Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study

Abstract

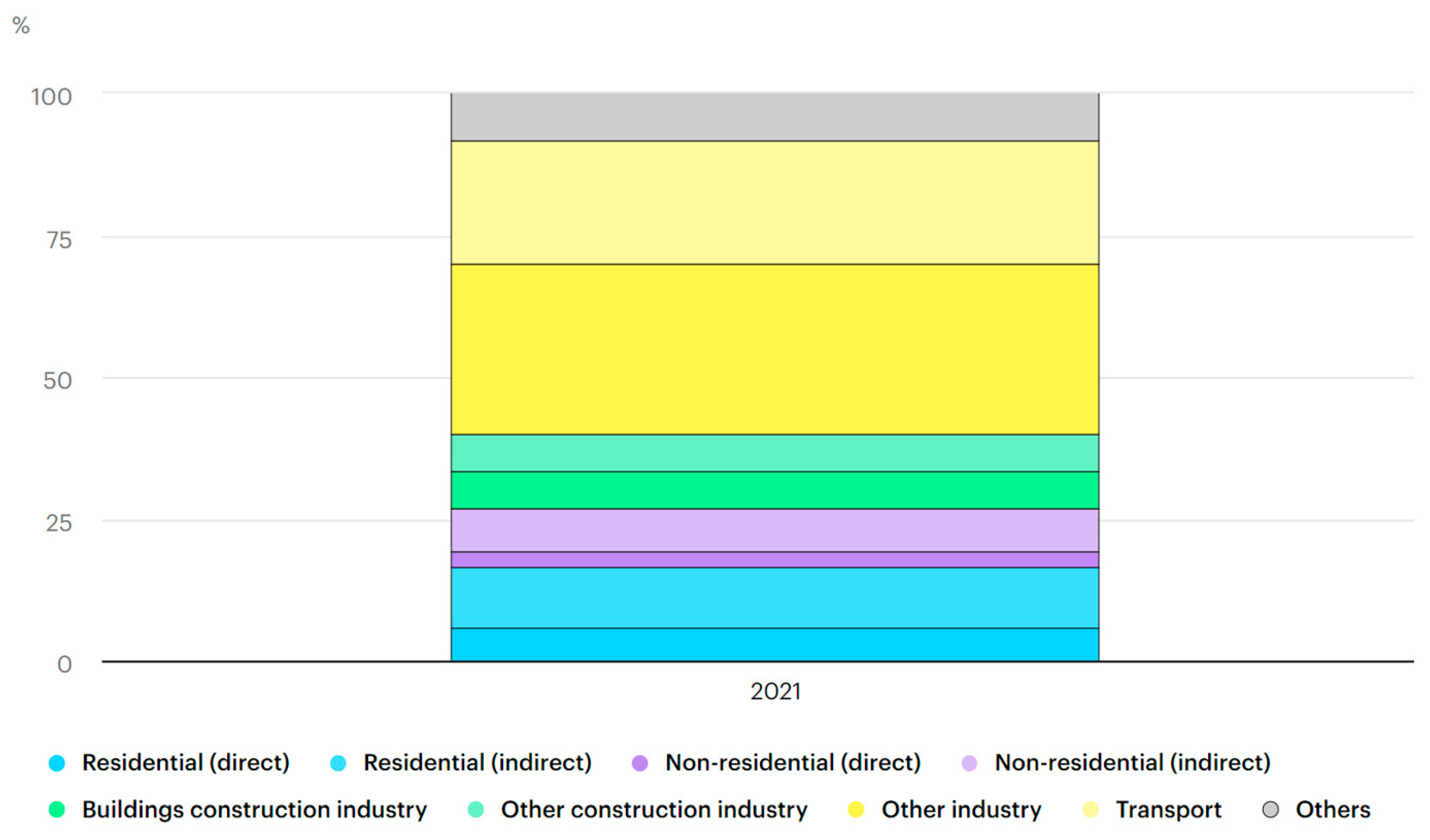

1. Introduction

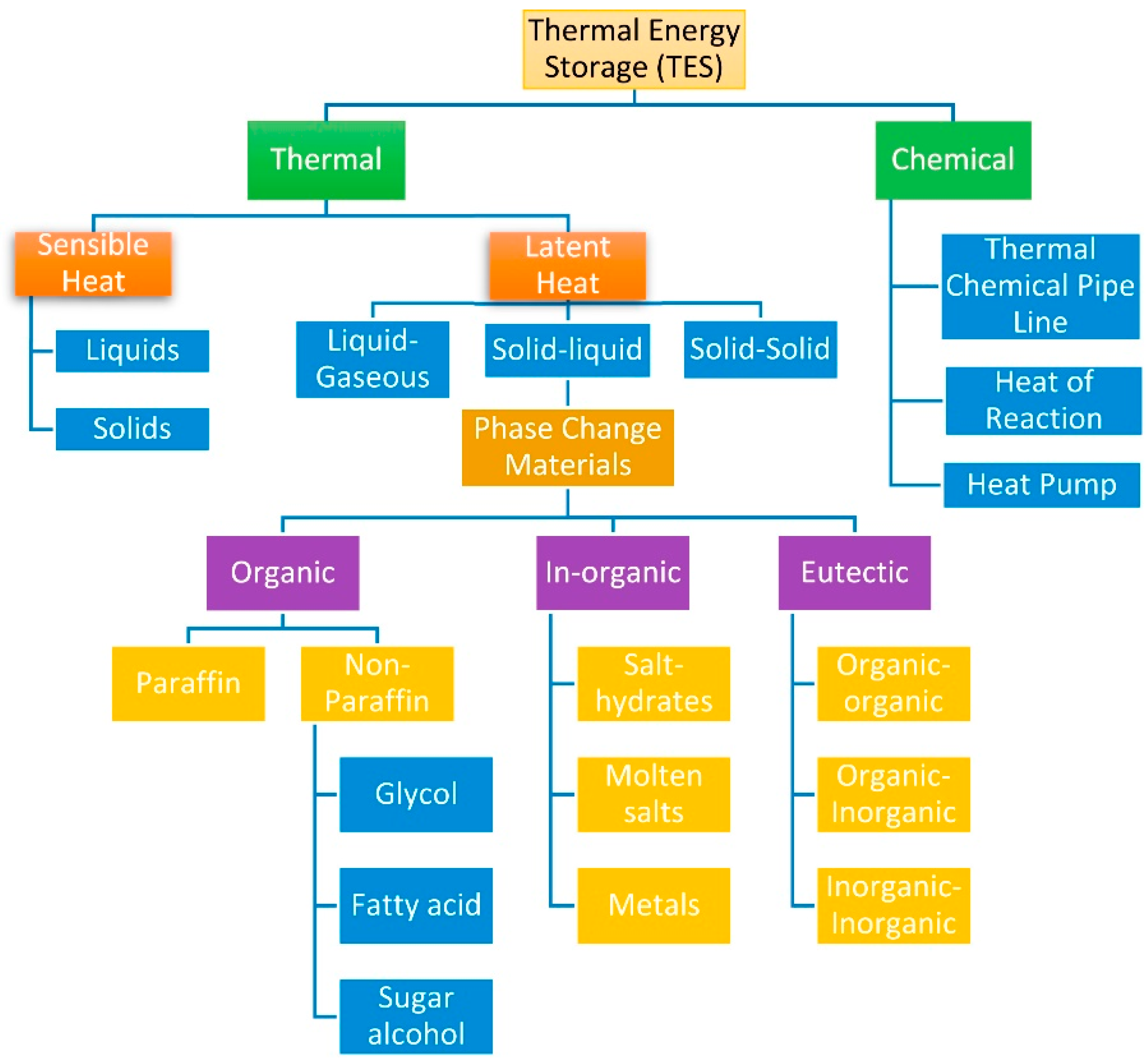

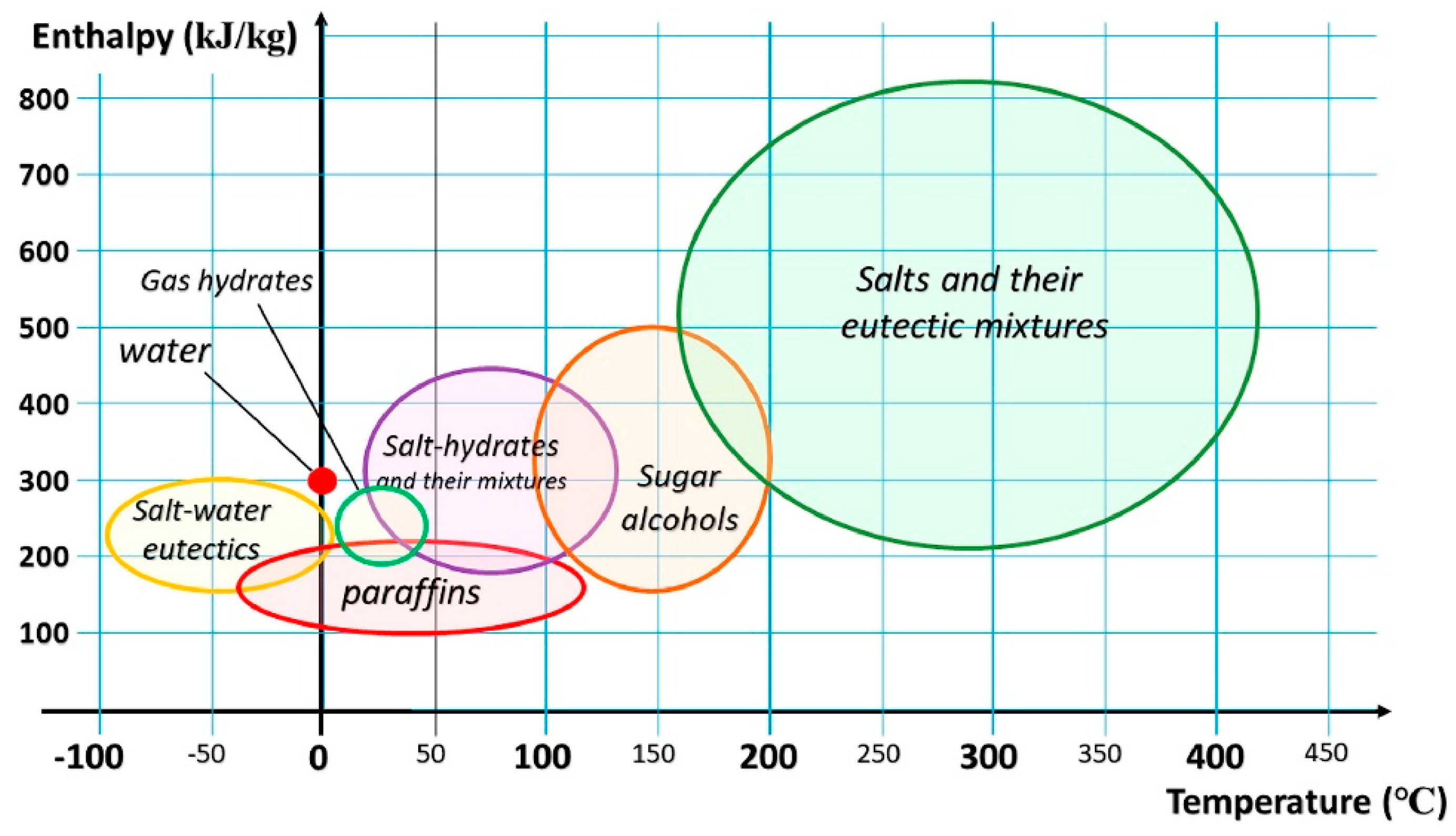

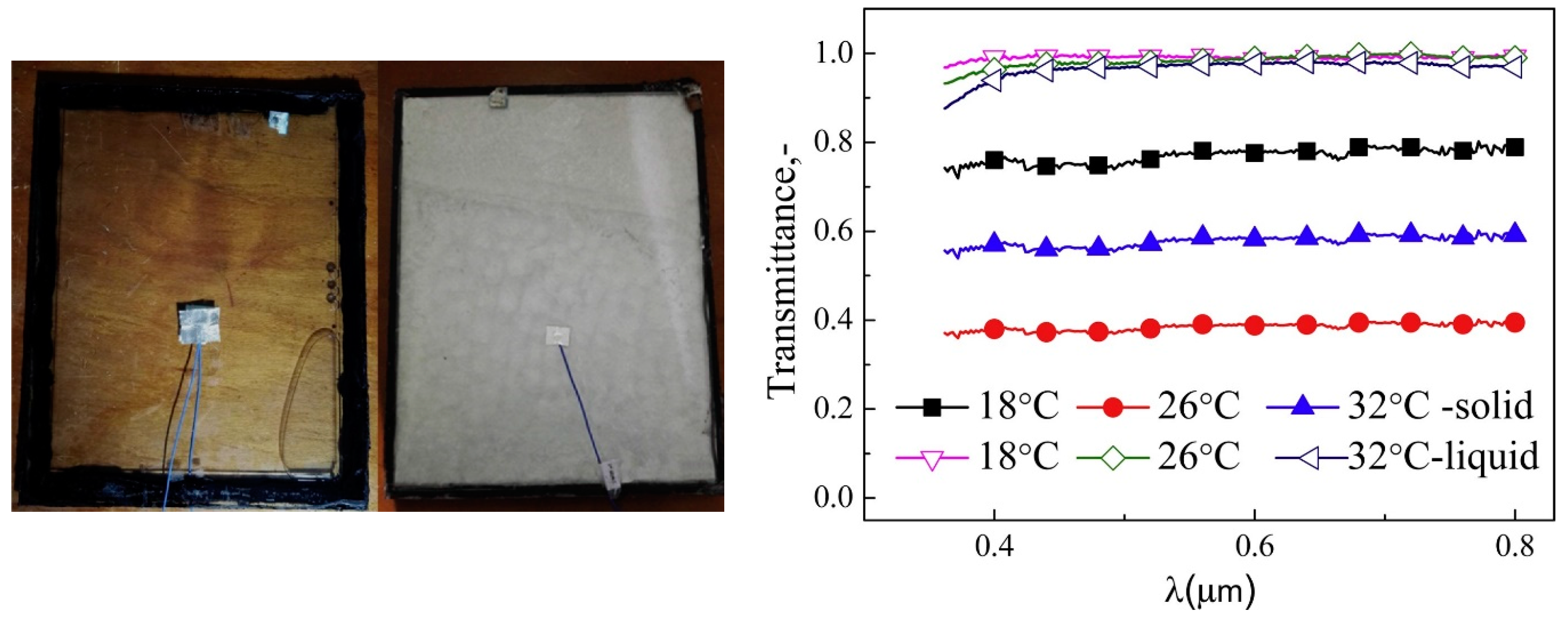

2. Phase Change Materials

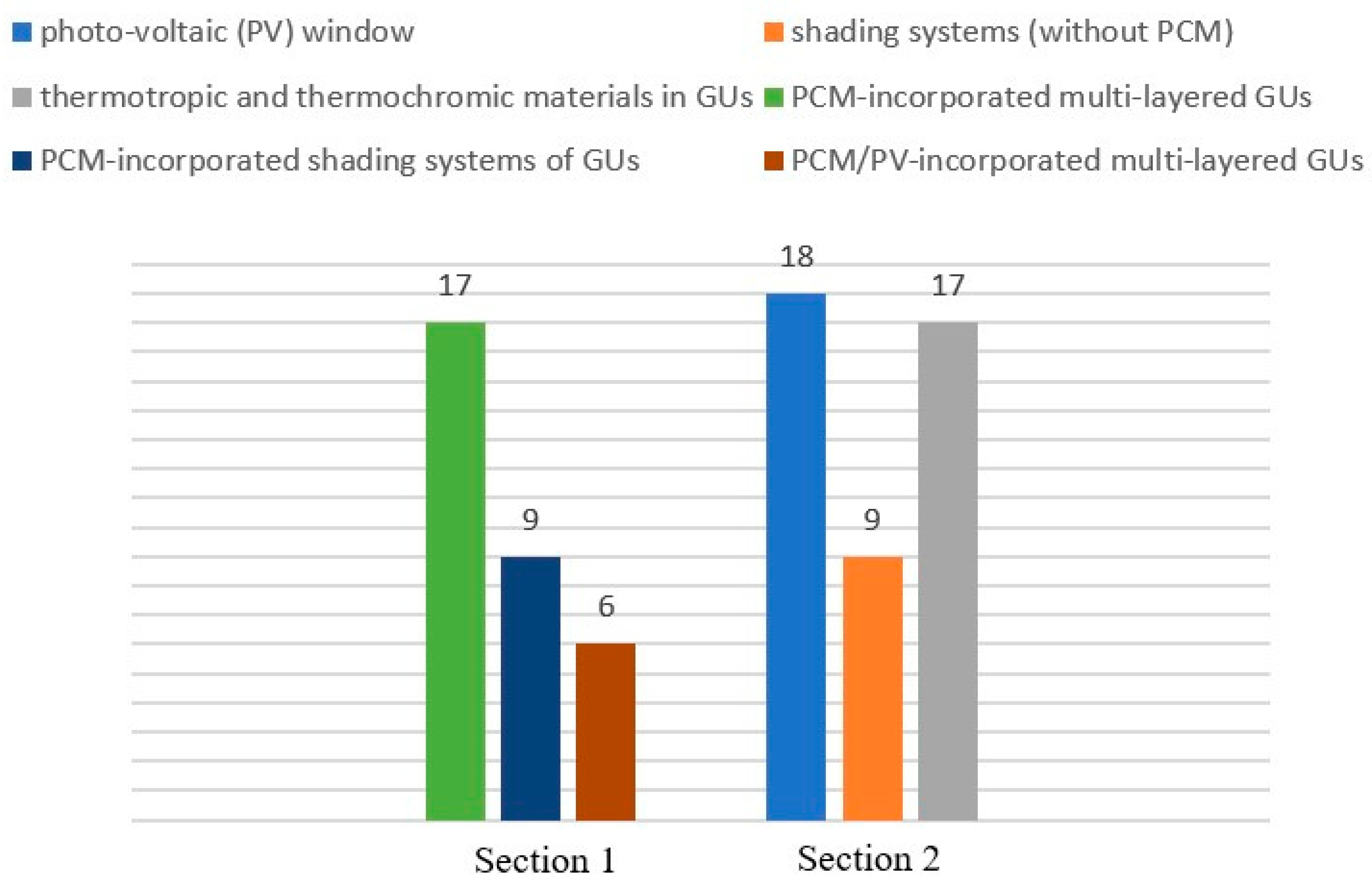

3. Energy-Saving Technologies of GUs

3.1. Technologies of GUs with PCM Utilization

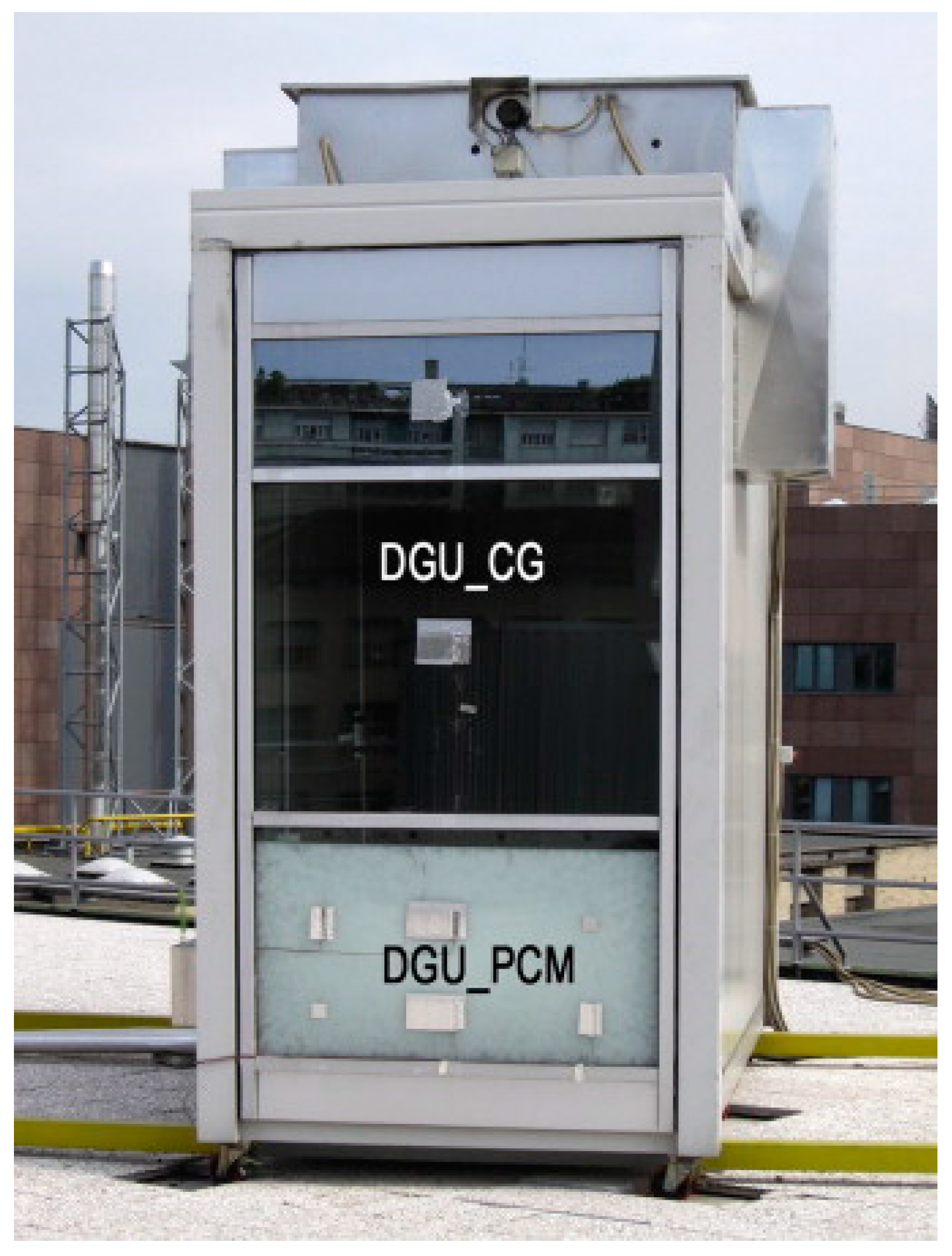

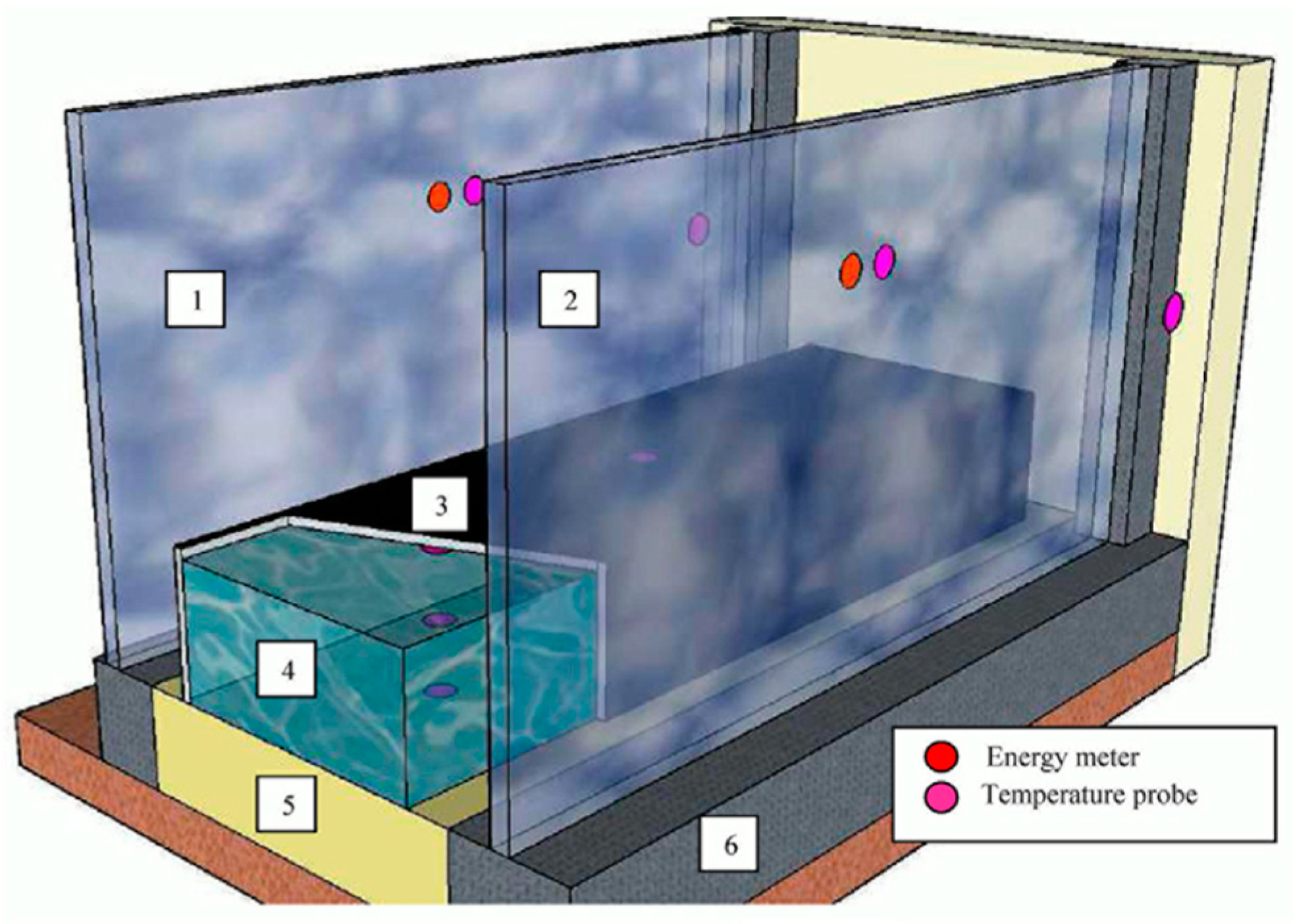

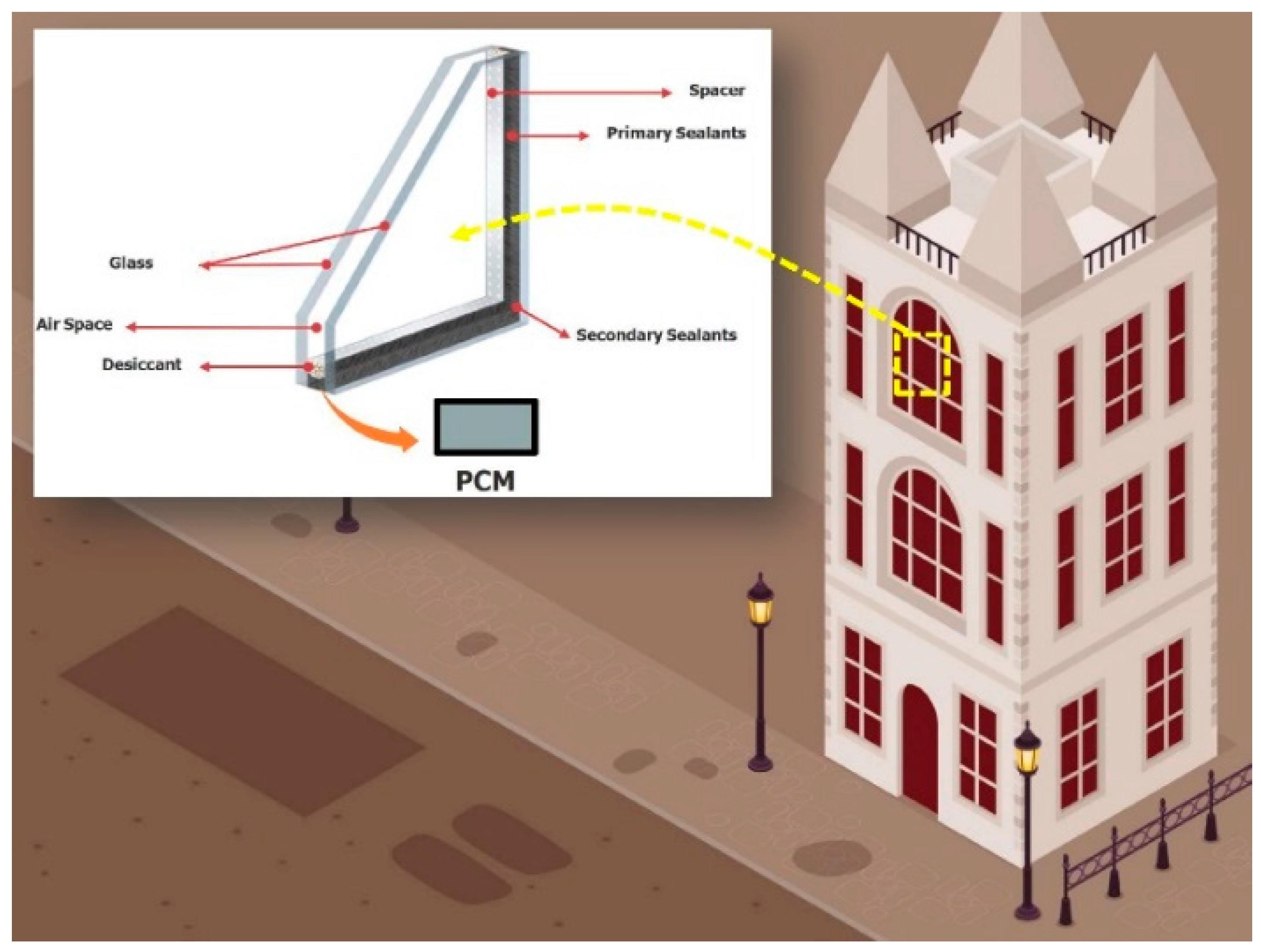

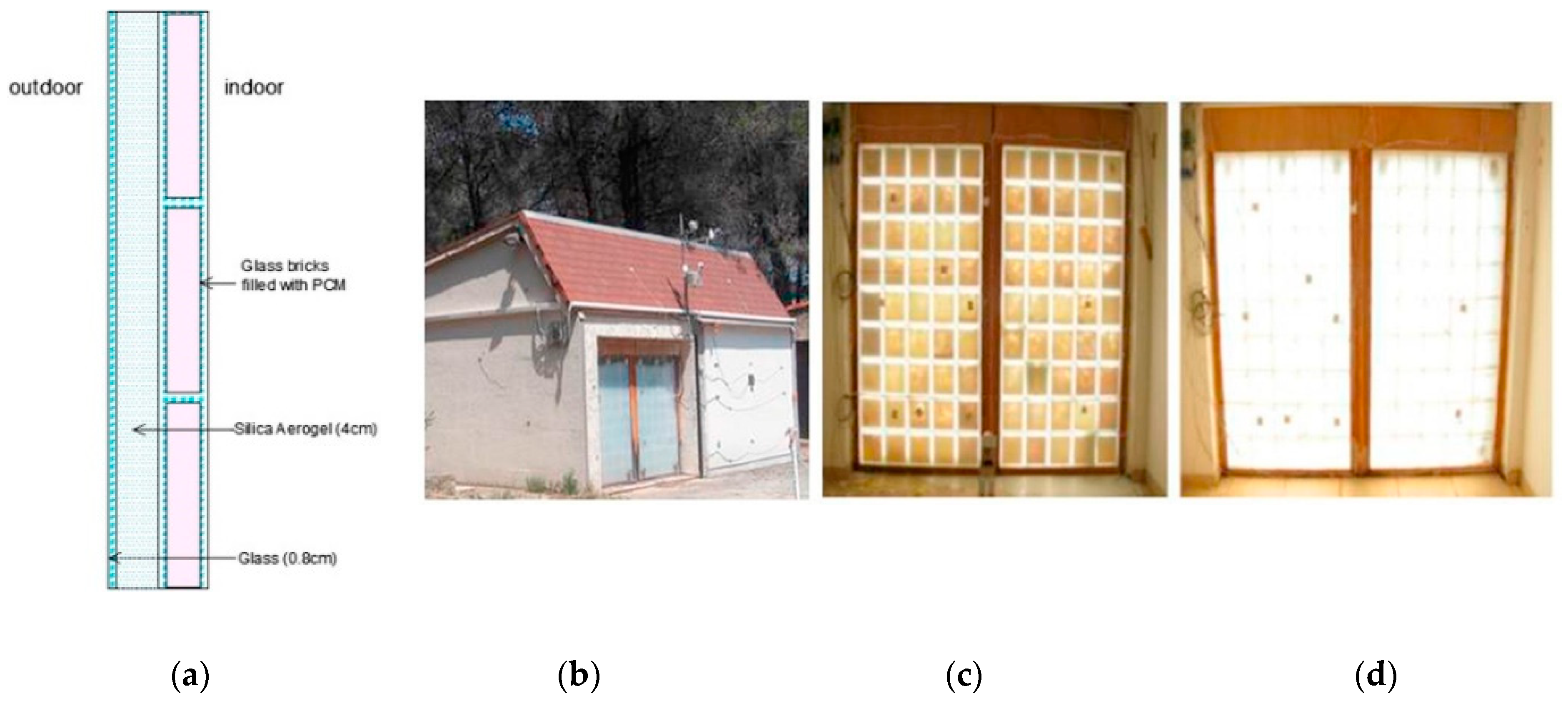

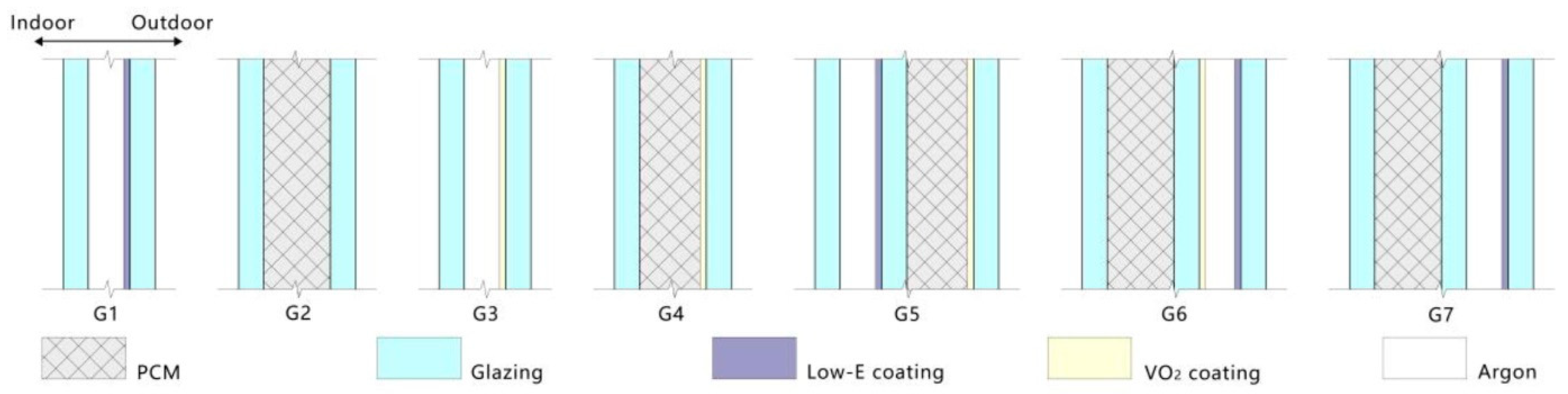

3.1.1. PCM-Incorporated Multi-Layered GUs

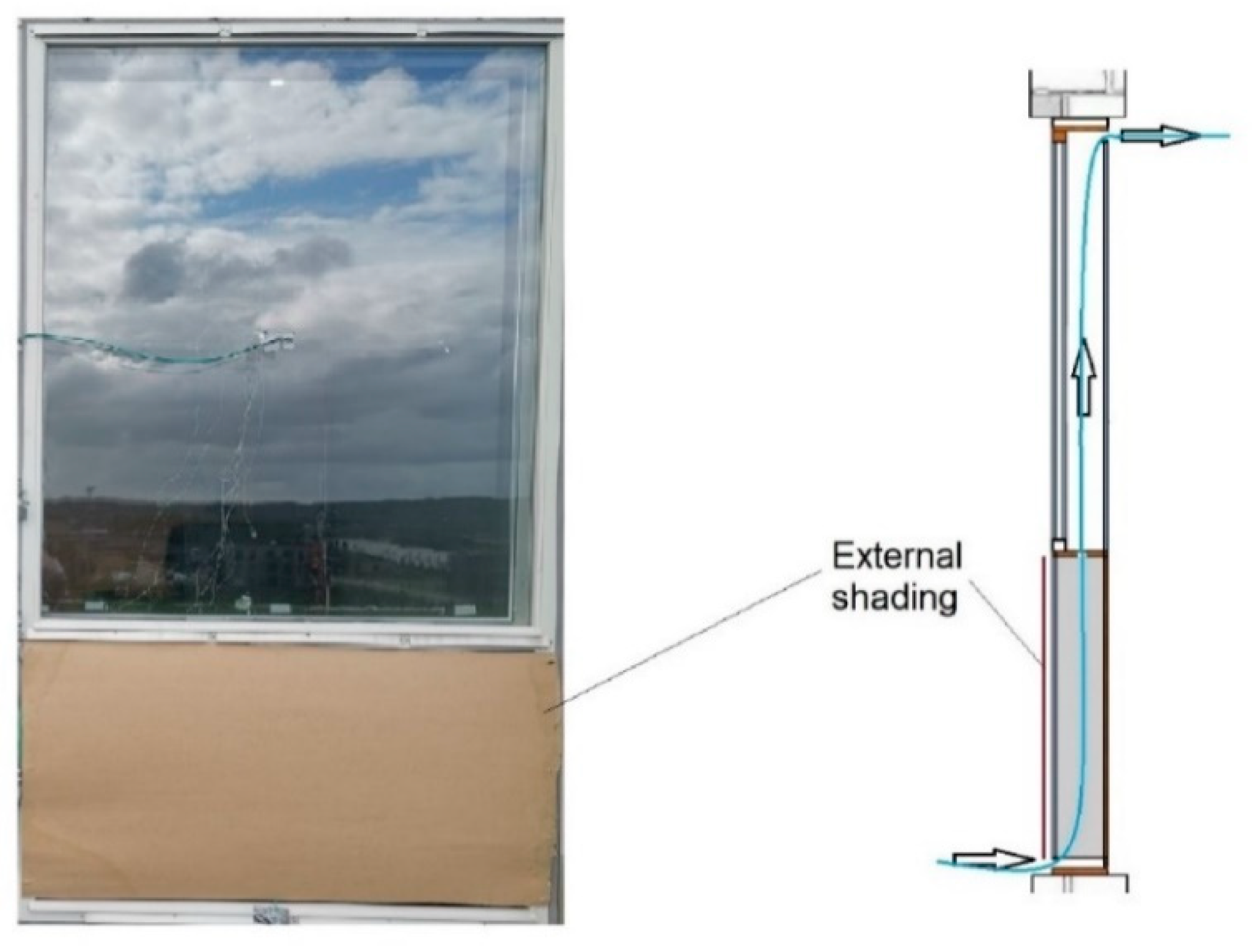

3.1.2. PCM-Incorporated Shading Systems of GUs

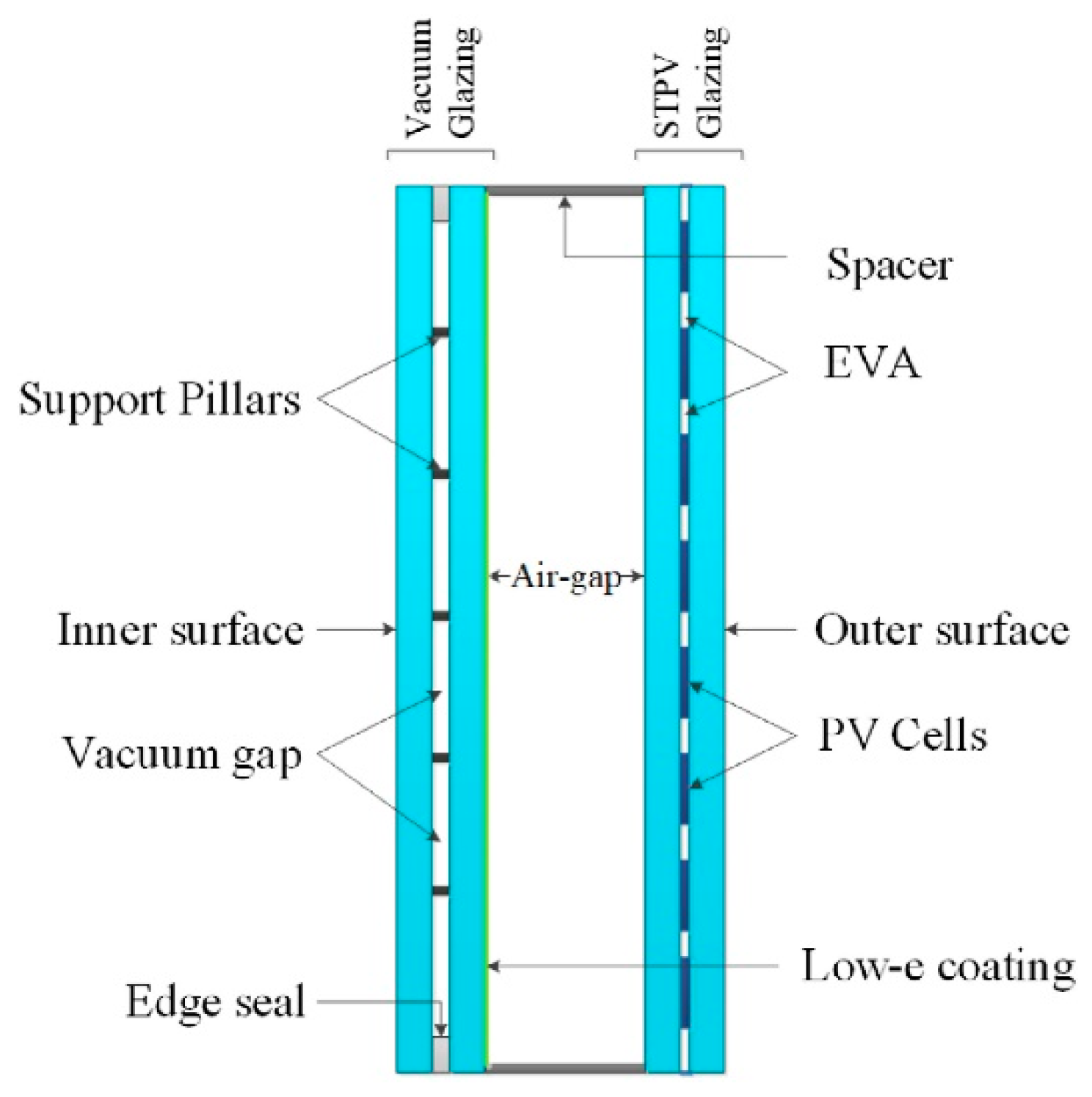

3.1.3. PCM/PV-Incorporated Multi-Layered GUs

3.2. Technologies of GUs without PCM Utilization

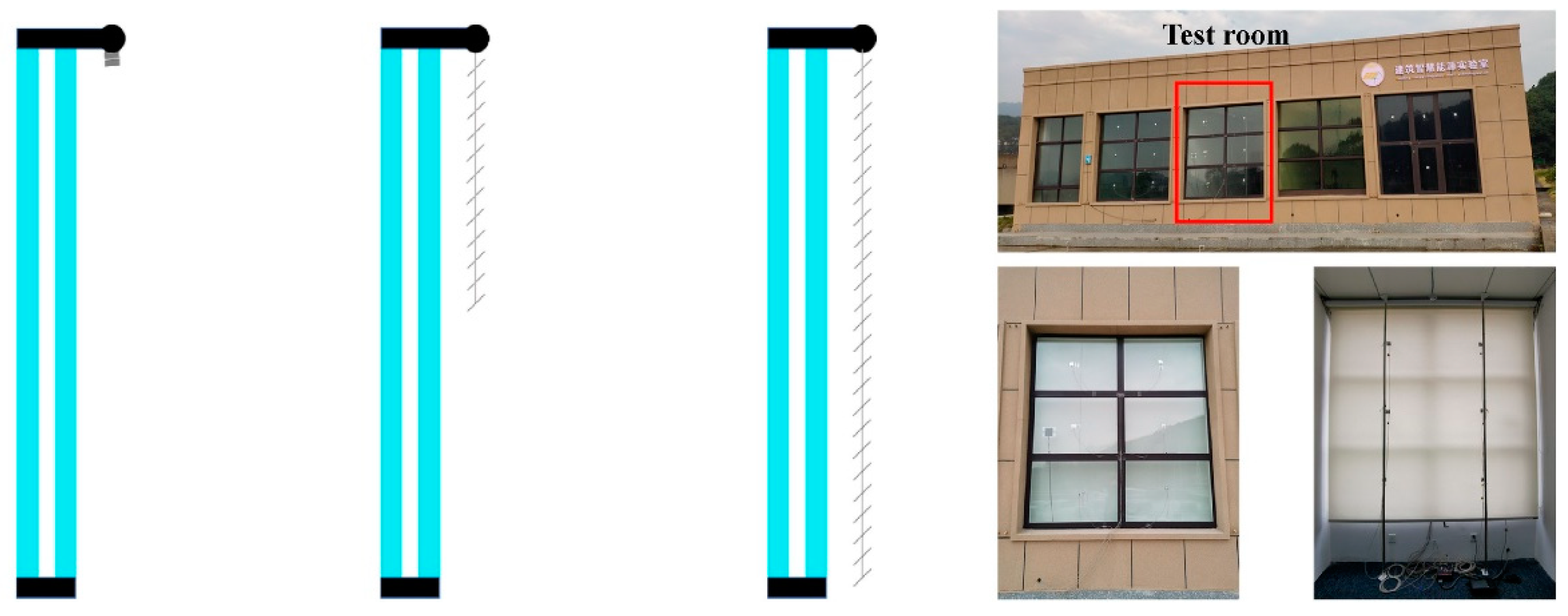

3.2.1. Photovoltaic (PV) Window

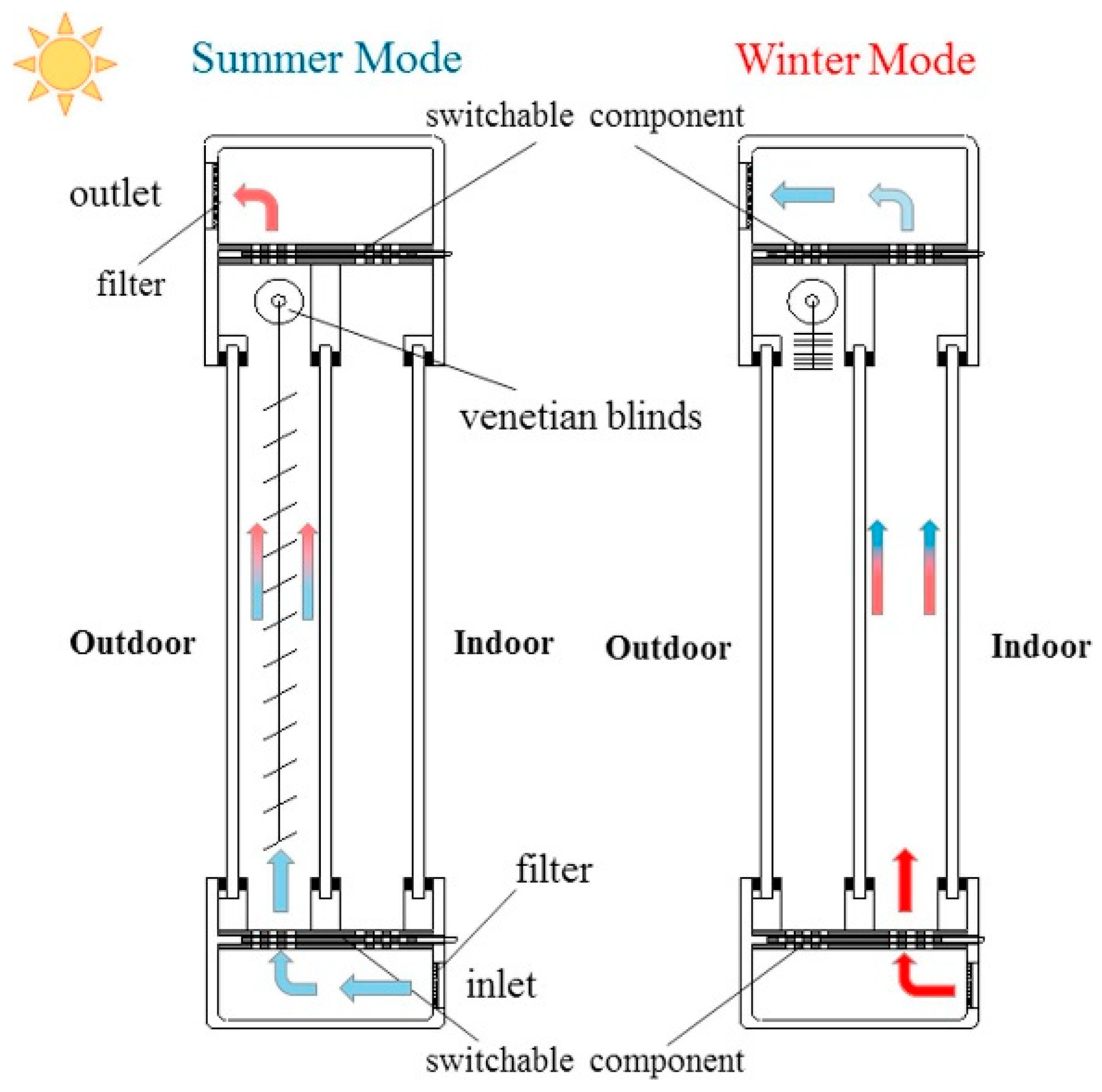

3.2.2. Shading Systems (without PCM)

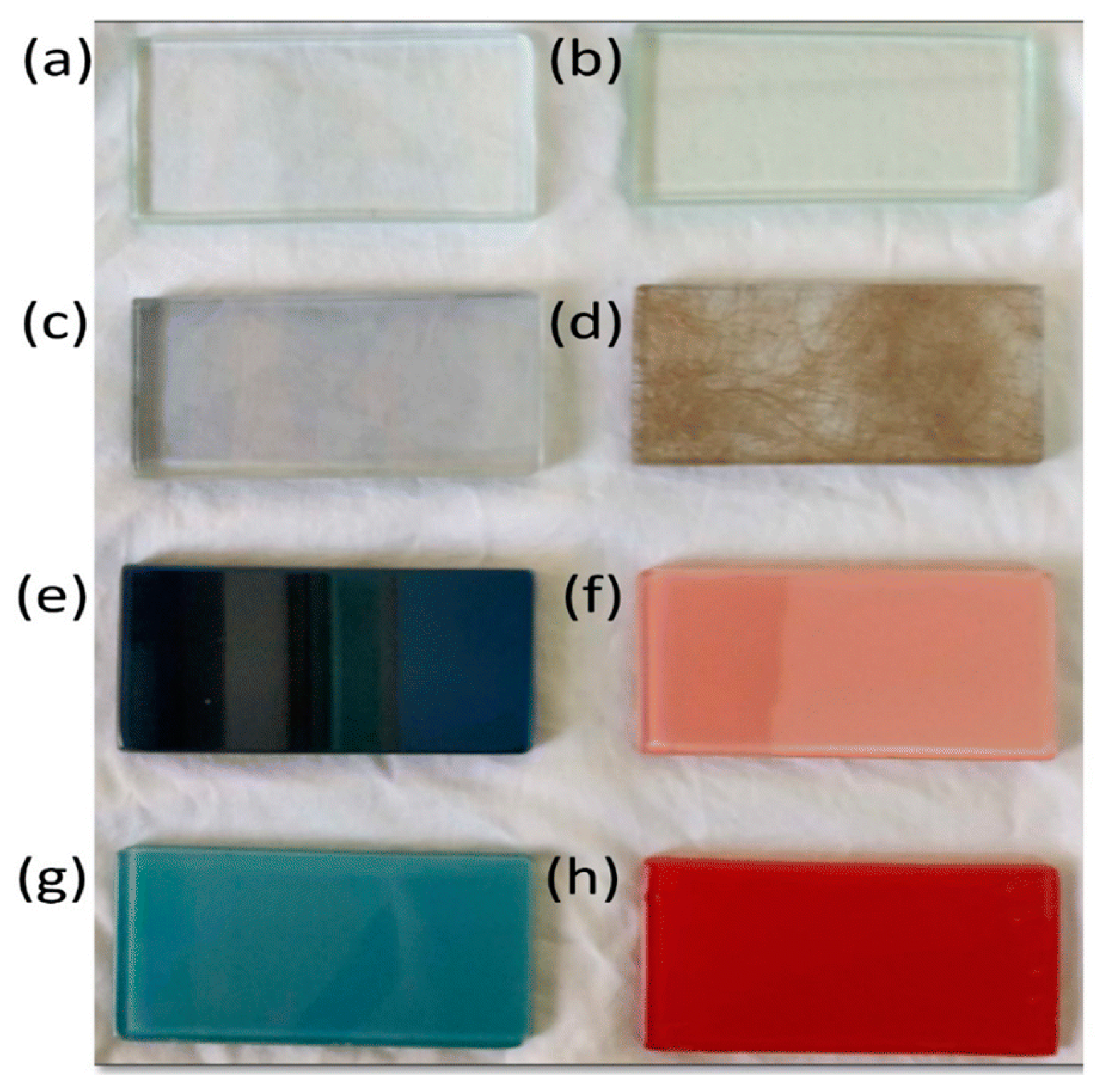

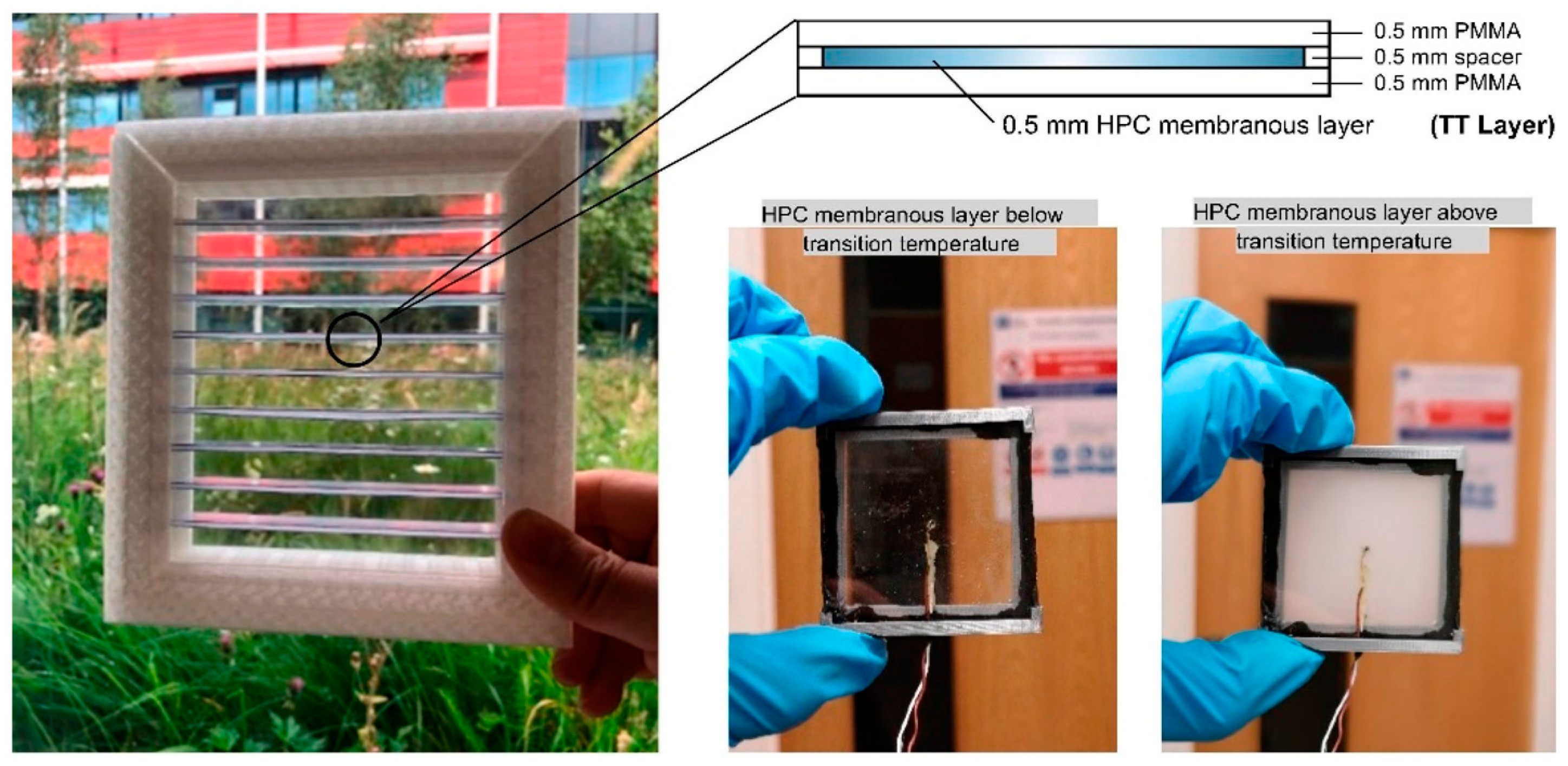

3.2.3. Chromogenic (Thermotropic and Thermochromic) Materials in GUs

4. Summary and Conclusions

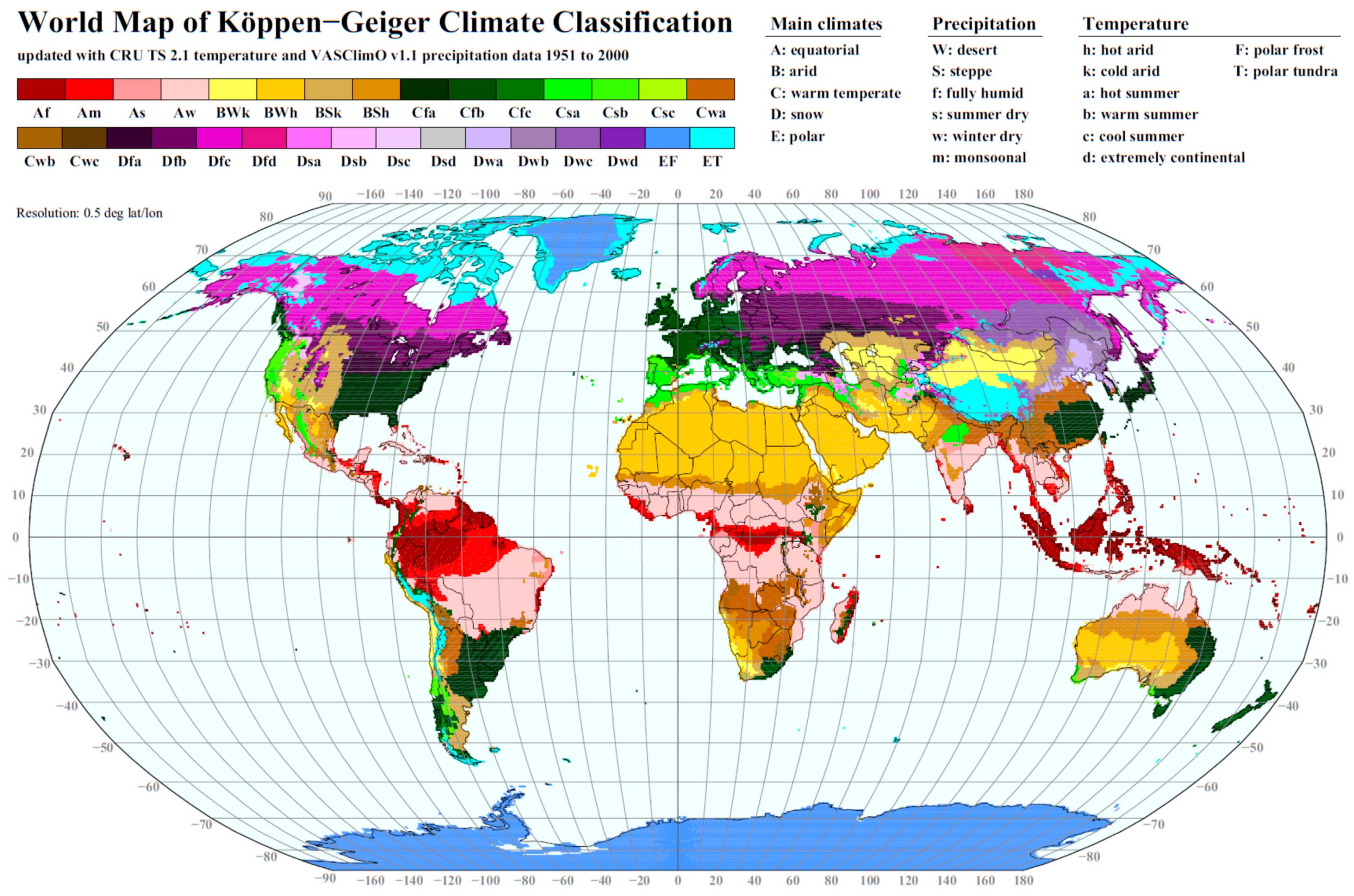

- PCM performs better in places where solar heat gain is greater. In addition, PCM is more successful in the summer and on clear days, whereas its efficacy in the winter and on overcast days is uncertain, necessitating the use of other passive and active approaches such as night ventilation.

- The PCM’s volume expansion during phase transition is an additional factor that must be considered. Another potential problem that has been discussed is the reduced solar transmittance of PCM solid phase in comparison to liquid phase. Using solid–solid translucent PCM, which can also remove leakage and volume-changing issues, is one way to avoid this problem.

- During the summer, when the PCM-integrated blind system is on the interior side of the GUs, the absorbed daytime heat must not be vented inside, necessitating nighttime ventilation. On the other hand, during winter it collects heat during the daytime and releases it to the inside, which is a beneficial effect, but it filters more sunlight during the day as additional opaque material has been added to the blind system. To minimize losing sunlight, cascaded PCM integration with multiple MTs is recommended.

