Value-Stream Mapping as a Tool to Improve Production and Energy Consumption: A Case Study of a Manufacturer of Industrial Hand Tools

Abstract

:1. Introduction

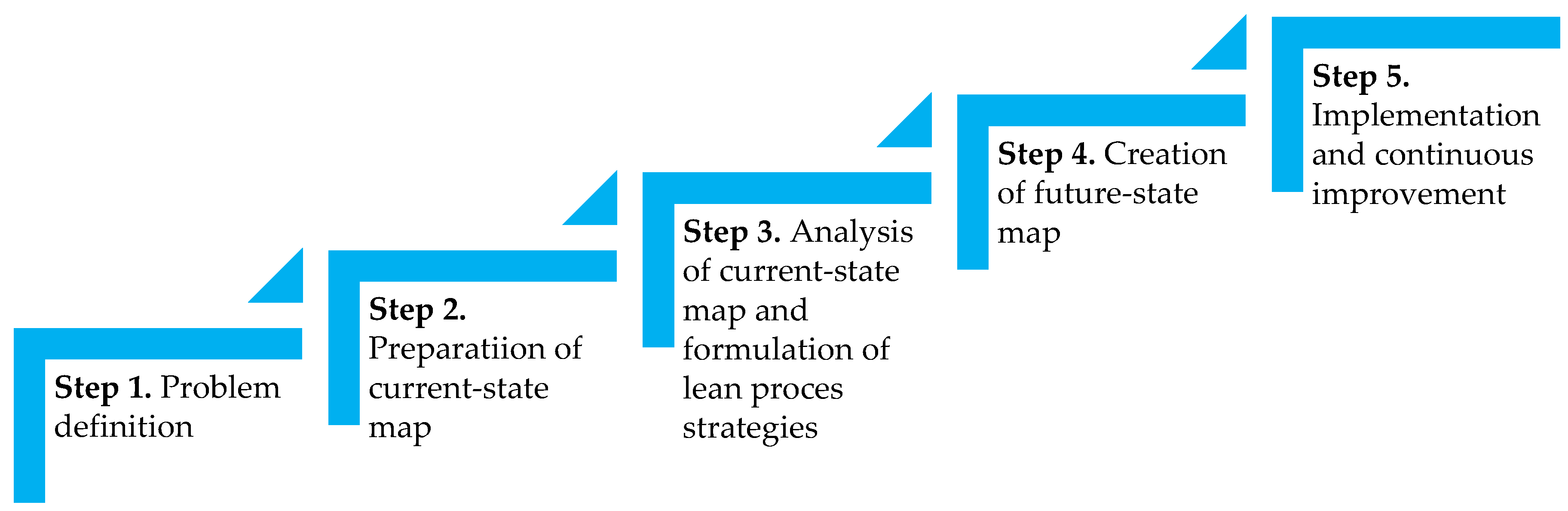

2. Research Methodology

2.1. Value-Stream Mapping

- How does VSM help identify areas for improvement in the production of hand tools used in the construction industry?

- How can we reduce waste and achieve better results in the analyzed production process, while maintaining the same financial, human and time expenditure?

- How will the improvements used affect electricity consumption, operation and reliability, and OEE?

- Analysis of the enterprise. In this step, basic information about the company was described. At this step, consultations with the company’s engineers and supervisors were made.

- Description of the production process and data collection. Data collecting consisted of tech tree analyzing and analyzing the actual process in the production hall. Based on this information, the current-state map was developed. This stage took place in February 2023, in the hand-tool production plant. We managed to obtain data of machines, operators, machine-changeover time, number of changes, production volume and level of non-compliances. In this phase the following actions were made:

- Interviews with operators about individual operations in specific units: At this stage, interviews were conducted with employees performing specific operations in the process. The purpose of these interviews was to gather knowledge of the details of and details-related-to given operations. Operators shared information about the time needed to perform the operation, the tools used, raw materials and any problems encountered during work.

- Live observation of the production process: This stage involved monitoring and documenting the actual course of the production process. Each stage of production was tracked, recording the duration of the operation, the efficiency of the machines, the number of products produced and any delays or problems. The observations were made live, which allowed the collection of accurate and up-to-date data on the process.

- Establishing working time standards: During this stage, data collected during observations of the work of operators and machines were analyzed. On their basis, the average time needed to perform individual operations and tasks in the production process was determined. During this stage, various factors are taken into account, such as the specifications of the hand tools used in construction, environmental and technical conditions, and the skills of the operators.

- Technology tree analysis—the technology tree was used as a source of information to create VSM. As part of this stage, information was collected about the duration of individual operations and activities in the analyzed production process, which had previously been identified in the technology tree.

- Analysis of machine changeover time: At this stage, data were collected of the time needed to changeover machines. Changeover time refers to the period between the end of the production of one product and the start of the production of the next. This is to identify periods when production is suspended due to a product change or a machine being adapted to a new task. Including it in the VSM allows you to identify areas where efficiency can be improved by reducing changeover time.

- Collecting data on electricity consumption: At this stage, the values for electricity consumption were read from information boards attached to the machines. Additionally, energy-consumption measurements were constantly made from the installed meters. Then, the collected data were analyzed.

- Based on the obtained data, a map of the current situation was developed. The main disadvantages of the current situation were pointed out, as were issues that should be improved.

- Consultations with supervisors about energy and improvement costs were made. Furthermore, the situation of the material-waste level was discussed. Joint analysis allowed for the ability to select proposed improvements and to define what changes are the most important in terms of the cost-effective implementation.

- Design of a future-state map. In the last stage, a map of the future state with proposed improvements was present. Based on the gathered data and consultations with operators and supervisors the future-state map has been developed. The map presents information of the material flow through the production system, in relation to the supplier and customer. Thanks to the improvements, the lead time is shortened and waste is reduced.

