Abstract

Co-combustion is a crucial route for the high-efficiency utilization and clean conversion of different carbonaceous feedstocks (biomass, coal, petroleum coke, etc.). The migration and transformation of alkali and alkaline earth metals (AAEMs) are not only related to ash-related issues in actual application, but also directly affect the reaction behavior of binary particles during co-conversion. This review paper summarizes research progress in the detection methods (online and offline) and influencing factors (feedstock type, feedstock blending ratio, reaction temperature, reaction time) of AAEMs migration and transformation during the co-combustion of carbonaceous feedstocks. Furthermore, it provides a detailed summary of research progress on factors (feedstock blending ratio, heating rate, etc.) influencing the co-combustion reactivity of carbonaceous feedstocks, synergy behavior, and its mechanisms. The influence of feedstock type on AAEMs migration and transformation during co-combustion is mainly related to the composition categories, chemical forms and contents of intrinsic mineral in binary feedstocks. The increase in the combustion temperature will intensify the release of inherent AAEMs in carbonaceous feedstocks, and promote AAEM deactivation. For high K and Cl-containing biomass, a higher biomass proportion in blends would result in more AAEMs release during the co-combustion process. Conversely, an increase in coal proportion in blends will directly favor the reduction or inhibition of AAEMs release. Synergy behavior during co-pyrolysis and subsequent char co-combustion is usually presented as an inhibition effect and an synergistic effect, respectively. The synergistic mechanisms of carbonaceous feedstock co-combustion reactions can be divided into two categories: non-catalytic synergistic mechanisms related to the excitation and migration of biomass-based free radicals and catalytic synergistic mechanisms related to biomass-based AAEMs catalysis. Additionally, future research prospects are also proposed based on the systematic review.

1. Introduction

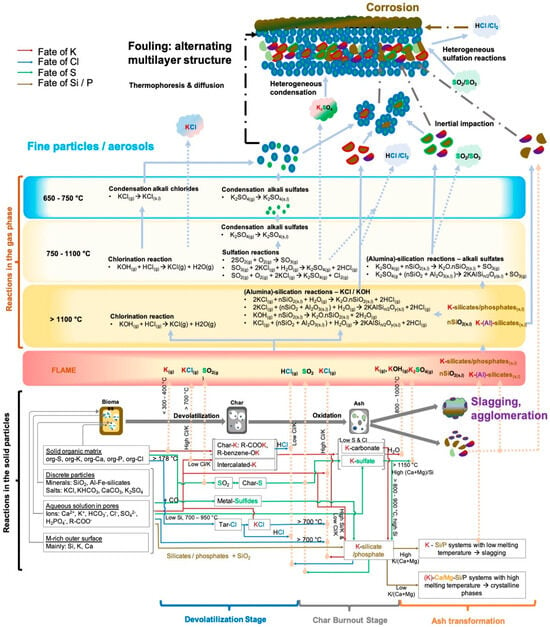

In recent years, large-scale boilers have primarily used raw materials such as coal, petroleum coke, and biomass (as illustrated in Figure 1) [1]. When coal and petroleum coke are directly used as primary fuels for combustion, the inherent sulfur and nitrogen elements are released into the atmosphere in the form of oxides, causing environmental hazards like acid rain and photochemical smog [2]. Additionally, the release of CO2 contributes to global greenhouse effects, with dire consequences. Biomass, as the only renewable carbonaceous feedstock [3], reduces environmental pollution. However, the high moisture content, high tar yield, low energy density, and seasonal supply of biomass limit its utility. The costs associated with transportation and storage often necessitate preprocessing steps such as drying, pyrolysis (producing coke, condensable liquids, and gas products during the heating process in anaerobic or low oxygen environments), and densification (preparing the loose and irregularly shaped biomass into particles with fixed shapes and high energy density) before combustion [4]. Additionally, the high concentrations of ash and alkali (alkaline earth) metal (AAEMs, K, Na, Ca, etc.) in biomass through devolatilization, nucleation, condensation, and reactions cause ash-related problems, such as slagging (mainly associated with alkali chlorides and sulfates), agglomeration (mainly dependent on the chemical characteristics and melting behavior of the coating, which are sensitive to the relative amount of calcium and potassium in fuel), corrosion (mainly related with the flue gas containing Cl2(g), HCl(g), NaCl(aerosol), KCl(aerosol), and others species, which accelerates the oxidation of the metal alloys) and fouling [5,6,7]. Ash transformation and ash-related mechanisms in biomass combustion are illustrated in Figure 2. Therefore, resolving these issues poses significant challenges in industrial biomass combustion.

Figure 1.

Pictures of typical biomass, petroleum coke and coal.

Figure 2.

Schematic diagram of ash transformation and ash-related mechanisms in biomass combustion. Copyright 2021 by Elsevier from [5].

Carbonaceous feedstock co-combustion (combustion of mixture of carbonaceous feedstocks, like biomass, petroleum coke, and coal) has attracted increasing attention from researchers and the industry compared with combustion of a single fuel. On the one hand, the drawbacks of an unstable supply and low energy density in biomass can be mitigated by adding petroleum coke/coal. On the other hand, co-combustion reduces emissions of harmful and greenhouse gases, decreasing environmental pollution. Furthermore, when high-AAEM-content biomass co-combusts with petroleum coke/coal, some of the AAEMs released from biomass into the gas phase can be adsorbed onto the surface of petroleum coke/coal coke and participate in subsequent combustion reactions. This phenomenon is known as synergistic behavior. It enhances the combustion reaction characteristics of petroleum coke/coal while reducing the release of AAEMs, thereby minimizing ash-related problems [8,9,10]. Thus, it could be concluded that co-combustion of biomass with petroleum coke/coal holds significant potential for efficient co-conversion, with addressing the above issued related to biomass, petroleum coke and coal.

Combustion reaction characteristics are important evaluation criteria for the adaptability of industrial fuels, significantly influencing the selection of operational conditions for industrial combustion systems, boiler efficiency, and economic benefits [11,12]. Different synergy behaviors (synergistic effects and inhibitory effects) between two types of particles during co-combustion have varying impacts on combustion reaction characteristics [13]. The primary reason for different synergy behaviors in coke combustion lies in the migration and transformation of AAEMs during co-combustion. However, a comprehensive review and outlook regarding the correlation between AAEMs migration and transformation pathways and co-combustion reaction characteristics remain insufficiently explored. Therefore, this article will focus on elucidating AAEMs migration and transformation pathways and co-combustion reaction synergy mechanisms, providing theoretical references for the optimization design and efficient operation of industrial boilers using mixtures of biomass and petroleum coke/coal as feedstock.

