Characteristics of Sludge from the Treatment of Soilless Plant Cultivation Wastewater in a Rotating Electrobiological Disc Contactor (REBDC)

Abstract

1. Introduction

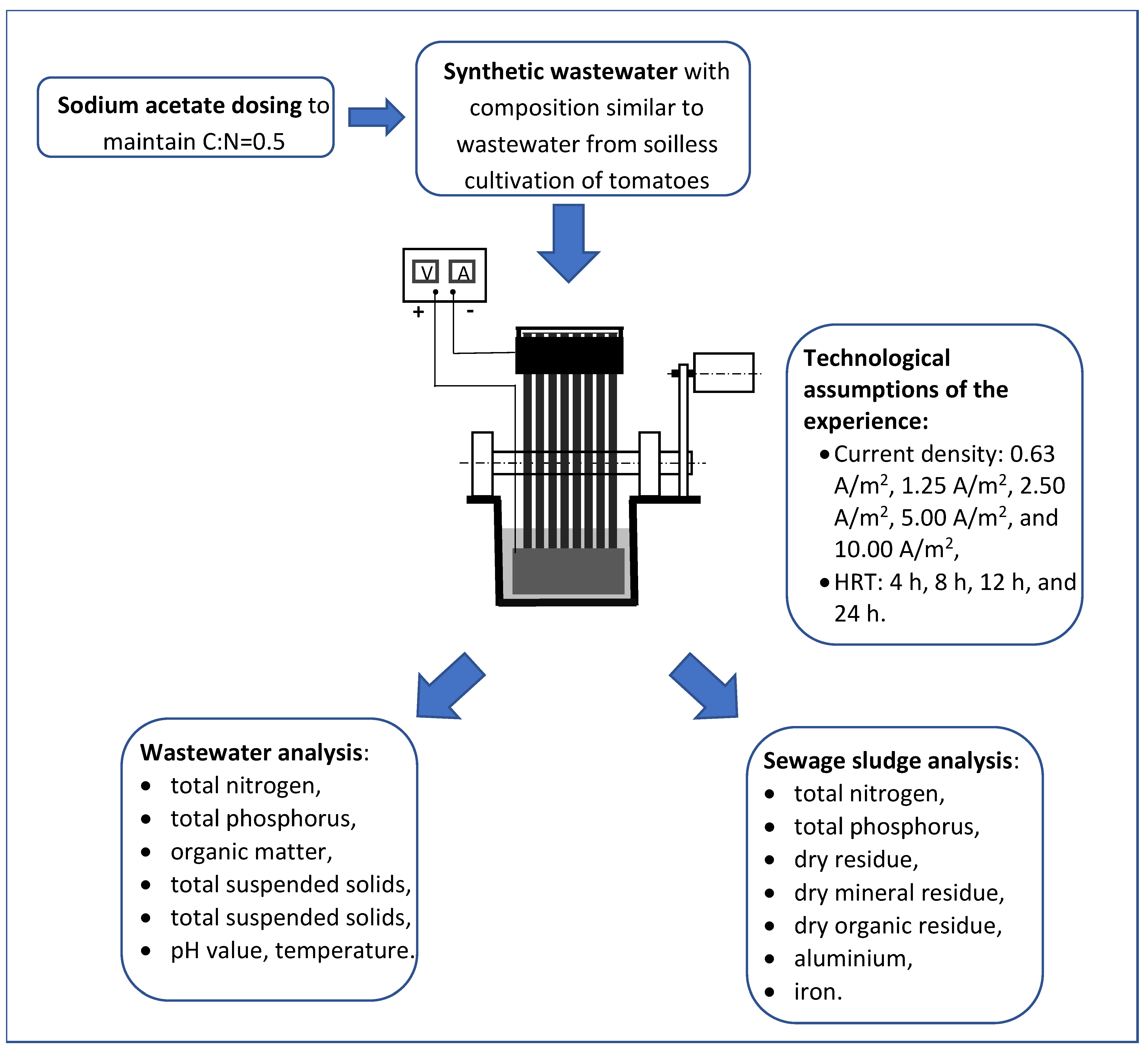

2. Materials and Methods

2.1. Wastewater Composition

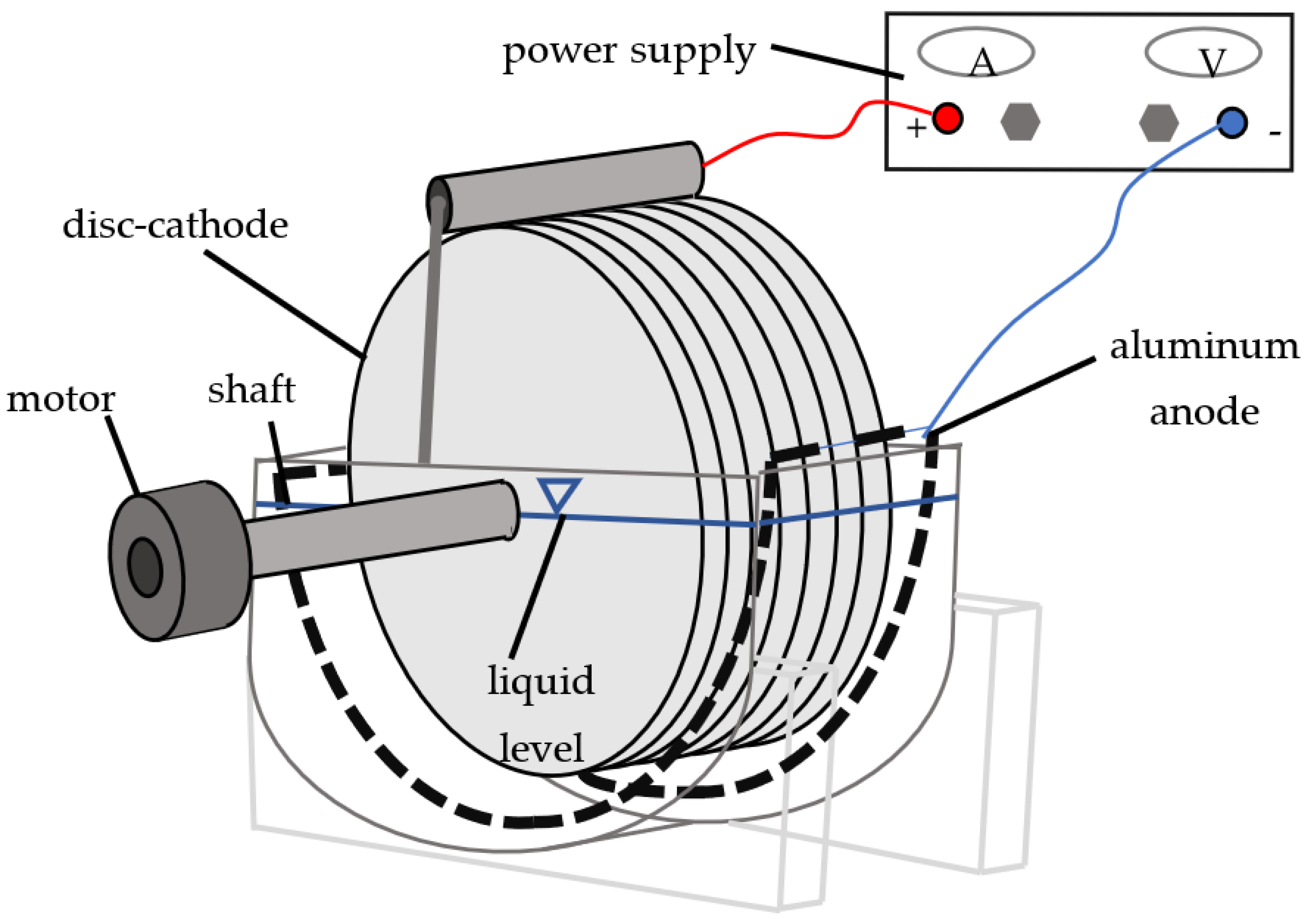

2.2. Experimental Model

- Total nitrogen, measured on a Total Organic Carbon Analyzer TOC-L CPH/CPN with TNM-L device (Shimadzu Corporation, Kyoto, Japan) using the method of oxidative combustion chemiluminescence;

- Total phosphorus (measurement accuracy to 0.01 mgP/L), measured on a UV-VIS 5000 DR spectrophotometer (HACH Lange, Düsseldorf, Germany) using the HACH Lange LCK 348–350 method;

- Organic matter, expressed as the COD value and measured with the bichromate method (PN-74/C-04578/03);

- Total suspended solids, measured using the gravimetric method (PN-EN 872:2007);

- pH value (measurement accuracy to 0.01 pH), temperature (exact to 1 °C), measured using a CP-105 pH meter (Elmetron, Zabrze, Poland).

