An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases

Abstract

:1. Introduction

1.1. HFC Phase-Down

1.2. Background and Scope of the Study

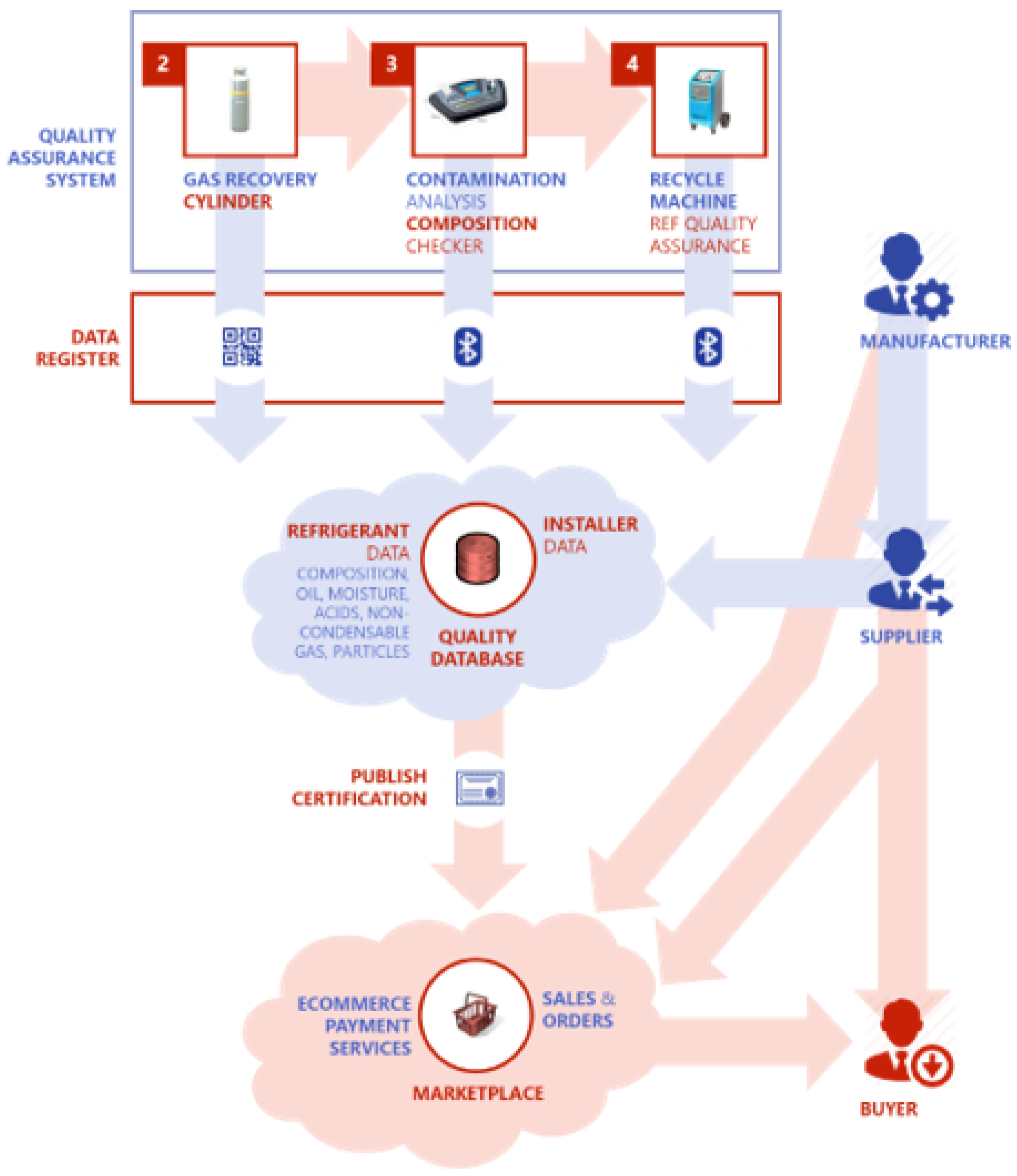

2. Outlining the 3R ECOSYSTEM

2.1. Innovative Aspects

- The alternative management of used F-gases at the end-of-life of HVAC-R systems by enabling the recovery of all refrigerants in the installed base. The two possible options are then either reuse through recycling/reclamation or appropriate disposal (if reuse is not possible). For this purpose, three F-gas quality grades have been specified [14]:

- A-grade refrigerants that can be recycled via a recycling machine and reused.

