Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation

Abstract

:1. Introduction

- A method based on fuzzy control is presented for addressing the maximum power tracking problem in photovoltaic power generation;

- A solution is presented to address the issue of significant fluctuations in photovoltaic power generation, involving the implementation of an energy storage system that utilizes a double closed-loop control strategy and PQ control;

- A control strategy is proposed for the energy storage battery, aiming to maintain constant voltage control during charge and discharge processes;

- Through the implementation of diverse control strategies, a comprehensive system is established to ensure consistent power operation across different conditions.

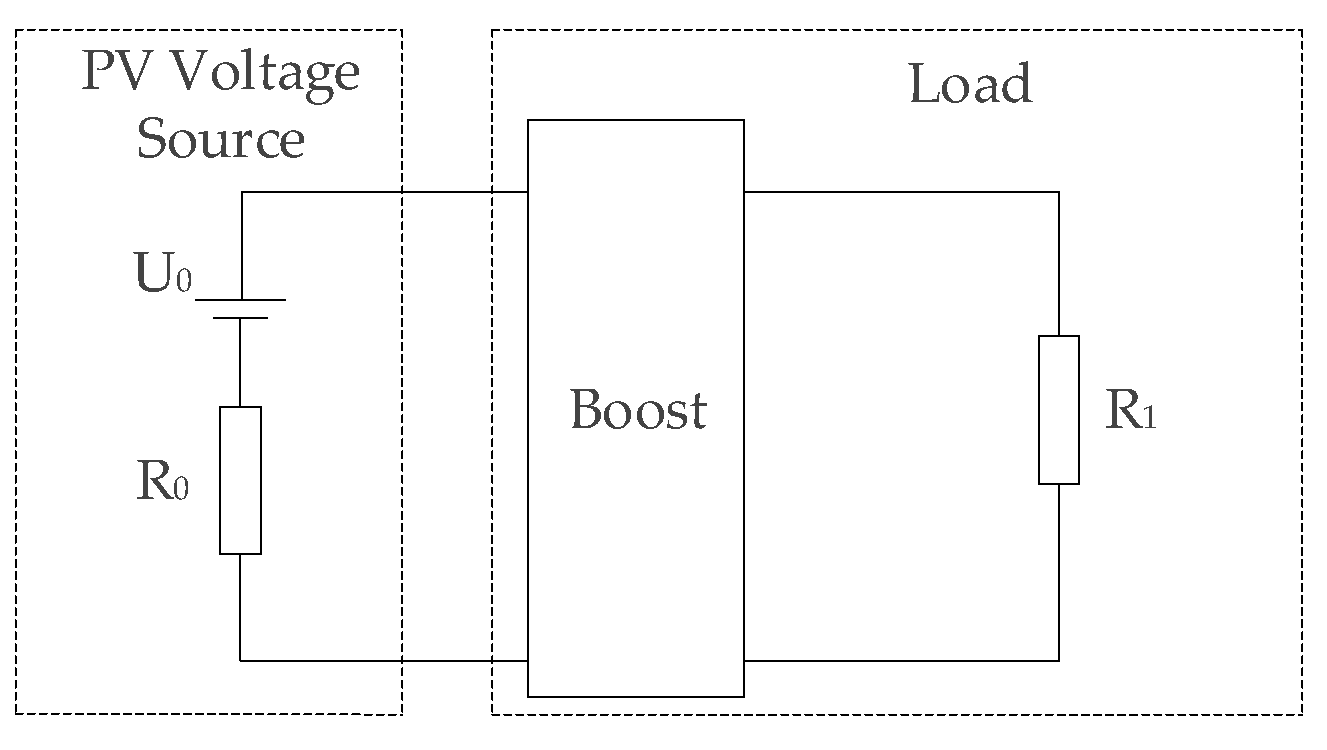

2. PV Maximum Power Point Tracking Principle and Control Strategies

2.1. PV MPPT Principle

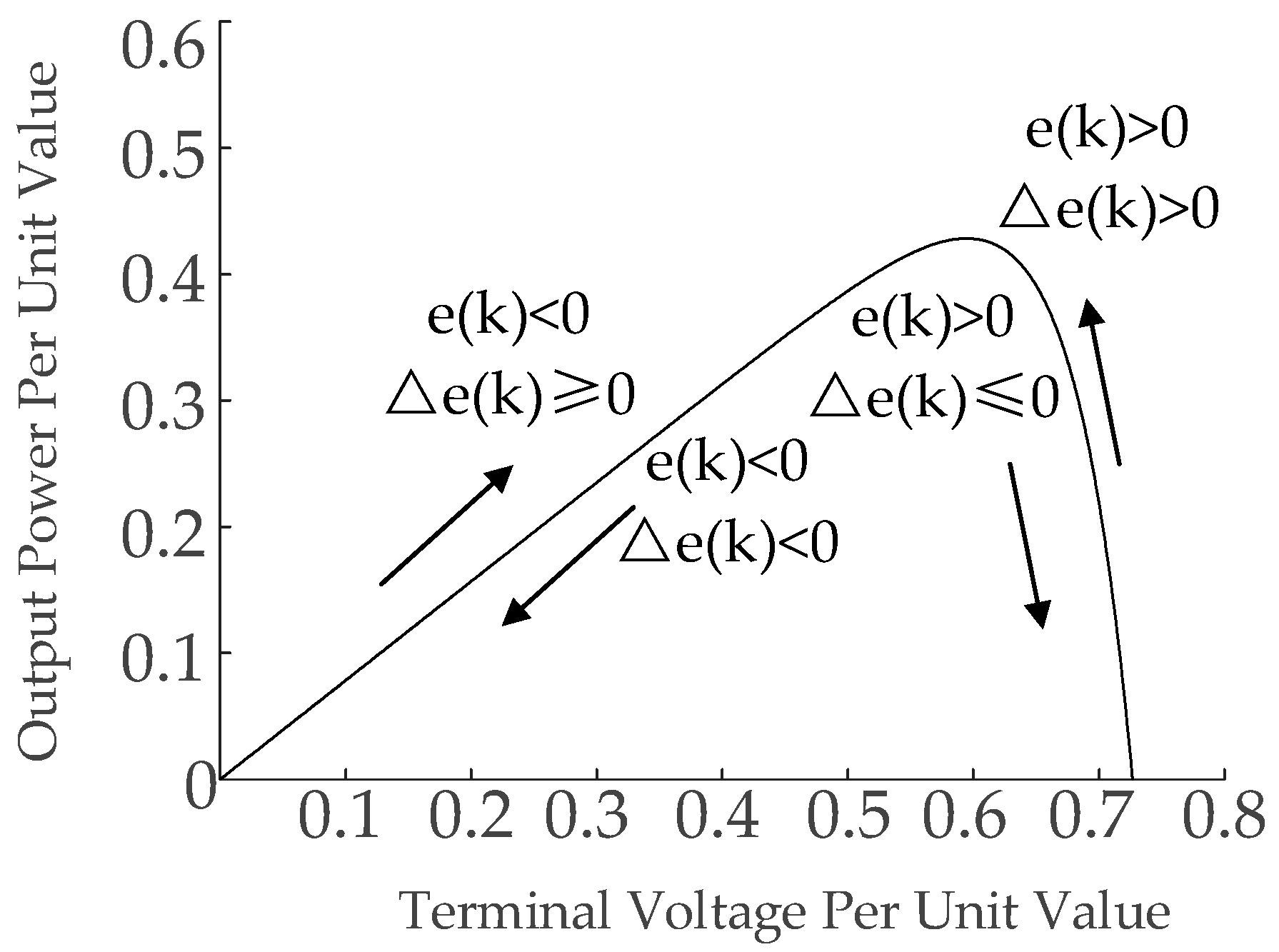

2.2. MPPT Control Strategy Based on Fuzzy Control

- When e(k) < 0 and ∆e(k) ≥ 0, P approaches the maximum power point from the left side. dU should be positive to ensure proximity to the maximum power point;

- When e(k) < 0 and ∆e(k) < 0, P deviates from the left side of the maximum power point. dU should be positive to maintain proximity to the maximum power point;

- When e(k) > 0 and ∆e(k) ≤ 0, P moves towards the maximum power point from the right side. In this case, dU should be negative for closer alignment with the maximum power point;

- When e(k) > 0 and ∆e(k) > 0, P deviates from the right side of the maximum work rate point. Then, dU should be negative for better approximation to the maximum power point.

