1. Introduction

As economic growth develops, consumers continue to demand a stable and high-quality power supply, and power companies continuously develop and maintain power facilities to meet this demand. Thus, the failure of power facilities causes enormous economic losses to the consumers and the power companies. For this reason, the power companies manage the power facilities in various ways, and power facility management technologies have been developed accordingly. Conventional power facilities depend on a time-based maintenance (TBM) method with regular cycles before exhausting the life of the facility [

1]. In introducing the TBM management method, the life of the power facility must be predicted through an experimental life evaluation. Accordingly, the overall lifespan of the power facilities is predicted through a life evaluation based on accelerated tests, and the TBM management method is accordingly operated.

Since the 1990s, condition-based maintenance (CBM) methods have been applied to monitor the conditions of the facilities online by attaching a sensor to the power facility, optimizing maintenance according to the abnormal signs of the facility and predicting the facility’s life. As the CBM method is applied, methods for predicting the life of the power facilities have become more diverse. However, these have certain limitations, such as limitations in sensing technologies and expensive diagnostic systems. Thus, most countries use the health index to predict the state of power facilities. The health index expresses the overall state of the power facilities as an indicator to establish a strategy for replacing the power facilities. The health index defined in the Council on Large Electric Systems (CIGRE) technical document is shown in

Table 1 [

2,

3,

4].

The criteria for evaluating and weighting the health index may vary depending on the physical characteristics of the equipment or the surrounding environment. For example, Kinetrics uses a weighted sum method to calculate the health index of power transformers. The health index is calculated using data such as Dissolved Gas Analysis (DGA), the power factor, and the load factor. Equation (1) is used by Kinetrics to calculate the HI score and

Table 2 shows the evaluation items and weights used by Kinetrics [

5].

In case the

,

Many countries use the CBM (condition-based maintenance) to evaluate the health index of overhead lines, but none of these methods consider costs. In [

6], they evaluate the health index of transmission lines by considering the visual inspection status of the poles, the condition of the insulators, and the ground resistance. In [

7], they evaluate the lines in a similar way to [

6], but also consider the surrounding environment where the lines are installed. In [

8], they evaluate the condition by reflecting the material condition of the lines in more detail than in [

6,

7]. The health index is evaluated by considering the distance from the beach to the lines, the pollution level of the surrounding air, and the diameter of the lines.

In the case of distribution facilities in Korea, the old facilities are being replaced through the power distribution facility diagnosis and the health index assessment to increase the efficiency of the facility operation and minimize the damage to power companies and consumers. Recently, considering the probability of failure of devices and the complex impact on systems, the environment, and the safety of workers, research has been conducted on the Risk-Based Maintenance (RBM) method, which is a maintenance direction that can meet the preferences of the facility operators and managers [

9]. The RBM method determines the priority of facility replacement based on the risk factors affecting a facility. Risk assessment is quantitatively derived by calculating the interaction between the probability of power facility failure and the ripple effect that ensues when failure occurs, where the facility operator analyzes and evaluates a case using calculated risks to establish replacement priorities [

10]. Although many research institutes and papers have applied or studied the asset management of power equipment using the RBM method, most of them were only for transmission and transformation power facilities [

11,

12]. In contrast, the power distribution facilities lack sufficient diagnostic failure data for asset management using the RBM method, and failure data are insufficient because the facilities are demolished as a preventive measure before a failure occurs. Therefore, the RBM method is hard to apply to the power distribution facilities. In addition, as the risk cost calculation used in RBM is determined by policy decision-making, the health index and diagnosis results are mainly used in the asset management of the distribution facilities in Korea. Therefore, in this paper, we propose a new risk-based health index assessment method that applies the facility risk costs to the health index assessment as a quantitative concept.