- B-grade refrigerants that must be reclaimed in a distillation factory.

- C-grade refrigerants that are contaminated to such an extent that they require destruction by certified means.

- The establishment of an online high-end marketplace to connect the relevant parties interested in trading their own recovered F-gases. The transparency and traceability of the transaction (price included) is regarded as an absolutely innovative aspect, as there is currently no fixed price index for recycled/reclaimed F-gases. Indeed, the Retradeables marketplace is intended to act like the stock market. This means that demand and supply are analysed and average prices for traded F-gases are displayed to all participants.

2.2. Self-Certification/Self-Declaration Platform

- Self-assessment: making use of the HVAC-R unit’s logbook. This is the current practice applied by F-gas technicians (self-declaration schemes).

- Measurement: making use of the HVAC-R unit’s logbook in combination with the initial analysis results of the portable composition analyser. This is the intended practice (self-declaration and self-certification schemes).

Database Design and Development

2.3. F-Gas Identification and Recycling Units

- Portable refrigerant composition analyser: Devices of this type are currently commercially available from various manufacturers for determining the purity of recovered F-gases in the HVAC-R market. However, laboratory testing is being conducted under the Retradeables project with the ultimate goal of producing a similar product but with more advanced operating characteristics to provide more detailed F-gas composition analysis data, including oil and moisture contamination rates. Consequently, two different approaches will be utilised in combination: one incorporating existing state-of-the-art measurement devices (classic composition analysers) and the other one based on time series analysis of specific thermodynamic parameters (advanced product under development).

- Recovery and recycling unit: Such a unit is now marketable from DENV, one of the key partners involved in the Retradeables project. It is easy to use and can be connected directly or via a recovery pump to the installed HVAC-R equipment. After connecting the cylinder(s), the F-gas recovery and recycling process is automatic. The advantageous feature of this device is the maximisation of the recovered F-gas quality through the three-step recycling mode applied to remove the majority of impurities [16]:

- Oil separation and electrostatic filtering.

- Filter drier to remove moisture.

- Liquid separation via evaporation.

Intercomparison Tests, Validity of Measurements and Performance of the Equipment

2.4. Retradeables Marketplace Platform

Development of the Platform

- Registration with legal check (F-gas certificate).

- F-gas recovery data input (at the location of the customer).

- F-gas quality documentation before and after recycling/reclamation (at the location of the customer).

- F-gas stock management.

- Supply and demand management, including aggregation of average prices on the market.

- Selling of used F-gas (supply side).

- Buying of used F-gas (demand side).

- Transactions between installers/installation companies and distributor/distribution companies, including price offers and secure payment methods.

- Data processing and information generation that are currently not accessible, as there is no mechanism/platform to support the collection and configuration of data directly at the time of input.

3. Impact on Europe’s Decarbonisation

3.1. General Assumptions

- Split units are considered with R410A.

- Semi-centralised direct expansion systems are considered with R410A and also with 0.5 kg of extra charge.

- Variable refrigerant flow systems are considered as a 10HP unit with an additional charge of half the pre-charge.

- Industrial and small heat pumps are a rough estimation of the market.

- F-gases GWP is considered to be equal to this of R410A: 1 metric ton of F-gas = 2087.5 metric tons of CO2e.

- 1 metric ton = 1000 kg.