2.2. Key Performance Indicators (KPIs)

2.2.1. KPIs in Production Department

2.2.2. KPIs in Quality Department

3. Literature Analysis

4. The Case Study

4.1. Company Analysis

- Steel cutting line: Work takes place 5 days a week; there are two shifts and both last 8 h (6:00–14:00 and 14:00–22:00); during the shift there are two breaks, one for 20 min and one for 15 min.

- Engraving station: Work takes place the same as the cutting line, for 5 days a week, for 8 h a day (6:00–14:00 and 14:00–22:00); there are two breaks, also 20 and 15 min.

- Welding with labelling station and assembly with packing station: Work takes place on the same unit for 5 days a week, for 8 h a day. There is one shift from 6:00 until 14:00 including two breaks—one for 20 min and another one for 15 min.

- Injection molding station: Work takes place over two shifts, and the working hours and breaks are the same as at the cutting line.

4.2. Description of the Production Process

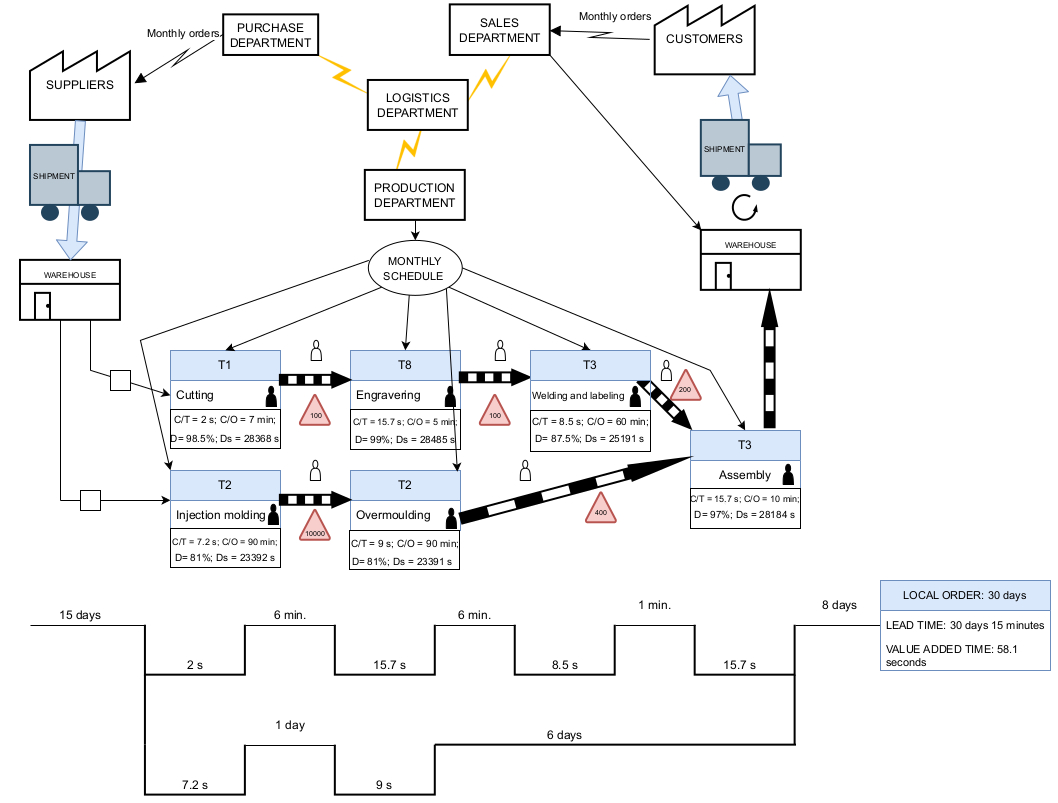

4.3. Mapping the Current State in the Plastering Trowel’s Manufacturing System

- C/T is the operation time;

- C/O is the changeover time;

- D is the availability of the machine, including changeover time;

- Ds is the available time of the machine.

