Abstract

This study aims to identify an equation for predicting the calorific value for heat-treated biomass using structural analysis. Different models were constructed using 129 samples of cellulose, hemicellulose, and lignin, and calorific values obtained from previous studies. These models were validated using 41 additional datasets, and an optimal model was identified using its results and following performance metrics: the coefficient of determination (R2), mean absolute error (MAE), root-mean-squared error (RMSE), average absolute error (AAE), and average bias error (ABE). Finally, the model was verified using 25 additional data points. For the overall dataset, R2 was ~0.52, and the RMSE range was 1.46–1.77. For woody biomass, the R2 range was 0.78–0.83, and the RMSE range was 0.9626–1.2810. For herbaceous biomass, the R2 range was 0.5251–0.6001, and the RMSE range was 1.1822–1.3957. The validation results showed similar or slightly poorer performances. The optimal model was then tested using the test data. For overall biomass and woody biomass, the performance metrics of the obtained model were superior to those in previous studies, whereas for herbaceous biomass, lower performance metrics were observed. The identified model demonstrated equal or superior performance compared to linear models. Further improvements are required based on a wider range of structural biomass data.

1. Introduction

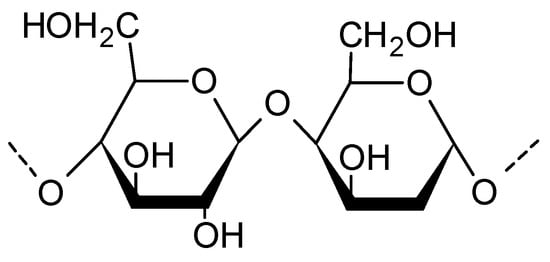

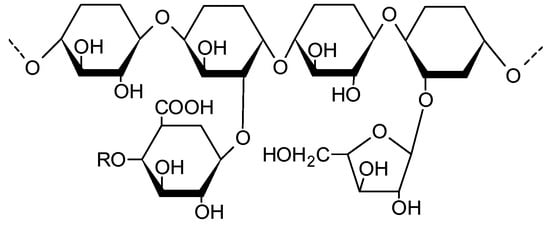

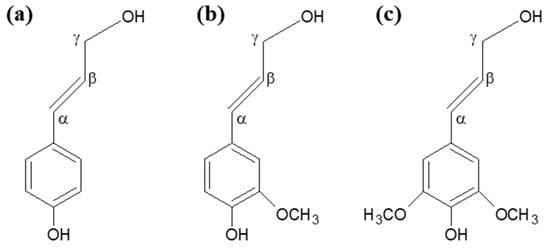

Biomass is used as a countermeasure against environmental pollution. Research has been conducted to use biomass as fuel [1], remove environmental pollution [2], or use it as an environmental improvement agent [3]. These biomass can be analysed using various methods, including elemental, proximate, and structural analyses. In the context of biomass composition, structural analysis refers to the method of analysing the contents of cellulose, hemicellulose, and lignin, which make up the biomass [4,5,6]. Cellulose is represented as [C6H10O5]n and consists of linear chains composed of hundreds to thousands of D-glucose units connected by beta (1→4) glycosidic bonds, as shown in Figure 1. Hemicellulose is composed of hexose sugars, such as glucose, mannose, galactose, and rhamnose, and pentose sugars, such as arabinose and xylose. They are classified based on the main sugar residues in their backbones, which can be xylan, mannan, or glucan, as shown in Figure 2. Lignin refers to hydrophobic phenolic molecules found in various components of woody plants, such as conifers and hardwoods. Precursor molecules like p-coumaryl alcohol (H), coniferyl alcohol (G), and sinapyl alcohol (S) (Figure 3) form complex three-dimensional polymer structures via β-O-4 or carbon-carbon linkages [7,8].

Figure 1.

Structure of cellulose.

Figure 2.

Structure of hemicellulose (arabinoglucuronoxylans).

Figure 3.

Structure of (a) p-coumaryl alcohol; (b) coniferyl alcohol; and (c) sinapyl alcohol.

Previous studies have predicted calorific values of different biomass considering based on their structural characteristics. Howard [9] investigated the variation in calorific values based on different parts of pinewood and highlighted the correlation between extractives and calorific values. Tillman [10] utilised a single variable in a model to estimate the higher heating value (HHV) of wood, which was expressed as dry weight as well as on a dry ash-free basis. White [11] introduced four equations, one of which calculated the calorific value of wood-containing extractives, whereas the other three calculated the calorific values of woods without extractives. Additionally, White proposed a fifth equation inspired by Tillman’s work. Callejón-Ferre et al. [12] predicted a correlation between the structural analysis and calorific values of plant residues within greenhouses in Almería, Spain. Subsequently, predictive equations for the heating value based on structural analysis were also proposed for various biomass and thermally treated biomass. Table 1 summarizes some of the previous studies that predicted HHV by analysing the structure.

