Porosity Assessment in Geological Cores Using 3D Data

Abstract

1. Introduction

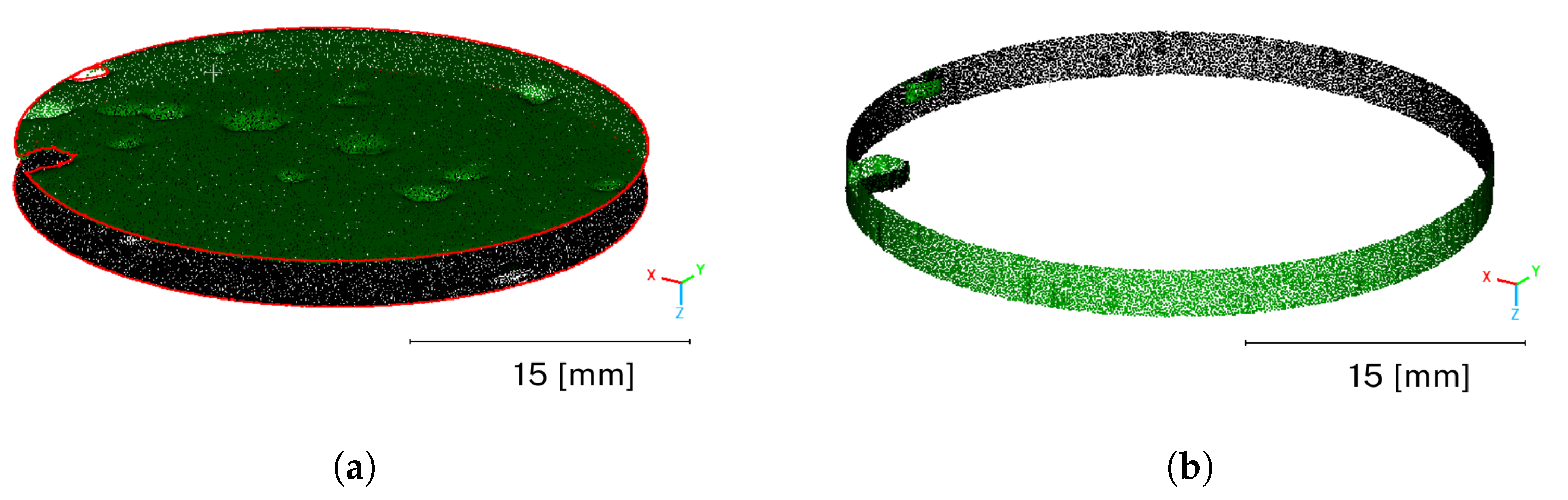

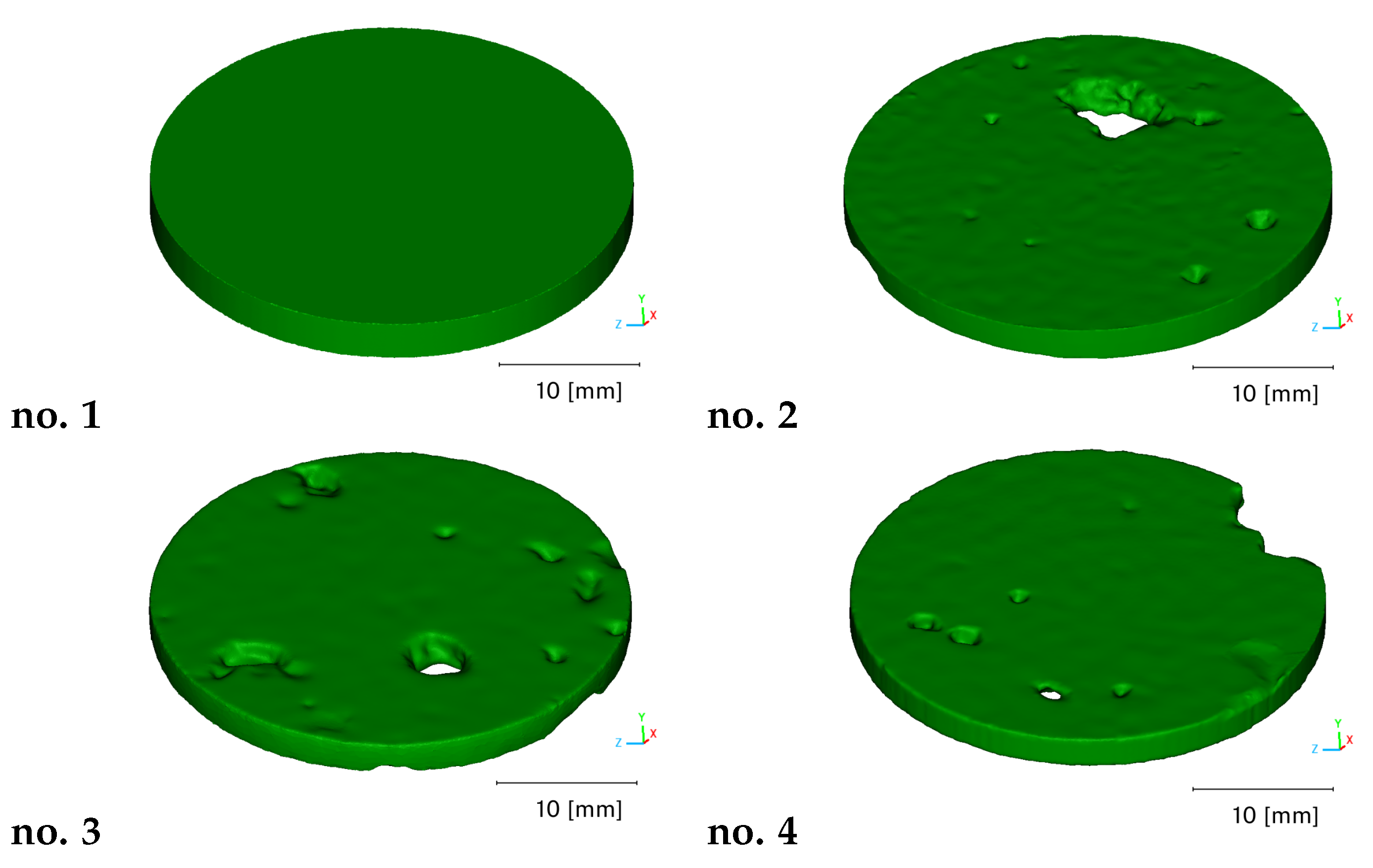

