Voltage-Induced Heating Defect Detection for Electrical Equipment in Thermal Images

Abstract

:1. Introduction

2. Related Works

2.1. Electrical Equipment Localization

2.2. Electrical Defect Detection

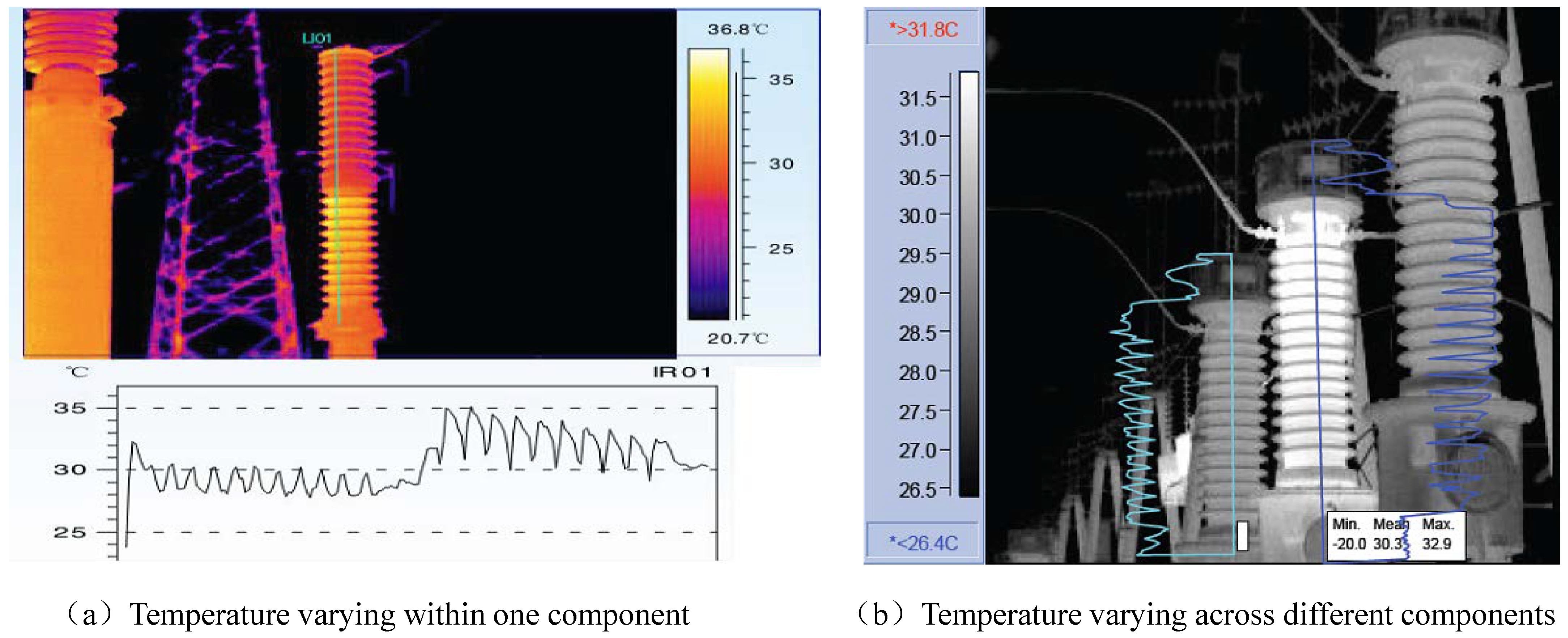

3. The Characteristics of Voltage-Induced Heating Defects

