Parameter Identification of Doubly-Fed Induction Wind Turbine Based on the ISIAGWO Algorithm

Abstract

1. Introduction

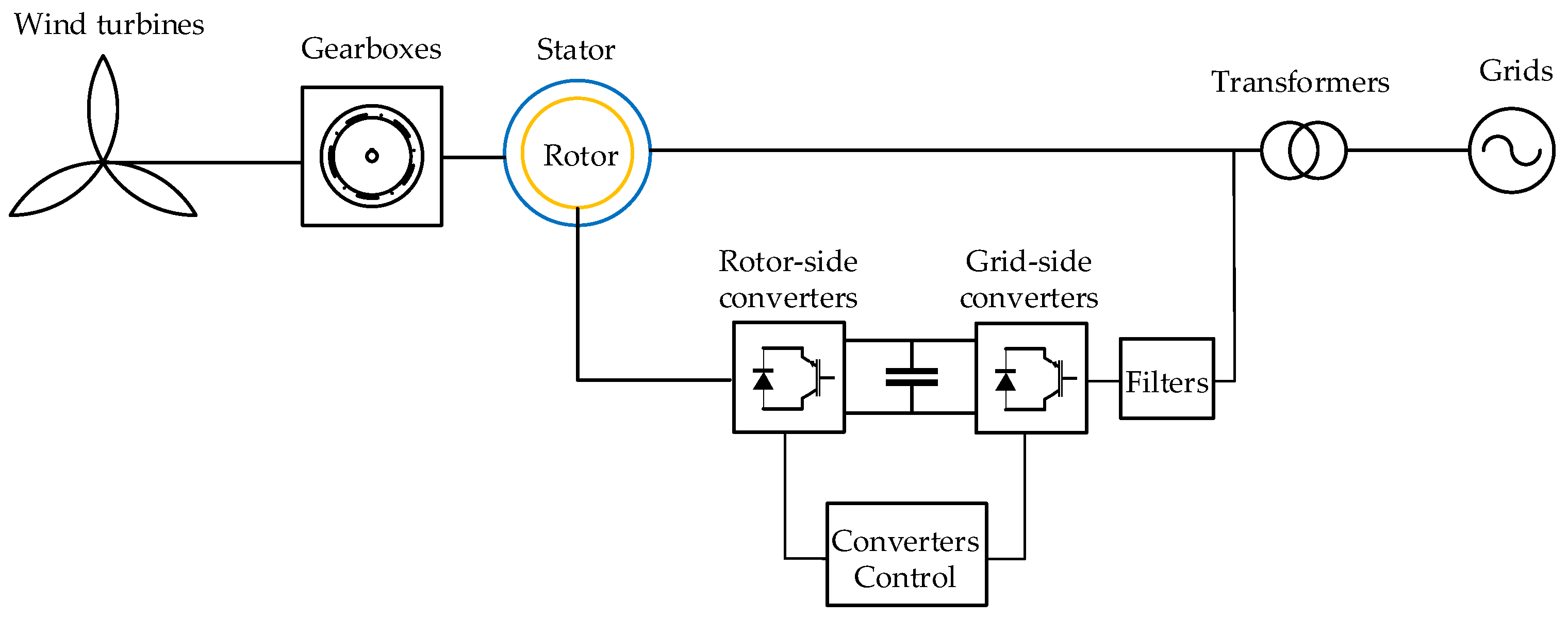

2. The Mathematical Model of DFIG

- (1)

- Voltage equation:

- (2)

- Magnetic chain equation:

- (3)