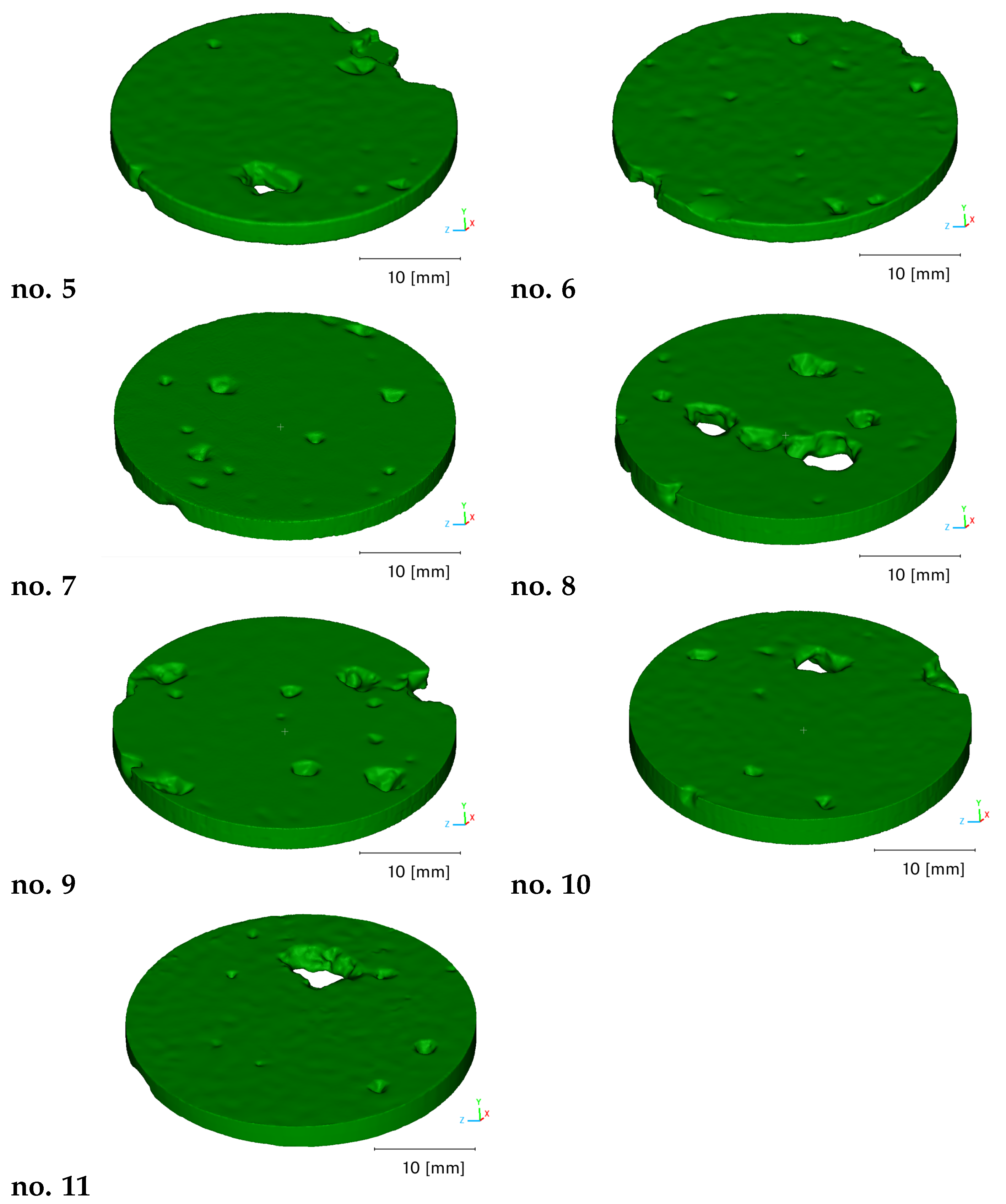

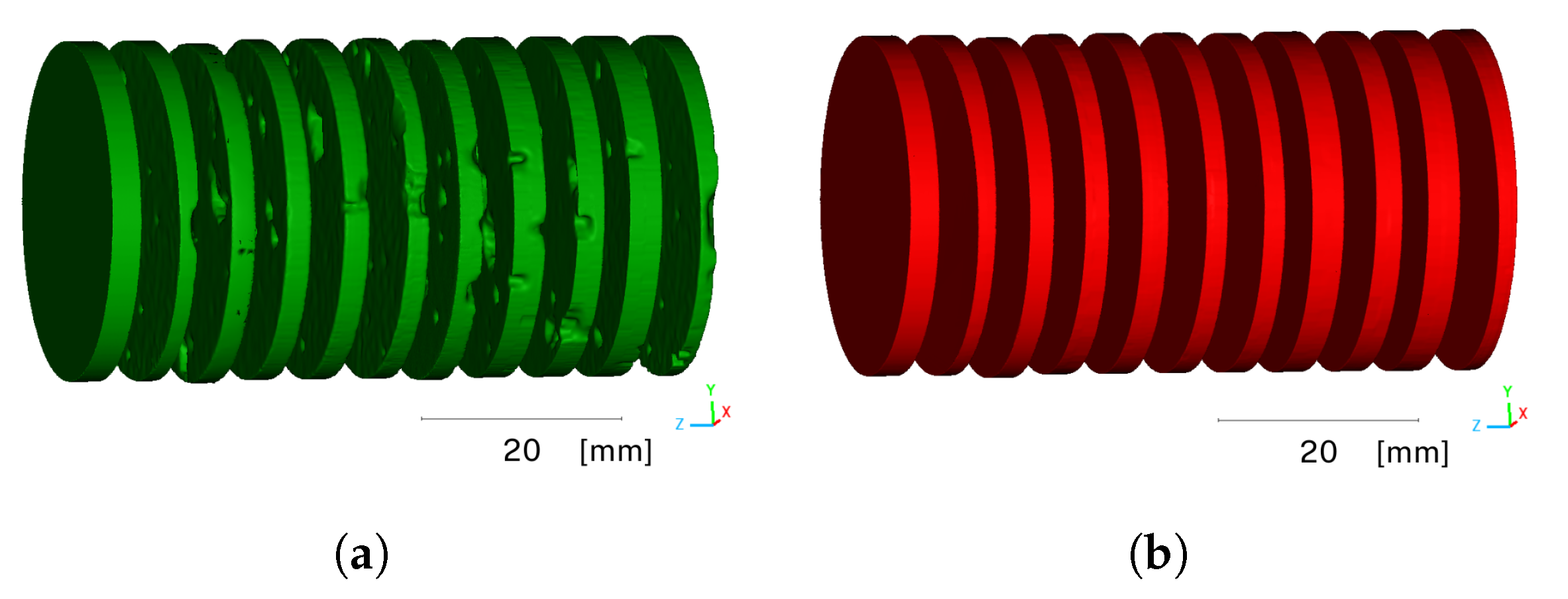

2. Materials and Methods

3. Results

4. Discussion

- (1)