3. Proposed Method

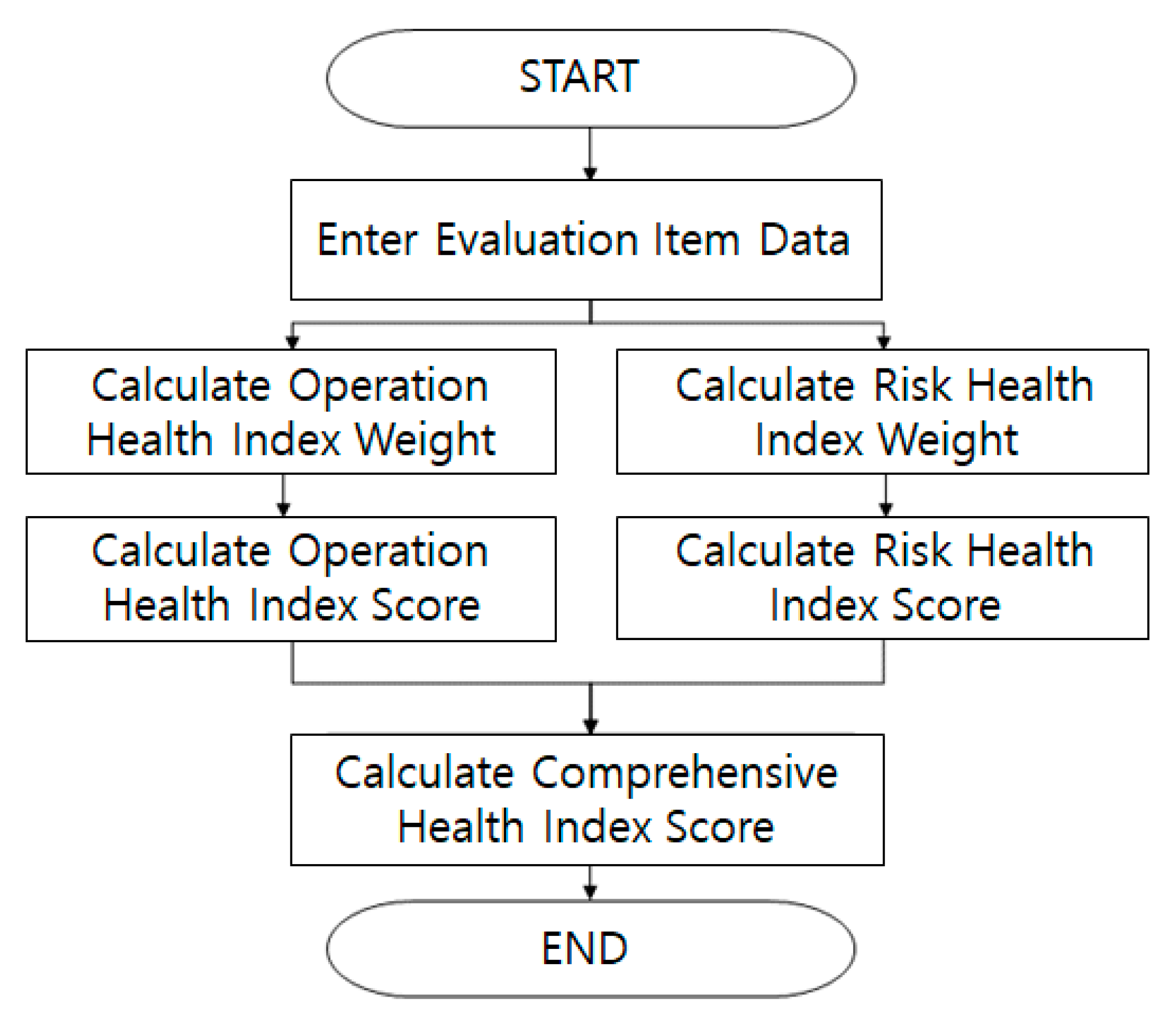

Figure 1 shows the health index assessment method proposed in this paper. Herein, the operation health and the risk health cost are calculated to determine the overall health score.