- Electromagnetic torque, power equation

3. Algorithm Introduction

3.1. Grey Wolf Algorithm

3.2. Adaptive Grey Wolf Algorithm Based on Information-Sharing Search Strategy (ISIAGWO)

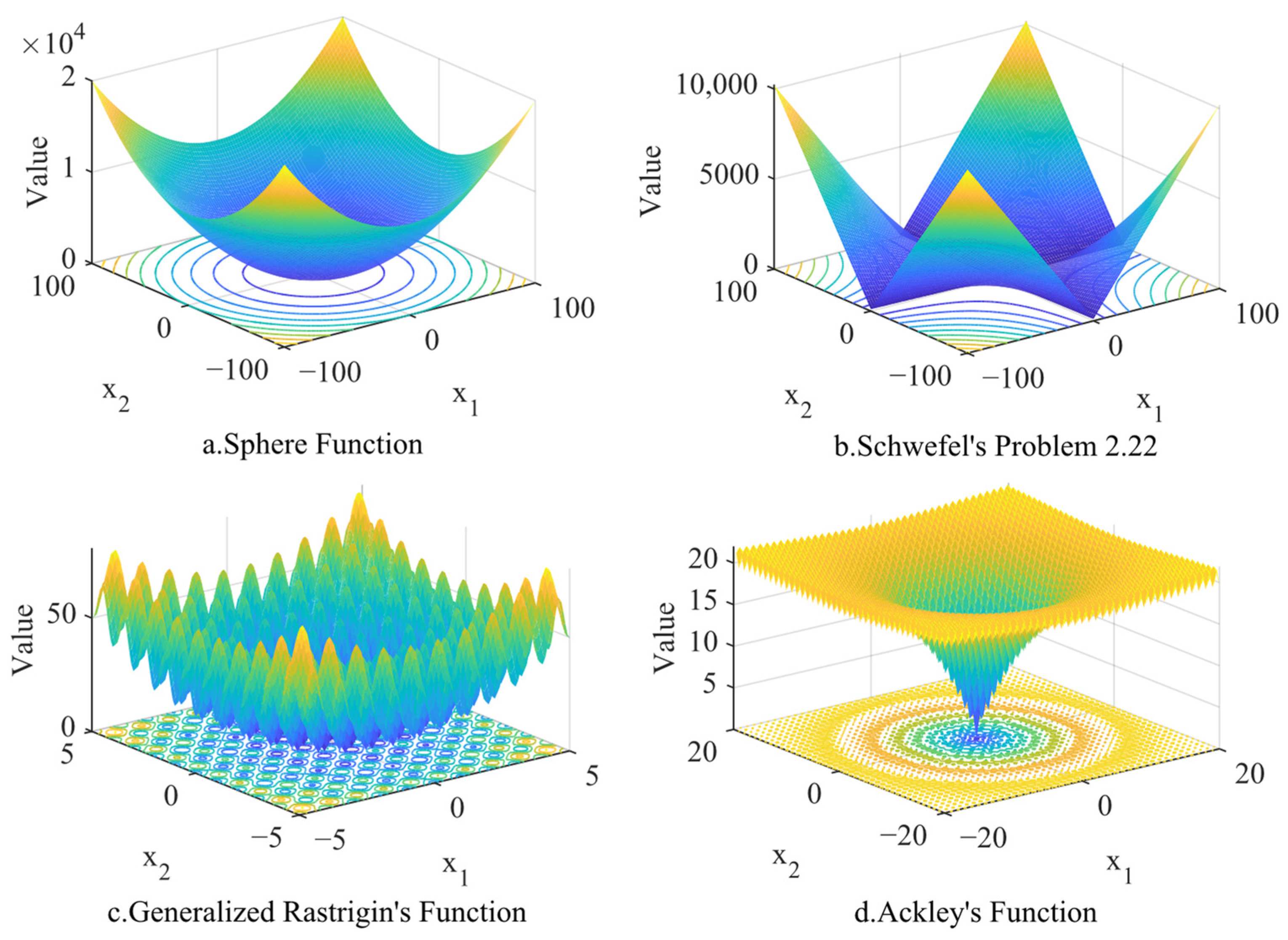

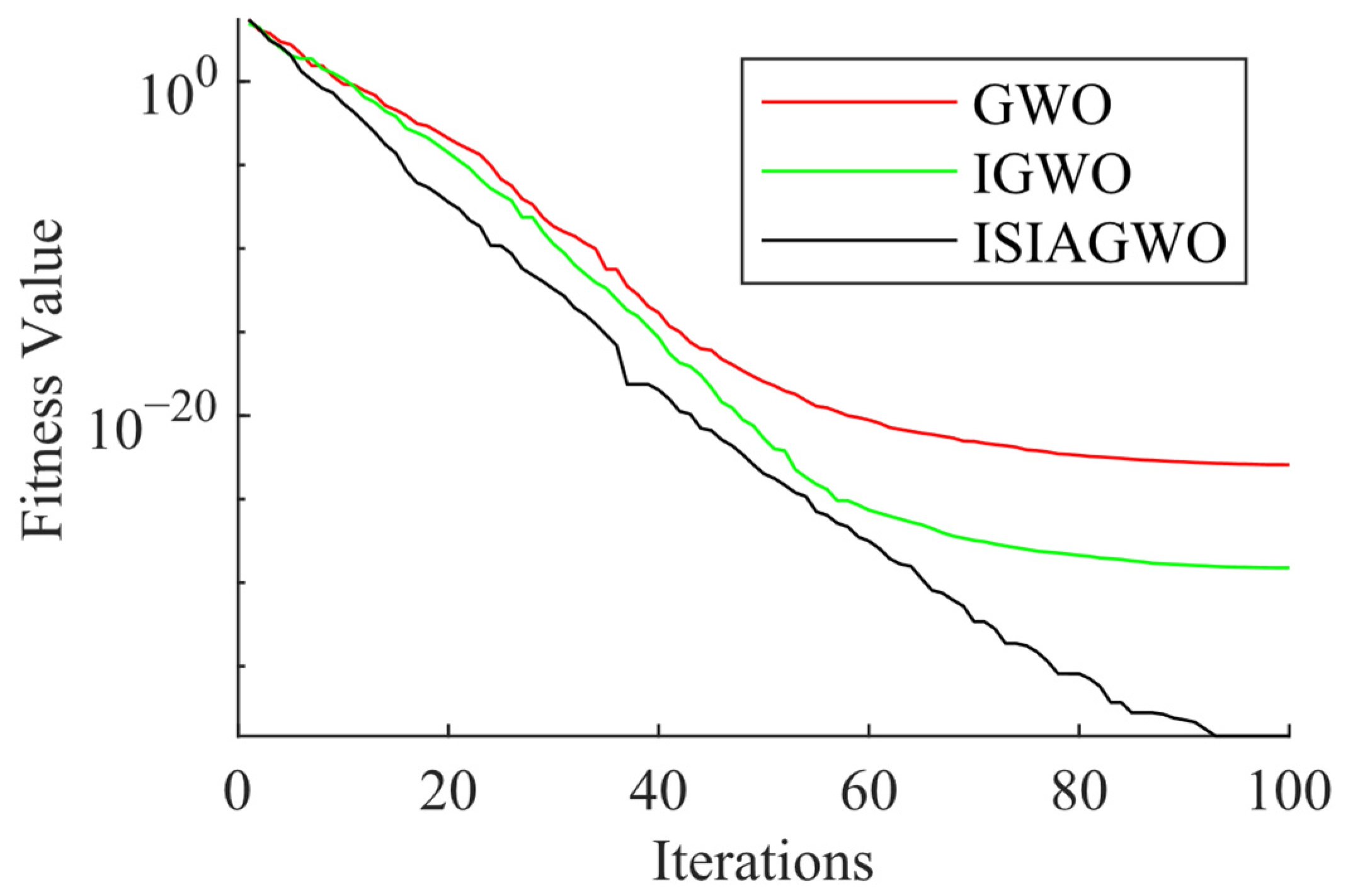

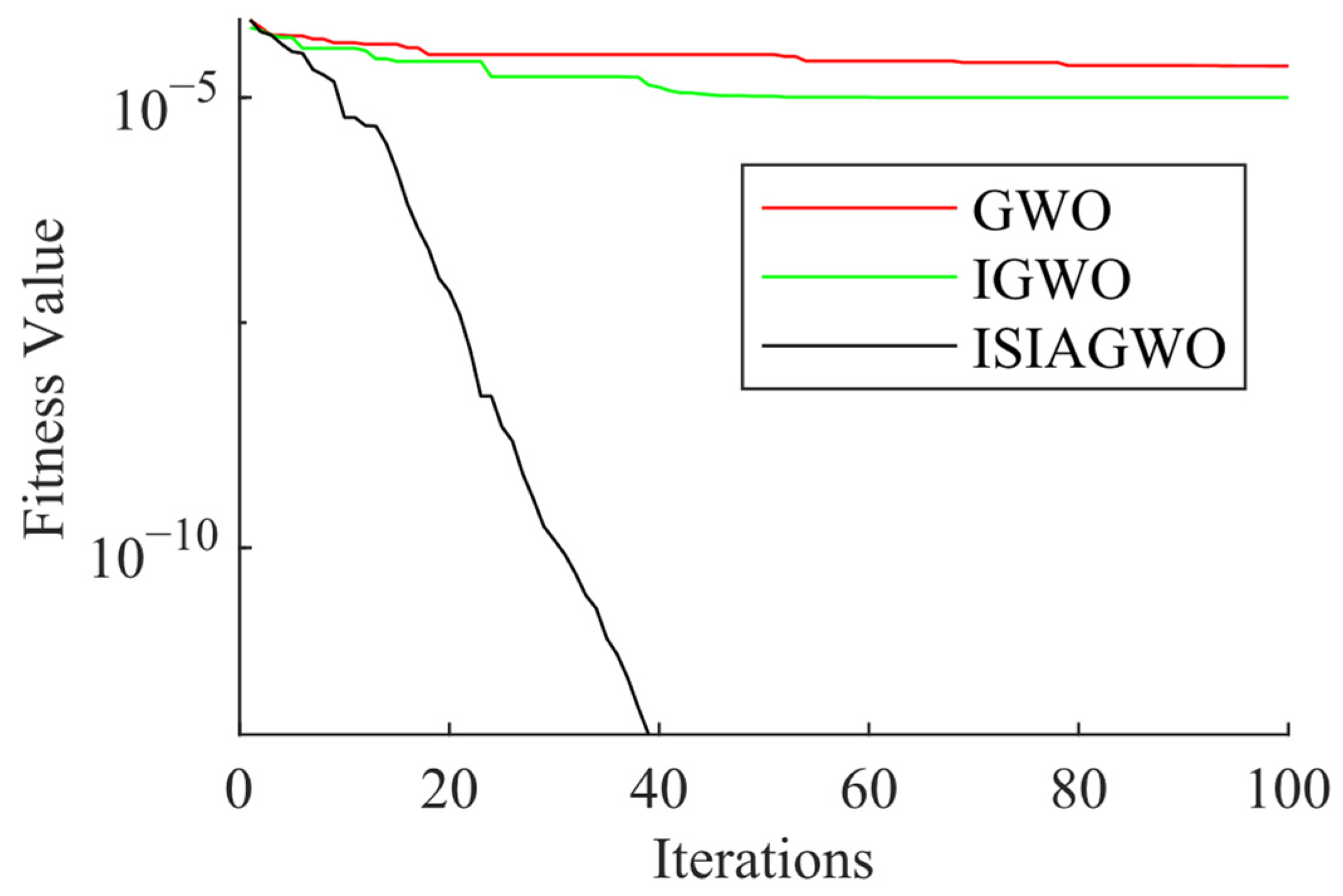

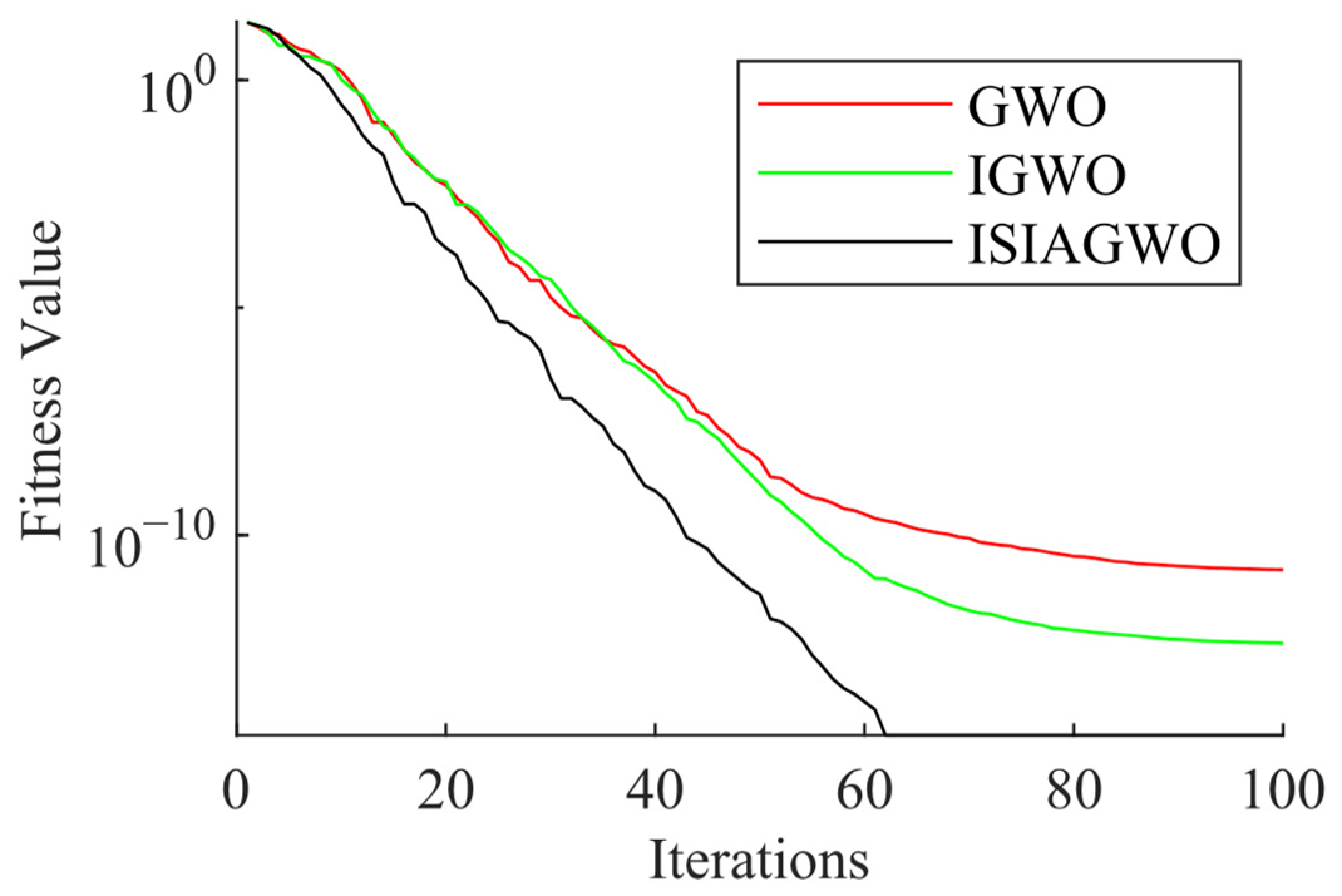

3.3. Algorithm Performance Test

4. DFIG Parameter Identification

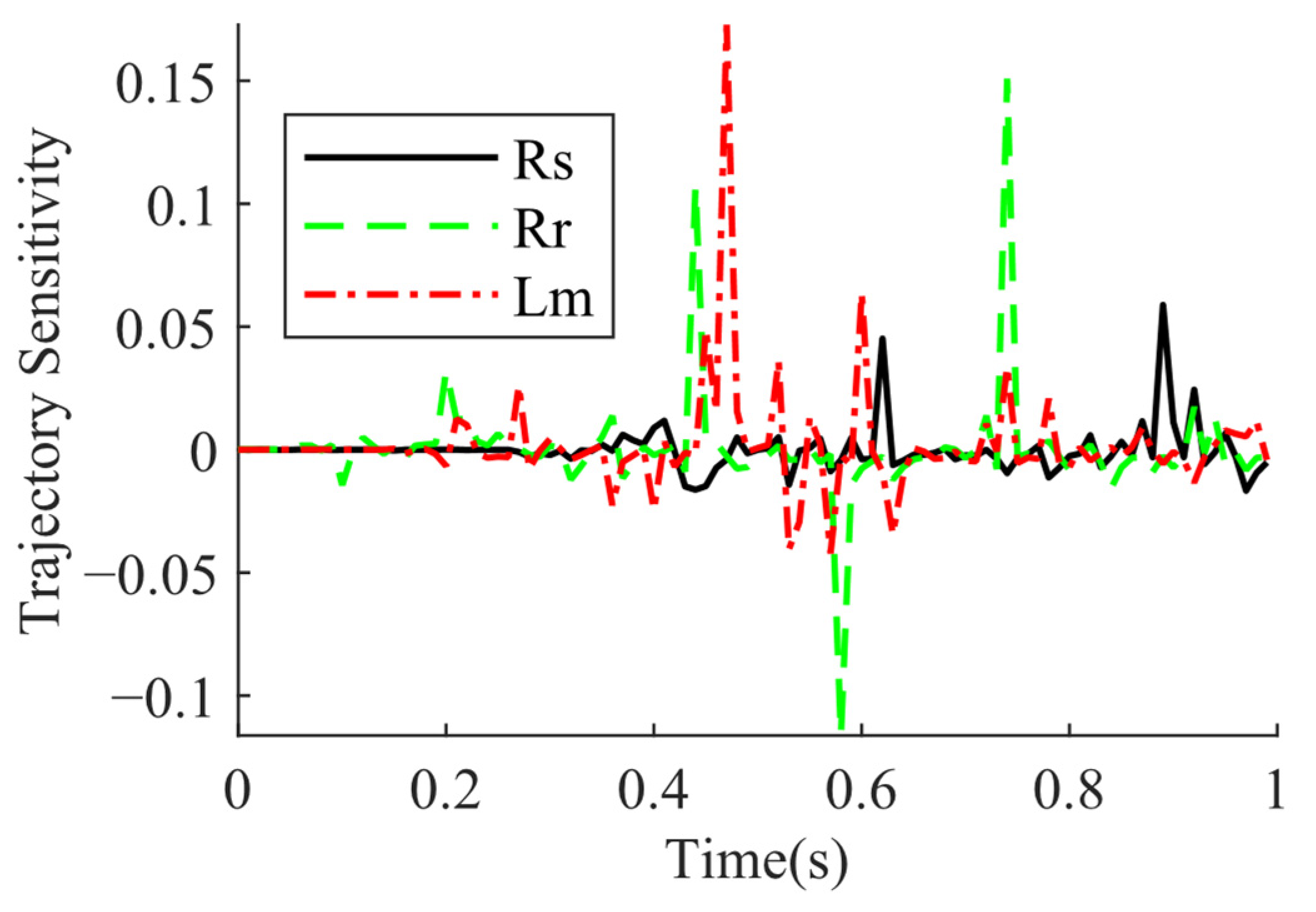

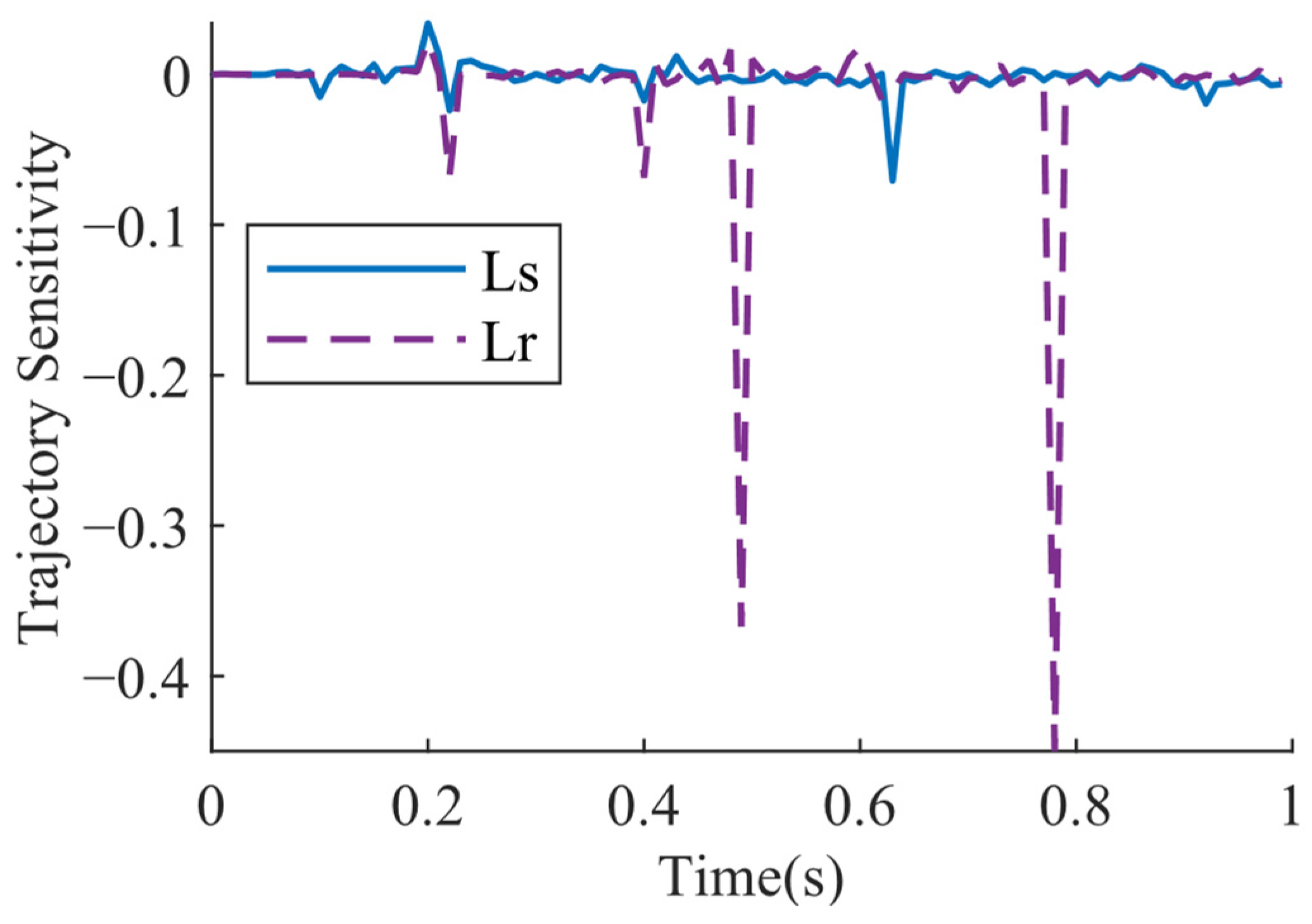

4.1. Identifiability of the Parameters

4.2. The DFIG Identification Model

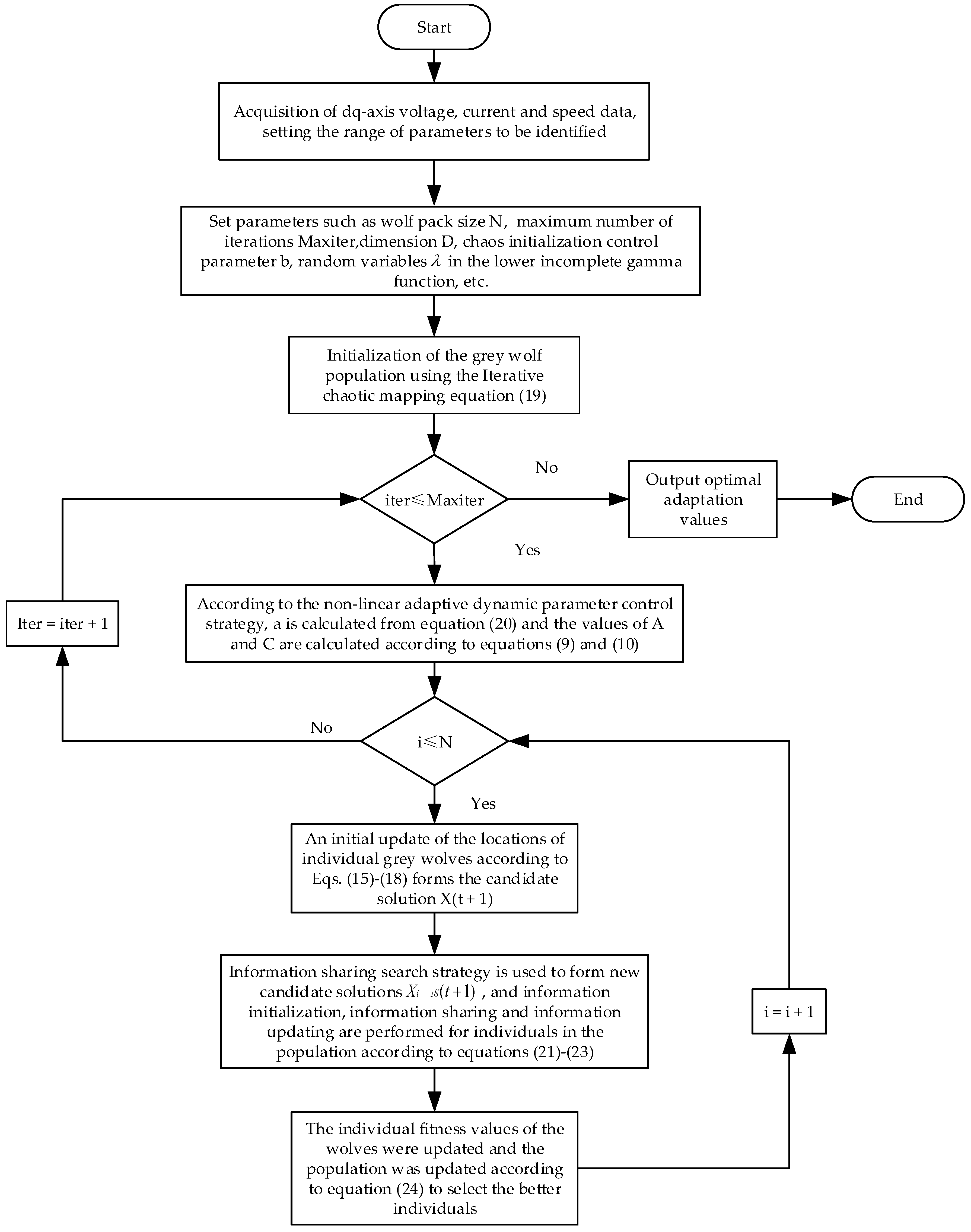

4.3. Principle and Steps of the ISIAGWO Algorithm for Identification

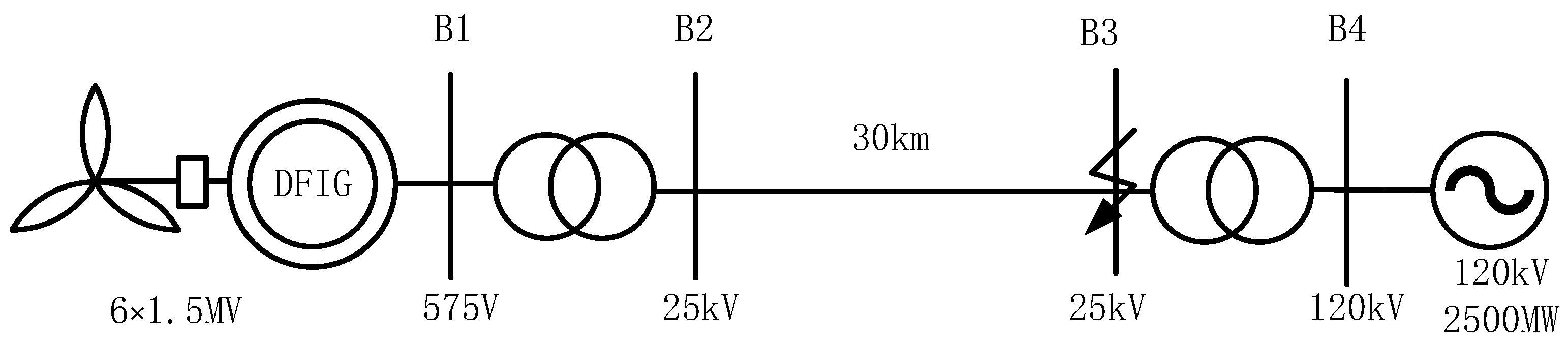

5. Simulation and Analysis

5.1. Parameter Settings