2. The Co-Combustion Process of Carbonaceous Feedstocks

Generally, co-combustion of carbonaceous feedstocks can be categorized into two stages, including co-pyrolysis and the subsequent char co-combustion [14,15]. Co-pyrolysis, as the foundational step of co-combustion, proceeds rapidly, generating light gases (CO, H2, CO2, CH4, etc.), liquid tar, and solid char as the temperature rises. Co-pyrolysis research often focuses on the secondary reactions of volatile components from different feedstocks with the solid char. The rate of co-combustion of mixed char is much slower than co-pyrolysis and can be considered as the controlling step in the combustion reaction rate. When there is an ample supply of oxygen, intense complete oxidation (combustion) is the primary chemical reaction, leading to the main product CO2 and the release of a significant amount of heat. When oxygen is limited, partial oxidation reactions that produce CO become the dominant chemical reactions. Additionally, combustion is accompanied by secondary reactions such as the Boudouard reaction and CO combustion reactions [16].

3. AAEMs Migration/Transformation Characteristics during Combustion of Carbonaceous Feedstock

3.1. Detection Methods for AAEMs Migration/Transformation

Detection methods are particularly important for monitoring the migration and transformation of minerals during the combustion of carbonaceous feedstocks. Currently, detection methods for minerals can be categorized into two types: online detection (in situ) and offline detection (characterization of experimental products). Table 1 summarizes the detection methods used in previous studies on mineral behavior during the combustion of carbonaceous feedstocks.

Table 1.

Main AAEMs detection methods used for carbonaceous feedstock combustion.

3.1.1. Online Detection Methods

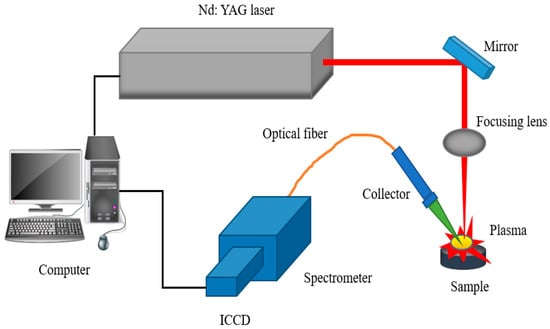

To obtain real-time and direct information about the behavior of minerals during thermochemical conversion, researchers have developed and utilized innovative online detection methods such as LIBS, FES, MS, LIPF, and others. Most of these methods rely on optical instruments to detect the radiation response of different minerals at high temperatures. Calibration curves are then used to correct the response intensity to obtain quantitative changes in concentration. LIBS involves using lasers to excite the test material into a plasma state (as shown in Figure 3) and then determining the substance’s concentration based on the spectral intensity released during the plasma cooling process [38]. Additionally, LIBS can detect the alkali precursors of molecular substances, allowing for the determination of total alkali content [35]. FES, which is simpler and more cost-effective than LIBS, operates on similar principles. It quantitatively analyzes the types and content of released elements based on the characteristic spectra emitted when elements return to their ground state after being excited by heat or energy [31]. FES can also provide additional information such as temperature [28]. He et al. [28] used FES to investigate the release pattern of potassium (K) during the combustion of rice husk balls and camphor wood balls. They found that the K release process of biomass balls consists of three stages: volatile decomposition, char combustion, and ash evaporation. Furthermore, the volatile content and moisture content in biomass have a significant impact on K release behavior. Online detection has provided significant insights into the release and migration of minerals. However, current technology is insufficient to determine the specific chemical forms of the detected substances because the minerals released during combustion are not in a single form. Moreover, in situ analysis instruments are influenced by response time and fluorescence effects, leading to potential errors [39]. Therefore, investigating mineral transformation requires the use of offline detection methods.

Figure 3.

The diagram of LIBS analysis [40].

3.1.2. Offline Detection Methods

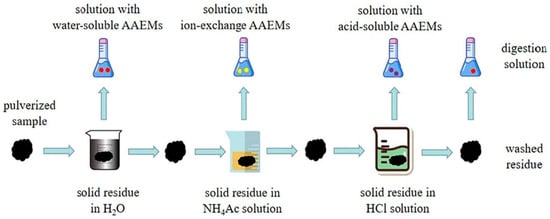

Offline detection methods involve collecting and processing semi-char obtained from the combustion of carbonaceous feedstocks. Subsequently, a range of characterization techniques are employed to obtain information about the initial and final states of the reaction. Currently, these characterization techniques include AMTT (Ash Melting Temperature Tester), XRD, SEM-EDS, and Inductively Coupled Plasma Techniques (ICP-OES, ICP-MS, ICP-AES). The aforementioned characterization techniques provide information about the macroscopic morphology, occurrence, and content changes in minerals on the surface or within the bulk of semi-char. In recent years, the use of CFA (which involves successive washing of semi-char with deionized water, ammonium acetate, and hydrochloric acid solutions, followed by digestion of the residue, as shown in Figure 4) to separate different forms of AAEMs has gained popularity [41]. This is followed by the use of Inductively Coupled Plasma instruments to detect the concentrations of metal minerals in different solutions.

Figure 4.

Experimental steps of CFA. Copyright 2023 by Elsevier from [41].

This method allows for the obtaining of solutions containing four different forms of AAEMs, i.e., water-soluble, ion-exchangeable, acid-soluble, and insoluble [41,42]. Generally, the first two forms of AAEMs are considered active AAEMs [43,44] as they can catalyze combustion reactions and lead to ash-related issues. However, the drawback of offline detection is that it cannot directly provide real-time information about changes during the reaction. Additionally, conducting batch experiments can be labor-intensive, and the state of the samples after processing may not accurately reflect their state during actual combustion processes.

3.2. AAEMs Migration/Transformation during Biomass Combustion

For binary co-combustion of carbonaceous feedstocks, the focus is often on the migration and transformation of AAEMs in biomass char because biomass typically has a higher ash content, and the migration of AAEMs, particularly potassium (K), is prominent. Therefore, it is important to first study the migration and transformation characteristics of AAEMs during biomass combustion alone. Various factors affect the behavior of AAEMs during biomass combustion, such as feedstock type, reaction temperature, and reaction time.

3.2.1. The Influence of Inherent Mineral Matter in Feedstock

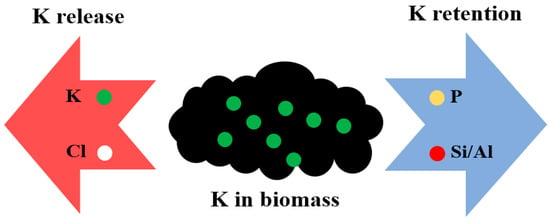

Feedstock type of biomass has an important influence on AAEMs migration and transformation during biomass combustion, which is mainly related on the difference in inherent inorganic species for different biomass. In general, agricultural biomass releases more AAEMs into the gas phase during combustion compared to forestry biomass because agricultural biomass contains higher levels of water-soluble AAEMs, which have lower melting points. Additionally, an increase in phosphorus (P) content in the feedstock can reduce the evaporation of K. Many studies add phosphorus-containing substances as adsorption inhibitors for K because K forms stable K-Ca/Mg-P minerals during combustion [45,46]. Similarly, elements such as silicon (Si) and aluminum (Al) have similar effects. The use of kaolin (a high-Si material) as a K adsorbent is well documented, as K forms stable K-Al-Si minerals or silicates during combustion, inhibiting K release [47,48]. However, this deactivation is limited by the presence of AAEMs in the feedstock, as Si/Al will prioritize the formation of stable Ca/Mg-Al-Si minerals in the presence of both AAEMs. Furthermore, the chlorine (Cl) content in the feedstock can also influence the release of AAEMs, typically leading to an increase in their release as higher Cl content lowers the melting points of alkali metal chlorides. Therefore, the influence of certain inorganic element contents in the feedstock on the release of K during combustion is shown in Figure 5, depicting a competitive relationship.

