Abstract

Water supply represents a significant electrical load worldwide. The operation of inefficient pumps contributes to increased energy demand and carbon footprint. Current methods for evaluating industrial water pumps present technical and economic challenges that need to be addressed. For these reasons, we developed a practical and cost-effective virtual instrument called the Pumping Evaluation System (PES). The PES tool performs real-time monitoring of electrical, hydraulic, and efficiency data, as well as the Operating Characteristic (OC) curves. The PES tool was implemented on a vertical pump currently used by a municipal water distribution plant in Mexicali, Mexico. A comparative analysis between the experimental data and the manufacturer’s data revealed potential energy savings of 361,455 kWh/year (24.35%) and an equivalent carbon footprint reduction of 157,233 kg of CO2eq/year if the old pump is replaced by a new one, which is the lowest cost alternative according to a Life Cycle Cost (LCC).

1. Introduction

Water and energy resources are vital for human existence and frequently influenced by economic, technological, demographic, and social pressures. It is estimated that 22% of world electricity consumption is used for pumping in water supply systems [1,2], while 80–90% of this consumption is absorbed by motor pump sets [3,4]. This cost represents one of the main operating costs associated with water supply systems. Cities worldwide are facing the demands of population growth and climate change. As the demand for water continues to increase, more cities are challenged to efficiently manage scarcer and less reliable water resources [5].

The world’s treated water supply is likely to be an unsustainable process in its current form due to the considerable energy consumption and CO2 emissions inherent in the various treatment and supply processes involved [6]. With growing global awareness of the impacts of energy consumption and CO2 emissions on climate change, humanity, finite resources, and the environment as a whole, efforts are being made to reduce such impacts in all sectors of society.

In Mexico, these systems can account for 5.19% [7] of the total energy consumption. Electricity accounts for 90 to 95% of the total energy consumed by these facilities. It is estimated that 75% of their pumping systems are oversized for contingency, often by more than 20% [8]. Water demand is projected to increase by 55% globally between 2000 and 2050. The increase in demand will mainly come from manufacturing (+400%), electricity (+140%), and domestic use (+130%) [9]. According to the United Nations [10], by 2030, the world’s objective should be to enhance international cooperation to facilitate access to clean energy research and technology, which encompasses renewable energy, energy efficiency, and advanced and cleaner fossil fuel technology; thus, promoting investment in energy infrastructure is crucial. Energy consumption required for water treatment and distribution will have important implications for climate change. Energy and water losses are often present due to the inevitable aging of the infrastructure; thus, sometimes, efficiency is neglected. A pump’s efficiency can degrade by as much as 10 to 25% before it is replaced, and efficiencies of 50 to 60% or lower are quite common [11]. Many end-users, already strained in terms of supporting day-to-day facility operations, lack the time and resources to perform a methodical engineering study of the many pumps within their facilities to understand their associated energy costs and the potential opportunities for energy savings [12]. By enhancing the efficiency of pumping systems, energy consumption can be reduced, leading to lower operational costs and a minimized environmental footprint. Efficient pumps can help to optimize energy utilization and encourage responsible resource management.

In a recent study, Robert B. Sowby and Annelise Capener [13] made significant contributions to the understanding of the energy and emissions intensity of water systems. Their research provides a pathway for water suppliers worldwide to estimate their emissions alongside their water and energy use. In a comprehensive study conducted by Louis Zib et al., [14], several strategies were found to reduce the carbon footprint of the water sector. The authors propose that significant water savings and a reduction in carbon footprint can be achieved by improving water use efficiency, particularly in the domestic sector. In their report, Bevan and Wilson [15] break down the energy inputs of a typical water-use cycle into five basic stages: source, treatment, distribution, use, and end-of-life. They also highlight that a significant majority of water providers and wastewater treatment plants receive the majority of their operating energy from electricity. Another study [16] explores the energy and air emission effects of different water supply options. It compares the environmental impacts of desalination, imported water, and groundwater and analyzes the effects of different electricity generation sources on these alternatives. However, seawater desalination has a larger energy and air emission footprint compared to imported water. The study also highlights the importance of considering energy consumption and material use effects when making water policy choices.

2. Case Study

This study was carried out to analyze a vertical pump of a municipal water distribution system that supplies fresh water to the city of Mexicali, B.C., Mexico. This city has a population of 988,417 inhabitants [17] and is located in the northwest of Mexico. Extreme maximum temperatures of up to 45 °C have been recorded between July and August, and rainfall is very low, with total annual precipitation being around 200 mm [18]. The pumping system consists of 12 identical vertical turbine pumps. The municipal water plant continuously operates (24 h) using 5 pumps to deliver an average water flow of 7200 m3/h with a gauge pressure of approximately 359 kPa (52 psi). The water supply is sourced from the Colorado River in the state of California, USA. The pump’s characteristics are displayed in Table 1.

Table 1.

Vertical pump specifications.