Table 1.

Models used in previous studies to predict a higher heating value (HHV) using structure analysis.

Equations for predicting the calorific value of heat-treated biomass have been proposed for elemental and proximate analyses [19,20]. However, few equations are available to predict the calorific value of heat-treated biomass based on structural analyses. Therefore, in this study, we aimed to present an equation for predicting the calorific value of heat-treated biomass based on structural analysis.

2. Materials and Methods

2.1. Collection of Data

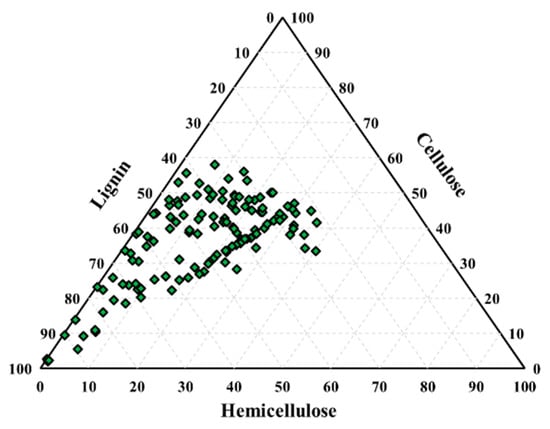

From previous studies, 111 structural analyses and calorific value data were collated for 59 woody and herbaceous biomass samples of 52 herbaceous plants [21,22,23,24,25,26,27,28,29,30,31,32,33,34,35]. All data are summarised in Table S1. The distributions of the structural composition and calorific value of the biomass are shown in Figure 4 and Figure 5.

Figure 4.

Scatter plot of structural composition of biomass.

Figure 5.

Histogram of calorific value.

2.2. Pearson Correlation Coefficient

The study employed the Pearson correlation coefficient (Equation (1)) to assess the relationships compositional (Cell, Hemi, and Lig) analyses and calorific value. This coefficient, as defined in Equation (1), was employed to evaluate the extent of correlation between two sets of data. It ranges from −1 to 1, where positive and negative values indicate a direct and inverse relationship, respectively. Values closer to −1 or 1 signify a stronger linear correlation, while those closer to 0 suggest a weaker correlation [36]. The analysis involved deriving correlation equations with varying goodness-of-fit values through linear and non-linear regressions applied to the final analysis data using IBM SPSS version 22.0. However, for exponential and logarithmic regression models, they were not applied due to the possibility of certain structural components becoming zero during thermal treatment. The data analysis in this study employed a combination of the “stepwise” and “enter” methods within the SPSS software. The input variables included C, H, L, squared (C2, H2, and L2), and squared roots (C0.5, H0.5, and L0.5).

2.2.1. Linear Regression

Linear regression is a statistical approach frequently employed to ascertain the value of a dependent variable using an independent variable [37]. This method relies on a mathematical equation that yields a single value by considering a combination of input characteristics. The linear regression equation is represented as follows [38]:

2.2.2. Polynomial Regression

Polynomial regression is a statistical technique in which data are approximated using a polynomial function [39]. It entails the incorporation of higher-order terms of variables to estimate the polynomial regression and construct a curved response surface [40]. As there is no universally applicable polynomial equation, the equation should be derived based on the specific problem under consideration. The general expression for a polynomial function is as follows [38]:

2.3. Model Evaluation

The suitability of the model was assessed using different performance metrics. Four performance metrics were used, namely the coefficient of determination (R2), mean absolute error (MAE), root-mean-squared error (RMSE), average absolute error (AAE), and average bias error (ABE). R2 was employed because of its advantage in facilitating relative performance comparisons using Equation (4). This quantifies the proportion of variance in the dependent variable that is predictable from the independent variables [39]. MAE was used because it measures the absolute difference between the observed and predicted values in the same units (Equation (5)), which makes it intuitive and straightforward to interpret. RMSE has the advantage of reducing the distortion in the values resulting from squaring the errors (Equation (6)). However, its drawback is that errors < 1 become even smaller owing to squaring, whereas errors > 1 become larger. AAE and ABE represent the average errors in the correlation equation (Equations (7) and (8)). ABE is evaluated such that positive values are rated higher, indicating a better fit, whereas negative values suggest a somewhat lower fit [37,38]. These metrics provide a comprehensive evaluation of the performance of a model by considering different aspects of its accuracy and fit.