Figure 5.

The effect of inorganic elements in biomass on K release/retention.

3.2.2. The Influence of Reaction Temperature

Regarding AAEMs migration, many studies have shown that increasing the combustion temperature leads to more K being released during the combustion of biomass (especially agricultural biomass), and the corresponding retention rate of K in the solid phase decreases [18,19,23,24]. This is because higher combustion temperatures can cause more different water-soluble AAEMs to evaporate and be released into the gas phase. Deng et al. [23] and Cao et al. [37] also found that the release of K from straw biomass remains relatively constant at temperatures between 400 °C and 600 °C, which should be because 600 °C has not reached the sharply released temperature of some K salts, such as KCl, which melts at around 770 °C, and is typically released in large quantities when the temperature exceeds 700 °C [49,50]. Regarding AAEMs transformation, Li et al. found that mixtures of rice straw and ammonium phosphate formed more KCaPO4 at higher temperatures, which has a higher and more stable melting point, reducing K release [18]. Wang et al. also found that corn straw char mixed with ammonium phosphate or corn straw mixed with calcium phosphate formed more KmgPO4 at higher temperatures [25]. Some studies have also found that higher temperatures are more favorable for K to form potassium silicate or inert substances such as K-Ca/Mg-P with Si, P, and AAEMs [33,44]. Therefore, it can be inferred that when the temperature rises, the K content in the solid reactants with catalytic effects decreases due to both evaporation and deactivation.

3.2.3. The Influence of Reaction Time

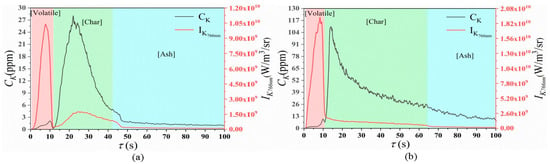

The duration of the reaction also affects the migration and transformation of AAEMs in co-combustion because different reaction times correspond to different reaction stages, and each stage has different dominant chemical reactions. For AAEMs migration, many researchers divide biomass combustion into three stages—volatile matter pyrolysis, char combustion, and ash decomposition—and each stage corresponds to different amounts of K release [29,30,31]. Figure 6 shows the curves of K characteristic spectral line radiation intensity and K release concentration with time for pine wood and rice straw during the three combustion stages [36]. From the figure, it can be seen that the two types of biomass have different K concentrations released in the three stages. Overall, the distribution of K concentration from high to low is char combustion stage > ash decomposition stage > volatile matter pyrolysis stage. In the volatile matter pyrolysis stage, the released K is mainly inorganic K (KCl and KOH) and organic K released during the thermal decomposition of organic matter, with the former being dominant at higher temperatures and the latter at lower temperatures [51]. In the char combustion and ash decomposition stages, the released K is mainly inorganic K [21].

Figure 6.

Changes in the characteristic spectral line radiation intensity and K concentration during biomass combustion versus time for (a) pine wood and (b) rice straw [36].

3.3. AAEMs Migration/Transformation during Carbonaceous Feedstock Co-Combustion

Co-combustion of biomass with coal or petroleum coke can not only enhance the reactivity of coal or petroleum coke but also mitigate ash-related issues caused by biomass combustion, reducing the release and deposition of AAEMs [5,6]. Therefore, studying the migration and transformation of AAEMs during the co-combustion of carbonaceous feedstocks is crucial. The factors influencing AAEMs migration and transformation during co-combustion include the type of feedstock, blending ratio, reaction temperature, and reaction time.

3.3.1. The Influence of Inherent Mineral Matter in Feedstocks

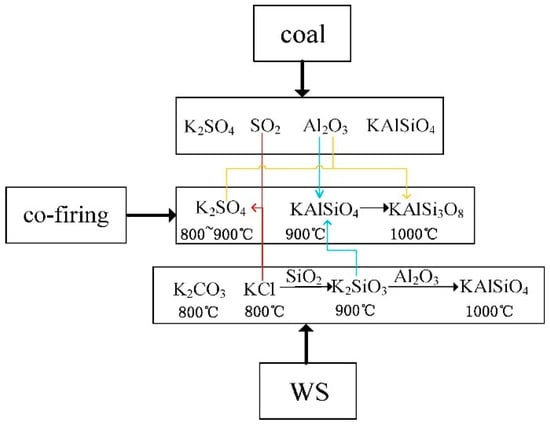

Han et al. co-combusted high-K roasted biomass with high Si/Al coal and characterized the ash, finding that during the roasting process, some S and Cl were released from the biomass, leading to more K being retained in the mixed ash [52]. This is consistent with the previous discussion that higher Cl elements in the raw materials during biomass combustion can promote the release of K salts. Similar results have been obtained in other studies as well [53]. Additionally, the AAEMs and Si/Al content in different coals also affect the migration and transformation of co-combustion AAEMs. When high-K biomass is co-combusted with high-Ca coal, it inhibits the formation of K silicates and aluminosilicates and instead forms more Ca silicates and aluminosilicates [49,52,54]. When coal contains more Si/Al, co-combustion also increases the formation of K silicates or aluminosilicates [55]. A biomass-derived K transformation pathway during co-combustion was summarized in Figure 7.

Figure 7.

Schematic diagram for biomass-derived K transformation pathway during co-combustion. WS-wheat straw. Copyright 2018 by Elsevier from [54].

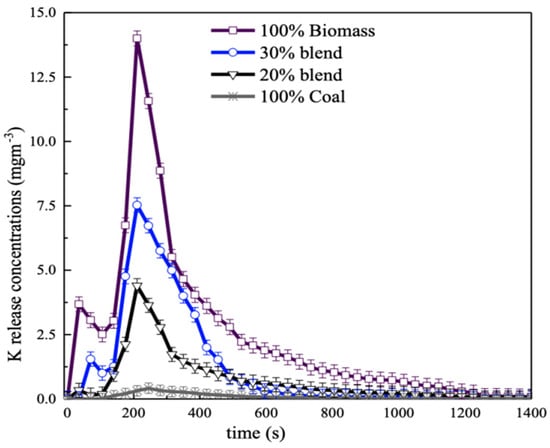

3.3.2. The Influence of the Feedstock Blending Ratio

The different ratios of biomass-coal mixtures similarly affect the migration and transformation characteristics of AAEMs during co-combustion, while the composition of inorganic elements in biomass and coal itself determines the direction of AAEMs migration and transformation changes. For mixtures containing high-K and Cl biomass, increasing the biomass mixture ratio leads to an increase in the release of AAEMs during co-combustion [35,37,56], because K, Na, and Cl can lower the melting point of the mixed ash, causing more AAEMs to evaporate at the same temperature [56,57,58]. Conversely, for mixtures containing high-Ca biomass, increasing the mixture ratio results in a higher ash melting point, thereby inhibiting the release behavior of ash during combustion [59,60]. Additionally, changes in the total Si/Al content in the mixture can influence the formation of silicate minerals during combustion, and silicate minerals often have the ability to suppress the release of AAEMs [60].