3. Methodology

3.1. Virtual Instrumentation

LabVIEW 2013® is a graphical programming environment that engineers use to develop automated research, validation, and production test systems [19]. With LabVIEW 2013®, the programmer can develop measurement and control systems known as Virtual Instruments (VIs). A VI comprises a computer with robust software, cost-effective hardware, and driver software, collectively fulfilling the roles of traditional instruments, effectively turning the computer into the instrument itself. The application of VIs has increased due to their speed of construction, flexibility, and low cost per acquisition channel [20]. Actually, the tools developed with the support of the Internet of Things (IoT) are frequently used and considered useful in the field of research [21,22,23,24,25,26,27]. Nowadays, international aerospace companies such as Boeing [28] and major government agencies such as NASA [29] are using VIs to create flexible, scalable, and low-cost instruments. They have validated the effectiveness of VIs by comparing the results obtained via previously utilized technologies. Hence, the benefits of employing virtual instrumentation may surpass certain limitations of comparable systems presently employed in various industries.

3.2. OC Curves Analysis

Developing a system curve is the first step in understanding a given pump system’s characteristics at various flow rates. Analyzing OC curves offers valuable insights into how the pump will operate at various flow rates [30,31,32,33]. By comparing the OC curves generated from actual measurements to those provided by the manufacturer, any differences or inconsistencies can be identified. Significant variations between the recorded data and the manufacturer’s data may indicate the need for changes, improvements, or a re-evaluation of the selected pump. The primary source of energy loss in the pumping system occurs when electrical energy is converted into mechanical energy, which is then transferred to the fluid as power gauge. Load losses occur due to viscosity and turbulence, while leakage losses result from gaps between moving and stationary parts. Internal friction losses originate from the non-active surfaces of the pump impeller, regardless of its energy transfer to the fluid. Additionally, energy losses occur in the suction and discharge pipelines due to friction between the fluid and the pipe walls. The analysis helps to determine whether the pump is achieving the expected results and whether it aligns with the project’s requirements regarding the flow rate, head, efficiency, and power usage. Engineers and professionals can confirm the effectiveness of optimization interventions using accurate performance and efficiency measurements. The interventions can range from comparisons to goal setting. Information presented may include rates, current and historical usage, averages, trending, year-by-year comparisons, neighborhood and regional information, and modeling through reports [34].

3.3. Proposed Pump Evaluation System

In the context of optimizing energy performance and reducing carbon emissions in industries that rely on fluid transportation systems, it is crucial to continuously monitor electrical and hydraulic parameters in operating pumps. Various pumping assessment tools have been developed in this field of research. Sabogal et al. [35] introduced an Excel program for calculating pump operating characteristics through manual data input. Sunela and Puust [36] developed an optimization tool to determine the optimal pump combinations using the Java programming language JFreeChart and Apache libraries for Excel file access. Kaya et al. [37] analyzed energy-saving opportunities by assessing the motor load and operating efficiency. Quezada et al. [38] created a monitoring and control system based on HMI-PLC for water management. Additionally, software tools like the Pumping System Assessment Tool (PSAT) and Pump System Improvement Modeling (PSIM) can be used to calculate potential energy savings and emission reductions [39]. Furthermore, commercial systems like Aquadvance™ offer real-time remote monitoring of electrical and hydraulic parameters, including water flow, gauge pressure, water level, electrical consumption, and performance indicators [40]. Based on this information, curves such as head-flow rate and power-flow rate can be generated.

The alternatives described above have certain disadvantages for pumping system management, including the need for specialized personnel for data processing, the absence of efficiency calculation, the potential inaccuracy of the results, the use of invasive measurement methods, and/or the high initial investment costs. The Pump Evaluation System (PES) tool offers a unique set of contributions that distinguish it from similar monitoring systems. The PES tool is a non-invasive, portable, cost-effective, and user-friendly tool with remote real-time monitoring capabilities. Real-time data monitoring includes electrical and hydraulic measurements, hydraulic power, electromechanical efficiency, pump efficiency, and OC curves: the head-flow rate, the power-flow rate, and, most importantly, the flow-efficiency curve. Therefore, the PES tool offers a comprehensive set of data to more accurately assess the pump’s operation.

The investment cost of the proposal is approximately 27% of the average price of less specialized monitoring systems; the PES tool costs USD 6000, covering equipment (computer, metering systems, and communication devices) and personnel training. The PES tool is composed of hardware and software components that are orchestrated to acquire measurements, perform calculations, and display user-friendly data. We achieved these advantages using the virtual instrumentation approach in conjunction with LabVIEW software. Innovation is supported by the creation of new VIs to solve specific problems by combining emerging technologies.

3.4. Software Programming

The software for the PES tool is a Virtual Instrument (VI) developed using the LabVIEW 2013® programming platform. Its architecture is illustrated in Figure 1.

Figure 1.

Architectural diagram of the PES tool software.

In Figure 1, the raw data consist of measurements of water flow, gauge pressures, and electrical demand. This raw data can be transmitted to the computer either via cables or wirelessly using radio frequency devices. The calculation process involves the utilization of definitions, equations, and procedures derived from the energy efficiency assessment manual published by the Inter-American Development Bank [41].