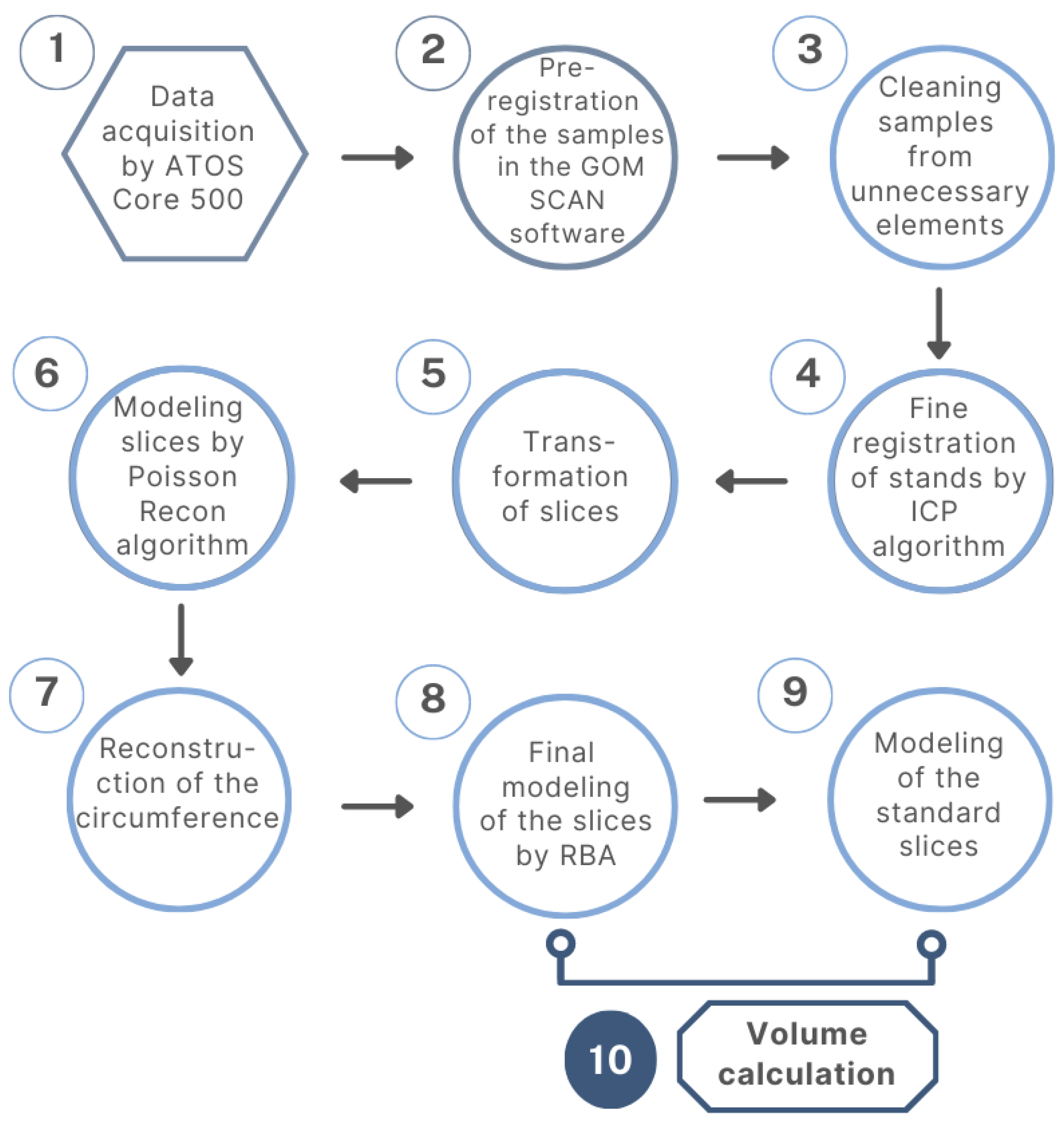

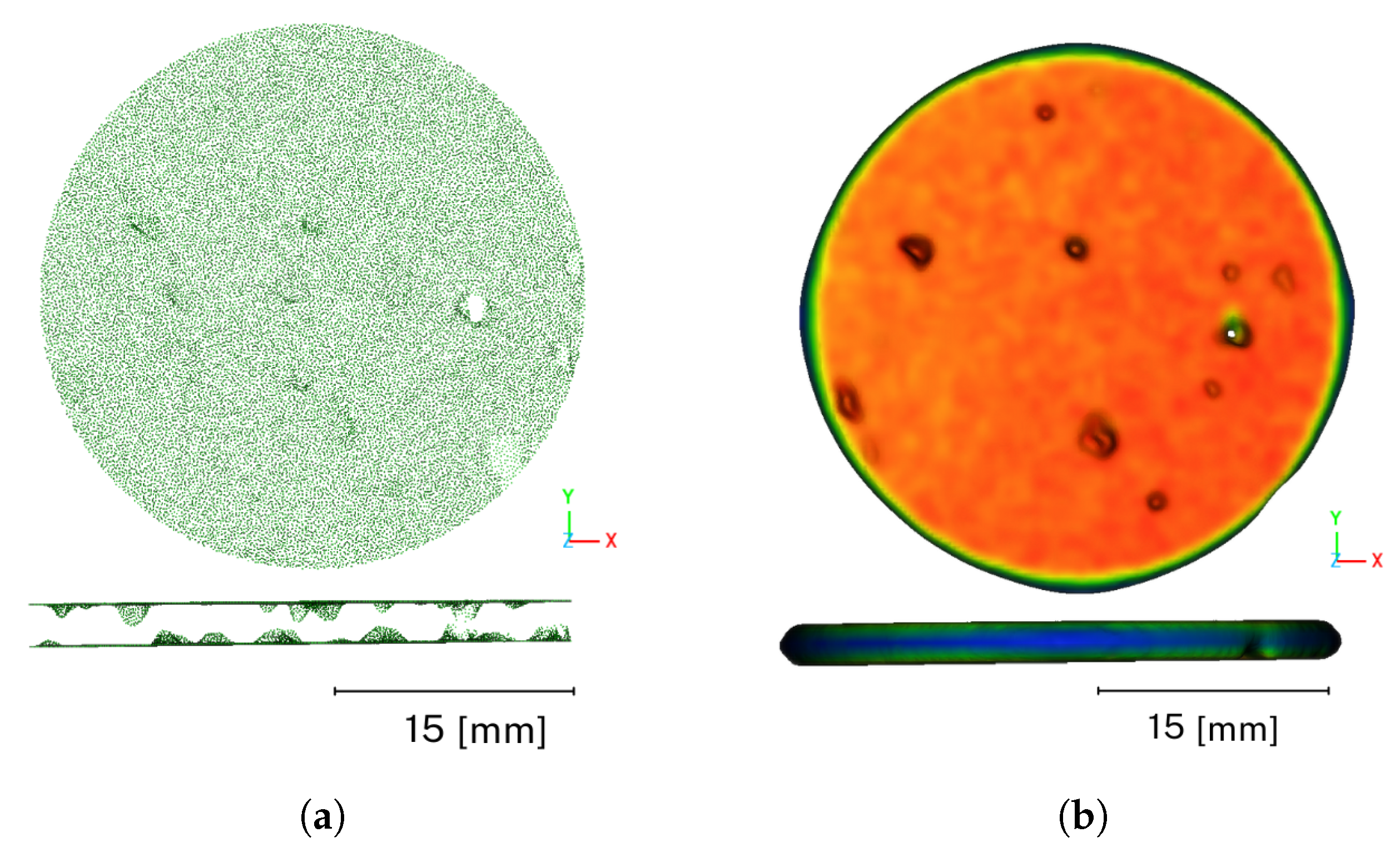

- The optical scanner used enables the detection of pores with the spatial resolution of the scanner, which is theoretically 0.19 mm. Observations during and after the measurement (scanning) indicate that not all holes with this minimum diameter were detected.

- (2)

