Abstract

Nowadays, a car’s engine oil change interval is an essential factor in reducing wear. The correct choice depends on various factors. This study analyzes the changes in the composition of three different engine oils (0W30, 5W30, and 5W40) during the generally accepted oil change interval (15,000 km) in gasoline and diesel cars during the post-warranty period. Commercially available low-level biofuel blends (B7 and E10) were used to power test vehicles in a field test. Engine oil samples were taken every 3000 km for more detailed analysis and tested in an accredited laboratory. The contaminants in the engine oil were determined using several testing methods: spectrometric analysis, gas chromatography, etc. Studies have shown that all used cars have an increase in the number of iron particles, an increased concentration of silicon, and also an increase in the number of nickel particles above 12,000 km. Tests also showed a sharp drop of molybdenum anti-friction additives 4.5 times and a gradual increase in fuel concentration for the Opel Insignia over 12,000 km, but over 9000 km, a significant increase in the concentration of chromium particles. Based on this research results, it is preferable to choose a maintenance interval of no more than 12,000 km for cars during the post-warranty period. In this way, the intensity of engine wear can be reduced due to the loss of adequate protective properties of the engine oil.

1. Introduction

Improvement of the environmental performance of internal combustion engines, especially to meet the requirements for reduced carbon dioxide (CO2) emissions—a major greenhouse gas—has been a global issue for the automotive industry for a long time and will remain until the complete replacement of internal combustion (IC) engines in the future. Considering that the major sources of CO2 emissions are cars, trucks, and buses, as well as the close connection of CO2 with fuel consumption, improving engine efficiency and its related solutions will continue to be relevant for engineers. In order to meet the necessary ecological targets, vehicle manufacturers have also introduced various improvements over time and used different solutions concerning engine design, operation, and exhaust gas treatment: advanced combustion systems, waste heat recovery systems, etc. [1,2]. In addition, engine downsizing, which allowed to reduce the weight and mechanical losses of the engine, different advanced powertrain technologies gained application, including hydrogen [3] and water injection, which was also studied by the authors [4].

It cannot be denied that considerable effort has been devoted to producing energy-efficient vehicles and machinery [5] in the last decade, where the reduction of IC engine friction was considered one of the possible solutions. As friction losses form about 11.5% of fuel energy in engines of typical passenger cars [5], lubrication of the contacting surfaces in the major engine subsystems will continue to represent a significant goal for the development of low-friction base engines [6]. Although the lubrication process that occurs within the lubrication systems is quite complex, and even today there is not a complete understanding from the mechanical and physicochemical point of view [7], there are studies on lubrication models for IC engines in order to investigate the friction, wear, and tribofilm formation on surfaces of moving parts, as well as the predicted lubricant life for conventional lubrication systems [8,9].

At the same time, it should not be forgotten that the usage of fuel-saving lubricants, together with emission reduction, will also reduce the life cycle of the vehicle, which could have an even greater negative effect on the environment [10]. This already opens up opportunities for this research and application of various coatings, thereby significantly extending the life of the vehicle [10], without having a great impact on the environment.

Designing engine oil lubricants for low friction operation and energy efficiency is also an important role that is dedicated to different additives like friction modifiers [11], low viscosity lubricants, anti-wear additives, etc. The choice is wide enough and basically depends on the field of application. In general, friction losses based on engine operation are subdivided into viscous losses connected with lubricant flow and frictional losses connected with boundary contact between systems [10]. The first ones could be reduced using lower-viscosity oils and smaller displacement volumes, while frictional losses can be reduced by using antifriction coatings and friction reduction additives in engine oil [10]. Environmental impact is also important in that case. For example, friction modifiers are divided into two categories: inorganic and organic, where the last one includes fatty amides and partial esters [12]. It should be noted that organic friction modifiers do not always show better results than inorganic ones [12], but the desire for ecological contribution forces scientists to look for the best solutions.

In this regard, another ecological problem can be inadvertently identified, which is the use of mineral based oil lubricants, which are harmful to the environment due to their nonbiodegradability and toxicity [13,14]. The use of biodegradable materials, such as vegetable oils, could significantly change this situation due to their higher viscosity index, good anti-wear characteristics, high load-carrying abilities, low toxicity [15,16], and excellent coefficient of friction [17]. They can also be effectively used for boundary and hydrodynamic lubrication because of the long fatty acid chain length and polar groups present in the oil [18]. This was also confirmed by research [19], with the aim of replacing mineral oil-based lubricants with biolubricants acquired from various vegetable oils. Results confirmed that olive oil use as an engine lubricating oil for heavy-duty engines is possible because of the better lubricating performance ensured by a lower coefficient of friction, wear scar diameter, and worn scar surface area than conventional lubricating oil. However, the number of such studies is limited.

Although this type of engine oil is not very popular now, fuel containing biofuel (biodiesel or ethanol) is a usual thing, as it is possible to purchase it at almost any fueling station in the EU. This could be applied to both gasoline and diesel in low-level blends. The main advantages of biodiesel favorable to friction are enhanced scuffing protection performance, effective film formation, and the presence of unsaturated fatty acid compounds [20], while there are also some disadvantages like oxidation, instability of properties, moisture absorption, acidic nature, etc. [21]. At the same time, ethanol has some tribological issues connected with engine oil dilution and corrosion [21] due to the inherent oxygen and moisture. Research [22] confirms that ethanol generally increases wear while having a minimal impact on the aging performance of lubricant oil [23]. Therefore, it could be concluded that conventional fuel modification by adding alternative fuels results in dilution and degradation of engine oil, which affect thermodynamic efficiency as well as friction [24] and increased wear in the contact pairs and bearing surfaces of an IC engine [1].