The equation for the total head developed by a pump is as follows:

where:

Total hydraulic pump head, m;

Discharge gage pressure, kPa;

Specific weight of water, kN/m2;

Elevation distance from the water level to the reference line, m;

Distance from reference level to pressure gage, m;

Suction pipe and accessories friction loss, m;

= Velocity head in the suction pipe, m;

Suction pipe velocity, m/s;

Acceleration due to gravity (9.81 m/s2).

The Darcy–Weisbach equation for friction loss in a pipe is as follows:

where:

Friction loss in the pipe, m;

Darcy–Weisbach friction loss coefficient;

Pipe length, m;

Pipe internal diameter, m;

Average velocity of the flow in the pipe, m/s.

The hydraulic power is given by:

where:

= Hydraulic power, kW;

Flow rate, m3/s;

Total pump head, m.

The equation for electromechanical efficiency is as follows:

where:

= Electromechanical efficiency, %;

= Electrical power, kW.

The equation for pump efficiency is as follows:

where:

= Pump efficiency, %;

= Nameplate motor efficiency, %.

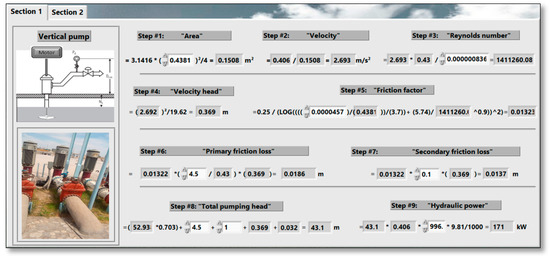

The data presented via the software are categorized into two groups, as depicted in Figure 2 and Figure 3.

Figure 2.

First data group (section 1) of the PES software.

Figure 3.

Second data group (section 2) of the PES software.

Figure 2 displays hydraulic parameters. The measurements, including water flow rate and gauge pressure, are 0.406 m3/s and 52.93 psi (3.72 kg/cm2), respectively. The value of Darcy’s friction factor is 4.57 × 10−5 m (carbon steel). Thermodynamic tables were utilized to acquire water properties based on the ambient temperature. This section assists users in establishing correlations between changes in water flow, total head, and hydraulic power.

Figure 3 shows the pump efficiency to be 0.657 (65.7%) and the electromechanical efficiency to be 0.618 (61.8%). Below this subsection, there is a table filled with the most relevant results. On the right, the OC curves are plotted in real time during software execution; the sampling frequency is set to one second. In the center, a virtual button can be used to save the image of the OC curves for a specific flow rate range. The OC curves can be observed as “Power—Flow rate”, “Total head—Flow rate”, and “Efficiency—Flow rate”.

The PES tool’s software is designed to operate on Windows-based computers and incorporates the configuration of a web server. The software comprises 16 programming blocks. The LabVIEW programming framework uses a graphical model through the connection of icons employing wires instead of programming based on typing complicated text lines, increasing the risk of making syntactic and logistic mistakes [20]. This software operates in a continuous loop and performs tasks in cycles until the user stops it. This process ensures the continuous monitoring of pump measurements. Additionally, it is compatible with computers with moderate system requirements and operating systems like Windows 7, 8, 10 and, potentially, future versions of Windows. The virtual image of the front panel can be remotely accessed through web browsers such as Internet Explorer. Remote access can be controlled using a standard user account and password.

Hardware Configuration

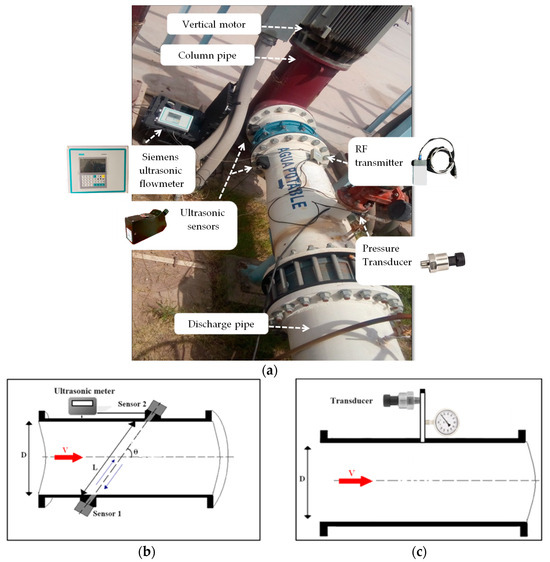

The hardware configuration consists of three main devices. Firstly, for the analysis of hydraulic performance, the measurements of volumetric flow and gauge pressure were essential, as shown in Figure 4.

Figure 4.

Pump under study (a), ultrasonic sensors (b), and pressure transducer (c) installation diagram.

