Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases

Abstract

:1. Introduction

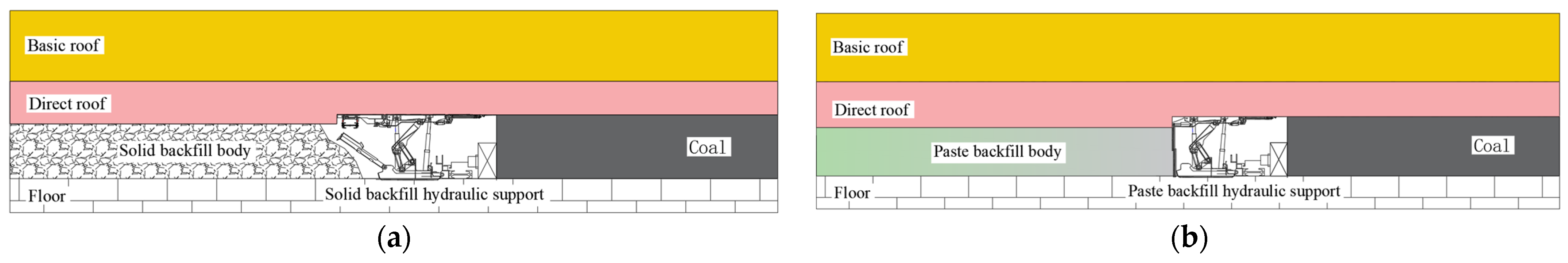

2. Backfill Coal Mining Concept and Classification

2.1. Concept of Backfill Coal Mining

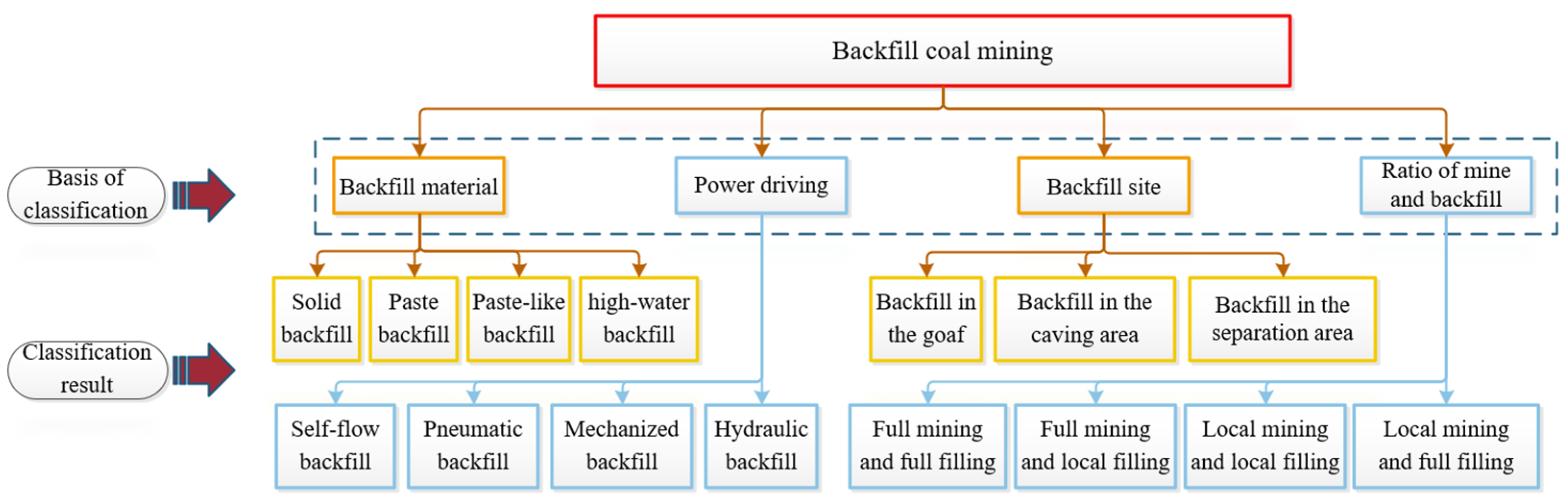

2.2. Classification of Backfill Coal Mining Methods in Use

2.3. A survey of Engineering Cases of Backfill Coal Mining

2.4. New Concepts for Classifying Backfill Coal Mining Methods

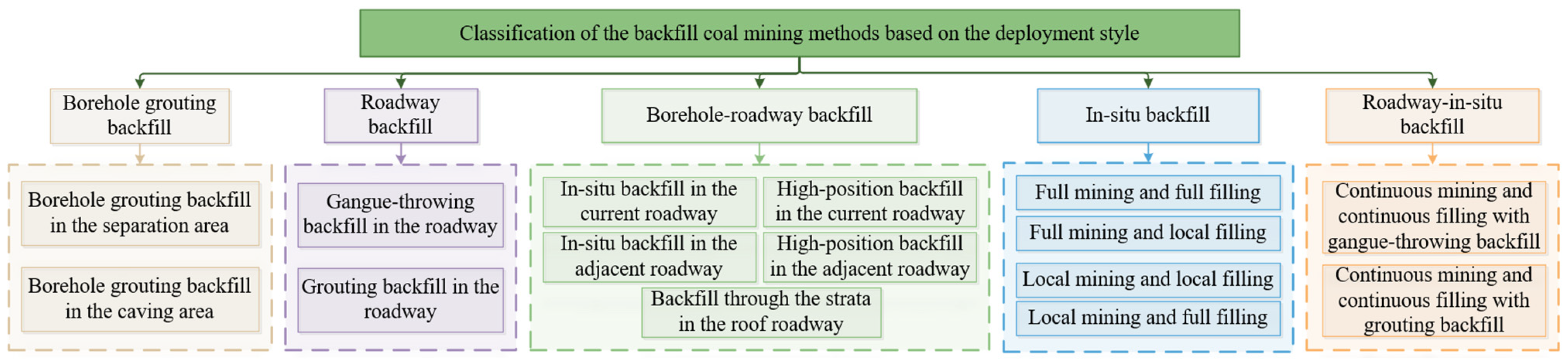