3.3.3. The Influence of Reaction Temperature

From the perspective of AAEMs migration, the release pattern of AAEMs during co-combustion processes with temperature is similar to biomass combustion. Most research concludes that increasing the combustion temperature leads to more AAEMs being released, and correspondingly, the retention rate of AAEMs in the solid phase decreases [35,56,57]. In general, higher temperatures can melt and evaporate more salts in the mixture, and some studies have shown that most of the released AAEMs are in a water-soluble state, with lower melting points compared to other forms of AAEMs [35].

From the perspective of AAEMs transformation; Zhou et al. [35] found that as the temperature rises from 600 °C to 1000 °C, the content of water-soluble K and ion-exchangeable K in the ash of the mixture decreases, while the content of insoluble K increases, indicating mutual conversion between them. The content of acid-soluble K shows an initial increase followed by a decrease, with a peak temperature of 800 °C. Some studies also found that at temperatures below 600 °C, an increase in temperature leads to the sulfidation of various AAEMs (if Ca and K coexist, Ca is preferentially reacted) [56,57]. When the temperature exceeds 600 °C, sulfate salts begin to decompose, and higher temperatures result in more AAEMs forming silicate or aluminosilicate compounds with Si/Al [35]. Unlike biomass combustion, during co-combustion with coal, due to the higher Ca/Mg content in coal, some Si/Al will preferentially form silicate or aluminosilicate compounds with AAEMs [56]

3.3.4. The Influence of Reaction Time

The pattern of co-combustion of AAEMs with biomass is similar to separate biomass combustion, and it varies at each stage with different reaction times [37,56]. As shown in Figure 8, for mixtures containing high-potassium (K) biomass, the release characteristics of K are determined by the biomass [37]. However, due to the different reactivity of different biomass types with coal, the start and end times of different stages during co-combustion are different. In the early stages of the reaction, it mainly involves the high-K biomass char combustion stage because of its higher reactivity compared to coal. The overlap in different stages of the two substances will certainly affect the migration and transformation of AAEMs, but there is currently limited research in this regard.

Figure 8.

Changes in K release concentration during co-combustion of corn stalks and lignite [35].

4. The Reactivity Characteristics and Synergy Mechanisms of Carbonaceous Feedstock Co-Combustion

4.1. Co-Combustion Reactivity Characteristics

The combustion reaction characteristics are important evaluation parameters for fuels, significantly affecting the operational selection, overall efficiency, and economic benefits of industrial combustion furnaces. In recent years, some scholars have explored the co-combustion reaction characteristics of carbonaceous feedstocks, and the influencing factors mainly include the type of raw materials, the mixing ratio of raw materials, and the heating rate.

4.1.1. The Influence of the Feedstock Blending Ratio

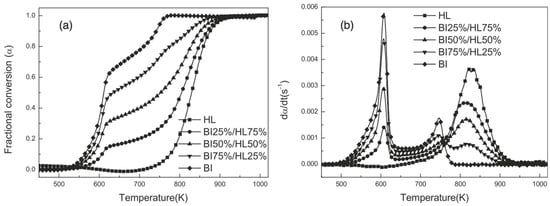

Similar to the influence of raw material types, the impact of the mixing ratio of raw materials on combustion reaction characteristics also depends primarily on the combustion reaction characteristics of the two respective raw materials [59,60,61,62,63,64,65]. In general, biomass has a larger pyrolysis peak, a smaller coke combustion peak, a lower ignition temperature, and coke combustion peak temperature, as well as higher combustion reaction activity compared to coal/petroleum coke. Therefore, when the proportion of biomass increases, the pyrolysis peak of the binary mixture in co-combustion increases, the coke combustion peak decreases, the ignition temperature and coke combustion peak temperature decrease, and combustion reaction activity increases (as shown in Figure 9).

Figure 9.

Reaction curves of pine wood (BI) and anthracite (HL) co-combustion at different mixing ratios: (a) Thermogravimetric (TG), (b) Derivative Thermogravimetric (DTG); Bl25%/HL75% represents the reaction curve of mixture with a BI–HL blended ratio of 1:3, etc. Copyright 2014 by Elsevier from [59].

4.1.2. The Influence of Heating Rate

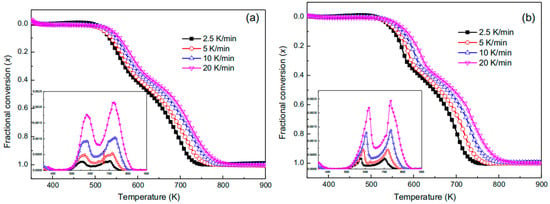

For the combustion reaction characteristics of carbonaceous feedstocks, most current research is based on non-isothermal conditions using TG analysis. As for different heating rates, the majority of existing research results tend to be consistent, as shown in Figure 10. A higher heating rate leads to an increase in the two-stage weight loss peaks and an increase in peak temperatures. The reaction termination temperature also increases, corresponding to a decrease in reaction time [59,60,63]. This is because reactions at lower temperatures do not have enough time to complete, causing them to overlap with reactions at higher temperatures. Additionally, a high heating rate can lead to temperature gradients inside and outside the sample, resulting in the aforementioned reaction outcomes [59,60,63].

Figure 10.

Co-combustion reaction curves of biomass and coal at different heating rates: (a) bituminous coal and rice husk; (b) bituminous coal and pine sawdust [63].

4.2. Synergy Behavior on Co-Combustion Reactivity and Its Mechanisms

4.2.1. Synergy Behavior

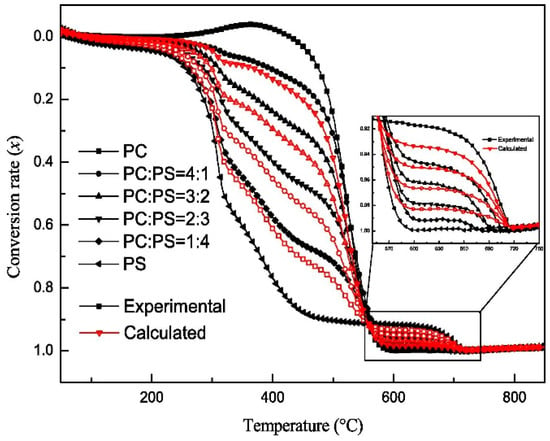

The synergy behavior in co-combustion can be categorized into three types: no interaction, an inhibition effect, and an synergy effect. As shown in Figure 11, the calculated conversion rate of paper sludge-derived hydrochar and petroleum coke co-combustion was higher than the corresponding experimental value at the low temperature zone (i.e., co-pyrolysis stage), but the converse trend could be observed at the high temperature zone (i.e., char co-combustion stage) [66]. This phenomenon demonstrates that there is an inhibition effect during the co-pyrolysis stage and a synergistic effect during the char co-combustion stage. The similar results were also reported in other literature [60,63,65]. During the pyrolysis stage, on one hand, due to the addition of coal/petroleum coke, the heat transfer in the mixed sample is poorer compared to that of biomass samples. This results in higher temperature gradients inside and outside the sample, and coal/petroleum coke particles hinder the diffusion of volatile components from biomass. On the other hand, AAEMs in the mixed sample effectively inhibit the decomposition of volatile components. Therefore, during the pyrolysis stage, a mixed sample experiences an inhibition effect, leading to a decrease in reaction activity [59,63]. During the char combustion stage, the explanation for the synergy effect usually stems from the active AAEMs originating from biomass, which catalyze the subsequent reactions of coal coke or petroleum coke with lower reactivity through processes like migration and transformation, resulting in an increase in reaction activity.