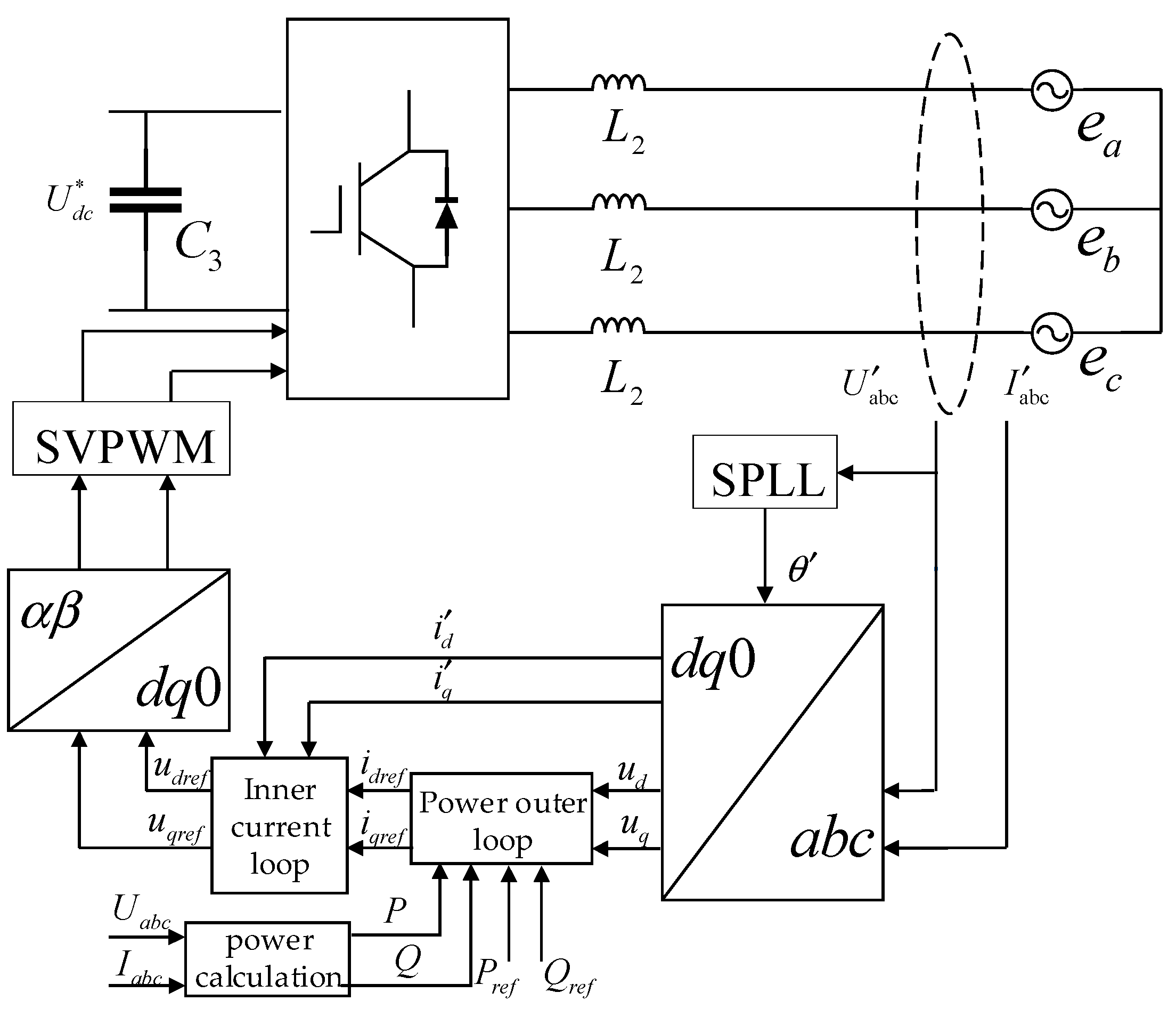

3. Mathematical Model Establishment of A PV Energy Storage System

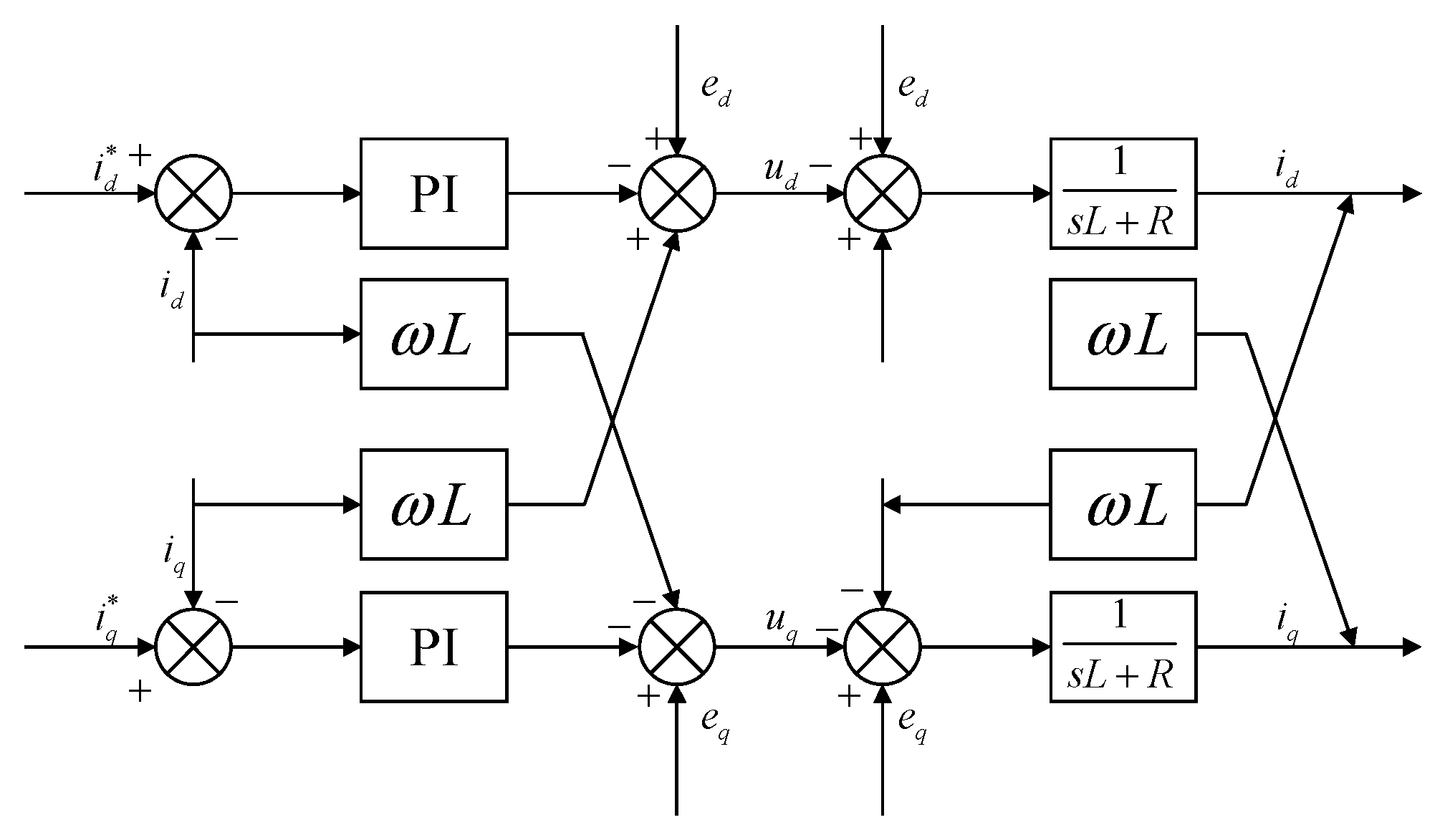

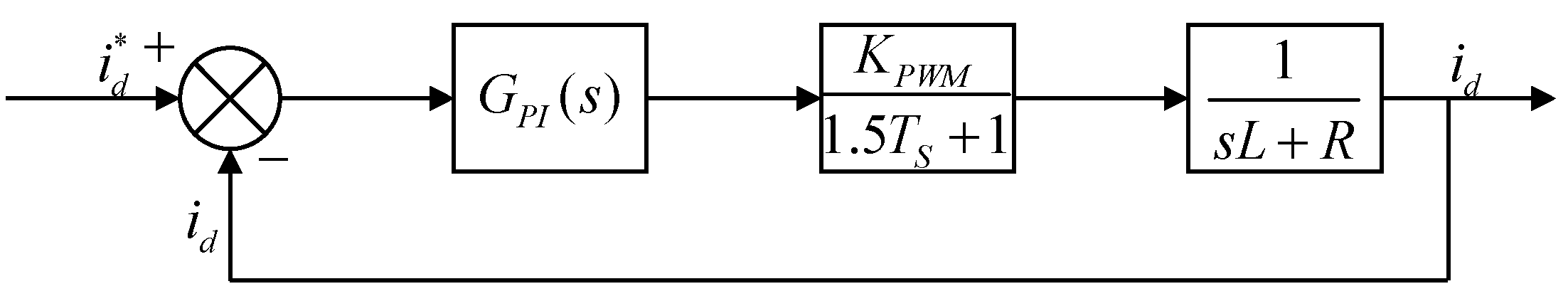

3.1. Mathematical Modeling of the Three-Phase Voltage-Type PWM Converter

3.2. Mathematical Modeling of Bidirectional DC/DC Converter

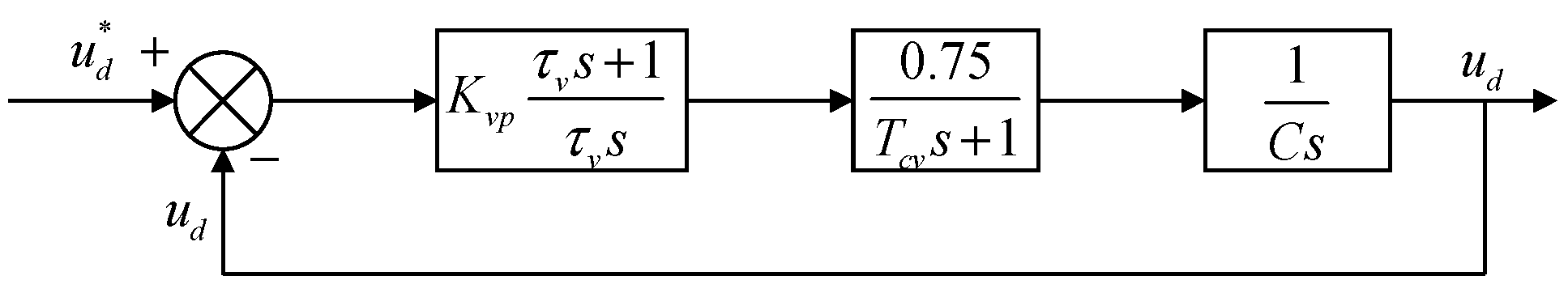

3.3. Control Strategy of the Three-Phase Voltage Source PWM Converter

- When Ppv > Pload, then Pbat < 0, Ppv = Pload + Pbat. The energy storage battery is in a state of charge, through rectification and depressurization, and SOC increases;

- When Ppv < Pload, then Pbat > 0, Ppv + Pbat = Pload. The storage battery is in the discharge state, through inverter and boost, and SOC decreases;

- When Ppv = Pload, then Pbat = 0. No energy flow occurs, and the battery SOC remains constant.