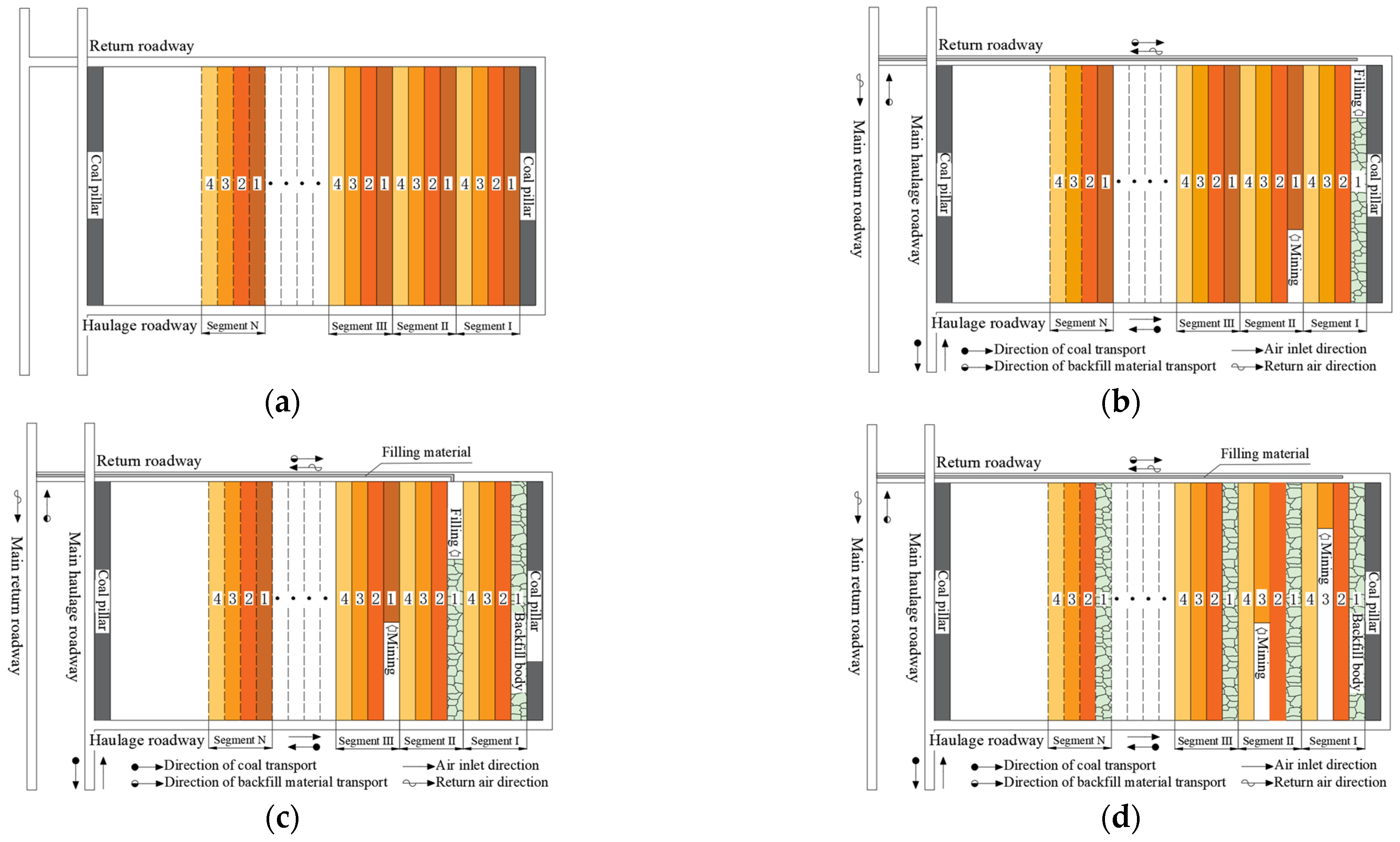

3. A Review of the Backfill Coal Mining Methods Classified by the Deployment Style

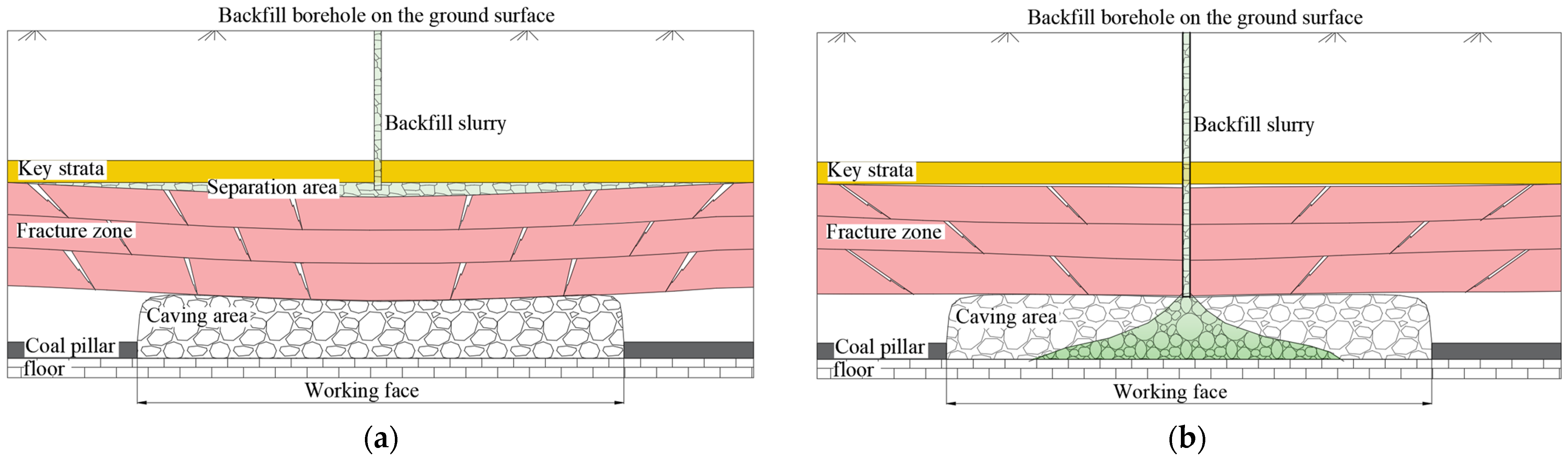

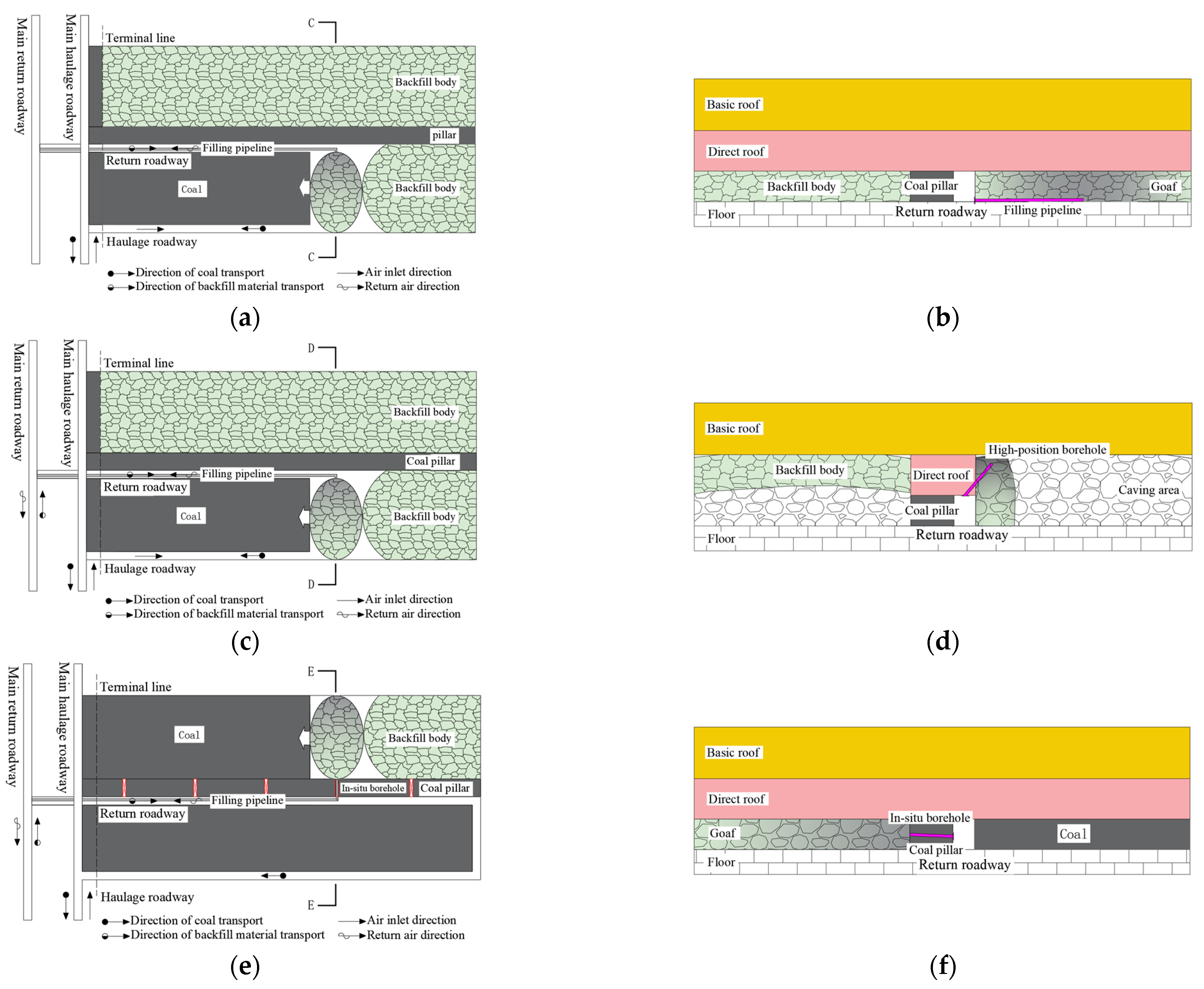

3.1. Deployment of the Borehole Grouting Backfill System

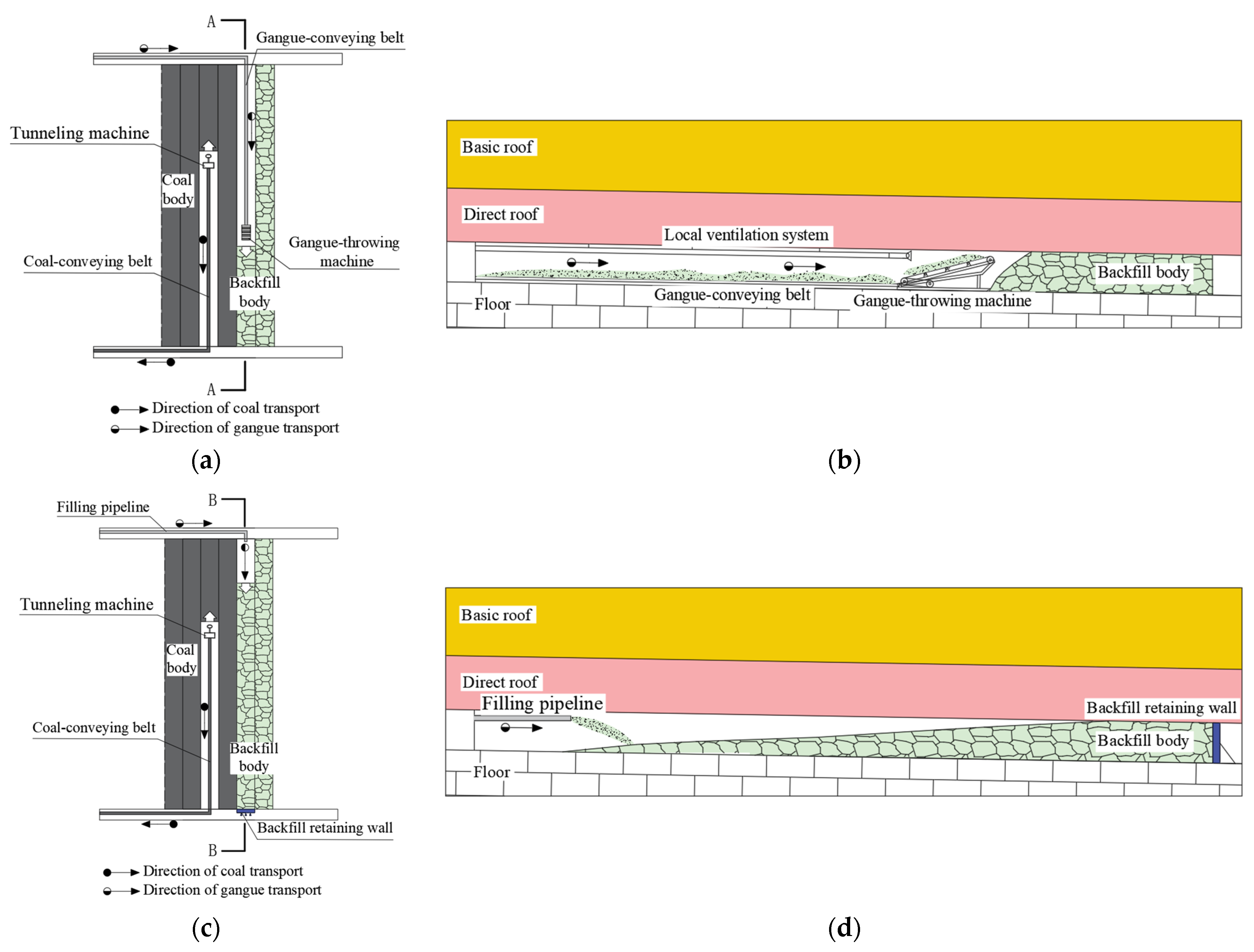

3.2. Deployment of the Roadway Backfill System

3.3. Deployment of the Roadway–Borehole Backfill System

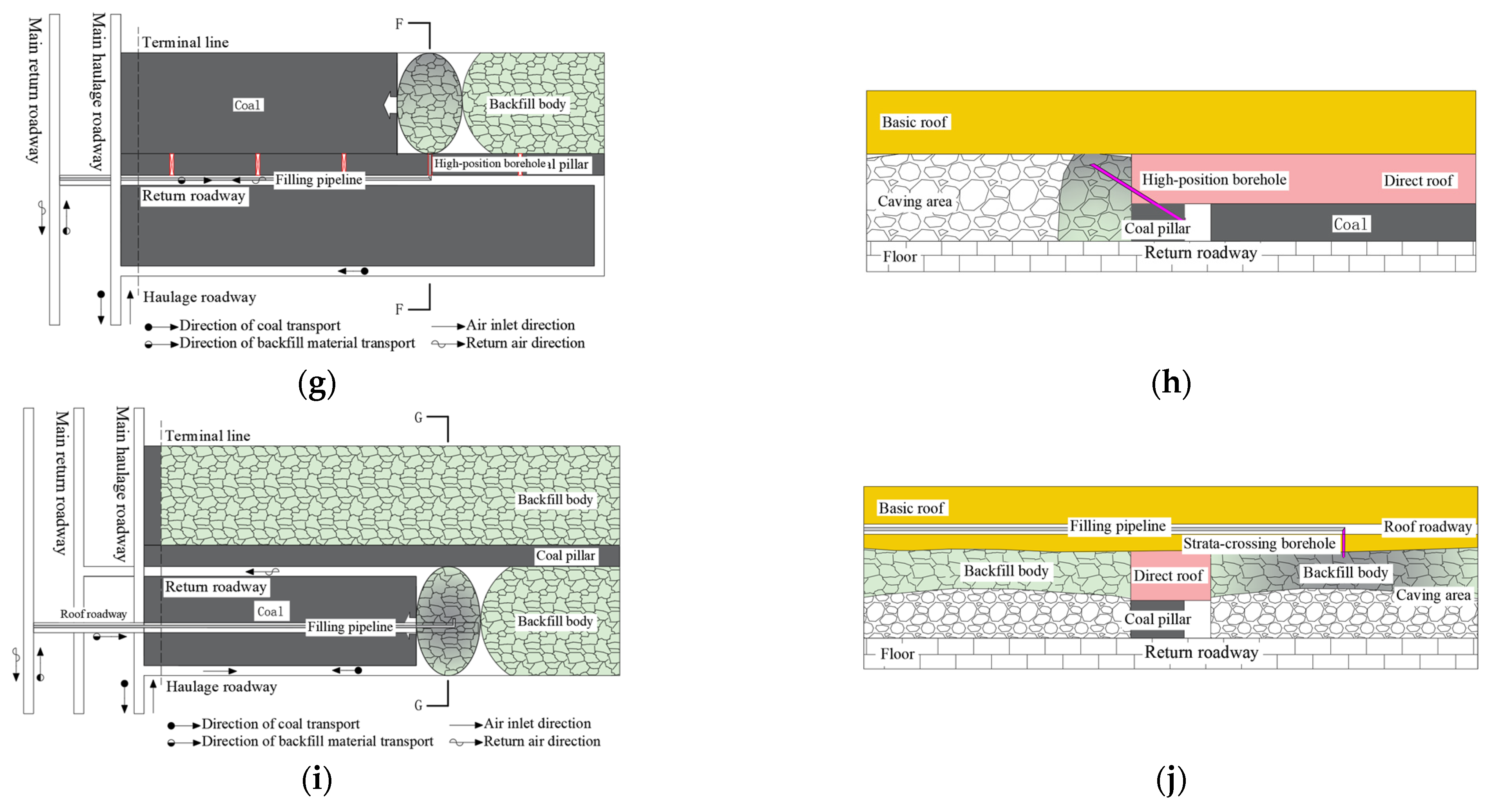

3.4. Deployment of the In Situ Backfill System