In Figure 4b, the volumetric flow rate was measured using an ultrasonic flowmeter equipped with non-invasive sensors mounted on the pipe structure. This flowmeter operates based on the transit-time principle and has a flow range of ±23 ft/s, as well as an accuracy of ±1%. Experimental data were compared to measurements derived via higher accuracy equipment (±0.5%), and deviations were found to be within 2.5%. The output signal of the flowmeter was programmed to produce a linearized output voltage of 0–5 V. Figure 4c illustrates the measurement point of the discharge gauge pressure () using a transducer installed on the pipe. This component was placed near the analog differential pressure gauge for the comparison of measurements; deviations were found within ± 2%. The linearized output signal of the transducer ranged from 0 to 4.5 V, corresponding to a pressure range of 0–100 psi.

Secondly, to characterize the electrical behavior, it was necessary to measure the electrical demand, as shown in Figure 5.

Figure 5.

Electric meter installed on the motor control center (a) and electric meter installation diagram (b).

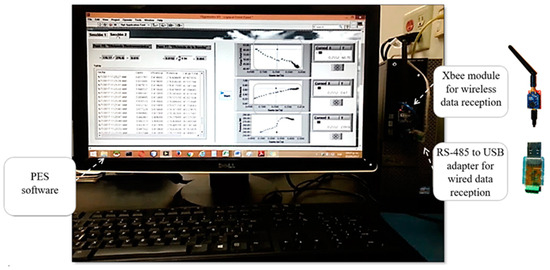

As shown in Figure 5, the 3-phase electric power of the motor was measured using a class 1 kWh energy meter. This energy meter was installed within the motor control center (MCC). The accuracy of the electrical readings was verified using a class A power quality analyzer that adhered to the IEC 61000-4-30 standard [42], with discrepancies observed within ±1.5%. Split-core current transformers were employed to ensure an uninterrupted power supply. Thirdly, the software for the PES tool ran on a dedicated computer, as shown in Figure 6.

Figure 6.

Computer equipped with the software for the PES tool and data receivers.

In Figure 6, two universal serial bus data receivers are used to receive data. The accuracy of the PES tool was ±3%, which was sufficient for the objectives of this study. The implementation of the PES tool can be performed by two trained technicians. On average, the installation tasks can be completed within 45 min. The installation of the metering equipment did not compromise the integrity of the pipelines and did not involve shutting down the pump, thus avoiding any disruption to the city’s water supply. The accuracy of the results obtained via the PES tool was validated using an Excel program. This Excel program has been tested in various pumping evaluation projects conducted by the authors.

4. Results and Discussion

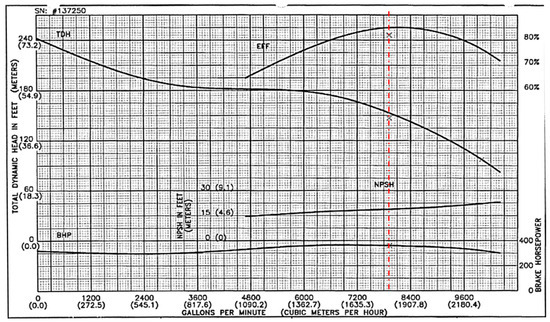

In the initial step, the manufacturer’s curves for the specific pump model provide design information about parameters such as volumetric flow, head, efficiency, and power consumption, as shown in Figure 7.

Figure 7.

OC curves of the pump under study provided by the manufacturer. Adapted from [43].

In Figure 7, the best efficiency point (BEP) represents the operating condition at which the pump achieves its highest efficiency. It signifies the optimal combination of the flow rate and head, where the pump can convert the maximum amount of input power into useful hydraulic power with minimal energy losses. The BEP is typically found on the pump’s performance curve or operational characteristic curve, where the efficiency is at its peak value. The BEP is indicated on the graph as a cross mark, with an efficiency of 82%, a power of 256.5 kW (equivalent to 359 BHP, considering the nominal efficiency of the electric motor as 0.958), and a total head of 44.8 m at a water flow rate of 1812 m3/h. The efficiency-flow rate graph shows that the selected pump can operate at various efficiency levels, ranging from 65 to 85%, with a flow rate approximately between 1000 and 2347 m3/h. It is important to note that these values are based on a motor speed of 1190 RPM.

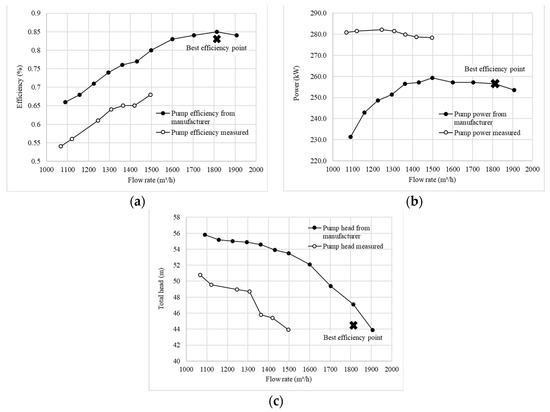

Secondly, the current OC curves generated via the PES tool can be overlayed with OC curves provided by the manufacturer. This step will enable a direct comparison, as shown in Figure 8.