4. Research on Grid-Connected Control Strategy of PV Energy Storage

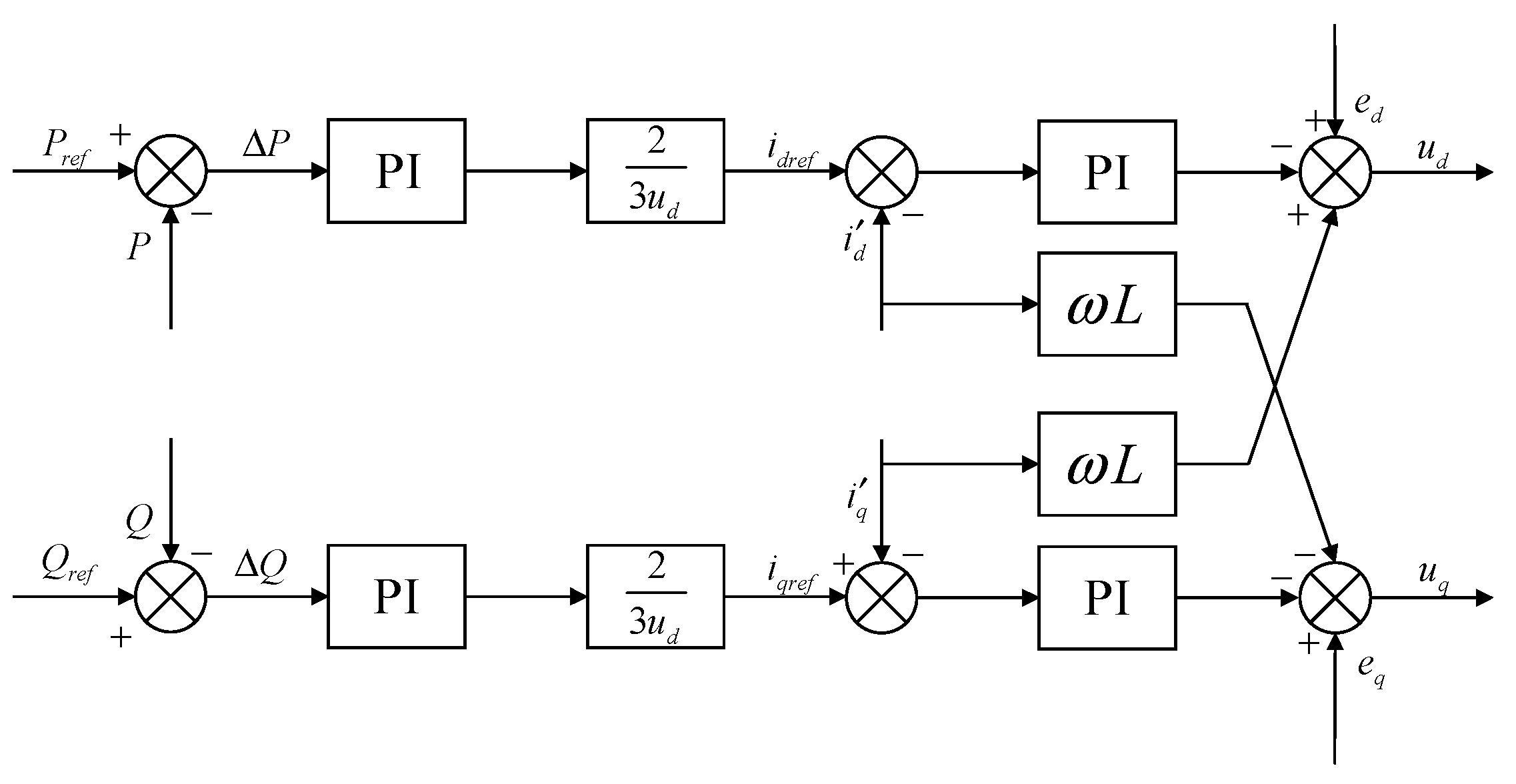

4.1. Control Strategy of the Three-Phase Voltage Source PWM Converter

4.2. PQ Control of Energy Storage System

4.3. Design of the Three-Phase Software Phase-Locked Loop

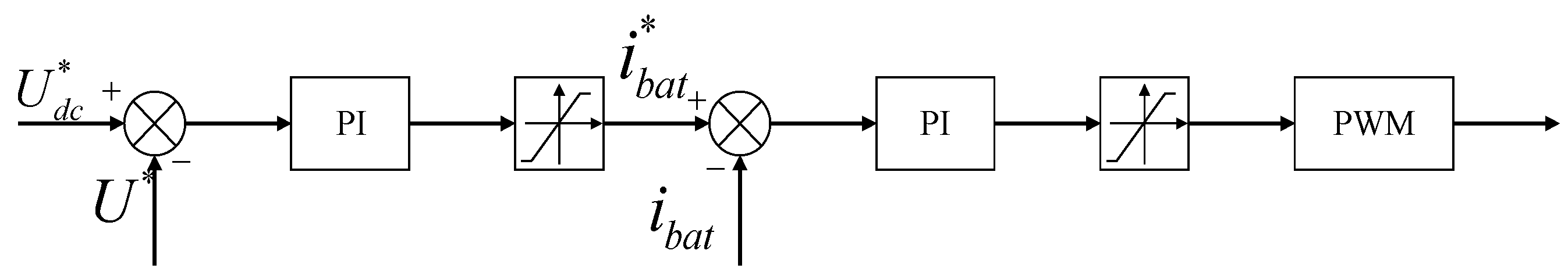

4.4. Control Strategy of Bidirectional DC/DC Converter

5. Simulation Analysis

5.1. MPPT Simulation Analysis Based on Fuzzy Control

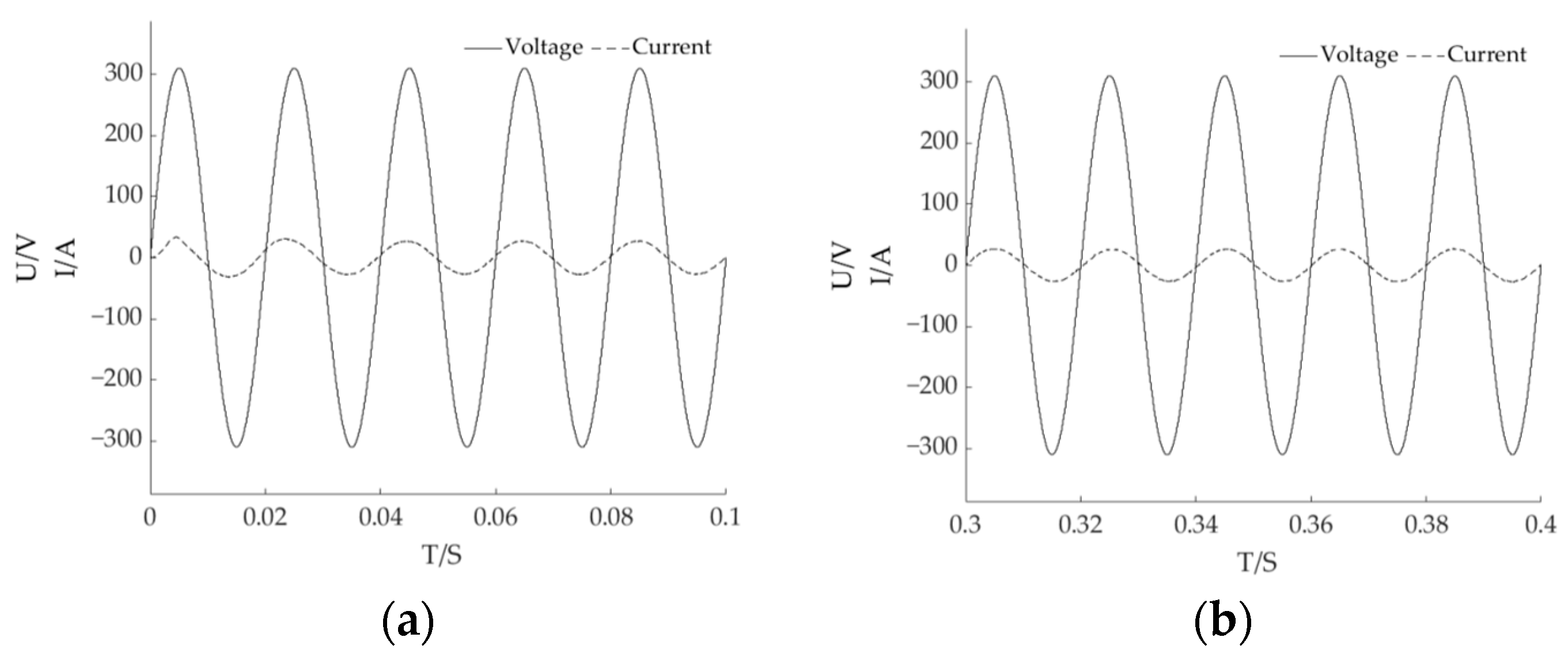

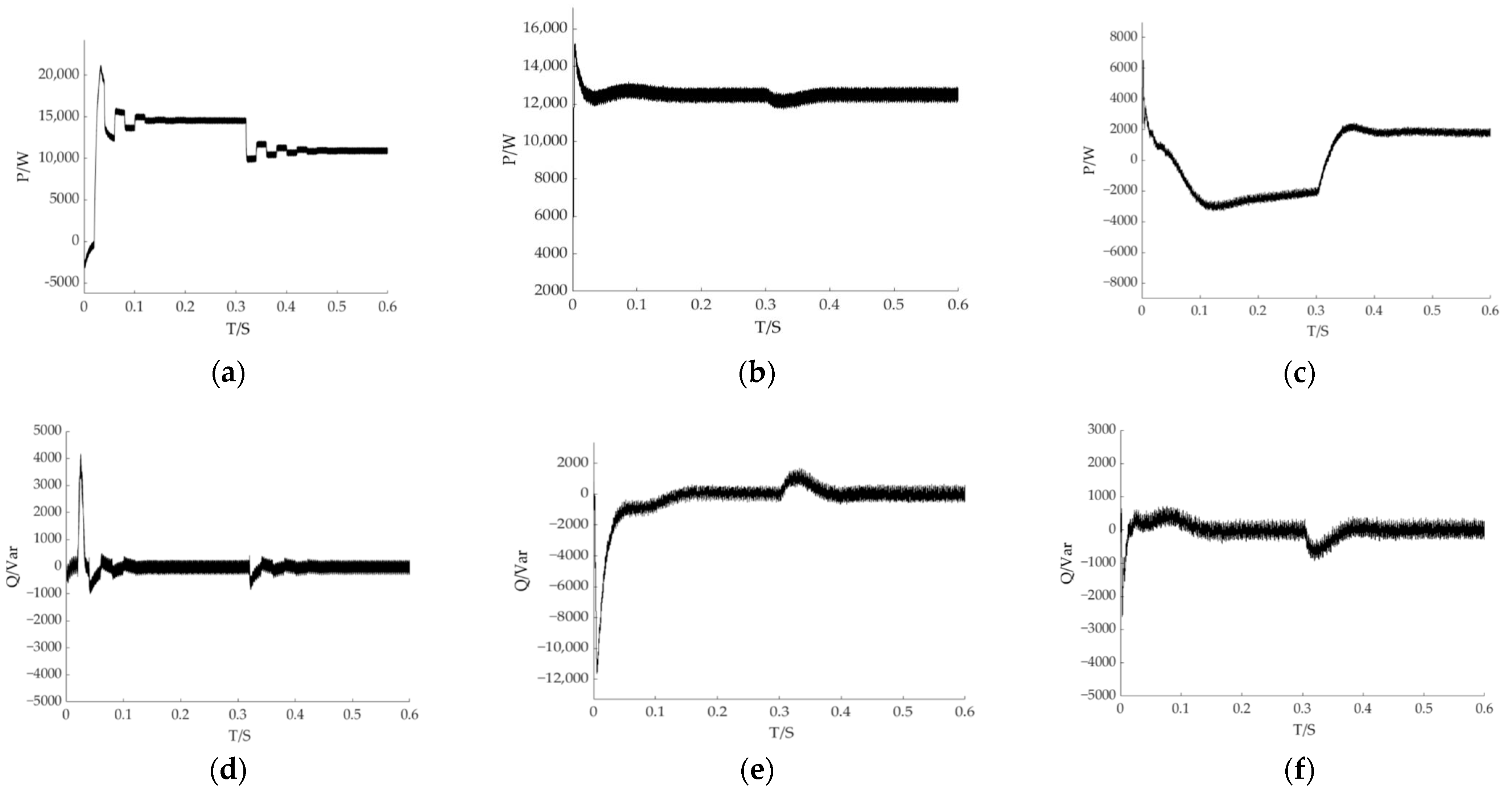

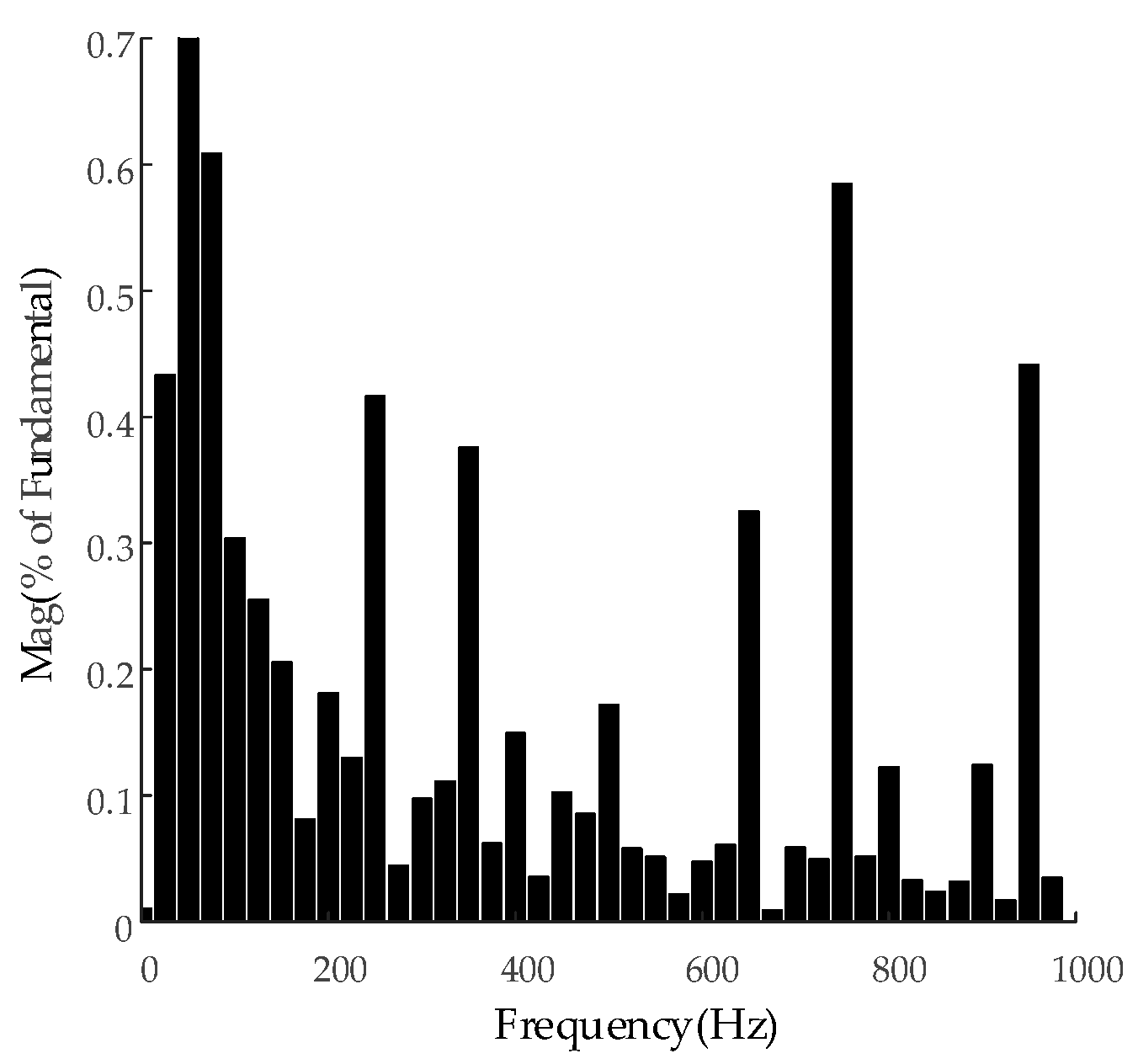

5.2. PV Energy Storage Grid-Connected Simulation Analysis

6. Discussion

- Employing higher-precision algorithms to address the maximum power tracking issue under partial shading conditions, aiming to achieve more accurate tracking;

- Designing three-level or even multi-level structures for three-phase voltage-type PWM converters to effectively reduce output current harmonics, minimize electromagnetic interference, reduce losses, and enhance power conversion efficiency and output voltage range;

- Adopting a hybrid energy storage approach, combining energy storage batteries with capacitors instead of using a single energy storage battery form, which can effectively mitigate power fluctuations caused by sudden changes in photovoltaic and load, thereby offering a longer service life and rapid response capability;