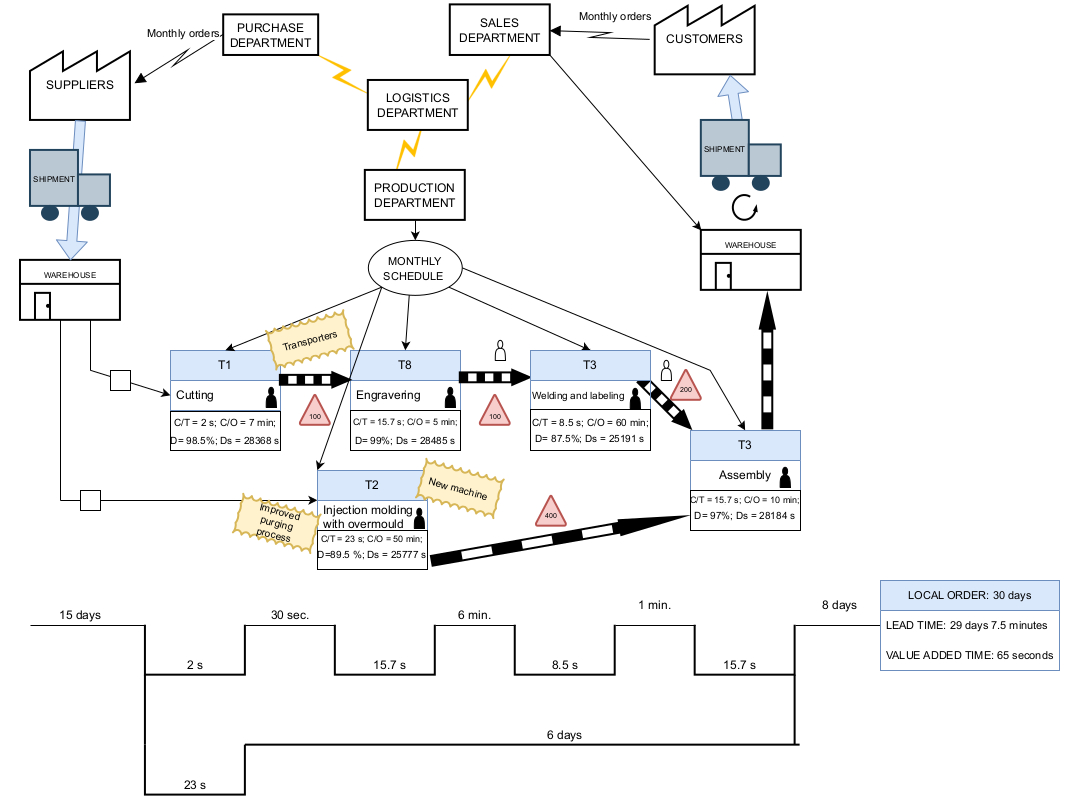

4.4. Future-State Map and Proposed Improvements

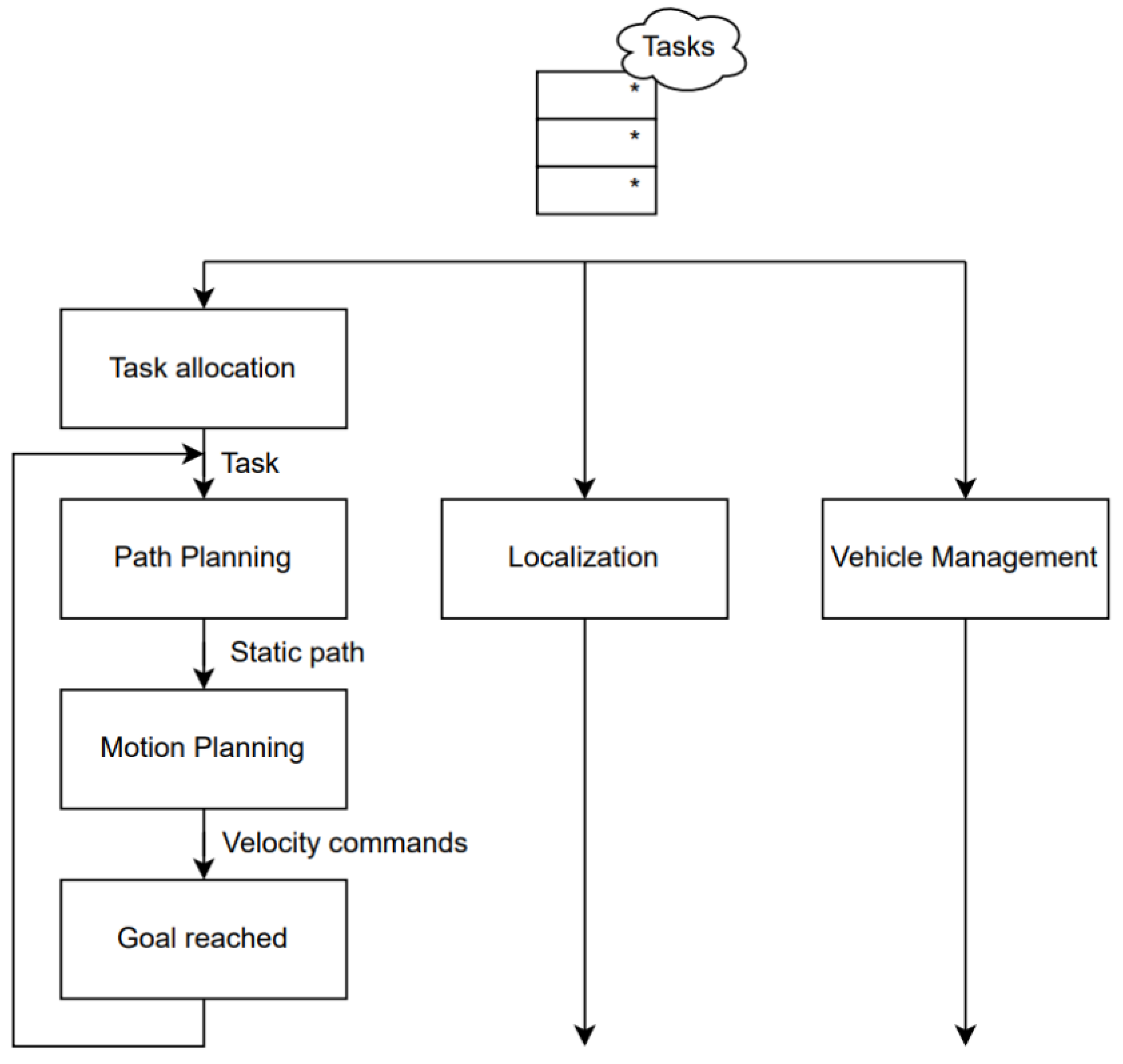

4.4.1. Improvement 1—Automatic Transporter

4.4.2. Improvement 2—Injection Purging-Liquid Sachets

4.4.3. Improvement 3—Two-Component Injection-Molder Machine

5. Key Performance Indicators (KPIs)

5.1. KPIs in Production Department

5.2. KPIs in Quality Department

6. Financial and Effectiveness Analysis of the Proposed Solutions

6.1. Purchase of Automatic Transporters

6.2. Purchase of Injection Molding Improvements

- TC is total cost;

- R is labor value;

- M is cost of the raw material of finished product;

- N is number of finished handles (monthly);

- I is inter operational stock of cores value;

- S is cost of the purging sachets;

- K is component cost.

- Availability (OEE takes into account the time during which machines used in the analyzed company are available and ready for work. This includes planned downtime (e.g., breaks to change tools), unplanned downtime (e.g., breakdowns) machines) and machine start-up time (start-up time after a break);

- Performance (performance refers to the efficiency of machinery while it is running. It determines how quickly a machine performs work compared to its theoretical or maximum efficiency);

- Quality (refers to the number of products or products produced without errors in relation to the total number produced).