Figure 8.

OC curves based on experimental data and the manufacturer’s data: (a) Flow rate—efficiency, (b) Flow rate—power, and (c) Flow rate—total head.

From Figure 8, the experimental data were obtained by adjusting the throttle valve from 0 to 100%. A comparison between the OC curves reveals significant differences. These differences range from 15 to 18% for efficiency, 7 to 21% for electrical power, and 9 to 18% for total head. When the throttle valve is fully open, the measured flow rate is 1496 m3/h, which is lower than the BEP flow rate of 1812 m3/h. This observation indicates a water flow loss of 316 m3/h (17.4%). The measured efficiency is 67%, resulting in a loss of 15% compared to the expected value. The optimal power demand is 256.5 kW, but the electrical measurement shows a higher value of 278.3 kW, indicating an increased power demand of 21.8 kW (8.49%). The measured total head is 43.9 m instead of the expected value of 53.5 m, resulting in a difference of 9.6 m (17.9%). A visual comparison is shown in Figure 9.

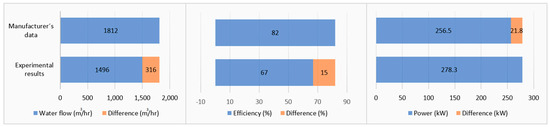

Figure 9.

Graphical comparison between manufacturer’s BEP data and experimental data.

In Figure 9, a significant loss of performance can be observed. To assess whether the differences and their impacts on the pump’s operation are within an acceptable range according to the manufacturer’s specifications, a performance indicator can be calculated. This indicator measures the proportion of electrical energy used by the pump to generate and distribute water. If we assume the pump continuously operates for 4380 h annually, we can estimate the specific energy consumption for each unit of water pumped. Based on the manufacturer’s BEP, the design performance indicator is 7.07 m3/kWh. Based on the experimental data, the calculated performance indicator is 5.348 m3/kWh, indicating a difference of 24.35%. This notable difference indicates subpar pumping performance, as the pump demands more electrical energy and delivers a lower water flow in comparison to the manufacturer’s BEP. Consequently, it is crucial to carry out a thorough analysis by comparing the pump manufacturer’s characteristic curves to the gathered pump data. This assessment will help to evaluate the true performance of the pumps and ascertain whether they meet the manufacturer’s specifications. Water treatment facility managers and academic researchers can make use of real-time OC curves to assess potential avenues for cost savings [39]. These avenues could involve actions like replacing less efficient pumps, refining maintenance schedules for pumps showing declining efficiencies, substituting high-power electric motors with correctly sized alternatives, adopting high-efficiency electric motors, and addressing issues related to cavitation.

4.1. Energy Saving and Carbon Footprint

Energy conservation and reducing the carbon footprint of industrial pumps are essential elements of conducting operations in a sustainable and environmentally responsible manner. In this case study, the calculation of energy savings can be performed as follows:

where:

= Energy saving, kWh/year;

= Operation time, h;

= Load coefficient;

= Actual performance indicator, m3/kWh;

= Manufacturer performance indicator, m3/kWh.

According to Equation (6), the potential energy savings in the first year for the case study would be 361,455 kWh/year if the inefficient pump is replaced with a new one to achieve the manufacturer’s specified BEP. The vertical water pump continuously operates at full capacity for 4380 h annually. Assuming an estimated local electricity cost of 0.07 USD/kWh in Mexicali, the annual energy savings amounts to USD 25,301.85.

Conversely, the carbon footprint linked to the energy usage of industrial pumps primarily pertains to the release of greenhouse gases produced during their operation within industrial environments. The carbon footprint of energy consumption by industrial pumps is impacted by factors like the power demands of the pumps, the efficiency of pump systems, and the energy sources utilized for their operation. In this case study, the possible decrease in carbon footprint can be calculated in the following manner:

where:

= Carbon footprint, kg of CO2/year;

= Factor of emission.

In Equation (7), the carbon footprint, used as an indicator of environmental sustainability, can be calculated by correlating the potential energy savings with an indirect CO2 emissions factor. In Mexico, according to Secretaría de Medio Ambiente y Recursos Naturales (SEMARNAT), the standard factor for calculating indirect greenhouse gas emissions from electricity consumption is 435 kgCO2/MWh when the Comisión Federal de Electricidad (CFE) is the energy provider [44]. Consequently, the carbon footprint reduction corresponding to the potential energy savings in the case study is 157,233 kg of CO2eq per year.

4.2. LCC Analysis

In order to enhance the efficiency of the replacement cycles for aging pumps, we suggest supplementing the potential energy savings and reduction in carbon footprint with a straightforward life cycle cost (LCC) analysis. LCC analysis is a technique employed to assess the overall cost of a system throughout its entire lifespan [45]. Pumping systems typically have a lifespan ranging from 15 to 20 years.