- Shifting from the PQ control strategy to employ the virtual synchronous generator (VSG) control algorithm for energy storage systems, enabling multi-level parallel operation of multiple energy storage systems, thereby achieving higher power state operation, and centralizing distributed power grids to realize the effect of photovoltaic microgrids, which is more in line with practical life requirements.

7. Conclusions

- The proposed MPPT control strategy, utilizing fuzzy theory, demonstrates enhanced tracking speed, improved tracking accuracy, and reduced oscillation. These advantages contribute to maximizing the output efficiency of PV cells;

- A control strategy is proposed for the three-phase voltage source PWM converter in the PV system, which involves an outer loop for voltage control and an inner loop for current control. Additionally, a control strategy is proposed for the converter in the energy storage system, which focuses on PQ control. The collaboration between the PV cell and the power grid is essential for optimizing energy utilization. When the PV cell generates more energy than the grid requires, it not only supplies electricity to the grid but also charges the energy storage battery to prevent energy wastage. Conversely, when the PV cell generates less energy than the power grid demands, the PV system and the energy storage system work in tandem to mitigate power fluctuations;

- A novel constant voltage control strategy is proposed for the bidirectional DC/DC converter, aiming to enhance the stability of the DC bus voltage and optimize the charging efficiency of the energy storage battery.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xin, P. Research on Solar Power Technology Economic Evaluation and Application Prospect. Master’s Thesis, North China Electric Power University, Beijing, China, 2015. [Google Scholar]

- Xu, D.; Yang, H. Optimal decision-making method for the ecological compensation of rural photovoltaic power generation adapted to rural revitalization and sustainable energy development. Trans. Chin. Soc. Agric. Eng. 2023, 39, 218–226. [Google Scholar]

- Ding, M.; Wang, W. A review on the effect of large-scale PV generation on power systems. Proc. CSEE 2014, 34, 1–14. [Google Scholar]

- Liu, C. Research on the influence of grid-connected photovoltaic system on power grid. Master’s Thesis, Shandong University, Jinan, China, 2020. [Google Scholar]

- Xu, W.; Bao, W. Review of impact on power quality of distributed power connecting to grid. Chin. J. Power Technol. 2015, 39, 2799–2802. [Google Scholar]

- De, S.; Urbanetz, J. Benefit Analysis of Grid Connected Photovoltaic Solar System with Energy Storage. Braz. Arch. Biol. Technol. 2021, 64, 122–142. [Google Scholar]