Figure 11.

Co-combustion reaction curve of paper sludge-derived hydrochar (PS) and petroleum coke (PC); PCPS = 4:1 represents the reaction curve of mixture with a PC–PS blended ratio of 4:1, etc. Copyright 2022 by Elsevier from [66].

4.2.2. Non-Catalytic Synergistic Mechanism

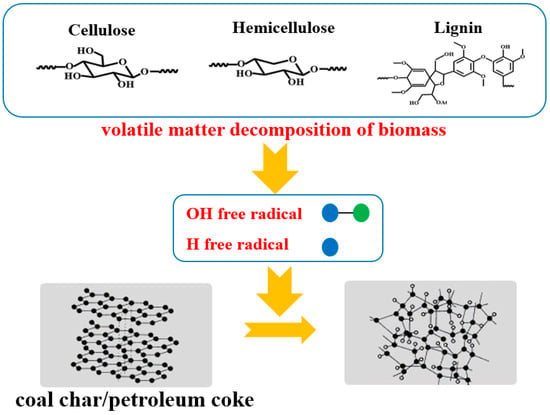

The volatile content of biomass is generally higher than that of coal/petroleum coke. Biomass contains a significant amount of hydroxyl and carboxyl groups in cellulose and hemicellulose, which release OH and H radicals during pyrolysis/combustion (as shown in Figure 12) [67,68]. These radicals migrate to the surface of coal coke/petroleum coke, reducing the carbon structure density of coal coke/petroleum coke and thereby enhancing their subsequent reactivity [69,70].

Figure 12.

Schematic diagram of non-catalytic synergistic mechanism of co-combustion.

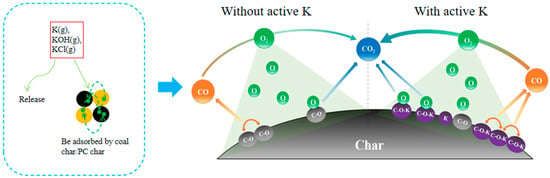

4.2.3. Catalytic Synergistic Mechanism

Figure 13 illustrates the catalytic synergistic mechanism involving AAEMs. In the co-combustion of high-potassium (K) biomass, the presence of active K in biomass is the primary reason for the synergy effect. Firstly, during the pyrolysis/combustion stage, biomass releases a substantial amount of active K into the gas phase. Some of this K exits the reactor, while the rest is adsorbed onto the surface of coal coke/petroleum coke [50]. Subsequently, coal coke/petroleum coke undergo catalytic and non-catalytic oxidation reactions. Oxygen molecules rapidly diffuse into the coke and form C(O) intermediates by adsorption, followed by further reactions with oxygen molecules on the coke surface to produce CO or CO2. In the case of catalytic combustion, oxygen molecules react with carbon I and active K to form C-O-K intermediates. The different electron distribution of C-O-K compared to C(O) makes C-O-K more conducive to reacting with oxygen molecules, leading to an enhancement in reaction activity [71,72].

Figure 13.

Schematic diagram of the catalysis synergistic mechanism of co-combustion.

5. Conclusions

- (1)

- The influence of feedstock types on AAEMs migration and transformation during co-combustion is mainly related to the composition categories (AAEMs and other components such as Si, Al, P, Cl, etc.), chemical forms (water-soluble, ion-exchangeable, acid-soluble, residual, etc.) and contents of intrinsic mineral in binary feedstocks. For instance, Si, Al, and P can inhibit the release of AAEMs, while Cl plays a promoting role. Therefore, the optimization and adjustment of inherent mineral component system (i.e., AAEMs-Cl-Si-Al-P system) in raw feedstock is suggested for actual application.

- (2)

- The increase in combustion temperature will intensify the release of inherent AAEMs, especially water-soluble AAEMs, in carbonaceous feedstocks. On the other hand, it will promote reactions between AAEMs and inert components like Si, Al, and P, leading to the existence of more AAEMs in non-reactive forms such as silicates and aluminosilicates. Therefore, low-temperature combustion is preferred for actual application, which is also favorable for the improvement of energy efficiency, the decrease in energy consumption and NOx emission in the co-combustion process.

- (3)

- For high K and Cl-containing biomass, a higher biomass proportion in blends would result in more AAEMs release during the co-combustion process. Conversely, an increase in coal proportion in blends directly leads to a decrease in the concentration of AAEMs components in the mixed material’s mineral system and an increase in inert component concentration, thereby favoring the reduction or inhibition of AAEMs release.

- (4)

- Reaction time directly determines different reaction stages (such as pyrolysis, char combustion, and ash decomposition) in the co-combustion process of carbonaceous feedstocks. Its impact on the migration and transformation characteristics of AAEMs throughout the entire reaction process is rather complex and has not yet been systematically understood.

- (5)

- The forms of synergy behavior in the co-combustion process of carbonaceous feedstocks mainly manifest in three categories: no interaction (also additive effect), inhibitory effect, and synergistic effect. Generally speaking, the form of synergy behavior during the co-pyrolysis process is inhibitory, which is mainly related to limited heat transfer and the inhibitory effect of AAEMs on the decomposition of volatiles. Subsequently, the form of synergy behavior during the char co-combustion process shows a synergistic effect. Therefore, how to weaken the inhibition effect during co-pyrolysis and enhance the synergistic effect during char co-combustion is important for the actual application.

- (6)

- The synergistic mechanisms of co-combustion reactions of carbonaceous feedstocks can be divided into two categories: non-catalytic synergistic mechanisms related to the excitation and migration of biomass-based free radicals and catalytic synergistic mechanisms related to biomass-based AAEMs catalysis.

6. Future Prospects

- (1)

- In situ characterization for AAEMs migration and transformation is particularly important. However, current online detection methods are only available for characterizing the atomic concentration in the gas phase and cannot determine the specific forms. In addition, in the case of AAEMs migration and transformation in semi-coke, in situ research is even more necessary. Therefore, the development of comprehensive in situ characterization techniques for AAEMs migration and transformation is urgently needed.

- (2)

- Currently, most research on the characteristics of co-combustion reactions is based on TG analysis. This small-scale reactor differs significantly from the parameters of large-scale industrial boilers. Therefore, it is necessary to study the co-combustion reaction characteristics of carbonaceous feedstocks based on larger-scale reactors.