A significant role in the case of wear and changes in the physico-chemical properties of the engine oil is also played by the quality of the oil. Increased temperature during engine operation affects the engine oil, resulting in increased wear and an increased number of contaminants that make the oil look darker. It should be noted that engine oil is exposed to 160 °C in gasoline engines and 315 °C in diesel engines [25]. Continuing exploitation of the engine with dirty oil increases wear and heat inside the engine, which can already have a negative impact on engine operation and, accordingly, fuel consumption. Additionally, engine oil loses its lubricating properties if usage of the same engine oil is realized for a long time [26]. Therefore, engine oil change interval has always been a pressing question for vehicle users, especially when there is no single answer on the best choice. Although automotive companies focus on new solutions regarding various direct and indirect evaluation methods of oils using proper algorithms [25], a number of modern base oils have also become available in wider, specially designed additive packages to comply with demanding conditions [27]. Different statements can indeed cause confusion. This is based on a number of studies, where the accuracy of these systems in terms of the tribological properties of the oils does not agree with the recommendations implemented by automotive companies [28].

Studies show that oil change intervals vary significantly, even from region to region. For example, in China, 56.1% of car owners change the oil every 5000 km [29], in Europe, every 10,000 to 30,000 km [30], while in Mexico, this interval is 10,000 km for Mazda cars or 5000 km for Nissan cars [31]. Mostly, it is based on two specifications—time and mileage, whichever comes first. Time-based service intervals are applied to older vehicles as natural degradation occurs in engine oil even if the user is not driving so frequently, and the quality of such oil can decrease due to various contaminations, like moisture. In the case of a mileage-based service, the user should change the oil before reaching the mileage limitation. This option is better suited for those who use the car on a daily basis and achieves higher mileage faster. Therefore, oil replacement must be realized more frequently. It should be noted that late replacement of used oil could increase repair costs of engine parts, while premature change of suitable engine oil could influence the environment and could be considered an inefficient action if resource depletion occurs [32].

The service life of the engine is largely related to the wear of the parts. Information regarding component wear rate and the origin of trace metals could normally be predicted by evaluating trace metal concentration increases in the lubricating oil based on usage intensity [33]. As oil contains much abnormal wear debris due to reciprocating motion, rotary motion, or adhesive and abrasive wear, a reduction in the anti-wear properties of lubricating oil should be expected [34]. The number of studies related to the research of the composition of wear products in engine oil with the increase in vehicle mileage is limited, especially in the case of oils with different viscosity grades, while there are some good examples.

For example, Kucera [35] studied wear particles using computer image analysis and concluded that it is the best way to recognize the main cause of particle generation. It is also highly recommended to change the oil immediately as soon as the first wear particles are identified. At the same time, Dorr [36] observed that some additives, such as zinc dialkyl dithiophosphate, used to reduce wear, can be lost and no longer detected after 6000 km mileage. Zoldy [37] suggested a proven test cycle on a state-of-the-art engine for validation of the fuel economy effect of engine oils, concluding that different engine oil additives cause essential differences in fuel consumption, carbon footprint, and physical properties.

Idzior [27] has tested so-called “long-life” oils with a replacement interval every 30,000 km, and he concluded that in the case of diesel engines, it is possible to establish an approximate mileage at which the oil should be changed, but for petrol engines, it is practically impossible. He stated the importance of the driving style of the driver, the area of use of a car with a turbocharged gasoline engine, and the high temperatures of the engine on the quality of the oil, concluding that oil should be changed more frequently than indicated by standards. Kral [38] agreed with that after testing 13 oil samples from cars, where the on-board computer and the car producer recommended oil for exchange based on the fact that oil checking is realized with the use of an algorithm that evaluates oil condition based on: cold start, driver profile, oil temperature, load, and engine speed.

Agocs [1] in a field study with petrol and diesel vehicles correlated fresh oil properties with operating conditions, and he observed that lubricant performance can significantly differ after a similar mileage, depending on different factors, including utilization profiles. He also concluded that short-range petrol vehicles demonstrate faster oil degradation, while diesel vehicles show more pronounced engine wear, as indicated by the iron content in the oils.

Zaharia [32] analyzed samples of SAE 5W30 engine oil for parameters like viscosity, density, flash point, contamination with fuel and solids, etc., taken from 14 cars. He concluded that the analysis of the lubrication can identify much earlier the wear degree and potential defects that may occur during the operation and proposed periodically analyzing engine oils between two technical revisions, knowing clearly several influencing factors. At the same time, another study [39] of fresh and used oils from vehicles with a mileage of 15,000 to 20,000 km concluded that the main changes in oil rheological parameters depend on the condition of the drive unit.

Overall, a limited number of studies have been published concerning oil degradation in ICEs of slightly used cars in a post-warranty period—most of the studies were carried out on cars with an average age of 5 years [31]; representing a small part of the vehicle fleet in Latvia. At the same time, most consumers strictly adhere to certain oil change intervals recommended by the car manufacturer, but this is not always realized for used cars for which the manufacturer’s warranty has expired. In this regard, it is essential to understand whether the oil characteristics change during the same recommended interval or whether it would be necessary to make appropriate adjustments to maintain engine performance and reduce the possibility of wear. Therefore, field tests were performed on several slightly used cars with gasoline and diesel engines powered by the commercially available fossil fuel with biofuel additives—B7 (7% v/v biodiesel additive to fossil diesel) and E10 (10% v/v ethanol additive to gasoline).

2. Materials and Methods

This study was conducted at the Faculty of Engineering and Information Technologies of the Latvia University of Life Sciences and Technologies from December 2020 to December 2021. The vehicles selected for field tests were Euro 5: one Opel Insignia with a diesel engine and two Peugeot 308 SWs with gasoline engines.

Cars in the post-warranty period were used for the tests. The total mileage of the cars before the start of the tests did not exceed 125,000 km (gasoline cars) and 175,000 km (diesel cars). Table 1 reports the main characteristics of test vehicles before tests.

Table 1.

Cars used in research and their technical characteristics.

The cars used in this research were powered by fuel containing a small admixture of biofuel—B7 (7% biodiesel and 93% fossil diesel (v/v)) and E10 (10% ethanol and 90% gasoline (v/v)). Since the fuel complies with EU standards, no additional analyses were performed. Starting a test, three mineral base oils with different viscosity grades were chosen, and completely fresh oil was used for each car. The main characteristics of these oils can be found in Table 2.

Table 2.

Engine oils used in tests.