6.3. Electricity Consumption—Purchase of Injection-Molding Improvements

6.4. Machine Exploitation and Reliability

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hidalgo Martins, G.; Gechele Cleto, M. Value Stream Mapping and Earned Value Analysis: A Case Study in the Paper Packaging Industry in Brazil. Braz. J. Oper. Prod. Manag. 2016, 13, 360. [Google Scholar] [CrossRef]

- Rother, M.; Shook, J. Learning to See: Value-Stream Mapping to Create Value and Eliminate Muda; Version 1.5; 20th Anniversary Edition; Lean Enterprise Inst: Boston, MA, USA, 2018; ISBN 978-0-9667843-0-5. [Google Scholar]

- Monden, Y. Toyota Production System; Springer US: Boston, MA, USA, 1993; ISBN 978-1-4615-9716-2. [Google Scholar]

- Keyte, B.; Locher, D. The Complete Lean Enterprise: Value Stream Mapping for Administrative and Office Processes; Productivity Press: New York, NY, USA, 2004; ISBN 978-1-56327-301-8. [Google Scholar]

- Salwin, M.; Jacyna-Gołda, I.; Bańka, M.; Varanchuk, D.; Gavina, A. Using Value Stream Mapping to Eliminate Waste: A Case Study of a Steel Pipe Manufacturer. Energies 2021, 14, 3527. [Google Scholar] [CrossRef]

- Hoekstra, S.; Romme, J.; Argelo, S.M. (Eds.) Integral Logistic Structures: Developing Customer-Oriented Goods Flow; Industrial Press: New York, NY, USA, 1992; ISBN 978-0-8311-3037-4. [Google Scholar]

- Graban, M.; Swartz, J.E. Healthcare Kaizen: Engaging Front-Line Staff in Sustainable Continuous Improvements; Taylor & Francis/CRC Press: Boca Raton, FL, USA, 2012; ISBN 978-1-4398-7296-3. [Google Scholar]

- Bell, S.; Orzen, M.A. Lean IT: Enabling and Sustaining Your Lean Transformation; Productivity Press: Boca Raton, FL, USA, 2011; ISBN 978-1-4398-1756-8. [Google Scholar]

- Parthanadee, P.; Buddhakulsomsiri, J. Production Efficiency Improvement in Batch Production System Using Value Stream Mapping and Simulation: A Case Study of the Roasted and Ground Coffee Industry. Prod. Plan. Control 2014, 25, 425–446. [Google Scholar] [CrossRef]

- Andrade, P.F.; Pereira, V.G.; Del Conte, E.G. Value Stream Mapping and Lean Simulation: A Case Study in Automotive Company. Int. J. Adv. Manuf. Technol. 2016, 85, 547–555. [Google Scholar] [CrossRef]

- Jeong, B.K.; Yoon, T.E. Improving IT Process Management through Value Stream Mapping Approach: A Case Study. JISTEM 2016, 13, 525–540. [Google Scholar] [CrossRef]

- Salwin, M. Design of Product-Service Systems in Printing Industry. Ph.D. Thesis, Lappeenranta-Lahti University of Technology LUT, Lappeenranta, Finland, 2021. [Google Scholar]

- Salwin, M.; Kraslawski, A.; Lipiak, J.; Gołębiewski, D.; Andrzejewski, M. Product-Service System Business Model for Printing Houses. J. Clean. Prod. 2020, 274, 122939. [Google Scholar] [CrossRef]

- Salwin, M.; Kraslawski, A.; Andrzejewski, M.; Lipiak, J. Product-Service System for the Pharmaceutical Industry. In Smart and Sustainable Collaborative Networks 4.0; Camarinha-Matos, L.M., Boucher, X., Afsarmanesh, H., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2021; Volume 629, pp. 485–493. ISBN 978-3-030-85968-8. [Google Scholar]

- Salwin, M.; Kraslawski, A.; Andrzejewski, M.; Lipiak, J. Product-Service System for the Pharmaceutical Industry—A New Opportunity for Machine Manufacturers. In Advances in Manufacturing III; Gorski, F., Rychlik, M., Păcurar, R., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 120–135. ISBN 978-3-030-99768-7. [Google Scholar]

- Salwin, M.; Lipiak, J.; Kulesza, R. Product-Service System—A Literature Review. Res. Logist. Prod. 2019, 9, 5–14. [Google Scholar] [CrossRef]

- Bańka, M.; Kukurba, M.; Waszkiewicz, A. The Impact of the COVID-19 Pandemic on Start-Ups’ Collaboration with Corporations. Procedia Comput. Sci. 2022, 207, 1283–1292. [Google Scholar] [CrossRef]

- Ebner, N.; Iacovidou, E. The Challenges of COVID-19 Pandemic on Improving Plastic Waste Recycling Rates. Sustain. Prod. Consum. 2021, 28, 726–735. [Google Scholar] [CrossRef]

- Masłowski, D.; Kulińska, E.; Salwin, M.; Pawlas, K.; Kulińska-Jachowska, K. Impact of Policy Regulations on the Functioning of Hospitals in Poland during the COVID-19 Pandemic: A Qualitative Analysis. Int. J. Manag. Econ. 2022, 58, 192–217. [Google Scholar] [CrossRef]

- Value of the Hand Tool Market Worldwide 2017–2027. Available online: https://www.statista.com/statistics/476871/global-value-hand-tool-market/ (accessed on 10 September 2023).

- Biron, M. Industrial Applications of Renewable Plastics: Environmental, Technological, and Economic Advances; Elsevier: Boston, MA, USA, 2017; ISBN 978-0-323-48065-9. [Google Scholar]

- Bańka, M.; Salwin, M.; Kukurba, M.; Rychlik, S.; Kłos, J.; Sychowicz, M. Start-Up Accelerators and Their Impact on Sustainability: Literature Analysis and Case Studies from the Energy Sector. Sustainability 2022, 14, 13397. [Google Scholar] [CrossRef]

- Lipiak, J.; Salwin, M. The Improvement of Sustainability with Reference to the Printing Industry—Case Study. In Advances in Manufacturing II; Hamrol, A., Grabowska, M., Maletic, D., Woll, R., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 254–266. ISBN 978-3-030-17268-8. [Google Scholar]

- Plastics Europe. Closed-Loop Plastics. Analysis of the Situation in Europe. 2021. Available online: https://plasticseurope.org/pl/wp-content/uploads/sites/7/2021/11/Raport-Tworzywa-w-Obiegu-Zamknietym_do-pobrania.pdf (accessed on 10 September 2023).

