Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria

Abstract

:1. Introduction

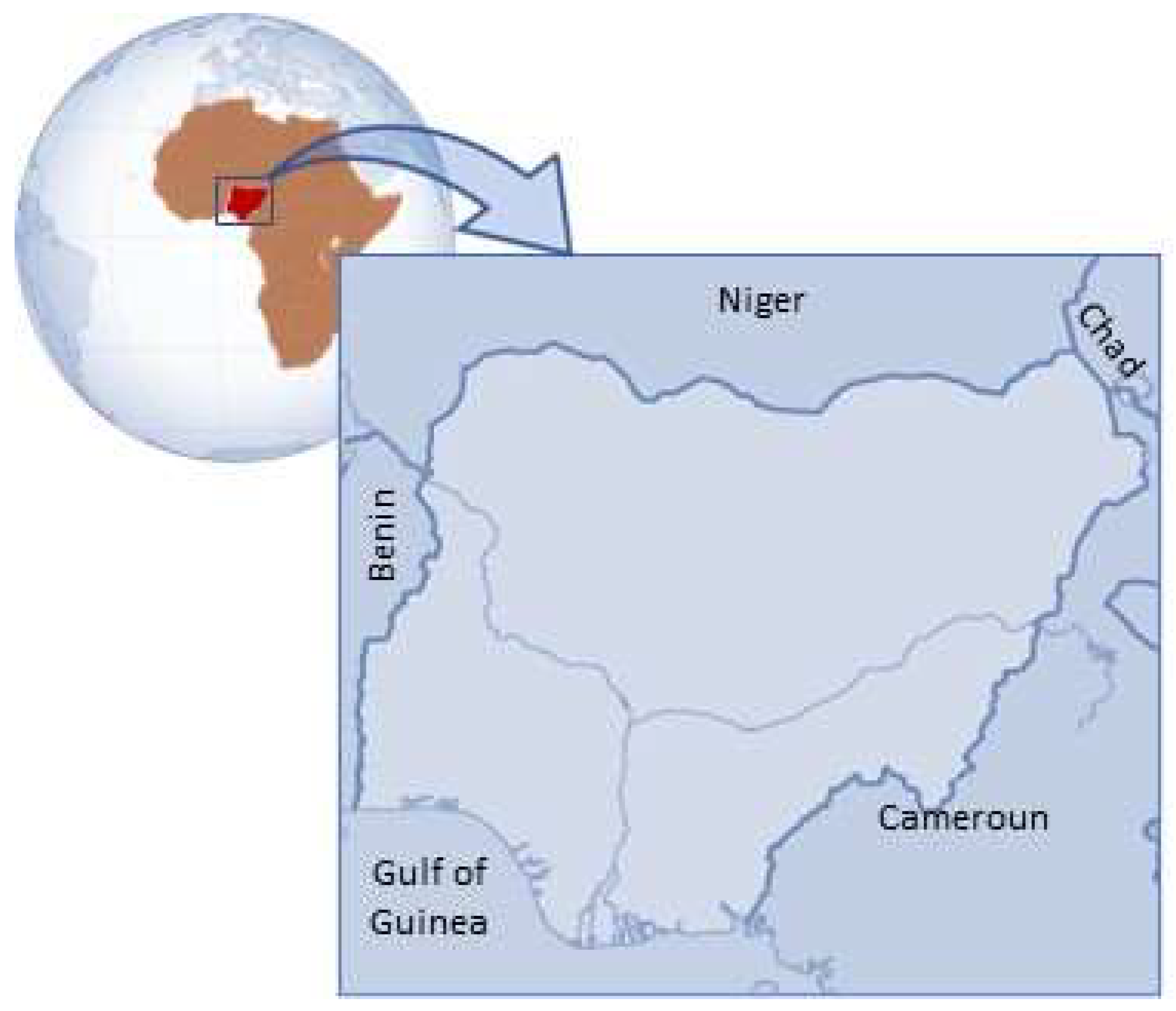

2. Biomass Situation in Nigeria

3. Solid Biofuel Production Technologies in Nigeria

| Machine Type | Solid Biofuel Produced and Material Utilized | Machine Description and Production Capacity | Mode of Operation and Comments | References |

|---|---|---|---|---|

| Hydraulic presses with single or multiple molds | ||||

| Hydraulic compression press with cylindrical mold | Briquettes from agglomerated charcoal fines and pine sawdust | Products were produced with applied pressure of 5 MPa | Binder was required. Manually operated press located at Federal Research Institute of Nigeria, Ibadan, Nigeria. | [30] |

| Uniaxial hydraulic compression press with cylindrical mold | Elephant grass briquettes | Press operated with compaction force of 355.03 N | Manually operated press. High moisture product. | [31] |

| Hydraulic briquetting machine with 3 molds | Bio-coal briquettes of groundnut husk | Press operated with compaction force of 276.36 N. Compaction pressure of 5 MPa. | Manually operated press. Binder was required. | [32] |

| Composite briquettes of coal and corncobs | [33] | |||

| Coal and cassava stalks | [34] | |||

| Lightweight hydraulic press with 4 molds | Water hyacinth and sawdust briquettes | Molds have diameter of 80 mm for briquette production | Manually operated press. Binder was required. | [35] |

| Hydraulic briquetting press with 4 molds | Rice husk, sawdust, and composite rice husk-sawdust briquettes | Cylindrical molds with press operated with a 3-ton hydraulic jack. Production capacity ranged between 20 and 30 kg/h. Compaction pressure ranged between 0.4 and 0.6 MPa. | Manually operated press. Binder was required. | [36] |

| Composite briquettes of orange peels and corncobs | Compaction pressure up to 15 MPa | Manually operated press. Binder was required. | [37] | |

| Hydraulic briquetting press with 12 molds | Composite briquettes of coal-banana leaves, and coal-banana pseudostem | Compaction force of 60 N and compaction pressure of 7 MPa | Manually operated. Binder was required. | [38] |

| Hydraulic briquetting press with replaceable molds | Torrefied corn husk, sawdust, and cassava peel briquettes | Capacity to produce 576 briquettes in 8 h. Working pressure of 15 MPa. | Manually operated. Binder was required. | [39] |

| Hydraulic briquetting press with 20 molds | Palm kernel granules | Press capacity of 10 tons. Briquettes of 28 mm diameter and 50 mm length. Compaction force of 215.3 N. | Manually operated. Binder was required. | [40] |

| Hydraulic briquetting press with 6 molds | Briquettes from elephant grass and spear grass | Molds produce briquettes with diameter of 39 mm. Working pressure of 5 MPa. | Manually operated. Binder was required. Press located at National Centre for Energy Research and Development, University of Nsukka, Nigeria. | [41] |

| Composite briquettes of pine-needle dust and coal | Rectangular briquettes of 86 × 62 mm cross section. Working pressure of 5 MPa. | [42] | ||

| Hydraulic briquetting press with 20 molds | Dokanut and Docent groundnut shells | Working pressure ranged between 0.2 and 10 MPa | Manually operated. Binder was required. | [43] |

| Hydraulic briquetting press with 36 molds | Sawdust briquettes | Press capacity was 20 tons. Each mold was 100 × 70 × 150 mm. | Binder was required. Manually operated. | [44] |

| Hydraulic press with 4 molds | Corncob and rice husk briquettes | Compaction pressure of 2.10 MPa. Square cross-section briquettes with dimension of 75 mm. | Manually operated. Binder was required. | [45] |

| Briquettes from corncob, groundnut shell, melon shell, cassava, and yam peels | [46] | |||

| Hydraulic press with single die | Corncob briquettes | Maximum compaction pressure of 25 MPa Cylindrical die of 50 mm. Heated die. | Manually operated. No binder required | [47,48,49] |

| Sawdust briquettes | [50] | |||

| Hydraulic press with pelleting mold | Rice husk pellet | Operating pressure range of 28 to 34 MPa. Pellet of 12 mm diameter and 20 mm length. | Manually operated. Wet compaction. | [51] |