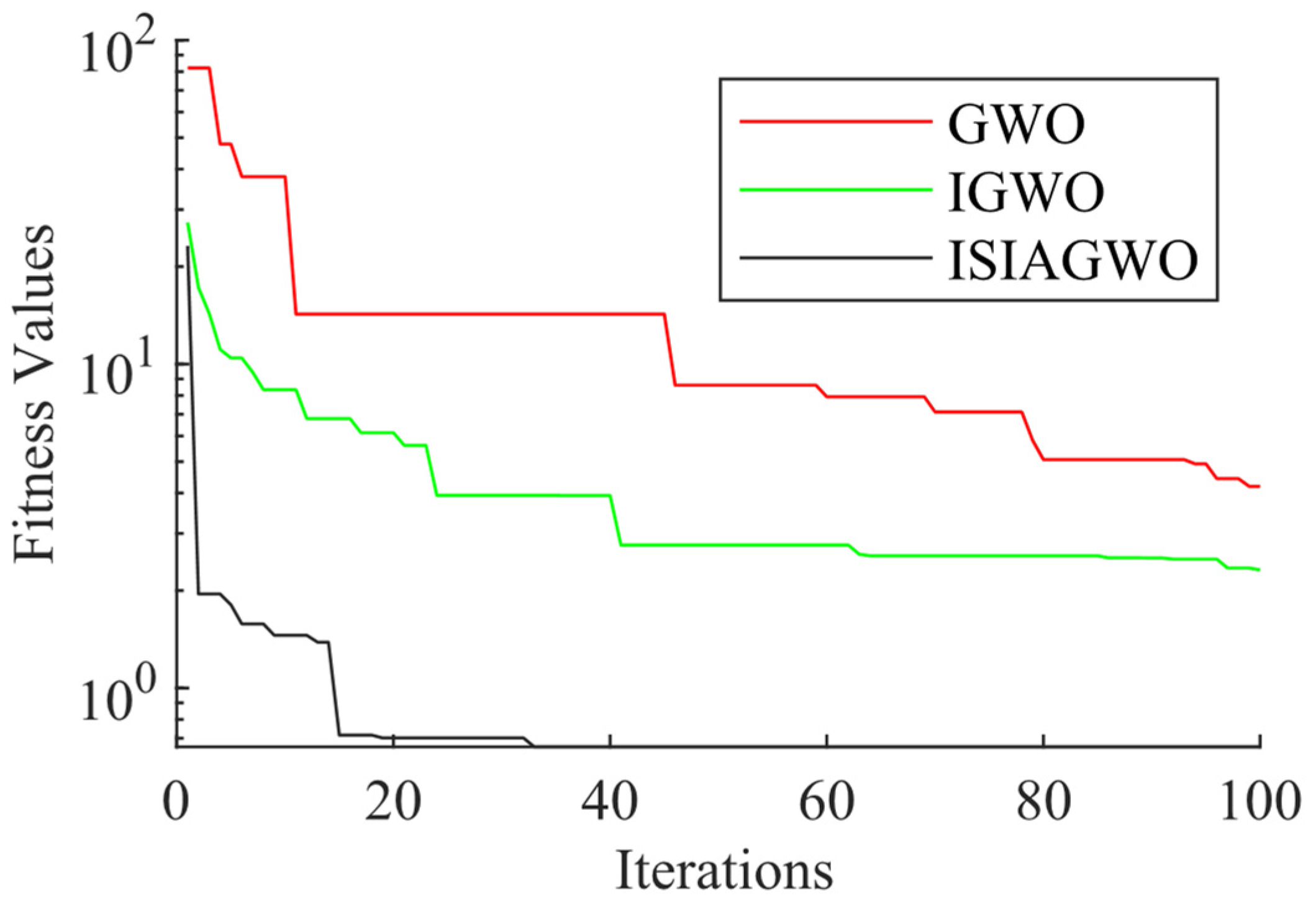

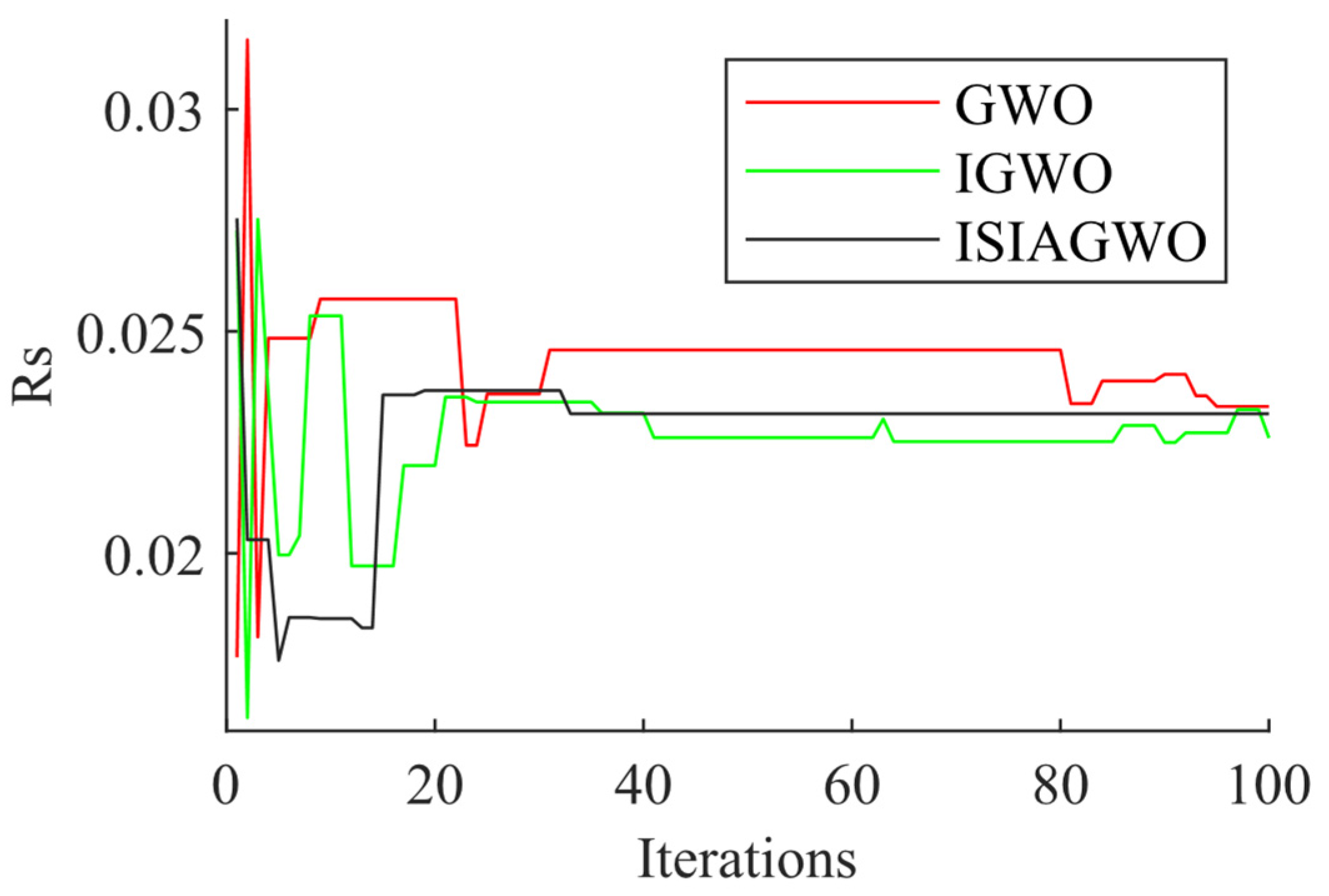

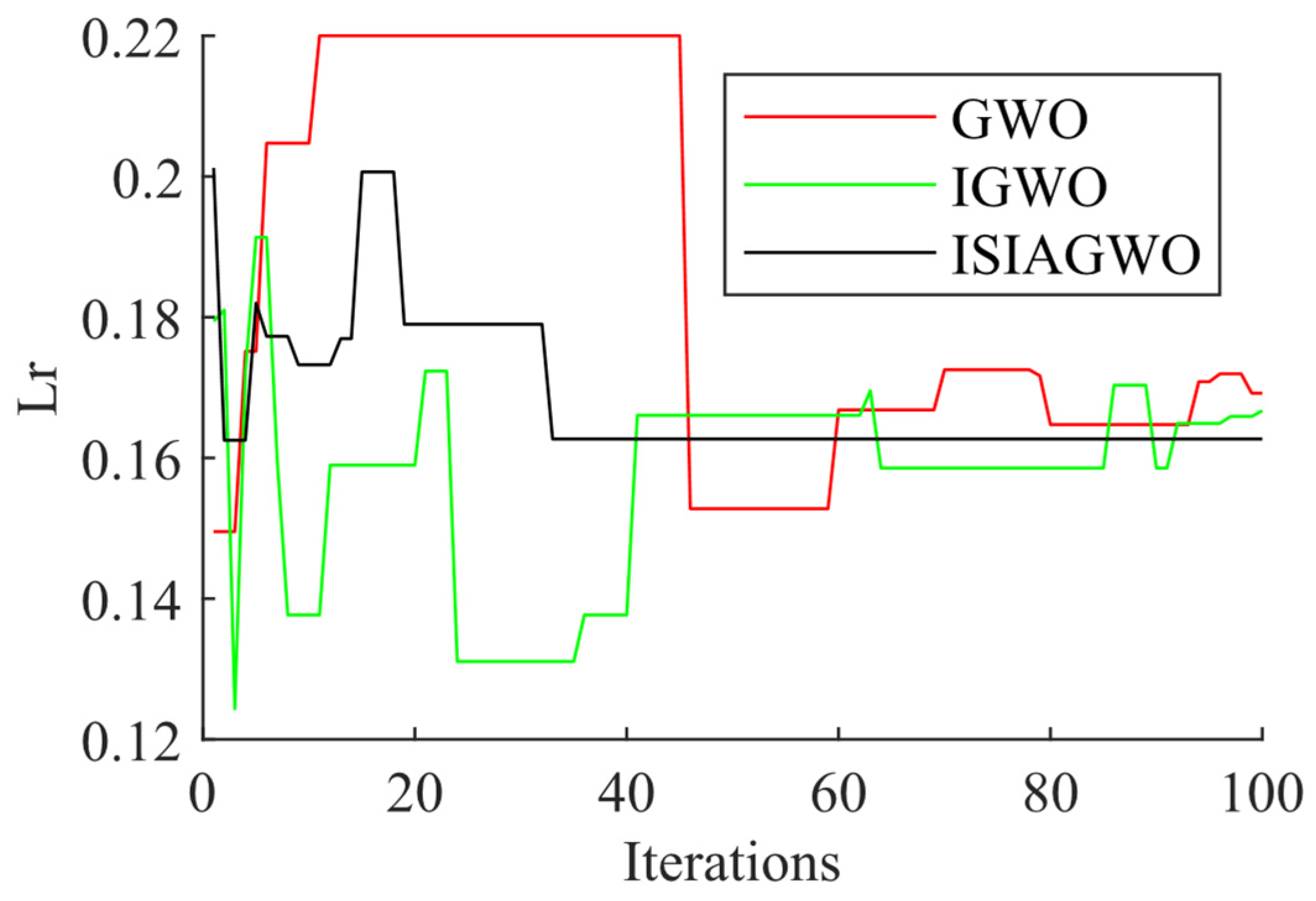

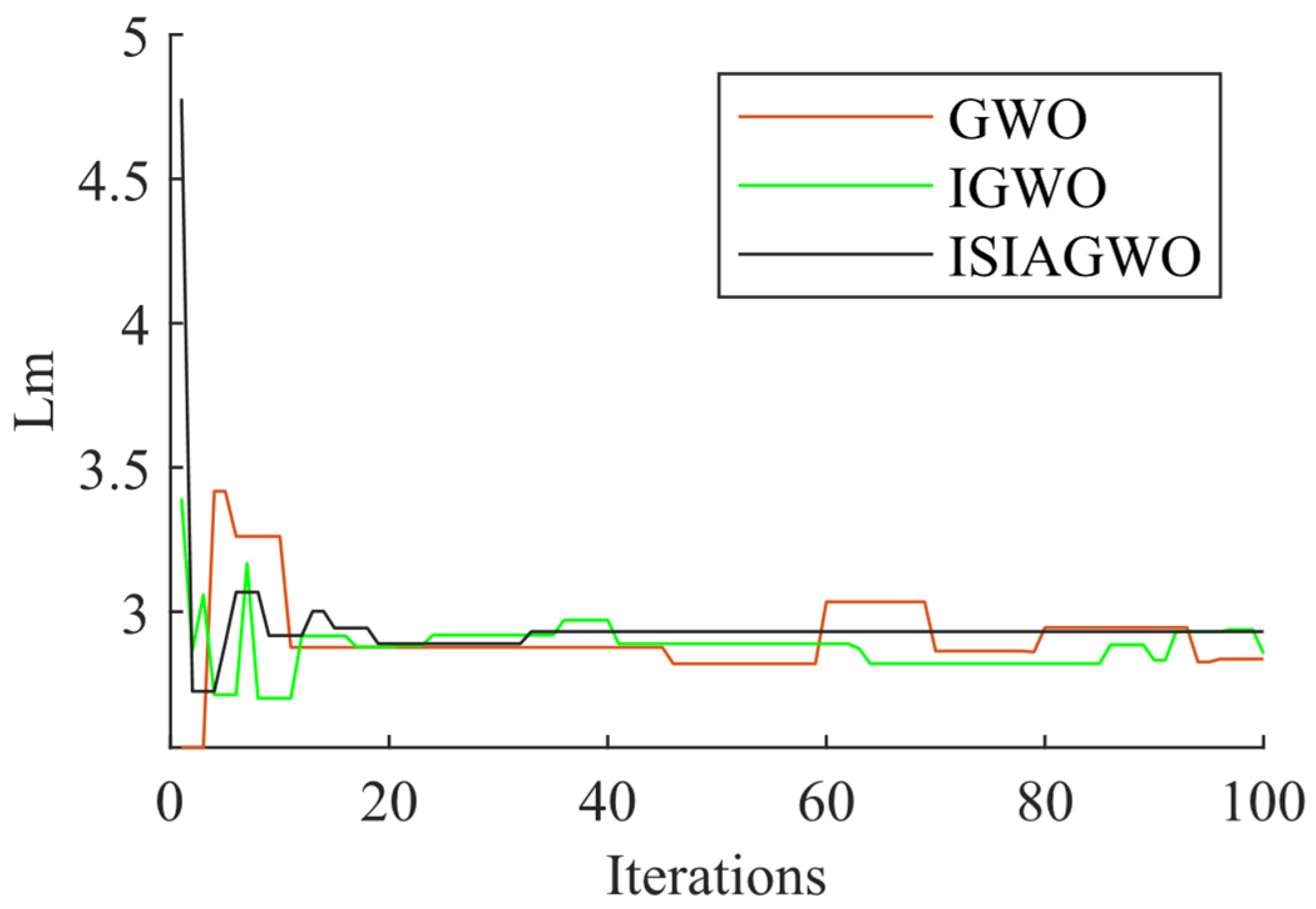

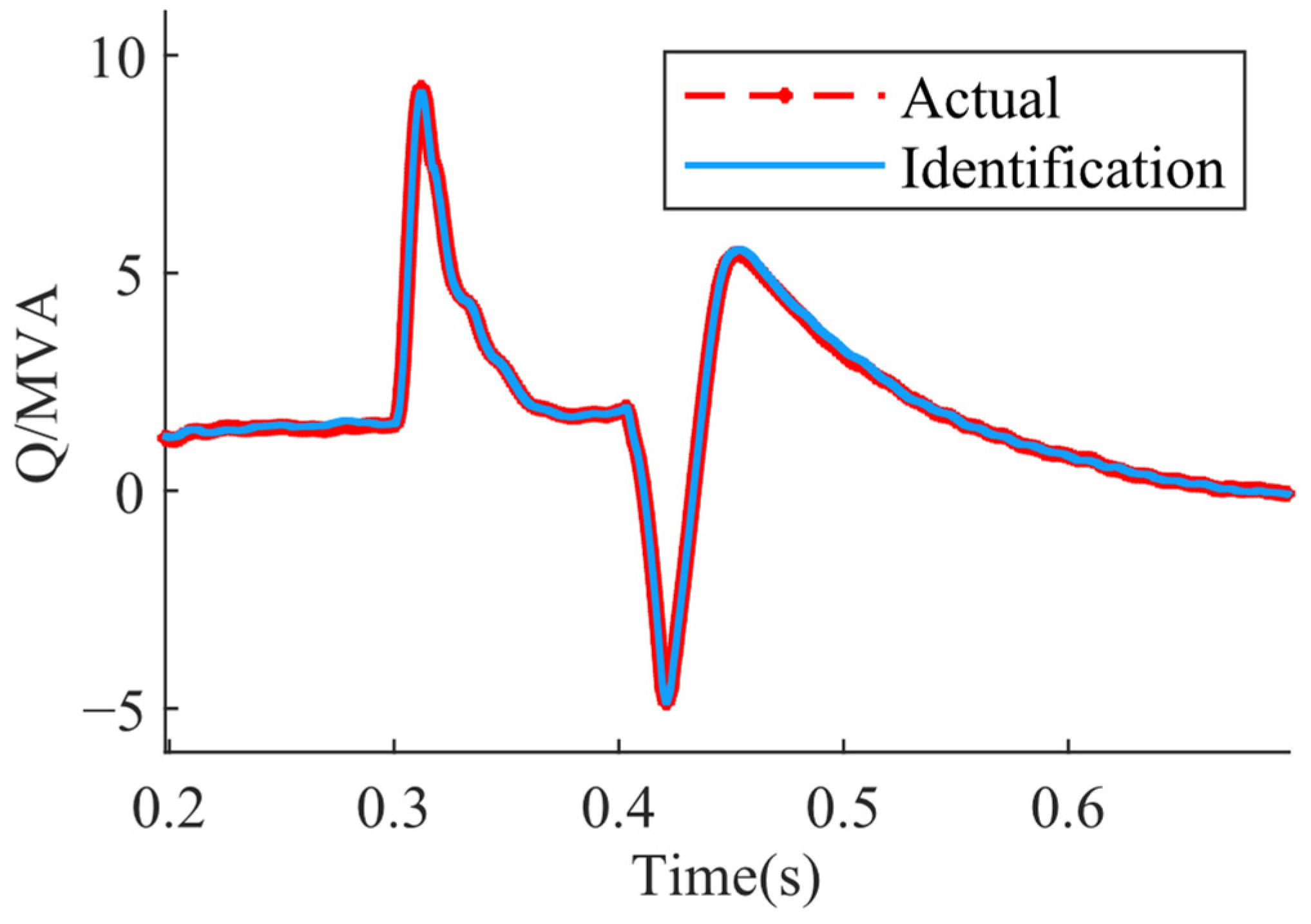

5.2. Results and Analysis

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fernández-Guillamón, A.; Gómez-Lázaro, E.; Muljadi, E.; Molina-García, A. Power systems with high renewable energy sources: A review of inertia and frequency control strategies over time. Renew. Sustain. Energy Rev. 2020, 115, 109369. [Google Scholar] [CrossRef]

- Jia, K.; Gu, C.; Li, L.; Xuan, Z.; Bi, T.; Thomas, D. Sparse voltage amplitude measurement based fault location in large-scale photovoltaic power plants. Appl. Energy 2018, 211, 568–581. [Google Scholar] [CrossRef]