- Combining a PV layer and a PCM layer in the glazing units appears to be a promising technique that requires additional research to be fully exploited. The PCM enables the PV module to operate safely, which improves the thermal performance of the smart glazing system. As the PV layer blocks sunlight transmittance, it might be employed to keep the PCM from overheating while also producing electricity.

- Since PV-window technology alone has been used more frequently than in combination with other smart glazing technologies, and has demonstrated a promising energy-saving performance, it could be combined with other passive technologies to achieve a higher thermal performance for smart glazing technology. In addition, solar cells show better performance in regions with less cloudy days.

- There are numerous individual utilizations of chromogenic materials, but only a few use them in combination with other passive techniques. Using their dynamic control of the sunlight entering buildings, PCM overheating may be prevented, and other technologies can work in a safer environment. They function better in locations with warm summers.

- An unsteady state analysis of the use of PCMs, along with other glazing technologies, over a long period of time is missing in the literature, as the available studies were mainly conducted on typical days in summer and winter.

- The hysteresis analysis for a large number of cycles for PCMs, as well as PV and chromogenic layers, is missing in the literature.

- A hygrothermal analysis and risk of mold growth due to using PCM combined with other technologies in the glazing systems is missing in the literature.

- The use of various technologies in smart glazing and identifying the optimum case for each climatic condition is also less studied in the literature.

- Incorporating Prisma glasses with other technologies to enhance the energy performance of the glazing units needs to be expanded to cover various operating conditions.

- The economic viability of incorporating PCMs in smart glazing is not justified in previous studies.

- Optical characteristics of smart glazing are of vital importance and need to be studied more deeply.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| List of symbols | |

| Pdry | Precipitation in the driest month (mm month−1) |