3.2. Demonstration Phase

3.2.1. Estimated Impact

3.2.2. Results and Discussion

3.3. Replication Phase

3.3.1. Proposed Roll-Out Schedule

3.3.2. Estimated Impact

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CZ | Czech Republic |

| DACE | Daikin Central Europe |

| DENV | Daikin Europe N.V. |

| EC | European Commission |

| EU | European Union |

| F-gases | Fluorinated Gases |

| GHG | Greenhouse Gas |

| Gt | Gigatonnes |

| GWP | Global Warming Potential |

| HCFCs | Hydrochlorofluorocarbons |

| HFCs | Hydrofluorocarbons |

| HFOs | Hydrofluoroolefins |

| HU | Hungary |

| HVAC-R | Heating, Ventilation, Air Conditioning and Refrigeration |

| IoT | Internet of Things |

| KPI | Key Performance Indicator |

| Mt | Megatonnes |

| NTUA | National Technical University of Athens |

| POM | Placed On the Market |

| SK | Slovakia |

| WEEE | Waste Electrical & Electronic Equipment |

References

- EEA (European Environment Agency). Hydrofluorocarbon Phase-Down in Europe. 2021. Available online: https://www.eea.europa.eu/ims/hydrofluorocarbon-phase-down-in-europe (accessed on 28 September 2023).

- EC (European Commission). Climate Action—Fluorinated Greenhouse Gases: Overview. Available online: https://climate.ec.europa.eu/eu-action/fluorinated-greenhouse-gases/overview_en (accessed on 28 September 2023).

- EU (European Union). Regulation (EU) No. 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No. 842/2006 (Text with EEA Relevance), OJ L 150, 20.5.2014. pp. 195–230. Available online: http://data.europa.eu/eli/reg/2014/517/oj (accessed on 28 September 2023).

- EPEE (European Partnership for Energy and the Environment). The New F-Gas Regulation. 2014. Available online: https://www.fluorocarbons.org/wp-content/uploads/2014/11/epee-faq-on-the-new-f-gas-rules-december-2014-1.pdf (accessed on 28 September 2023).

- EIA (Environmental Investigation Agency). EU F-Gas Regulation Handbook: Keeping Ahead of the Curve as Europe Phases Down HFCs, Chapter 1: The HFC Phase-Down. 2015. Available online: https://eia-international.org/wp-content/uploads/F-Gas-Handbook-1-The-HFC-Phase-Down1.pdf (accessed on 28 September 2023).

- Castro, P.J.; Aráujo, J.M.M.; Martinho, G.; Pereiro, A.B. Waste management strategies to mitigate the effects of fluorinated greenhouse gases on climate change. Appl. Sci. 2021, 11, 4367. [Google Scholar] [CrossRef]

- Martinho, G.; Castro, P.J.; Santos, P.; Alves, A.; Araújo, J.M.M.; Pereiro, A.B. A social study of the technicians dealing with refrigerant gases: Diagnosis of the behaviours, knowledge and importance attributed to the F-gases. Int. J. Refrig. 2023, 146, 341–348. [Google Scholar] [CrossRef]

- EC (European Commission). Commission Welcomes Agreement on new Legislation to Prevent 500 Million Tonnes of Emissions From Fluorinated Gases and Ozone Depleting Substances. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_4781 (accessed on 28 September 2023).

- Council of the EU (European Union). Press Release. 5 October 2023. Fluorinated Gases and Ozone-Depleting Substances: Council and Parliament Reach Agreement. Available online: https://www.consilium.europa.eu/en/press/press-releases/2023/10/05/fluorinated-gases-and-ozone-depleting-substances-council-and-parliament-reach-agreement/ (accessed on 28 September 2023).

- Council of the EU (European Union). Proposal for a Regulation of the European Parliament and of the Council on Fluorinated Greenhouse Gases, Amending Directive (EU) 2019/1937 and Repealing Regulation (EU) No 517/2014. Available online: https://data.consilium.europa.eu/doc/document/ST-14409-2023-INIT/en/pdf (accessed on 28 September 2023).