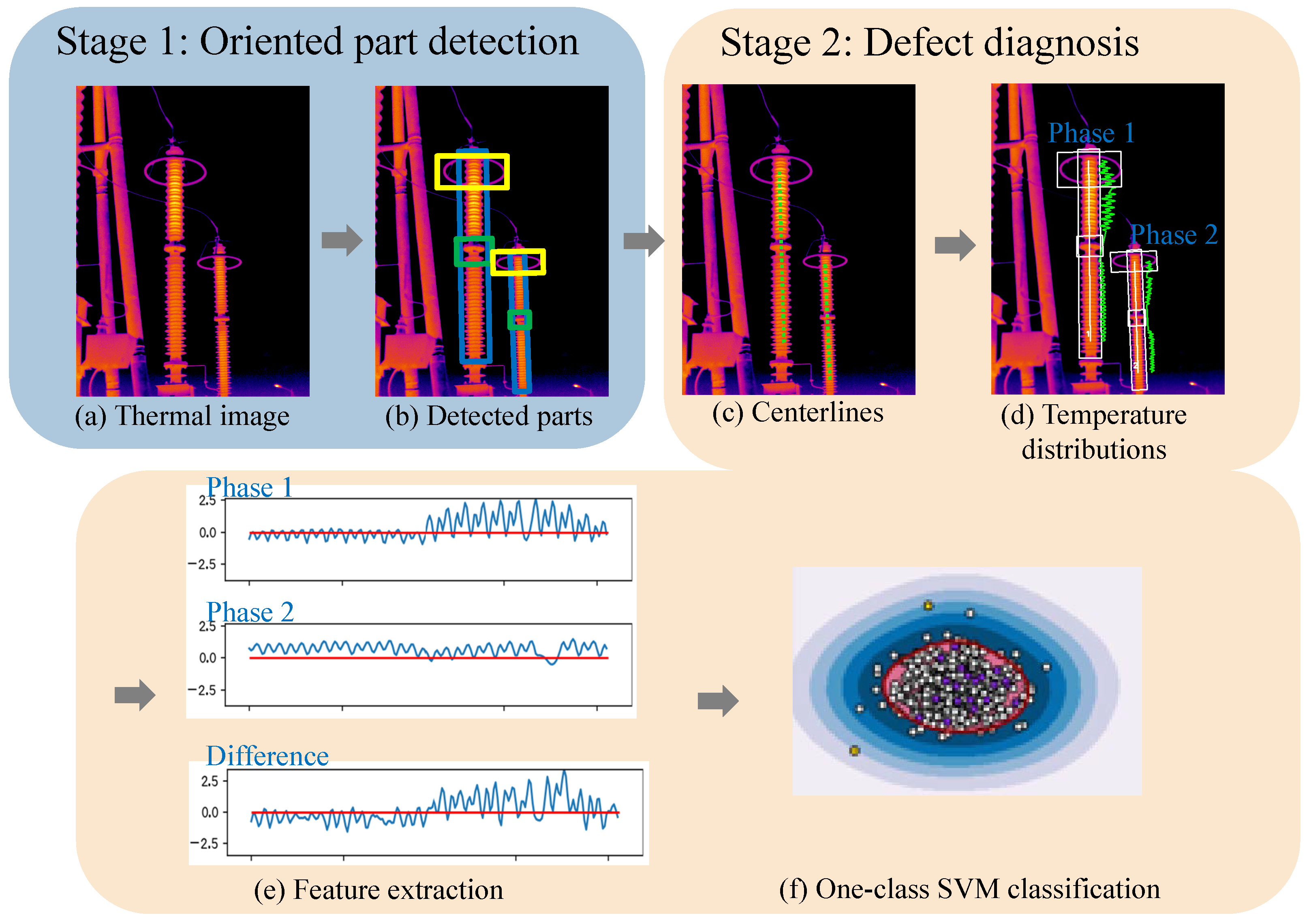

4. The Proposed Method

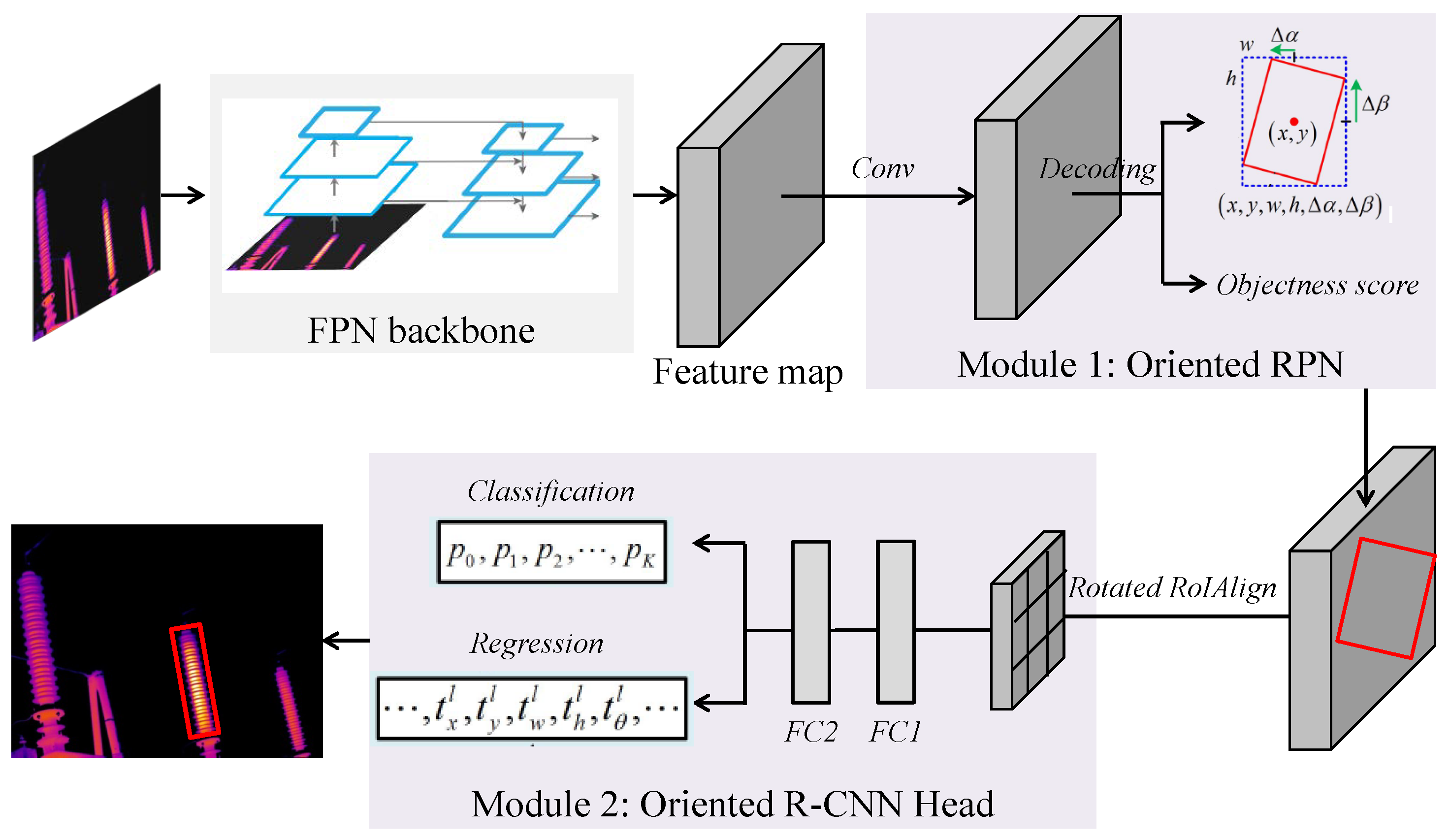

4.1. Oriented R-CNN-Based Part Detection

4.1.1. Oriented RPN

4.1.2. Oriented R-CNN Head

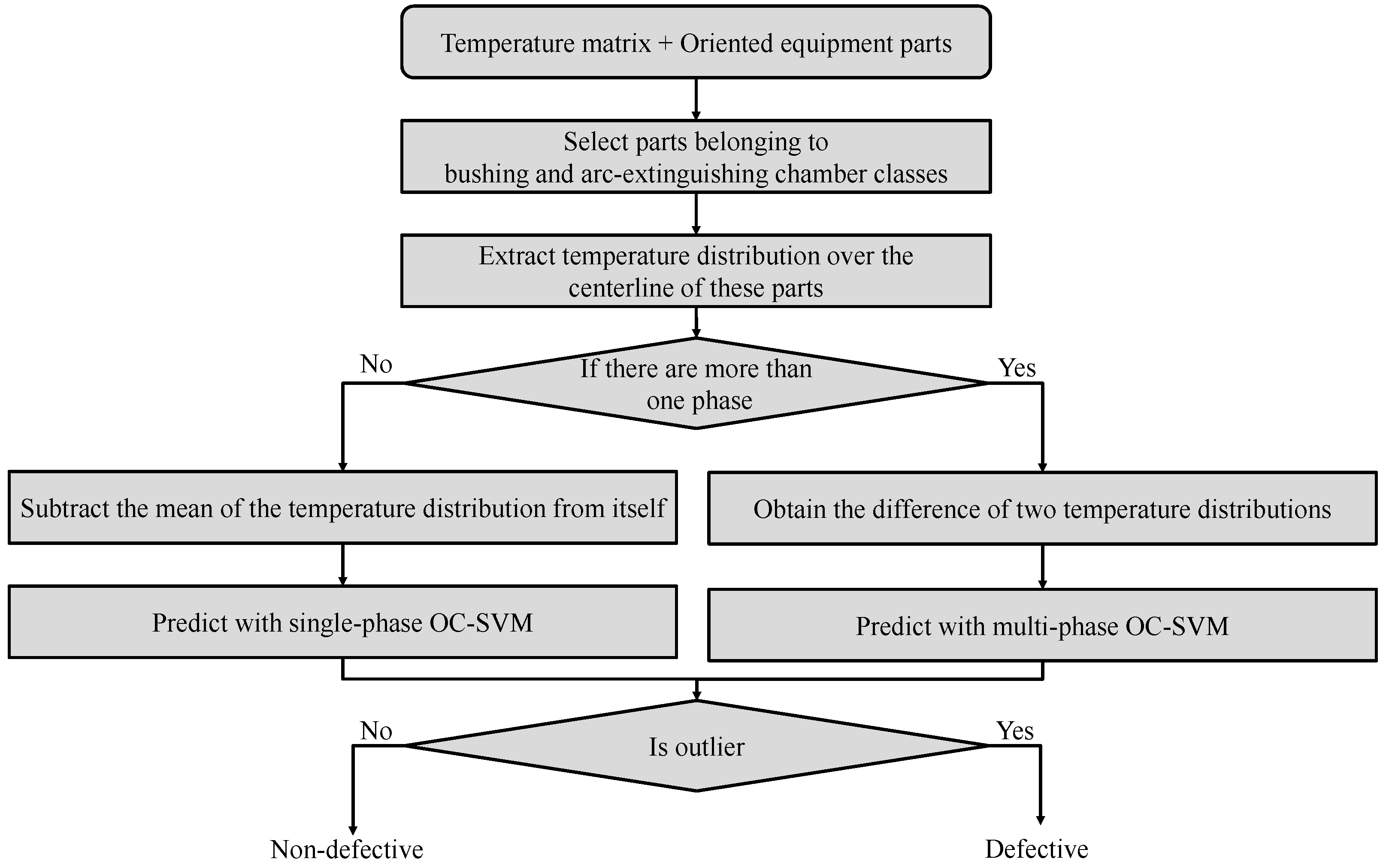