| Mechanical presses with single or multiple molds | ||||

| Motorized vibratory briquetting machine with 2 molds | Rice husk briquettes | Tapered cylindrical molds producing hollow briquettes | Motorized press. Binder was required. | [52] |

| Power screw operated presses with single or multiple molds | ||||

| Horizontal axis power screw operated press | Wastepaper and coconut husk admixtures | Press produces briquettes with average of 73 mm diameter and 37 mm length | Manually operated | [53] |

| Vertical axis power screw-operated press with 4 molds | Maize stalk briquettes | Press produces briquettes with 70 mm diameter and 50 mm length. Compaction force was 205.8 N. | Manually operated | [54] |

| Vertical axis power screw-operated press with 2 molds | Rice husk, sawdust, and maize stalk briquettes | Press produces briquettes with diameter of 70 mm. Working pressure of 0.42 MPa. | Manually operated | [55] |

| Power-screw-operated press | Water hyacinth briquettes | Cylindrical mold with diameter of 230 mm | Manually operated. Binder was required. Mold can be used as stove. | [56] |

| Dual-operated screw briquetting press | Carbonized melon seed shells | Machine capacity was 0.0025 kg/s and 0.0055 kg/s for manual and motorized operation, respectively. Briquette force was 47.13 N and power requirement was 0.785 kW. Produces briquettes with diameter of 25 mm. | Operation can switch between manual and motorized. Binder was required. | [57] |

| Motorized briquetting machine | Groundnut shell briquettes | Pressure exerted is 10 MPa | Motorized press. Binder was required. | [58] |

| Groundnut shell and wastepaper admixture | [59] | |||

| Solid biofuel equipment based on screw extrusion | ||||

| Screw-type pelleting machine | Pellets from palm kernel shell, palm fiber, empty fruit bunch | Capacity of 5 kg/h. Operating pressure of 1.2 kPa. | Electrically powered. Binder required. | [60,61] |

| Pellets from blends of coal and palm kernel shell | [62] | |||

| Screw extruder briquetting machine with heated die | Water hyacinth briquettes | Machine has a capacity of 120 kg/h and efficiency of 85%. Produces 90 briquettes per hour. Produces 50 mm diameter briquettes with 200 mm length and 10 mm center hole. | No binder was required. Electrically operated. | [63] |

| Screw extruder briquetting machine | Briquettes from blend of water hyacinth and groundnut shell | Machine has a capacity of 72 g/h and power consumption of 1.3 kW. Produces briquettes with 50 mm diameter. Efficiency of 90%. | [64] | |

| Screw extruder briquetting machine | Sawdust briquettes | Operating pressure of 2000 Pa. Die temperature of 450 °C. | Motorized machine. Heated die requiring dried biomass. No binder was required. | [65] |

| Screw extruder briquetting machine | Sawdust | Machine consists of a power unit, speed reducer gear assembly, extrusion assembly, and control panel. Die temperature of 300 °C. | No binder was required. Electrically operated. | [66] |

| Screw extruder briquetting machine | Rice husks and sugarcane bagasse briquettes | Machine produces briquettes of 56 mm with 100 mm length. Power rating of 949.5 W. Efficiency of 60%. Capacity of 60 briquettes in 30 min. | Binder was required. Electrically powered motorized machine. | [67] |

| Screw extruder briquetting machine | Municipal solid wastes | Throughput capacity of 2605.4 kg/h. Power rating of 5 hp. Minimum and maximum operating temperature of 327 and 412 °C. | No binder required. Motorized machine. | [68] |

| Screw extruder briquetting machine | Sawdust, rice husk, and palm fruit shell briquettes | Machine has capacity of 0.5 kg/s. | Motorized and electrically driven. Binder was required. | [69] |

| Screw extruder briquetting machine | Sawdust | Design capacity of 100 kg/h. Power rating of 30 kW. Heated die. | Electrically powered. No binder was required. | [70] |

| Mechanical piston briquetting machine | ||||

| Mechanical piston-type briquetting machine | Sawdust and rice husk briquettes | Machine produces briquettes with rectangular cross section. Machine has a capacity of 0.2 kg/s. | Motorized and electrically operated. Binder was required. | [71] |

4. Potential Utilization of Solid Biofuels for Domestic Energy Generation

5. Potential for Industrial Utilization of Solid Biofuel in Nigeria

6. Challenges of Solid Biofuel Production and Utilization

6.1. Indoor Air Pollution

6.2. Durability

6.3. Infrastructure

6.4. Supply Chain

7. Opportunities in Solid Biofuel Production and Utilization Sector

8. Policies Governing the Production and Utilization of Solid Biofuels in Nigeria

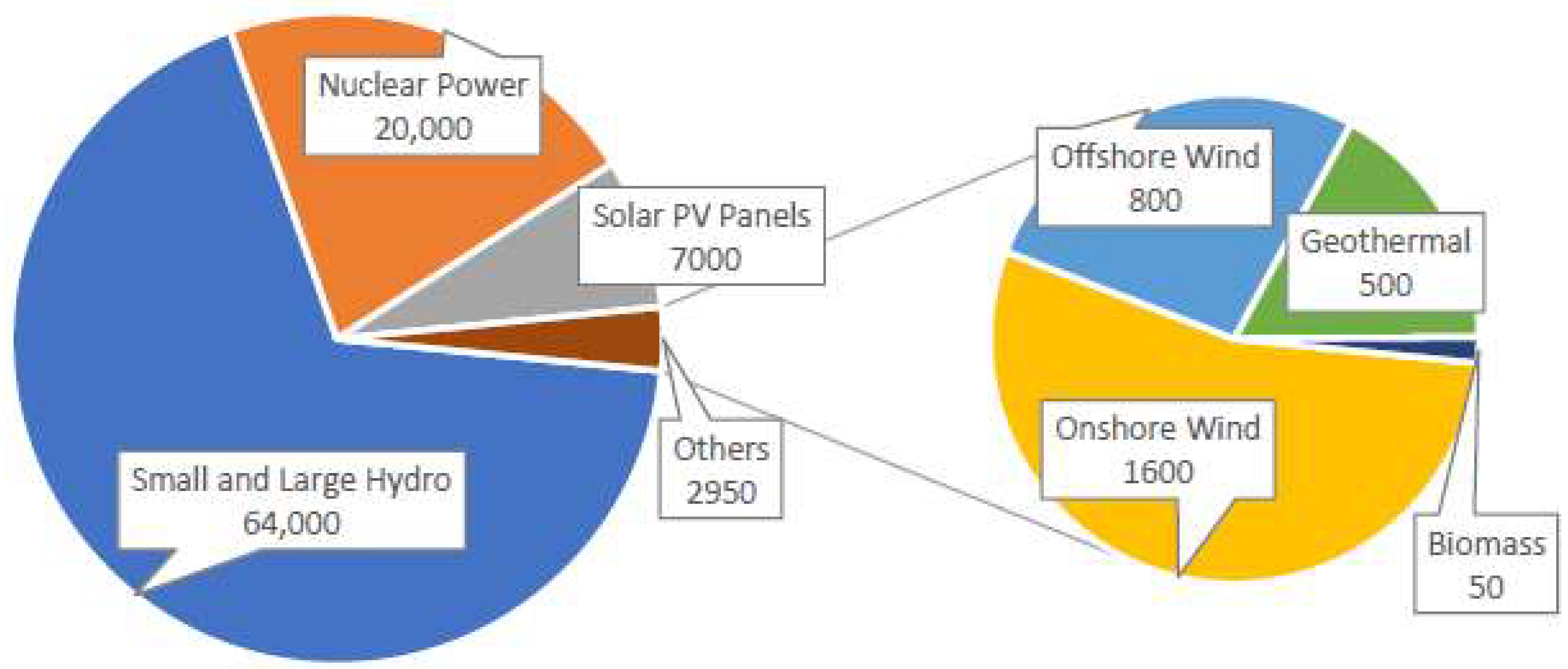

9. Advancing Nigeria’s Energy Transition through Solid Biofuel Production

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ECN | Energy Commission of Nigeria |