3.5. Deployment of the In Situ Roadway Backfill System

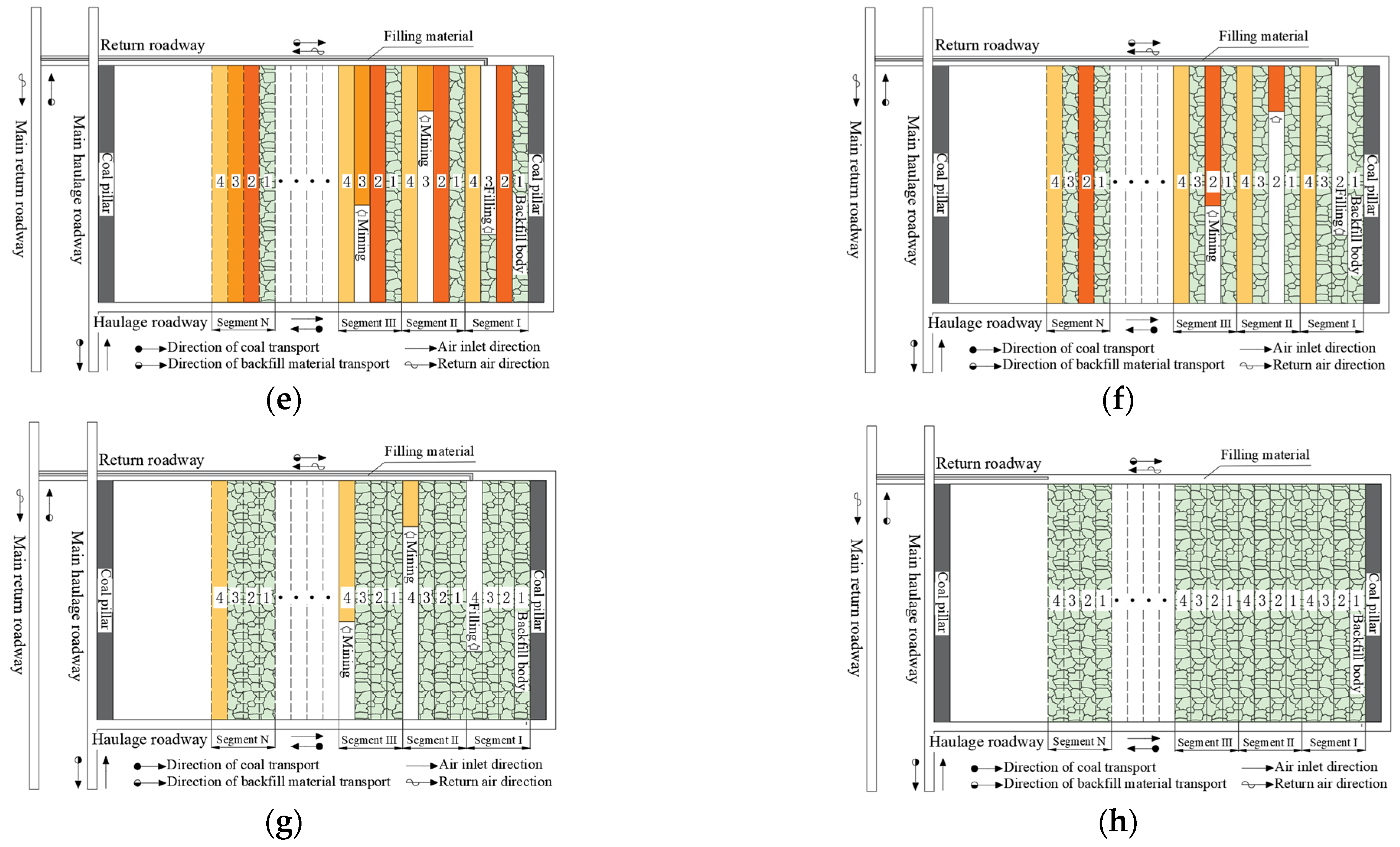

4. Design Methods for Backfill Coal Mining and Engineering Cases

4.1. Engineering Design Methods for Backfill Coal Mining and Workflow

- (1)

- Identify the backfill targets

- (2)

- Analyze the feasibility of backfill system deployment

- (3)

- Compare the engineering quantities of the schemes

- (4)

- Estimate the economic efficiency of backfill

- (5)

- Backfill performance tracking and monitoring

4.2. Case Analysis of Backfill Engineering Design in Xingdong Coal Mine

4.3. Case Analysis of Backfill Engineering Design in Bailongshan Coal Mine

5. Conclusions and Outlook

- (1)

- This study reviewed the existing backfill coal mining systems in China. Based on findings from a survey of engineering cases, we identified five main types of new backfill coal mining methods depending on deployment style: borehole grouting backfill, roadway backfill, borehole–roadway backfill, in situ backfill, and in situ roadway backfill.