- Total nitrogen, by oxidative incineration chemiluminescence (Total Organic Carbon Analyzer TOC-L CPH/CPN) with a TNM-L device (Shimadzu Corporation, Kyoto, Japan)

- Total phosphorus, with the sludge digested using perchloric and nitric acids and measured with the HACH Lange LCK 348–350 method and a UV-VIS 5000 DR spectrophotometer (HACH Lange, Düsseldorf, Germany);

- Dry residue, using the gravimetric method (PN-EN 12880:2004);

- Dry mineral residue and dry organic residue, using the gravimetric method (PN-EN 12879:2004),

- Aluminium, with the sludge digested by perchloric and nitric acids, measured by the HACH Lange LCK 301 method using a UV-VIS 5000 DR spectrophotometer (HACH Lange, Düsseldorf, Germany),

- Iron, with the sludge digested by perchloric and nitric acids, measured using the HACH Lange LCK 321 method with a UV-VIS 5000 DR spectrophotometer (HACH Lange, Düsseldorf, Germany).

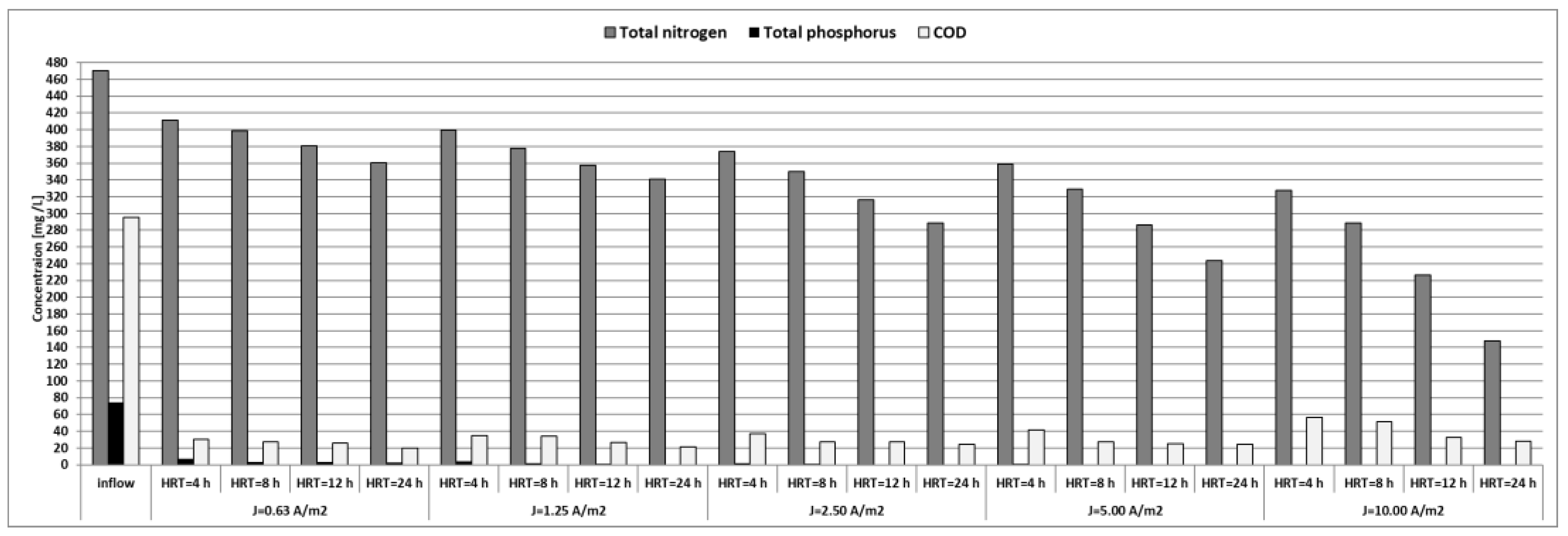

3. Results and Discussion

3.1. Characteristics of the Biofilm Immobilized on the Disks

3.2. Quantitative and Qualitative Characteristics of Sewage Sludge Generated in the Electrobiological Disk Contactor

4. Conclusions

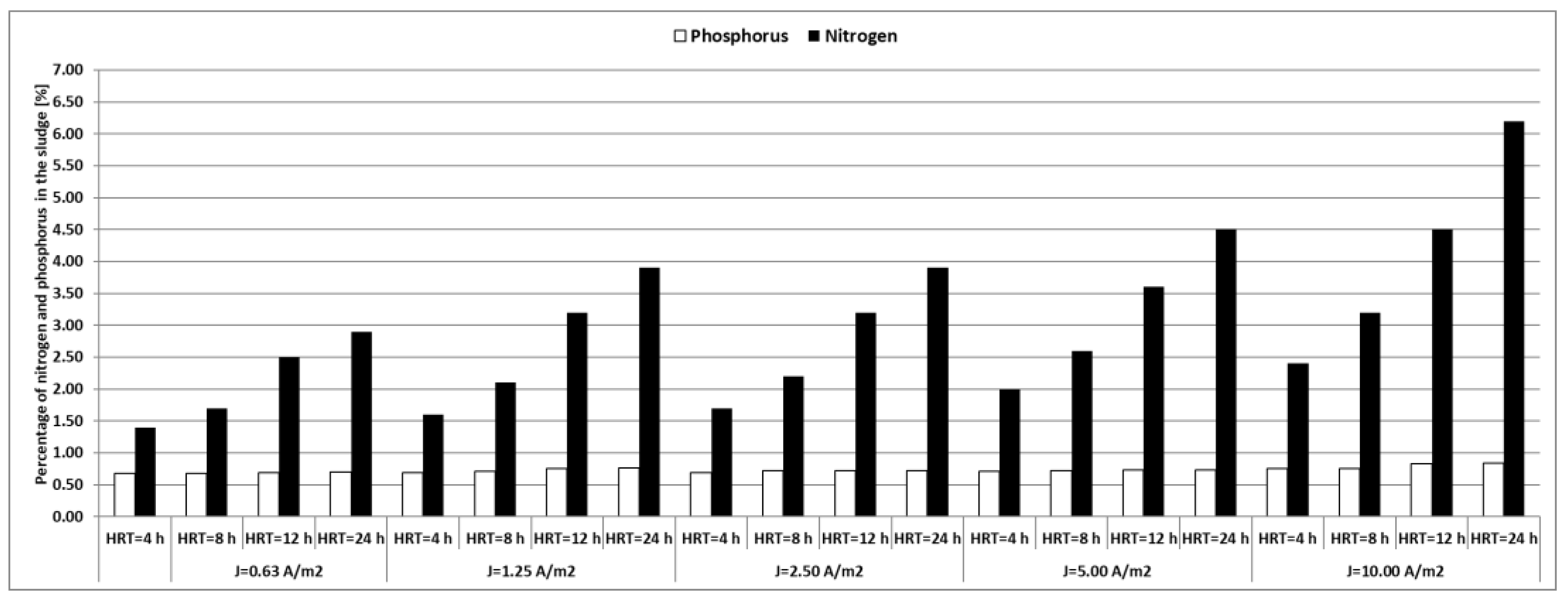

- Increasing the electrical current density in the rotating electrobiological contactor resulted in increased percentage content of phosphorus and nitrogen in the dry matter of the suspended solids. Phosphorous content accounted for 0.7% to 0.8%, whereas nitrogen content accounted for 1.4% to 6.2% of sludge dry matter.