- Van Oosterhout, L.; Dijkstra, H.; Borst, D.; Duijndam, S.; Rehdanz, K.; Van Beukering, P. Triggering Sustainable Plastics Consumption Behavior: Identifying Consumer Profiles across Europe and Designing Strategies to Engage Them. Sustain. Prod. Consum. 2023, 36, 148–160. [Google Scholar] [CrossRef]

- Waaijers-van Der Loop, S.; Van Bruggen, A.; Beijer, N.R.M.; Sips, A.; De Roda Husman, A.M.; Cassee, F.; Peijnenburg, W. Improved Science-Based Transformation Pathways for the Development of Safe and Sustainable Plastics. Environ. Int. 2022, 160, 107055. [Google Scholar] [CrossRef] [PubMed]

- Salwin, M.; Lipiak, J.; Wałachowski, P. Production Improvement by Using the SMED Method—Case Study. Res. Logist. Prod. 2019, 9, 137–152. [Google Scholar] [CrossRef]

- Marr, B. Key Performance Indicators: The 75 Measures Every Manager Needs to Know, 1st ed.; Always learning; Pearson: Harlow, UK; Munich, Germany, 2012; ISBN 978-0-273-75011-6. [Google Scholar]

- Kerzner, H. Project Management Metrics, KPIs, and Dashboards: A Guide to Measuring and Monitoring Project Performance, 4th ed.; Wiley: Hoboken, NJ, USA, 2023; ISBN 978-1-119-85155-4. [Google Scholar]

- De Ryck, M.; Versteyhe, M.; Debrouwere, F. Automated Guided Vehicle Systems, State-of-the-Art Control Algorithms and Techniques. J. Manuf. Syst. 2020, 54, 152–173. [Google Scholar] [CrossRef]

- Velimirović, D.; Velimirović, M.; Stanković, R. Role and Importance of Key Performance Indicators Measurement. Serbian J. Manag. 2011, 6, 63–72. [Google Scholar] [CrossRef]

- Bevilacqua, M.; Ciarapica, F.E.; Giacchetta, G. Value Stream Mapping in Project Management: A Case Study. Proj. Manag. J. 2008, 39, 110–124. [Google Scholar] [CrossRef]

- Haefner, B.; Kraemer, A.; Stauss, T.; Lanza, G. Quality Value Stream Mapping. Procedia CIRP 2014, 17, 254–259. [Google Scholar] [CrossRef]

- Grewal, C. An Initiative to Implement Lean Manufacturing Using Value Stream Mapping in a Small Company. IJMTM 2008, 15, 404. [Google Scholar] [CrossRef]

- Tapping, D.; Shuker, T. Value Stream Management for the Lean Office; Productivity Press: New York, NY, USA, 2018; ISBN 978-1-4822-7817-0. [Google Scholar]

- Klimecka-Tatar, D. Context of Production Engineering in Management Model of Value Stream Flow According to Manufacturing Industry. Prod. Eng. Arch. 2018, 21, 32–35. [Google Scholar] [CrossRef]

- Tabanli, R.M.; Ertay, T. Value Stream Mapping and Benefit–Cost Analysis Application for Value Visibility of a Pilot Project on RFID Investment Integrated to a Manual Production Control System—A Case Study. Int. J. Adv. Manuf. Technol. 2013, 66, 987–1002. [Google Scholar] [CrossRef]

- Teichgräber, U.K.; De Bucourt, M. Applying Value Stream Mapping Techniques to Eliminate Non-Value-Added Waste for the Procurement of Endovascular Stents. Eur. J. Radiol. 2012, 81, e47–e52. [Google Scholar] [CrossRef] [PubMed]

- Stadnicka, D.; Litwin, P. Value Stream Mapping and System Dynamics Integration for Manufacturing Line Modelling and Analysis. Int. J. Prod. Econ. 2019, 208, 400–411. [Google Scholar] [CrossRef]

- Ruiz-de-Arbulo-Lopez, P.; Fortuny-Santos, J.; Cuatrecasas-Arbós, L. Lean Manufacturing: Costing the Value Stream. Ind. Manag. Data Syst. 2013, 113, 647–668. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation; Rev. and updated, 1. paperback ed.; Simon & Schuster: London, UK, 2003; ISBN 978-0-7432-3164-0. [Google Scholar]

- Paredes-Rodríguez, A.M. Aplicación de La Herramienta Value Stream Mapping a Una Empresa Embaladora de Productos de Vidrio. Entramado 2017, 13, 262–277. [Google Scholar] [CrossRef]

- Braglia, M.; Carmignani, G.; Zammori, F. A New Value Stream Mapping Approach for Complex Production Systems. Int. J. Prod. Res. 2006, 44, 3929–3952. [Google Scholar] [CrossRef]

- Manos, T. Value Stream Mapping an Introduction. Qual. Prog. 2006, 39, 64–69. [Google Scholar]

- Serrano Lasa, I.; Ochoa Laburu, C.; De Castro Vila, R. An Evaluation of the Value Stream Mapping Tool. Bus. Process Manag. J. 2008, 14, 39–52. [Google Scholar] [CrossRef]

- Das, A.K.; Das, M.C. Productivity Improvement Using Different Lean Approaches in Small and Medium Enterprises (SMEs). Manag. Sci. Lett. 2023, 13, 51–64. [Google Scholar] [CrossRef]

- Sekaninová, M. Value Stream Mapping in Advanced Management Systems. IJEK 2022, 10, 68–79. [Google Scholar] [CrossRef]