- (2)

- Fifteen backfill techniques belonging to these five types were further identified; namely, borehole grouting backfill in the separation area, borehole grouting backfill in the caving area, gangue-throwing backfill in the roadway, grouting backfill in the roadway, in situ backfill in the current roadway, high-position backfill in the current roadway, in situ backfill in the adjacent roadway, high-position backfill in the adjacent roadway, backfill through the strata in the roof roadway, full mining and full filling, full mining and local filling, local mining and full filling, local mining and local filling, continuous mining and continuous filling with gangue-throwing backfill, and continuous mining and continuous filling with grouting backfill.

- (3)

- An engineering design method for backfill coal mining consisting of five steps was proposed; namely, identifying the targets of backfill, analyzing the feasibility of deploying the backfill system, comparing the volumes of different engineering schemes, estimating the economic efficiency of backfill, and backfill performance tracking and monitoring. This method was further applied to the case analyses of backfill engineering design in two coal mines in China; namely, the Xingdong Coal Mine and the Bailongshan Coal Mine.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, M.; Xu, J.; Wang, J. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13. [Google Scholar]

- Xie, H.P.; Wang, J.; Wang, G.F.; Ren, H.; Liu, J.; Ge, S.; Ren, S. New ideas of coal revolution and layout of coal science and technology development. J. China Coal Soc. 2018, 43, 1187–1197. [Google Scholar]

- Liu, J.; Li, X.; He, T. Application status and development of coal mine filling mining in China. Coal J. 2020, 45, 141–150. [Google Scholar]

- Miao, X.; Ju, F.; Huang, Y.; Guo, G. New progress and prospect of filling coal mining theory and technology. J. China Univ. Min. Technol. 2015, 44, 391–399+429. [Google Scholar]

- Xu, J.; Xuan, D.; Zhu, W.; Wang, X.; Wang, B. Research and practice of partially filled coal mining technology. J. Coal 2015, 40, 1303–1312. [Google Scholar]

- Qin, W.; Xu, J.; Xuan, D.; Ju, J.; Cheng, X. Research on green mining technology and economic evaluation method of coal mine. J. Min. Saf. Eng. 2023, 40, 1092–1101. [Google Scholar]

- Zhou, N.; Yao, Y.; Song, W. Present situation and prospect of gangue treatment technology in coal mine. J. Min. Saf. Eng. 2020, 37, 136–146. [Google Scholar]

- Tu, S.; Hao, D.; Li, W.; Liu, X. Theoretical and technical system construction of selective mining in ‘mining-selection-filling + X’ integrated mine. J. Min. Saf. Eng. 2020, 37, 81–92. [Google Scholar]

- Zhang, J.; Zhang, Q.; Zhou, N.; Li, M.; Huang, P. Research progress and prospect of coal-based solid waste filling mining technology. Coal J. 2022, 47, 4167–4181. [Google Scholar]

- Yang, K.; Zhao, X.; He, X.; Wei, Z. Basic theory and technical system of multi-source coal-based solid waste green filling. Coal J. 2022, 47, 4201–4216. [Google Scholar]

- Zhang, J.; Tu, S.; Cao, Y.; Tan, Y.; Xin, H. Intelligent separation and filling technology and engineering application of coal gangue in underground coal mine. J. China Univ. Min. Technol. 2021, 50, 417–430. [Google Scholar]

- Yuan, Y.; Zhu, C.; Wang, W. Method for optimizing the layout of coal mining-filling space in deep coal mines. J. China Univ. Min. Technol. 2023, 52, 286–299. [Google Scholar]

- Zhang, Q.; Yang, K.; Zhang, H.; Xia, K.; Zhang, Q. Study on the weakening law and characterization of pressure behavior in solid filling mining. J. China Univ. Min. Technol. 2021, 50, 479–488. [Google Scholar]

- Zhang, J.; Zhang, Q.; Ju, F.; Duan, Y.; Li, H. Theory and technique of greening mining integrating mining, separating and backfilling in deep coal resources. J. China Coal Soc. 2018, 43, 377–389. [Google Scholar]

- Jia, K.; Feng, G.; Wang, Y.; Duan, Y.; Li, H. Instability mechanism and prevention of super high water material bag filling body in inclined mining. J. China Univ. Min. Technol. 2015, 44, 409–415. [Google Scholar]

- Sun, J.; Wang, L.; Zhao, G. Stability criterion of aquiclude in strip filling overlying strata in Shendong special water-preserved mining coal seam. J. China Univ. Min. Technol. 2018, 47, 957–968. [Google Scholar]

- Zhang, J.; Zhou, N.; Gao, F.; Yan, H. Filling method of gangue grouting in subsequent space of coal mining. Coal J. 2023, 48, 150–162. [Google Scholar]

- Liu, J.; Bi, J.; Zhao, L. Research and application of automatic control of fully mechanized solid filling coal mining. Coal Sci. Technol. 2016, 44, 149–156. [Google Scholar]

- Xu, L.; Zhang, K.; Liu, X. Deformation characteristics and surface subsidence control effect of key strata in separated layer grouting mining. Coal J. 2023, 48, 931–942. [Google Scholar]

- Ma, L.; Wang, S.; Yu, Y. Technology and practice of wall-type continuous mining and water-preserved coal mining. J. Min. Saf. Eng. 2021, 38, 902–910+987. [Google Scholar]

- Zhang, J.X.; Ju, F.; Li, M.; Zhou, N.; Zhang, Q. Coal gangue underground separation collaborative in-situ filling mining method. Coal J. 2020, 45, 131–140. [Google Scholar]

- Zhang, J.; Zhang, Q.; Ju, F. Practice and technique of green mining with integration of mining, dressing, backfilling and X in coal resources. J. China Coal Soc. 2019, 44, 64–73. [Google Scholar]

- Xie, H.; Zhang, J.; Gao, F.; Li, B.; Li, C. Theory and technical conception of negative carbon efficient filling mining in coal mine. Coal J. 2023, 11, 23. [Google Scholar]

- Xu, W.; Chen, W.; Zhang, Y.; Chen, B. Study on rheological properties of gangue-fly ash slurry in deep filling mining. Coal Sci. Technol. 2023, 51, 85–93. [Google Scholar]

- Huang, Y.; Zhang, J.; Du, J. Study on time-dependent characteristics of filling body in fully mechanized solid filling coal mining. J. China Univ. Min. Technol. 2012, 41, 697–701. [Google Scholar]

- Gao, P. Key technology research and engineering demonstration of filling mining under construction in Xingdong Mine. Coal Chem. Ind. 2023, 46, 22–26. [Google Scholar]

- Ren, W. Practice of layered filling mining technology in thick coal seam of Xingtai Mine. Coal Chem. Ind. 2021, 44, 19–21. [Google Scholar]

- Li, G.; Wang, Y.; Cui, P. Research on key technology of in-situ filling mining of protective layer. Coal Eng. 2022, 54, 12–17. [Google Scholar]