Validation of the optimal conditions was conducted based on the performance metrics mentioned above, using the data listed in Table 2.

Table 2.

Validation data for suggested model.

To compare the optimal model selected based on the validation data with those of previous studies, we used the test dataset provided in Table 3 for verification.

Table 3.

Verification test dataset for comparison validation model and previous studies.

3. Results and Discussion

3.1. Result of Pearson Correlation Coefficient

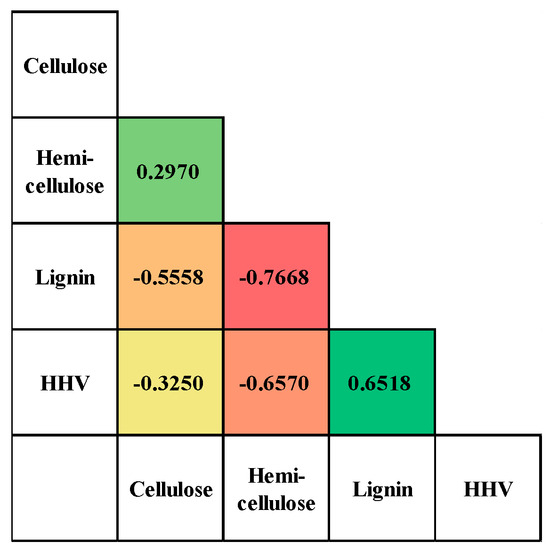

The results of the Pearson’s correlation coefficient are summarized in Figure 6. In the case of cellulose, a positive correlation was observed with hemicellulose, while a negative correlation was found with calorific value. The reason for the positive correlation between hemicellulose and cellulose is likely because they share precursor structures composed of pentose or hexose sugar monomers. For hemicellulose, there was a negative correlation with calorific value and lignin. Particularly, the strong negative correlation of −0.7668 with lignin suggests that in heat-treated samples, the presence of hemicellulose decreases while the lignin content increases due to the decomposition of hemicellulose. In the case of cellulose, it decomposes at high temperatures and decreases like hemicellulose, which is inversely proportional to the increase in HHV. However, due to lower decomposition rate compared with hemicellulose, it has a negative correlation, but it appears to be a weaker correlation than the correlation between hemicellulose and HHV. Lignin, on the other hand, exhibited a strong positive correlation of 0.6518 with the calorific value. This can be attributed to the fact that lignin is a polymer with a high carbon content, and in heat-treated samples, the lignin content tends to be higher, leading to an increase in calorific value.

Figure 6.

Result of Pearson correlation coefficient.

3.2. Prediction Model Using Total Biomass

The equations for predicting the calorific value of the overall biomass are summarised in Table 4. Given the diverse characteristics of the various biomass samples, they exhibited substantial variations, which likely contributed to the lower R2 values. Various input variables were applied, and the highest R2P value of 0.5814 was obtained for T3.

Table 4.

Calorific value prediction model using overall lignocellulosic biomass.

T1 and T2 had an R2P value of 0.5423 and 0.5719, respectively. T3 had the highest value of RMSEP at 1.5455, whereas T1 had the lowest RMSEP of 1.3858. AAEP for T1 was calculated as 5.3455%. However, T2 and T3 exhibited an error rate of 5.7280% and 5.8641%, respectively. Furthermore, among the prediction models that used the overall biomass, the predicted values were higher, resulting in positive ABEP values. T1 exhibited the lowest ABEP of 0.4302%. Hence, T2 predicted more accurately than the ABEP of T2 and T3, which were 2.1895% and 2.9964%, respectively. Given that the performance metrics did not meet the desired level of accuracy, a decision was made to enhance the model’s performance by separating the predictions for woody and herbaceous biomass. This separation was undertaken as the simultaneous prediction of both hardwoods and softwoods may have contributed to the reduced accuracy observed in the model.

3.3. Prediction Model Using Woody Biomass

Three prediction models for woody biomass are presented in Table 5. When compared to the previous prediction models for lignocellulosic biomass, the R2P values for woody biomass were notably higher, ranging from 0.82 to 0.83. Similarly, the RMSEP values for these models fell within the range of 0.96 to 1.18.

Table 5.

Calorific value prediction model using woody biomass.