To evaluate the effects of the aging of the oil during tests, mileage before the mandatory change of the oil was divided into 5 parts, and periodical sampling was carried out for every 3000 km with a slight delay depending on possible operating conditions. Oil samples from each car were taken with the engine warmed up to operating temperature and quenched for a period of time not exceeding 2 min to limit possible particle deposition. For testing, the samples were sent to the “POLARIS Laboratories” branch in Poland, where monitoring tests using spectrometric analysis and analysis of engine oil properties were performed.

All used lubricants were characterized from a physico-chemical point of view using standard analytical equipment and methods. The presence of metals was determined using spectrometric analysis according to ASTM D5185. Fuel contamination as a percentage of the sample amount was determined by gas chromatography according to ASTM D7593. The ash and water content as a percentage of the sample was determined with an FTIR spectrometer according to ASTM E2412. Engine oil viscosity was measured according to the standard ASTM D445. Oxidation in engine oil samples was determined simultaneously with the determination of ash and water composition, according to ASTM E2412, using Fourier transform infrared spectrometry. As there is no universal standard for alarm parameters in engine oil except a guide teaching statistical techniques for evaluating the reasonability of those limits [40], the critical and limit values were determined according to laboratory testing methodologies based on the specific engine oil brand, composition, vehicle mileage, and other factors.

In order to fully determine the metal content, the obtained results were compared with a fresh, unused sample of the same engine oil.

3. Results

This research results are summarized in five sub-sections, depending on the type of component or contaminant present in the oil.

3.1. Wear Metals

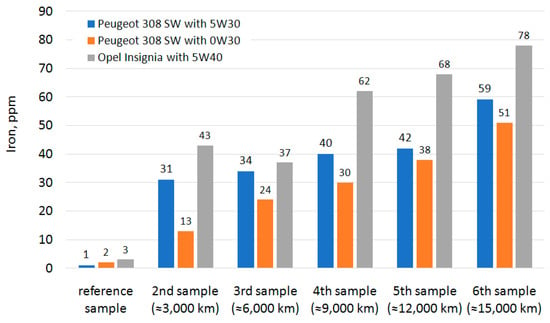

Research results confirm that all cars show a gradual increase in iron particles (Figure 1), which can be explained both by the mutual friction of engine assemblies and the washing of engine oil against iron and steel parts, as well as the release of iron oxide under the influence of acids. The presence of iron particles is considered a normal phenomenon since it is impossible to completely exclude the occurrence of friction in the engine assemblies. Although the iron level is increasing, it does not reach the critical or threshold values for any car. At the same time, a reduction of iron particles for Opel Insignia was observed at 6000 km, explaining it with sediment of these particles in the oil filter. With the increase in mileage, not all of those particles can be absorbed inside the filter.

Figure 1.

Iron particle concentration in engine oil.

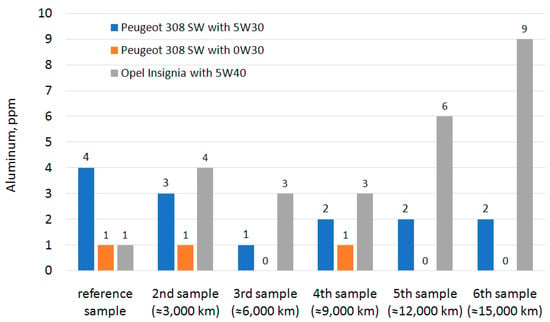

Aluminum particles (Figure 2) for the Peugeot 308 SW made by PSA Group in Sochaux (France) remained at the same low level both with SAE 5W30 and SAE 0W30 engine oil, whereas for the Opel Insignia made by General Motors in Rüsselsheim (Germany), a rapid increase in aluminum particles was observed after 9000 km of mileage. Aluminum particles can be released when engine oil is flushed into the aluminum piping or crankcase cover, as well as in the oil cooling heat exchanger, or as a result of friction between the oil pump housing and the pump wheel. However, it should be noted that a content of 9 ppm aluminum in engine oil is still a relatively low value that does not indicate a significant intensification of wear processes.

Figure 2.

Aluminum particle concentration in engine oil.

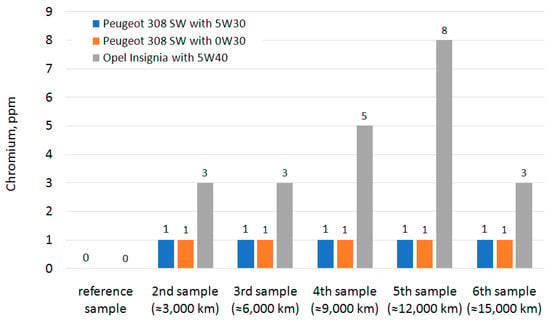

At the same time, it has been found that the Opel Insignia has an increased chromium content (Figure 3) in the engine oil at higher mileage, which may occur as a result of friction between the cylinder and the compression rings. Chromium observed in the case of the Peugeot 308 SW may have been released by engine oil washing against the stainless steel pipes, as there was no evidence of damage to this car. For Peugeot 308 SW, both with SAE 5W30 and SAE 0W30 engine oils, the chromium level remains consistently low throughout the entire oil change interval and does not reach the limit values, concluding that no significant release of chromium is observed as a result of wear. For Opel Insignia, the level of chromium particles was moderately high throughout the oil change interval and reached its maximum value at 12,000 km. Chromium is used in the manufacture of piston ring coatings, which is most likely the cause of the presence of chromium particles in these samples. As the piston rings rub against the cylinder walls, chromium particles could enter the engine oil.

Figure 3.

Chromium particle concentration in engine oil.

Despite the fact that the number of particles is not high, wear on the compression rings is possible in the future. The reduction in concentration of chromium particles for Opel Insignia from 12,000 to 15,000 km was probably due to an error in the measuring system or a contamination in the oil sample.

Nickel is used in the manufacture of slide bearings, and its presence in the engine oil samples of all vehicles after higher mileage indicates increased friction or washout of the slide bearings. As can be seen from Figure 4, the number of nickel particles is negligible and does not indicate a significant intensification of wear processes; however, it serves as an indicator of the degradation of the engine oil’s lubricating ability.

Figure 4.

Nickel particle concentration in engine oil.