4.2. One-Class SVM-Based Defect Diagnosis

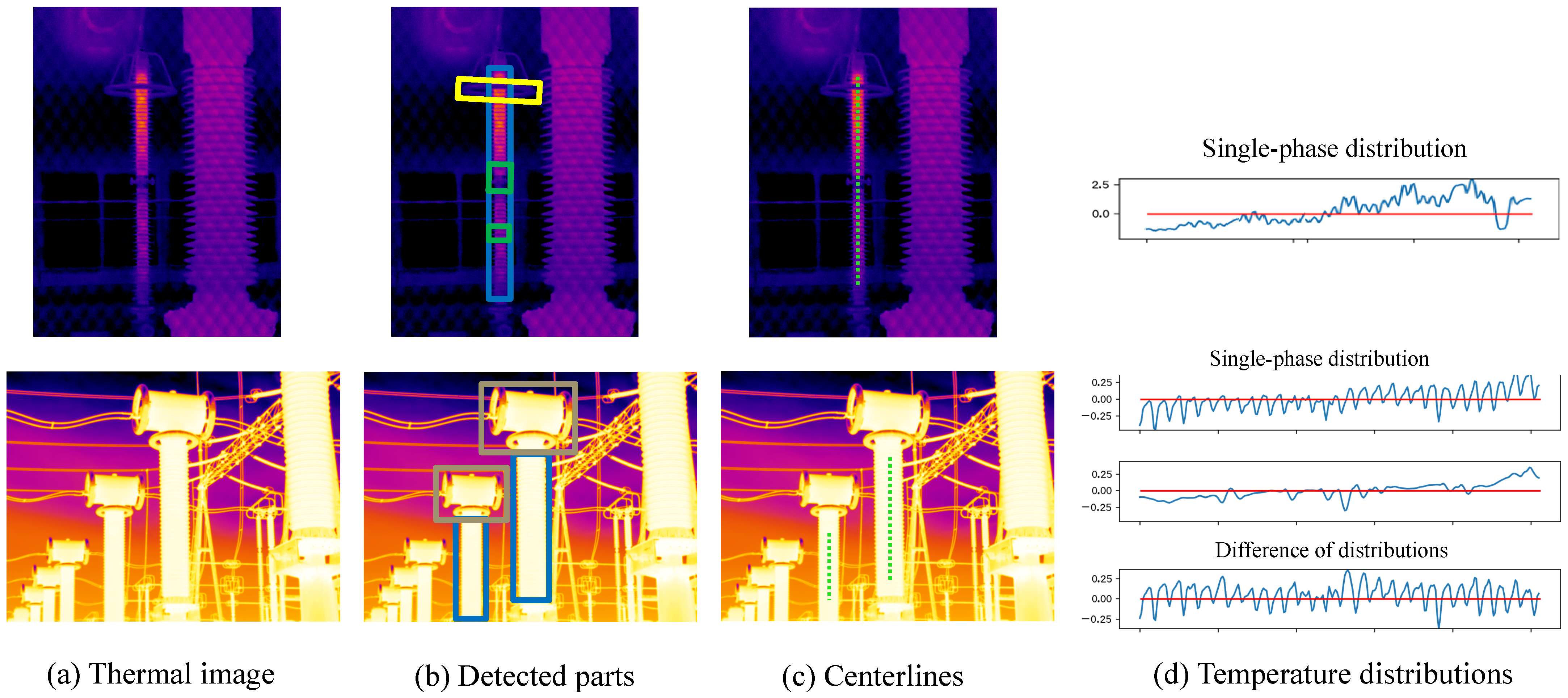

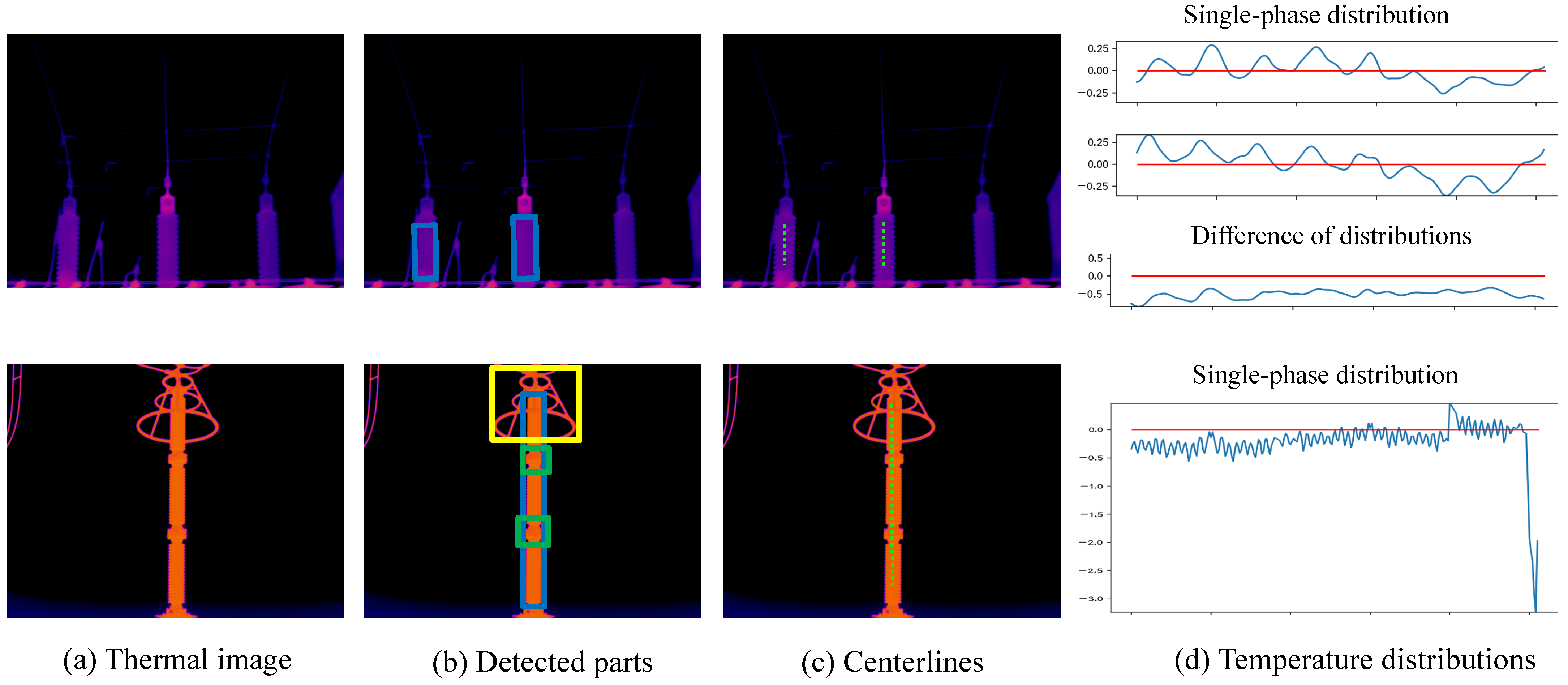

4.2.1. Feature Extraction

4.2.2. One-Class SVM

5. Experiments

5.1. Dataset and Evaluation Metrics

5.2. Implementation Details

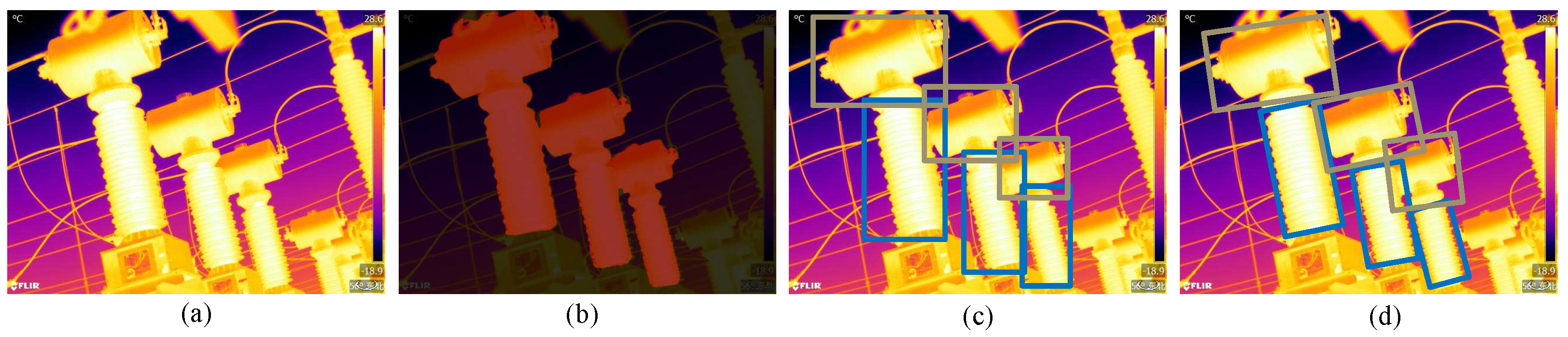