Interestingly, in most cases, an increase in the number of input variables tended to result in higher R2P values, which could indicate a risk of overfitting. However, it is worth noting that for the prediction models of woody biomass, the model with the highest number of input variables, W1, exhibited the lowest R2P value and the highest RMSEP. On the contrary, the model with the fewest input variables, W3, demonstrated reasonable performance, boasting an R2P of 0.8392 and an RMSEP of 0.9626.

3.4. Prediction Model for Herbaceous Biomass

The prediction models for herbaceous biomass are outlined in Table 6. The R2P values for these models varied in the range of 0.82 to 0.87. Interestingly, the model with the fewest input variables, H1, had the lowest R2P, whereas the model with the most input variables, H3, had the highest R2P. However, when considering the RMSEP, H1 had the highest value at 1.2958. In terms of ABEP, only H2 had a positive value, while H1 and H3 had negative values, indicating an underestimation in the latter cases. The reason for the low accuracy of herbaceous biomass was due to be extractive and non-uniformity compared with woody biomass. In general, it is known that the extractive and ash content of herbaceous biomass is higher than that of woody biomass [50,51]. Because this was not considered in this study, it was determined to be low.

Table 6.

Calorific value prediction model using herbaceous biomass.

3.5. Validation of Calorific Value Prediction Models

A validation process was carried out to determine the most suitable model among the presented models. Table 7 displays the validation outcomes for overall lignocellulosic biomass. The validation results reveal that T2 achieved the highest R2CV, standing at 0.7870. However, it also displayed the lowest RMSECV, which was 1.1258. Both T1 and T3 demonstrated R2CV values of approximately 0.4920. Comparing MAECV and AAECV, T2 demonstrated satisfactory performances. In conclusion, based on the validation results, T2 emerged as the optimal model.

Table 7.

Validation of the results obtained from the model using overall lignocellulosic biomass.

Regarding woody biomass (Table 8), most models displayed R2CV values within the range of 0.60 to 0.69. However, W3 stood out with the highest R2CV value of 0.8108. The RMSECV values generally fell between 1.44 and 1.45 for most models, although W1 had a slightly higher RMSECV at 2.0387. When considering ABECV, W3 had the highest value, reaching 5.2810, compared to W1 and W2 with values of 3.7659. Despite its higher ABECV, W3 was deemed the optimal choice due to its combination of a high R2CV, low RMSECV, and a reduced number of input variables.

Table 8.

Validation of the results obtained from the model using woody biomass.

In the case of herbaceous biomass (Table 9), the R2CV values were notably higher, increasing within the range of 0.528 to 0.8959. Additionally, their RMSECV values ranged from 1.3266 to 2.1312, respectively. The R2cv of H1 was the highest at 0.8959, but RMSECV was 2.1312, higher than H2’s 1.3266. H2 and H3 showed better performance in RMSECV, MAECV, AAECV, and ABECV. Despite a lower R2cv, H2 was determined to be optimal.

Table 9.

Validation of the results obtained from the model using woody biomass.

3.6. Comparison of the Model with Previous Models

Using a verification dataset, we conducted a comparison between the calorific value prediction model developed in our study and models from previous research. For this study, we chose the model by Demirbaş [13], which was based on non-wood biomass, and the model by Domingos et al. [18], which utilized equations formulated using heat-treated biomass.

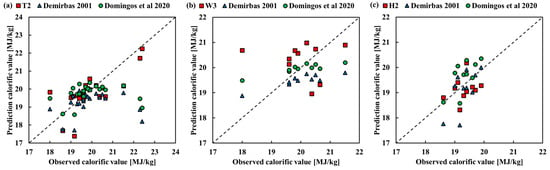

The biomass test results are outlined in Table 10. The RMSE values for T2, Demirbaş [13], and Domingos et al. [18] were recorded as 0.7702, 1.3534, and 1.1298, respectively. The T2 model proposed in our study exhibited the lowest RMSE. In the case of torrefied biomass, Domingos et al. [18] displayed a lower RMSE compared to Demirbaş [13]. The R2 values were relatively low due to the variations in biomass properties, with a notably low R2 value of 0.0059 observed in previous studies. Since both previous studies predicted only lignin as a variable, R2 was observed to have the same value. In the case of previous studies, it was predicted based on lignin alone, but other studies indicate that there are other properties that have significant weight in changes in HHV in addition to lignin [50,52]. Through actual analysis, it was confirmed that cellulose and hemicellulose affected HHV. In all model, a negative ABE was noted, indicating an underestimation, as depicted in Figure 7a.

Table 10.

Validation of the results obtained from the model using overall biomass.

Figure 7.

Scatter plot for predicted and observed calorific values when different biomass types were used: (a) overall lignocellulosic biomass, (b) woody biomass, (c) herbaceous biomass [13,18].