- Liu, X.; Tian, Y.; Cao, X. Deformation control of high and steep mountain under multi-coal seam mining conditions. Coal Sci. Technol. 2021, 49, 180–190. [Google Scholar]

| Serial Number | Coal Mine | Backfill Background | Mining Height /Meter | Type of the Mining Process | Deployment of the Backfill System |

|---|---|---|---|---|---|

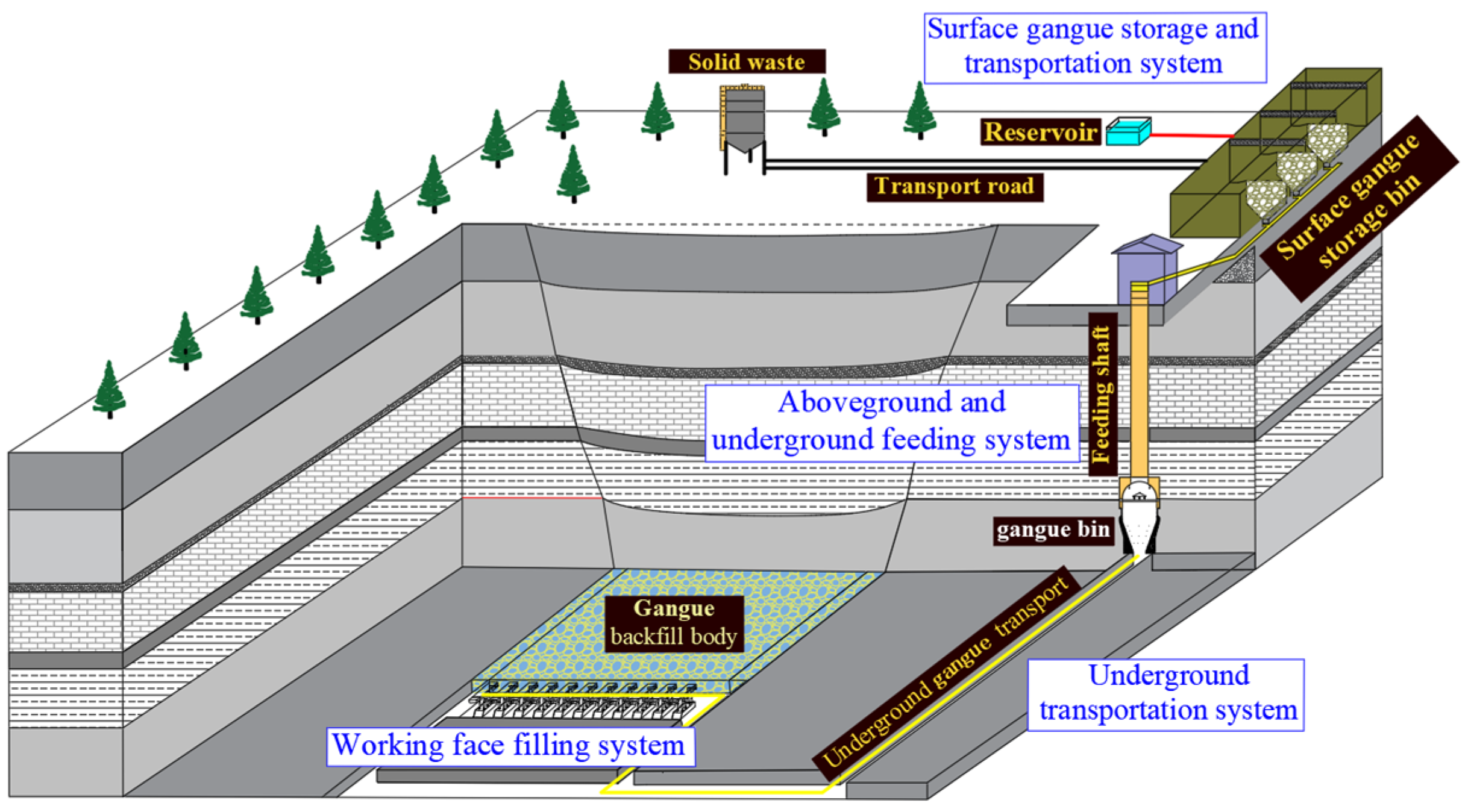

| 1 | Xingdong Coal Mine | Mining under buildings | 4.6 | Fully-mechanized coal mining | 1. Gangue storage and transport above the ground; 2. Vertical feeding; 3. Underground transport; 4. Solid compaction and filling in the working face |

| 2 | Weijiadi Coal Mine | Recycled use of coal gangue | 14.3 | Fully-mechanized coal caving | 1. Prepare the slurry above the ground using gangue as the main raw material; 2. Grout in the caving area through the gas extraction hole on the ground. |

| 3 | Hongqinghe Coal Mine | Recycled use of coal gangue | 5.7 | Fully-mechanized coal mining | 1. Prepare slurry above the ground; 2. Drill a grouting borehole; |

| 4 | Xuchang Coal Mine | Coal pillar recycling in strip mining | 4.9 | Roadway mining | 1. Gangue crushing and transport; 2. Gangue-throwing backfill in the roadway |

| 5 | Gucheng Coal Mine | Mining under buildings | 6.0 | Fully-mechanized coal mining | 1. Gangue crushing, storage, and transport above the ground; 2. Vertical feeding; 3. Underground transport; 4. Solid backfill in the working face |

| 6 | Huangling No. 2 Coal Mine | Greening and emissions reduction through recycled use of coal gangue | 3.12 | Fully-mechanized coal mining | 1. Prepare the slurry above the ground; 2. Transport via pipelines; 3. Drill a grouting borehole in the adjacent position; 4. Grout the caving area |

| 7 | Yangliu Coal Mine | Mining under buildings | 3.0 | Fully-mechanized coal mining | 1. Prepare the slurry above the ground; 2. Drill a grouting borehole; |