| Psdry | Precipitation in the driest month in summer (mm month−1) |

| Pwdry | Precipitation in the driest month in winter (mm month−1) |

| Pswet | Precipitation in the wettest month in summer (mm month−1) |

| Pwwet | Precipitation in the wettest month in winter (mm month−1) |

| T | Temperature (°C) |

| Tcold | The air temperature of the coldest month (°C) |

| Thot | The air temperature of the warmest month (°C) |

| Tmon10 | The number of months with air temperature >10 °C |

| Abbreviations | |

| a-Si | Amorphous Silicon |

| CdTe | Cadmium telluride |

| CFD | Computational fluid dynamics |

| DG | Double glazing |

| DGU | Double glazing unit |

| DGW | Double glazing window |

| DSF | Double skin facade |

| DSSC | Dye-sensitized solar cell |

| EVA | Ethylene vinyl acetate |

| GU | Glazing unit |

| HISG | High insulation solar glass |

| HPC | Hydroxypropyl cellulose |

| LCST | Lower critical solution temperature |

| MAT | Mean annual air temperature (°C) |

| MAP | Mean annual precipitation (mm y−1) |

| MT | Melting temperature |

| ND | n-docosane |

| NE | n-eicosane |

| NO | n-octadecane |

| SIS | Switchable insulation systems |

| TES | Thermal energy storage |

| TG | Triple glazing |

| TGU | Triple glazing unit |

| TGF | Triple glazing façade |

| TSF | Triple skin façade |

| PCM | Phase Change Material |

| PSC | Perovskite solar cell |

| PV | Photovoltaic |

| PVB | Photovoltaic-blind |

| QG | Quadruple-glazing |

| QGU | Quadruple-glazing unit |

| WWR | Window-to-wall ratio |

References

- International Energy Agency. Tracking Buildings 2021. Available online: https://www.iea.org/topics/buildings (accessed on 14 January 2023).

- Zhou, Y.; Zheng, S.; Liu, Z.; Wen, T.; Ding, Z.; Yan, J.; Zhang, G. Passive and active phase change materials integrated building energy systems with advanced machine-learning based climate-adaptive designs, intelligent operations, uncertainty-based analysis and optimisations: A state-of-the-art review. Renew. Sustain. Energy Rev. 2020, 130, 109889. [Google Scholar] [CrossRef]

- Wei, L.; Li, G.; Ruan, S.-T.; Qi, H. Dynamic coupled heat transfer and energy conservation performance of multilayer glazing window filled with phase change material in summer day. J. Energy Storage 2022, 49, 104183. [Google Scholar] [CrossRef]