- (3)

- During the combustion process, the migration and transformation of AAEMs not only affect their catalytic effects on the reaction but also alter the physical and chemical structure of the combustion char. Changes in the physical and chemical structure of the char can, in turn, influence the migration and transformation of AAEMs and combustion reaction characteristics. These three aspects are closely intertwined, so designing an experimental plan for systematic research on them is something that needs to be considered.

- (4)

- For actual application, AAEMs migration and transformation during the co-combustion process have positive effects in terms of reactivity promotion and a negative effect in terms of ash-related problem formation at the same time. Therefore, how to simultaneously realize a large amount of AAEMs retention to make full use of its catalysis as well as enable a small amount of AAEMs release to avoid ash-related problems is a great challenge for researchers and the industry. Finding the optimum feedstock and reaction conditions are paramount, and more work should be conducted to this effect in the future.

- (5)

- Ash derived from carbonaceous feedstock combustion is a good choice as a carbon dioxide adsorbent due to its superior physicochemical properties. In future work, researchers could put more efforts towards studying and enhancing the inherent mineral matter on the in situ capture and storage of CO2 released from co-combustion.

Author Contributions

All authors made valuable contributions to this paper. Conceptualization, Y.J. and J.W.; investigation, L.T.; writing—original draft preparation, Y.J. and S.Y.; writing—review and editing, Z.W. and J.X.; Supervision, X.S. and J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This work is financially supported by the National Natural Science Foundation of China (22208164, 32201487, 22108132), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (22KJB470017, 21KJB220010), the Postdoctoral Research Excellence Funding Project of Zhejiang Province of China (ZJ2023135) and the State Key Laboratory of High efficiency Utilization of Coal and Green Chemical Engineering, Ningxia University (2022-K39).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no known competing financial interest or personal relationship that could have appeared to influence the work reported in this paper.

References

- Chen, C.; Huang, Y.; Yang, S.; Qin, S.; Chen, F. Effect of oxygen enriched atmospheres on combustion of bagasse, coal and theirs blends by thermogravimetric analysis. J. Environ. Chem. Eng. 2020, 8, 104398. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, Y.; Wang, X.; Dai, G.; Tan, H.; Rahman, Z. Nitrogen oxide reduction in pressurized oxy-coal combustion. Combust. Flame 2022, 246, 112418. [Google Scholar] [CrossRef]

- Jiao, Y.; Xu, K.; Xiao, H.; Mei, C.; Li, J. Biomass-derived carbon aerogels for ORR/OER bifunctional oxygen electrodes. Nanomaterials 2023, 13, 2397. [Google Scholar] [CrossRef] [PubMed]

- Thengane, S.K.; Kung, K.S.; Gomez-Barea, A.; Ghoniem, A.F. Advances in biomass torrefaction: Parameters, models, reactors, applications, deployment, and market. Prog. Energy Combust. Sci. 2022, 93, 101040. [Google Scholar] [CrossRef]

- Míguez, J.; Porteiro, J.; Behrendt, F.; Blanco, D.; Patiño, D.; Dieguez-Alonso, A. Review of the use of additives to mitigate operational problems associated with the combustion of biomass with high content in ash-forming species. Renew. Sustain. Energy Rev. 2021, 141, 110502. [Google Scholar] [CrossRef]

- Niu, Y.; Tan, H. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Wang, L.; Hustad, J.E.; Skreiberg, Ø.; Skjevrak, G.; Grønli, M. A critical review on additives to reduce ash related operation problems in biomass combustion applications. Energy Procedia 2012, 20, 20–29. [Google Scholar] [CrossRef]

- Zhou, C.; Liu, G.; Wang, X.; Qi, C. Co-combustion of bituminous coal and biomass fuel blends: Thermochemical characterization, potential utilization and environmental advantage. Bioresour. Technol. 2016, 218, 418–427. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, Z.; Liu, J.; Zhuang, P.; Evrendilek, F.; Huang, S.; Chen, T.; Xie, W.; He, Y.; Sun, S. Optimizing co-combustion synergy of soil remediation biomass and pulverized coal toward energetic and gas-to-ash pollution controls. Sci. Total Environ. 2023, 857, 159585. [Google Scholar] [CrossRef]

- Rago, Y.P.; Collard, F.X.; Görgens, J.F.; Surroop, D.; Mohee, R. Co-combustion of torrefied biomass-plastic waste blends with coal through TGA: Influence of synergistic behaviour. Energy 2022, 239, 121859. [Google Scholar] [CrossRef]

- Qin, K.; Thunman, H. Diversity of chemical composition and combustion reactivity of various biomass fuels. Fuel 2015, 147, 161–169. [Google Scholar] [CrossRef]

- Chuahy, F.D.F.; Kokjohn, S.L. Effects of the direct-injected fuel’s physical and chemical properties on dual-fuel combustion. Fuel 2017, 207, 729–740. [Google Scholar] [CrossRef]

- Wei, J.; Wang, M.; Li, B.; Song, X.; Yu, G.; Zhang, J.; Zhang, H.; Xu, D. Synergy mechanism of biochar and petcoke co-combustion based on potassium migration and transformation. Fuel Process. Technol. 2023, 250, 107927. [Google Scholar] [CrossRef]

- Wang, P.; Wang, G.; Zhang, J.; Lee, J.; Li, Y.; Wang, C. Co-combustion characteristics and kinetic study of anthracite coal and palm kernel shell char. Appl. Therm. Eng. 2018, 143, 736–745. [Google Scholar] [CrossRef]

- Zhang, H.; Shu, Y.; Yue, S.; Chen, Y.; Mikulcic, H.; Rahman, Z.U.; Tan, H.; Wang, X. Preheating pyrolysis-char combustion characteristics and kinetic analysis of ultra-low calorific value coal gangue: Thermogravimetric study. Appl. Therm. Eng. 2023, 229, 120583. [Google Scholar] [CrossRef]

- Straka, P.; Náhunková, J.; Žaloudková, M. Analysis of unburned carbon in industrial ashes from biomass combustion by thermogravimetric method using Boudouard reaction. Thermochim. Acta 2014, 575, 188–194. [Google Scholar] [CrossRef]

- Kim, S.S.; Kang, Y.S.; Lee, H.D.; Kim, J.K.; Hong, S.C. Release of potassium and sodium species during combustion of various rank coals, biomass, sludge and peats. J. Ind. Eng. Chem. 2012, 18, 2199–2203. [Google Scholar] [CrossRef]

- Li, H.; Han, K.; Wang, Q.; Lu, C. Influence of ammonium phosphates on gaseous potassium release and ash-forming characteristics during combustion of biomass. Energy Fuels 2015, 29, 2555–2563. [Google Scholar] [CrossRef]

- Qi, J.; Li, H.; Han, K.; Zuo, Q.; Gao, J.; Wang, Q.; Lu, C. Influence of ammonium dihydrogen phosphate on potassium retention and ash melting characteristics during combustion of biomass. Energy 2016, 102, 244–251. [Google Scholar] [CrossRef]

- Mason, P.E.; Darvell, L.I.; Jones, J.M.; Williams, A. Observations on the release of gas-phase potassium during the combustion of single particles of biomass. Fuel 2016, 182, 110–117. [Google Scholar] [CrossRef]