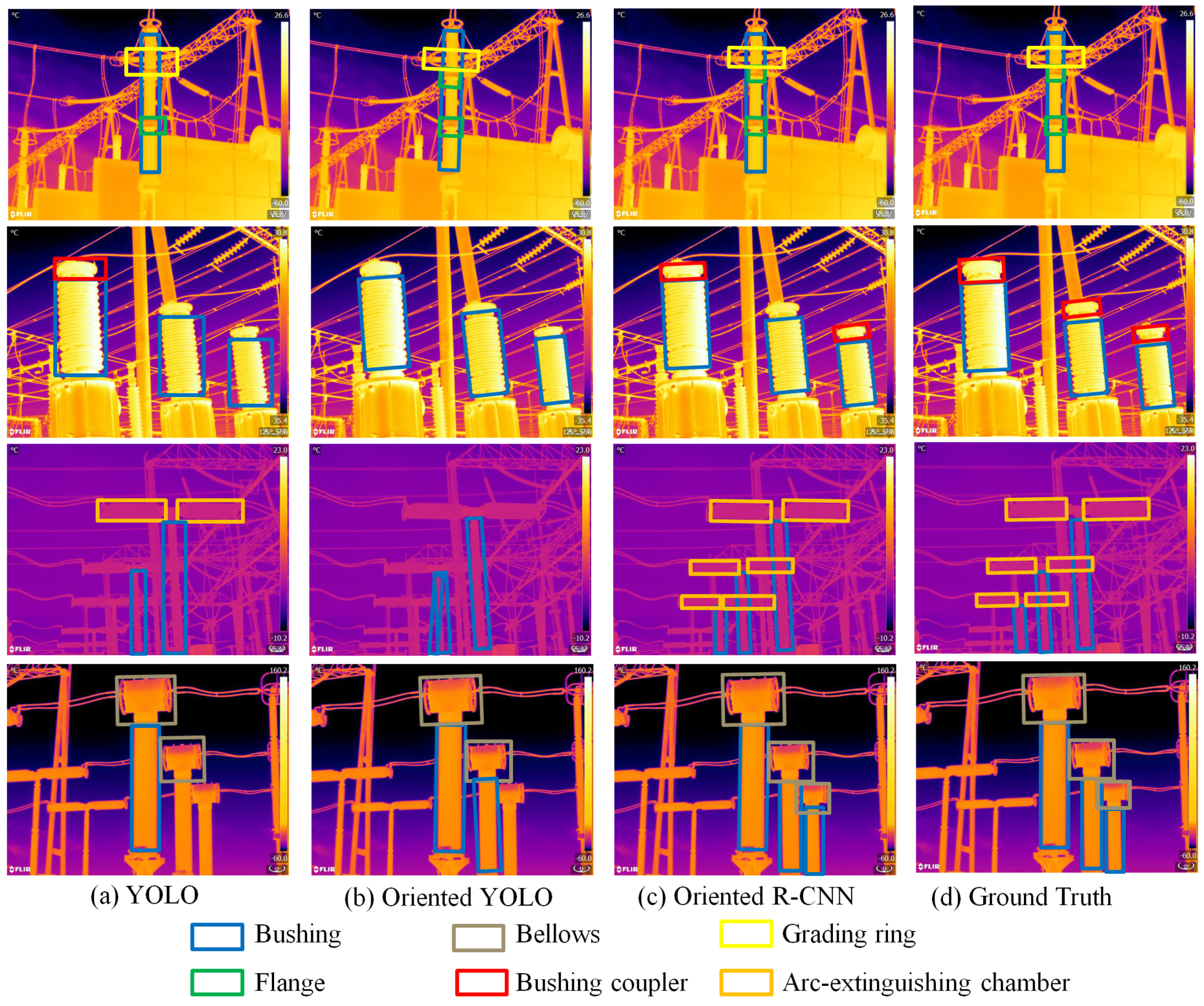

5.3. Effectiveness of Oriented Part Detection

5.4. Effectiveness of Defect Diagnosis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hou, F.; Zhang, Y.; Zhou, Y.; Zhang, M.; Lv, B.; Wu, J. Review on Infrared Imaging Technology. Sustainability 2022, 14, 11161. [Google Scholar] [CrossRef]

- Jadin, M.S.; Taib, S. Recent progress in diagnosing the reliability of electrical equipment by using infrared thermography. Infrared Phys. Technol. 2012, 55, 236–245. [Google Scholar] [CrossRef]

- Guo, C.; Ren, M.; Xia, C.; Dong, M.; Wang, B. Fault Diagnosis of Power Equipment Based on Infrared Image Analysis. In Proceedings of the 2020 IEEE International Conference on Advances in Electrical Engineering and Computer Applications (AEECA), Dalian, China, 25–27 August 2020; pp. 659–663. [Google Scholar] [CrossRef]