3.1. Operation Health Index Weight

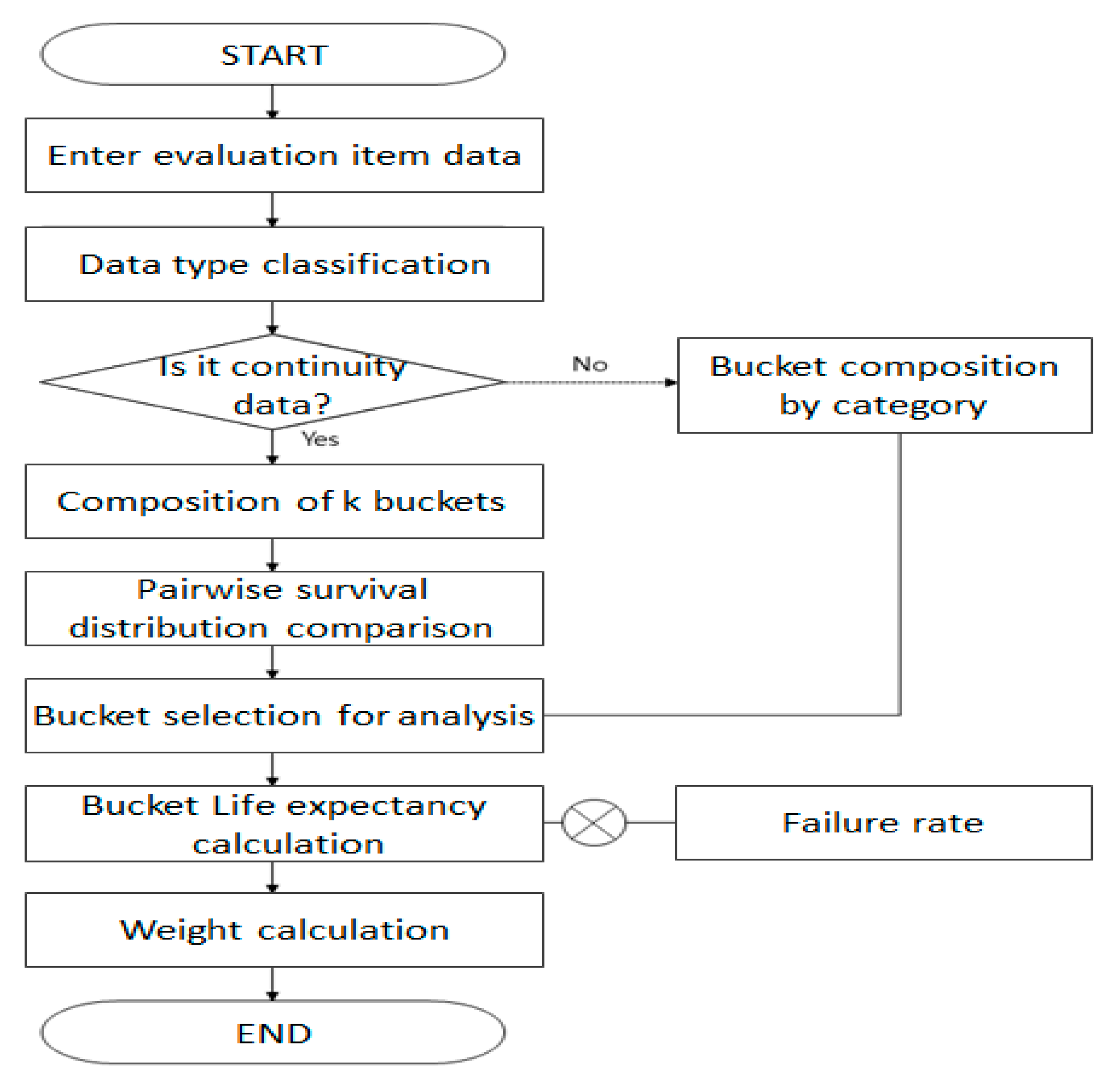

As mentioned in

Section 2.3, the overhead lines are simply replaced every four years based on visual inspections, so detailed failure data is insufficient. So, in this paper, the weights of the operation health index assessment items were calculated using survival analysis. The calculation process is shown in

Figure 2.

Using the weights calculated for each evaluation item, the operation health index assessment formula was constructed as shown in Equation (2). At this time, the operation health index assessment score was based on a perfect score of 100 points.

In the case when

,

3.2. Risk Health Index Weight

In the event of a breakdown of the lines, the customer suffers from power failure and the power company incurs costs to solve it. In the event of a facility failure, the cost of sales loss for each line that suffers from the failure to supply power to the power company and the line replacement cost for restoring the power facilities in the event of a failure are defined. Therefore, in this paper, two items, the power outage equipment cost and the line replacement cost in the event of a line failure, were defined and used as risk costs.

When calculating the risk cost, the failure probability of each line calculated through the survival analysis was applied to the risk cost defined in this paper, and the failure risk cost for each line was calculated using the average annual power consumption per region.

The failure risk cost relational expression defined in this study is shown in Equation (3).

Equation (4) shows the method for calculating the failure risk cost score using the risk cost. Here, the failure risk cost score was based on 100 points.

The line replacement cost, defined as a risk factor in this study, was calculated using the KEPCO construction standard unit price and the wire length as follows:

The method for calculating the line replacement score using the line replacement cost is shown in Equation (6). Here, the line replacement score was based on 100 points.

Because the power supply interruption and the line replacement always accompany each other in the event of a failure, the health index of the total risk cost evaluation was calculated by defining the health index score of the failure risk cost and the health index score of the line replacement cost at a ratio of 0.5:0.5. This was calculated on a scale of 100 points.

Therefore, the overall health index assessment formula for the overhead lines in this paper was calculated as shown in Equation (9).