The LCC analysis does not guarantee a pre-defined outcome. It allows the comparison of different options. A typical LCC analysis includes various cost components, such as investment, installation and setup, energy usage, maintenance, downtime, environmental factors, and decommissioning and disposal. Generally, energy consumption costs constitute the largest portion of expenses. To provide context, the assumptions for the LCC analysis are as follows:

- I.

- Vertical water pump works continuously for 4380 h/year.

- II.

- There is no decommissioning cost, downtime cost, environmental and disposal cost, or other associated yearly costs.

- III.

- The project’s useful life is 15 years.

- IV.

- According to CFE’s tariff database [46], it is estimated an energy inflation rate of 4%. The estimated electricity cost in Mexicali for the first year is 0.07 USD/kWh.

- V.

- The municipal water facility incurs an annual cost of USD 1000 for routine maintenance.

To perform the LCC calculations, we rely on the net present value (NPV) approach to assess and compare the cost-effectiveness of pump replacement. The outcomes of these computations are outlined in Table 2. The equation for calculating the NPV is as follows:

where:

Table 2.

LCC for the pump replacement.

= Net present value, USD;

= Net cash flow during a single period t, USD;

= Discount rate, %;

t = Number of time periods.

As shown in Table 2, replacing the old pump with a new one yields the lowest LCC, making it the preferred choice. According to SEMARNAT’s database, from 2017 to 2022, the calculated cumulative carbon footprint reduction up to 2037 is 2,346,204.4 kg of CO2eq. Additionally, it is advisable to replace the old pump with a more efficient model.

5. Conclusions

Existing pump assessment tools are expensive and present various technical and financial limitations. We have introduced a practical and cost-effective solution called PES, which costs 73% less. The innovation relies on the automated and real-time generation of OC curves and the calculation of pump efficiencies during pump operation. Additionally, it is developed using the virtual instrumentation approach through LabVIEW 2013®. Virtual instruments, like the PES tool, can be used by academics, researchers, professionals, and practitioners to reduce the time intervals between experimental tests in studies related to tasks like impeller trimming, assessing cavitation effects, and implementing pump liners.

The PES tool can be applied throughout an entire pumping system, enabling water industry personnel to easily calculate monthly metrics related to energy consumption, pump efficiency, water demand, and carbon footprint indicators associated with energy usage. Furthermore, by utilizing virtual instruments, such as the PES tool, decision makers in the water sector can pinpoint enhancements in pumping systems that lead to the highest energy savings and the lowest carbon emissions. This approach offers the following benefits:

- I.

- Compliance with water policies by utilizing accurate indicators;

- II.

- Improved precision in forecasting future trends in water supply, energy demand, and carbon footprint;

- III.

- Immediate calculation of energy savings and carbon footprint reduction using dependable measurements;

- IV.

- Efficient scheduling of maintenance, optimization of operating conditions, or consideration of alternative pump models for units with declining efficiency;

- V.

- Assessment of the performance of new pumps to ensure alignment with the specified operational parameters.

In the future, our goal is to implement the PES tool for every vertical pump within the municipal water system. This initiative will support the expansion of water services and enhance their dependability, reducing both the frequency and duration of interruptions. Replacing inefficient pumps within municipal water systems is of the utmost importance, especially in urban regions with arid climates, such as Mexicali city.

Author Contributions

All authors contributed to the work in this manuscript. A.P.-S. and C.G. contributed to the design of the virtual instrument. M.C. contributed to the writing of the Materials and Methods section. D.R.B.G. and M.G.S.R. developed the PES software. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by La Secretaría de Educación Pública (SEP), México (Grant number UABC-PTC-574).

Data Availability Statement

Data is unavailable due to ethical restrictions.

Acknowledgments

The authors give special thanks to the editor and reviewers of this paper for their patience and the valuable comments used to revise the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Berndtsson, J.C.; Jinno, K. Sustainability of urban water system: Examples from Fukuoka, Japan. Water Policy 2010, 10, 501–513. [Google Scholar] [CrossRef]

- Waide, P.; Brunner, C.U. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems. In International Energy Agency (IEA) Energy Efficiency Series; Working Paper; IEA: Paris, France, 2011; Available online: https://iea.blob.core.windows.net/assets/d69b2a76-feb9-4a74-a921-2490a8fefcdf/EE_for_ElectricSystems.pdf (accessed on 10 October 2022).

- Botto, S.; Niccolucci, V.; Rugani, B.; Nicolardi, V.; Bastianoni, S.; Gaggi, C. Towards lower carbon footprint patterns of consumption: The case of drinking water in Italy. Environ. Sci. Policy 2011, 14, 388–395. [Google Scholar] [CrossRef]

- Brown, L.E.; Mitchell, G.; Holden, J.; Folkard, A.; Wright, N.; Beharry-Borg, N.; Berry, G.; Brierley, B.; Chapman, P.; Clarke, S.J.; et al. Priority water research questions as determined by UK practitioners and policy makers. Sci. Total Environ. 2010, 409, 256–266. [Google Scholar] [CrossRef]

- UNESCO. Urban Water Management Programme. Available online: https://en.unesco.org/uwmp (accessed on 11 April 2023).