- Liu, R.; Cui, H. Study of thermal performance of building using glass curtain wall with phase change material (PCM). In Proceedings of the 5th International Conference on Information Engineering for Mechanics and Materials, Huhhot, China, 25–26 July 2015; Atlantis Press: Amsterdam, The Netherlands, 2015; pp. 811–817. [Google Scholar]

- Zhang, S.; Ma, Y.; Li, D.; Liu, C.; Yang, R. Thermal performance of a reversible multiple-glazing roof filled with two PCM. Renew. Energy 2022, 182, 1080–1093. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, Y.; Xie, K.; Medina, M.A. A parametric study on the thermal response of a building wall with a phase change material (PCM) layer for passive space cooling. J. Energy Storage 2022, 47, 103548. [Google Scholar] [CrossRef]

- Khattari, Y.; Arid, A.; El Ouali, A.; Kousksou, T.; Janajreh, I. CFD study on the validity of using PCM in a controlled cooling ceiling integrated in a ventilated room. Dev. Built Environ. 2022, 9, 100066. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.; Ling, Z.; Fang, X.; Zhang, Z. Experimental investigation on the thermal performance of double-layer PCM radiant floor system containing two types of inorganic composite PCMs. Energy Build. 2020, 211, 109806. [Google Scholar] [CrossRef]

- Huang, Y.; El Mankibi, M.; Cantin, R.; Coillot, M. Application of fluids and promising materials as advanced inter-pane media in multi-glazing windows for thermal and energy performance improvement: A review. Energy Build. 2021, 253, 111458. [Google Scholar] [CrossRef]

- Li, D.; Yang, R.; Arıcı, M.; Wang, B.; Tunçbilek, E.; Wu, Y.; Liu, C.; Ma, Z.; Ma, Y. Incorporating phase change materials into glazing units for building applications: Current progress and challenges. Appl. Therm. Eng. 2022, 210, 118374. [Google Scholar] [CrossRef]

- Li, D.; Zhuang, B.; Chen, Y.; Li, B.; Landry, V.; Kaboorani, A.; Wu, Z.; Wang, X.A. Incorporation technology of bio-based phase change materials for building envelope: A review. Energy Build. 2022, 260, 111920. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Gupta, N.K.; Yadav, D.; Shukla, S.K.; Kaul, S. Thermal performance of the building envelope integrated with phase change material for thermal energy storage: An updated review. Sustain. Cities Soc. 2022, 79, 103690. [Google Scholar] [CrossRef]