| FCR | Fuel conversion rate |

| FPM | Fine particulate matter |

| GHGs | Greenhouse gases |

| MSW | Municipal solid wastes |

| NREEEP | National Renewable Energy and Energy Efficiency Policy |

| NBPI | National Biofuel Policy and Incentives |

| NEMP | National Energy Master Plan |

| NEP | National Energy Policy |

| NPCCRS | National Policy on Climate Change and Response Strategy |

| REMP | Renewable Energy Master Plan |

| SESP | Strategic Education and Sensitization Programs |

| SFC | Specific fuel consumption |

| SGR | Specific gasification rate |

| SSA | Sub-Saharan Africa |

References

- Karlberg, L.; Hoff, H.; Flores-López, F.; Götz, A.; Matuschke, I. Tackling biomass scarcity—From vicious to virtuous cycles in sub-saharan africa. Curr. Opin. Environ. Sustain. 2015, 15, 1–8. [Google Scholar] [CrossRef]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Vakulchuk, R.; Overland, I.; Scholten, D. Renewable energy and geopolitics: A review. Renew. Sustain. Energy Rev. 2020, 122, 109547. [Google Scholar] [CrossRef]

- Mensah, T.N.O.; Oyewo, A.S.; Breyer, C. The role of biomass in sub-Saharan Africa’s fully renewable power sector–the case of Ghana. Renew. Energy 2021, 173, 297–317. [Google Scholar] [CrossRef]

- World Bank Group. African Pulse. An Analysis of Issues Shaping Africa’s Economic Future; International Bank for Reconstruction and Development: Washington, DC, USA; The World Bank: Washington, DC, USA, 2018; Volume 17. [Google Scholar]

- IRENA—International Renewable Energy Agency. Scaling up Renewable Energy Deployment in Africa. 2020. Available online: https://www.irena.org/-/media/files/irena/agency/publication/2020/feb/irena_africa_impact_report_2020.pdf (accessed on 3 May 2023).

- IRENA, D. Biomass Potential in Africa. Report Authors: K. Stecher, A. Brosowski, D. Thrän. The International Renewable Energy Agency (IRENA), Abu Dhabi. 2013. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2013/IRENA-DBFZ_Biomass-Potential-in-Africa.pdf?rev=ab215979c40949108096459f449c27c1 (accessed on 3 May 2023).

- Wilson, D.C.; Rodic, L.; Modak, P.; Soos, R.; Carpintero, A.; Velis, K.; Iyer, M.; Simonett, O. Global Waste Management Outlook; United Nations Environment Programme: Nairobi, Kenya, 2015; Available online: https://eprints.whiterose.ac.uk/99773/1/GWMO_report.pdf (accessed on 11 May 2023).

- Mwampamba, T.H.; Owen, M.; Pigaht, M. Opportunities, challenges and way forward for the charcoal briquette industry in sub-saharan africa. Energy Sustain. Dev. 2013, 17, 158–170. [Google Scholar] [CrossRef]

- Cabrales, H.; Arzola, N.; Araque, O. The effects of moisture content, fiber length and compaction time on African oil palm empty fruit bunches briquette quality parameters. Heliyon 2020, 6, e05607. [Google Scholar] [CrossRef] [PubMed]

- Ngubane, N.F.; Oyekola, O. Optimisation of the production of pyrolysed corn stover briquettes and its techno-economic analysis. Waste Biomass Valorization 2023, 14, 1333–1354. [Google Scholar] [CrossRef]

- Obi, O.F.; Adeboye, B.S.; Aneke, N.N. Biomass briquetting and rural development in Nigeria. Int. J. Sci. Environ. Technol. 2014, 3, 1043–1052. [Google Scholar]

- Bot, B.V.; Axaopoulos, P.J.; Sakellariou, E.I.; Sosso, O.T.; Tamba, J.G. Energetic and economic analysis of biomass briquettes production from agricultural residues. Appl. Energy 2022, 321, 119430. [Google Scholar] [CrossRef]

- Bot, B.V.; Sosso, O.T.; Tamba, J.G.; Lekane, E.; Bikai, J.; Ndame, M.K. Preparation and characterization of biomass briquettes made from banana peels, sugarcane bagasse, coconut shells and rattan waste. Biomass Convers. Biorefinery 2021, 13, 7937–7946. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Balances. Available online: https://www.Iea.Org/data-and-statistics/data-product/world-energy-balances-highlights (accessed on 13 May 2023).

- International Energy Agency. Africa energy outlook. A focus on energy prospect in sub saharan Africa. World Energy Outlook Spec. Rep. 2014. Available online: http://www.iea.org/publications/freepublications/publication/WEO2014_AfricaEnergyOutlook.pdf (accessed on 11 May 2023).

- Röder, M.; Chong, K.; Thornley, P. The future of residue-based bioenergy for industrial use in sub-Saharan Africa. Biomass Bioenergy 2022, 159, 106385. [Google Scholar] [CrossRef]

- Ogwo, J.N.; Dike, O.C.; Mathew, S.O.; Akabuogu, E.U. Overview of biomass energy production in Nigeria: Implications and challenges. Asian J. Nat. Appl. Sci. 2012, 1, 46–51. [Google Scholar]

- Ohunakin, O.S. Energy utilization and renewable energy sources in Nigeria. J. Eng. Appl. Sci. 2010, 5, 171–177. [Google Scholar]

- Ben-Iwo, J.; Manovic, V.; Longhurst, P. Biomass resources and biofuels potential for the production of transportation fuels in Nigeria. Renew. Sustain. Energy Rev. 2016, 63, 172–192. [Google Scholar] [CrossRef]

- Olaoye, T.; Ajilore, T.; Akinluwade, K.; Omole, F.; Adetunji, A. Energy crisis in Nigeria: Need for renewable energymix. Am. J. Electr. Electron. Eng. 2016, 4, 1–8. [Google Scholar]

- Jekayinfa, S.O.; Orisaleye, J.I.; Pecenka, R. An assessment of potential resources for biomass energy in Nigeria. Resources 2020, 9, 92. [Google Scholar] [CrossRef]

- Simonyan, K.; Fasina, O. Biomass resources and bioenergy potentials in Nigeria. Afr. J. Agric. Res. 2013, 8, 4975–4989. [Google Scholar]

- Sokan-Adeaga, A.A.; Ana, G.R. A comprehensive review of biomass resources and biofuel production in Nigeria: Potential and prospects. Rev. Environ. Health 2015, 30, 143–162. [Google Scholar] [CrossRef]

- Giwa, A.; Alabi, A.; Yusuf, A.; Olukan, T. A comprehensive review on biomass and solar energy for sustainable energy generation in Nigeria. Renew. Sustain. Energy Rev. 2017, 69, 620–641. [Google Scholar] [CrossRef]

- Abakr, Y.A.; Abasaeed, A.E. Experimental evaluation of a conical-screw briquetting machine for the briquetting of carbonized stalks in Sudan. J. Eng. Sci. Technol. 2006, 1, 212–220. [Google Scholar]

- Lamido, S.I.; Lawal, M.; Salami, H. Briquetting business in Nigeria: A solution to unemployment. Int. J. Eng. Dev. Res. 2018, 6, 101–106. [Google Scholar]

- Ojolo, S.J.; Orisaleye, J.I.; Ismail, S.O.; Abolarin, S.M. Technical potential of biomass energy in Nigeria. Ife J. Technol. 2012, 21, 60–65. [Google Scholar]

- Danjuma, M.N.; Maiwada, B.; Tukur, R. Disseminating biomass briquetting technology in Nigeria: A case for briquettes production initiatives in Katsina State. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 12–20. [Google Scholar]