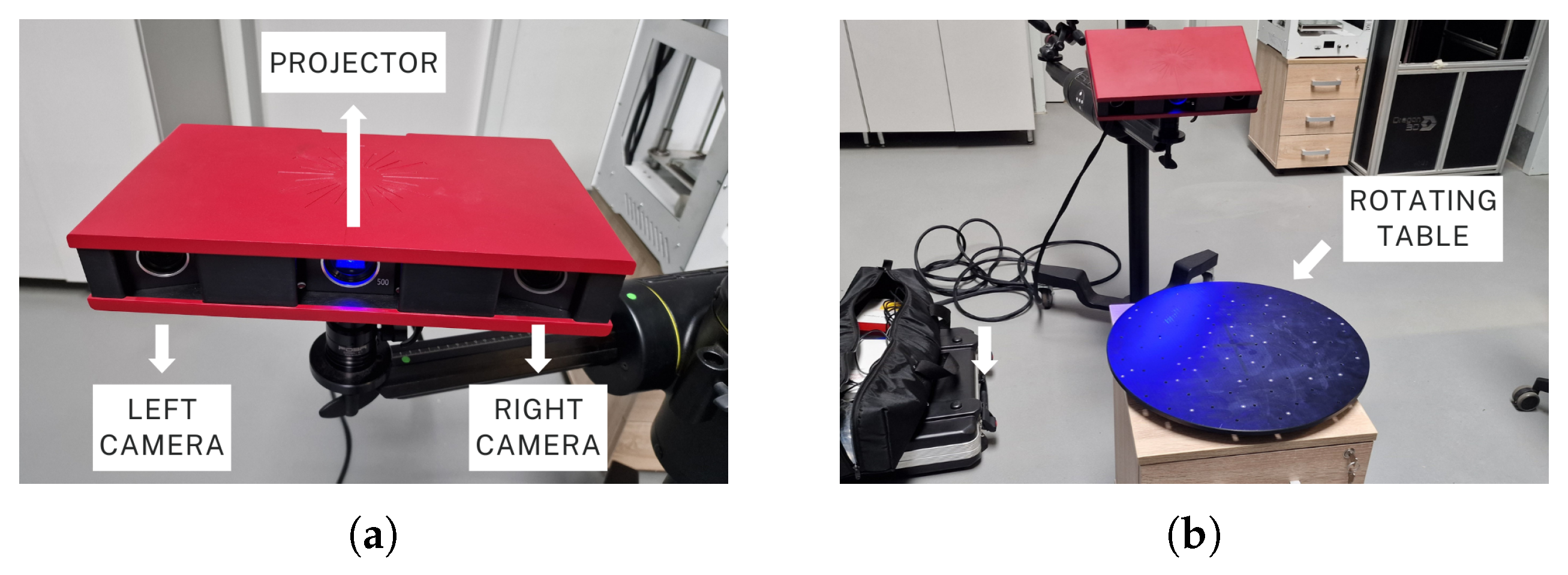

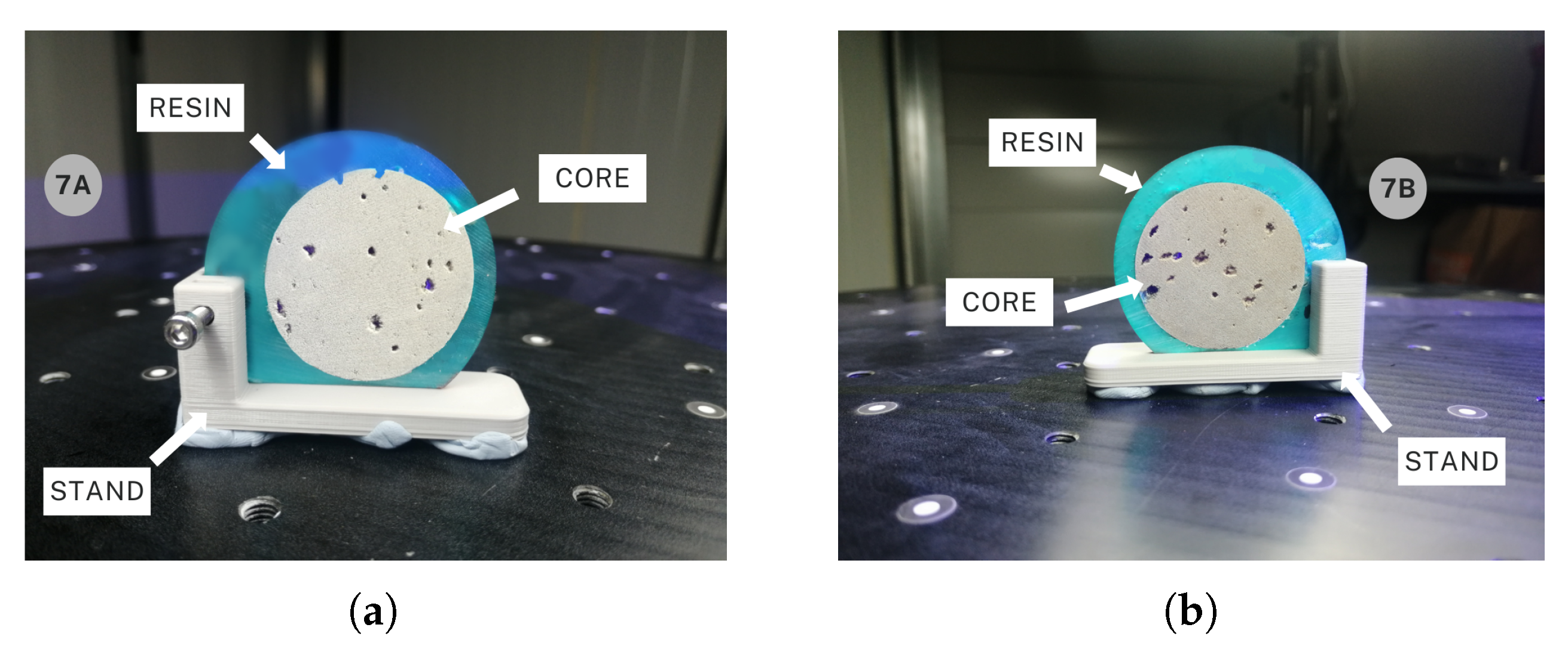

- The slice placed in the stand during the entire scanning process is fixed on a rotating table, which provides an equal pattern of reference points and allows pre-registration. The object cannot be turned upside down to scan the innermost parts of the pores. In addition, optical scanner measurement is possible when at least three reference points are visible. Therefore, the position of the scanner position relative to the table cannot be set below its height. This makes it impossible to capture the full geometry of the holes, especially those with complex structures.

- (3)

- Underexposed areas are also undetectable by the scanner, which was the case for narrow and deep holes.

- (4)

- Incomplete capture of the holes with the scanner, especially the deeper parts, can result in erroneous surface reconstruction with the Poisson algorithm. Moreover, a void, which should be open because it occurs on several slices, may have been closed in the wrong place.

- (5)

- The circumferences of the slices were created using the perimeter line of the two edges of the slice: the top and bottom. They met at the mid-height of the slice. In fact, the shape of this cylinder plane should run smoothly.

- (6)

- Calculation of the volume of standard slices with filled voids was based on a model created by fitting planes to real surfaces. The real surfaces of the slices are not perfectly flat, and as the result, the volume was larger or absent in some places.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BPA | Ball-Pivoting Algorithm |

| ICP | Iterative Closest Point |

| RMS | Root Mean Square |

References

- Lu, J.; Meng, X.; Wang, Y.; Yang, Z. Prediction of coal seam details and mining safety using multicomponent seismic data: A case history from China. Geophysics 2016, 81, B149–B165. [Google Scholar] [CrossRef]