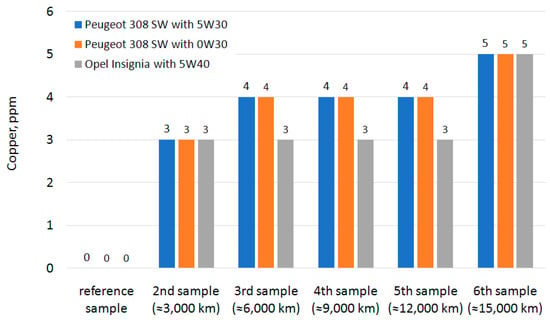

With the increase in mileage since the engine oil change, an increase in copper particles (Figure 5) was observed in all the cars used in the test. Release of copper particles is possible when valve stems rub against valve guides made of copper alloy—bronze; as well as a result of friction occurring in bronze bushings. In none of the cars does the amount of copper particles reach high values, which indicate typical, normal wear of parts as a result of friction.

Figure 5.

Copper particle concentration in engine oil.

3.2. Multi-Source Metals

From Figure 6, it can be seen that a large amount of titanium particles was detected for the Peugeot 308 SW with SAE 5W30 engine oil, which gradually decreased with increasing mileage. In this case, titanium is added as an engine oil additive to improve its anti-friction properties. In the Peugeot 308 SW with SAE 0W30 engine oil and Opel Insignia, a much lower number of titanium particles was detected with a similar trend, which indicates that titanium was also used as an additive in these engine oils, only in a relatively lower concentration. At the same time, the concentration of titanium particles in the Peugeot 308 with 5W30 could be reduced due to the degradation of this friction reduction additive with the increase in oil usage.

Figure 6.

Titanium particle concentration in engine oil.

Molybdenum was used as an additive metal in the engine oils of all cars used in the experiment to improve their anti-friction properties. As can be seen in Figure 7, a higher concentration of molybdenum additive was detected for the Peugeot 308 SW with SAE 0W30 engine oil. Such indicators can be explained by the fact that molybdenum additives are used in engine oil to ensure anti-friction properties. Molybdenum is also used in iron alloys, especially in the manufacture of piston rings, so an increase in molybdenum can indicate wear on the piston rings.

Figure 7.

Molybdenum particle concentration in engine oil.

The concentration of molybdenum particles in the samples of all cars used in the experiment remains at a uniform level throughout the entire oil change interval, but in the period between sample 4 and sample 5, an increase in the number of molybdenum particles was observed for the Peugeot 308 SW with both engine oils used in the experiment. This could be a characteristic of increased friction between the piston rings and the cylinder walls caused by the low viscosity of the engine oil and the increased fuel concentration. A rapid decrease in the number of molybdenum particles was observed for Opel Insignia during this period, which indicates the depletion of additives.

Boron is usually added to engine oil as a flushing additive to clean the engine. An increase in boron particles, combined with an increase in sodium and potassium, could indicate a coolant leak; however, no increase in these elements was detected. Therefore, it can be concluded that boron was added as an engine oil additive to improve the oil’s flushing properties. Figure 8 shows that for a Peugeot 308 SW with SAE 5W30 engine oil, the number of boron particles remains constant throughout the oil change interval, but using SAE 0W30 engine oil, a higher initial concentration of boron particles and their gradual decrease were observed. This can be explained by the gradual depletion of rinsing additives.

Figure 8.

Boron particle concentration in engine oil.

The number of antimony and manganese particles in the engine oil samples of all cars was not analyzed as it remained steady without sharp jumps. Probably antimony and manganese were added in small amounts as additives, while, for example, the lithium additive was not detected at all.

3.3. Contaminants

This section summarizes the data on the concentration of pollution elements in the engine oil samples obtained as a result of the engine oil monitoring analyses. Contamination elements could enter the engine oil from the environment, cooling, and technical fluids, as well as fuel leaks in the lubrication system.

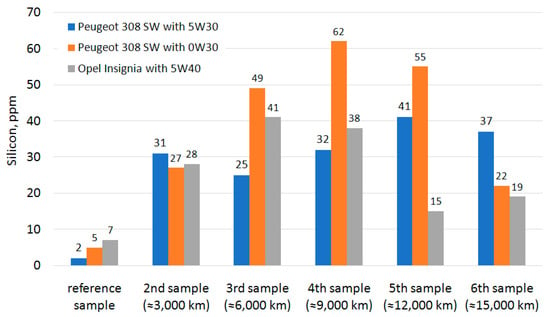

One of such elements is silicon, which can get into the engine oil in the form of dust particles or when the engine oil washes over the components of the engine structure, for which silicone sealant was used during assembly. Silicon can also be added as an engine oil additive in small amounts. Getting dust particles into the engine oil is a normal and natural phenomenon, especially in dry weather, when wind-blown dust can get into the engine oil.

As can be seen from Figure 9, the silicon concentration for the Peugeot 308 SW with SAE 0W30 engine oil reached a critical limit at 9000 km mileage, but then the silicon level decreased again. Considering the construction of the wet timing belt used in this car (similar to the drive chain, the timing belt is inside the engine block, in a constant bath of engine oil), the presence of silicon could also be explained by the flushing of the engine oil against the timing belt. On the Opel Insignia, shortly before the start of the experiment, engine repairs were carried out, which resulted in an increased presence of silicon particles in the engine oil samples. Since the construction of both cars is carried out in such a way that the crankcase cover is screwed to the engine block and silicone sealant is used as a sealing element between these surfaces, the presence of these particles could also be explained by the washing of engine oil against the used silicone sealant.

Figure 9.

Silicon particle concentration in engine oil.

This study confirms that fuel pollution is high for all the cars used in the test. The presence of fuel in the engine oil usually indicates damage to the fuel injection system or wear of the cylinder walls and piston rings of the engine block, as a result of which an increased portion of the fuel mixture enters the crankcase, where the fuel settles and mixes with the engine oil. The presence of fuel significantly reduces the viscosity; therefore, the ability of the engine oil to provide a full-fledged oil film and the formation of an oil wedge in the engine nodes are reduced.

Figure 10 shows that the Opel Insignia has a steady increase in fuel concentration, which increases significantly between 12,000 and 15,000 km. Some laboratories indicate the permissible fuel content in oil is 2–4%. However, there are no specific standards in this regard, and the presence of fuel in engine oil may be a temporary phenomenon.