- Shamsu Anuar, M.A.; Mansor, M.A. Application of Value Stream Mapping in the Automotive Industry: A Case Study. JMMST 2022, 6, 34–41. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Esrafilian, R.; Kardan, R.; Shiwakoti, N.; Stasinopoulos, P. Lean Construction Analysis of Concrete Pouring Process Using Value Stream Mapping and Arena Based Simulation Model. Mater. Today Proc. 2021, 42, 1279–1286. [Google Scholar] [CrossRef]

- Mangers, J.; Minoufekr, M.; Plapper, P. Value Stream Mapping (VSM) to Evaluate and Visualize Interrelated Process-Chains Regarding Circular Economy. In Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems; Dolgui, A., Bernard, A., Lemoine, D., Von Cieminski, G., Romero, D., Eds.; IFIP Advances in Information and Communication Technology; Springer International Publishing: Cham, Switzerland, 2021; Volume 633, pp. 534–542. ISBN 978-3-030-85909-1. [Google Scholar]

- Dadashnejad, A.-A.; Valmohammadi, C. Investigating the Effect of Value Stream Mapping on Overall Equipment Effectiveness: A Case Study. Total Qual. Manag. Bus. Excell. 2019, 30, 466–482. [Google Scholar] [CrossRef]

- Cardoso, W. Value Stream Mapping as Lean Healthcare’s Tool to See Wastes and Improvement Points: The Case of the Emergency Care of a University Hospital. J. Innov. Healthc. Manag. 2019, 2, 360–380. [Google Scholar] [CrossRef]

- Deshkar, A.; Kamle, S.; Giri, J.; Korde, V. Design and Evaluation of a Lean Manufacturing Framework Using Value Stream Mapping (VSM) for a Plastic Bag Manufacturing Unit. Mater. Today Proc. 2018, 5, 7668–7677. [Google Scholar] [CrossRef]

- Huang, Y.; Tomizuka, M. Production Flow Analysis through Environmental Value Stream Mapping: A Case Study of Cover Glass Manufacturing Facility. Procedia CIRP 2017, 61, 446–450. [Google Scholar] [CrossRef]

- Li, W.; Thiede, S.; Kara, S.; Herrmann, C. A Generic Sankey Tool for Evaluating Energy Value Stream in Manufacturing Systems. Procedia CIRP 2017, 61, 475–480. [Google Scholar] [CrossRef]

- Lacerda, A.P.; Xambre, A.R.; Alvelos, H.M. Applying Value Stream Mapping to Eliminate Waste: A Case Study of an Original Equipment Manufacturer for the Automotive Industry. Int. J. Prod. Res. 2016, 54, 1708–1720. [Google Scholar] [CrossRef]

- Rohac, T.; Januska, M. Value Stream Mapping Demonstration on Real Case Study. Procedia Eng. 2015, 100, 520–529. [Google Scholar] [CrossRef]

- Rosenbaum, S.; Toledo, M.; González, V. Improving Environmental and Production Performance in Construction Projects Using Value-Stream Mapping: Case Study. J. Constr. Eng. Manag. 2014, 140, 04013045. [Google Scholar] [CrossRef]

- Erikshammar, J.; Lu, W.; Stehn, L.; Olofsson, T. Discrete Event Simulation Enhanced Value Stream Mapping: An Industrialized Construction Case Study. Lean Constr. J. 2013, 10, 47–65. [Google Scholar]

- Luna, L.B.; Klökner, P.E.D.; Ferreira, J.C.E. Applying Value Stream Mapping to Identify and Evaluate Waste in a Company of the Ceramic Sector. In Advances in Sustainable and Competitive Manufacturing Systems; Azevedo, A., Ed.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Heidelberg, Germany, 2013; pp. 1515–1525. ISBN 978-3-319-00556-0. [Google Scholar]

- Gurumurthy, A.; Kodali, R. Design of Lean Manufacturing Systems Using Value Stream Mapping with Simulation: A Case Study. J. Manuf. Technol. Manag. 2011, 22, 444–473. [Google Scholar] [CrossRef]

- Rahani, A.R.; al-Ashraf, M. Production Flow Analysis through Value Stream Mapping: A Lean Manufacturing Process Case Study. Procedia Eng. 2012, 41, 1727–1734. [Google Scholar] [CrossRef]

- Chen, J.C.; Li, Y.; Shady, B.D. From Value Stream Mapping toward a Lean/Sigma Continuous Improvement Process: An Industrial Case Study. Int. J. Prod. Res. 2010, 48, 1069–1086. [Google Scholar] [CrossRef]

- Venkataraman, K.; Ramnath, B.V.; Kumar, V.M.; Elanchezhian, C. Application of Value Stream Mapping for Reduction of Cycle Time in a Machining Process. Procedia Mater. Sci. 2014, 6, 1187–1196. [Google Scholar] [CrossRef]

| No | Industry | Description | References |

|---|---|---|---|

| 1. | Foundry—rail trolley. | NVA time was reduced from 107 min to 56 min, and foundry turnaround time was reduced from 208 min to 157 min, allowing customers to be met on time. | [46] |

| 2. | Analysis of the assembly process of a turbomolecular pump representing an axial turbine in which rotating blades ensure gas compression in the direction of pumping. | Reduction of the process-execution time by 26% from 1380 min to 1020 min. | [47] |

| 3. | Production and assembly of various types of motorcycles and scooters. | There was an improvement, respectively: lead time from 497 h to 164.03 h (67% reduction) and non-added-value time from 437 h to 113.8 h (74% reduction). | [48] |

| 4. | Steel tubes of various dimensions for upholstered furniture. | Productivity rates on the slitting line can improve by 17%, and the waste of polypropylene strapping should be reduced by 1.7 times. Change of availability index on the slitting line from 67% to 79%. | [5] |