- Ajimotokan, H.A.; Ehindero, A.O.; Ajao, K.S.; Adeleke, A.A.; Ikubanni, P.P.; Shuaib-Babata, Y.I. Combustion characteristics of fuel briquettes made from charcoal particles and sawdust agglomerates. Sci. Afr. 2019, 6, e00202. [Google Scholar] [CrossRef]

- Orhorhoro, E.K.; Chukudi, O.M.; Oghenekevwe, O.; Onogbotsere, M.E. Design and fabrication of an improved low-cost biomass briquetting machine suitable for use in Nigeria. Int. J. Eng. Technol. Sci. 2017, 4, 128–138. [Google Scholar] [CrossRef]

- Ikelle, I.I.; Sunday, N.J.; Sunday, N.F.; John, J.; Okechukwu, O.J.; Elom, N. Thermal analyses of briquette fuels produced from coal dust and groundnut husk. Acta Chem. Malays. 2020, 4, 24–27. [Google Scholar] [CrossRef]

- Ikelle, I.I.; Ivoms, O.S.P. Determination of the heating ability of coal and corncob briquettes. IOSR J. Appl. Chem. 2014, 7, 77–82. [Google Scholar] [CrossRef]

- Ikelle, I.I.; Nworie, F.S.; Ogah, A.O.; Ilochi, N.O. Study on the combustion properties of bio-coal briquette blends of cassava stalk. ChemSearch J. 2017, 8, 29–34. [Google Scholar]

- Okwu, O.M.; Omonigbo, O.B. Development of a Light Weight Briquetting Machine for Small and Medium Scale Enterprise. FUPRE J. Sci. Ind. Res. 2018, 2, 71–87. [Google Scholar]

- Aliyu, M.; Mohamed, I.S.; Lawal, H.A.; Dauda, S.M.; Balami, A.A.; Usman, M.; Abdullahi, L.; Abubakar, M.; Ndagi, B. Effect of compaction pressure and biomass type (rice husk and sawdust) on some physical and combustion properties of briquettes. Arid Zone J. Eng. Technol. Environ. 2021, 17, 61–70. [Google Scholar]

- Aliyu, M.; Mohammed, I.S.; Usman, M.; Dauda, S.M.; Igbetua, I.J. Production of composite briquettes (orange peels and corncobs) and determination of its fuel properties. Agric. Eng. Int. CIGR J. 2020, 22, 133–144. [Google Scholar]

- Oyelaran, O.A.; Olorunfemi, B.J.; Sanusi, O.M.; Fagbemigun, A.O.; Balogun, O. Investigating the performance and combustion characteristics of composite bio-coal briquette. J. Mater. Eng. Struct. 2018, 5, 173–184. [Google Scholar]

- Akogun, O.A.; Waheed, M.A. Development and performance evaluation of a piston type hydraulically operated briquetting machine with replaceable moulds. Agric. Eng. Int. CIGR J. 2022, 24, 113–127. [Google Scholar]

- Osarenmwinda, J.O.; Ihenyen, O.I. The preliminary design and fabrication of a manually operated briquetting machine. J. Appl. Sci. Environ. Manag. 2012, 16, 167–170. [Google Scholar]

- Onuegbu, T.U.; Ekpunobi, U.E.; Ogbu, I.M.; Ekeoma, M.O.; Obumselu, F.O. Comparative studies of ignition time and water boiling test of coal and biomass briquettes blend. Int. J. Recent Res. Appl. Stud. 2011, 7, 153–159. [Google Scholar]

- Ofoefule, A.U.; Igweagwu, J.C.; Ugwu, M.N.; Mgbadike, C.D.; Esonye, C. Effects of pine needle (Pinus pinaster) dust on the performance characteristics of sub-bituminous coal briquette for energy generation. J. Phys. Chem. Sci. 2019, 7, 1–6. [Google Scholar]

- Adimuabah, O.H.; Chuka, N.S. Determination of optimum particulate size for the production of some agricultural waste briquettes. Int. J. Eng. Math. Intell. 2019, 6, 1–18. [Google Scholar]

- Obi, O.F.; Akubuo, C.O.; Okonkwo, W.I. Development of an appropriate briquetting machine for use in rural communities. Int. J. Eng. Adv. Technol. 2013, 2, 578–582. [Google Scholar]

- Oladeji, J.T. Fuel characterization of briquettes produced from corncob and rice husk residues. Pac. J. Sci. Technol. 2010, 11, 101–106. [Google Scholar]

- Oladeji, J.T. Comparative study of briquetting of few selected agro-residues commonly found in Nigeria. Pac. J. Sci. Technol. 2012, 13, 80–86. [Google Scholar]

- Orisaleye, J.I.; Jekayinfa, S.O.; Adebayo, A.O.; Ahmed, N.A.; Pecenka, R. Effect of densification variables on density of corn cob briquettes produced using a uniaxial compaction biomass briquetting press. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 3019–3028. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Pecenka, R.; Onifade, T.B. Effect of densification variables on water resistance of corn cob briquettes. Agron. Res. 2019, 17, 1722–1734. [Google Scholar]

- Jekayinfa, S.O.; Pecenka, R.; Orisaleye, J.I. Empirical model for prediction of density and water resistance of corn cob briquettes. Int. J. Renew. Energy Technol. 2019, 10, 212–228. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Braimoh, O.M.; Edhere, V.O. Empirical models for physical properties of abura (Mitragyna ciliata) sawdust briquettes using response surface methodology. Clean. Eng. Technol. 2022, 7, 100447. [Google Scholar] [CrossRef]

- Japhet, J.A.; Tokan, A.; Muhammad, M.H. Production and characterization of rice husk pellet. Am. J. Eng. Res. 2015, 4, 112–119. [Google Scholar]

- Gbabo, A.; Gana, I.M.; Efomah, N.A.; Aturu, B.O. Evaluation of some combustion properties of rice husk briquettes produced at varying binder concentrations from a modified block briquetting machine. Direct Res. J. Agric. Food Sci. 2018, 6, 231–237. [Google Scholar]

- Olorunnisola, A. Production of fuel briquettes from waste paper and coconut husk admixtures. Agric. Eng. Int. CIGR Ejournal 2007, 9, EE06006. [Google Scholar]

- Eze-Ilochi, N.O.; Oti, W.J.O. The design and fabrication of a briquette press using locally available raw materials in Nigeria: An approach towards briquette technology sustainability in Nigeria. Indo Am. J. Pharm. Sci. 2017, 4, 450–456. [Google Scholar]

- Ojaomo, E.K.; Maliki, O.B.; Olusanya, A.J. Development of a simple briquetting machine for small scale application. Int. J. Eng. Res. Technol. 2015, 4, 1428–1432. [Google Scholar]

- Ighodalo, O.A.; Zoukumor, K.; Egbon, C.; Okoh, S.; Odu, K. Processing water hyacinth into biomass briquettes for cooking purposes. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 305–307. [Google Scholar]

- Fadeyibi, A.; Adebayo, K.R. Development of a dually operated biomass briquette press. Songklanakarin J. Sci. Technol. 2021, 43, 737–743. [Google Scholar]

- Oyelaran, O.A. The effect of storage on some properties of groundnut shell biomass briquettes. J. Renew. Energy Environ. 2014, 1, 36–40. [Google Scholar]

- Oyelaran, O.A.; Bolaji, B.O.; Waheed, M.A.; Adekunle, M.F. An experimental study of the combustion characteristics of groundnut shell and waste paper admixture briquettes. KKU Eng. J. 2015, 42, 283–286. [Google Scholar]

- Onochie, U.P.; Obanor, A.L.; Aliu, S.A.; Ighodaro, O.O. Fabrication and performance evaluation of a pelletizer for oil palm residues and other biomass waste materials. J. Niger. Assoc. Math. Phys. 2017, 40, 443–446. [Google Scholar]