- Balakrishnan, G.K.; Yaw, C.T.; Koh, S.P.; Abedin, T.; Raj, A.A.; Tiong, S.K.; Chen, C.P. A Review of Infrared Thermography for Condition-Based Monitoring in Electrical Energy: Applications and Recommendations. Energies 2022, 15, 6000. [Google Scholar] [CrossRef]

- Attallah, O.; Ibrahim, R.A.; Zakzouk, N.E. Fault diagnosis for induction generator-based wind turbine using ensemble deep learning techniques. Energy Rep. 2022, 8, 12787–12798. [Google Scholar] [CrossRef]

- Attallah, O.; Ibrahim, R.A.; Zakzouk, N.E. CAD system for inter-turn fault diagnosis of offshore wind turbines via multi-CNNs & feature selection. Renew. Energy 2023, 203, 870–880. [Google Scholar] [CrossRef]

- Huda, A.; Taib, S. Suitable features selection for monitoring thermal condition of electrical equipment using infrared thermography. Infrared Phys. Technol. 2013, 61, 184–191. [Google Scholar] [CrossRef]

- Zarco-Periñán, P.J.; Martínez-Ramos, J.L.; Zarco-Soto, F.J. A novel method to correct temperature problems revealed by infrared thermography in electrical substations. Infrared Phys. Technol. 2021, 113, 103623. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, W.; Zhang, H.; Bai, D.; Li, J.; Xu, R. An intelligent infrared image fault diagnosis for electrical equipment. In Proceedings of the 2020 5th Asia Conference on Power and Electrical Engineering (ACPEE), Chengdu, China, 4–7 June 2020; pp. 1829–1833. [Google Scholar] [CrossRef]

- Xie, X.; Cheng, G.; Wang, J.; Yao, X.; Han, J. Oriented R-CNN for Object Detection. In Proceedings of the 2021 IEEE/CVF International Conference on Computer Vision (ICCV), Montreal, BC, Canada, 11–17 October 2021; pp. 3500–3509. [Google Scholar] [CrossRef]

- Schölkopf, B.; Williamson, R.; Smola, A.; Shawe-Taylor, J.; Platt, J. Support Vector Method for Novelty Detection. In Proceedings of the Neural Information Processing Systems, NIPS’99; MIT Press: Cambridge, MA, USA, 1999; pp. 582–588. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. In Proceedings of the Advances in Neural Information Processing Systems; Cortes, C., Lawrence, N., Lee, D., Sugiyama, M., Garnett, R., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2015; Volume 28. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar] [CrossRef]

- Duan, K.; Bai, S.; Xie, L.; Qi, H.; Huang, Q.; Tian, Q. CenterNet: Keypoint Triplets for Object Detection. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Republic of Korea, 27 October–2 November 2019; pp. 6568–6577. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, X.; Pei, S.; Ma, Z.; Zhang, G.; Lin, Y.; Chen, Y. Research on automatic location and recognition of insulators in substation based on YOLOv3. High Voltage 2020, 5, 62–68. [Google Scholar] [CrossRef]

- Han, S.; Yang, F.; Yang, G.; Gao, B.; Zhang, N.; Wang, D. Electrical equipment identification in infrared images based on ROI-selected CNN method. Electr. Power Syst. Res. 2020, 188, 106534. [Google Scholar] [CrossRef]

- Jiang, C.; Ren, H.; Ye, X.; Zhu, J.; Zeng, H.; Nan, Y.; Sun, M.; Ren, X.; Huo, H. Object detection from UAV thermal infrared images and videos using YOLO models. Int. J. Appl. Earth Obs. Geoinf. 2022, 112, 102912. [Google Scholar] [CrossRef]

- Han, S.; Yang, F.; Jiang, H.; Yang, G.; Wang, D.; Zhang, N. Statistical analysis of infrared thermogram for CNN-based electrical equipment identification methods. Appl. Artif. Intell. 2022, 36, 2004348. [Google Scholar] [CrossRef]

- Chen, L.C.; Zhu, Y.; Papandreou, G.; Schroff, F.; Adam, H. Encoder-Decoder with Atrous Separable Convolution for Semantic Image Segmentation. In Proceedings of the European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; Ferrari, V., Hebert, M., Sminchisescu, C., Weiss, Y., Eds.; Springer: Cham, Switzerland, 2018; pp. 833–851. [Google Scholar]

- Wang, F.; Guo, Y.; Li, C.; Lu, A.; Ding, Z.; Tang, J.; Luo, B. Electrical Thermal Image Semantic Segmentation: Large-Scale Dataset and Baseline. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Gong, X.; Yao, Q.; Wang, M.; Lin, Y. A Deep Learning Approach for Oriented Electrical Equipment Detection in Thermal Images. IEEE Access 2018, 6, 41590–41597. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, Y.; Sun, Y.; Li, J.; Shi, Z.; Zhang, C.; Lai, C.S.; Lai, L.L. Arbitrary-Oriented Detection of Insulators in Thermal Imagery via Rotation Region Network. IEEE Trans. Ind. Inform. 2022, 18, 5242–5252. [Google Scholar] [CrossRef]