In the case of woody biomass (Table 11), the W3 model proposed in our study displayed the lowest RMSE. Conversely, the Demirbaş equation had a higher RMSE of 1.7427 compared to the other two equations. Also, the R2 value was higher for W3, measuring 0.4152. When considering ABE, W3 was the only equation with a positive value, while that of Demirbaş exhibited a significantly negative value of −4.8843%, indicating an underestimation. Consequently, as depicted in Figure 7b, W3 is represented by a positive trendline, whereas the two equations from previous studies exhibit negative trends.

Table 11.

Comparison of the model with those defined in previous studies by using woody biomass test dataset.

For herbaceous biomass (Table 12), H1 showed an RMSE of 0.5176, whereas Domingos et al. [18] reported an RMSE of 0.5784. The Demirbaş equation exhibited the highest RMSE among the three at 0.6208. However, the R2 value for the Demirbaş and Domingos et al. equation was the highest. Regarding the ABE, only the H1 and Demirbaş equation showed negative values, whereas the Domingos et al. equation had positive values. This is illustrated in Figure 7c. The trend line of Domingos et al. exhibited an upward positive trend, suggesting that predictions from the equations tended to overestimate the values. In contrast, the Demirbaş equation and H1 resulted in an underestimation.

Table 12.

Comparison of the model with those defined in previous studies by using herbaceous biomass test dataset.

4. Conclusions

In this study, the calorific value of lignocellulose using structural analyses was predicted. Building on previous research, we predicted the calorific value by classifying biomass as overall lignocellulose biomass, woody biomass, and herbaceous biomass. When using the overall biomass dataset, the presented models yielded relatively low R2P values, ranging from 0.5423 to 0.5814. However, when analysing the models separately for woody and herbaceous biomass, R2 values of woody biomass ranged from 0.7811 to 0.8392, and those of herbaceous biomass ranged from 0.8256 to 0.8739.

The optimal model was identified after validation. Equations (9)–(11) were identified as the optimal model equations.

Furthermore, the chosen equations were assessed using a test dataset, revealing that T1 and W3 exhibited improved performance compared to previous studies, while H1 showed lower performance compared to prior research. Although the R2 of H1 was low, the RMSE was low compared to previous studies, so it is seemed to be sufficiently usable. In the case of other studies, they were conducted in an extractive-free biomass, but it is important to note that this study presented a calorific value prediction model that did not consider extractive-free biomass. Also, the accuracy of the model using cellulose, hemicellulose, and lignin was confirmed to be higher than that of the conventional lignin-based calorific value prediction model.

This study aimed to encompass various biomass types but was based on a dataset of 111 biomass samples for model construction. However, the prediction rates for calorific values were relatively low for herbaceous and lignocellulosic biomass datasets. Future research should prioritize the development of models capable of predicting cellulose, hemicellulose, lignin, and calorific values across various biomass types and a wide range of heat treatment conditions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en16237896/s1, Table S1: Data from previous studies, 111 structural analyses and calorific value data.

Author Contributions

Conceptualization, S.P., S.Y.K., H.E.K. and D.K.; methodology, S.P., S.Y.K. and H.E.K.; validation, S.P., K.C.O., S.Y.K. and H.E.K.; investigation, S.P., K.C.O., Y.K.J. and L.H.C.; formal analysis, S.P., S.J.K. and K.C.O.; writing—original draft, S.P. and D.K.; writing—review and editing, S.P., K.C.O. and D.K.; data curation, S.P. and K.C.O.; writing—review and editing, D.K.; supervision, D.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study was carried out with the supported of a research grant of Kangwon National University in 2023. Also, this work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) through Agriculture, Food and Rural Affairs Convergence Technologies Program for Educating Creative Global Leader, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) (Project No. 320001-4), Republic of Korea. This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2021R1A6A1A0304424211).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Park, S.; Kim, S.J.; Oh, K.C.; Jeon, Y.K.; Kim, Y.; Cho, A.Y.; Lee, D.; Jang, C.S.; Kim, D.H. Biochar from Agro-Byproducts for Use as a Soil Amendment and Solid Biofuel. J. Biosyst. Eng. 2023, 48, 93–103. [Google Scholar] [CrossRef]