- Novara, D.; McNabola, A. A model for the extrapolation of the characteristic curves of Pumps as Turbines from a datum Best Efficiency Point. Energy Convers. Manag. 2018, 174, 1–7. [Google Scholar] [CrossRef]

- SIE. Electricity Sales, by Tariff. Available online: https://sie.energia.gob.mx/bdiController.do?action=cuadro&subAction=applyOptions (accessed on 10 March 2023).

- Hydraulic Institute (HI); Europump. U.S. Department of Energy (DOE). Variable Speed Pumping; 2004. Available online: https://energy.gov/sites/prod/files/2014/05/f16/variable_speed_pumping.pdf (accessed on 10 October 2022).

- OECD. OECD Environmental Outlook to 2050: The Consequences of Inaction. OECD Publishing, Paris. 2012. Available online: https://www.oecd-ilibrary.org/environment/oecd-environmental-outlook-to-2050_9789264122246-en (accessed on 21 February 2023).

- United Nations (UN). Sustainable Development Goals. Available online: https://www.un.org/sustainabledevelopment/energy/ (accessed on 11 October 2022).

- U.S. Department of Energy (DOE). Energy Tips-Pumping Systems: Test for Pumping System Efficiency; DOF: Washington, DC, USA, 2005. Available online: https://energy.gov/sites/prod/files/2014/05/f16/test_pumping_system__pumping_systemts4.pdf (accessed on 3 October 2019).

- Casada, D.; McElhaney, K. Identifying Energy Savings Opportunities in Industrial Pumping Systems; Oak Ridge National Lab: Oak Ridge, TN, USA, 1999. [Google Scholar]

- Sowby, R.B.; Capener, A. Reducing Carbon Emissions through Water Conservation: An Analysis of 10 Major U.S. Cities. Energy Nexus 2022, 7, 100094. [Google Scholar] [CrossRef]

- Zib, L.; Byrne, D.M.; Marston, L.T.; Chini, C.M. Operational Carbon Footprint of the U.S. Water and Wastewater Sector’s Energy Consumption. J. Clean. Prod. 2021, 321, 128815. [Google Scholar] [CrossRef]

- Bevan, G.-S.; Wilson, W. The Carbon Footprint of Water. Available online: http://eec.ucdavis.edu/events/documents/water-energy_rivernetwork_carbon-footprint-of-water.pdf (accessed on 10 September 2020).

- Jennifer, R.S.; Horva, A. Energy and Air Emission Effects of Water Supply. Environ. Sci. Technol. 2009, 43, 2680–2687. [Google Scholar] [CrossRef]

- National Institute of Statistic and Geography. Population. Available online: http://cuentame.inegi.org.mx/monografias/informacion/bc/poblacion/ (accessed on 20 October 2022).

- National Institute of Statistic and Geography. Weather. Available online: https://cuentame.inegi.org.mx/monografias/informacion/bc/territorio/clima.aspx (accessed on 20 February 2023).

- National Instruments (NI). What Is LabVIEW? Available online: http://www.ni.com/en-us/shop/labview.html (accessed on 10 January 2020).

- Pérez, A.; Ramos, R.; Montero, G.; Coronado, M.; García, C.; Pérez, R. Virtual Instrument for Emissions Measurement of Internal Combustion Engines. J. Anal. Methods Chem. 2016, 2016, 13. [Google Scholar] [CrossRef]

- Bonilla, D.; Samaniego, M.G.; Ramos, R.; Campbell, H. Practical and low-cost monitoring tool for building energy management systems using virtual instrumentation. Sustain. Cities Soc. 2018, 39, 155–162. [Google Scholar] [CrossRef]

- Dahiya, R. Condition monitoring of wind turbine for rotor fault detection under non stationary conditions. Ain Shams Eng. J. 2018, 9, 2441–2452. [Google Scholar] [CrossRef]

- Mahfouz, A.; Gad, M.; El Fatih, A.; Emara, A. Comparative study of combustion characteristics and exhaust emissions of waste cooking-diesel oil blends. Ain Shams Eng. J. 2018, 9, 3123–3134. [Google Scholar] [CrossRef]

- Sheikh, M.F.; Kamal, K.; Rafique, F.; Sabir, S.; Zaheer, H.; Khan, K. Corrosion detection and severity level prediction using acoustic emission and machine learning based approach. Ain Shams Eng. J. 2021, 12, 3891–3903. [Google Scholar] [CrossRef]

- Mohsen, M.; Mohamed, A.M.; Ahmed, S.; Ibrahim, K. Bilateral control of a 2-dof teleoperated manipulator using udp scheme. Ain Shams Eng. J. 2022, 14, 102065. [Google Scholar] [CrossRef]

- El-Naggar, M.F.; Mosaad, M.I.; Hasanien, H.M.; AbdulFattah, T.A.; Bendary, A.F. Elephant herding algorithm-based optimal PI controller for LVRT enhancement of wind energy conversion systems. Ain Shams Eng. J. 2021, 12, 599–608. [Google Scholar] [CrossRef]

- Al-Amyal, F.; Számel, L.; Hamouda, M. An enhanced direct instantaneous torque control of switched reluctance motor drives using ant colony optimization. Ain Shams Eng. J. 2023, 14, 101967. [Google Scholar] [CrossRef]

- National Instruments (NI). Boeing Measures Reduced Aircraft Noise Emissions with NI PXI and LabVIEW. Available online: http://sine.ni.com/cs/app/doc/p/id/cs-684# (accessed on 11 October 2020).