Figure 10.

Fuel concentration (wt.%) in engine oil.

In the case of the Opel Insignia, a faster development of flushing additives was also observed, which could explain the inability of engine oil to neutralize the increased amount of fuel. In the Peugeot 308 SW, with both types of engine oil, a high concentration of fuel was observed, which could be due to a part of the fuel mixture leaking from the cylinder to the block artery. Such high fuel readings indicate wear on the piston rings and cylinder walls. Considering that the fuel used in the car is gasoline, the fluctuation shown in the graphs using SAE 5W30 engine oil in the car should be explained by the evaporation of gasoline as the engine oil heats up. For the same reason, when using SAE 0W30 engine oil in a car, no sharp increase or decrease in fuel concentration was observed.

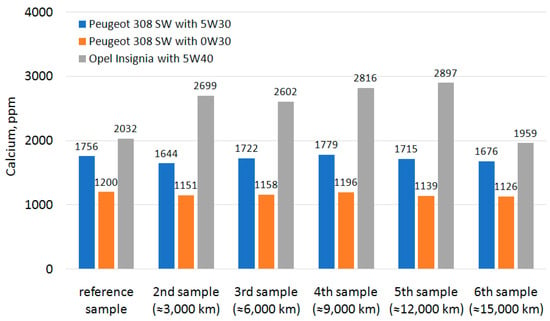

3.4. Additive Metals

Additionally, attention was paid to the number of additive metals in the analyzed engine oil samples. Usually, additive metals are added to the base engine oil to improve its properties and should remain at the same level throughout the oil change interval. The reduction of such additives most often indicates the end of the engine oil’s service life.

As a rule, magnesium, calcium, and barium are added to engine oils as flushing additives, the task of which is to clean the lubrication system from oil sludge and prevent the formation of ash deposits in the oil. Based on the results obtained in the test, it is possible to determine that only SAE 0W30 engine oil used in the Peugeot 308 SW had a barium additive added, and this additive was not detected in the other engine oil samples. The magnesium level for all cars remained at a steady level, except the Peugeot 308 SW with SAE 5W30, which showed a sharper decrease between 3000 and 6000 km. Despite this jump, the data obtained during the analyses did not indicate any damage or excessive development of barium and magnesium additives. This study found that a stable amount of calcium additives (Figure 11) was observed in the Peugeot 308 SW with both types of engine oil, but in the Opel Insignia, at the end of the oil change interval, a rapid decrease in calcium additives was found at the engine oil change, which may indicate a rapid depletion of additives.

Figure 11.

Calcium particle concentration in engine oil.

3.5. Viscosity and Other Properties

Figure 12 and Figure 13 demonstrate a steady, gradual decrease in viscosity for all samples over their first lifetime, i.e., up to a mileage of about 3000 km. This phenomenon can be attributed, among other factors, to the impact of oil dilution by fuel, which consistently penetrates the crankcase in small amounts. Subsequently, the kinematic viscosity value of the oils stabilizes or slightly decreases.

Figure 12.

Viscosity of engine oil samples at 40 °C.

Figure 13.

Viscosity of engine oil samples at 100 °C.

However, it was found that the presence of fuel in the oil did not lead to a decrease in the kinematic viscosity of the oil below the permissible limit specified in the SAE J300 standard. According to this standard, the minimum value of the kinematic viscosity measured at 100 °C cannot be lower than 3.8 cSt (Figure 13). Also, it should be pointed out that a small amount of fuel is often found in engine oil, as confirmed by research conducted by Xe et al. [41].

Figure 14 demonstrates an increase in oxidation for the Peugeot 308 SW with SAE 5W30 engine oil at 15,000 km. This can be explained by the sampling time in the summer months—July and August 2021.

Figure 14.

Oxidation of engine oil.

At this time, air temperatures were higher; therefore, the temperature of the engine and engine oil also increased, accelerating the oxidation of the engine oil. For the Opel Insignia, the oxidation remained at a steady level, but for the Peugeot 308 SW with SAE 0W30 engine oil, the oxidation level increased. No critical values were found in any test. According to engine oil manufacturers, the permissible limit for oxidation is 25 abs·cm−1 [42]. It should be noted, however, that there are no limit values for the indicated parameter that would be specified in the appropriate standards.

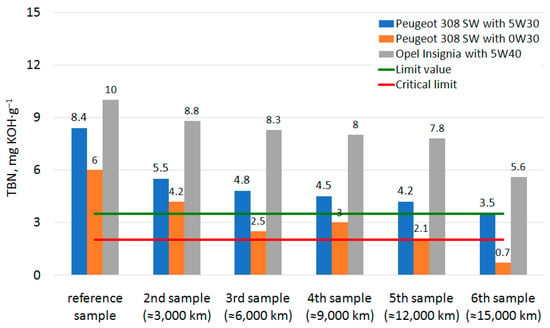

The total base number (TBN) indicates the engine oil’s ability to neutralize acids that enter the engine oil. As the TBN decreases, the engine oil is no longer able to neutralize the acids that are produced in the crankcase when the combustion gases mix with the engine oil.

As a result, the environment inside the engine becomes more acidic than necessary, and oxidation of the iron in the engine structure occurs. Engine oil whose TBN has reached its limit or critical value is recommended to be replaced. Figure 15 shows that the TBN for all the cars used in the experiment decreased during the length of the engine oil change interval.

Figure 15.

TBN of engine oils.

For the Opel Insignia, between 12,000 and 15,000 km of mileage, a sharper reduction in TBN was observed, which indicates the end of the engine oil’s working life. For a Peugeot 308 SW with SAE 5W30 engine oil, the TBN reached the limit at 15,000 km. Using SAE 0W30 engine oil, TBN fluctuated around the threshold value from 6000 to 12,000 km, after which the total number of bases decreased sharply, and at a mileage of 15,000 km, it already reached a critically low value.