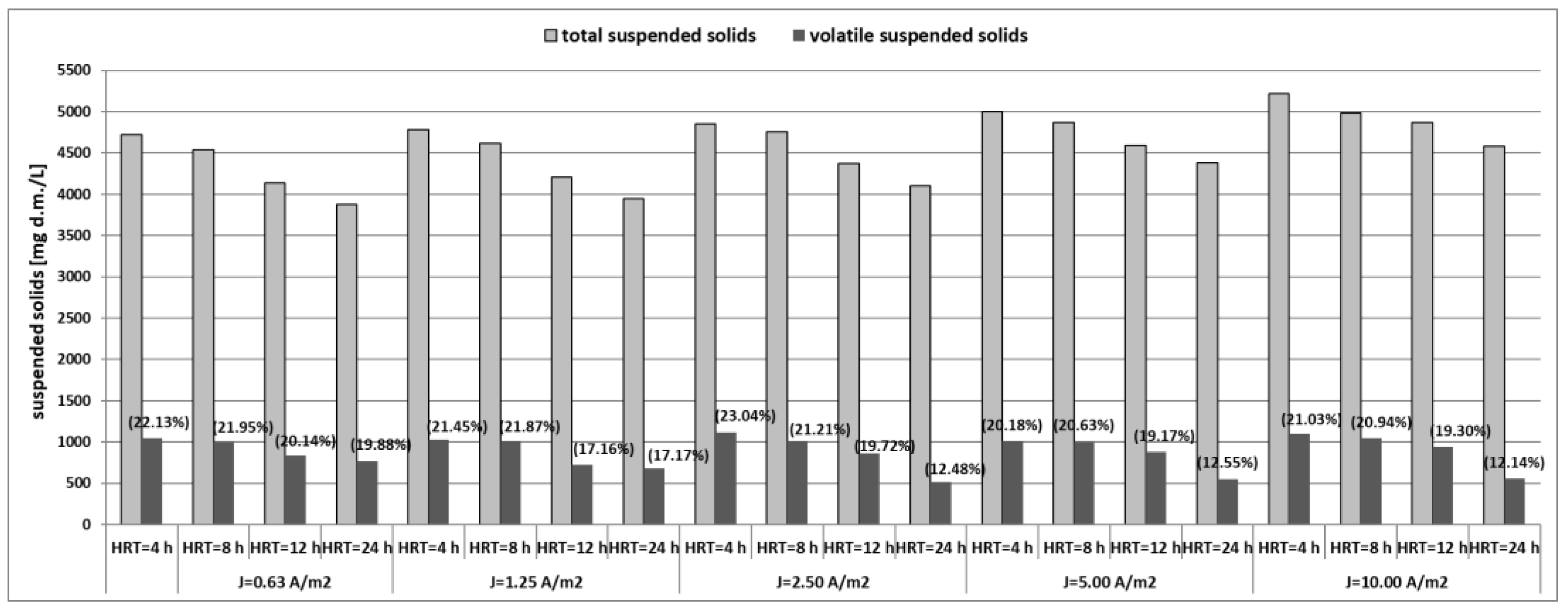

- The increase in electrical current density caused an increase in the volume of sludge outflowing from the REBDC, whereas HRT extension at a given current density resulted in a lower volume of sludge produced and in a lower percentage content of organic substances.

- The very low percentage content of organic matter in the suspended solids in the effluent from the rotating electrobiological contactor (from 12.14 to 23.04%) means that the sludge formed during treatment of wastewater from soilless tomato cultivation is stabilized and does not require additional stabilizing measures if intended for use in agriculture.

- Due to the lack of a potential source of sanitary contamination of the sludge, there is no risk of it being contaminated with eggs of Ascaris sp., Trichuris sp., or Toxocara sp. parasites or pathogenic bacteria from the genus Salmonella, which would exclude its application in agriculture and for reclamation of soils intended for agricultural purposes.

- Sludge from soilless tomato cultivation may be used as a source of nitrogen, phosphorus, and carbon, and may serve as a viable alternative to conventional mineral fertilizers applied in agriculture.

- The present study results confirm that larger amounts of sludge are produced in direct current (DC)-mode aerobic REBDCs than in alternating current (AC)-mode anaerobic reactors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Putra, P.A.; Yuliando, H. Soilless culture system to support water use efficiency and product quality: A review. Agric. Agric. Sci. Procedia 2015, 3, 283–288. [Google Scholar] [CrossRef]

- Mielcarek, A.; Rodziewicz, J.; Janczukowicz, W.; Dobrowolski, A. Analysis of wastewater generated in greenhouse soilless tomato cultivation in central Europe. Water 2019, 11, 2538. [Google Scholar] [CrossRef]

- Saxena, P.; Bassi, A. Removal of nutrients from hydroponic greenhouse effluent by alkali precipitation and algae cultivation method. J. Chem. Technol. Biotechnol. 2013, 88, 858–863. [Google Scholar] [CrossRef]

- Daneshgar, S.; Callegari, A.; Capodaglio, A.G.; Vaccari, D. The potential phosphorus crisis: Resource conservation and possible escape technologies: A review. Resources 2018, 7, 37. [Google Scholar] [CrossRef]

- Moghiseh, Z.; Rezaee, A.; Dehghani, S. Minimization of hazardous sludge production using a bioelectrochemical system supplied by an alternating current electric field. Bioelectrochemistry 2020, 132, 107446. [Google Scholar] [CrossRef]

- Bryszewski, K.Ł.; Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Jóźwiakowski, K. Investigation on the improved electrochemical and bio-electrochemical treatment processes of soilless cultivation drainage (SCD). Sci. Total Environ. 2021, 783, 146846. [Google Scholar] [CrossRef]

- Koide, S.; Satta, N. Separation performance of ionexchange membranes for electrolytes in drainage nutrient solutions subjected to electrodialysis. Biosyst. Eng. 2004, 87, 89–97. [Google Scholar] [CrossRef]

- Gagnon, V.; Maltais-Landry, G.; Puigagut, J.; Chazarenc, F.; Brisson, J. Treatment of hydroponics wastewater using constructed wetlands in winter conditions. Water Air Soil Pollut. 2010, 212, 483–490. [Google Scholar] [CrossRef]

- Park, J.-H.; Kim, S.-H.; Delaune, R.D.; Cho, J.-S.; Heo, J.-S.; Ok, Y.S.; Seo, D.-C. Enhancement of nitrate removal in constructed wetlands utilizing a combined autotrophic and heterotrophic denitrification technology for treating hydroponic wastewater containing high nitrate and low organic carbon concentrations. Agric. Water Manag. 2015, 162, 1–14. [Google Scholar] [CrossRef]