- Kozieł, K.; Skoczylas, N.; Soroko, K.; Gola, S. Gas and Dolomite Outbursts in Ore Mines—Analysis of the Phenomenon and the Energy Balance. Energies 2020, 13, 2999. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Li, X.; Zhou, J.; Wang, S.; Liu, B. Some developments and new insights of environmental problems and deep mining strategy for cleaner production in mines. J. Clean. Prod. 2019, 210, 1562–1578. [Google Scholar] [CrossRef]

- Ziętek, B.; Banasiewicz, A.; Zimroz, R.; Szrek, J.; Gola, S. A Portable Environmental Data-Monitoring System for Air Hazard Evaluation in Deep Underground Mines. Energies 2020, 13, 6331. [Google Scholar] [CrossRef]

- Hebda-Sobkowicz, J.; Gola, S.; Zimroz, R.; Wyłomańska, A. Pattern ofH2Sconcentration in a deep copper mine and its correlation with ventilation schedule. Measurement 2019, 140, 373–381. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, R.; Dong, S.; Wang, W.; Sun, H.; Mao, D. Scanning for water hazard threats with sequential water releasing tests in underground coal mines. J. Hydrol. 2020, 590, 125350. [Google Scholar] [CrossRef]

- Bocheńska, T.; Fiszer, J.; Kalisz, M. Prediction of groundwater inflow into copper mines of the Lubin Glogow Copper District. Environ. Geol. 2000, 39, 587–594. [Google Scholar] [CrossRef]

- Motyka, J.; Czop, M. Influence of Karst Phenomena on Water Inflow to Zn-Pb Mines in the Olkusz District (S Poland). Environ. Earth Sci. 2010, 449–454. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, Y.; Tan, T.; Zhang, L.; Zhu, S.; Xu, F. Evolution and modeling of mine water inflow and hazard characteristics in southern coalfields of China: A case of Meitanba mine. Int. J. Min. Sci. Technol. 2022, 32, 513–524. [Google Scholar] [CrossRef]

- Bonacci, O.; Ljubenkov, I.; Roje-Bonacci, T. Karst flash floods: An example from the Dinaric karst (Croatia). Nat. Hazards Earth Syst. Sci. 2006, 6, 195–203. [Google Scholar] [CrossRef]