- Mason, P.E.; Jones, J.M.; Darvell, L.I.; Williams, A. Gas phase potassium release from a single particle of biomass during high temperature combustion. Proc. Combust. Inst. 2017, 36, 2207–2215. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Z.; Adeosun, A.; Liu, B.; Ruan, R.; Li, S.; Tan, H. Particulate matter emission and K/S/Cl transformation during biomass combustion in an entrained flow reactor. J. Energy Inst. 2018, 91, 835–844. [Google Scholar] [CrossRef]

- Deng, L.; Jiang, J.; Tie, Y.; Ma, S.; Fan, G.; Zhu, T.; Che, D. Potassium transformation and release during biomass combustion. Can. J. Chem. Eng. 2023, 101, 337–346. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Shen, F.; Dong, Y. Insights into the Effects of Atmosphere and Chlorine on Potassium Release during Biomass Combustion: Temporal Measurement and Kinetic Studies. Energy Fuels 2018, 32, 12523–12531. [Google Scholar] [CrossRef]

- Wang, Q.; Han, K.; Qi, J.; Zhang, J.; Li, H.; Lu, C. Investigation of potassium transformation characteristics and the influence of additives during biochar briquette combustion. Fuel 2018, 222, 407–415. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Z.; Xia, J.; Vervisch, L.; Wan, K.; He, Y.; Whiddon, R.; Bahai, H.; Cen, K. Measurement and kinetics of elemental and atomic potassium release from a burning biomass pellet. Proc. Combust. Inst. 2019, 37, 2681–2688. [Google Scholar] [CrossRef]

- Clery, D.S.; Mason, P.E.; Rayner, C.M.; Jones, J.M. The effects of an additive on the release of potassium in biomass combustion. Fuel 2018, 214, 647–655. [Google Scholar] [CrossRef]

- He, Z.; Lou, C.; Fu, J.; Lim, M. Experimental investigation on temporal release of potassium from biomass pellet combustion by flame emission spectroscopy. Fuel 2019, 253, 1378–1384. [Google Scholar] [CrossRef]

- Liu, Y.; Wan, K.; He, Y.; Wang, Z.; Xia, J.; Cen, K. Experimental study of potassium release during biomass-pellet combustion and its interaction with inhibitive additives. Fuel 2020, 260, 116346. [Google Scholar] [CrossRef]

- Zhao, H.; Wakil, M.A.; Viljanen, J.; Song, Q.; Yao, Q.; Kwong, C.W.; Alwahabi, Z.T. In situ measurement of potassium release during biomass combustion using Laser-Induced Breakdown Spectroscopy: Effect of silicate on potassium release. Energy Fuels 2020, 34, 3262–3271. [Google Scholar] [CrossRef]

- Paulauskas, R.; Striugas, N.; Sadeckas, M.; Sommersacher, P.; Retschitzegger, S.; Kienzl, N. Online determination of potassium and sodium release behaviour during single particle biomass combustion by FES and ICP-MS. Sci Total Environ. 2020, 746, 141162. [Google Scholar] [CrossRef] [PubMed]

- Weng, W.; Li, S.; Costa, M.; Li, Z. Particle temperature and potassium release during combustion of single pulverized biomass char particles. Proc. Combust. Inst. 2021, 38, 3949–3958. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Q.; Zhong, W.Q.; Yu, Z.W. Migration and transformation law of potassium in the combustion of biomass blended coal. J. Fuel Chem. Technol. 2020, 48, 929–936. [Google Scholar] [CrossRef]

- Hedayati, A.; Lindgren, R.; Skoglund, N.; Boman, C.; Kienzl, N.; Öhman, M. Ash transformation during single-pellet combustion of agricultural biomass with a focus on potassium and phosphorus. Energy Fuels 2021, 35, 1449–1464. [Google Scholar] [CrossRef]

- Chansa, O.; Luo, Z.; Eddings, E.G.; Yu, C. Determination of alkali release during oxyfuel co-combustion of biomass and coal using laser-induced breakdown spectroscopy. Fuel 2021, 289, 119658. [Google Scholar] [CrossRef]

- Li, K.; Yan, W.; Huang, X.; Yu, L.; Chen, Y.; Lou, C. In-situ measurement of temperature and potassium concentration during the combustion of biomass pellets based on the emission spectrum. Fuel 2021, 289, 119863. [Google Scholar] [CrossRef]

- Cao, W.; Li, J.; Lin, L.; Zhang, X. Release of potassium in association with structural evolution during biomass combustion. Fuel 2021, 287, 119524. [Google Scholar] [CrossRef]

- Bie, N.X.; Wang, J.F.; Lv, P.; Zhang, Y.J.; Bai, Y.H.; Song, X.D.; Su, W.G.; Yu, G.S. Research progress on alkali metal migration and detection during co-pyrolysis of coal and biomass. Clean Coal Technol. 2021, 28, 31–41. [Google Scholar]

- Wei, J.; Wang, M.; Tang, G.; Akhtar, M.A.; Xu, D.; Song, X.; Yu, G.; Li, B.; Zhang, H.; Zhang, S. Advances on in-situ analysis of char structure evolution during thermochemical conversion of coal/biomass: A review. Fuel Process. Technol. 2022, 230, 107221. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, T.; Li, H. Application of laser-induced breakdown spectroscopy (LIBS) in environmental monitoring. Spectrochim. Acta Part B At. Spectrosc. 2021, 181, 106218. [Google Scholar] [CrossRef]

- Wang, M.; Xu, D.; Bai, Y.; Yu, G.; Zhang, J.; Zhang, S.; Xu, J.; Zhang, H.; Zhang, S.; Wei, J. Dynamic investigation on potassium migration and transformation during biochar combustion and its correlation with combustion reactivity. Fuel 2023, 340, 127540. [Google Scholar] [CrossRef]

- Wang, B.; Huang, J.; Wang, Z.; Xie, D.; Qiao, Y. Interactions of potassium vapor with reactor tubes made of different materials and their impacts on particulate matter emission during pulverized biomass combustion. Proc. Combust. Inst. 2023, 39, 3401–3408. [Google Scholar] [CrossRef]

- Wei, J.; Guo, Q.; He, Q.; Ding, L.; Yoshikawa, K.; Yu, G. Co-gasification of bituminous coal and hydrochar derived from municipal solid waste: Reactivity and synergy. Bioresour. Technol. 2017, 239, 482–489. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Gong, Y.; Guo, Q.; Chen, X.; Ding, L.; Yu, G. A mechanism investigation of synergy behaviour variations during blended char co-gasification of biomass and different rank coals. Renew. Energy 2019, 131, 597–605. [Google Scholar] [CrossRef]

- Morris, J.D.; Daood, S.S.; Nimmo, W. The use of kaolin and dolomite bed additives as an agglomeration mitigation method for wheat straw and miscanthus biomass fuels in a pilot-scale fluidized bed combustor. Renew. Energy 2022, 196, 749–762. [Google Scholar] [CrossRef]