- UNEP (United Nations Environment Programme). Handbook for the Montreal Protocol on Substances that Deplete the Ozone Layer, 14th ed.; Ozone Secretariat: Nairobi, Kenya, 2020; Available online: https://ozone.unep.org/sites/default/files/Handbooks/MP-Handbook-2020-English.pdf (accessed on 28 September 2023).

- EC (European Commission). EU Ratifies Kigali Amendment to the Montreal Protocol. 2018. Available online: https://ec.europa.eu/clima/news/eu-ratifies-kigali-amendment-montreal-protocol_en (accessed on 28 September 2023).

- Retradeables. Europe’s First Used F-Gas Trading Platform Launched. Press Release. 2021. Available online: https://retradeables.com/news/press-release-europes-first-used-f-gas-trading-platform-launched/ (accessed on 28 September 2023).

- Retradeables. Terms and Conditions: Listed Product Qualities. Terms of Use; Attachment A. Available online: https://retradeables.com/terms-and-conditions/ (accessed on 28 September 2023).

- NTUA (National Technical University of Athens). Database Structure. 2022. Available online: https://retradeables.com/wp-content/uploads/2022/09/28_Database-structure.pdf (accessed on 28 September 2023).

- DACE (Daikin Central Europe). RRDQ-V1: Portable Unit for Recovery and Recycling of Refrigerant. Products, Solutions, Services. Available online: https://www.daikin-ce.com/en_us/products/rrdq-v1.html (accessed on 28 September 2023).

- DENV (Daikin Europe, N.V.). IOT Functionalities on the Prototype Unit. 2021. Available online: https://retradeables.com/wp-content/uploads/2022/09/23_IOT-functionalities-on-the-prototype_UPDATED.pdf (accessed on 28 September 2023).

- Argirusis, N.; Karvelis, P.; Sourkouni, G.; Konstantaras, J.; Baroncelli, A.; Segers, P.; Argirusis, C. Machine learning methods for the discrimination of refrigerant gases. In Proceedings of the Emerging Tech Conference “Edge Intelligence” 2023 (ETCEI 2023), Thessaloniki, Greece, 19–20 October 2023. [Google Scholar]

- AHRI (The Air-Conditioning, Heating, and Refrigeration Institute). AHRI Standard 700: Standard for Specifications for Refrigerants. 2019. Available online: https://www.ahrinet.org/system/files/2023-06/AHRI_Standard_700_2019.pdf (accessed on 28 September 2023).

- MAT4NRG GmbH (The Society for Materials and Energy Applications). Intercomparison Tests/Validity of Measurements/Proposed Equipment & Analysers. 2021. Available online: https://retradeables.com/wp-content/uploads/2022/09/15_Intercomparison-tests_validity-of-measurements_proposed-equipment-analysers.pdf (accessed on 28 September 2023).

- DENV (Daikin Europe, N.V.). Marketplace Platform. 2021. Available online: https://retradeables.com/wp-content/uploads/2022/09/16_Marketplace-platform.pdf (accessed on 28 September 2023).

- Barmparitsas, N.; Baronchelli, A.; Karellas, S.; Pallis, P.; Thanopoulos, S. Retradeables: The first online marketplace for used F-gases in Europe. In Proceedings of the 7th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Ioannina, Greece, 23–25 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- EC (European Commission). Energy Performance of Buildings Directive. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en (accessed on 28 September 2023).

- EU (European Union). Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. OJ (L 156): 75–91. 2018. Available online: http://data.europa.eu/eli/dir/2018/844/oj (accessed on 28 September 2023).

- Eurostat. Population on 1 January by Age and Sex (2021); Last Update: 29 September 2023. Available online: https://ec.europa.eu/eurostat/databrowser/view/DEMO_PJAN__custom_672114/bookmark/table?lang=en&bookmarkId=ed42e163-2b0d-48ec-9a88-1fa699d80c4b (accessed on 28 September 2023).