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.-H.; Wang, C.-X.; He, L.; Nie, H.-T.; Wang, J.-C.; Zhang, J.-C.; Fan, B.-G.; et al. Regeneration Mechanism of a Novel High-Performance Biochar Mercury Adsorbent Directionally Modified by Multimetal Multilayer Loading. J. Environ. Manag. 2023, 326, 116790. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Cho, A.Y.; Kim, Y.; Lee, D.H.; Oh, K.C.; Jang, C.S.; Kim, D.H. Effect of Agro-byproduct Biochar Fertilization on Cherry Tomato Growth and Carbon Sequestration. J. Agric. Life Environ. Sci. 2022, 34, 229–237. [Google Scholar] [CrossRef]

- Motta, I.L.; Miranda, N.T.; Maciel Filho, R.; Wolf Maciel, M.R. Biomass Gasification in Fluidized Beds: A Review of Biomass Moisture Content and Operating Pressure Effects. Renew. Sustain. Energy Rev. 2018, 94, 998–1023. [Google Scholar] [CrossRef]

- Gardner, K.H.; Blackwell, J. The Structure of Native Cellulose. Biopolymers 1974, 13, 1975–2001. [Google Scholar] [CrossRef]

- Yeo, J.Y.; Chin, B.L.F.; Tan, J.K.; Loh, Y.S. Comparative Studies on the Pyrolysis of Cellulose, Hemicellulose, and Lignin Based on Combined Kinetics. J. Energy Inst. 2019, 92, 27–37. [Google Scholar] [CrossRef]

- Ralph, J.; Lapierre, C.; Boerjan, W. Lignin Engineering-Special Issue for Lignin Structure and Its Engineering. Curr. Opin. Biotechnol. 2019, 56, 240–249. [Google Scholar] [CrossRef]

- Vanholme, R.; Morreel, K.; Ralph, J.; Boerjan, W. Lignin Engineering. Curr. Opin. Plant Biol. 2008, 11, 278–285. [Google Scholar] [CrossRef]

- Howard, E.T. Heat of Combustion of Various Southern Pine Materials. Wood Sci. 1973, 5, 194–197. [Google Scholar]

- Tillman, D.A. Wood as an Energy Resource; Academic Press: New York, NY, USA, 1978. [Google Scholar]

- White, R.H. Effect of lignin content and extractives on the higher heating value of wood. Wood Fiber. Sci. 1987, 19, 446–452. [Google Scholar]

- Callejón-Ferre, A.J.; Carreño-Sánchez, J.; Suárez-Medina, F.J.; Pérez-Alonso, J.; Velázquez-Martí, B. Prediction Models for Higher Heating Value Based on the Structural Analysis of the Biomass of Plant Remains from the Greenhouses of Almería (Spain). Fuel 2014, 116, 377–387. [Google Scholar] [CrossRef]

- Demirbas, A. Relationships between Lignin Contents and Heating Values of Biomass. Energy Convers. Manag. 2001, 42, 183–188. [Google Scholar] [CrossRef]

- Demirbaş, A. Biodiesel Fuels from Vegetable Oils via Catalytic and Non-Catalytic Supercritical Alcohol Transesterifications and Other Methods: A Survey. Energy Convers. Manag. 2003, 44, 2093–2109. [Google Scholar] [CrossRef]

- Acar, S.; Ayanoglu, A. Determination of Higher Heating Values (HHVs) of Biomass Fuels. Energy Educ. Sci. Technol. Part A Energy Sci. Res. 2012, 28, 749–758. [Google Scholar]

- Álvarez, A.; Pizarro, C.; García, R.; Bueno, J.L. Spanish Biofuels Heating Value Estimation Based on Structural Analysis. Ind. Crops Prod. 2015, 77, 983–991. [Google Scholar] [CrossRef]

- Ruiz-Aquino, F.; Ruiz-Ángel, S.; Feria-Reyes, R.; Santiago-García, W.; Suárez-Mota, M.E.; Rutiaga-Quiñones, J.G. Wood Chemical Composition of Five Tree Species from Oaxaca, Mexico. Bioresources 2019, 14, 9826–9839. [Google Scholar] [CrossRef]

- Domingos, I.; Ayata, U.; Ferreira, J.; Cruz-Lopes, L.; Sen, A.; Sahin, S.; Esteves, B. Calorific Power Improvement of Wood by Heat Treatment and Its Relation to Chemical Composition. Energies 2020, 13, 5322. [Google Scholar] [CrossRef]

- Qian, C.; Li, Q.; Zhang, Z.; Wang, X.; Hu, J.; Cao, W. Prediction of Higher Heating Values of Biochar from Proximate and Ultimate Analysis. Fuel 2020, 265, 116925. [Google Scholar] [CrossRef]