4. Discussion

The IC engine is a very complicated technical and chemical system where the degradation of lubricant could be affected by many factors in interaction with other elements and fluids at relatively high temperatures. Accurate estimation of engine oil lifetime was always an actual task for vehicle manufacturers, as it was directly connected with additional costs in cases of frequent oil changes. At the same time, untimely engine oil changes can contribute to engine damage, which contributes to larger unexpected costs. While the setting of oil change intervals is widely described in many literature sources, precise results can only be confirmed by detailed scientific studies.

The concentration of iron, which is the basic chemical element in the construction of engines, increased during the operation process. This was accompanied by higher silicon concentrations, which may indicate greater engine wear [43]. A slight increase in the nickel particles used in the slide bearings was observed, reaching 12,000 km for all test cars. An accelerated depletion of calcium and molybdenum additives was observed for the Opel Insignia after 12,000 km of mileage, which could be based on tribofilm partially removing from the sliding surfaces, resulting in the removal of film particles. Therefore, these particles cannot be dissolved again in the engine oil and are then sedimented or filtered out by the oil filter [1].

A rapid drop in TBN was observed for Peugeot 308 SW with SAE 0W30 engine oil used after 12,000 km of mileage, as a result of which the ability of the engine oil to neutralize acids caused by incomplete fuel combustion decreased rapidly, which is important in protecting the engine components from corrosion [44] and may be used as an indication for the engine oil’s replacement time [45]. Loss of additives resulted in an increase in degradation products, like oxidation, which was also observed in another study [46]. Similar to Golebiowski’s study [30], this research also confirms an upward trend in oxidation depending on the degree of oil use. As oxidation severely reduces the oil’s ability to protect internal components [44], an increase in wear is also obvious, which was observed in this research. Oxidation can also affect the viscosity [44], which showed a slight decrease at the end of the oil change interval. Similar results of viscosity reduction were also observed in other research [43], where the decrease in kinematic viscosity did not exceed a limit of 15–20% of the new oil after 21,000 km of mileage.

Considering these results, it is preferable to choose a maintenance interval of no more than 12,000 km for cars in the post-warranty period. In this way, as the oil change interval approaches its end, the number of parameters that have exceeded the critical limit will decrease, and the chances of engine damage will also decrease as the engine oil loses some of its properties.

Also, the different driving habits of drivers and car operating modes should be considered. Driving in city mode, the engine oil degrades faster compared to extra-urban or combined driving modes. Research [1,47] agrees that lubricant performance strongly depends on the utilization profile of vehicles, and field tests could provide the necessary input to produce lubricants close to reality. At the same time, another solution for a more accurate determination of the maintenance period could be used. It is necessary to determine this period in engine hours, not depending on kilometers driven. In this way, it would be possible to determine a single technical maintenance period that would be equally helpful for most drivers and would allow for avoiding situations where the car owner would have to analyze his driving mode and choose the corresponding engine oil change interval.

Another important aspect of extending the life of the engine is the choice of high-quality engine oil. As a rule, high-quality and well-known brands of engine oils contain a more complete additive package, which allows the engine oil to last longer and ensures its ability to perform its function more fully even when the maintenance period is nearing its end. At the same time, it does not guarantee that the quality of the oil will be ensured at the same level throughout the period of operation recommended by the manufacturer, which is also confirmed by other studies [38].

Examining Opel Insignia engine oil test reports revealed that the Valvoline Syn-Power additive package of the used engine oil does not match the laboratory’s available data on the additive composition of this brand and viscosity. Although nothing was found in the used engine oil, which would indicate that the engine oil was not in accordance with the specifications of the car manufacturer, this situation shows that oil bought in stores will not always correspond to the characteristics written on the package. For this reason, it is necessary to pay attention to the quality of engine oil at the time of its purchase.

Another option could also be the use of nano-additives, as the aging of the lubricant does not alter the performance of the nano-additive, and based on other research [44], formulated nano-additives appear to be a good low-cost solution to reduce fuel consumption without engine modification. Although such advanced lubricants need to be evaluated in “real-world” systems to confirm their beneficial performance, selecting the proper vehicle or system-level test [48].

When making a choice for the engine oil, the client must be sure that the oil fully meets the specifications set by the car manufacturer, as the composition of the oil can directly harm the operation of the engine. For example, the Peugeot 308 SW uses a wet timing belt design, and if an ester-based engine oil were used in this car, the timing belt would gradually break down, rubber particles would clog the lubrication channels, the engine would be starved of oil, and its service life would be noticeably reduced. Therefore, in the specific car as well as in all cars in general, it is necessary to use engine oil that meets the specific standard set by the manufacturer.

Overall, although there are methods of determining the optimal oil change interval for both diesel and gasoline vehicles [49,50], regular oil analysis or measurement of oil condition in real time would be an excellent choice for monitoring lubricant condition, but this cannot always be conducted by an ordinary car owner. Therefore, it would be recommended to establish a well-functioning engine lubricant condition monitoring scheme, providing early detection of engine and lubricant issues. Although car manufacturers have developed appropriate recommendations, this scheme should always be given more attention during the car’s post-warranty period to avoid unexpectedly high costs related to engine repairs.

5. Conclusions

- Particles of various metals were detected in the tested oils, which may indicate progressive engine wear. However, in this respect, there are no limit values specified in the relevant standards, which makes the interpretation of the results difficult. For this reason, the obtained test results should be interpreted in relation to the reference parameters of fresh oil.

- The presence of nickel in engine oil was not detected during vehicle operation. Trace amounts of nickel detected in the final phase of the test do not indicate progressive engine wear.

- An increased content of chromium particles was reached for the Opel Insignia at 9000 and 12,000 km, indicating increased friction between the piston rings and the cylinder walls.

- A rapid drop of molybdenum anti-friction additives by 4.5 times and flushing of calcium additives by 32% were observed for the Opel Insignia, indicating a rapid depletion of the additives and the end of the engine oil’s service life.

- A gradual increase in fuel concentration by 2% between 12,000 and 15,000 km and exceeding the critical limit by 32% has been observed for the Opel Insignia car running on diesel fuel.

- A gradual decrease in viscosity has been observed for the Opel Insignia, while reduced viscosity during the entire maintenance period was observed for the Peugeot 308 SW with SAE 0W30 engine oil. However, the obtained viscosity values remained above the limit specified in the SAE J300 standard.