- National Instruments (NI). NASA Uses NI LabVIEW to Save Time, Reduce Costs in Automated Testing of Microshutters. Available online: http://sine.ni.com/cs/app/doc/p/id/cs-632 (accessed on 13 October 2020).

- Wang, Z.; Andiroglu, E.; Wang, G.; Song, L. Accuracy improvement of virtual pump water flow meters using calibrated characteristics curves at various frequencies. Energy Build. 2019, 191, 143–150. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Theoretical model of energy performance prediction and BEP determination for centrifugal pump as turbine. Energy 2019, 172, 712–732. [Google Scholar] [CrossRef]

- Thongkruer, P.; Aree, P. Power-flow initialization of fixed-speed pump as turbines from their characteristic curves using unified Newton-Raphson approach. Electr. Power Syst. Res. 2023, 218, 109214. [Google Scholar] [CrossRef]

- Hanafizadeh, P.; Raffiee, A.H.; Saidi, M.H. Experimental investigation of characteristic curve for gas-lift pump. J. Pet. Sci. Eng. 2014, 116, 19–27. [Google Scholar] [CrossRef]

- Gupta, A.K.; Roach, D.C.; Rinehart, S.M.; Best, L.A. Decision-Making Impacts on Energy Consumption Display Design. Energy Technol. Policy 2015, 2, 133–142. [Google Scholar] [CrossRef]

- Sabogal, B.R.; Palacios, J.A.; Pantoja, C.L. Optimización de energía en sistemas de bombeo. Infor. Téc. 2013, 77, 47–58. [Google Scholar] [CrossRef][Green Version]

- Sunela, M.I.; Puust, R. Simple Visual Tool to Analyze Pump Battery Efficiencies for Various Pump Combinations. Procedia Eng. 2014, 89, 525–532. [Google Scholar] [CrossRef]

- Kaya, D.; Alptekin, E.; Suleyman, K.; Canka, F.; Salih, A.; Celik, C. Energy efficiency in pumps. Energy Convers. Manag. 2008, 49, 1662–1673. [Google Scholar] [CrossRef]

- Quezada, J.C.; Flores, E.; Bautista, J.; Quezada, V. Diseño e implementación de un sistema de control y monitoreo basado en MMI-PLC para un pozo de agua potable. Ing. Investig. Y Tecnol. 2014, 15, 41–50. Available online: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S1405-77432014000100005&lng=es&tlng=es (accessed on 10 September 2023).

- Hydraulic Institute. Flow Modeling Tools. Available online: http://pumps.org/Education/Free_Pump_Software.aspx (accessed on 10 September 2023).

- Suez. Suezsmartsolutions, AquadvancedTM. Available online: https://www.suezsmartsolutions.com/en/gamme-fiche-produits/smart-operations/our-solutions/aquadvanced-R-well-watch (accessed on 20 September 2023).

- Inter-American Development Bank (IDB). Evaluation of Water Pumping Systems: Energy Efficiency Assessment Manual, 1st ed.; IDB: Washington, DC, USA, 2011; pp. 12–45. Available online: https://publications.iadb.org/handle/11319/2814 (accessed on 20 October 2018).

- Legarreta, A.E.; Figueroa, J.H.; Bortolin, J.A. An IEC 61000-4-30 class a—Power quality monitor: Development and performance analysis. In Proceedings of the 11th International Conference on Electrical Power Quality and Utilization, Lisbon, Portugal, 17–19 October 2011; pp. 1–6. [Google Scholar] [CrossRef]

- Curve No. 06-008A; Pump Performance Curve. American-Marsh Pumps: Collierville, TN, USA, 2006.

- Secretary of Environment and Natural Resources (SEMARNAT). National Emissions Registry. 2023. Available online: https://www.gob.mx/cms/uploads/attachment/file/807500/aviso_fesen_2022.pdf (accessed on 17 January 2023).

- Tolvanen, J. Life cycle energy cost savings through careful system design and pump selection. World Pumps 2007, 34, 36–37. [Google Scholar] [CrossRef]

- Comisión Federal de Electricidad (CFE). Esquema Tarifario Vigente. Available online: https://app.cfe.mx/Aplicaciones/CCFE/Tarifas/TarifasCREIndustria/Industria.aspx (accessed on 10 September 2020).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).