- Oh, K.C.; Kim, J.; Park, S.Y.; Kim, S.J.; Cho, L.H.; Lee, C.G.; Roh, J.; Kim, D.H. Development and Validation of Torrefaction Optimization Model Applied Element Content Prediction of Biomass. Energy 2021, 214, 119027. [Google Scholar] [CrossRef]

- Ben, H.; Ragauskas, A.J. Torrefaction of Loblolly Pine. Green Chem. 2012, 14, 72–76. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Madissoo, M.; Pärn, L.; Virro, I.; Kikas, T. Torrefaction of Agricultural and Wood Waste: Comparative Analysis of Selected Fuel Characteristics. Energies 2021, 14, 2774. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Chen, W.H.; Colin, B.; Pétrissans, A.; Lopes Quirino, R.; Pétrissans, M. Thermodegradation Characterization of Hardwoods and Softwoods in Torrefaction and Transition Zone between Torrefaction and Pyrolysis. Fuel 2022, 310, 122281. [Google Scholar] [CrossRef]

- Reza, M.T.; Uddin, M.H.; Lynam, J.G.; Coronella, C.J. Engineered Pellets from Dry Torrefied and HTC Biochar Blends. Biomass Bioenergy 2014, 63, 229–238. [Google Scholar] [CrossRef]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of Pyrolysis Temperature and Wood Species on the Properties of Biochar Pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Chin, K.L.; H’ng, P.S.; Go, W.Z.; Wong, W.Z.; Lim, T.W.; Maminski, M.; Paridah, M.T.; Luqman, A.C. Optimization of Torrefaction Conditions for High Energy Density Solid Biofuel from Oil Palm Biomass and Fast Growing Species Available in Malaysia. Ind. Crops Prod. 2013, 49, 768–774. [Google Scholar] [CrossRef]

- Ivanovski, M.; Goricanec, D.; Krope, J.; Urbancl, D. Torrefaction Pretreatment of Lignocellulosic Biomass for Sustainable Solid Biofuel Production. Energy 2022, 240, 122483. [Google Scholar] [CrossRef]

- Chen, W.H.; Hsu, H.C.; Lu, K.M.; Lee, W.J.; Lin, T.C. Thermal Pretreatment of Wood (Lauan) Block by Torrefaction and Its Influence on the Properties of the Biomass. Energy 2011, 36, 3012–3021. [Google Scholar] [CrossRef]

- Valdez, E.; Tabil, L.G.; Mupondwa, E.; Cree, D.; Moazed, H. Microwave Torrefaction of Oat Hull: Effect of Temperature and Residence Time. Energies 2021, 14, 4298. [Google Scholar] [CrossRef]

- Granados, D.A.; Ruiz, R.A.; Vega, L.Y.; Chejne, F. Study of Reactivity Reduction in Sugarcane Bagasse as Consequence of a Torrefaction Process. Energy 2017, 139, 818–827. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Shen, Y.; Wang, J.; Yang, Y.; Zhang, W.; Wang, S. Oxygen Migration Characteristics during Bamboo Torrefaction Process Based on the Properties of Torrefied Solid, Gaseous, and Liquid Products. Biomass Bioenergy 2019, 128, 105300. [Google Scholar] [CrossRef]

- Kanwal, S.; Chaudhry, N.; Munir, S.; Sana, H. Effect of Torrefaction Conditions on the Physicochemical Characterization of Agricultural Waste (Sugarcane Bagasse). Waste Manag. 2019, 88, 280–290. [Google Scholar] [CrossRef]

- Xu, F.; Linnebur, K.; Wang, D. Torrefaction of Conservation Reserve Program Biomass: A Techno-Economic Evaluation. Ind. Crops Prod. 2014, 61, 382–387. [Google Scholar] [CrossRef]

- Joshi, Y.; Di Marcello, M.; De Jong, W. Torrefaction: Mechanistic Study of Constituent Transformations in Herbaceous Biomass. J. Anal. Appl. Pyrolysis 2015, 115, 353–361. [Google Scholar] [CrossRef]

- Chen, C.; Qu, B.; Wang, W.; Wang, W.; Ji, G.; Li, A. Rice Husk and Rice Straw Torrefaction: Properties and Pyrolysis Kinetics of Raw and Torrefied Biomass. Environ. Technol. Innov. 2021, 24, 101872. [Google Scholar] [CrossRef]

- Chicco, D.; Warrens, M.J.; Jurman, G. The Coefficient of Determination R-Squared Is More Informative than SMAPE, MAE, MAPE, MSE and RMSE in Regression Analysis Evaluation. PeerJ Comput. Sci. 2021, 7, e623. [Google Scholar] [CrossRef]