- Hee, W.J.; Alghoul, M.A.; Bakhtyar, B.; Elayeb, O.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Saber, H.H.; Hajiah, A.E. 3D Numerical Modeling for Assessing the Energy Performance of Single-Zone Buildings with and without Phase Change Materials. In Proceedings of the Gulf Conference on Sustainable Built Environment; Springer: Berlin/Heidelberg, Germany, 2020; pp. 419–438. [Google Scholar]

- Gloriant, F.; Joulin, A.; Tittelein, P.; Lassue, S. Using heat flux sensors for a contribution to experimental analysis of heat transfers on a triple-glazed supply-air window. Energy 2021, 215, 119154. [Google Scholar] [CrossRef]

- Beck, H.E.; Zimmermann, N.E.; McVicar, T.R.; Vergopolan, N.; Berg, A.; Wood, E.F. Present and future Köppen-Geiger climate classification maps at 1-km resolution. Sci. Data 2018, 5, 180214. [Google Scholar] [CrossRef]

- Leśniak, A.; Górka, M. Evaluation of selected lightweight curtain wall solutions using multi criteria analysis. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 1978, p. 240003. [Google Scholar]

- Yu, F.; Wennersten, R.; Leng, J. A state-of-art review on concepts, criteria, methods and factors for reaching ‘thermal-daylighting balance’. Build. Environ. 2020, 186, 107330. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- Khamlich, I.; Zeng, K.; Flamant, G.; Baeyens, J.; Zou, C.; Li, J.; Yang, X.; He, X.; Liu, Q.; Yang, H. Technical and economic assessment of thermal energy storage in concentrated solar power plants within a spot electricity market. Renew. Sustain. Energy Rev. 2021, 139, 110583. [Google Scholar] [CrossRef]

- Navakrishnan, S.; Vengadesan, E.; Senthil, R.; Dhanalakshmi, S. An experimental study on simultaneous electricity and heat production from solar PV with thermal energy storage. Energy Convers. Manag. 2021, 245, 114614. [Google Scholar] [CrossRef]

- Koşan, M.; Aktaş, M. Experimental investigation of a novel thermal energy storage unit in the heat pump system. J. Clean. Prod. 2021, 311, 127607. [Google Scholar] [CrossRef]

- Heier, J.; Bales, C.; Martin, V. Combining thermal energy storage with buildings—A review. Renew. Sustain. Energy Rev. 2015, 42, 1305–1325. [Google Scholar] [CrossRef]

- Hanchi, N.; Hamza, H.; Lahjomri, J.; Oubarra, A. Thermal behavior in dynamic regime of a multilayer roof provided with two phase change materials in the case of a local conditioned. Energy Procedia 2017, 139, 92–97. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renew. Sustain. Energy Rev. 2020, 119, 109579. [Google Scholar] [CrossRef]