- Onochie, U.P.; Obanor, A.I.; Aliu, S.A.; Ighodaro, O.O. Determination of some thermal characteristics of fuel pellets obtained from oil palm residues. J. Natl. Assoc. Math. Phys. 2017, 40, 447–450. [Google Scholar]

- Onochie, U.P.; Onoroh, F.; Onwurah, C.; Ofomatah, A.C. The effect of Elaeis guineensis residue on CO2 and SO2 emissions from coal pellets combustion. IOP Conf. Ser. Earth Environ. Sci. 2021, 730, 012012. [Google Scholar] [CrossRef]

- Okwu, M.O.; Samuel, O.D.; Otanocha, O.B.; Akporhonor, E.; Tartibu, L.K. Development of a novel integrated hopper briquette machine for sustainable production of pellet fuels. Procedia Comput. Sci. 2023, 317, 1719–1733. [Google Scholar] [CrossRef]

- Okwu, M.O.; Samuel, O.D. Adapted hyacinth briquetting machine for mass production of briquettes. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 2853–2866. [Google Scholar] [CrossRef]

- Aina, O.M.; Adetogun, A.C.; Iyiola, K.A. Heat energy from value-added sawdust briquettes of Albizia zygia. Ethiop. J. Environ. Stud. Manag. 2009, 2, 42–49. [Google Scholar] [CrossRef]

- Bello, R.S.; Onilude, M.A. Physico-mechanical characteristics of high density briquettes produced from composite sawdust. J. Appl. Sci. Environ. Manag. 2020, 24, 779–787. [Google Scholar] [CrossRef]

- Abdullahi, A. Development of a Low-Cost Briquette Making Machine. Master’s Thesis, Department of Mechanical Engineering, Federal University of Technology, Minna, Nigeria, 2022. [Google Scholar]

- Okegbile, O.J.; Bori, I.; Danlami, S.M. Development of Screw-Type Briquetting Machine for Municipal Solid Waste. In Proceedings of the Second International Engineering Conference (IEC), Federal University of Technology, Minna, Nigeria, 26–27 February 2017; pp. 389–393. [Google Scholar]

- Inegbedion, F.; Francis-Akilaki, T.I. Design and Fabrication of a briquetting machine. J. Energy Technol. Environ. 2022, 4, 11–20. [Google Scholar]

- Orisaleye, J.I. Parametric Analysis and Design Optimization of Screw Extruder Biomass Briquetting Machines. Ph.D. Thesis, Department of Mechanical Engineering, University of Lagos, Akoka, Nigeria, 2019. [Google Scholar]

- Pelumi, I.P.; Tobiloba, O.; Wallace, O.; Oluwatoba, O.; Akanni, A.A.; Oluwole, A.O.; Sola, O.T. Performance evaluation of briquette produced from a designed and fabricated piston-type briquetting machine. Int. J. Eng. Res. Technol. 2019, 12, 1227–1238. [Google Scholar]

- Nnaji, M.; Eze, A.A.; Uzoma, C.C.; Nnaji, C.E. Addressing household cooking fuel options in Nigeria. IOP Conf. Ser. Earth Environ. Sci. 2020, 730, 012038. [Google Scholar] [CrossRef]

- Bello, R.S.; Adegbulugbe, T.A.; Onilude, M.A. Characterization of three conventional cookstoves in South Eastern Nigeria. Agric. Eng. Int. CIGR J. 2015, 17, 122–129. [Google Scholar]

- Kabir, I.; Yacob, M.R.; Ariffin, M.; Emang, D.; Adamu, A. Assessing the extent of traditional biomass cookstove usage and related cooking practices: Evidence from rural households in Northern Nigeria. IOSR J. Humanit. Soc. Sci. 2018, 23, 39–46. [Google Scholar]

- Fajola, A.; Fakunle, B.; Aguwa, E.N.; Ogbonna, C.; Ozioma-Amechi, A. Effect of an improved cookstove on indoor particulate matter, lung function and fuel efficiency of firewood users. Am. J. Res. Commun. 2014, 2, 189–207. [Google Scholar]

- Ojolo, S.J.; Ismail, S.O.; Orisaleye, J.I.; Odutayo, A.F. Development of an inverted downdraft biomass gasifier cookstove. J. Emerg. Trends Eng. Appl. Sci. 2012, 3, 513–516. [Google Scholar]

- Ekpunobi, U.; Onyenze, C.; Agbo, S.; Umennadi, P.; Ifeagwu, O. Development of high energy and fuel economy ceramic insulated biomass multi cooking system. J. Chem. Soc. Niger. 2022, 47, 1125–1140. [Google Scholar] [CrossRef]

- Obi, O.F.; Okechukwu, M.E.; Okongwu, K.C. Energy and exergy efficiencies of four biomass cookstoves using wood chips. Biofuels 2021, 12, 869–878. [Google Scholar] [CrossRef]

- Obi, O.F.; Ezeoha, S.L.; Okorie, I.C. Energetic performance of a top-lit updraft (TLUD) cookstove. Renew. Energy 2016, 99, 730–737. [Google Scholar] [CrossRef]

- Yunusa, S.U.; Isiaka, M.; Saleh, A. Development of double burner natural-draft biomass cookstove. Agric. Eng. Int. CIGR J. 2022, 24, 194–206. [Google Scholar]

- Yunusa, S.U.; Isiaka, M.; Saleh, A. Effect of air-vent on performance of an improved natural-draft biomass cookstove. In Proceedings of the PASAE/NIAE International Conference, Abuja, Nigeria, 19–22 April 2021; pp. 149–155. [Google Scholar]

- Igboanugo, A.C.; Ajieh, M.U.; Azi, S.O. Performance evaluation of a biomass stove using particulate matter and carbon monoxide emission from briquette and fuel wood. Niger. J. Technol. 2015, 34, 484–490. [Google Scholar] [CrossRef]

- Abasiryu, T.; Ayuba, A.; Zira, A.E. Performance evaluation of some locally fabricated cookstoves in Mubi, Adamawa State, Nigeria. Niger. J. Technol. 2016, 35, 48–53. [Google Scholar] [CrossRef]

- Bello, R.S.; Onilude, M.A. Characterization of conventional cooking stoves in South Eastern Nigeria. Int. Lett. Nat. Sci. 2014, 13, 89–99. [Google Scholar] [CrossRef]

- Odesola, I.F.; Ige, E.O.; Yunus, I.O. Design and performance evaluation of energy efficient biomass gasifier cook stove using multi fuels. J. Energy Res. Rev. 2019, 3, 1–7. [Google Scholar] [CrossRef]

- Odesola, I.F.; Kazeem, A.O. Design, construction and performance evaluation of a biomass cookstove. J. Emerg. Trends Eng. Appl. Sci. 2014, 5, 358–362. [Google Scholar]

- Umogbai, V.I.; Orkuma, J.G. Development and evaluation of a biomass stove. J. Emerg. Trends Eng. Appl. Sci. 2011, 2, 514–520. [Google Scholar]

- Adewole, B.Z.; Akinkunmi, A.A.; Lasebikan, O.F. Energy performance and air emissions of a new design household firewood cookstove. In Proceedings of the OAU Faculty of Technology Conference, Ile Ife, Nigeria, 20–25 September 2015; pp. 139–144. [Google Scholar]

- Kuhe, A.; Iortyer, H.A.; Iortsor, A. Performance of clay wood cook stove: An analysis of cost and fuel savings. J. Technol. Innov. Renew. Energy 2014, 3, 94–98. [Google Scholar] [CrossRef]

- Muye, H.M.; Abubakar, J. Comparative performance evaluation of two improved clay–lined charcoal cook stove. Int. J. Eng. Res. Technol. 2015, 4, 1247–1251. [Google Scholar]