- JRAIA (The Japan Refrigeration and Air Conditioning Industry Association). World Air Conditioner Demand by Region. 2019. Available online: https://www.jraia.or.jp/english/World_AC_Demand.pdf (accessed on 28 September 2023).

- Voigt, A. The EPEE Gapometer. Achieving the HFC Phase-Down in Europe. Brussels, Belgium. 2018. Available online: https://ec.europa.eu/clima/system/files/2018-03/2018_03_06_gapometer_en.pdf (accessed on 28 September 2023).

- Directive 2006/40/EC of the European Parliament and of the Council of 17 May 2006 Relating to Emissions from Air Conditioning Systems in Motor Vehicles and Amending Council Directive 70/156/EEC (Text with EEA Relevance), OJ L 161, 14.6.2006. pp. 12–18. Available online: http://data.europa.eu/eli/dir/2006/40/oj (accessed on 28 September 2023).

- Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (Recast) (Text with EEA Relevance), OJ L 197, 24.7.2012. p. 38. Available online: http://data.europa.eu/eli/dir/2012/19/2018-07-04 (accessed on 28 September 2023).

| Category | Standard Classification | High-Level Classification |

|---|---|---|

| Split Units | Small Residential Unit | Residential |

| Semi-Centralised Direct Expansion Systems | Commercial Light Unit | Commercial |

| Variable Refrigerant Flow Systems | Big Commercial Unit | Commercial |

| Packaged Units | Commercial Light Unit | Commercial |

| Mini Chillers | Commercial Light Unit | Commercial |

| Small Chillers | Commercial Light Unit | Commercial |

| Medium Chillers | Big Commercial Unit | Industrial |

| Large Chillers | Big Commercial Unit | Industrial |

| Centrifugal Chillers | Big Commercial Unit | Industrial |

| Air Handling Units | NA | NA |

| REFR-Stationary Light Commercial | Commercial Light Unit | Commercial Refrigeration |

| REFR-Stationary Big Commercial | Big Commercial Unit | Commercial Refrigeration |

| REFR-Stationary Big Commercial | Big Commercial Unit | Commercial Refrigeration |

| H H/P | Small Heat Pumps | Residential |

| H Boiler | NA | NA |

| Type of Unit | Charge (kg/Unit) | Average Lifetime of Equipment (Years) | Renovation Rate (%) |

|---|---|---|---|

| Small Residential Units | 1.5 | 10 | 10 |

| Commercial Light Units | 2.9 | 10 | 15 |

| Big Commercial Units | 18.8 | 15 | 20 |

| Small Heat Pumps | 4.0 | 10 | 10 |

| Industrial Units | 300.0 | 10 | 25 |

| Country | Type of Unit | Units (Pieces/Year) | Total F-Gas * (kg/Year) | Estimation of Installed Base ** (Metric Tons Refrigerant) | Estimation of Installed Base (106 Metric Tons CO2e) |