- Park, J.B.K.; Craggs, R.J.; Sukias, J.P.S. Treatment of hydroponic wastewater by denitrification filters using plant prunings as the organic carbon source. Bioresour. Technol. 2008, 99, 2711–2716. [Google Scholar] [CrossRef]

- El-Abbassi, A.; Khayet, M.; Hafidi, A. Micellar enhanced ultrafiltration process for the treatment of olive mill wastewater. Water Res. 2011, 45, 4522–4530. [Google Scholar] [CrossRef]

- Castellar, J.A.C.; Formosa, J.; Fernández, A.I.; Jové, P.; Bosch, M.G.; Morató, J.; Brixe, H.; Arias, C.A. Cork as a sustainable carbon source for nature-based solutions treating hydroponic wastewaters—Preliminary batch studies. Sci. Total Environ. 2019, 650, 267–276. [Google Scholar] [CrossRef] [PubMed]

- Jóźwiak, T.; Mielcarek, A.; Janczukowicz, W.; Rodziewicz, J.; Majkowska-Gadomska, J.; Chojnowska, M. Hydrogel chitosan sorbent application for nutrient removal from soilless plant cultivation wastewater. Environ. Sci. Pollut. Res. 2018, 25, 18484–18497. [Google Scholar] [CrossRef] [PubMed]

- Dunets, C.S.; Zheng, Y. Removal of phosphate from greenhouse wastewater using hydrated lime. Environ. Technol. 2014, 35, 2852–2862. [Google Scholar] [CrossRef] [PubMed]

- Dunets, C.S.; Zheng, Y. Combined precipitation/flocculation method for nutrient recovery from greenhouse wastewater. HortScience 2015, 50, 921–926. [Google Scholar] [CrossRef]

- Dunets, C.S.; Zheng, Y.; Dixon, M. Use of phosphorus-sorbing materials to remove phosphate from greenhouse wastewater. Environ. Technol. 2015, 36, 1759–1770. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Jóźwiak, T.; Struk–Sokołowska, J.; Bryszewski, K. The share of electrochemical reduction, hydrogenotrophic and heterotrophic denitrification in nitrogen removal in rotating electrobiological contactor (REBDC) treating wastewater from soilless cultivation systems. Sci. Total Environ. 2019, 683, 21–28. [Google Scholar] [CrossRef]

- Rodziewicz, J.; Mielcarek, A.; Bryszewski, K.; Janczukowicz, W.; Kłobukowska, K. Energy Consumption for nutrient removal from high-nitrate and high-phosphorus wastewater in aerobic and anaerobic bioelectrochemical reactors. Energies 2022, 15, 7251. [Google Scholar] [CrossRef]

- Shalaby, A.; Nassef, E.; Mubarak, A.; Hussein, M. Phosphate removal from wastewter by electrocoagulation using aluminium electrodes. Am. J. Environ. Eng. Sci. 2014, 1, 90–98. [Google Scholar]

- Kłodowska, I.; Rodziewicz, J.; Janczukowicz, W.; Cydzik-Kwiatkowska, A.; Parszuto, K. Effect of citric acid on the efficiency of the removal of nitrogen and phosphorus compounds during simultaneous heterotrophic-autotrophic denitrification (HAD) and electrocoagulation. Ecol. Eng. 2016, 95, 30–35. [Google Scholar] [CrossRef]

- Cordell, D.; Drangert, J.-O.; White, S. The story of phosphorus: Global food security and food for thought. Glob. Environ. Change 2009, 19, 292–305. [Google Scholar] [CrossRef]

- Karamati-Niaragh, E.; Moghaddam, M.R.A.; Emamjomeh, M.M.; Nazlabadi, E. Evaluation of direct and alternating current on nitrate removal using a continuous electrocoagulation process: Economical and environmental approaches through RSM. J. Environ. Manag. 2019, 230, 245–254. [Google Scholar] [CrossRef]

- Wysocka, I. Wastewater parameters after the process of phosphorus compounds removal by the metal dissolution method in comparison with precipitation and electrocoagulation methods. Environ. Prot. Nat. Res. 2017, 28, 8–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, C.; Wang, Q.; Yang, Y.; Zhang, Z.; Sugiura, N. Nitrate removal from groundwater by cooperating heterotrophic with autotrophic denitrification in a biofilm–electrode reactor. J. Hazard. Mater. 2011, 192, 1033–1039. [Google Scholar] [CrossRef] [PubMed]

- Prystay, W.; Lo, K.V. Treatment of greenhouse wastewater using constructed wetlands. J. Environ. Sci. Health B 2001, 36, 341–353. [Google Scholar] [CrossRef] [PubMed]