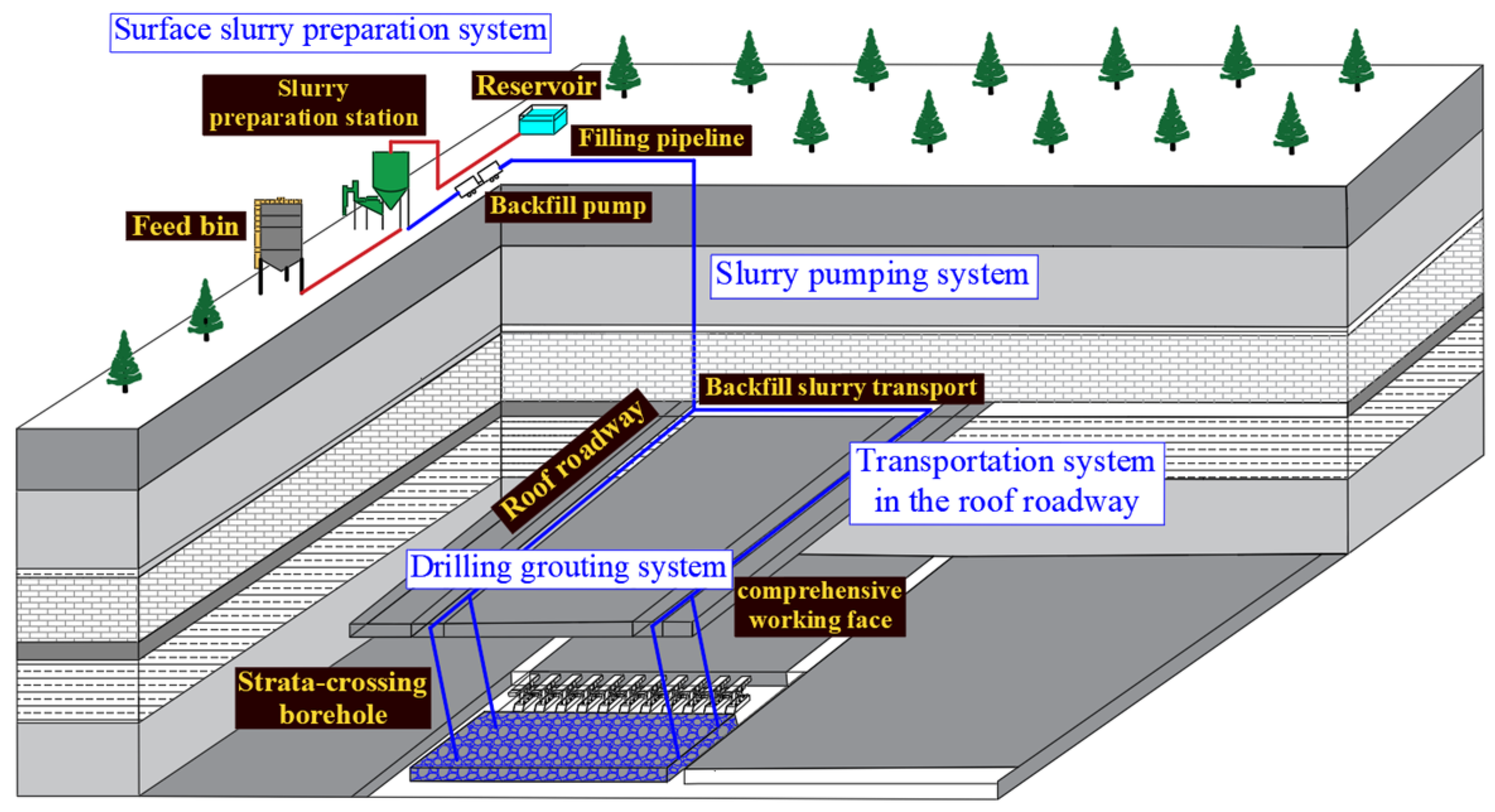

| 8 | Bailongshan Coal Mine | Mining under the conservation area | 1.8 | Fully-mechanized coal mining | 1. Prepare the slurry above the ground; 2. Drill a grouting borehole in the high-position gas extraction roadway; 4. Grout the caving area |

| 9 | A coal mine in Shanxi | Greening and emissions reduction through recycled use of coal gangue | 4.0 | Fully-mechanized coal mining | 1. Prepare the slurry above the ground; 2. Transport the slurry via pipelines; |

| 10 | Mahuangliang Coal Mine | Mining under buildings | 3.5 | Roadway mining | 1. Prepare the slurry; 2. Transport the slurry by pumping; 3. Continuous mining and continuous filling in the four-stage working face |

| 11 | Taoyi Coal Mine | Mining under buildings | 4.0 | Fully-mechanized coal mining | 1. Transport the backfill material; 2. Prepare the slurry by mixing; 3. Bag-type filling of the high-water backfill |

| 12 | A coal mine in Northern Shaanxi | Coal pillar recycling | 3.5 | Roadway mining | 1. Prepare and transport the paste backfill by pumping; 2. Grouting backfill in the roadway |

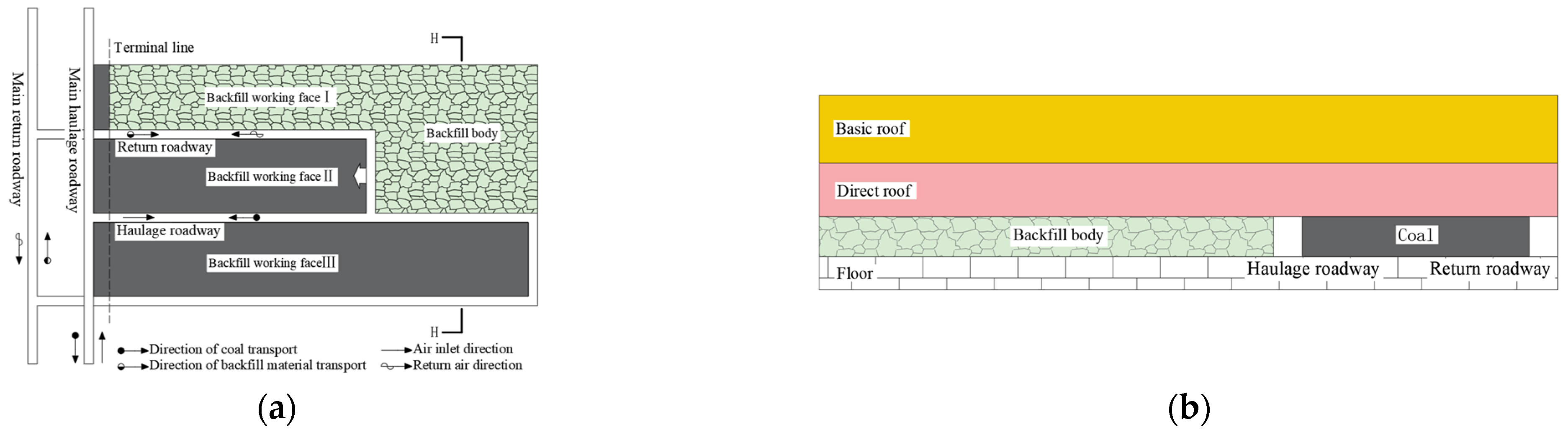

| Classification of the Backfill Coal Mining Methods Based on the Deployment Style | Performance Analysis | Conditions for System Deployment | |

|---|---|---|---|

| Borehole grouting backfill | Borehole grouting backfill in the separation area | 1. High backfill performance but poor stability; 2. Poor solid waste treatment ability | 1. Land available for expropriation 2. Suitable for borehole drilling on the ground; 3. The presence and stability of the grouting space |

| Borehole grouting backfill in the caving area | |||

| Roadway backfill | Gangue-throwing backfill in the roadway | 1. High backfill performance but poor stability; 2. High solid waste disposal ability | 1. The coal seal thickness is not larger than the height of the extraction roadway; 2. The roadway has a dip angle; 3. The roadway space is intact and stable |

| Grouting backfill in the roadway | 1. High backfill performance and stability; 2. Poor solid waste disposal ability | ||

| Roadway-borehole backfill | In situ backfill in the current roadway | 1. Poor backfill performance and stability 2. Poor solid waste disposal ability | 1. Proper backfill roadway; 2. Suitable for borehole drilling in the roof |

| High-position backfill in the current roadway | |||

| In situ backfill in the adjacent roadway | |||

| High-position backfill in the adjacent roadway | |||

| Backfill through the strata in the roof roadway | |||

| In situ backfill | Full mining and full filling (FM + FF) | 1. High backfill performance and stability; 2. High solid waste disposal ability; 3. Applicable for recycling residual coal pillars | 1. The mining thickness should not be too large; 2. Applicable for recycling residual coal pillars |

| Full mining and local filling (FM + LF) | |||

| Local mining and local filling (LM + LF) | |||

| Local mining and full filling (LM + FF) | |||

| In situ Roadway backfill | Continuous mining and continuous filling with gangue-throwing backfill | 1. High backfill performance but poor stability; 2. High solid waste disposal ability | 1. The coal seal thickness is not larger than the height of the extraction roadway; 2. The roadway has a dip angle; 3. The roadway space is intact and stable; 4. Reasonable succession of mining and filling |

| Continuous mining and continuous filling with grouting backfill | 1. High backfill performance and stability; 2. Poor solid waste disposal ability | ||