- Akeiber, H.; Nejat, P.; Majid, M.Z.A.; Wahid, M.A.; Jomehzadeh, F.; Zeynali Famileh, I.; Calautit, J.K.; Hughes, B.R.; Zaki, S.A. A review on phase change material (PCM) for sustainable passive cooling in building envelopes. Renew. Sustain. Energy Rev. 2016, 60, 1470–1497. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, R.; Wu, Y.; Zhao, C.Y. Parametric analysis of using PCM walls for heating loads reduction. Energy Build. 2018, 172, 328–336. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Wang, B.; Liu, C.; Arıcı, M. Optical and thermal performance of glazing units containing PCM in buildings: A review. Constr. Build. Mater. 2020, 233, 117327. [Google Scholar] [CrossRef]

- Akram, M.W.; Hasannuzaman, M.; Cuce, E.; Cuce, P.M. Global technological advancement and challenges of glazed window, facade system and vertical greenery-based energy savings in buildings: A comprehensive review. Energy Built Environ. 2021, 4, 206–226. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Improving thermal comfort conditions by means of PCM glazing systems. Energy Build. 2013, 60, 442–452. [Google Scholar] [CrossRef]

- Goia, F.; Perino, M.; Serra, V. Experimental analysis of the energy performance of a full-scale PCM glazing prototype. Sol. Energy 2014, 100, 217–233. [Google Scholar] [CrossRef]

- King, M.F.L.; Rao, P.N.; Sivakumar, A.; Mamidi, V.K.; Richard, S.; Vijayakumar, M.; Arunprasath, K.; Kumar, P.M. Thermal performance of a double-glazed window integrated with a phase change material (PCM). Mater. Today Proc. 2022, 50, 1516–1521. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Zhu, Y.; Li, D.; Ma, L. Experimental investigation of optical and thermal performance of a PCM-glazed unit for building applications. Energy Build. 2018, 158, 794–800. [Google Scholar] [CrossRef]

- Tafakkori, R.; Fattahi, A. Introducing novel configurations for double-glazed windows with lower energy loss. Sustain. Energy Technol. Assess. 2021, 43, 100919. [Google Scholar] [CrossRef]

- Musiał, M. Experimental and Numerical Analysis of the Energy Efficiency of Transparent Partitions with a Thermal Storage Unit. J. Ecol. Eng. 2020, 21, nr 6. [Google Scholar] [CrossRef]

- Musiał, M.; Lichołai, L. The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials 2021, 14, 2512. [Google Scholar] [CrossRef] [PubMed]

- Duraković, B.; Mešetović, S. Thermal performances of glazed energy storage systems with various storage materials: An experimental study. Sustain. Cities Soc. 2019, 45, 422–430. [Google Scholar] [CrossRef]

- Khetib, Y.; Alotaibi, A.A.; Alshahri, A.H.; Rawa, M.; Cheraghian, G.; Sharifpur, M. Impact of phase change material on the amount of emission in the double-glazed window frame for different window angles. J. Energy Storage 2021, 44, 103320. [Google Scholar] [CrossRef]

- Gao, Y.; Zheng, Q.; Jonsson, J.C.; Lubner, S.; Curcija, C.; Fernandes, L.; Kaur, S.; Kohler, C. Parametric study of solid-solid translucent phase change materials in building windows. Appl. Energy 2021, 301, 117467. [Google Scholar] [CrossRef]

- Yang, R.; Li, D.; Wei, W.; Wang, F. A Mie optimization model to determine optical properties of PCM based nanofluids for solar thermal applications of glazing window. Optik 2020, 212, 164664. [Google Scholar] [CrossRef]

- Li, S.; Zou, K.; Sun, G.; Zhang, X. Simulation research on the dynamic thermal performance of a novel triple-glazed window filled with PCM. Sustain. Cities Soc. 2018, 40, 266–273. [Google Scholar] [CrossRef]

- Wieprzkowicz, A.; Heim, D. Modelling of thermal processes in a glazing structure with temperature dependent optical properties—An example of PCM-window. Renew. Energy 2020, 160, 653–662. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, G.; Arıcı, M.; Bian, J.; Li, D. Thermal performance of non-ventilated multilayer glazing facades filled with phase change material. Sol. Energy 2019, 177, 464–470. [Google Scholar] [CrossRef]

- Kara, Y.A.; Kurnuç, A. Performance of coupled novel triple glass unit and pcm wall. Appl. Therm. Eng. 2012, 35, 243–246. [Google Scholar] [CrossRef]

- Souayfane, F.; Biwole, P.H.; Fardoun, F. Thermal behavior of a translucent superinsulated latent heat energy storage wall in summertime. Appl. Energy 2018, 217, 390–408. [Google Scholar] [CrossRef]

- Maduru, V.R.; Shaik, S. Laminated glazing for buildings: Energy saving, natural daylighting, and CO2 emission mitigation prospective. Environ. Sci. Pollut. Res. 2022, 29, 14299–14315. [Google Scholar] [CrossRef] [PubMed]

- Weinlaeder, H.; Koerner, W.; Heidenfelder, M. Monitoring results of an interior sun protection system with integrated latent heat storage. Energy Build. 2011, 43, 2468–2475. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, C.Y. Parametric investigations of using a PCM curtain for energy efficient buildings. Energy Build. 2015, 94, 33–42. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Development of a window shutter with phase change materials: Full scale outdoor experimental approach. Energy Build. 2015, 88, 110–121. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Performance of a window shutter with phase change material under summer Mediterranean climate conditions. Appl. Therm. Eng. 2015, 84, 246–256. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Amaral, C.; Figueiredo, A. Thermal performance of a window shutter containing PCM: Numerical validation and experimental analysis. Appl. Energy 2016, 179, 64–84. [Google Scholar] [CrossRef]

- Park, J.H.; Yun, B.Y.; Chang, S.J.; Wi, S.; Jeon, J.; Kim, S. Impact of a passive retrofit shading system on educational building to improve thermal comfort and energy consumption. Energy Build. 2020, 216, 109930. [Google Scholar] [CrossRef]

- Li, Y.; Darkwa, J.; Kokogiannakis, G.; Su, W. Phase change material blind system for double skin façade integration: System development and thermal performance evaluation. Appl. Energy 2019, 252, 113376. [Google Scholar] [CrossRef]

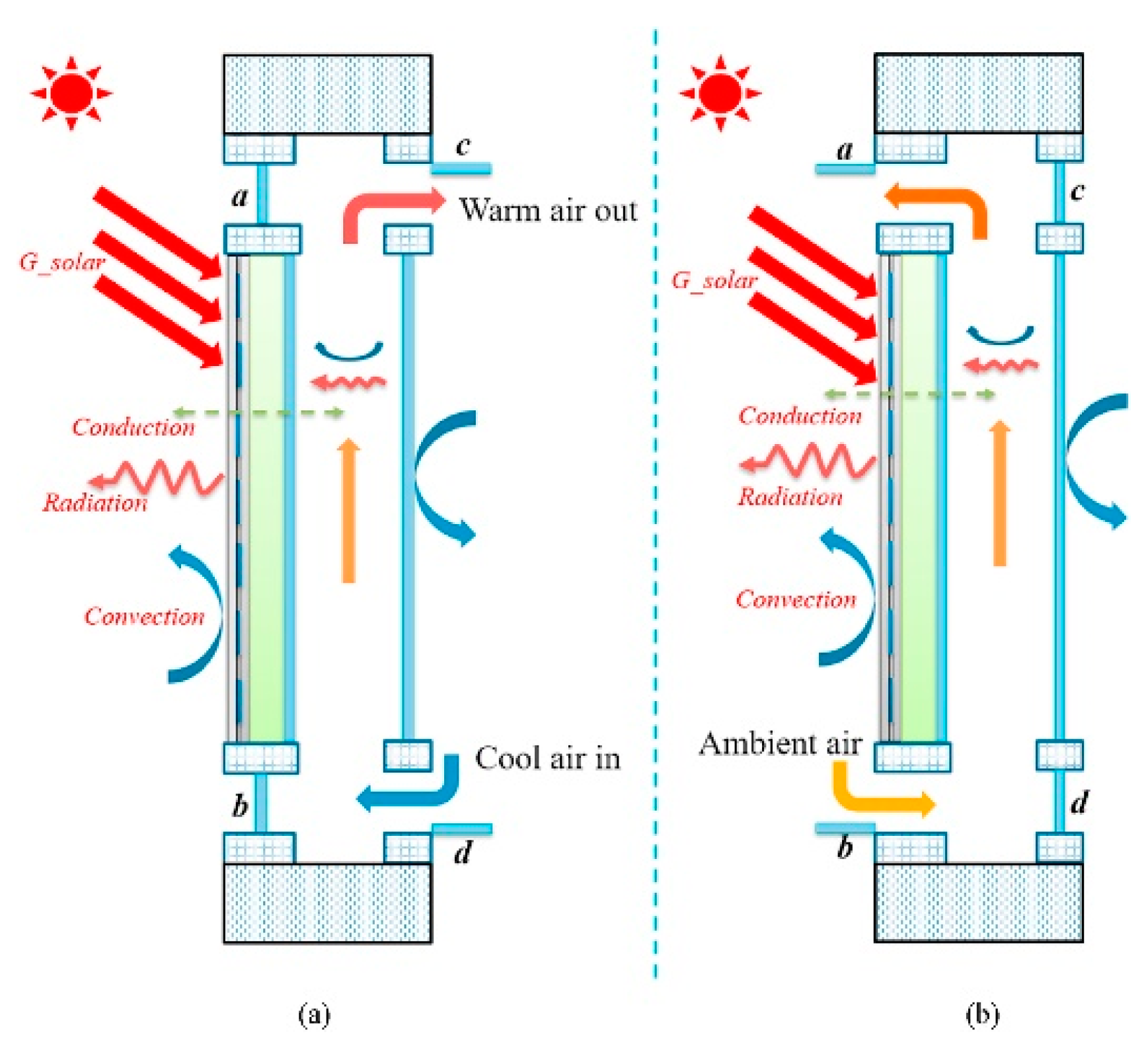

- Hu, Y.; Guo, R.; Heiselberg, P.K. Performance and control strategy development of a PCM enhanced ventilated window system by a combined experimental and numerical study. Renew. Energy 2020, 155, 134–152. [Google Scholar] [CrossRef]

- Elarga, H.; Goia, F.; Zarrella, A.; Dal Monte, A.; Benini, E. Thermal and electrical performance of an integrated PV-PCM system in double skin façades: A numerical study. Sol. Energy 2016, 136, 112–124. [Google Scholar] [CrossRef]

- Elarga, H.; Dal Monte, A.; Andersen, R.K.; Benini, E. PV-PCM integration in glazed building. Co-simulation and genetic optimization study. Build. Environ. 2017, 126, 161–175. [Google Scholar] [CrossRef]

- Ziasistani, N.; Fazelpour, F. Comparative study of DSF, PV-DSF and PV-DSF/PCM building energy performance considering multiple parameters. Sol. Energy 2019, 187, 115–128. [Google Scholar] [CrossRef]

- Heydari, A.H.; Haghighi Khoshkhoo, R. Techno-economical analysis of DSF, BIPV and PCM in administrative buildings in four climates of Iran. Int. J. Ambient Energy 2022, 43, 8474–8485. [Google Scholar] [CrossRef]

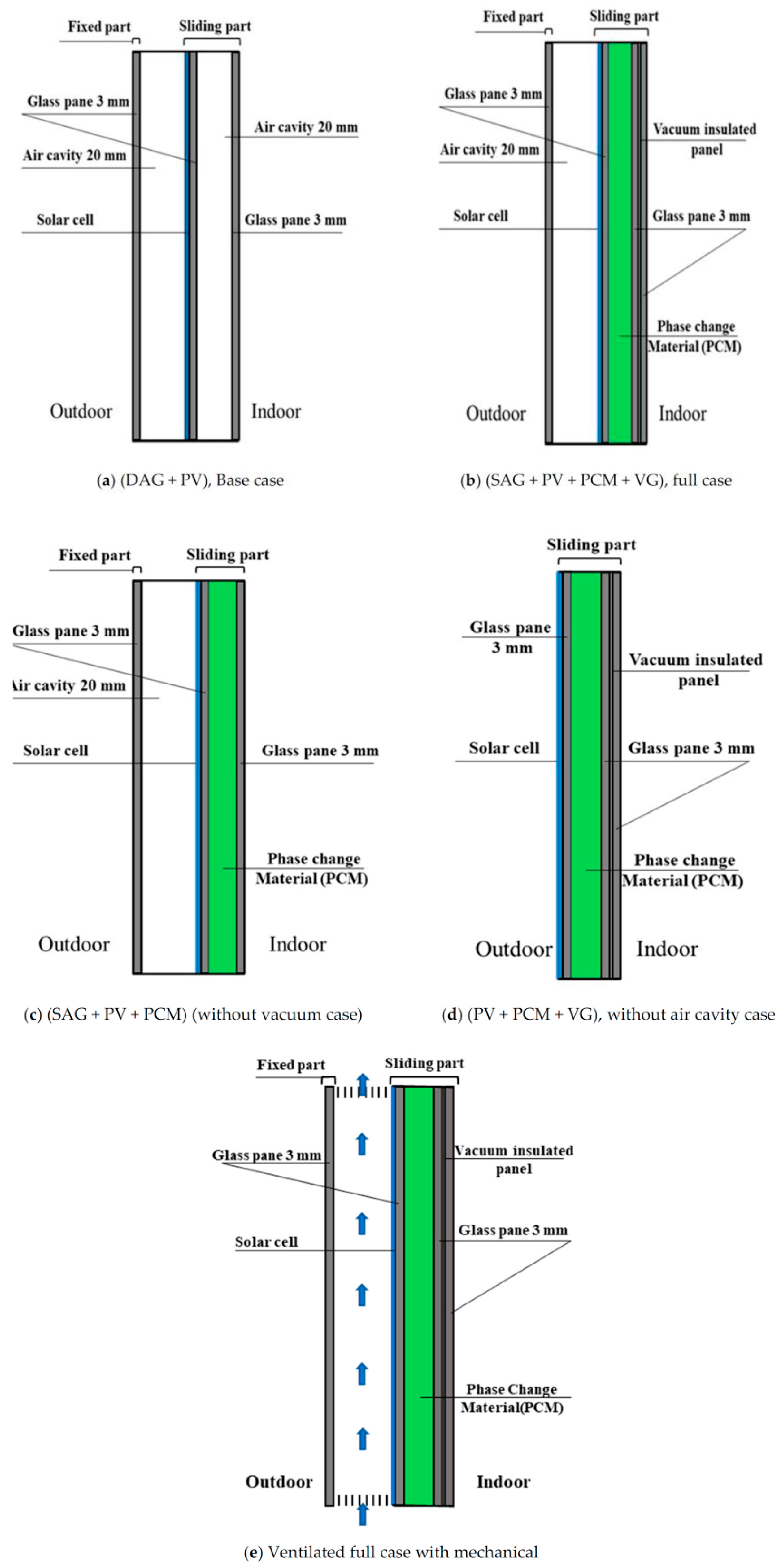

- Ahmed, M.; Radwan, A.; Serageldin, A.; Memon, S.; Katsura, T.; Nagano, K. Thermal Analysis of a New Sliding Smart Window Integrated with Vacuum Insulation, Photovoltaic, and Phase Change Material. Sustainability 2020, 12, 7846. [Google Scholar] [CrossRef]