- A decrease in the TBN was observed for all cars used in the test. For a Peugeot 308 SW with 5W30 engine oil used, the TBN limit value had been reached at the time of taking the 5th sample. While using SAE 0W30 engine oil, the TBN at the time of taking the 5th sample was 2.8 times lower than the critical limit.

Author Contributions

Conceptualization, R.S. and A.B.; methodology, R.S., K.A. and A.B.; software, K.G.; validation, R.S., K.A. and K.G.; formal analysis, R.S., A.B. and K.A.; investigation, R.S., A.B. and S.K.; resources, K.A. and K.G.; data curation, R.S. and A.B.; writing—original draft preparation, R.S., K.A. and K.G.; writing—review and editing, A.B., K.A. and S.K.; visualization, R.S.; supervision, R.S. and K.A.; project administration, R.S. and K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data will be made available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Agocs, A.; Nagy, A.L.; Tabakov, Z.; Perger, J.; Rohde-Brandenburger, J.; Schandl, M.; Besser, C.; Dorr, N. Comprehensive assessment of oil degradation patterns in petrol and diesel engines observed in a field test with passenger cars—Conventional oil analysis and fuel dilution. Tribol. Int. 2021, 161, 107079. [Google Scholar] [CrossRef]

- Wong, V.W.; Tung, S.C. Overview of automotive engine friction and reduction trends–Effects of surface, material, and lubricant-additive technologies. Friction 2016, 4, 1–28. [Google Scholar] [CrossRef]

- Wasiak, A.; Orynycz, O.; Tucki, K.; Świć, A. Hydrogen enriched hydrocarbons as new energy resources—As studied by means of computer simulations. Adv. Sci. Technol. Res. J. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- Amatnieks, K.; Smigins, R.; Birkavs, A. Thermodynamic and NOx emission analysis of diesel engine with intake manifold steam injection. In Proceedings of the International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 24–26 May 2023; Volume 22, pp. 145–151. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Knauder, C.; Allmaier, H.; Sander, D.E.; Sams, T. Investigations of the friction losses of different engine concepts. Part 1: A combined approach for applying subassembly-resolved friction loss analysis on a modern passenger-car diesel engine. Lubricants 2019, 7, 39. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Béjar-Gómez, L.; López-Velázquez, A.; Maya-Yescas, R.; Nápoles-Rivera, F. Maximizing lubricant life for internal combustion engines. Processes 2022, 10, 2070. [Google Scholar] [CrossRef]

- Fang, C.; Meng, X.; Xie, Y. A piston tribodynamic model with deterministic consideration of skirt surface grooves. Tribol. Int. 2017, 110, 232–251. [Google Scholar] [CrossRef]

- Domínguez-García, S.; Maya-Yescas, R.; Béjar-Gómez, L. Reduction of lubricant life in lubrication systems for internal combustion engines due to high lubricant supply rates. Mater. Lett. 2022, 313, 131785. [Google Scholar] [CrossRef]

- Lee, P.; Zhmud, B. Low friction powertrains: Current advances in lubricants and coatings. Lubricants 2021, 9, 74. [Google Scholar] [CrossRef]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Dubey, M.K.; Chaudhary, R.; Emmandi, R.; Seth, S.; Mahapatra, R.; Harinarain, A.K.; Ramakumar, S.S.V. Tribological evaluation of passenger car engine oil: Effect of friction modifiers. Results Eng. 2022, 16, 100727. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Masjuki, H.; Kalam, M.; Bhuiya, M.; Mehat, H. Comparative tribological investigation of bio-lubricant formulated from a non-edible oil source (Jatropha oil). Ind. Crops. Prod. 2013, 47, 323–330. [Google Scholar] [CrossRef]

- Birkavs, A.; Smigins, R. Experimental research on compatibility of mineral and biobased hydraulic oils. Agron. Res. 2018, 16, 968–976. [Google Scholar] [CrossRef]

- Smigins, R.; Zakis, A. Impact of diethyl ether/rapeseed oil blends on performance and emissions of a light-duty diesel vehicle. Energies 2020, 13, 3788. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The effects of pressure and temperature on the process of auto-ignition and combustion of rape oil and its mixtures. Sustainability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Mobarak, H.M.; Mohamad, E.N.; Masjuki, H.H.; Kalam, M.A.; Al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Erhan, S.Z.; Perez, J.M. Tribological studies of thermally and chemically modified vegetable oils for use as environmentally friendly lubricants. Wear 2004, 257, 359–367. [Google Scholar] [CrossRef]

- Kalam, M.A.; Masjuki, H.H.; Cho, H.M.; Mosarof, M.H.; Mahmud, M.I.; Chowdhury, M.A.; Zulkifli, N.W.M. Influences of thermal stability, and lubrication performance of biodegradable oil as an engine oil for improving the efficiency of heavy duty diesel engine. Fuel 2017, 196, 36–46. [Google Scholar] [CrossRef]

- Markiewicz, M.; Aleksandrowicz, P.; Muślewski, Ł.; Pająk, M. Testing and analysis of selected operating parameters of a vehicle powered by fuel with the addition of biocomponents. Energies 2023, 16, 3159. [Google Scholar] [CrossRef]

- Sudan, M.; Dandu, R.; Nanthagopal, K. Tribological aspects of biofuels–A review. Fuel 2019, 258, 116066. [Google Scholar] [CrossRef]

- Costa, H.L.; Cousseau, T.; Souza, R.M. Current knowledge on friction, lubrication, and wear of ethanol-fuelled engines—A review. Lubricants 2023, 11, 292. [Google Scholar] [CrossRef]

- Besser, C.; Schneidhofer, C.; Dorr, N.; Novotny-Farkas, F.; Allmaier, G. Investigation of long-term engine oil performance using labbased artificial ageing illustrated by the impact of ethanol as fuel component. Tribol. Int. 2012, 46, 174–182. [Google Scholar] [CrossRef]

- Nagy, A.L.; Knaup, J.; Zsoldos, I. A friction and wear study of laboratory aged engine oil in the presence of diesel fuel and oxymethylene ether. Tribol. Mater. Surf. Interfaces 2019, 13, 20–30. [Google Scholar] [CrossRef]