- Krokosky, E.M.; Husak, A. Strength characteristics of basalt rock in ultra-high vacuum. J. Geophys. Res. 1968, 73, 2237–2247. [Google Scholar] [CrossRef]

- Szlavin, J. Relationships between some physical properties of rock determined by laboratory tests. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1974, 11, 57–66. [Google Scholar] [CrossRef]

- Van Eeckhout, E.M.; Peng, S.S. The effect of humidity on the compliances of coal mine shales. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1975, 12, 335–340. [Google Scholar] [CrossRef]

- Li, G.C.; Qi, C.C.; Sun, Y.T.; Tang, X.L.; Hou, B.Q. Experimental Study on the Softening Characteristics of Sandstone and Mudstone in Relation to Moisture Content. Shock Vib. 2017, 2017, 4010376. [Google Scholar] [CrossRef]

- Shen, Y.J.; Wang, Y.Z.; Zhao, X.D.; Yang, G.S.; Jia, H.L.; Rong, T.L. The influence of temperature and moisture content on sandstone thermal conductivity from a case using the artificial ground freezing(AGF) method. Cold Reg. Sci. Technol. 2018, 155, 149–160. [Google Scholar] [CrossRef]

- Kalisz, M.; Niedbał, M. Wpływ odwadniania utworów triasowych w trakcie głȩbienia szybu R–XI na warunki hydrodynamiczne i powierzchniowe w północnej czȩści OG “Rudna”. In Materiały Sympozjum Naukowo–Technicznego “Problemy Hydrogeologiczne Górnictwa Rud Miedzi”; KGHM Polska Miedź S.A.: Lubin, Poland, 2004; pp. 148–160. [Google Scholar]

- Butra, J. Rozwój górnictwa rud miedzi [Development in copper ore mining]. Rudy i Metale Nieżelazne 2005, 50, 481–484. [Google Scholar]

- Chudy, K.; Worsa-Kozak, M.; Pikuła, M. Rozwój metod rozpoznania warunków hydrogeologicznych na potrzeby wykonywania pionowych wyrobisk udostȩpniaja̧cych złoże–przykład LGOM. Przegla̧d Geologiczny 2017, 65, 1035–1043. [Google Scholar]

- Taud, H.; Martinez-Angeles, R.; Parrot, J.; Hernandez-Escobedo, L. Porosity estimation method by X-ray computed tomography. J. Pet. Sci. Eng. 2005, 47, 209–217. [Google Scholar] [CrossRef]

- Galkin, S.; Efimov, A.; Krivoshchekov, S.; Savitskiy, Y.; Cherepanov, S. X-ray tomography in petrophysical studies of core samples from oil and gas fields. Russ. Geol. Geophys. 2015, 56, 782–792. [Google Scholar] [CrossRef]

- Romano, C.; Minto, J.M.; Shipton, Z.K.; Lunn, R.J. Automated high accuracy, rapid beam hardening correction in X-Ray Computed Tomography of multi-mineral, heterogeneous core samples. Comput. Geosci. 2019, 131, 144–157. [Google Scholar] [CrossRef]

- Geiger, J.; Hunyadfalvi, Z.; Bogner, P. Analysis of small-scale heterogeneity in clastic rocks by using computerized X-ray tomography (CT). Eng. Geol. 2009, 103, 112–118. [Google Scholar] [CrossRef]

- Sergeevich, O.M.; Valeriyevich, R.P.; Aleksandrovich, S.I.; Tarasovich, L.V. The application of X-ray Micro Computed Tomography (Micro-CT) of core sample for estimation of physicochemical treatment efficiency. In Proceedings of the SPE Russian Petroleum Technology Conference, Moscow, Russia, 26–28 October 2015. [Google Scholar]

- Zhang, P.; Lee, Y.I.; Zhang, J. A review of high-resolution X-ray computed tomography applied to petroleum geology and a case study. Micron 2019, 124, 102702. [Google Scholar] [CrossRef] [PubMed]

- Bai, Y.; Berezovsky, V.; Popov, V. Digital core 3d reconstruction based on micro-ct images via a deep learning method. In Proceedings of the 2020 International Conference on High Performance Big Data and Intelligent Systems (HPBD&IS), Shenzhen, China, 23 May 2020; pp. 1–6. [Google Scholar]

- Liu, D.; Zhao, Z.; Cai, Y.; Sun, F.; Zhou, Y. Review on Applications of X-ray Computed Tomography for Coal Characterization: Recent Progress and Perspectives. Energy Fuels 2022, 36, 6659–6674. [Google Scholar] [CrossRef]

- Wiltsche, M.; Donoser, M.; Kritzinger, J.; Bauer, W. Automated serial sectioning applied to 3D paper structure analysis. J. Microsc. 2011, 242, 197–205. [Google Scholar] [CrossRef]

- Echlin, M.P.; Burnett, T.L.; Polonsky, A.T.; Pollock, T.M.; Withers, P.J. Serial sectioning in the SEM for three dimensional materials science. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100817. [Google Scholar] [CrossRef]

- Mehra, A.; Howes, B.; Manzuk, R.; Spatzier, A.; Samuels, B.M.; Maloof, A.C. A Novel Technique for Producing Three-Dimensional Data Using Serial Sectioning and Semi-Automatic Image Classification. Microsc. Microanal. 2022, 28, 2020–2035. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.; Glover, P.W.; Zhao, P.; Li, D. 3D digital rock modeling of the fractal properties of pore structures. Mar. Pet. Geol. 2020, 122, 104706. [Google Scholar] [CrossRef]

- Szrek, J.; Zimroz, R.; Wodecki, J.; Michalak, A.; Góralczyk, M.; Worsa-Kozak, M. Application of the Infrared Thermography and Unmanned Ground Vehicle for Rescue Action Support in Underground Mine—The AMICOS Project. Remote Sens. 2020, 13, 69. [Google Scholar] [CrossRef]

- Wróblewski, A.; Wodecki, J.; Trybała, P.; Zimroz, R. A Method for Large Underground Structures Geometry Evaluation Based on Multivariate Parameterization and Multidimensional Analysis of Point Cloud Data. Energies 2022, 15, 6302. [Google Scholar] [CrossRef]