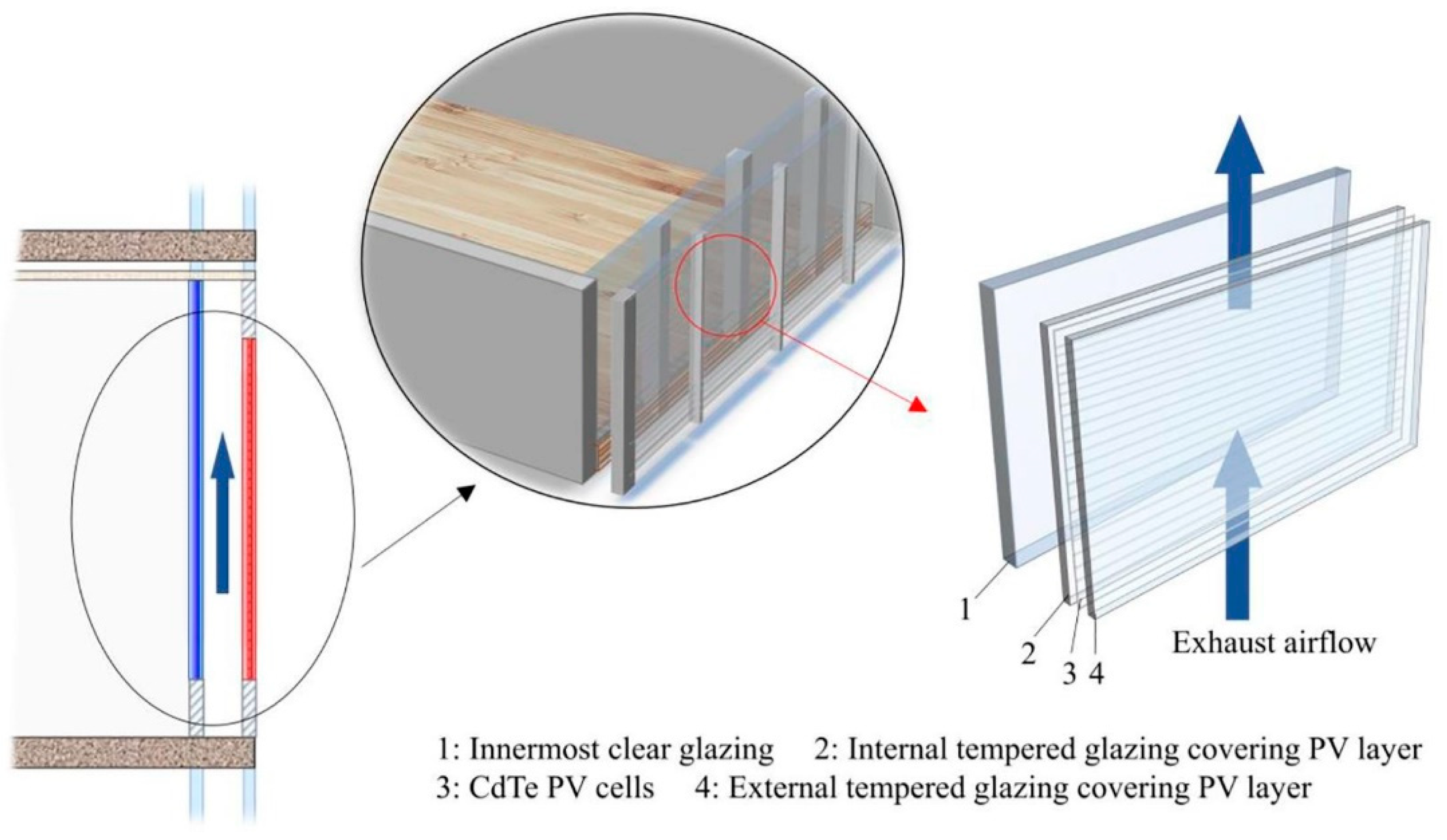

- Ke, W.; Ji, J.; Wang, C.; Zhang, C.; Xie, H.; Tang, Y.; Lin, Y. Comparative analysis on the electrical and thermal performance of two CdTe multi-layer ventilated windows with and without a middle PCM layer: A preliminary numerical study. Renew. Energy 2022, 189, 1306–1323. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Young, C.-H. Energy saving potential of heat insulation solar glass: Key results from laboratory and in-situ testing. Energy 2016, 97, 369–380. [Google Scholar] [CrossRef]

- Sharma, M.K.; Preet, S.; Mathur, J.; Chowdhury, A.; Mathur, S. Exploring the advantages of photo-voltaic triple skin façade in hot summer conditions. Sol. Energy 2021, 217, 317–327. [Google Scholar] [CrossRef]

- Tang, Y.; Ji, J.; Wang, C.; Xie, H.; Ke, W. Performance prediction of a novel double-glazing PV curtain wall system combined with an air handling unit using exhaust cooling and heat recovery technology. Energy Convers. Manag. 2022, 265, 115774. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Wang, X.; Xie, L.; Liu, Z.; Wu, J.; Zhang, Y.; He, X. A comparative study on thermal performance evaluation of a new double skin façade system integrated with photovoltaic blinds. Appl. Energy 2017, 199, 281–293. [Google Scholar] [CrossRef]

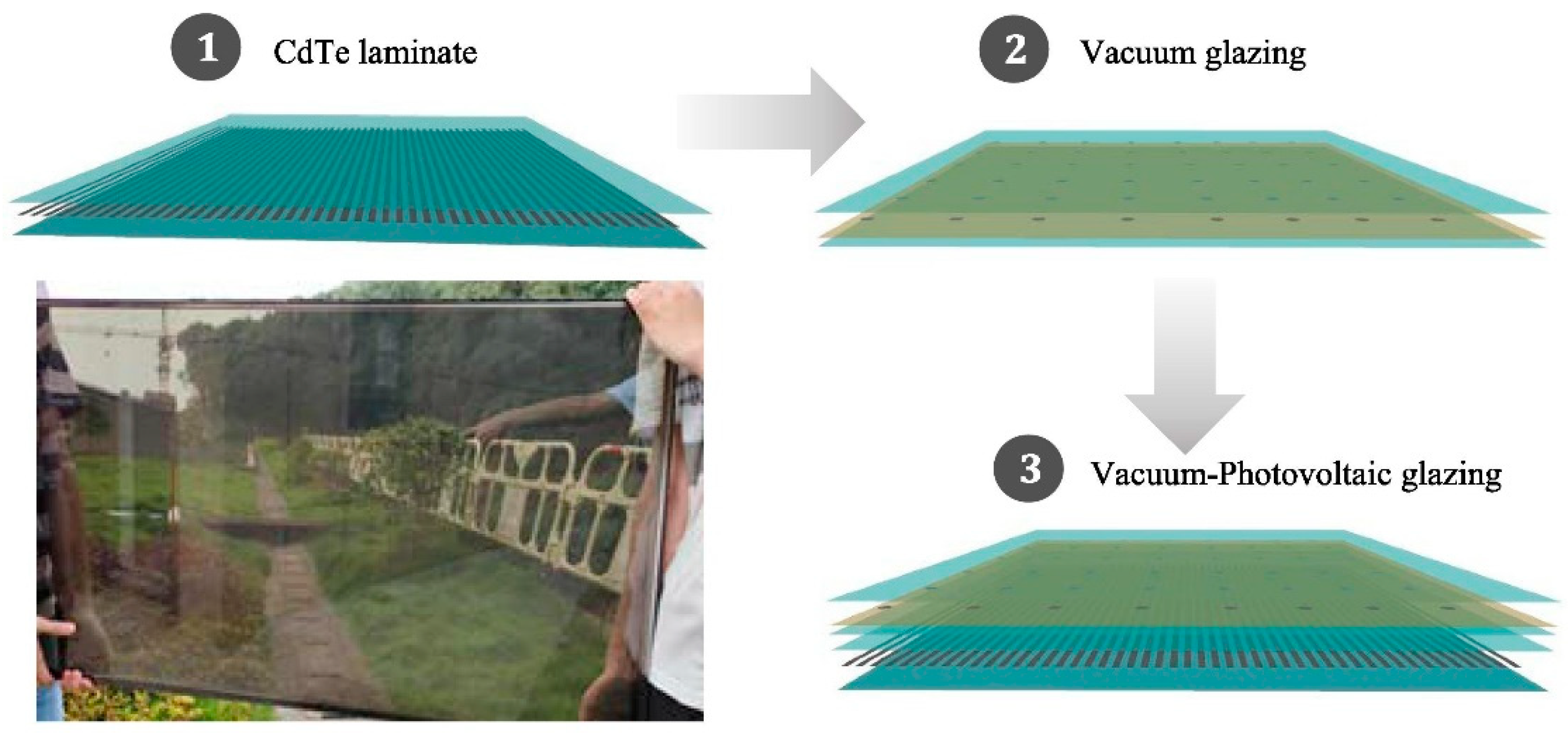

- Tan, Y.; Peng, J.; Luo, Y.; Luo, Z.; Curcija, C.; Fang, Y. Numerical heat transfer modeling and climate adaptation analysis of vacuum-photovoltaic glazing. Appl. Energy 2022, 312, 118747. [Google Scholar] [CrossRef]

- Uddin, M.M.; Wang, C.; Zhang, C.; Ji, J. Investigating the energy-saving performance of a CdTe-based semi-transparent photovoltaic combined hybrid vacuum glazing window system. Energy 2022, 253, 124019. [Google Scholar] [CrossRef]

- Wang, C.; Uddin, M.M.; Ji, J.; Yu, B.; Wang, J. The performance analysis of a double-skin ventilated window integrated with CdTe cells in typical climate regions. Energy Build. 2021, 241, 110922. [Google Scholar] [CrossRef]

- Alrashidi, H.; Issa, W.; Sellami, N.; Sundaram, S.; Mallick, T. Thermal performance evaluation and energy saving potential of semi-transparent CdTe in Façade BIPV. Sol. Energy 2022, 232, 84–91. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, J.; Wang, C.; Ke, W.; Xie, H.; Yu, B. Experimental and numerical studies on the thermal and electrical performance of a CdTe ventilated window integrated with vacuum glazing. Energy 2022, 244, 123128. [Google Scholar] [CrossRef]

- Castillo, M.S.; Liu, X.; Abd-AlHamid, F.; Connelly, K.; Wu, Y. Intelligent windows for electricity generation: A technologies review. In Proceedings of the Building Simulation; Springer: Berlin/Heidelberg, Germany, 2022; pp. 1–27. [Google Scholar]

- Musameh, H.; Alrashidi, H.; Al-Neami, F.; Issa, W. Energy performance analytical review of semi-transparent photovoltaics glazing in the United Kingdom. J. Build. Eng. 2022, 54, 104686. [Google Scholar] [CrossRef]

- Yu, G.; Yang, H.; Luo, D.; Cheng, X.; Ansah, M.K. A review on developments and researches of building integrated photovoltaic (BIPV) windows and shading blinds. Renew. Sustain. Energy Rev. 2021, 149, 111355. [Google Scholar] [CrossRef]

- Wang, C.; Ji, J.; Uddin, M.M.; Yu, B.; Song, Z. The study of a double-skin ventilated window integrated with CdTe cells in a rural building. Energy 2021, 215, 119043. [Google Scholar] [CrossRef]

- Qiu, C.; Yang, H. Dynamic coupling of a heat transfer model and whole building simulation for a novel cadmium telluride-based vacuum photovoltaic glazing. Energy 2022, 250, 123745. [Google Scholar] [CrossRef]

- Wang, C.; Li, N.; Yu, B.; Uddin, M.M.; Ji, J. A novel solar spectrum-splitting utilization photocatalytic CdTe double-skin façade: Concept, design and performance investigation. Build. Environ. 2021, 195, 107776. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Luo, Y.; Liu, Z.; Yang, H.; Wang, X. Conceptualization and preliminary analysis of a novel reversible photovoltaic window. Energy Convers. Manag. 2021, 250, 114925. [Google Scholar] [CrossRef]

- Wang, C.; Ji, J.; Yu, B.; Zhang, C.; Ke, W.; Wang, J. Comprehensive investigation on the luminous and energy-saving performance of the double-skin ventilated window integrated with CdTe cells. Energy 2022, 238, 121757. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Luo, Y.; Liu, Z. Energy performance of a reversible window integrated with photovoltaic blinds in Harbin. Build. Environ. 2022, 213, 108861. [Google Scholar] [CrossRef]

- Touma, A.A.; Ouahrani, D. Shading and day-lighting controls energy savings in offices with fully-Glazed façades in hot climates. Energy Build. 2017, 151, 263–274. [Google Scholar] [CrossRef]

- Dutta, A.; Samanta, A.; Neogi, S. Influence of orientation and the impact of external window shading on building thermal performance in tropical climate. Energy Build. 2017, 139, 680–689. [Google Scholar] [CrossRef]

- Fedorczak-Cisak, M.; Nowak, K.; Furtak, M. Analysis of the effect of using external venetian blinds on the thermal comfort of users of highly glazed office rooms in a transition season of temperate climate—Case study. Energies 2019, 13, 81. [Google Scholar] [CrossRef]

- Kuczyński, T.; Staszczuk, A.; Gortych, M.; Stryjski, R. Effect of thermal mass, night ventilation and window shading on summer thermal comfort of buildings in a temperate climate. Build. Environ. 2021, 204, 108126. [Google Scholar] [CrossRef]

- Carlier, R.; Dabbagh, M.; Krarti, M. Energy Performance of Integrated Wall and Window Switchable Insulated Systems for Residential Buildings. Energies 2022, 15, 1056. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, Q.; Jia, J. Numerical study on performance optimization of an energy-saving insulated window. Sustainability 2021, 13, 935. [Google Scholar] [CrossRef]