|---|---|---|---|---|---|

| Slovakia (SK) | Small Residential Units | 27,630 | 41,445 | 414 | 0.87 |

| Commercial Light Units | 2500 | 7250 | 73 | 0.15 | |

| Big Commercial Units | 700 | 13,160 | 197 | 0.41 | |

| Small Heat Pumps | 2085 | 8340 | 83 | 0.17 | |

| Industrial Units | 45 | 13,500 | 135 | 0.28 | |

| Commercial Refrigeration Units | 27,600 | 138 | 0.29 | ||

| Total | 30,830 | 111,295 | 1040 | 2.17 | |

| Czech Republic (CZ) | Small Residential Units | 27,000 | 40,500 | 405 | 0.85 |

| Commercial Light Units | 7529 | 21,834 | 218 | 0.46 | |

| Big Commercial Units | 2524 | 47,451 | 710 | 1.48 | |

| Small Heat Pumps | 2325 | 9300 | 93 | 0.19 | |

| Industrial Units | 200 | 60,000 | 600 | 1.25 | |

| Commercial Refrigeration Units | 69,000 | 345 | 0.72 | ||

| Total | 37,053 | 248,085 | 2371 | 4.95 | |

| Hungary (HU) | Small Residential Units | 144,194 | 216,291 | 2163 | 4.52 |

| Commercial Light Units | 4430 | 12,847 | 128 | 0.27 | |

| Big Commercial Units | 2203 | 41,416 | 620 | 1.29 | |

| Small Heat Pumps | 2680 | 10,720 | 107 | 0.22 | |

| Industrial Units | 250 | 75,000 | 750 | 1.57 | |

| Commercial Refrigeration Units | 92,000 | 460 | 0.96 | ||

| Total | 153,757 | 448,274 | 4228 | 8.83 | |

| Total in Trial Countries | 221,640 | 807,655 | 7639 | 15.95 |

| Type of Unit | SK: F-Gas Recovered via 3R | CZ: F-Gas Recovered via 3R | HU: F-Gas Recovered via 3R | Final Results | ||||

|---|---|---|---|---|---|---|---|---|

| Tonnes * F-gas | Tonnes CO2e | Tonnes F-gas | Tonnes CO2e | Tonnes F-gas | Tonnes CO2e | Tonnes F-gas | Tonnes CO2e | |

| Small Residential Units | 41.4 | 86,516 | 40.5 | 84,544 | 216.3 | 451,507 | 298.2 | 622,568 |

| Commercial Light Units | 10.9 | 22,702 | 32.8 | 68,368 | 19.3 | 40,227 | 62.9 | 131,297 |

| Big Commercial Units | 39.4 | 82,195 | 142.0 | 296,373 | 123.9 | 258,680 | 305.3 | 637,249 |

| Small Heat Pumps | 8.3 | 17,410 | 9.3 | 19,414 | 10.7 | 22,378 | 28.4 | 59,202 |

| Industrial Units | 33.8 | 70,453 | 150.0 | 313,125 | 187.5 | 391,406 | 371.3 | 774,984 |

| Commercial Refrigeration Units | 62.1 | 29,634 | 155.3 | 324,084 | 207.0 | 432,113 | 424.4 | 885,831 |

| Total | 195.9 | 408,910 | 529.8 | 1,105,908 | 764.7 | 1,596,312 | 1490.4 | 3,111,129 |

| Trial Countries | Slovakia, Hungary, Czech Republic |

|---|---|

| Step 1 | |

| Immediate expansion * | Austria, Croatia, Slovenia, Poland, Bulgaria, Romania, Albania, Kosovo, North Macedonia, Moldova, Serbia, Bosnia-Herzegovina and Montenegro |

| Step 2 | |

| 2024 | Germany, Netherlands, Portugal |

| 2025 | Italy, France, United Kingdom (UK) |

| 2026 | Spain, Belgium, Greece |

| 2027 | Norway, Sweden |

| Market potential to be assessed | Finland, Ireland |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barmparitsas, N.; Karellas, S.; Pallis, P.; Thanopoulos, S.; Kobelt, D. An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases. Energies 2023, 16, 7705. https://doi.org/10.3390/en16237705

Barmparitsas N, Karellas S, Pallis P, Thanopoulos S, Kobelt D. An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases. Energies. 2023; 16(23):7705. https://doi.org/10.3390/en16237705

Chicago/Turabian StyleBarmparitsas, Nikolaos, Sotirios Karellas, Platon Pallis, Sotirios Thanopoulos, and Daniel Kobelt. 2023. "An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases" Energies 16, no. 23: 7705. https://doi.org/10.3390/en16237705

APA StyleBarmparitsas, N., Karellas, S., Pallis, P., Thanopoulos, S., & Kobelt, D. (2023). An Innovative Heating, Ventilation, Air Conditioning and Refrigeration Circular Economy System for Reducing Carbon Dioxide Emissions in Europe via Extensive Reuse of Existing Fluorinated Gases. Energies, 16(23), 7705. https://doi.org/10.3390/en16237705