- Janczukowicz, W.; Rodziewicz, J.; Czaplicka, K.; Kłodowska, I.; Mielcarek, A. The effect of volatile fatty acids (VFAs) on nutrient removal in SBR with biomass adapted to dairy wastewater. J. Environ. Sci. Health A 2013, 48, 809–816. [Google Scholar] [CrossRef]

- Behbahani, M.; Moghaddam, A.; Arami, M. A comparison between aluminum and iron electrodes on removal of phosphate from aqueous solutions by electrocoagulation process. Int. J. Environ. Res. 2011, 5, 403–412. [Google Scholar]

- Lacasa, E.; Cañizares, P.; Sáez, C.; Fernández, F.J.; Rodrigo, M.A. Removal of nitrates from groundwater by electrocoagulation. Chem. Eng. J. 2011, 171, 1012–1017. [Google Scholar] [CrossRef]

- Janczukowicz, W.; Klimiuk, E. The influence of the raw wastes dosing system on technological parameters of the rotating biological disc (RBD) process. Bioresour. Technol. 1992, 42, 241–245. [Google Scholar] [CrossRef]

- Cortez, S.; Teixeira, P.; Oliveira, R.; Mota, M. Rotating biological contactors: A review on main factors affecting performance. Rev. Environ. Sci. Biotechnol. 2008, 7, 155–172. [Google Scholar] [CrossRef]

- Metcalf & Eddy, Inc. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

- Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Bryszewski, K.; Jabłońska-Trypuć, A.; Wydro, U. Technological parameters of rotating electrochemical and electrobiological disk contactors depending on the effluent quality requirements. Appl. Sci. 2022, 12, 5503. [Google Scholar] [CrossRef]

- Grady, C.P.L.; Daigger, G.T.; Love, N.G.; Filipe, C.D.M. Biological Wastewater Treatment, 3rd ed.; Taylor and Francis Group: Boca Raton, FL, USA, 2011. [Google Scholar]

- Dehghani, S.; Rezaee, A.; Hosseinkhani, S. Effect of alternating electrical current on denitrifying bacteria in a microbial electrochemical system: Biofilm viability and ATP assessment. Environ. Sci. Pollut. Res. 2018, 25, 33591–33598. [Google Scholar] [CrossRef] [PubMed]

- Hoseinzadeh, E.; Rezaee, A.; Farzadkia, M. Enhanced biological nitrate removal by alternating electric current bioelectrical reactor: Selectivity and mechanism. J. Mol. Liq. 2017, 246, 93–102. [Google Scholar] [CrossRef]

- Hoseinzadeh, E.; Rezaee, A.; Farzadkia, M. Nitrate removal from pharmaceutical wastewater using microbial electrochemical system supplied through low frequency-low voltage alternating electric current. Bioelectrochemistry 2018, 120, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Kłodowska, I.; Rodziewicz, J.; Janczukowicz, W. Effect of electrical current and the external source of carbon on the characteristics of sludge from the sequencing batch biofilm reactors. J. Ecol. Eng. 2018, 19, 143–152. [Google Scholar] [CrossRef]

- Sahu, O.; Mazumdar, B.; Chaudhari, P.K. Treatment of wastewater by electrocoagulation: A review. Environ. Sci. Pollut. Res. 2014, 21, 2397–2413. [Google Scholar] [CrossRef]

- Akyol, A. Treatment of paint manufacturing wastewater by electrocoagulation. Desalination 2012, 285, 91–99. [Google Scholar] [CrossRef]

- Wilson, E.L.; Kim, Y. The yield and decay coefficients of exoelectrogenic bacteria in bioelectrochemical system. Water Res. 2016, 94, 233–239. [Google Scholar] [CrossRef] [PubMed]

- Brown, R.K.; Harnisch, F.; Dockhorn, T.; Schröder, U. Examining sludge production in bioelectrochemical systems treating domestic wastewater. Bioresour. Technol. 2015, 198, 913–917. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, Y.; Li, Y.; Hu, Z.; Zhou, L.; Zhou, M. Three-dimensional electrochemical process for wastewater treatment: A general review. Chem. Eng. J. 2013, 228, 455–467. [Google Scholar] [CrossRef]

- Batstone, D.J.; Keller, J.; Angelidaki, I.; Kalyuzhny, S.V.; Pavlostathis, S.G.; Rozzi, A.; Sander, W.T.M.; Siegrist, H.; Vavilin, V.A. Anaerobic Digestion Model No. 1 (ADM1); IWA Publishing: London, UK, 2002. [Google Scholar]