- Zou, H.; Huang, F. An intelligent fault diagnosis method for electrical equipment using infrared images. In Proceedings of the 2015 34th Chinese Control Conference (CCC), Hangzhou, China, 28–30 July 2015; pp. 6372–6376. [Google Scholar] [CrossRef]

- Ullah, I.; Khan, R.U.; Yang, F.; Wuttisittikulkij, L. Deep Learning Image-Based Defect Detection in High Voltage Electrical Equipment. Energies 2020, 13, 392. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet Classification with Deep Convolutional Neural Networks. In Proceedings of the Advances in Neural Information Processing Systems; Pereira, F., Burges, C., Bottou, L., Weinberger, K., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2012; Volume 25. [Google Scholar]

- Li, B.; Wang, T.; Hu, Z.; Yuan, C.; Zhai, Y. Two-Level Model for Detecting Substation Defects from Infrared Images. Sensors 2022, 22, 6861. [Google Scholar] [CrossRef] [PubMed]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask R-CNN. In Proceedings of the 2017 IEEE International Conference on Computer Vision (ICCV), Venice, Italy, 22–29 October 2017; pp. 2980–2988. [Google Scholar] [CrossRef]

- Bolya, D.; Zhou, C.; Xiao, F.; Lee, Y.J. YOLACT: Real-Time Instance Segmentation. In Proceedings of the 2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Republic of Korea, 27 October–2 November 2019; pp. 9156–9165. [Google Scholar] [CrossRef]

- DL/T 664-2016; Infrared Diagnostic Application Specification for Live Equipment. China Electric Power Research Institute: Beijing, China, 2016.

- Lin, T.Y.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature Pyramid Networks for Object Detection. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 936–944. [Google Scholar] [CrossRef]

| Equipment | Current Transformer | Potential Transformer | Arrester | Breaker | Total No. of Parts | |

|---|---|---|---|---|---|---|

| Part | ||||||

| Bushing | 2365 | 1641 | 1506 | 1771 | 7283 | |

| Bellows | 2365 | 0 | 0 | 0 | 2365 | |

| Grading ring | 0 | 478 | 1506 | 0 | 1984 | |

| Bushing coupler | 0 | 334 | 0 | 0 | 334 | |

| Flange | 0 | 1737 | 1847 | 0 | 3584 | |

| Arc-extinguishing chamber | 0 | 0 | 0 | 2019 | 2019 | |

| Total no. of equipment (no. of images) | 2365 (1123) | 1641 (1159) | 1506 (644) | 1984 (1136) | 7283 (4062) | |

| Backbone | Epochs | Augmentation | mAP (%) |

|---|---|---|---|

| ResNet50 | 12 | H, V, D | 89.8 |

| H | 90.5 | ||

| 40 | H, V, D | 93.3 | |

| H | 94.5 | ||

| Swin-T | 40 | H, V, D | 93.8 |

| H | 95.4 |

| Part | Bushing | Bellows | Bushing Coupler | Grading Ring | Flange | Arc-Extinguishing Chamber | mAP (%) | |

|---|---|---|---|---|---|---|---|---|

| Method | ||||||||

| Faster R-CNN [12] | 82.9 | 84.8 | 95.0 | 90.8 | 95.2 | 54.5 | 83.9 | |

| YOLO [13] | 78.1 | 81.7 | 94.3 | 87.2 | 91.0 | 53.5 | 81.0 | |

| Oriented YOLO [21] | 82.0 | 83.3 | 90.3 | 95.3 | 93.5 | 71.8 | 86.0 | |

| Oriented R-CNN | 90.9 | 90.9 | 99.8 | 99.9 | 99.9 | 90.9 | 95.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.; Li, Z.; Sun, Y.; Yang, Y.; Zheng, W. Voltage-Induced Heating Defect Detection for Electrical Equipment in Thermal Images. Energies 2023, 16, 8036. https://doi.org/10.3390/en16248036

Lin Y, Li Z, Sun Y, Yang Y, Zheng W. Voltage-Induced Heating Defect Detection for Electrical Equipment in Thermal Images. Energies. 2023; 16(24):8036. https://doi.org/10.3390/en16248036

Chicago/Turabian StyleLin, Ying, Zhuangzhuang Li, Yiwei Sun, Yi Yang, and Wenjie Zheng. 2023. "Voltage-Induced Heating Defect Detection for Electrical Equipment in Thermal Images" Energies 16, no. 24: 8036. https://doi.org/10.3390/en16248036

APA StyleLin, Y., Li, Z., Sun, Y., Yang, Y., & Zheng, W. (2023). Voltage-Induced Heating Defect Detection for Electrical Equipment in Thermal Images. Energies, 16(24), 8036. https://doi.org/10.3390/en16248036