- Oyejide, O.J.; Okwu, M.O.; Tartibu, L.K. Adaptive design and development of a modular water hyacinth briquette stove. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 45, 6515–6533. [Google Scholar] [CrossRef]

- Adedayo, K.; Owoola, E.; Ogunjo, S. The Development of an Enhanced Biomass Gasifier Stove. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2018, 92, 303–309. [Google Scholar] [CrossRef]

- El-jummah, A.M.; Adam, U.M.; Kolo, M.B.; Musa, A.N. Modification, development and design experimental investigation of an updraft biomass gasifier stove with sawdust as fuel. Cont. J. Eng. Sci. 2014, 12, 19–33. [Google Scholar]

- Spliethoff, H. Power Generation from Biomass and Waste. In Power Generation from Solid Fuels. Power Systems; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Ejiofor, O.S.; Okoro, P.A.; Ogbuefi, U.C.; Nnabuike, C.V.; Okedu, K.E. Off-grid electricity generation in Nigeria based on rice husk gasification technology. Clean. Eng. Technol. 2020, 1, 100009. [Google Scholar] [CrossRef]

- Sobamowo, M.G.; Ojolo, S.J. Techno-economic analysis of biomass energy utilization through gasification technology for sustainable energy production and economic development in Nigeria. J. Energy 2018, 2018, 4860252. [Google Scholar] [CrossRef]

- Garba, A.; Kishk, M. Economic assessment of biomass gasification technology in providing sustainable electricity in Nigerian rural areas. In Proceedings of the International Sustainable Ecological Engineering Design for Society (SEEDS) Conference, Leeds, UK, 17–18 September 2015; p. 545. [Google Scholar]

- Diyoke, C.; Idogwu, S.; Ngwaka, U.C. An economic assessment of biomass gasification for rural electrification in Nigeria. Int. J. Renew. Energy Technol. Res. 2014, 3, 1–17. [Google Scholar]

- Akhator, P.E.; Obanor, A.I. Review on synthesis gas production in a downdraft biomass gasifier for use in internal combustion engines in Nigeria. J. Appl. Sci. Environ. Manag. 2018, 22, 1689–1696. [Google Scholar] [CrossRef]

- Akhator, P.E.; Obanor, A.I.; Sadjere, E.G. Design and development of a small-scale biomass downdraft gasifier. Niger. J. Technol. 2019, 38, 922–930. [Google Scholar] [CrossRef]

- Salisu, J. Performance Evaluation of Downdraft Gasifier for Syngas Production Using Rice Husk. Master’s Thesis, Department of Chemical Engineering, Ahmadu Bello University, Zaria, Nigeria, 2016. [Google Scholar]

- Ojolo, S.J.; Orisaleye, J.I. Design and development of a laboratory scale biomass gasifier. J. Energy Power Eng. 2010, 4, 16–23. [Google Scholar]

- Bukar, A.A.; Oumarou, M.B.; Oluwole, F.A. Design and development of a blower for downdraft biomass gasifier. Arid Zone J. Eng. Technol. Environ. 2018, 14, 292–303. [Google Scholar]

- Akinyemi, O.R.; Olaiya, N.G. Development of a sawdust fluidized bed gasifier: Design and fabrication. J. Eng. Res. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Zhao, P.; Ge, S.; Yoshikawa, K. An orthogonal experimental study on Solid fuel production from sewage sludge by employing steam explosion. Appl. Energy 2013, 112, 1213–1221. [Google Scholar] [CrossRef]

- Mohammed, T.I.; Olugbade, T.O. Burning Rate of Briquettes Produced from Rice Bran and Palm Kernel Shells. Int. J. Mater. Sci. Innov. 2015, 3, 68–73. [Google Scholar]

- Namioka, T.; Morohashi, Y.; Yamane, R.; Yoshikawa, K. Hydrothermal treatment of dewatered sewage sludge cake for solid fuel production. J. Environ. Eng. 2009, 4, 68–77. [Google Scholar] [CrossRef]

- Mohammed, T.I.; Olugbade, T.O. Characterisation of briquettes from Rice Bran and Palm Kernel Shell. Int. J. Mater. Sci. Innov. 2015, 3, 60–67. [Google Scholar]

- Yang, Y.; Liu, Y.; Peng, L.; Zhang, S.; Yuan, C.; Li, W.; Liu, Z.; Ma, Y. Cooking or heating with solid fuels increased the all-cause mortality risk among mid-aged and elderly People in China. Environ. Health 2022, 21, 1–9. [Google Scholar] [CrossRef]

- Olugbade, T.; Ojo, O.; Mohammed, T. Influence of Binders on Combustion Properties of Biomass Briquettes: A Recent Review. Bioenerg. Res. 2019, 12, 241–259. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Ojo, O.T. Binderless briquetting technology for lignite briquettes: A review. Energy Ecol. Environ. 2021, 6, 69–79. [Google Scholar] [CrossRef]

- Chao, H.; Chunyan, T.; Chuanhao, L.; Jihui, Y.; Khanh-Quang, T.; Quang-Vu, B.; Rongliang, Q.; Yanhui, Y. Wet torrefaction of biomass for high quality solid fuel production: A review. Renew. Sustain. Energy Rev. 2018, 91, 259–271. [Google Scholar]

- Olugbade, T.O.; Ojo, O.T. Biomass Torrefaction for the Production of High-Grade Solid Biofuels: A Review. Bioenerg. Res. 2020, 13, 999–1015. [Google Scholar] [CrossRef]

- Peitao, Z.; Yafei, S.; Shifu, G.; Zhenqian, C.; Kunio, Y. Clean solid biofuel production from high moisture content waste biomass employing hydrothermal treatment. Appl. Energy 2014, 131, 345–367. [Google Scholar]

- Hensgen, F.; Richter, F.; Wachendorf, M. Integrated generation of solid fuel and biogas from green cut material from landscape conservation and private households. Bioresour. Technol. 2011, 102, 10441–10450. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Li, X.; Fan, J.; Chang, J. Solid fuel production by hydrothermal carbonization of black liquor. Bioresour. Technol. 2012, 110, 715–718. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Yue, D.l; You, F.; Synder, S.W. Biomass-to-bioenergy and biofuel supply chain optimization: Overview, key issues and challenges. Comput Chem Eng. 2014, 66, 36–56. [Google Scholar] [CrossRef]

- Chu, B.C.; Nwogu, N.A.; Agulanna, A.C.; Nwakanma, H.O. Potentials of biomass briquetting and utilization: The Nigerian perspective. Pac. Int. J. 2020, 2, 2663–8991. [Google Scholar]

- Hwang, I.H.; Aoyama, H.; Matsuto, T.; Nakagishi, T.; Matsuo, T. Recovery of solid fuel from municipal solid waste by hydrothermal treatment using subcritical water. Waste Manag. 2012, 32, 410–416. [Google Scholar] [CrossRef] [PubMed]

- Yuhazri, M.; Sihombing, H.; Umar, N.; Saijod, L.; Phongsakorn, P. Solid Fuel from Empty Fruit Bunch Fiber and Waste Papers Part 1: Heat Released from Combustion Test. Glob. Eng. Technol. Rev. 2012, 2, 7–13. [Google Scholar]

- He, C.; Giannis, A.; Wang, J.Y. Conversion of sewage sludge to clean solid fuel using hydrothermal 1504 carbonization: Hydrochar fuel characteristics and combustion behavior. Appl. Energy 2013, 111, 257–266. [Google Scholar] [CrossRef]

- Federal Republic of Nigeria, Ministry of Power. National Renewable Energy and Energy Efficiency Policy (NREEEP). 2015. Available online: http://admin.theiguides.org/Media/Documents/NREEE%20POLICY%202015-%20FEC%20APPROVED%20COPY.pdf (accessed on 23 May 2023).