- Cho, H.M.; Yang, S.; Wi, S.; Chang, S.J.; Kim, S. Hygrothermal and energy retrofit planning of masonry façade historic building used as museum and office: A cultural properties case study. Energy 2020, 201, 117607. [Google Scholar] [CrossRef]

- Tan, Y.; Peng, J.; Luo, Y.; Gao, J.; Luo, Z.; Wang, M.; Curcija, D.C. Parametric study of venetian blinds for energy performance evaluation and classification in residential buildings. Energy 2022, 239, 122266. [Google Scholar] [CrossRef]

- Zhang, C.; Gang, W.; Wang, J.; Xu, X.; Du, Q. Experimental investigation and dynamic modeling of a triple-glazed exhaust air window with built-in venetian blinds in the cooling season. Appl. Therm. Eng. 2018, 140, 73–85. [Google Scholar] [CrossRef]

- Seeboth, A.; Ruhmann, R.; Mühling, O. Thermotropic and thermochromic polymer based materials for adaptive solar control. Materials 2010, 3, 5143–5168. [Google Scholar] [CrossRef]

- Yao, J.; Zhu, N. Evaluation of indoor thermal environmental, energy and daylighting performance of thermotropic windows. Build. Environ. 2012, 49, 283–290. [Google Scholar] [CrossRef]

- Goia, F.; Bianco, L.; Cascone, Y.; Perino, M.; Serra, V. Experimental analysis of an advanced dynamic glazing prototype integrating PCM and thermotropic layers. Energy Procedia 2014, 48, 1272–1281. [Google Scholar] [CrossRef]

- Connelly, K.; Wu, Y.; Ma, X.; Lei, Y. Transmittance and reflectance studies of thermotropic material for a novel building integrated concentrating photovoltaic (BICPV)‘smart window’system. Energies 2017, 10, 1889. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, X.; Ming, Y.; Liu, X.; Mahon, D.; Wilson, R.; Liu, H.; Eames, P.; Wu, Y. Energy and daylight performance of a smart window: Window integrated with thermotropic parallel slat-transparent insulation material. Appl. Energy 2021, 293, 116826. [Google Scholar] [CrossRef]

- Sun, Y.; Wilson, R.; Liu, H.; Wu, Y. Numerical investigation of a smart window system with thermotropic Parallel Slat Transparent Insulation Material for building energy conservation and daylight autonomy. Build. Environ. 2021, 203, 108048. [Google Scholar] [CrossRef]

- Long, L.; Ye, H.; Gao, Y.; Zou, R. Performance demonstration and evaluation of the synergetic application of vanadium dioxide glazing and phase change material in passive buildings. Appl. Energy 2014, 136, 89–97. [Google Scholar] [CrossRef]

- Jin, Q.; Long, X.; Liang, R. Numerical analysis on the thermal performance of PCM-integrated thermochromic glazing systems. Energy Build. 2022, 257, 111734. [Google Scholar] [CrossRef]

- Ke, Y.; Tan, Y.; Feng, C.; Chen, C.; Lu, Q.; Xu, Q.; Wang, T.; Liu, H.; Liu, X.; Peng, J.; et al. Tetra-Fish-Inspired aesthetic thermochromic windows toward Energy-Saving buildings. Appl. Energy 2022, 315, 119053. [Google Scholar] [CrossRef]

- Tao, Y.; Fang, X.; Zhang, H.; Zhang, G.; Tu, J.; Shi, L. Impacts of thermo-optical properties on the seasonal operation of thermochromic smart window. Energy Convers. Manag. 2022, 252, 115058. [Google Scholar] [CrossRef]

- Lin, K.; Chao, L.; Lee, H.H.; Xin, R.; Liu, S.; Ho, T.C.; Huang, B.; Yu, K.M.; Tso, C.Y. Potential building energy savings by passive strategies combining daytime radiative coolers and thermochromic smart windows. Case Stud. Therm. Eng. 2021, 28, 101517. [Google Scholar] [CrossRef]

- Arnesano, M.; Pandarese, G.; Martarelli, M.; Naspi, F.; Gurunatha, K.L.; Sol, C.; Portnoi, M.; Ramirez, F.V.; Parkin, I.P.; Papakonstantinou, I.; et al. Optimization of the thermochromic glazing design for curtain wall buildings based on experimental measurements and dynamic simulation. Sol. Energy 2021, 216, 14–25. [Google Scholar] [CrossRef]

- Arnaoutakis, G.E.; Katsaprakakis, D.A. Energy Performance of Buildings with Thermochromic Windows in Mediterranean Climates. Energies 2021, 14, 6977. [Google Scholar] [CrossRef]

- Hong, X.; Shi, F.; Wang, S.; Yang, X.; Yang, Y. Multi-objective optimization of thermochromic glazing based on daylight and energy performance evaluation. In Proceedings of the Building Simulation; Springer: Berlin/Heidelberg, Germany, 2021; Volume 14, pp. 1685–1695. [Google Scholar]

- Teixeira, H.; Glória Gomes, M.; Moret Rodrigues, A.; Aelenei, D. Assessment of the visual, thermal and energy performance of static vs. thermochromic double-glazing under different European climates. Build. Environ. 2022, 217, 109115. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, Y.; Jiang, T.; Yang, R.; Tan, G.; Long, Y. Thermochromic smart windows with highly regulated radiative cooling and solar transmission. Nano Energy 2021, 89, 106440. [Google Scholar] [CrossRef]

- Aburas, M.; Ebendorff-Heidepriem, H.; Lei, L.; Li, M.; Zhao, J.; Williamson, T.; Wu, Y.; Soebarto, V. Smart windows—Transmittance tuned thermochromic coatings for dynamic control of building performance. Energy Build. 2021, 235, 110717. [Google Scholar] [CrossRef]

| 1st | 2nd | 3rd | Description | Criterion a |

|---|---|---|---|---|

| A | Tropical | Not (B) & | ||

| f |

| |||

| m |

| Not (Af) & | ||

| w |

| Not (Af) & | ||

| B | Arid | |||

| w |

| |||

| s |

| |||

| h |

| |||

| k |

| |||

| C | Temperate | Not (B) & & | ||

| s |

| & | ||

| w |

| |||

| f |

| Not (Cs) or (Cw) | ||

| a |

| |||

| b |

| Not (a) & | ||

| c |

| Not (a or b) & | ||

| D | Cold | Not (B) & & | ||

| s |

| & | ||

| w |

| |||

| f |

| Not (Ds) or (Dw) | ||

| a |

| |||

| b |

| Not (a) & | ||

| c |

| Not (a, b, or d) | ||

| d |

| Not (a or b) & | ||

| E | Polar | Not (B) & | ||

| T |

| |||

| F |

|

| Material Property | TES Sensible Heat | TES Latent Heat | ||

|---|---|---|---|---|

| Material | Rock | Water | Organic PCM | Inorganic PCM |

| Density (kg/m3) | 2240 | 1000 | 800 | 1600 |

| Specific heat (kJ/(kg·K)) | 1 | 4.2 | 2 | 2 |

| Latent heat (kJ/kg) | - | - | 190 | 230 |

| Latent heat (kJ/m3) | - | - | 152 | 368 |

| Mass of storage for 106 J (kg) | 67,000 | 16,000 | 5300 | 4350 |

| Volume of storage for 106 J (m3) | 30 | 16 | 6.6 | 2.7 |

| Mass of relative storage (-) | 15 | 4 | 1.25 | 1 |

| Volume of relative storage (-) | 11 | 6 | 2.5 | 1 |

| Ref. | PCM Type (MT °C) | Climate Code | Study Type | Envelope Element | Application | Findings and Remarks |

|---|---|---|---|---|---|---|

| [31] | RT35 paraffin (35) | Cfa | E, N | DGW | Cooling and heating |

|

| [32] | RT35 paraffin (35) | Cfa | E | DGW | Cooling and heating |

|

| [33] | RT35 paraffin (29–36) | Aw | E | DGW | Cooling |

|

| [34] | Paraffin wax (18, 26, 32) | - | E | DGW | Cooling |

|

| [35] | Paraffin, MG29 (27) | Bwh | N | DGW | Cooling |

|

| [36] | RT28 paraffin (28) | Cfb | E, N | DGW | Cooling and heating |

|

| [37] | n–octadecane (25.05–26.11) n-eicosane (33.63–35.64) n-docosane (42.21–43.15) | Dwa | N | Exterior | Cooling and heating |

|

| [38] | RT27 paraffin (27) | Cfa | E | DGW | Cooling and heating |

|

| [39] | n-eicosane (37) | - | N | DGW | Cooling |

|

| [40] | Different PCM variables (20, 30, 40, 50) | Warm, mixed, and cold | N | DGW | Cooling and heating |

|

| [41] | Paraffin wax | - | N | Glazing window | - |

|

| [42] | Paraffin MG29 (27–29) | Cfa | E, N | TGW | Cooling and heating |

|

| [43] | Paraffin wax (18, 22, 25, 28. 31) | Dfb | E, N | TGW | Cooling |

|

| [44] | (25–28) | Dwa | E, N | FGW | Heating |

|

| Ref. | PCM Type (MT °C) | Climate Code | Study Type | Shading Position of the GU | Application | Findings and Remarks |

|---|---|---|---|---|---|---|

| [48] | Salt hydrate (26–30) | Cfb | E | Interior | Cooling and heating |

|

| [49] | Paraffin (28, 29, 30) n-Eicosane (37) | Cfa | N | Interior | Cooling |

|

| [50] | Paraffin RT28HC (27–29) | Csb | E | Interior | Heating |

|

| [51] | Paraffin RT28HC (27–29) | Csb | E | Interior | Cooling |

|

| [52] | Paraffin RT28HC (27–29) | Csb | N | Interior | Cooling |

|

| [53] | n–octadecane (25.05–26.11) n-eicosane (33.63–35.64) n-docosane (42.21–43.15) | Dwa | N | Exterior | Cooling and heating |

|

| [54] | PX35 as an organic PCM (35) | Cfa | E, N | Between the panes | Cooling |

|

| [55] | mixture of fiber and paraffin (20.7) | Cfb | E, N | Between the panes | Cooling and heating |

|

| Ref. | PCM Type (MT °C) | Solar Cell Type | Climate Code | Study Type | Application | Findings and Remarks |

|---|---|---|---|---|---|---|

| [56] | RT42 (42) RT55 (55) | a-Si | Cfa, Dfb Bwh | N | Cooling and heating |

|

| [57] | RT35 (35) | a-Si | - | N | Cooling and heating |

|

| [58] | BioPCM -M182/Q25 (25) | monocrystalline silicon | Bwh BSk, | N | Cooling and heating |

|

| [59] | BioPcm-Q23 (23) | a-Si | Cfa, Bsk, Bwh | N | Cooling and heating |

|

| [60] | RT35HC (34–36) | Silicon wafer | Bwh | N | Cooling |

|

| [61] | (27–29) for cooling (18–20) for heating | CdTe | Cfa | N | Cooling and heating |

|

| Ref. | Solar Cell Type | Climate Code | Study Type | Envelope Element | Application | Findings and Remarks |

|---|---|---|---|---|---|---|

| [62] | a-Si + TiO2 nano-coating | Cfa | E | DGW | Cooling and heating |

|

| [63] | CdTe | Bsh | E | DGW + a sheet | Cooling |

|

| [64] | CdTe | Cfa | N | DGW | Cooling |

|

| [65] | a-Si | Cfa | E, N | DGW | Cooling and heating |

|

| [66] | CdTe | Dwa, Cfa, Cwa, Cwb | E, N | DGW | Cooling and heating |

|

| [67] | CdTe | Bsk, Dwa, Cfa, Cwa, Cwb | E, N | DGW | Cooling and heating |

|

| [68] | CdTe | Cfa, Dwb, Cwa | E, N | DGW | Cooling and heating |

|

| [69] | CdTe | Cfb | E | DGW | Cooling |

|

| [70] | CdTe | Cfa | E, N | DGW | Cooling and heating |

|

| [79] | CdTe, a-Si, DSSC, PSC | - | N | DGW | Cooling and heating |

|

| Ref. | Climate Code | Study Type | Shading Position of the GU | Application | Findings and Remarks |

|---|---|---|---|---|---|

| [80] | Bwh | E, N | External | Cooling and heating |

|

| [81] | Aw | E, N | External | Cooling and heating |

|

| [82] | Dfb | E | External | Cooling spring |

|

| [83] | Cfb | E | External | Cooling |

|

| [84] | Csa, Cfb | N | External | Cooling and heating |

|

| [85] | Dwa | E, N | Internal | Cooling and heating |

|

| [86] | Dwa | E, N | Internal | Cooling and heating |

|

| [87] | Cfa, Dfa | E, N | Internal | Cooling and heating |

|

| [88] | Cfa | E, N | Between the panes | Cooling and heating |

|

| Ref. | Chromogenic Material | Climate Code | Study Type | Envelope Element | Application | Findings and Remarks |

|---|---|---|---|---|---|---|

| [90] | NaCl + HPMC + Water | Cfa | N | DGW | Cooling and heating |

|

| [91] | n-alkane mixture | Cfa | E | TGW | Cooling and heating |

|

| [92] | HPC polymer | Cfb | N | DGW | Cooling and heating |

|

| [93] | parallel slat | Cfb, Csa, Dfb, Af | E, N | DGW | Cooling and heating |

|

| [94] | parallel slat | Cfb | N | DGW | Cooling and heating |

|

| [95] | VO2 | Cfa | E | DGW | Cooling and heating |

|

| [96] | VO2 | Cfa | N | DGW, TGW | Cooling and heating |

|

| [97] | Tetra-fish-inspired layer | Cwa, Aw, Dwa, Af | E | SGW | Cooling and heating |

|

| [98] | Six different thermotropic materials | Cfa | N | DGW | Cooling and heating |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arasteh, H.; Maref, W.; Saber, H.H. Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study. Energies 2023, 16, 1058. https://doi.org/10.3390/en16031058

Arasteh H, Maref W, Saber HH. Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study. Energies. 2023; 16(3):1058. https://doi.org/10.3390/en16031058

Chicago/Turabian StyleArasteh, Hossein, Wahid Maref, and Hamed H. Saber. 2023. "Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study" Energies 16, no. 3: 1058. https://doi.org/10.3390/en16031058

APA StyleArasteh, H., Maref, W., & Saber, H. H. (2023). Energy and Thermal Performance Analysis of PCM-Incorporated Glazing Units Combined with Passive and Active Techniques: A Review Study. Energies, 16(3), 1058. https://doi.org/10.3390/en16031058