- Kardoš, S.; Pietriková, A. Evaluation of motor oil characteristics and degradation factors for possibilities of continuous diagnostics. Acta Electrotech. Inform. 2016, 16, 20–24. [Google Scholar] [CrossRef]

- Akbiyik, T.; Kahraman, N.; Taner, T. Investigation of the effect of boron additive to lubricating oil on engine performance, exhaust, and emissions. Fuel 2022, 312, 122931. [Google Scholar] [CrossRef]

- Idzior, M. Aging of engine oils and their influence on the wear of an internal combustion engine. Combust. Engines 2021, 185, 15–20. [Google Scholar] [CrossRef]

- Zbigniew, S. Premature degradation of lubricating oil during the service life of the positive-ignition engine. Tribol Online 2021, 16, 31–37. [Google Scholar] [CrossRef]

- Lei, W.; Haitao, D.; Yongliang, J.; Dan, J.; Bingxue, C.; Jianfang, L.; Jian, L. Motor oil degradation during urban cycle road tests. Friction 2021, 9, 1002–1011. [Google Scholar] [CrossRef]

- Golebiowski, W.; Wolak, A.; Zajac, G. Definition of oil change intervals based on the analysis of selected physicochemical properties of used engine oils. Combust. Engines 2018, 172, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Carrera-Rodríguez, M.; Villegas-Alcaraz, J.F.; Salazar-Hernández, C.; Mendoza-Miranda, J.M.; Jiménez-Islas, H.; Segovia Hernández, J.G.; Ortíz-Alvarado, J.D.; Juarez-Rios, H. Monitoring of oil lubrication limits, fuel consumption, and excess CO2 production on civilian vehicles in Mexico. Energy 2022, 257, 124765. [Google Scholar] [CrossRef]

- Zaharia, C.; Niculescu, R.; Năstase, M.; Clenci, A.; Iorga-Simăn, V. Engine oil analysis to evaluate the degree of its wear during the period of operation of the vehicle. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1220, 012037. [Google Scholar] [CrossRef]

- Gupta, J.G.; Agarwal, A.K. Engine durability and lubricating oil tribology study of a biodiesel fuelled common rail direct injection medium-duty transportation diesel engine. Wear 2021, 486–497, 204104. [Google Scholar] [CrossRef]

- Ravikumar, K.P.; Ramakrishna, H.V.; Amriya, T.H.R. Monitoring engine health by lubricating oil analysis—A review. Int. J. Innovat. Res. Sci. Eng. Technol. 2017, 6, 9046–9052. [Google Scholar]

- Kucera, M.; Hnilicova, M.; Ales, Z. Inspection of wear particles contaminating used engine oils. Acta Fac. XIX 2014, 2, 39–47. [Google Scholar]

- Dorr, N.; Agocs, A.; Besser, C.; Ristic, A.; Frauscher, M. Engine oils in the field: A comprehensive chemical assessment of engine oil degradation in a passenger car. Tribol. Lett. 2019, 67, 1–21. [Google Scholar] [CrossRef]

- Zöldy, M. Engine oil test method development. Teh. Vjesn. 2021, 28, 1012–1016. [Google Scholar] [CrossRef]

- Kral, J., Jr.; Konecny, B.; Kral, J.; Madac, K.; Fedorko, G.; Molnar, V. Degradation and chemical change of longlife oils following intensive use in automobile engines. Measurement 2014, 50, 34–42. [Google Scholar] [CrossRef]

- Landowski, B.; Baran, M. Analysis of selected results of engine oil tests. MATEC Web Conf. 2019, 302, 01010. [Google Scholar] [CrossRef]

- ASTM D7720-21; Standard Guide for Statistically Evaluating Measurand Alarm Limits When Using Oil Analysis to Monitor Equipment and Oil for Fitness and Contamination. ASTM International: West Conshohocken, PA, USA, 2021.

- He, X.; Williams, A.; Earl Christensen, E.; Burton, J.; McCormick, R. Biodiesel impact on engine lubricant dilution during active regeneration of after treatment systems. SAE Int. J. Fuels Lubr. 2011, 4, 158–178. [Google Scholar] [CrossRef]

- Shinde, H.M.; Bewoor, A.K. Evaluating petrol engine oil deterioration through oxidation and nitration parameters by low-cost IR sensor. Appl. Petrochem. Res. 2020, 10, 83–94. [Google Scholar] [CrossRef]

- Sejkorová, M.; Hurtová, I.; Glos, J.; Pokorný, J. Definition of a motor oil change interval for high-volume diesel Engines Based on its Current Characteristics Assessment. Acta Univ. Agric. Silvic. Mendel. Brun. 2017, 65, 481–490. [Google Scholar] [CrossRef]

- Sgroi, M.F.; Asti, M.; Gili, F.; Deorsola, F.A.; Bensaid, S.; Fino, D.; Kraft, G.; Garcia, I.; Dassenoy, F. Engine bench and road testing of an engine oil containing MoS2 particles as nano-additive for friction reduction. Tribol. Int. 2017, 105, 317–325. [Google Scholar] [CrossRef]

- Ratiu, S.A.; Mihon, L.; Armioni, M.A. A review on the contamination of used engine oil. Ing. Automob. 2020, 26, 121–142. [Google Scholar]

- Hönig, V.; Procházka, P.; Obergruber, M.; Kučerová, V.; Mejstřík, P.; Macků, J.; Bouček, J. Determination of tractor engine oil change interval based on material properties. Materials 2020, 13, 5403. [Google Scholar] [CrossRef]

- Moricova, K.; Papucova, I.; Durisova, S.; Janik, R. Determination of engine oil characteristics. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012099. [Google Scholar] [CrossRef]

- Devlin, M.T. Common properties of lubricants that affect vehicle fuel efficiency: A North American historical perspective. Lubricants 2018, 6, 68. [Google Scholar] [CrossRef]

- Hönig, V. Determination of oil change interval for diesel engines according to the quantity of non-ferrous metals. Manuf. Technol. 2017, 17, 857–863. [Google Scholar] [CrossRef]

- Hönig, V. Determination of oil change interval for gasoline engines according to the amount of non-ferrous metals. Manuf. Technol. 2017, 17, 710–717. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).