- Kuptz, D.; Kuchler, C.; Rist, E.; Eickenscheidt, T.; Mack, R.; Schön, C.; Drösler, M.; Hartmann, H. Combustion behaviour and slagging tendencies of pure, blended and kaolin additivated biomass pellets from fen paludicultures in two small-scale boilers < 30 kW. Biomass Bioenergy 2022, 164, 106532. [Google Scholar]

- Bläsing, M.; Müller, M. Co-gasification of waste wood with coal: Release of condensable and non-condensable inorganic gas species. Int. J. Hydrogen Energy 2018, 43, 435–441. [Google Scholar] [CrossRef]

- Fatehi, H.; Costa, M.; Bai, X.-S. Numerical study on K/S/Cl release during devolatilization of pulverized biomass at high temperature. Proc. Combust. Inst. 2021, 38, 3909–3917. [Google Scholar] [CrossRef]

- Weng, W.; Aldén, M.; Li, Z. Insight into KOH and KCl release behavior of burning wood and straw pellets using quantitative in situ optical measurements. Proc. Combust. Inst. 2023, 39, 3239–3248. [Google Scholar] [CrossRef]

- Wei, J.; Wang, M.; Xu, D.; Shi, L.; Li, B.; Bai, Y.; Yu, G.; Bao, W.; Xu, J.; Zhang, H.; et al. Migration and transformation of alkali/alkaline earth metal species during biomass and coal co-gasification: A review. Fuel Process. Technol. 2022, 235, 107376. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, W. Modeling potassium release in biomass pyrolysis. In Fifth International Conference on Thermochemical Biomass Conversion; Blackwell Science: Hoboken, NJ, USA, 2008; pp. 1107–1115. [Google Scholar]

- Sahu, S.G.; Chakraborty, N.; Sarkar, P. Coal–biomass co-combustion: An overview. Renew. Sustain. Energy Rev. 2014, 39, 575–586. [Google Scholar] [CrossRef]

- Zahng, B.; Zhong, Z.; Xue, Z.; Xue, J.; Xu, Y. Release and transformation of potassium in co-combustion of coal and wheat straw in a BFB reactor. Appl. Therm. Eng. 2018, 144, 1010–1016. [Google Scholar] [CrossRef]

- Han, J.; Yu, D.; Wu, J.; Yu, X.; Liu, F.; Xu, M. Effects of torrefaction on ash-related issues during biomass combustion and co-combustion with coal. Part 3: Ash slagging behavior. Fuel 2023, 339, 126925. [Google Scholar] [CrossRef]

- Pu, G.; Tan, B. Study on fusion characteristics of ash produced by co-combustion biomass and high-sulfur low grade coal. Proc. CSEE 2011, 31, 108–114. [Google Scholar]

- Kai, X.P.; Yang, T.H.; Sun, Y.; He, Y.G.; Li, R.D.; Wei, L.H. Study on migration mechanism of alkali metals during co-firing of tice straw and coal. Proc. CSEE 2012, 32, 133–138+60. [Google Scholar]

- Yan, J.F.; Shi, K.Q.; Wu, T. The influence of coal and biomass co combustion process on ash characteristics. J. Chongqing Univ. 2011, 34, 106–109. [Google Scholar]

- Oladejo, J.M.; Adegbite, S.; Pang, C.; Liu, H.; Lester, E.; Wu, T. In-situ monitoring of the transformation of ash upon heating and the prediction of ash fusion behaviour of coal/biomass blends. Energy 2020, 199, 117330. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Shao, J.; Ren, S. Characterisation and model fitting kinetic analysis of coal/biomass co-combustion. Thermochim. Acta 2014, 591, 68–74. [Google Scholar] [CrossRef]

- Garcia, E.; Ejim, I.F.; Liu, H. Thermogravimetric analysis of co-combustion of a bituminous coal and coffee industry by-products. Thermochim. Acta 2022, 715, 179256. [Google Scholar] [CrossRef]

- Varol, M.; Atimtay, A.T.; Bay, B.; Olgun, H. Investigation of co-combustion characteristics of low quality lignite coals and biomass with thermogravimetric analysis. Thermochim. Acta 2010, 510, 195–201. [Google Scholar] [CrossRef]

- Haykiri-Acma, H.; Yaman, S.; Kucukbayrak, S. Co-combustion of low rank coal/waste biomass blends using dry air or oxygen. Appl. Therm. Eng. 2013, 50, 251–259. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, J.; Shao, J.; Liu, Z.; Zhang, G.; Xu, T.; Guo, J.; Wang, H.; Xu, R.; Lin, H. Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers. Manag. 2016, 124, 414–426. [Google Scholar] [CrossRef]

- Gil, M.V.; Casal, D.; Pevida, C.; Pis, J.J.; Rubiera, F. Thermal behaviour and kinetics of coal/biomass blends during co-combustion. Bioresour. Technol. 2010, 101, 5601–5608. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Goldfarb, J.L.; Song, J.; Chang, C.; Ma, Q. Enhancing cleaner biomass-coal co-combustion by pretreatment of wheat straw via washing versus hydrothermal carbonization. J. Clean. Prod. 2022, 366, 132991. [Google Scholar] [CrossRef]

- Mao, R.; Shao, J.; Wang, G.; Wang, F.; Wang, C. Thermal behavior and kinetics analysis of co-combustion of petroleum coke and paper sludge-derived hydrochar. Waste Manag. 2022, 153, 405–414. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Syed-Hassan, S.S.A.; Zhou, J.; Deng, W.; Xiong, Y.; Wang, X.; Hu, X.; Xu, J.; Jiang, L.; Su, S.; et al. Effect of alkali and alkali earth metals on reactions of stable free radicals during biomass pyrolysis: An in-situ EPR study. Fuel Process. Technol. 2023, 250, 107916. [Google Scholar] [CrossRef]

- Xin, X.; Dell, K.; Udugama, I.A.; Young, B.R.; Baroutian, S. Transforming biomass pyrolysis technologies to produce liquid smoke food flavouring. J. Clean. Prod. 2021, 294, 125368. [Google Scholar] [CrossRef]

- Meng, H.; Wang, S.; Chen, L.; Wu, Z.; Zhao, J. Study on product distributions and char morphology during rapid co-pyrolysis of platanus wood and lignite in a drop tube fixed-bed reactor. Bioresour. Technol. 2016, 209, 273–281. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Zhu, L.; Zhang, Z.; Xiao, H. Experimental study on co-pyrolysis of petroleum coke and coals: Synergy effects and co-gasification reactivity. Fuel 2020, 279, 118368. [Google Scholar] [CrossRef]

- Zha, X.; Zhang, Z.; Zhao, Z.; Li, X.; Luo, C.; Wu, F.; Zhang, L. Experimental and kinetic study on the catalytic effect of AAEMs on coal char combustion under O2/CO2 atmospheres. Fuel 2023, 333, 126462. [Google Scholar] [CrossRef]

- Yang, H.; Song, H.; Zhao, C.; Hu, J.; Li, S.; Chen, H. Catalytic gasification reactivity and mechanism of petroleum coke at high temperature. Fuel 2021, 293, 120469. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).