- Vargas, S.A.; Telles Esteves, G.R.; Macaira, P.M.; Bastos, B.Q.; Cyrino Oliveira, F.L.; Souza, R.C. Wind Power Generation: A Review and a Research Agenda. J. Clean. Prod. 2019, 218, 850–870. [Google Scholar] [CrossRef]

- Daniel, M. Doubly fed induction generator system for wind turbines. IEEE Ind. Appl. Mag. 2002, 8, 26–33. [Google Scholar]

- Liu, T.; Zhang, Y.; Wang, M.; Zhang, Y.; Qin, X.; Wang, Y. A short-circuit current calculation method for doubly-fed wind turbines considering the control strategy switching process. Chin. J. Electr. Eng. 2021, 41, 3330–3338+3659. [Google Scholar] [CrossRef]

- Yingying, J. Study of Swarm Intelligence Algorithm for Parameter Identification of Doubly-Fed Wind Turbine. Master’s Thesis, Jiangnan University, Wuxi, China, 2016. [Google Scholar]

- Belmokhtar, K.; Ibrahim, H.; Merabet, A. Online parameter identification for a DFIG driven wind turbine generator based on recursive least squares algorithm. In Proceedings of the 2015 IEEE 28th Canadian Conference on Electrical and Computer Engineering (CCECE), Halifax, NS, Canada, 3–6 May 2015; pp. 965–969. [Google Scholar] [CrossRef]

- Kong, M.; Sun, D.; He, J.; Nian, H. Control Parameter Identification in Grid-side Converter of Directly Driven Wind Turbine Systems. In Proceedings of the 2020 12th IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 20–23 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Gao, B.; Liu, G.Z.; Zhang, J.; Wang, S. SOC estimation of lithium-ion batteries by traceless Kalman filtering. Battery 2021, 51, 270–274. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, S.; Fu, J.; Li, Y. Current predictive control of permanent magnet synchronous motor based on model reference adaptive parameter identification. Electr. Mach. Control. Appl. 2017, 44, 48–53. [Google Scholar]

- Zhang, L.W.; Zhang, P.; Liu, Y.F.; Zhang, C.; Liu, J. Parameter identification of permanent magnet synchronous motor based on variable Step Size Adaline neural network. Trans. Electrotech. Soc. 2018, 33, 377–384. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Chu, X.; Liu, Q.; Xue, D. Anomaly detection and critical SCADA parameters identification for wind turbines based on LSTM-AE neural network. Renew. Energy 2021, 172, 829–840. [Google Scholar] [CrossRef]

- Gu, R.; Dai, J.; Zhang, J.; Miao, F.; Tang, Y. Research on Equivalent Modeling of PMSG-based Wind Farms using Parameter Identification method. In Proceedings of the 2020 12th IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 20–23 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, L.; Lee, W.J. Robustness Analysis of Dynamic Equivalent Model of DFIG Wind Farm for Stability Study. IEEE Trans. Ind. Appl. 2018, 54, 5682–5690. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, X.; Ju, P. Parameter identification of doubly fed induction generator based on improved particle swarm optimization algorithm. J. Hohai Univ. (Nat. Sci. Ed.) 2014, 42, 273–277. [Google Scholar]

- Wu, B.; Zeng, S.; Wang, T. Multi-parameter identification based on hierarchical immune coevolutionary particle swarm optimization algorithm for doubly-fed fans. Sci. Technol. Eng. 2019, 19, 179–185. [Google Scholar]