- Henze, M. (Ed.) Activated Sludge Models ASM1, ASM2, ASM2d and ASM3; IWA Publishing: London, UK, 2000. [Google Scholar]

- Mielcarek, A.; Rodziewicz, J.; Janczukowicz, W.; Thornton, A.J.; Jóźwiak, T.; Szymczyk, P. Effect of the C:N:P ratio on the denitrifying dephosphatation in a sequencing batch biofilm reactor (SBBR). J. Environ. Sci. 2015, 38, 119–125. [Google Scholar] [CrossRef] [PubMed]

- Das, P.P.; Sharma, M.; Purkait, M.K. Recent progress on electrocoagulation process for wastewater treatment: A review. Sep. Purif. Technol. 2022, 292, 121058. [Google Scholar] [CrossRef]

- Ghafari, S.; Hasan, M.; Aroua, M.K. Bio–electrochemical removal of nitrate from water and wastewater—A review. Bioresour. Technol. 2008, 99, 3965–3974. [Google Scholar] [CrossRef]

- Ghanizadeh, G.; Shariati Neghab, G.; Salem, M.; Khalagi, K. Taguchi experimental design for electrocoagulation process using alternating and direct current on fluoride removal from water. Desalin. Water Treat. 2016, 57, 12675–12683. [Google Scholar] [CrossRef]

- Directive of the Council 86/278/EWG of 12 June 1986 on the protection of environment, soil in particular, in the case of sewage sludge use in agriculture. Off. J. Eur. Union 1986, L 181, 6–12.

- Regulation of the Minister of the Environment of 6 February 2015 on Municipal Sewage Sludge Dz. U. (J. Laws) 2015. 257. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000257/O/D20150257.pdf (accessed on 15 November 2022). (In Polish)

- Komosa, A. (Ed.) Nutrition of Horticultural Plants: Fundamentals and Perspectives; PWRiL: Poznań, Poland, 2012. (In Polish) [Google Scholar]

| Parameter | Value |

|---|---|

| Number of discs | 8 |

| Single disc diameter [cm] | 22 |

| Discs total area [m2] | 0.56 |

| Percent immersion of the discs [%] | 40 |

| Flow tank volume [L] | 2.0 |

| Rotation speed [rpm] | 10 |

| Parameters | Value Mean | Standard Deviation |

|---|---|---|

| COD [mg O2/L] | 259.5 | 39.7 |

| Total nitrogen [mg N/L] | 470.3 | 14.7 |

| Total phosphorus [mg P/L] | 74.4 | 10.0 |

| pH | 6.98 | - |

| HRT [h]. | Electric Current Density [A/m2] | ||||

|---|---|---|---|---|---|

| 0.63 | 1.25 | 2.50 | 5.00 | 10.00 | |

| 4 | 4718 | 4783 | 4853 | 4996 | 5215 |

| 8 | 4542 | 4614 | 4757 | 4871 | 4980 |

| 12 | 4136 | 4207 | 4370 | 4590 | 4870 |

| 24 | 3873 | 3944 | 4102 | 4384 | 4580 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodziewicz, J.; Mielcarek, A.; Janczukowicz, W.; Tavares, J.M.R.; Jóźwiakowski, K. Characteristics of Sludge from the Treatment of Soilless Plant Cultivation Wastewater in a Rotating Electrobiological Disc Contactor (REBDC). Energies 2023, 16, 1022. https://doi.org/10.3390/en16031022

Rodziewicz J, Mielcarek A, Janczukowicz W, Tavares JMR, Jóźwiakowski K. Characteristics of Sludge from the Treatment of Soilless Plant Cultivation Wastewater in a Rotating Electrobiological Disc Contactor (REBDC). Energies. 2023; 16(3):1022. https://doi.org/10.3390/en16031022

Chicago/Turabian StyleRodziewicz, Joanna, Artur Mielcarek, Wojciech Janczukowicz, Jorge Manuel Rodrigues Tavares, and Krzysztof Jóźwiakowski. 2023. "Characteristics of Sludge from the Treatment of Soilless Plant Cultivation Wastewater in a Rotating Electrobiological Disc Contactor (REBDC)" Energies 16, no. 3: 1022. https://doi.org/10.3390/en16031022

APA StyleRodziewicz, J., Mielcarek, A., Janczukowicz, W., Tavares, J. M. R., & Jóźwiakowski, K. (2023). Characteristics of Sludge from the Treatment of Soilless Plant Cultivation Wastewater in a Rotating Electrobiological Disc Contactor (REBDC). Energies, 16(3), 1022. https://doi.org/10.3390/en16031022