4. Case Study

4.1. Health Index Weight

In this paper, the weights of the health index assessment were calculated using the data of about 4.7 million overhead lines installed in Korea. The average values for 2021 were used for the unit price and blackout time in the health index assessment items of risk cost, and the operation health index assessment items were defined as factors that affect the performance of the overhead lines for the operation health index assessment. The operation health index assessment items are listed in

Table 6 [

16].

In evaluating the health index, the data types must be classified for each evaluation item and the maximum value must be selected for each evaluation item. For this purpose, the results of the data type classification and the bucket selection of the evaluation items are shown in

Table 7 [

17].

Table 7 shows the average life expectancy at the point where the survival probability is 0.995 using the analysis bucket for each evaluation item. Here, the life expectancy of each bucket is used only for weight calculation, where the failure rate for each evaluation item in the failure data was multiplied by the reciprocal of the average life. The final calculations for the weights for each evaluation item are shown in

Table 8. Here, the sum of the weights was calculated out of 100 points.

Here, the salt damage grade and the kind of overhead line are categorical data. The weight calculated by multiplying the life expectancy and the failure rate for each grade is shown in

Table 9.

The final operation health index calculation formula using the calculated weight is shown in Equation (10).

Here, in case of ;

in case of ;

in case of ;

in case of ;

in case of ;

in case of ;

in case of ;

in case of .