- Li, H.; Wu, Y.; Li, Q.; Gong, L.; Yang, W. Improved identification method of doubly-fed induction generator based on trajectory sensitivity analysis. Int. J. Electr. Power Energy Syst. 2021, 125, 106472. [Google Scholar] [CrossRef]

- Wu, L.; Liu, H.; Zhang, J.; Liu, C.; Sun, Y.; Li, Z.; Li, J. Identification of Control Parameters for Converters of Doubly Fed Wind Turbines Based on Hybrid Genetic Algorithm. Processes 2022, 10, 567. [Google Scholar] [CrossRef]

- Xian, M. Study on DFIG Virtual Synchronous Machine Grid-Connected Controller When the Power Grid Is Unbalanced. Master’s Thesis, Guizhou University, Guizhou, China, 2022. [Google Scholar]

- Gao, M. Research on parameter identification of doubly-fed wind turbine and dynamic equivalent method of wind farm. Master’s Thesis, North China Electric Power University, Beijing, China, 2021. [Google Scholar]

- Gao, Q. Research on parameter optimization of doufly-fed fan based on proportional integral differential optimization algorithm. Master’s Thesis, Guangxi University, Nanning, China, 2021. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Lu, C.; Gao, L.; Yi, J. Grey Wolf Optimizer with Cellular Topological Structure. Expert Syst. Appl. 2018, 107, 89–114. [Google Scholar] [CrossRef]

- Tu, Q.; Chen, X.; Liu, X. Hierarchy Strengthened Grey Wolf Optimizer for Numerical Optimization and Feature Selection. IEEE Access 2019, 7, 78012–78028. [Google Scholar] [CrossRef]

- Wu, C.; Fu, X.; Pei, J. Research on adaptive Gray Wolf Algorithm based on information sharing search strategy. Electro-Opt. Control. 2022, 29, 22–28. [Google Scholar]

- Wang, M.; Wang, Q.; Wang, X. An improved Gray Wolf Optimization Algorithm based on Iterative Mapping and Simplex Method. Comput. Appl. 2018, 38, 16–20+54. [Google Scholar]

- Nadimi-Shahraki, M.H.; Taghian, S.; Mirjalili, S. An improved grey wolf optimizer for solving engineering problems. Expert Syst. Appl. 2021, 166, 113917. [Google Scholar] [CrossRef]

- Ju, P. Power System Modeling Theory and Method; Science Press: Beijing, China, 2010. [Google Scholar]

- Jiang, Y.; Tian, N.; Ji, Z. Parameter identification of DFIG based on improved competitive particle swarm optimization algorithm. Control. Eng. 2018, 25, 122–130. [Google Scholar] [CrossRef]

- Pan, X.; Yin, Z.Y.; Ju, P.; Wu, F.; Jin, Y.-Q.; Ma, Q. Model parameters of doubly-fed induction generators based on short-circuit current identification. Power Autom. Equip. 2017, 37, 27–31. [Google Scholar] [CrossRef]

| Name of Function | Functions | Value Range | Optimum |

|---|---|---|---|

| Sphere Function | [−100, 100] | 0 | |

| Schwefel’s Problem 2.22 | [−10, 10] | 0 | |

| Generalized Rastrigin’s Function | [−5.12, 5.12] | 0 | |

| Generalized Griewank’s Function | [−32, 32] | 0 |

| Functions | GWO | IGWO | ISIAGWO | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Optimum | Mean | Variance | Optimum | Mean | Variance | Optimum | Mean | Variance | |

| 2.286 × 10−21 | 6.680 × 101 | 4.357 × 102 | 7.842 × 10−24 | 6.775 × 101 | 4.494 × 102 | 6.679 × 10−42 | 2.654 × 101 | 1.639 × 102 | |

| 2.580 × 10−13 | 4.817 × 10−1 | 2.082 | 2.681 × 10−15 | 4.532 × 10−1 | 3.107 | 4.228 × 10−22 | 3.406 × 10−1 | 1.886 | |

| 4.979 | 9.456 | 6.765 | 9.950× 10−1 | 3.987 | 6.235 | 0.000 | 1.531 | 6.168 | |

| 1.737× 10−11 | 7.779× 10−1 | 2.888 | 4.232× 10−13 | 7.137× 10−1 | 2.801 | 3.997× 10−15 | 6.900× 10−1 | 2.697 | |

| Components | Parameters | Values |

|---|---|---|

| Doubly-fed generator | Stator resistance (p.u.) | 0.023 |

| Stator inductors (p.u.) | 0.180 | |

| Rotor resistance (p.u.) | 0.016 | |

| Rotor inductors (p.u.) | 0.160 | |

| Stator-rotor mutual inductance (p.u.) | 2.900 | |

| Wind Turbine | Rotor inertia time constant (s) | 0.685 |

| Wind turbine inertia time constants (s) | 4.320 | |

| Damping factor of the shaft system (p.u.) | 1.110 | |

| Shaft system stiffness factor (p.u.) | 1.500 | |

| polar logarithms | 3.000 | |

| Grid | Grid voltage (kV) | 120.000 |

| Grid capacity (MVA) | 2500.000 |

| Parameters | Initialization Range | True Value |

|---|---|---|

| Stator resistance | 0.01500~0.03200 | 0.02300 |

| Rotor resistance | 0.01000~0.02200 | 0.01600 |

| Stator inductors | 0.10000~0.22000 | 0.1800 |

| Rotor inductors | 0.10000~0.22000 | 0.1600 |

| Stator-rotor mutual inductance | 1.50000~5.00000 | 2.900 |

| Algorithms | Minimum | Average | Variance |

|---|---|---|---|

| GWO | 3.2388 | 9.0968 | 10.0749 |

| IGWO | 2.3159 | 4.3267 | 3.5354 |

| ISIAGWO | 0.6576 | 1.01616 | 2.26446 |

| Algorithms | ||||||

|---|---|---|---|---|---|---|

| GWO | True value | 0.02300 | 0.01600 | 0.18000 | 0.16000 | 2.90000 |

| Identifying value | 0.02331 | 0.01671 | 0.16764 | 0.16921 | 2.83616 | |

| Relative error% | −1.34% | −4.44% | 6.87% | −5.75% | 2.20% | |

| IGWO | True value | 0.02300 | 0.01600 | 0.18000 | 0.16000 | 2.90000 |

| Identifying value | 0.02260 | 0.01582 | 0.17441 | 0.16671 | 2.85539 | |

| Relative error% | 1.75% | 1.10% | 3.11% | −4.19% | 1.54% | |

| ISIAGWO | True value | 0.02300 | 0.01600 | 0.18000 | 0.16000 | 2.90000 |

| Identifying value | 0.02314 | 0.01614 | 0.18137 | 0.16269 | 2.93127 | |

| Relative error% | −0.63% | −0.85% | −0.76% | −1.68% | −1.08% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, F.; Zeng, Y.; Qian, J.; Li, Y.; Xie, S. Parameter Identification of Doubly-Fed Induction Wind Turbine Based on the ISIAGWO Algorithm. Energies 2023, 16, 1355. https://doi.org/10.3390/en16031355

Yang F, Zeng Y, Qian J, Li Y, Xie S. Parameter Identification of Doubly-Fed Induction Wind Turbine Based on the ISIAGWO Algorithm. Energies. 2023; 16(3):1355. https://doi.org/10.3390/en16031355

Chicago/Turabian StyleYang, Fanjie, Yun Zeng, Jing Qian, Youtao Li, and Shihao Xie. 2023. "Parameter Identification of Doubly-Fed Induction Wind Turbine Based on the ISIAGWO Algorithm" Energies 16, no. 3: 1355. https://doi.org/10.3390/en16031355

APA StyleYang, F., Zeng, Y., Qian, J., Li, Y., & Xie, S. (2023). Parameter Identification of Doubly-Fed Induction Wind Turbine Based on the ISIAGWO Algorithm. Energies, 16(3), 1355. https://doi.org/10.3390/en16031355