- Ishola, M.M.; Brandberg, T.; Sanni, S.A.; Taherzadeh, M.J. Biofuels in Nigeria: A critical and strategic evaluation. Renew. Energy 2013, 55, 554–560. [Google Scholar] [CrossRef]

- Nasidi, M.; Akunna, J.; Deeni, Y.; Blackwood, D.; Walker, G. Bioethanol in Nigeria: Comparative analysis of sugarcane and sweet sorghum as feedstock sources. Energy Environ. Sci. 2010, 3, 1447–1457. [Google Scholar] [CrossRef]

- Mohammed, Y.S.; Mustafa, M.W.; Bashir, N.; Ibrahem, I.S. Existing and recommended renewable and sustainable energy development in Nigeria based on autonomous energy and microgrid technologies. Renew. Sustain. Energy Rev. 2017, 75, 820–838. [Google Scholar] [CrossRef]

- Ohimain, E.I. A review of the Nigerian biofuel policy and incentives. Renew. Sustain. Energy. 2007, 22, 246–256. [Google Scholar] [CrossRef]

- Shaaban, M.; Petinrin, J.O. Renewable energy potential in Nigeria: Meeting rural energy needs. Renew. Sustain. Energy Rev. 2014, 29, 72–84. [Google Scholar] [CrossRef]

- Elum, Z.A.; Modise, D.M.; Nhamo, G. Climate change mitigation: The potential of agriculture as a renewable energy source in Nigeria. Environ. Sci. Pollut. Res. 2017, 24, 3260–3273. [Google Scholar] [CrossRef] [PubMed]

- Nwozor, S.O.; Ogundele, O. Energy poverty and environmental sustainability in Nigeria: An exploratory assessment. IOP Conf. Ser. Earth Environ. Sci. 2019, 331, 1. [Google Scholar] [CrossRef]

- ECN & UNDP. Renewable Energy Master Plan (REMP). 2005. Available online: https://www.iea.org/policies/4967-renewable-energy-master-plan (accessed on 20 October 2023).

- Okafor, C.C.; Nzekwe, C.A.; Ajaero, C.C.; Ibekwe, J.C.; Otunomo, F.A. Biomass utilization for energy production in Nigeria: A review. Clean. Energy Syst. 2022, 3, 100043. [Google Scholar] [CrossRef]

- Ohimain, E.I. The evaluation of pioneering bioethanol projects in Nigeria following the announcement and implementation of the Nigerian biofuel policy and incentives. Energy Sources Part B Econ. Plan. Policy 2015, 10, 51–58. [Google Scholar] [CrossRef]

- Federal Ministry of Environment. Nigeria’s Intended Nationally Determined Contribution. 2015. Available online: https://www.fao.org/faolex/results/details/en/c/LEX-FAOC187295/ (accessed on 20 October 2023).

- Nwozor, A.; Owoeye, G.; Olowojolu, O.; Ake, M.; Adedire, S.; Ogundele, O. Nigeria’s quest for alternative clean energy through biofuels: An assessment. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 655, p. 012054. [Google Scholar]

- Indrawan, B.; Prawisudha, P.; Yoshikawa, K. Chlorine-free solid fuel production from municipal solid waste by hydrothermal process. J. Jpn. Inst. Energy 2011, 90, 1177–1182. [Google Scholar] [CrossRef]

- Dairo, O.U.; Adeleke, A.E.; Shittu, T.; Ibrahim, N.A.; Adeosun, O.J.; Iyerimah, R.B. Development and performance evaluation of a low-cost hydraulic-operated biomass briquetting machine. FUOYE J. Eng. Technol. 2018, 3, 2579–2617. [Google Scholar] [CrossRef]

- Iglinski, B.; Kujawski, W.; Kielkowska, U. Pyrolysis of waste biomass: Technical and process achievements, and future development-A review. Energies 2023, 16, 1829. [Google Scholar] [CrossRef]

- Cheba, K.; Bak, I.; Pietrzak, M. Conditions of the green transformation. the case of the European union. Technol. Econ. Dev. Econ. 2023, 29, 438–467. [Google Scholar] [CrossRef]

- Calvo, G.; Valero, A. Strategic mineral resources: Availability and future estimations for the renewable energy sector. Environ. Dev. 2022, 41, 100640. [Google Scholar] [CrossRef]

- Balcerzak, A.P.; Uddin, G.S.; Igliński, B.; Pietrzak, M.B. Global energy transition: From the main determinants to economic challenges. Equilib. Q. J. Econ. Econ. Policy 2023, 18, 597–608. [Google Scholar] [CrossRef]

- Liu, H.Y.; Khan, I.; Zakari, A.; Alharthi, M. Roles of trilemma in the world energy sector and transition towards sustainable energy: A study of economic growth and the environment. Energy Policy 2022, 170, 113238. [Google Scholar] [CrossRef]

- Farid, S.; Karim, S.; Naeem, M.A.; Nepal, R.; Jamasb, T. Co-movement between dirty and clean energy: A time-frequency perspective. Energy Econ. 2023, 119, 106565. [Google Scholar] [CrossRef]

- Fraser, T.; Chapman, A.J.; Shigetomi, Y. Leapfrogging or lagging? Drivers of social equity from renewable energy transitions globally. Energy Res. Soc. Sci. 2023, 98, 103006. [Google Scholar] [CrossRef]

- Gao, C.J.; Chen, H.X. Electricity from renewable energy resources: Sustainable energy transition and emissions for developed economies. Util. Policy 2023, 82, 101543. [Google Scholar] [CrossRef]

- Pietrzak, M.B.; Iglinski, B.; Kujawski, W.; Iwanski, P. Energy transition in Poland-assessment of the renewable energy sector. Energies 2021, 14, 2046. [Google Scholar] [CrossRef]

- Olabi, A.G.; Abdelkareem, M.A. Renewable energy and climate change. Renew. Sustain. Energy Rev. 2022, 158, 112111. [Google Scholar] [CrossRef]

| Domestic Energy Source | Availability/Utilization (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 2008 | 2013 | 2018 | |||||||

| National | Urban | Rural | National | Urban | Rural | National | Urban | Rural | |

| Electricity/gas | 1.6 | 3.7 | 0.5 | 2.7 | 5.3 | 0.7 | 14.7 | 26.8 | 4.0 |

| Kerosene | 25.6 | 51.6 | 11.3 | 25.5 | 47.6 | 8.7 | 15.0 | 24.3 | 6.8 |

| Wood/charcoal | 67.4 | 41.3 | 83.6 | 67.2 | 43.9 | 84.9 | 67.6 | 47.4 | 85.5 |

| Agric. waste/dung | 1.0 | 0.7 | 1.1 | 1.9 | 0.2 | 3.2 | 1.0 | 0.3 | 1.6 |

| % Solid biofuel used | 70.1 | 42.1 | 85.6 | 69.1 | 44.1 | 88.1 | 68.6 | 47.7 | 87.0 |

| Electricity coverage (%) | 50.3 | 84.8 | 31.4 | 55.6 | 83.6 | 34.4 | 59.4 | 82.7 | 38.9 |

| Stove Type | Fuel Used | Design Details | Performance | Emission Characteristics | References |

|---|---|---|---|---|---|

| Inverted downdraft gasifier cooking stove | Wood shavings | Diameter of 180 mm and height of 600 mm | Fuel conversion rate (FCR) was 1.89 kg/h. | Not determined | [76] |

| Wood chips, corncobs, coconut shells, palm kernel shells | FCR of 1.60 to 1.82 kg/h. SGR between 85.89 and 102.25 kg/m2h. Efficiency of 20.76%. | [47] | |||

| Ceramic-insulated biomass multi-cooking system | - | - | Insulating properties of ceramics for Inyi clay and its utilization in production of improved cookstove were investigated | Not determined | [77] |

| Top-lit updraft cooking stove | Wood chips | 280 mm diameter and 400 mm height | Efficiency in cold and hot start was similar. Energy efficiency of the cookstove reached 89%. | Not determined | [78] |