- Liu, J.; Chen, X. Overview on hybrid solar photovoltaic-electrical energy storage technologies for power supply to buildings. Energy Convers. Manag. 2019, 187, 103–121. [Google Scholar] [CrossRef]

- Luo, L.; Abdulkareem, S. Optimal scheduling of a renewable based microgrid considering photovoltaic system and battery energy storage under uncertainty. J. Energy Storage 2020, 28, 103–121. [Google Scholar] [CrossRef]

- Kitworawut, P.; Ketjoy, N. Best Practice in Battery Energy Storage for PV Systems in Low Voltage Distribution Network: A Case Study of Thailand Provincial Electricity Authority Network. Energies 2023, 16, 2469. [Google Scholar] [CrossRef]

- Soares, L.; Souza, A.; Silva, W. Grid-Connected PV Systems with Energy Storage for Ancillary Services. Energies 2023, 16, 7379. [Google Scholar] [CrossRef]

- Du, J.; Zhao, H. Outer loop voltage control method based on DC power control of three-phase grid-connected inverter. Acta Energiae Solaris Sin. 2019, 40, 2622–2629. [Google Scholar]

- Akbari, H.; Browne, M. Efficient energy storage technologies for photovoltaic systems. Sol. Energy 2019, 192, 144–168. [Google Scholar] [CrossRef]

- Huang, K.; Chao, K. Maximum Power Point Tracking of PV Module Arrays Based on a Modified Gray Wolf Optimization Algorithm. Energies 2023, 16, 4329. [Google Scholar] [CrossRef]