- Haleem, A.; Gupta, P.; Bahl, S.; Javaid, M.; Kumar, L. 3D scanning of a carburetor body using COMET 3D scanner supported by COLIN 3D software: Issues and solutions. Mater. Today Proc. 2021, 39, 331–337. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Pratap Singh, R.; Suman, R. Industrial perspectives of 3D scanning: Features, roles and it’s analytical applications. Sensors Int. 2021, 2, 100114. [Google Scholar] [CrossRef]

- Sedlak, J.; Polzer, A.; Chladil, J.; Slany, M.; Jaros, A. Reverse engineering method used for inspection of stirrer´s gearbox cabinet prototype. MM Sci. J. 2017, 2017, 1877–1882. [Google Scholar] [CrossRef]

- Bernal, C.; De Agustina, B.; Marín, M.M.; Camacho, A.M. Performance evaluation of optical scanner based on blue LED structured light. Procedia Eng. 2013, 63, 591–598. [Google Scholar] [CrossRef]

- Petrides, G.; Clark, J.R.; Low, H.; Lovell, N.; Eviston, T.J. Three-dimensional scanners for soft-tissue facial assessment in clinical practice. J. Plast. Reconstr. Aesthetic Surg. 2021, 74, 605–614. [Google Scholar] [CrossRef] [PubMed]

- Ye, H.; Lv, L.; Liu, Y.; Liu, Y.; Zhou, Y. Evaluation of the Accuracy, Reliability, and Reproducibility of Two Different 3D Face-Scanning Systems. Int. J. Prosthodont. 2016, 29, 213–218. [Google Scholar] [CrossRef] [PubMed]

- Iuliano, L.; Minetola, P. Rapid manufacturing of sculptures replicas: A comparison between 3D optical scanners. In Proceedings of the CIPA 2005 XX International Symposium, Torino, Italy, 26 September–1 October 2005; Volume 26. [Google Scholar]

- Rocchini, C.; Cignoni, P.; Montani, C.; Pingi, P.; Scopigno, R. A low cost 3D scanner based on structured light. Comput. Graph. Forum 2001, 20, 299–308. [Google Scholar] [CrossRef]

- Lazarević, D.; Nedić, B.; Jović, S.; Šarkoćević, Ž.; Blagojević, M. Optical inspection of cutting parts by 3D scanning. Phys. A Stat. Mech. Appl. 2019, 531, 121583. [Google Scholar] [CrossRef]

- Brajlih, T.; Tasic, T.; Igor, D.; Valentan, B.; Hadžistević, M.; Pogačar, V.; Balic, J.; Acko, B. Possibilities of Using Three-Dimensional Optical Scanning in Complex Geometrical Inspection. Strojniški Vestnik 2011, 57, 826–833. [Google Scholar] [CrossRef]

- Duguid, J.O.; Lee, P.C.Y. Flow in Fractured Porous Media. Water Resour. Res. 1977, 13, 558–566. [Google Scholar] [CrossRef]

- Motyka, J.; Pulido-Bosch, A. Karstic phenomena in calcareous-dolomitic rocks and their influence over the inrushes of water in lead-zinc mines in Olkusz region (South of Poland). Int. J. Mine Water 1985, 4, 1–11. [Google Scholar] [CrossRef]

- Motyka, J.; Pulido-Bosch, A.; Borczak, S.; Gisbert, J. Matrix hydrogeological properties of Devonian carbonate rocks of Olkusz (Southern Poland). J. Hydrol. 1998, 211, 140–150. [Google Scholar] [CrossRef]

- Borczak, S.; Motyka, J.; Pulido-Bosch, A. The hydrogeological properties of the matrix of the chalk in the Lublin coal basin (southeast Poland). Hydrol. Sci. J. 1990, 35, 523–534. [Google Scholar] [CrossRef]

- Motyka, J. A conceptual model of hydraulic networks in carbonate rocks, illustrated by examples from Poland. Hydrogeol. J. 1998, 6, 469–482. [Google Scholar] [CrossRef]

- Zuber, A.; Motyka, J. Matrix porosity as the most important parameter of fissured rocks for solute transport at large scales. J. Hydrol. 1994, 158, 19–46. [Google Scholar] [CrossRef]

- Motyka, J.; Postawa, A. Influence of contaminated Vistula River water on the groundwater entering the Zakrzowek limestone quarry, Cracow region, Poland. Environ. Geol. 2000, 39, 398–404. [Google Scholar] [CrossRef]

- Todd, D.K.; Mays, L.W. Groundwater Hydrology, 3rd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2004; pp. 1–656. [Google Scholar]

- Dowgiałło, J.; Kleczkowski, A.; Macioszczyk, T.; Różkowski, A. Słownik Hydrogeologiczny [Hydrogeological Dictionary]; Państwowego Instytutu Geologicznego: Warszawa, Poland, 2002; p. 461. [Google Scholar]

- Duliński, W. Aparat do Badania Przepuszczalności z Uszczelnieniem Pneumatycznym; Wiadomości Naftowe: Kraków, Poland, 1965; Volume 7, pp. 117–118. [Google Scholar]

- ATOS Core Optical 3D Scanner for Quality Control. Brochure. 2020. Available online: https://scanare3d.com/wp-content/uploads/2020/07/GOM_Brochure_ATOS_Core_EN.pdf, (accessed on 16 January 2023).

- Zhang, Z. Iterative point matching for registration of free-form curves and surfaces. Int. J. Comput. Vis. 1994, 13, 119–152. [Google Scholar] [CrossRef]

- Zinßer, T.; Schmidt, J.; Niemann, H. Point set registration with integrated scale estimation. In Proceedings of the International Conference on Pattern Recognition and Image Processing, Bath, UK, 22–25 August 2005; pp. 116–119. [Google Scholar]

- Pomerleau, F.; Colas, F.; Siegwart, R. A review of point cloud registration algorithms for mobile robotics. Found. Trends® Robot. 2015, 4, 1–104. [Google Scholar] [CrossRef]

- Tombari, F.; Remondino, F. Feature-based automatic 3D registration for cultural heritage applications. In Proceedings of the 2013 Digital Heritage International Congress (DigitalHeritage), Marseille, France, 28 October–1 November 2013; Volume 1, pp. 55–62. [Google Scholar] [CrossRef]

