicago/Turabian StyleNahar Myyas, Ra’ed, Marcos Tostado-Véliz, Manuel Gómez-González, and Francisco Jurado. 2023. "Review of Bioenergy Potential in Jordan" Energies 16, no. 3: 1393. https://doi.org/10.3390/en16031393

APA StyleNahar Myyas, R., Tostado-Véliz, M., Gómez-González, M., & Jurado, F. (2023). Review of Bioenergy Potential in Jordan. Energies, 16(3), 1393. https://doi.org/10.3390/en16031393