- Liu, H.; Fang, Q. Application of improved ODPSO algorithm in photovoltaic MPPT. Control. Eng. China 2023, 30, 1357–1367. [Google Scholar]

- Benhadouga, S.; Belkaid, A. Experimental Comparative Study MPPT between P&O and Sliding Control of a Small PV System. Int. J. Renew. Energy Res. 2022, 12, 863–869. [Google Scholar]

- Bhattacharyya, S.; Kumar, P. Steady Output and Fast Tracking MPPT (SOFT-MPPT) for P&O and InC Algorithms. IEEE Trans. Sustain. Energy 2021, 12, 293–302. [Google Scholar]

- Nguyen, H.; Huynh, T. Comparative Efficiency Assessment of MPPT Algorithms in Photovoltaic Systems. Int. J. Renew. Energy Res. 2022, 12, 2061–2067. [Google Scholar]

- Kordestani, M.; Mirzaee, A.; Safavi, A. Maximum Power Point Tracker (MPPT) for PV Power Systems-A Systematic Literature Review. In Proceedings of the 2018 European Control Conference (ECC), Limassol, Cyprus, 12–15 June 2018. [Google Scholar]

- Manohar, M.; Koley, E. An efficient MPPT and reliable protection scheme for PV-integrated microgrid under partial shading and array faults. Mod. Maximum Power Point Track. Tech. PV Energy Syst. 2020, 10, 303–329. [Google Scholar]

- Allahyari, S.; Taheri, N. A novel adaptive neural MPPT algorithm for photovoltaic system. Int. J. Automot. Mech. Eng. 2018, 15, 5421–5434. [Google Scholar] [CrossRef]

- Muftah, M.; Salem, M. A grid-tied PV-fuel cell multilevel inverter under PQ open-loop control scheme. Front. Energy Res. 2022, 10, 968371. [Google Scholar] [CrossRef]

- Yusof, N.; Ishak, D. Improved Control in Single Phase Inverter Grid-Tied PV System Using Modified PQ Theory. Intell. Autom. Soft Comput. 2023, 37, 2441–2457. [Google Scholar] [CrossRef]

- Lao, K.; Deng, W. PQ-Coupling Strategy for Droop Control in Grid-Connected Capacitive-Coupled Inverter. IEEE Access 2019, 7, 31663–31671. [Google Scholar] [CrossRef]

- Seo, S.; Choi, H. Digital Implementation of Fractional Order PID-Type Controller for Boost DCDC Converter. IEEE Access 2019, 7, 142652–142662. [Google Scholar] [CrossRef]

- Do, D.; Nguyen, M. Three-Level Quasi-Switched Boost T-Type Inverter: Analysis, PWM Control, and Verification. IEEE Trans. Ind. Electron. 2018, 65, 8320–8329. [Google Scholar] [CrossRef]

- Chandrasekar, B.; Nallaperumal, C. Non-Isolated High-Gain Triple Port DC–DC Buck-Boost Converter with Positive Output Voltage for PV Applications. IEEE Access 2020, 8, 113649–113666. [Google Scholar] [CrossRef]

- Wang, T.; Chen, K. Research on coordinated control strategy of photovoltaic energy storage system. Energy Rep. 2023, 9, 224–233. [Google Scholar] [CrossRef]

- Jusoh, M.; Daud, M. Fuzzy logic-based control strategy for hourly power dispatch of grid-connected photovoltaic with hybrid energy storage. Prz. Elektrotechniczny 2022, 98, 112–132. [Google Scholar] [CrossRef]

- Ayeng’o, S.; Axelsen, H. A model for direct-coupled PV systems with batteries depending on solar radiation, temperature and number of serial connected PV cells. Solar Energy 2019, 183, 120–131. [Google Scholar] [CrossRef]

- Park, H.; Kim, Y. PV Cell Model by Single-diode Electrical Equivalent Circuit. J. Electr. Eng. Technol. 2016, 11, 1323–1331. [Google Scholar] [CrossRef]

- Nabipour, M.; Razaz, M. A new MPPT scheme based on a novel fuzzy approach. Renew. Sustain. Energy Rev. 2017, 74, 1147–1169. [Google Scholar] [CrossRef]

- Loukil, K.; Abbes, H. Design and implementation of reconfigurable MPPT fuzzy controller for photovoltaic systems. Ain Shams Eng. J. 2020, 11, 319–328. [Google Scholar] [CrossRef]

- Chen, Z. The Research on Nonlinear Control Strategy of the Three-Phase Voltage Type PWM Converter. Master’s Thesis, Shanxi University, Taiyuan, China, 2018. [Google Scholar]

| ∆e | NB | NS | Z | PS | PB | |

|---|---|---|---|---|---|---|

| e | ||||||

| NB | PB | PB | PB | Z | Z | |

| NS | PS | PS | PS | Z | Z | |

| Z | PS | PS | Z | NS | NB | |

| PS | Z | Z | NS | NS | NB | |

| PB | Z | Z | NB | NB | NB | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Lin, C.; Zheng, K.; Zhao, W.; Wang, X. Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation. Energies 2023, 16, 8056. https://doi.org/10.3390/en16248056

Wang T, Lin C, Zheng K, Zhao W, Wang X. Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation. Energies. 2023; 16(24):8056. https://doi.org/10.3390/en16248056

Chicago/Turabian StyleWang, Tao, Cunhao Lin, Kuo Zheng, Wei Zhao, and Xinglu Wang. 2023. "Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation" Energies 16, no. 24: 8056. https://doi.org/10.3390/en16248056

APA StyleWang, T., Lin, C., Zheng, K., Zhao, W., & Wang, X. (2023). Research on Grid-Connected Control Strategy of Photovoltaic (PV) Energy Storage Based on Constant Power Operation. Energies, 16(24), 8056. https://doi.org/10.3390/en16248056