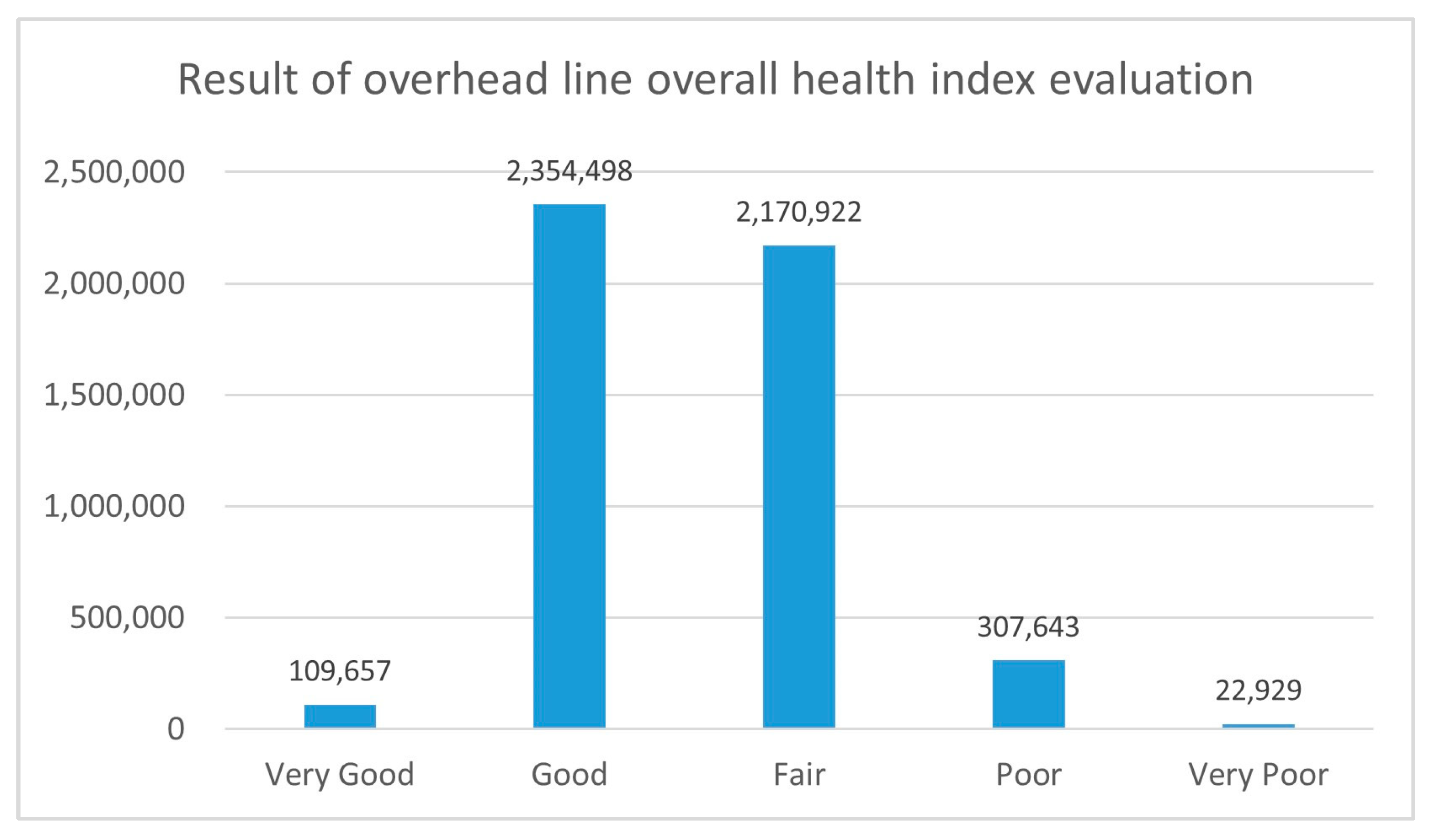

4.2. Result of Overhead Line Total Health Index

Currently, in Korea, the health index ratings are distinguished in units of 20 points. The overall health index assessment results by grade are shown in

Figure 3 and

Table 10. The Gyeongbuk and Gangwon regions apparently have plenty of extremely poor supplies, whereas the Seoul and Namseoul Headquarters have a few.

Table 11 and

Table 12 show that the forest rates in the Gangwon and North Gyeongsang regions were higher than those in other regions, whereas the underground rate was low [

18]. Given the many long-span lines in the mountainous areas, and because the construction cost for replacing them is high, these characteristics are reflected by the large number of replacement items of the health index.

Analyzing the number of actual spans for each level of the health index and its ratio to the total number of spans, as shown in

Table 13, we see that there were many lines with an actual span of 50 m or more in the Gangwon, Chungbuk, and Gyeongbuk regions. In particular, the number of spans in Gangwon and Gyeongbuk was higher than that in other regions; therefore, the number of spans with an actual span of 50 m or more was the highest in Gangwon and Gyeongbuk. This proves that the replacement cost of the overhead cables is high because the underground rate is low and there are many long-span sections in the forest area.

In Seoul and South Seoul Headquarters, the very poor quantity was calculated to be significantly less. This means the overhead cable operating environment was good because the number of overhead cables was low in the downtown area, the pollution level was good, and the wind speed was not as strong as that in other areas. In the past, we used the replacement method of overhead lines that relied only on instantaneous/diagnostic extraction. However, according to the health evaluation method developed in this paper, a risk-based replacement can prevent consumer life/property damage through a stable power supply and prevent power facility accidents.

4.3. Analysis of Economic Effects

Overhead line aging replacement was previously performed solely by visual inspection. This paper analyzes the cost-effectiveness of replacing overhead lines using the conventional method and the proposed method. The expected replacement quantity of extra-high-voltage overhead lines in the future was calculated to analyze the economic effects of the health index assessment model proposed in this study. As for the lifetime of the overhead lines, the manufacturer’s warranty period of 30 years was applied.

Table 14 shows the calculation of the quantity of the extra-high-voltage overhead lines over 30 years for the next 3 years and the analysis of such replacement quantity using the method proposed in this study.

As shown in the above results, it is necessary to replace a much smaller quantity when replacing the extra-high-voltage overhead lines using the method proposed in this paper than when replacing simple old overhead lines. This can reduce the annual replacement cost by more than 400 million won and can increase the accuracy of failure prevention by investing in activities such as precise diagnosis of overhead lines with reduced costs.

5. Conclusions

In this paper, a method for evaluating the health index of overhead lines was proposed to establish criteria for the efficient replacement of the power distribution facilities.

For the major power distribution facilities, there is an old replacement standard called the health index assessment, but there is no old replacement standard for the about 4.7 million power distribution overhead lines based on span, which were replaced only through diagnoses and visual inspections. This resulted in excessive diagnostic costs. In addition, by preemptively replacing overhead lines to prevent failure, excessive facility investment has been executed due to preemptive replacement even though the durability of the overhead lines remains. Thus, in this paper, a health index assessment model was proposed to establish the cost-effective power distribution facility operating costs and the facility replacement standards for overhead cables. The overhead lines were evaluated based on the failure risk cost, which considers the health index and the probability of failure risk. It was confirmed that the proposed method is more economical than the conventional aging replacement method when used to replace the equipment.

In future works, we plan to apply the algorithm developed in this study to an actual operating environment, perform replacements for more than 1 year, analyze statistical data on failure occurrence and old demolition, and consider machine learning-based algorithm accuracy verification results and expert opinions. In addition, we plan to increase the accuracy of the equipment condition estimation by adjusting the weights of the operation health and risk cost health using an analytic hierarchy process and calculating the optimal overall health weight.