| 5. | A concrete construction project that is underway consisting of two stories, each requiring 420 m3 of concrete to be placed in accordance with the design specifications. The operation is carried out in two phases: concreting slabs and beams and concreting walls and columns. | Reduction of concrete pumping-cycle time from 8.5 min to 6 min. Reducing the cycle time of the vibrating and finishing processes by approximately 35% and 20%, respectively. Ultimately, adding two trucks to the entire process leads to a production-lead-time reduction of nearly 35%. Lead time shortened from 11 to 7 days, value-added time decreased from 38.2 min to 22.5 min. The tact time has also been reduced from 138 s to 93 s. | [49] |

| 6. | Plastic products. | Lead time was shortened from 11.6 h to 0.96 h. The CO2 equivalent was reduced from 48.1 kgCO2-eq/fu to 16.9 kgCO2-eq/fu. Energy consumption has been reduced from 174.9 kWh/fu to 47.50 kWh/fu. | [50] |

| 7. | Production. | Elimination of problems related to delivery delays, machine failures and the quality of finished products. | [39] |

| 8. | Production of various models of ball valves for gas. | Improvement of the OEE index from 76% to 83%. | [51] |

| 9. | Mapping the flow of values in the emergency services of a university hospital. | Lead time of production has been reduced from 5.31 h to 5.12 h. Processing time has been reduced from s = 4.36 h to 4.26 h. | [52] |

| 10. | Production of plastic bags. | Reduction of TAKT time from 46 min to 26.6 min. The number of rolls produced per day increased from 28 to 50. The implementation of the lean manufacturing framework increased the value-added time by 74.5% (from 15% to 89.85%). Non-value-added time reduced from 55% to 9.54%. Cycle time reduced from 12 min to 10 min. | [53] |

| 11. | Cover glass—flat glass for smartphones and electronics. | Operator’s walking time reduced by 33%. The time a product spends from the receiving dock to shipping dock reduced by 27%. CO2 reduction can be reduced from 8.5 kgCO2eq per head to 4.6 kgCO2eq per head, a reduction of approximately 46%. | [54] |

| 12. | Aluminum recycling. | Reduction of machine failures and reduction of gas consumption. | [55] |

| 13. | Production of simple fold paper bags. | Lead time has been reduced from 33 days to 12 days. Processing time has been reduced from 11.85 s to 2.85 s. | [1] |

| 14. | Providing IT services—support and database management. | The total lead time has been reduced from 20 days to 3 days, which means a 92% reduction in the total time of the database provisioning process. Lead time at the planning stage was reduced by 89.7% (from 20 days 130 min to 2 days 95 min), at the implementation stage by 96.2% (from 8 days to 505 min 445 min), and at the quality control and by almost 98% (from 3 days 120 min to 80 min). | [11] |

| 15. | Car parts—15 plastic parts used in the interior of luxury cars. | The cycle time in the assembly sub-process was reduced from 370 to 140 s; the number of operators was reduced from four to three; and the stock level of the semi-finished product was reduced by 25%. | [56] |

| 16. | Car parts clutch disc assembly process. | Shortened lead time from 60.5 to 4.14 days. Simulations were carried out using current and future states to support suggested improvements and verified a 7% reduction in total production time as well as a 10% increase in job occupancy. | [10] |

| 17. | Plastic products dedicated to the medical industry. | Total lead time reduced from 296.36 days to 96.00 days. | [57] |

| 18. | Construction of a medical center. | Reducing the cycle time from 62 min/m2 to 39 min/m2. | [58] |

| 19. | Production process in a roasted and ground coffee plant. | Reducing the total cycle time from 92.59 min to 69.40 min. | [9] |

| 20. | Production of windows, patio doors and other components for industrialized builders of single-family houses. | Mean-cycle-time reduction from 345.65 h to 246.75 h. Reduction of the average WIP index from 98.76 to 23.05. | [59] |

| 21. | Red ceramics. | Lead-time reduction from 36.7 days to 11.34 days and value-added time from 83.5 min/thousand bricks to 77.4 min/thousand bricks. | [60] |

| 22. | PVC doors and windows. | VA time shortened from 63.36 min to 42.72 min. Production lead time shortened from 37.87 days to 12.68 days. Increasing the daily demand from 40 to 60 windows and from 160 to 240 squares. | [61] |

| 23. | Automotive engine components. | The overall reduction in man time was 15.99 s or 16.9%, while machine time was reduced to 299,832 s or 14.17%. | [62] |

| 24. | Manufacture of electrical devices. | The plasma-cutting process has been improved and the cycle time has been reduced from 47 min to 30 min. The cycle time in the manufacturing stage is reduced to 128.5 min. | [63] |

| 25. | Crankshaft production system in car-manufacturing plant. | Production lead-time reduction from 1,644,300 s to 251,100 s and value-added time from 9627 s to 2933 s. | [64] |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Working time | 40 h | 40 h |

| B. | Non-normative working time | 16.04 h | 12.29 h |

| C. | Setting and adjustment time in non-normative working time | 11.87 h | 8.12 h |

| D. | Employee performance EP = ((A − B)·100/A) | 59.9% | 69.3% |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Planned production | 25,000 pcs | 25,000 pcs |

| B. | Actual production | 21,900 pcs | 23,900 pcs |

| C. | Quantitative production indicator WI = ((B/A)·100) | 87.6% | 95.6% |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Number of complaints | 19 pcs | 80 |

| B. | Number of complained-about products | 8185 pcs | 795 pcs |

| QI1. | Comparison of number of complaints | 321% higher after the improvement | |

| QI2. | Comparison of number of complained-about products | 90.3% lower after the improvement | |

| Label | Kind of Scrap | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Plastics | 5200 kg | 2770 kg |

| B. | Steel | 18,920 kg | 14,650 kg |

| C. | Aluminum | 1326 kg | 0 kg |

| SI1. | Plastic-scrap comparison | 46.73% lower after the improvement | |

| SI2. | Steel-scrap comparison | 22.57% lower after the improvement | |

| SI3. | Aluminum-scrap comparison | 100% lower after the improvement | |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Time of the transport (monthly) | 240 min | 20 min |