- Besl, P.; McKay, N.D. A method for registration of 3-D shapes. IEEE Trans. Pattern Anal. Mach. Intell. 1992, 14, 239–256. [Google Scholar] [CrossRef]

- Chen, Y.; Medioni, G. Object modelling by registration of multiple range images. Image Vis. Comput. 1992, 10, 145–155. [Google Scholar] [CrossRef]

- Rusinkiewicz, S.; Levoy, M. Efficient variants of the ICP algorithm. In Proceedings of the Third International Conference on 3-D Digital Imaging and Modeling, Quebec City, QC, Canada, 28 May–1 June 2001; pp. 145–152. [Google Scholar]

- Kazhdan, M.; Bolitho, M.; Hoppe, H. Poisson Surface Reconstruction. In Proceedings of the Symposium on Geometry Processing; Sheffer, A., Polthier, K., Eds.; The Eurographics Association: Eindhoven, The Netherlands, 2006. [Google Scholar] [CrossRef]

- Kazhdan, M.; Hoppe, H. Screened poisson surface reconstruction. ACM Trans. Graph. 2013, 32, 1–13. [Google Scholar] [CrossRef]

- Alexiou, E.; Bernardo, M.V.; Da Silva Cruz, L.A.; Dmitrovic, L.G.; Duarte, C.; Dumic, E.; Ebrahimi, T.; Matkovic, D.; Pereira, M.; Pinheiro, A.; et al. Point Cloud Subjective Evaluation Methodology based on 2D Rendering. In Proceedings of the 2018 10th International Conference on Quality of Multimedia Experience, QoMEX 2018, Sardinia, Italy, 29–31 May 2018. [Google Scholar] [CrossRef]

- Kazhdan, M.; Chuang, M.; Rusinkiewicz, S.; Hoppe, H. Poisson Surface Reconstruction with Envelope Constraints. Eurographics Symp. Geom. Process. 2020, 39, 173–182. [Google Scholar] [CrossRef]

- Nocerino, E.; Stathopoulou, E.K.; Rigon, S.; Remondino, F. Surface Reconstruction Assessment in Photogrammetric Applications. Sensors 2020, 20, 5863. [Google Scholar] [CrossRef] [PubMed]

- Bernardini, F.; Mittleman, J.; Rushmeier, H.; Silva, C.; Taubin, G. The ball-pivoting algorithm for surface reconstruction. IEEE Trans. Vis. Comput. Graph. 1999, 5, 349–359. [Google Scholar] [CrossRef]

- Cignoni, P.; Callieri, M.; Corsini, M.; Dellepiane, M.; Ganovelli, F.; Ranzuglia, G. MeshLab: An Open-Source Mesh Processing Tool. In Proceedings of the Eurographics Italian Chapter Conference, Salerno, Italy, 2–4 July 2008; Volume 2008, pp. 129–136. [Google Scholar]

- Mariosa, G.; Fioraio, N.; Franchi, A.; Stefano, L.D. Surface Reconstruction from Range Images. In Proceedings of the Smart Tools and Apps for Graphics–Eurographics Italian Chapter Conference; Pintore, G., Stanco, F., Eds.; The Eurographics Association: Eindhoven, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Maruvanchery, V.; Liu, G. Water effects on rock strength and stiffness degradation. Acta Geotech. 2016, 11, 713–737. [Google Scholar] [CrossRef]

| Measuring area [mm] | 500 × 380 |

| Working distance [mm] | 440 |

| Sensor dimensions [mm] | 361 × 205 × 64 |

| Spatial resolution [mm] | 0.19 (0.31) * |

| Weight [kg] | 2.9 |

| Temperature range [°C] | +5 to +40, non-condensing |

| Power supply [V] | 90–230 |

| No. of Slice and Stand | RMS Value [mm] |

|---|---|

| no. 1 | 0.413 |

| no. 2 | 0.294 |

| no. 3 | 0.263 |

| no. 4 | - |

| no. 5 | 0.205 |

| no. 6 | 0.203 |

| no. 7 | 0.206 |

| no. 8 | 0.211 |

| no. 9 | 0.223 |

| no. 10 | 0.210 |

| no. 11 | 0.269 |

| MEAN: | 0.250 |

| Standard (without Voids) [mm] | Real (with Voids) [mm] | Voids [mm] | |

|---|---|---|---|

| no. 1 | 2722.92 | 2722.36 | 0.57 |

| no. 2 | 2021.99 | 1985.41 | 36.58 |

| no. 3 | 2291.52 | 2214.09 | 77.43 |

| no. 4 | 2287.05 | 2228.79 | 58.26 |

| no. 5 | 2402.19 | 2296.07 | 106.12 |

| no. 6 | 2131.82 | 2117.95 | 13.87 |

| no. 7 | 2291.45 | 2267.89 | 23.57 |

| no. 8 | 2753.07 | 2542.97 | 210.10 |

| no. 9 | 2343.45 | 2259.65 | 83.80 |

| no. 10 | 2753.88 | 2674.08 | 79.80 |

| no. 11 | 2044.86 | 1971.82 | 73.04 |

| 26,044.21 | 25,281.08 | 763.13 | |

| 100% | 97.07% | 2.93% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kujawa, P.; Chudy, K.; Banasiewicz, A.; Leśny, K.; Zimroz, R.; Remondino, F. Porosity Assessment in Geological Cores Using 3D Data. Energies 2023, 16, 1038. https://doi.org/10.3390/en16031038

Kujawa P, Chudy K, Banasiewicz A, Leśny K, Zimroz R, Remondino F. Porosity Assessment in Geological Cores Using 3D Data. Energies. 2023; 16(3):1038. https://doi.org/10.3390/en16031038

Chicago/Turabian StyleKujawa, Paulina, Krzysztof Chudy, Aleksandra Banasiewicz, Kacper Leśny, Radosław Zimroz, and Fabio Remondino. 2023. "Porosity Assessment in Geological Cores Using 3D Data" Energies 16, no. 3: 1038. https://doi.org/10.3390/en16031038

APA StyleKujawa, P., Chudy, K., Banasiewicz, A., Leśny, K., Zimroz, R., & Remondino, F. (2023). Porosity Assessment in Geological Cores Using 3D Data. Energies, 16(3), 1038. https://doi.org/10.3390/en16031038