- Majumder, A.K.; Jain, R.; Banerjee, P.; Barnwal, J.P. Development of a New Proximate Analysis Based Correlation to Predict Calorific Value of Coal. Fuel 2008, 87, 3077–3081. [Google Scholar] [CrossRef]

- Elmaz, F.; Yücel, Ö.; Mutlu, A.Y. Makine Öğrenmesi Ile Kısa ve Elemental Analiz Kullanarak Katı Yakıtların Üst Isı Değerinin Tahmin Edilmesi. Int. J. Adv. Eng. Pure Sci. 2020, 32, 145–151. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, Q.; Wang, Q. Model Detection for Functional Polynomial Regression. Comput. Stat. Data Anal. 2014, 70, 183–197. [Google Scholar] [CrossRef]

- Gendy, T.S.; El-Shiekh, T.M.; Zakhary, A.S. A Polynomial Regression Model for Stabilized Turbulent Confined Jet Diffusion Flames Using Bluff Body Burners. Egypt. J. Pet. 2015, 24, 445–453. [Google Scholar] [CrossRef][Green Version]

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Akhtar, J.; Imran, M.; Ali, A.M.; Nawaz, Z.; Muhammad, A.; Butt, R.K.; Jillani, M.S.; Naeem, H.A. Torrefaction and Thermochemical Properties of Agriculture Residues. Energies 2021, 14, 4218. [Google Scholar] [CrossRef]

- Li, M.F.; Shen, Y.; Sun, J.K.; Bian, J.; Chen, C.Z.; Sun, R.C. Wet Torrefaction of Bamboo in Hydrochloric Acid Solution by Microwave Heating. ACS Sustain. Chem. Eng. 2015, 3, 2022–2029. [Google Scholar] [CrossRef]

- Li, Y.; Fan, X.; Zhang, H.; Ai, F.; Jiao, Y.; Zhang, Q.; Zhang, Z. Pretreatment of Corn Stover by Torrefaction for Improving Reducing Sugar and Biohydrogen Production. Bioresour. Technol. 2022, 351, 126905. [Google Scholar] [CrossRef] [PubMed]

- Li, M.F.; Chen, C.Z.; Li, X.; Shen, Y.; Bian, J.; Sun, R.C. Torrefaction of Bamboo under Nitrogen Atmosphere: Influence of Temperature and Time on the Structure and Properties of the Solid Product. Fuel 2015, 161, 193–196. [Google Scholar] [CrossRef]

- Strandberg, M.; Olofsson, I.; Pommer, L.; Wiklund-Lindström, S.; Åberg, K.; Nordin, A. Effects of Temperature and Residence Time on Continuous Torrefaction of Spruce Wood. Fuel Process. Technol. 2015, 134, 387–398. [Google Scholar] [CrossRef]

- Mafu, L.D.; Neomagus, H.W.J.P.; Everson, R.C.; Carrier, M.; Strydom, C.A.; Bunt, J.R. Structural and Chemical Modifications of Typical South African Biomasses during Torrefaction. Bioresour. Technol. 2016, 202, 192–197. [Google Scholar] [CrossRef] [PubMed]

- Grams, J.; Kwapińska, M.; Jędrzejczyk, M.; Rzeźnicka, I.; Leahy, J.J.; Ruppert, A.M. Surface Characterization of Miscanthus × Giganteus and Willow Subjected to Torrefaction. J. Anal. Appl. Pyrolysis 2019, 138, 231–241. [Google Scholar] [CrossRef]

- Yang, W.; Wu, S.; Wang, H.; Ma, P.; Shimanouchi, T.; Kimura, Y.; Zhou, J. Effect of Wet and Dry Torrefaction Process on Fuel Properties of Solid Fuels Derived from Bamboo and Japanese Cedar. Bioresources 2017, 12, 8629–8640. [Google Scholar] [CrossRef]

- Smit, A.; Huijgen, W. Effective Fractionation of Lignocellulose in Herbaceous Biomass and Hardwood Using a Mild Acetone Organosolv Process. Green Chem. 2017, 19, 5505–5514. [Google Scholar] [CrossRef]

- Thammasouk, K.; Tandjo, D.; Penner, M.H. Influence of Extractives on the Analysis of Herbaceous Biomass†. J. Agric. Food Chem. 1997, 45, 437–443. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Lopes, D.; Alves, A.; Lousada, J. Thermal Properties of Residual Agroforestry Biomass of Northern Portugal. Energies 2019, 12, 1418. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).