| Wood chips, coconut shell, and rice husk briquettes | Performance was significantly influenced by type of fuel. Wood chips had better performance than rice husk briquette and coconut shell. Lowest specific fuel consumption (SFC) was 8.54 kJ/kg. | Not determined | [79] | ||

| Batch-fed natural draft cooking stove | Charcoal | 126 mm diameter and 521 mm height. Ceramic insulated. | Thermal efficiency between 17.2 and 33%. Boiling time was 0.172 to 0.354 h/kg of water. | Not determined | [80] |

| Thermal efficiency was 25% with SFC of 0.213 h/kg. | [81] | ||||

| Natural convection rocket-type biomass stove | Sawdust briquette and fuelwood | 190 mm diameter and 500 mm height | Briquette burning rate of 20.5 g/min and fuelwood burning rate of 16.8 g/min. Thermal efficiency was 14.5% for briquettes but 31.1% for fuelwood. | Fuelwood emitted more particulate matter than briquette. Mean CO emission was also higher using fuelwood. | [82] |

| Metal shield stove, clay charcoal stove, and metal charcoal stove | Fuelwood (metal shield stove) and wood charcoal (metal and clay charcoal stoves) | Mass of metal shield stove, metal charcoal stove, and clay charcoal stove were 0.75, 1.15, and 3.05 kg, respectively | Thermal efficiency of metal shield stove, metal charcoal stove, and clay charcoal stove were 11.64%, 20.02%, and 17.06%, respectively | Not determined | [83] |

| Sawdust/rice husk stove and charcoal metal stove | Sawdust and charcoal | Charcoal stove was 150 mm wide and 230 mm high. Sawdust stove had 140 mm diameter and 160 mm height. | Thermal efficiency of sawdust stove was 52.64% but 64.38% for charcoal stove | Not determined | [84] |

| Natural draft gasifier biomass cooking stove | Sawdust, wood, groundnut husk, and charcoal | Fiber insulated. Height of 460 mm, reactor diameter of 160 mm. | Thermal efficiency was 32.18, 80.10, 38.73, and 50.33% for charcoal, sawdust, wood, and groundnut husk, respectively | CO emission was highest in wood. Emission of CO reduced with time. CO emissions ranged between 150 and 850 ppm. | [85] |

| Forced draft biomass cooking stove | Charcoal | Insulated with fire clay (sawdust 50%, kaolin 40%, and ball clay 10%) | Efficiency ranging between 52 and 61.4% with a heat utilization of 40.65%. Stove operates between 1.40 and 1.66 kW. | Not determined | [86] |

| Portable improved cooking stove | Wood | Ceramic combustion chamber with metal casing. Combustion chamber of 120 mm diameter. | Burning rate and firepower were 6.7 g/min and 2192 kW during cold start, and 3.9 g/min for hot start. Thermal efficiency was 66%. | Not determined | [87] |

| Envirofit improved stove | Fuelwood | - | The fuelwood consumption was reduced by up to three times when improved cooking stove was used compared with the tripod stove | Significant reduction in mean particulate matter concentration. Lung function of cooking stove users improved. | [75] |

| Fuelwood cooking stove | Hardwood and softwood | The fuelwood stove had the highest thermal efficiency, highest average firepower, and lowest SFC compared to a 3-stone stove and traditional metal stove | There was little to no smoke generation. CO generated per kg of dry wood consumed ranged between 245 and 310.8 mg/m3. | [88] | |

| Improved wood fuel clay cooking stoves | Fuelwood | External diameter of 450 mm and height of 380 mm | Improved stoves had firepower between 7.72 and 8.59 kW. Thermal efficiency ranged between 13.8 and 35%. | Not determined | [89] |

| Improved clay-lined cooking stoves | Charcoal | Two stoves: pyramidal and rectangular stoves | SFC ranged from 28,302 kJ/kg-s to 36,092 kJ/kg-s. Thermal efficiencies were 49.57% and 13.49% for pyramidal and rectangular cooking stoves. | Not determined | [90] |

| Modular briquette cooking stove | Water hyacinth briquettes | Stove diameter of 390 mm and a height of 750 mm. Chimney added to increase air flow to burner. | Thermal efficiency was 70.51% for water hyacinth briquettes and between 15 and 52% for other fuels. | Not determined | [91] |

| Enhanced biomass gasifier cooking stove | Palm kernel shell | It has four compartments, which perform various functions related to stove performance | Cooking stove had better performance than kerosene stove and compared favorably with the gas stove. Thermal efficiency of 36.98%. | Lower CO emissions compared to other stoves | [92] |

| Updraft biomass gasifier cooking stove | Sawdust | Reactor diameter of 300 mm and height of 850 mm | Performance of stove depended on loading capacities | Not determined | [93] |

| S/N | Policy/Initiatives | Objective(s) | Year | References |

|---|---|---|---|---|

| 1 | National Renewable Energy and Energy Efficiency Policy (NREEEP) | (a) Increase in grid-renewable energy supply by 2030. | 2015 | [123] |

| 2 | National Biofuel Policy and Incentives (NBPI) | (a) More attention on crops as feedstock—cassava sugarcane, oil palm, and others. (b) Tackling the food vs. energy conflict. (c) Development and promotion of solid biofuel industry using agricultural products. | 2007 | [20,123,124,125,126,127] |

| 3 | Strategic Education and Sensitization Programs (SESP), Technological and socio-political | (a) Creating more awareness programs and campaigns for Nigerians on the potential health, environmental, and economic benefits from using solid biofuels. (b) Providing instructional manuals and guides on the proper installation and usage of solid-biofuel-making machines. (c) Making available the technical standardization and specifications for effective production and performance. | [125,126] | |

| 4 | National Energy Policy (NEP) | (a) Steady increase in the production of solid biofuel materials/crops since 2004 after the initiation of NEP. (b) Production grew by 19% for cassava between 2004 and 2011, 59% for maize and 70% for sugarcane. | 2003, updated in 2013; 2018 | [22,128,129] |

| 5 | Renewable Energy Master Plan (REMP) | (a) Reducing GHG emissions. (b) Transition to clean and environmentally friendly energy sources. (c) Exploiting renewable energy sources to meet the proposed energy needs of the country. (d) Expanding the role of renewable energy in its energy mix. | 2005, update in 2011 | [129,130,131] |

| 6 | Investment policy and legislative issues, Clean energy alternatives | (a) Developing new markets for solid biofuels. (b) Tax exemptions. (c) Providing avenues for easy setup of solid biofuel businesses in any part of Nigeria. (d) Upholding the existing forestry policies. | [126,132,133] | |

| 7 | National Policy on Climate Change and Response Strategy (NPCC-RS) | (a) Mitigation and adaptation measures. (b) Establishing research and development programs necessary to strengthen research institutes. (c) Promoting low carbon and enhancing economic growth. | 2012 | [134] |

| 8 | National Energy Master Plan (NEMP) | (a) Coordinating the implementation of government policies. (b) Enhancing the performance in the energy sector through proper coordination. | 2014 | [135] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obi, O.F.; Olugbade, T.O.; Orisaleye, J.I.; Pecenka, R. Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria. Energies 2023, 16, 7966. https://doi.org/10.3390/en16247966

Obi OF, Olugbade TO, Orisaleye JI, Pecenka R. Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria. Energies. 2023; 16(24):7966. https://doi.org/10.3390/en16247966

Chicago/Turabian StyleObi, Okey Francis, Temitope Olumide Olugbade, Joseph Ifeolu Orisaleye, and Ralf Pecenka. 2023. "Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria" Energies 16, no. 24: 7966. https://doi.org/10.3390/en16247966

APA StyleObi, O. F., Olugbade, T. O., Orisaleye, J. I., & Pecenka, R. (2023). Solid Biofuel Production from Biomass: Technologies, Challenges, and Opportunities for Its Commercial Production in Nigeria. Energies, 16(24), 7966. https://doi.org/10.3390/en16247966