| B. | Labor value | EUR 21 | EUR 0 |

| C. | Number of operators | 1 | 0 |

| D. | Energy cost | EUR 0 | EUR 2 |

| E. | Monthly difference | EUR 19 | |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| R | Labor value | EUR 3840 | EUR 1920 |

| M | Cost of the raw material of finished products | EUR 0.24 | EUR 0.24 |

| N | Number of finished handles (monthly) | 9790 pcs | 11,160 pcs (improvement allows production of 1370 more pcs) |

| I | Inter operational stock of cores value | EUR 1060 | EUR 530 |

| S | Cost of the purging sachets | EUR 800 | EUR 840 |

| TC | Total cost | EUR 8049.6 | EUR 5968.4 |

| K | Component cost | EUR 0.82 | EUR 0.53 |

| Number of machines | 2 | 1 | |

| Number of operators | 2 | 1 | |

| Monthly difference | EUR 2081.2 | ||

| Lean Metrics | Before the Improvement | After the Improvement | |

|---|---|---|---|

| Label | Availability | Minutes | Minutes |

| Tz | Total working time | 2880 | 2880 |

| Tpp | Planned brakes | 150 | 150 |

| Tpz | Setting and adjustments | 810 | 405 |

| Tpnp | Unplanned interruptions | 0 | 0 |

| Taw | Breakdowns | 0 | 0 |

| Tw | Effective working time (Tz − (Tpp + Tpz)) | 1920 | 2325 |

| Ttop | Planned production time (Tz − Tpp) | 2730 | 2730 |

| Ttop | Planned production time (Ttop·100/Tz) in % | 94.79% | 94.79% |

| Td | Availability (Ttop − Tpz) | 1920 | 2325 |

| W | Waste (Ttop − Td) | 810 | 405 |

| Td | Availability in % (Td·100/Ttop) | 70.33% | 85.16% |

| Performance | |||

| Pd | Product details (good and bad) | 6400 pcs | 8835 pcs |

| P1 | Maximum performance on machine | 200 pcs/h | 228 pcs/h |

| P2 | Actual machine performance (Pd/Tw) | 3.33 | 3.80 |

| P | Performance (P2·60/P1) in % | 100% | 100% |

| Quality | |||

| Nd | Number of defects | 320 pcs | 0 pcs |

| Q | Quality ((Pd − Nd)/Pd·100) | 95% | 100% |

| Overall equipment effectiveness | |||

| E | OEE (E = Td·P·Q) | 66.81% | 85.16% |

| Measurement No. | Injection Molding | Over Molding | Sum |

|---|---|---|---|

| 1. | 1.86 kWh | 2.33 kWh | 4.19 kWh |

| 2. | 1.81 kWh | 2.27 kWh | 4.08 kWh |

| 3. | 1.83 kWh | 2.30 kWh | 4.13 kWh |

| 4. | 1.95 kWh | 2.45 kWh | 4.40 kWh |

| 5. | 1.92 kWh | 2.41 kWh | 4.33 kWh |

| 6. | 1.87 kWh | 2.35 kWh | 4.22 kWh |

| 7. | 1.90 kWh | 2.38 kWh | 4.28 kWh |

| 8. | 1.79 kWh | 2.25 kWh | 4.04 kWh |

| 9. | 1.83 kWh | 2.29 kWh | 4.12 kWh |

| 10. | 1.82 kWh | 2.29 kWh | 4.11 kWh |

| Average | 1.86 kWh | 2.33 kWh | 4.19 kWh |

| Label | Description | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Number of pcs (monthly) | 9790 pcs | 11,160 pcs |

| B. | Power consumption (monthly) | 41,020.1 kWh | 16,366.1 kWh |

| C. | Energy saving per month | 24,654 kWh | |

| D. | Financial saving per month | EUR 4437.73 | |

| Label | Injection Molding | Before the Improvement | After the Improvement |

|---|---|---|---|

| A. | Total working time | 49 h/month | 49 h/month |

| B. | Downtime | 16 h/month | 9.25 h/month |

| C. | Produced details | 9790 pcs | 11,160 pcs |

| D. | Breakdowns quantity | 3 per month | 1 per month |

| E. | Machine exploitation costs | EUR 7500 | EUR 3200 |

| F. | Income from sold handles | EUR 7600 | EUR 8400 |

| G. | ROE (Return of Equity) | 1.3% | 162.5% |

| H. | OEE | 66.81% | 85.16% |

| I. | MTBF (Mean Time Between Failures) | 21.7 h | 58.25 h |

| J. | MTTR (Mean Time To Repair) | 2.3 h | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salwin, M.; Pszczółkowska, K.; Pałęga, M.; Kraslawski, A. Value-Stream Mapping as a Tool to Improve Production and Energy Consumption: A Case Study of a Manufacturer of Industrial Hand Tools. Energies 2023, 16, 7292. https://doi.org/10.3390/en16217292

Salwin M, Pszczółkowska K, Pałęga M, Kraslawski A. Value-Stream Mapping as a Tool to Improve Production and Energy Consumption: A Case Study of a Manufacturer of Industrial Hand Tools. Energies. 2023; 16(21):7292. https://doi.org/10.3390/en16217292

Chicago/Turabian StyleSalwin, Mariusz, Karolina Pszczółkowska, Michał Pałęga, and Andrzej Kraslawski. 2023. "Value-Stream Mapping as a Tool to Improve Production and Energy Consumption: A Case Study of a Manufacturer of Industrial Hand Tools" Energies 16, no. 21: 7292. https://doi.org/10.3390/en16217292

APA StyleSalwin, M., Pszczółkowska, K., Pałęga, M., & Kraslawski, A. (2023). Value-Stream Mapping as a Tool to Improve Production and Energy Consumption: A Case Study of a Manufacturer of Industrial Hand Tools. Energies, 16(21), 7292. https://doi.org/10.3390/en16217292