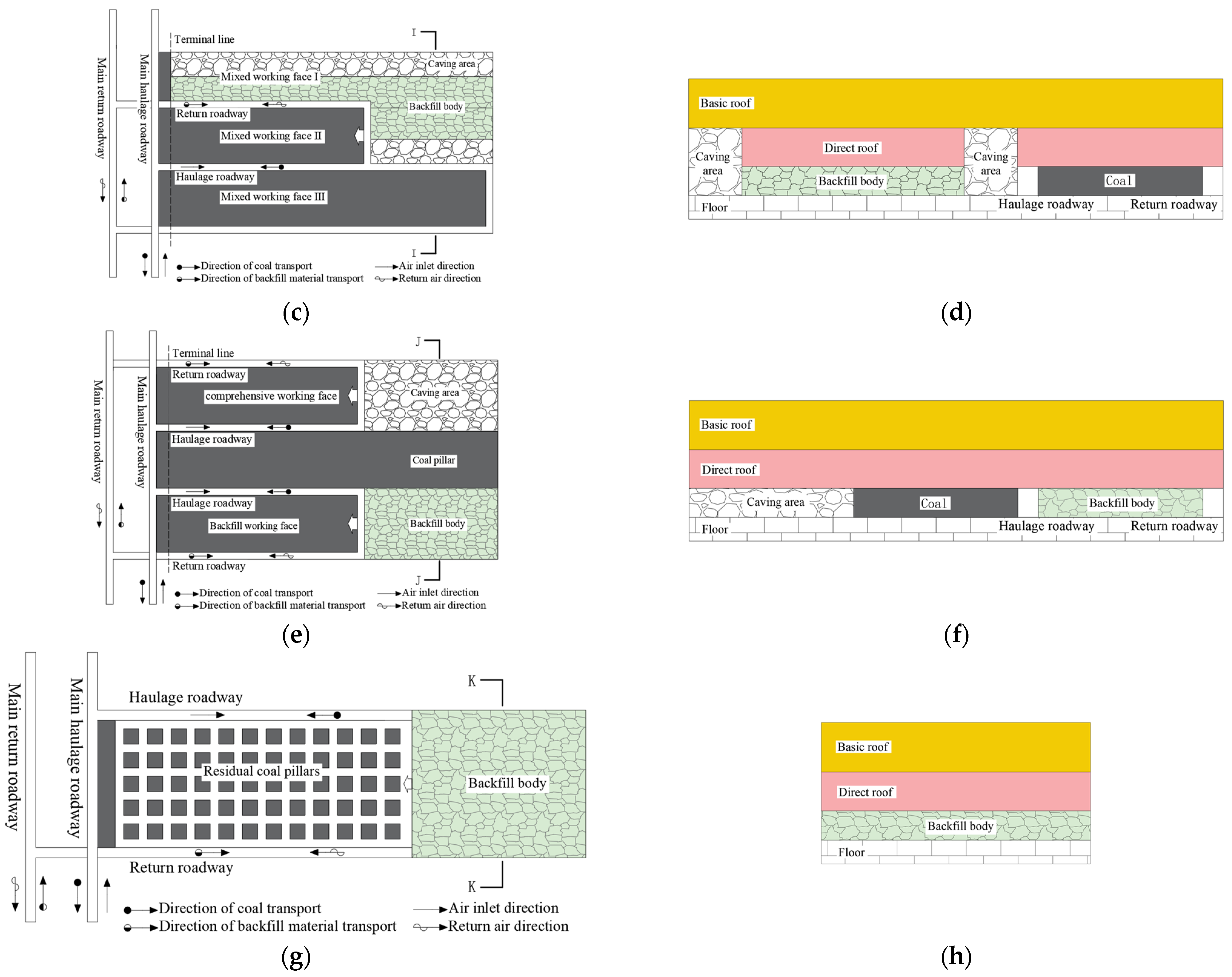

| Classification of the Backfill Coal Mining Methods Based on the Deployment Style | Engineering Quantity Analysis | |||

|---|---|---|---|---|

| Construction Quantity | Newly Added Equipment | Transport Pipelines | ||

| Borehole grouting backfill | Borehole grouting backfill in the separation area | Slurry preparation station and surface borehole drilling | Slurry preparation equipment, slurry transport pipelines, and backfill pump | Surface transport |

| Borehole grouting backfill in the caving area | ||||

| Roadway backfill | Gangue-throwing backfill in the roadway | None | Belt conveyor, gangue-throwing machine, etc. | Roadway transport |

| Grouting backfill in the roadway | Slurry preparation station, backfill retaining wall, etc. | Slurry preparation equipment, slurry transport pipelines, and backfill pump | Surface, aboveground and underground, and roadway transport | |

| Roadway-borehole backfill | In situ backfill in the current roadway | Slurry preparation station, grouting borehole, etc. | Slurry preparation equipment, slurry transport pipelines, and backfill pump | Surface, aboveground and underground, and roadway transport |

| High-position backfill in the current roadway | ||||

| In situ backfill in the adjacent roadway | ||||

| High-position backfill in the adjacent roadway | ||||

| Backfill through the strata in the roof roadway | ||||

| In situ backfill | Full mining and full filling (FM + FF) | Crushing station or slurry preparation station | Backfill supports, belt conveyor, or slurry transport pipeline | Surface, aboveground and underground, and roadway transport, and transport in the working face |

| Full mining and local filling (FM + LF) | ||||

| Local mining and local filling (LM + LF) | ||||

| Local mining and full filling (LM + FF) | ||||

| In situ roadway backfill | Continuous mining and continuous filling with gangue-throwing backfill | None | Belt conveyor, gangue-throwing machine, etc. | Roadway transport |

| Continuous mining and continuous filling with grouting backfill | Slurry preparation station, backfill retaining wall, etc. | Slurry preparation equipment, slurry transport pipelines, and backfill pump | Surface, aboveground and underground, and roadway transport | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, P.; Zhang, Q.; Yang, K.; Lv, H.; Cao, J.; Wang, W. Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases. Energies 2023, 16, 8074. https://doi.org/10.3390/en16248074

Cui P, Zhang Q, Yang K, Lv H, Cao J, Wang W. Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases. Energies. 2023; 16(24):8074. https://doi.org/10.3390/en16248074

Chicago/Turabian StyleCui, Pengfei, Qiang Zhang, Kang Yang, Haonan Lv, Jinming Cao, and Wei Wang. 2023. "Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases" Energies 16, no. 24: 8074. https://doi.org/10.3390/en16248074

APA StyleCui, P., Zhang, Q., Yang, K., Lv, H., Cao, J., & Wang, W. (2023). Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases. Energies, 16(24), 8074. https://doi.org/10.3390/en16248074